The Properties of Binary and Ternary Ti Based Coatings Produced by Thermionic Vacuum Arc (TVA) Technology

Abstract

:1. Introduction

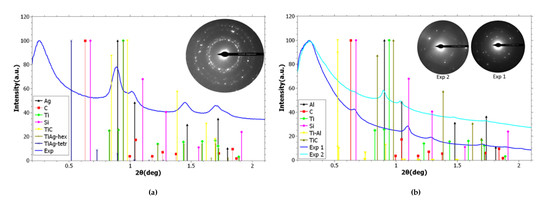

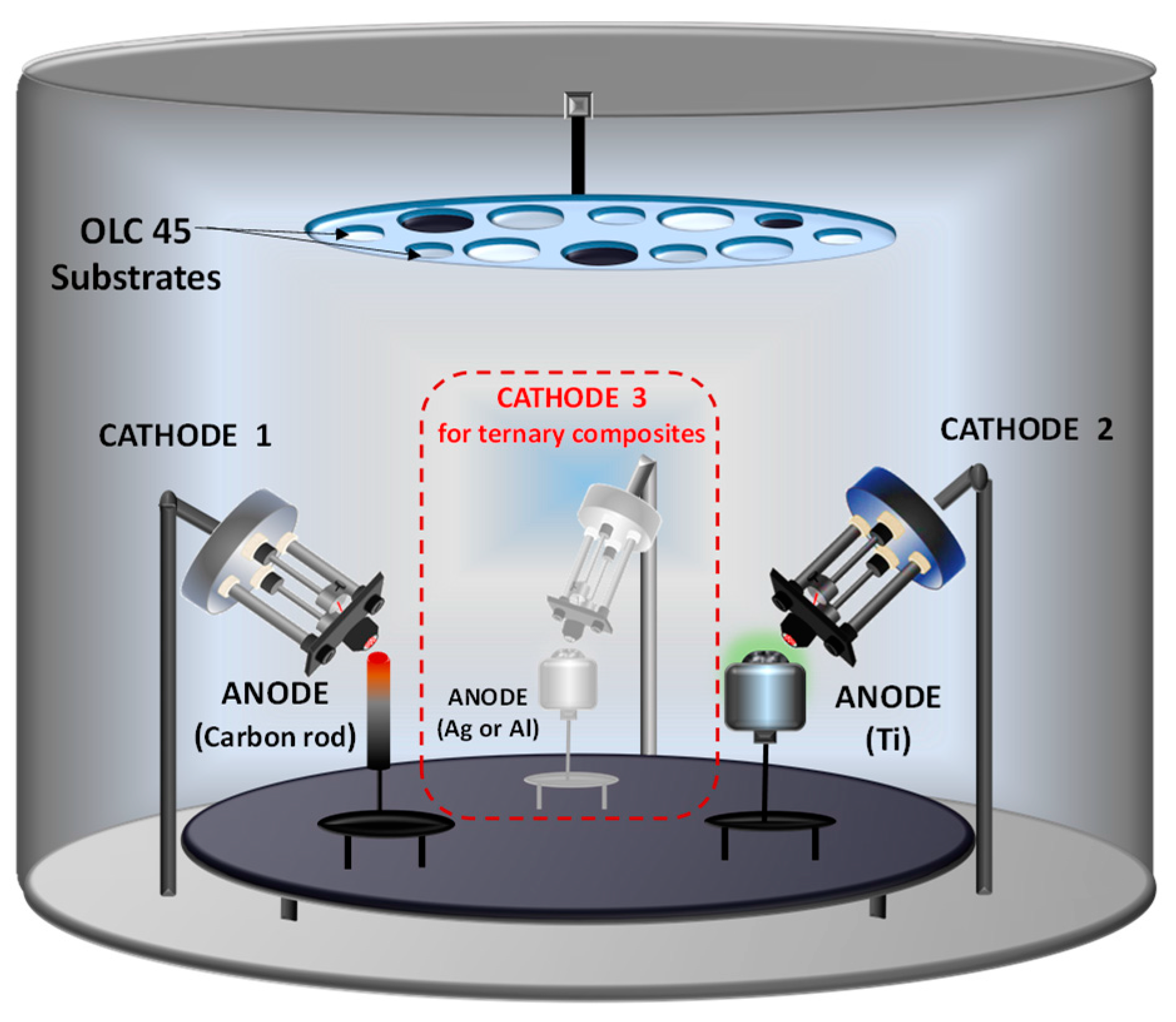

2. Materials and Methods

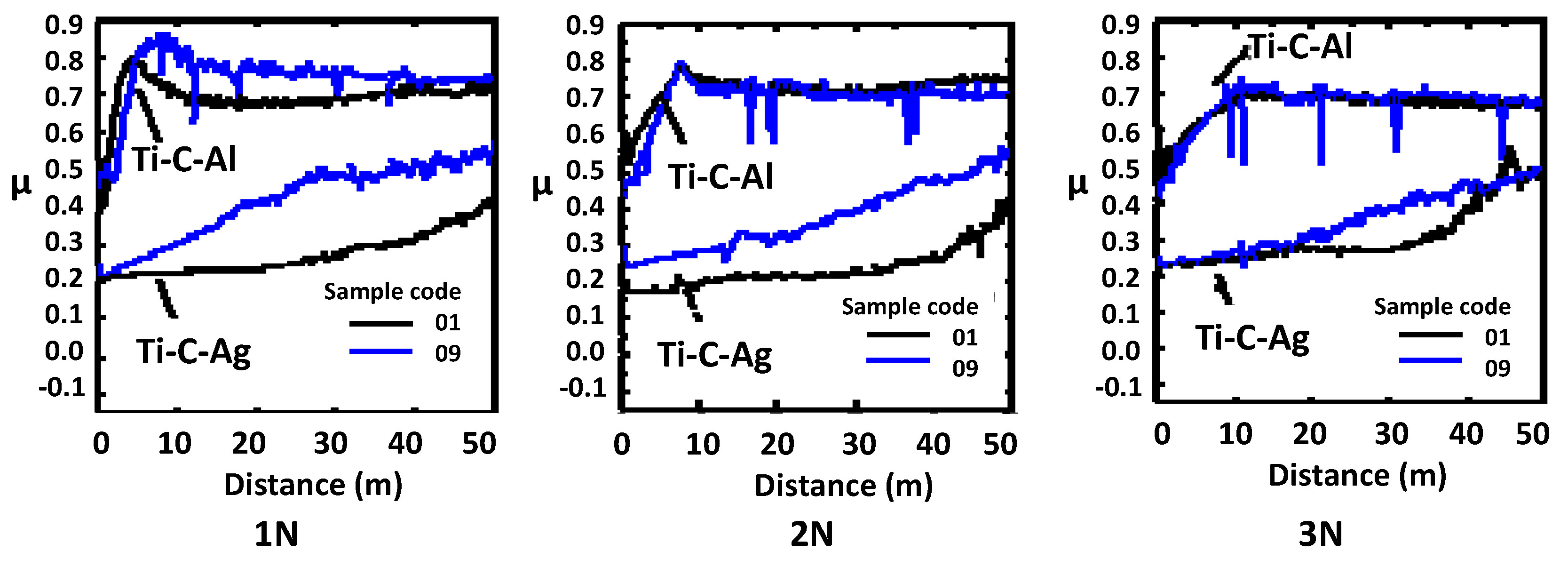

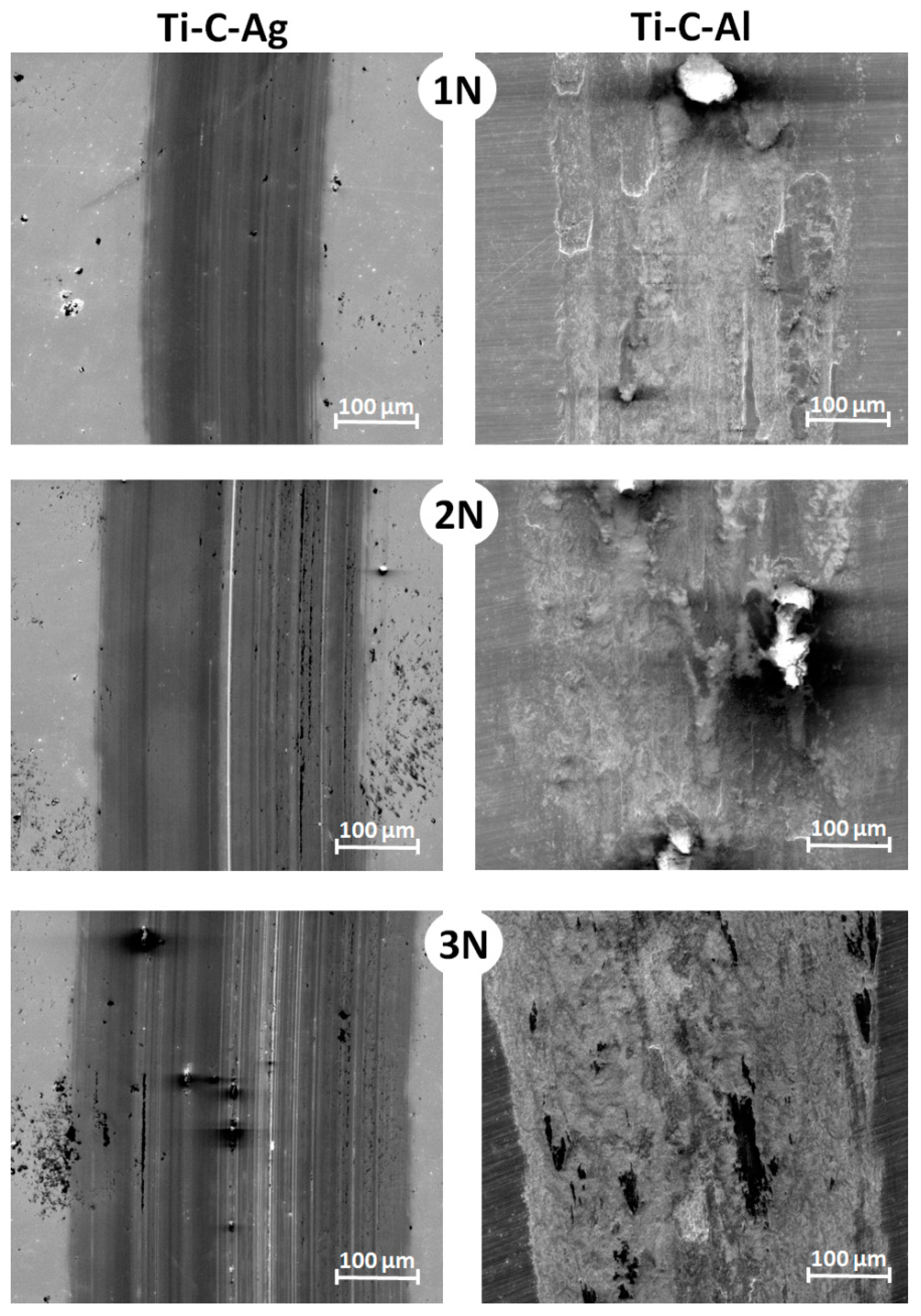

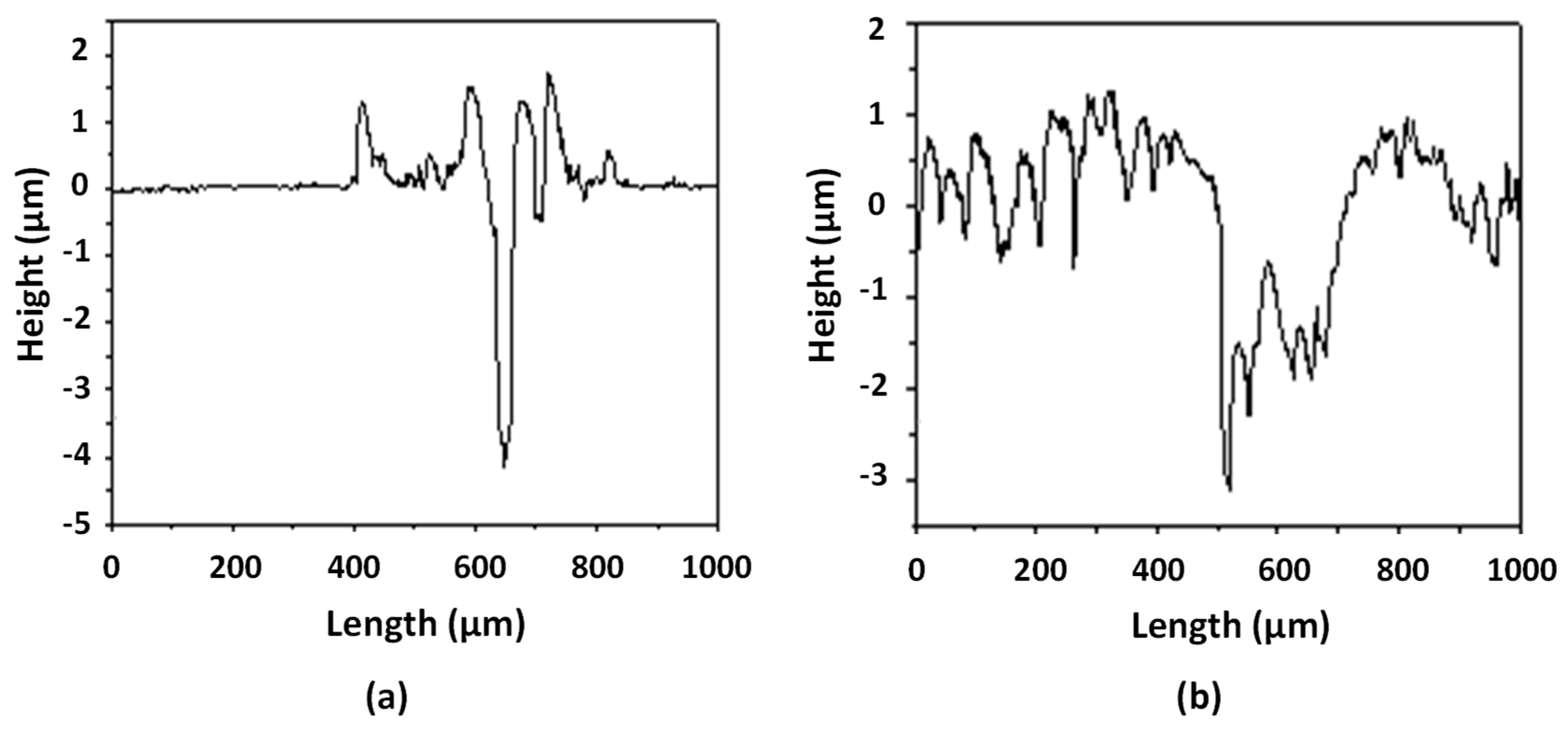

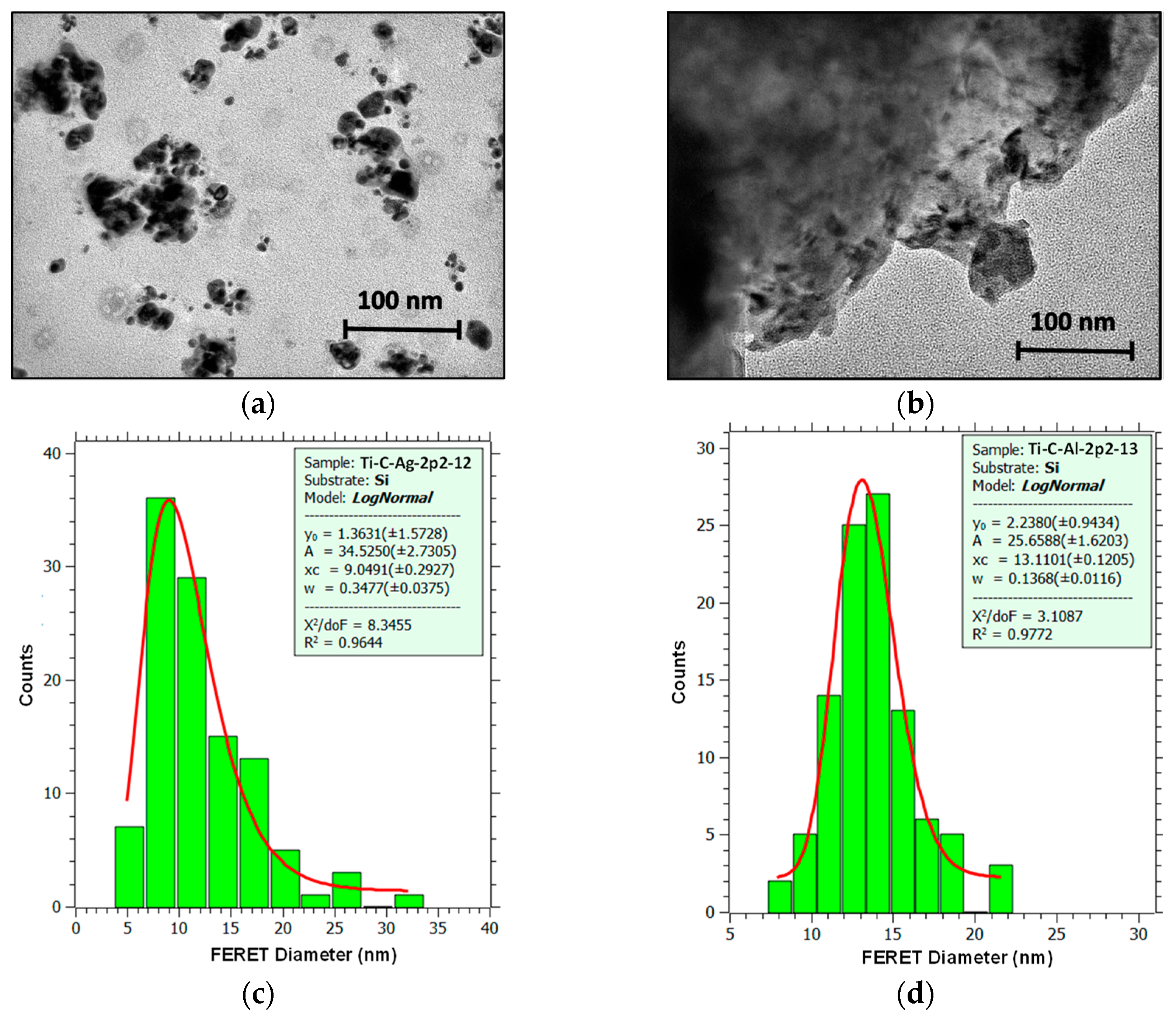

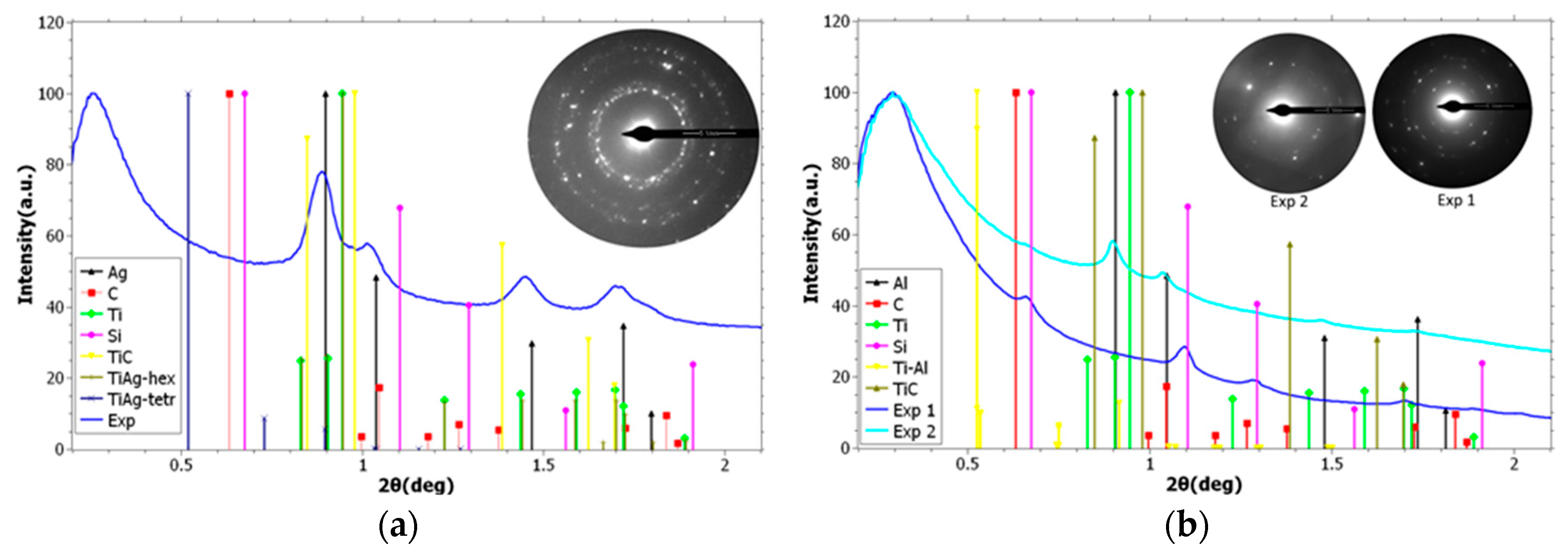

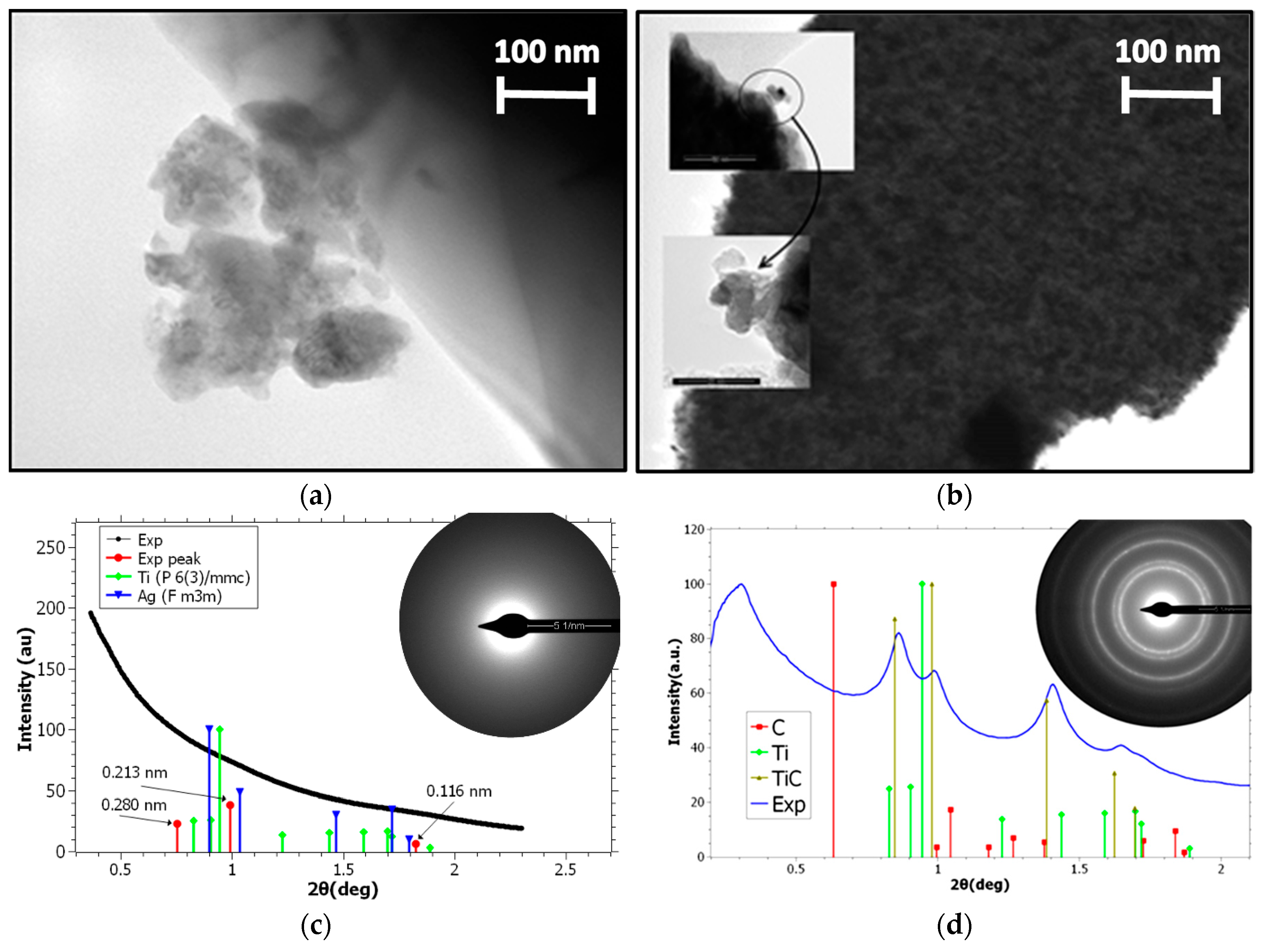

3. Results

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Lee, K.; Jeong, Y.-H.; Brantley, W. A.; Choe, H.-C. Surface characteristics of hydroxyapatite films deposited on anodized titanium by an electrochemical method. Thin Solid Films 2013, 546, 185–188. [Google Scholar] [CrossRef]

- Yang, C.; Jiang, B.; Liu, Z.; Feng, L.; Hao, J. Nanocrystalline titanium films deposited via thermal-emission-enhanced magnetron sputtering. Thin Solid Films 2015, 597, 117–124. [Google Scholar] [CrossRef]

- Cordill, M.J.; Taylor, A.A. Thickness effect on the fracture and delamination of titanium films. Thin Solid Films 2015, 589, 209–214. [Google Scholar] [CrossRef]

- Caschera, D.; Federici, F.; Pandolfi, L.; Kaciulis, S.; Sebastiani, M.; Bemporad, E.; Padeletti, G. Effect of composition on mechanical behaviour of diamond-like carbon coatings modified with titanium. Thin Solid Films 2011, 519, 3061–3067. [Google Scholar] [CrossRef]

- Sarkar, J.; McDonald, P.; Gilman, P. Surface characteristics of titanium targets and their relevance to sputtering performance. Thin Solid Films 2009, 517, 1970–1976. [Google Scholar] [CrossRef]

- El-Hossary, F.M.; Negm, N.Z.; Khalil, S.M.; Raaif, M. Surface modification of titanium by radio frequency plasma nitriding. Thin Solid Films 2006, 497, 196–202. [Google Scholar] [CrossRef]

- Zábranský, L.; Buršíková, V.; Daniel, J.; Souček, P.; Vašina, P.; Dugáček, J.; St’ahel, P.; Caha, O.; Buršík, J.; Peřina, V. Comparative analysis of thermal stability of two different nc-TiC/a-C:H coatings. Surf. Coat. Technol. 2015, 267, 32–39. [Google Scholar] [CrossRef]

- Bai, W.Q.; Wang, X.L.; Gu, C.D.; Tu, J.P. Influence of duty cycle on microstructure, tribological and corrosion behaviors of a-C/a-C:Ti multilayer films. Thin Solid Films 2015, 584, 214–221. [Google Scholar] [CrossRef]

- Bai, W.Q.; Li, L.L.; Wang, X.L.; He, F.F.; Liu, D.G.; Jin, G.; Tu, J.P. Effects of Ti content on microstructure, mechanical and tribological properties of Ti-doped amorphous carbon multilayer films. Surf. Coat. Technol. 2015, 266, 70–78. [Google Scholar] [CrossRef]

- Braic, M.; Zoita, N.C.; Danila, M.; Grigorescu, C.E.A.; Logofatu, C. Hetero-epitaxial growth of TiC films on MgO(001) at 100 °C by DC reactive magnetron sputtering. Thin Solid Films 2015, 589, 590–596. [Google Scholar] [CrossRef]

- Li, Q.H.; Savalani, M.M.; Zhang, Q.M.; Huo, L. High temperature wear characteristics of TiC composite coatings formed by laser cladding with CNT additives. Surf. Coat. Technol. 2014, 239, 206–211. [Google Scholar] [CrossRef]

- Kumar, N.; Natarajan, G.; Dumpala, R.; Pandian, R.; Bahuguna, A.; Srivastava, S.K.; Ravindran, T.R.; Rajagopalan, S.; Dash, S.; Tyagi, A.K.; et al. Microstructure and phase composition dependent tribological properties of TiC/a-C nanocomposite thin films. Surf. Coat. Technol. 2014, 258, 557–565. [Google Scholar] [CrossRef]

- Kumar, N.; Natarajan, G.; Kumar, D.D.; Krishna, N.G.; Ravindran, T.R.; Dash, S.; Tyagi, A.K. Wear resistant multiphase compound of Ti(C,O,N)/a-C:H nanocomposite film. Thin Solid Films 2015, 590, 17–27. [Google Scholar] [CrossRef]

- Hossein-Babaei, F.; Rahbarpour, S. Titanium and silver contacts on thermally oxidized titanium chip: Electrical and gas sensing properties. Solid-State Electron. 2011, 56, 185–190. [Google Scholar] [CrossRef]

- Damm, C.; Israel, G. Photoelectric properties and photocatalytic activity of silver-coated titanium dioxides. Dyes Pigments 2007, 75, 612–618. [Google Scholar] [CrossRef]

- Guo, C.; Chen, J.; Zhou, J.; Zhao, J.; Wang, L.; Yu, Y.; Zhou, H. Microstructure and tribological properties of TiAg intermetallic compound coating. Appl. Surf. Sci. 2011, 257, 10692–10698. [Google Scholar] [CrossRef]

- Cao, H.; Liu, X.; Meng, F.; Chu, P.K. Biological actions of silver nanoparticles embedded in titanium controlled by micro-galvanic effects. Biomaterials 2011, 32, 693–705. [Google Scholar] [CrossRef] [PubMed]

- Song, D.-H.; Uhm, S.-H.; Lee, S.-B.; Han, J.-G.; Kim, K.-N. Antimicrobial silver-containing titanium oxide nanocomposite coatings by a reactive magnetron sputtering. Thin Solid Films 2011, 519, 7079–7085. [Google Scholar] [CrossRef]

- Wang, Z.; Cai, X.; Chen, Q.; Chu, P. K. Effects of Ti transition layer on stability of silver/titanium dioxide multilayered structure. Thin Solid Films 2007, 515, 3146–3150. [Google Scholar] [CrossRef]

- Kerti, I. Production of TiC reinforced-aluminum composites with the addition of elemental carbon. Mater. Lett. 2005, 59, 3795–3800. [Google Scholar] [CrossRef]

- Song, M.S.; Huang, B.; Zhang, M.X.; Li, J.G. Study of formation behavior of TiC ceramic obtained by self-propagating high-temperature synthesis from Al–Ti–C elemental powders. Int. J. Refract. Met. Hard Mater. 2009, 27, 584–589. [Google Scholar] [CrossRef]

- Xiao, G.; Fan, Q.; Gu, M.; Jin, Z. Microstructural evolution during the combustion synthesis of TiC–Al cermet with larger metallic particles. Mater. Sci. Eng. A 2006, 425, 318–325. [Google Scholar] [CrossRef]

- Song, M.S.; Zhang, M.X.; Zhang, S.G.; Huang, B.; Li, J.G. In situ fabrication of TiC particulates locally reinforced aluminium matrix composites by self-propagating reaction during casting. Mater. Sci. Eng. A 2008, 473, 166–171. [Google Scholar] [CrossRef]

- Lauridsen, J.; Eklund, P.; Jensen, J.; Hultman, L. Effects of A-elements (A = Si, Ge or Sn) on the structure and electrical contact properties of Ti–A–C–Ag nanocomposites. Solid Films 2012, 520, 5128–5136. [Google Scholar] [CrossRef]

- Sarius, N.G.; Lauridsen, J.; Lewin, E.; Lu, J.; Högberg, H.; Öberg, A.; Ljungcrantz, H.; Leisner, P.; Eklund, P.; Hultman, L. Ni and Ti diffusion barrier layers between Ti–Si–C and Ti–Si–C–Ag nanocomposite coatings and Cu-based substrates. Surf. Coat. Technol. 2012, 206, 2558–2565. [Google Scholar] [CrossRef]

- Almeida Alves, C.F.; Oliveira, F.; Carvalho, I.; Piedade, A.P.; Carvalho, S. Influence of albumin on the tribological behavior of Ag–Ti (C, N) thin films for orthopedic implants. Mater. Sci. Eng. C 2014, 34, 22–28. [Google Scholar] [CrossRef] [PubMed]

- Musa, G.; Ehrich, H.; Mausbach, M. Studies on thermionic cathode anodic vacuum arcs. J. Vac. Sci. Technol. A 1994, 12, 2887–2895. [Google Scholar] [CrossRef]

- Vladoiu, R.; Mandes, A.; Dinca-Balan, V.; Prodan, G.; Kudrna, P.; Tichy, M. Magnesium plasma diagnostics by heated probe and characterization of the Mg thin films deposited by thermionic vacuum arc technology. Plasma Sources Sci. Technol. 2015, 24, 035008. [Google Scholar] [CrossRef]

- Mandes, A.; Vladoiu, R.; Dinca, V.; Prodan, G. Binary C-Ag Plasma breakdown and structural characterization of the deposited thin films by thermionic vacuum arc (TVA) method. IEEE Trans. Plasma Sci. 2014, 42, 2806–2807. [Google Scholar] [CrossRef]

- Ciupina, V.; Morjan, I.; Vladoiu, R.; Nicolescu, V. Application of carbon-tungsten, carbon-beryllium and carbon-aluminium nanostructures in divertors coatings from fusion reactor. J. Optoelectron. Adv. Mater. 2013, 15, 1450–1456. [Google Scholar]

- Ciupina, V.; Vladoiu, R.; Popov, P.; Dinca, V.; Contulov, M.; Mandes, A.; Lungu, C.P. Characterization of nanostructured TiC thin films synthesized by TVA (Thermionic Vacuum Arc) method. J. Mater. Sci. Eng. A 2012, 2, 16–21. [Google Scholar]

- Vladoiu, R.; Ciupina, V.; Mandes, A.; Dinca, V.; Prodan, M.; Musa, G. Growth and characteristics of tantalum oxide thin films deposited using Thermionic Vacuum Arc (TVA) technology. J. Appl. Phys. 2010, 108, 093301. [Google Scholar] [CrossRef]

- Vladoiu, R.; Mandes, A.; Dinca, V.; Contulov, M.; Ciupina, V.; Lungu, C.P.; Musa, G. Industrial Plasma Technology: Applications from Environmental to Energy Technologies; Wiley-VCH: Weinheim, Germany, 2010; pp. 357–365. [Google Scholar]

- Worner, H.W. The structure of the titanium-silver alloys in the range 0–30 at % silver. J. Inst. Met. 1953, 82, 222–226. [Google Scholar]

- Van Thyne, R.J.; Kessler, H.D.; Rostoker, W. Observations on the Ti Ag. J. Met. 1953, 197, 670–671. [Google Scholar]

- Wyckoff, R.W.G. WWW-MINCRYST, SILVER-4219. Cryst. Struct. 1963, 1, 7–10. [Google Scholar]

- Wyckoff, R.W.G. WWW-MINCRYST, TITANIUM-4770. Cryst. Struct. 1963, 1, 9–11. [Google Scholar]

- Christensen, A.N. The Temperature Factor Parameters of Some Transition Metal Carbides and Nitrides by Single Crystal X-ray and Neutron Diffraction. Acta Chem. Scand. A 1978, 32, 89–90. [Google Scholar] [CrossRef]

- Patterson, A.L. The Scherrer formula for X-ray particle size determination. Phys. Rev. 1939, 56, 978. [Google Scholar] [CrossRef]

- Langford, J.I. The accuracy of cell dimensions determined by Cohen’s method of least squares and the systematic indexing of powder data. J. Appl. Cryst. 1973, 6, 190–196. [Google Scholar] [CrossRef]

- Nelson, J.B.; Riley, D.P. An experimental investigation of extrapolation methods in the derivation of accurate unit-cell dimensions of crystals. Proc. Phys. Soc. 1945, 57, 160–176. [Google Scholar] [CrossRef]

- Braun, J.; Ellner, M.; Predel, B. ZurStruktur der Hochtemperaturphase Ti1−xAI1+x. J. Alloys Compd. 1994, 203, 189–193. [Google Scholar] [CrossRef]

- Wyckoff, R.W.G. WWW-MINCRYST, TITANIUM-4771. Cryst. Struct. 1963, 1, 9–11. [Google Scholar]

- Wyckoff, R.W.G. WWW-MINCRYST, ALUMINIUM-136. Cryst. Struct. 1963, 1, 7–10. [Google Scholar]

| Parameters | Ternary | Binary | ||||||

|---|---|---|---|---|---|---|---|---|

| Ti-C-Ag | Ti-C-Al | Ti-C | Ti-Ag | |||||

| C | Ti | Ag | C | Ti | Al | |||

| If (A) | 76 | 38 | 36 | 76 | 38 | 38 | 57 | 54 |

| Ua (kV) | 2.0 | 0.8 | 1.1 | 2.0 | 0.8 | 1.3 | 1.35 | 0.8 |

| Ia (A) | 1.00 | 1.12 | 0.30 | 1.0 | 1.12 | 0.5 | 0.3 | 0.7 |

| Rate of deposition (Ǻ/s) | 0.76 | 0.86 | 0.06 | 0.05 | ||||

| Thickness (nm) | 400 | 1800 | 125 | 100 | ||||

| Pressure during deposition (Pa) | 2.6 × 10−3 | 9.9 × 10−4 | 7.0 × 10−4 | 6.0 × 10−4 | ||||

| Sample | Wear Area (μm2) | Wear Rate (mm3/N m) | Wear Area (μm2) | Wear Rate (mm3/N m) |

|---|---|---|---|---|

| Loading Forces 2 N | Loading Forces 3 N | |||

| Ti-C-Ag/OLC 45 | 6.05 | 1.31 × 10−7 | 645.46 | 2.58 × 10−5 |

| Ti-C-Al/OLC 45 | 18.17 | 4.24 × 10−7 | 58.37 | 2.33 × 10−6 |

| Samples | Contact Angle θ [°] | Free Surface Energy [mJ/m2] | |

|---|---|---|---|

| Water | Ethylene Glycol | ||

| Ti-C-Ag | 137.18 | 86.16 | 13.66 |

| Ti-C-Al | 87.71 | 61.59 | 26.14 |

| Ti-C | 53.70 | 62.50 | 38.30 |

| Ti-Ag | 56.40 | 42.50 | 43.89 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mandes, A.; Vladoiu, R.; Prodan, G.; Dinca, V.; Porosnicu, C.; Dinca, P. The Properties of Binary and Ternary Ti Based Coatings Produced by Thermionic Vacuum Arc (TVA) Technology. Coatings 2018, 8, 114. https://doi.org/10.3390/coatings8030114

Mandes A, Vladoiu R, Prodan G, Dinca V, Porosnicu C, Dinca P. The Properties of Binary and Ternary Ti Based Coatings Produced by Thermionic Vacuum Arc (TVA) Technology. Coatings. 2018; 8(3):114. https://doi.org/10.3390/coatings8030114

Chicago/Turabian StyleMandes, Aurelia, Rodica Vladoiu, Gabriel Prodan, Virginia Dinca, Corneliu Porosnicu, and Paul Dinca. 2018. "The Properties of Binary and Ternary Ti Based Coatings Produced by Thermionic Vacuum Arc (TVA) Technology" Coatings 8, no. 3: 114. https://doi.org/10.3390/coatings8030114

APA StyleMandes, A., Vladoiu, R., Prodan, G., Dinca, V., Porosnicu, C., & Dinca, P. (2018). The Properties of Binary and Ternary Ti Based Coatings Produced by Thermionic Vacuum Arc (TVA) Technology. Coatings, 8(3), 114. https://doi.org/10.3390/coatings8030114