The Influence of Process Parameters on the Structure, Phase Composition, and Texture of Micro-Plasma Sprayed Hydroxyapatite Coatings

Abstract

:1. Introduction

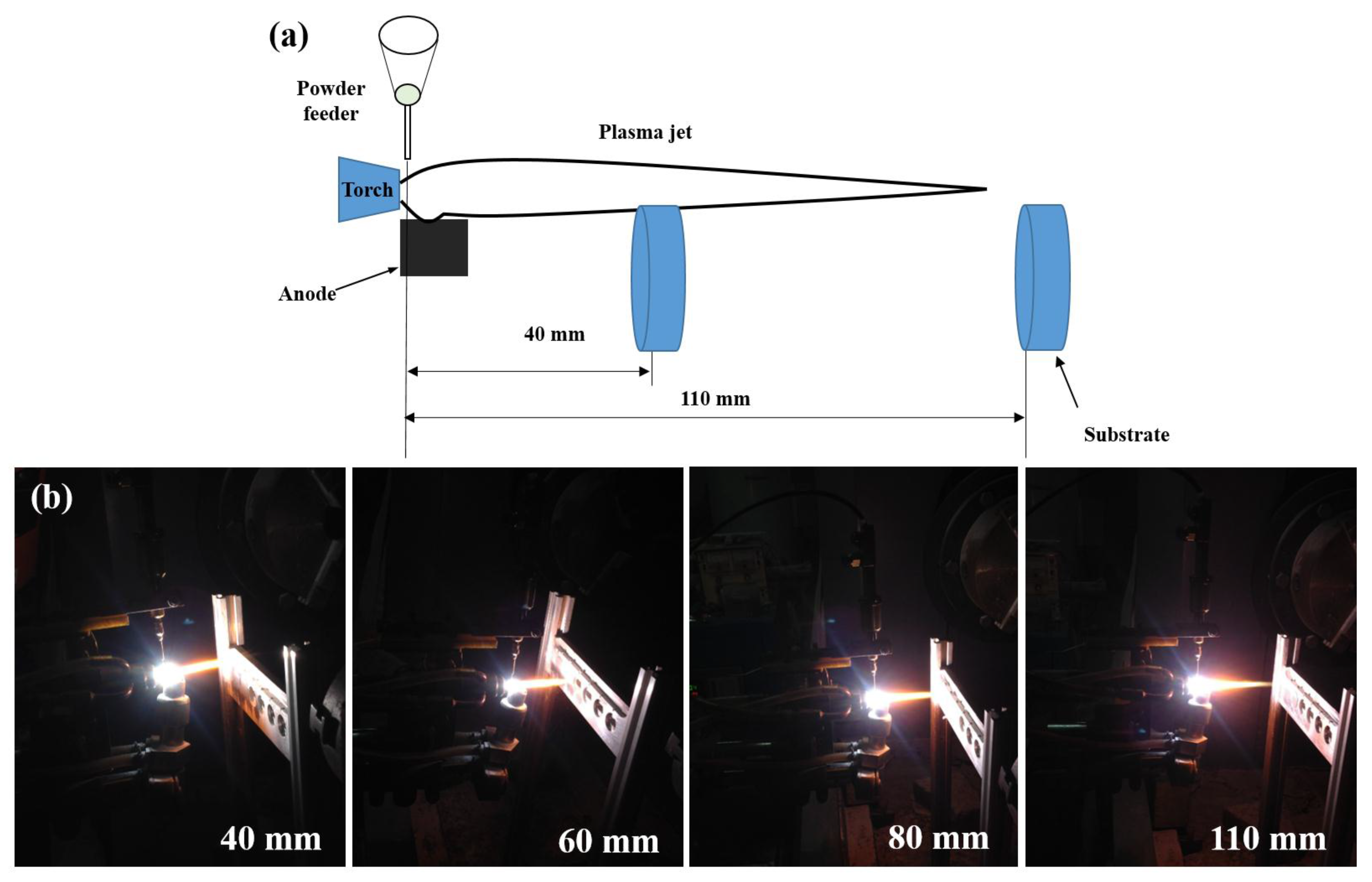

2. Materials and Methods

3. Results

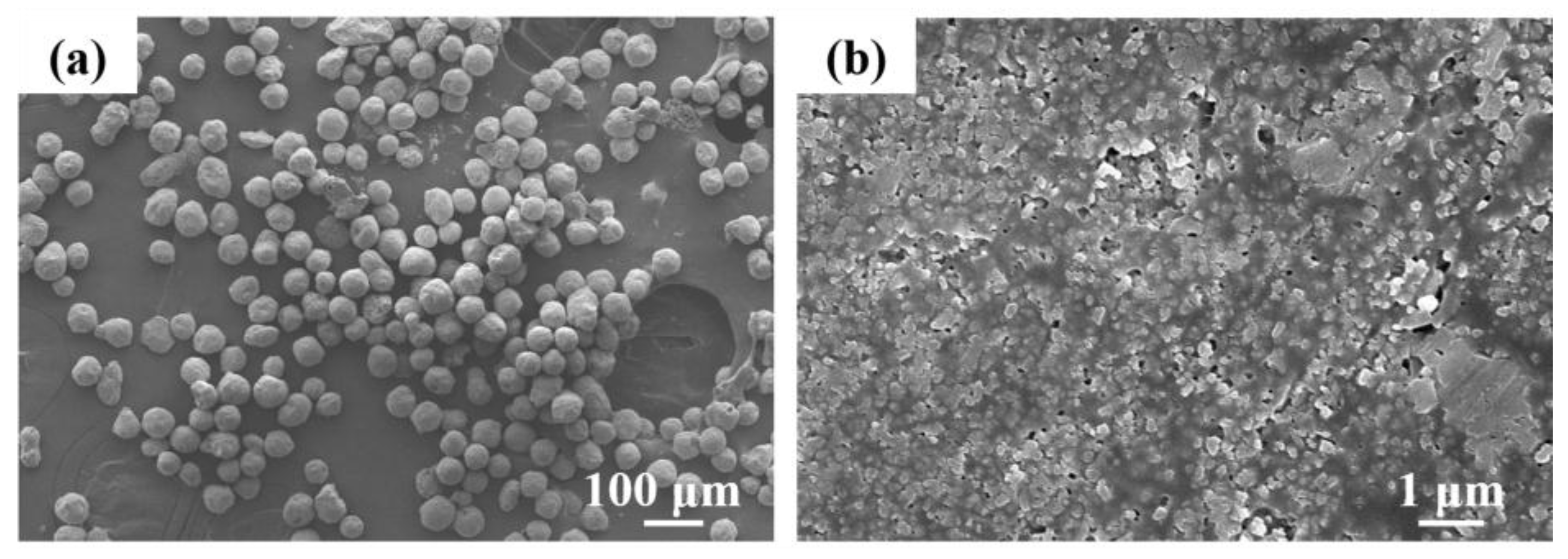

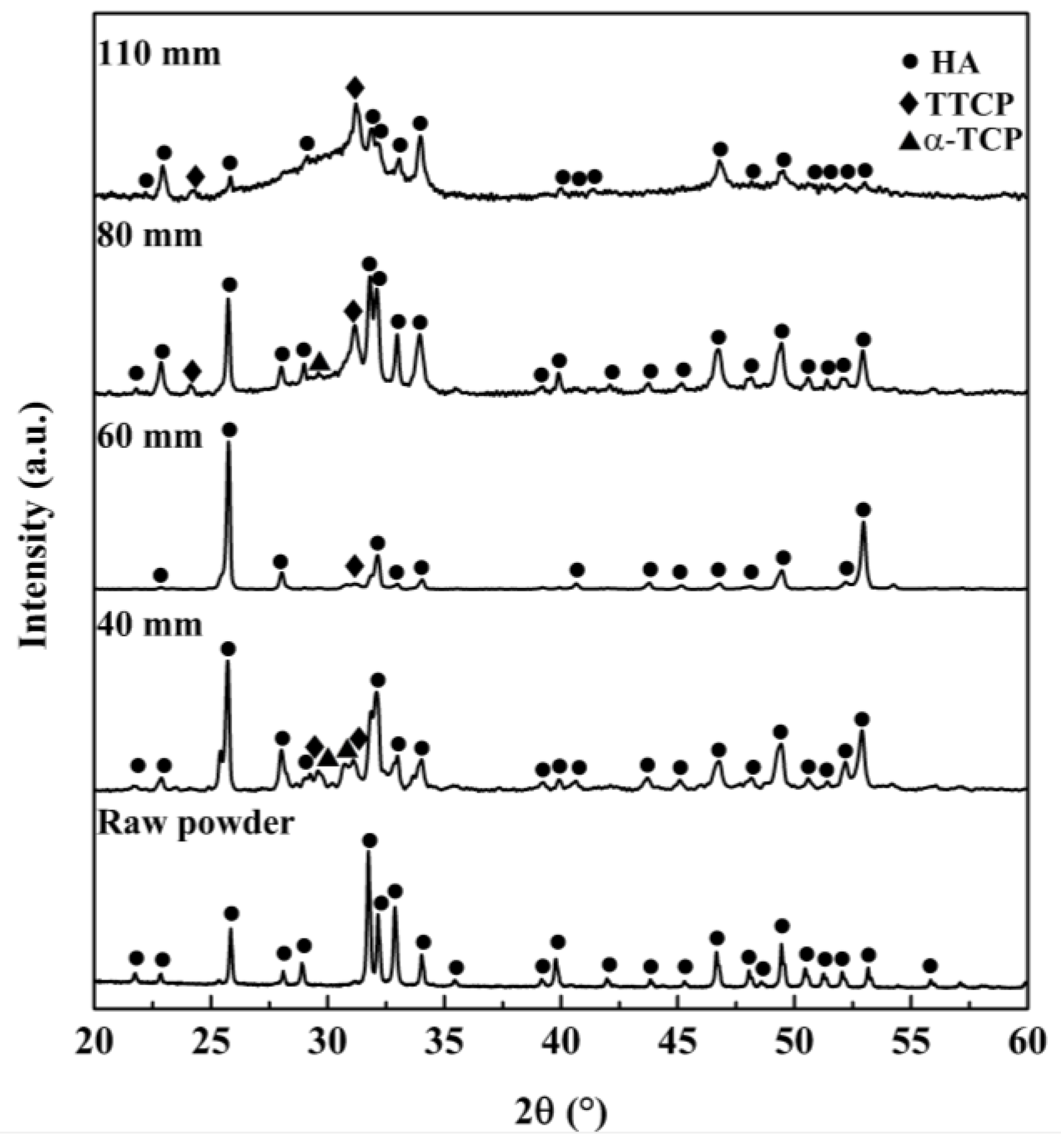

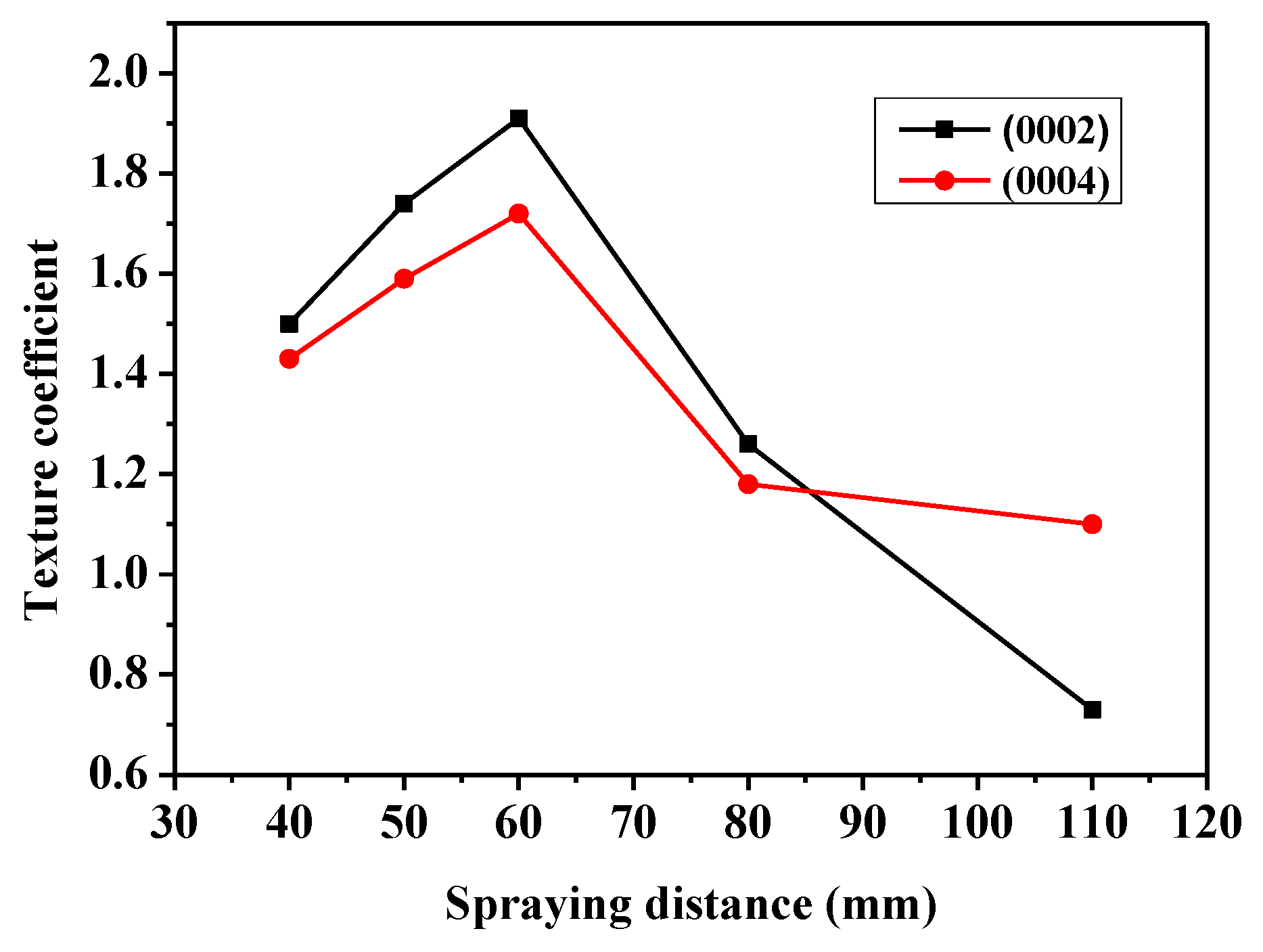

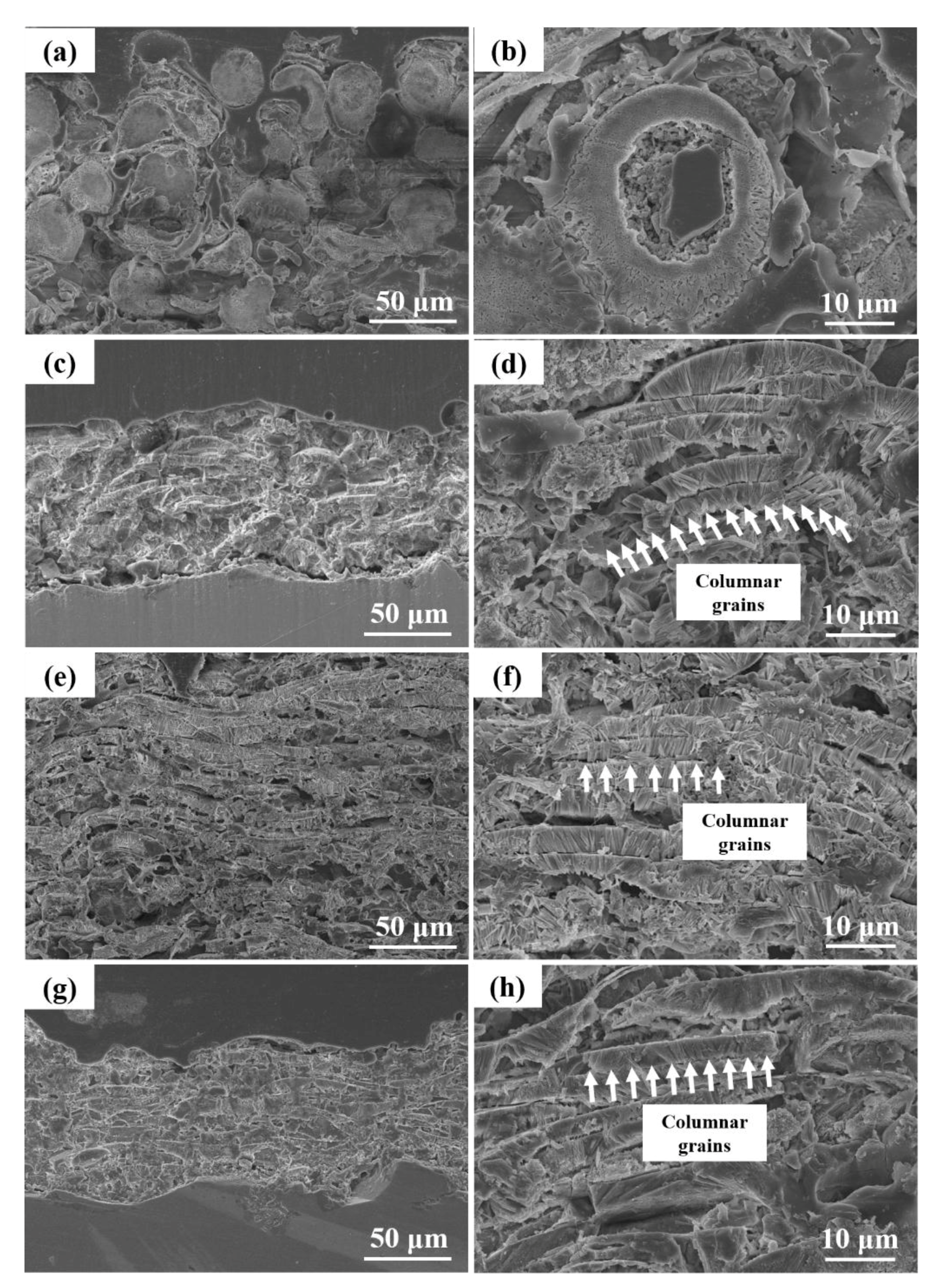

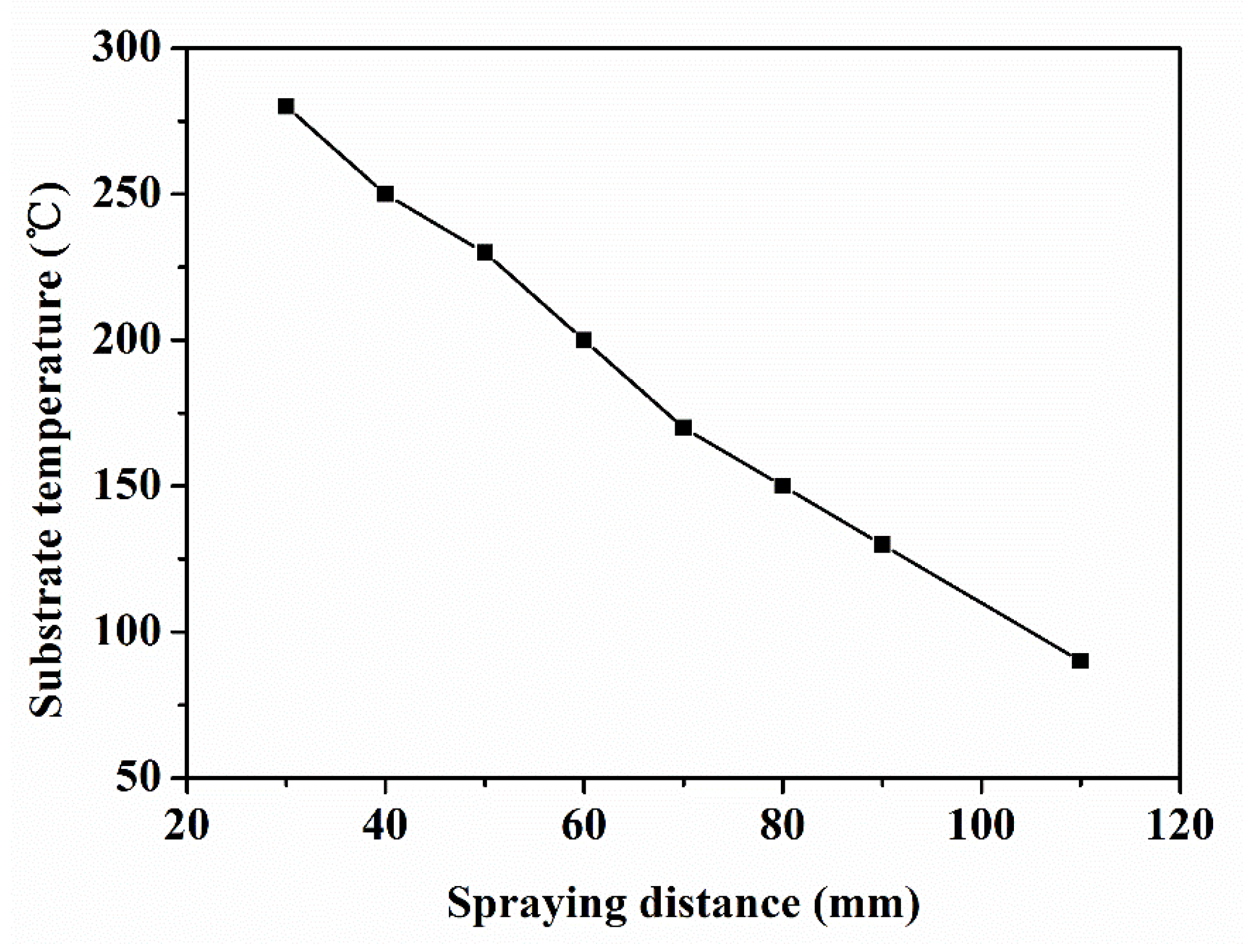

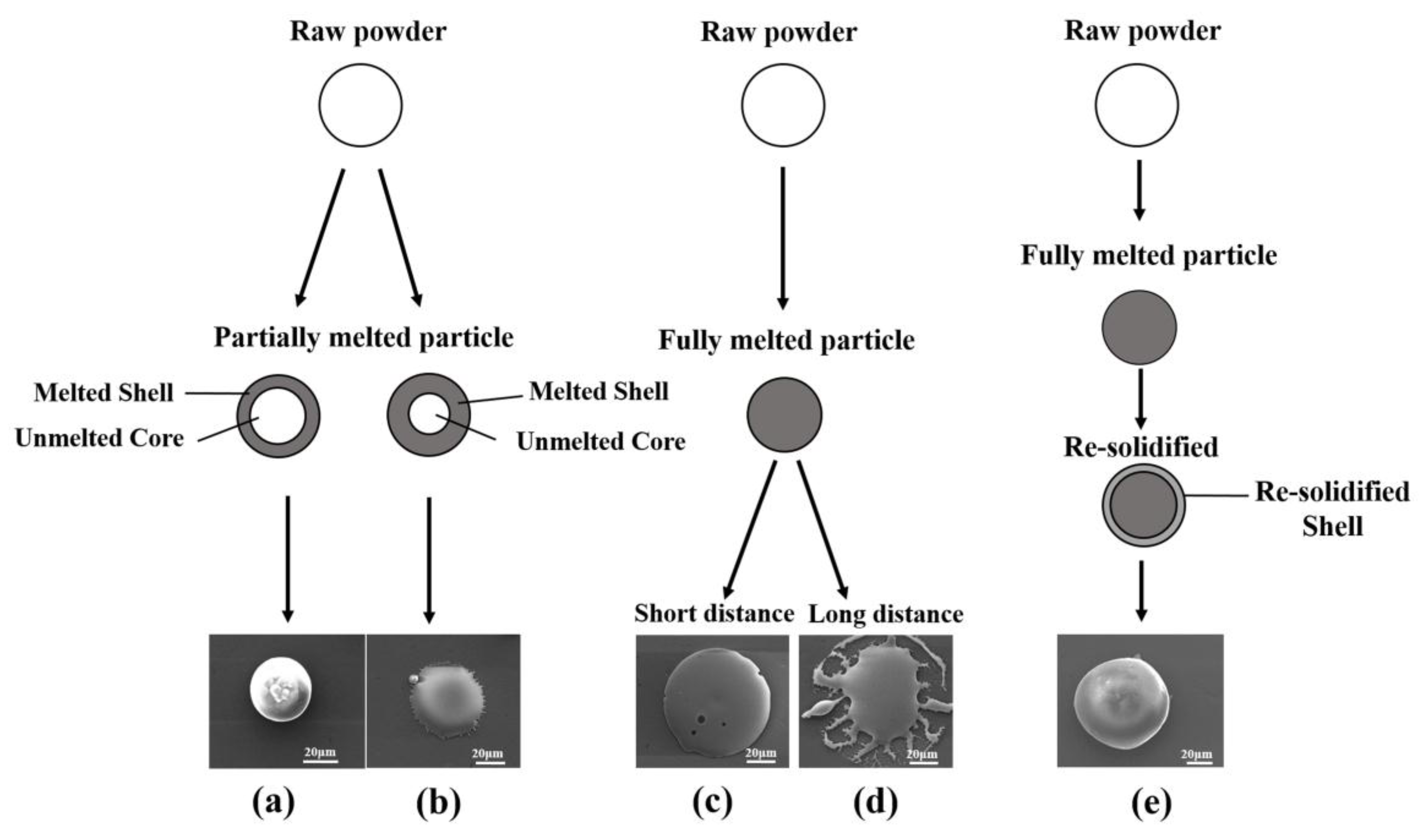

3.1. Microstructure of As-Sprayed Coatings at Different Spraying Distances

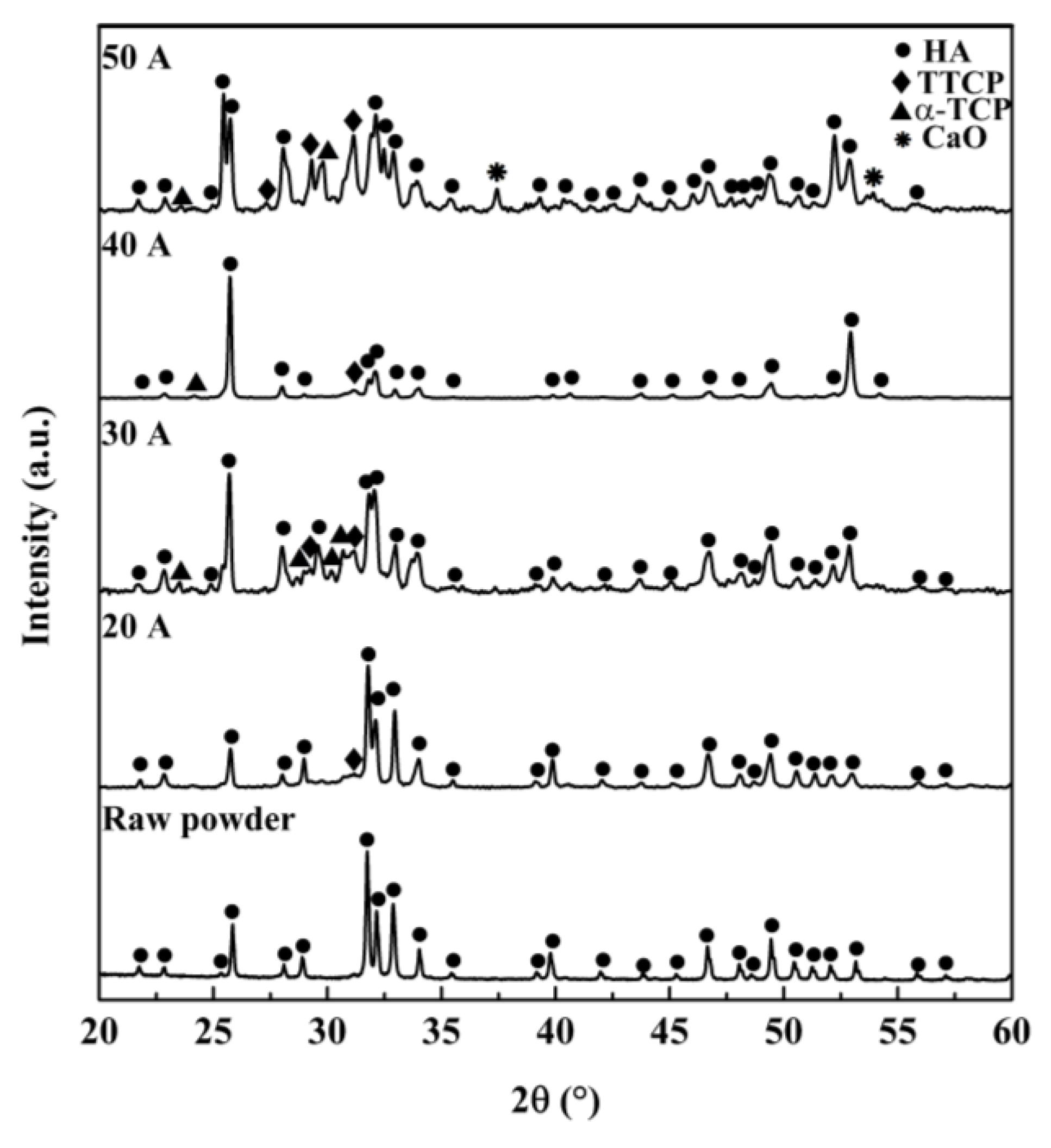

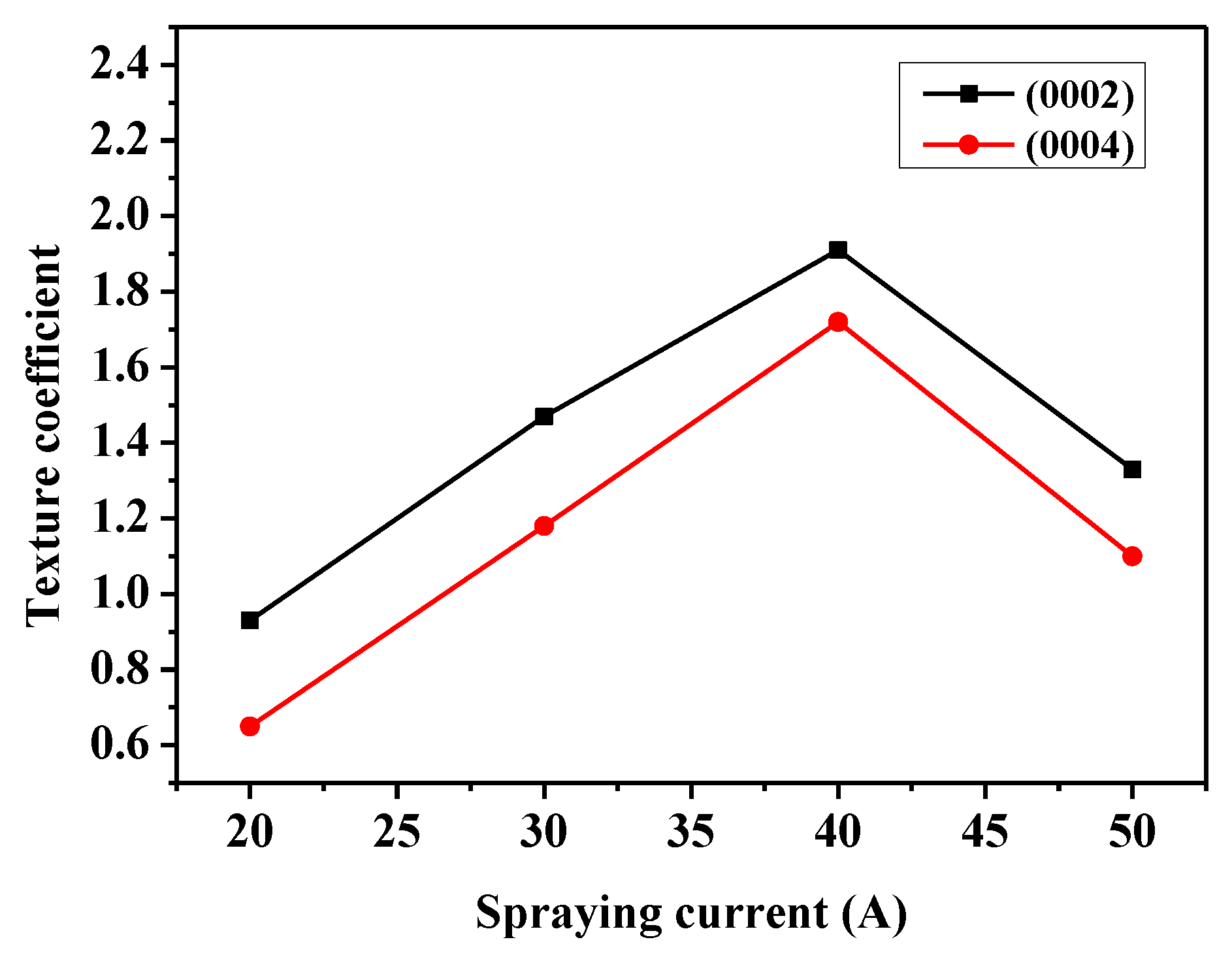

3.2. Microstructure of As-Sprayed Coatings at Different Spraying Currents

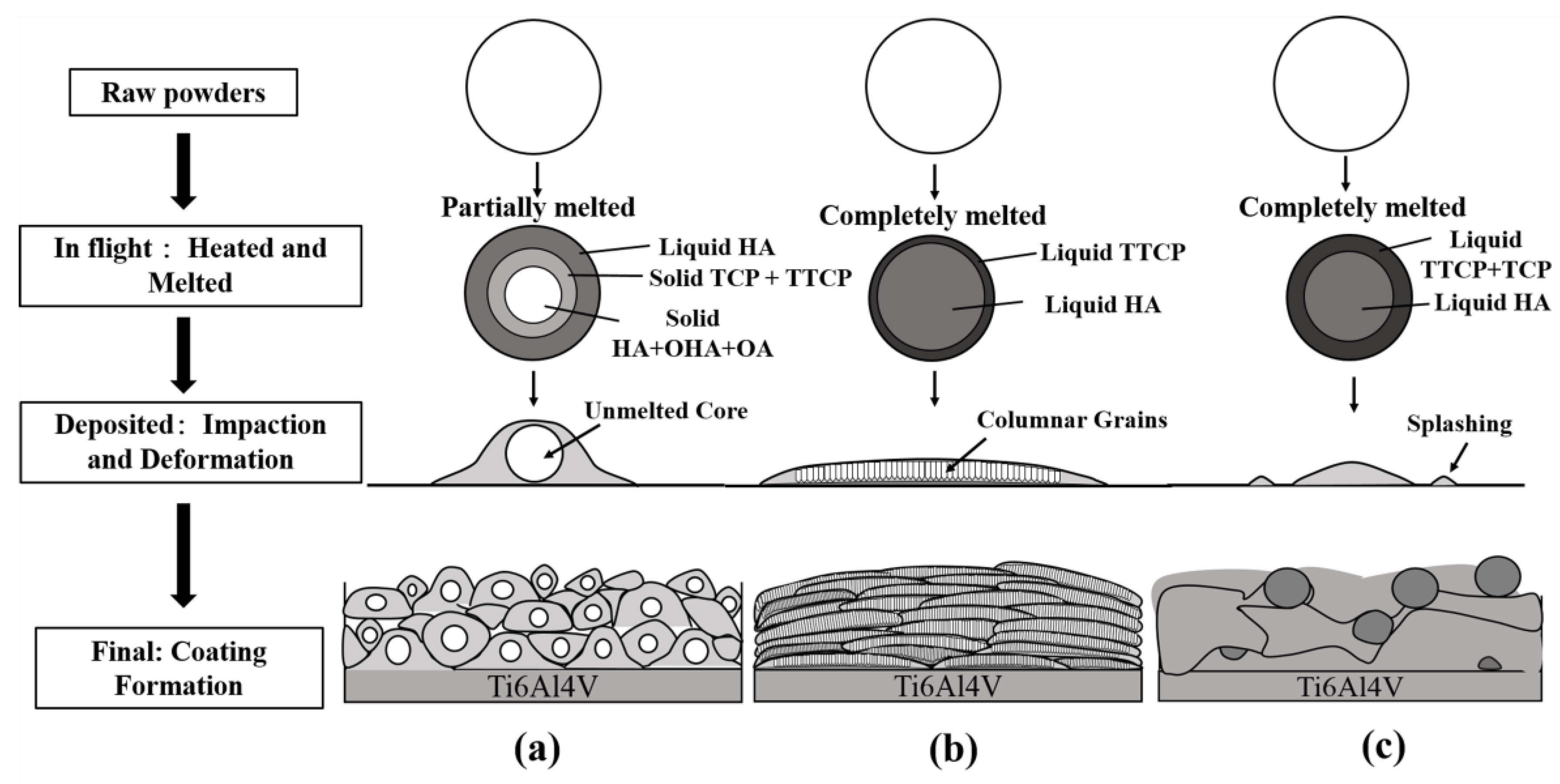

4. Discussion

5. Conclusions

- The process parameters had a significant influence on the phase composition of the coatings. Meanwhile, the texture intensity of the c-axis of HA was greatly influenced by spraying distance and spraying current. The strongest c-axis texture was found in the coating by 60 mm spraying distance with a spraying current of 40 A. Uniform distribution columnar grains with hexagon sections were observed in the upper part of the coating (~100 μm).

- An increase in the number of fully melted particles was connected to an increase in columnar grain ratio. This can be attributed to the fact that the disk shape splats were formed by fully melted particles and that columnar grains preferred to grow within disk shape splats.

- All the texture intensity variation was ascribed to the growth probability of columnar grains during MPS spraying. The texture intensity in MPS-sprayed HA coatings can be controlled by adjusting the melting state of the in-flight particles and the splat type.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Suchanek, W.; Yoshimura, M. Processing and properties of hydroxyapatite-based biomaterials for use as hard tissue replacement implants. J. Mater. Res. 1998, 13, 94–117. [Google Scholar] [CrossRef]

- Heimann, R.B. Structure, properties, and biomedical performance of osteoconductive bioceramic coatings. Surf. Coat. Technol. 2013, 233, 7–28. [Google Scholar] [CrossRef]

- Bhadang, K.A.; Gross, K.A. Influence of fluorapatite on the properties of thermally sprayed hydroxyapatite coatings. Biomaterials 2004, 25, 4935–4945. [Google Scholar] [CrossRef] [PubMed]

- Heimann, R.B. Plasma-sprayed hydroxylapatite-based coatings: Chemical, mechanical, microstructural, and biomedical properties. J. Therm. Spray Technol. 2016, 25, 827–850. [Google Scholar] [CrossRef]

- Vahabzadeh, S.; Roy, M.; Bandyopadhyay, A.; Bose, S. Phase stability and biological property evaluation of plasma sprayed hydroxyapatite coatings for orthopedic and dental applications. Acta Biomater. 2005, 17, 47–55. [Google Scholar] [CrossRef] [PubMed]

- Ong, J.L.; Carnes, D.L.; Bessho, K. Evaluation of titanium plasma-sprayed and plasma-sprayed hydroxyapatite implants In Vivo. Biomaterials 2004, 25, 4601–4606. [Google Scholar] [CrossRef] [PubMed]

- Chen, Q.; Thouas, G.A. Metallic implant biomaterials. Mater. Sci. Eng. R Rep. 2015, 87, 1–57. [Google Scholar] [CrossRef]

- Hung, K.Y.; Lai, H.C.; Yang, Y.C.; Feng, H.P. Characterization of hydroxyapatite (HA) sputtering targets by APS methods. Coatings 2017, 7, 197. [Google Scholar] [CrossRef]

- Zhao, L.; Bobzin, K.; Ernst, F.; Zwick, J.; Lugscheider, E. Study on the influence of plasma spray process and spray parameters on the structure and crystallinity of hydroxyapatite coatings. Mater. Werkst. 2006, 37, 516–520. [Google Scholar] [CrossRef]

- Ducheyne, P.; Radin, S.; King, L. The effect of calcium phosphate ceramic composition and structure on in vitro behavior. I. Dissolution. J. Biomed. Mater. Res. 1993, 27, 25–34. [Google Scholar] [CrossRef] [PubMed]

- Lugscheider, E.; Bobzin, K.; Zhao, L.; Zwick, J. Assessment of the microplasma spraying process for coating application. Adv. Eng. Mater. 2006, 8, 635–639. [Google Scholar] [CrossRef]

- Surmenev, R.A.; Surmeneva, M.A.; Ivanova, A.A. Significance of calcium phosphate coatings for the enhancement of new bone osteogenesis—A review. Acta Biomater. 2014, 10, 557–579. [Google Scholar] [CrossRef] [PubMed]

- Borisov, Y.; Voynarovych, S.G.; Kislitsa, A.N.; Borisova, A.L.; Karpetz, M.V.; Tunik, A.Y. Effect of microplasma spray conditions on structure, phase composition and texture of hydroxyapatite coatings. In Proceedings of the 2006 International Thermal Spray Conference, Seattle, WA, USA, 15–18 May 2006; pp. 29–34. [Google Scholar]

- Wang, Y.M.; Fan, T.T.; Zhou, Z.; He, D.Y. Hydroxyapatite coating with strong (002) crystallographic texture deposited by micro-plasma spraying. Mater. Lett. 2016, 185, 484–487. [Google Scholar] [CrossRef]

- Dey, A.; Mukhopadhyay, A.K.; Gangadharan, S.; Sinha, M.K.; Basu, D. Characterization of microplasma sprayed hydroxyapatite coating. J. Therm. Spray Technol. 2009, 18, 578–592. [Google Scholar] [CrossRef]

- Roy, M.; Bandyopadhyay, A.; Bose, S. Induction plasma sprayed nano hydroxyapatite coatings on titanium for orthopaedic and dental implants. Surf. Coat. Technol. 2011, 205, 2785–2792. [Google Scholar] [CrossRef] [PubMed]

- Almora-Barrios, N.; Austen, K.F.; de Leeuw, N.H. Density functional theory study of the binding of glycine, proline, and hydroxyproline to the hydroxyapatite (0001) and (0110) surfaces. Langmuir 2009, 25, 5018–5025. [Google Scholar] [CrossRef] [PubMed]

- Dong, X.L.; Zhou, H.L.; Wu, T.; Wang, Q. Behavior regulation of adsorbed proteins via hydroxyapatite surface texture control. J. Phys. Chem. C 2008, 112, 4751–4759. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.M.; Liu, X.M.; Fan, T.T.; Tan, Z.; Zhou, Z.; He, D.Y. In vitro evaluation of hydroxyapatite coatings with (002) crystallographic texture deposited by micro-plasma spraying. Mater. Sci. Eng. C 2017, 75, 596–601. [Google Scholar] [CrossRef] [PubMed]

- Kim, H.; Camata, R.P.; Chowdhury, S.; Vohra, Y.K. In vitro dissolution and mechanical behavior of the c-axis preferentially oriented hydroxyapatite thin films fabricated by pulsed laser deposition. Acta Biomater. 2010, 6, 3234–3241. [Google Scholar] [CrossRef] [PubMed]

- Dinu, M.; Ivanova, A.A.; Surmeneva, M.A.; Braic, M.; Tyurin, A.I.; Braic, V.; Vladescu, A. Tribological behaviour of RF-magnetron sputter deposited hydroxyapatite coatings in physiological solution. Ceram. Int. 2017, 43, 6858–6867. [Google Scholar] [CrossRef]

- Ivanova, A.A.; Surmeneva, M.A.; Surmenev, R.A.; Depla, D. Influence of deposition conditions on the composition, texture and microstructure of RF-magnetron sputter-deposited hydroxyapatite thin films. Thin Solid Films 2015, 591, 368–374. [Google Scholar] [CrossRef]

- Ivanova, A.A.; Surmeneva, M.A.; Surmenev, R.A.; Depla, D. Structural evolution and growth mechanisms of RF-magnetron sputter-deposited hydroxyapatite thin films on the basis of unified principles. Appl. Surf. Sci. 2017, 425, 497–506. [Google Scholar] [CrossRef]

- Fanni, L.; Aebersold, B.A.; Alexander, D.T.L.; Ding, L.; Morales Masis, M.; Nicolay, S.; Ballif, C. c-texture versus a-texture low pressure metalorganic chemical vapor deposition ZnO films: Lower resistivity despite smaller grain size. Thin Solid Films 2014, 565, 1–6. [Google Scholar] [CrossRef]

- Liu, X.M.; He, D.Y.; Wang, Y.M.; Zhou, Z.; Wang, G.H.; Tan, Z.; Wang, Z.J. The influence of spray parameters on the characteristics of hydroxyapatite in-flight particles, splats and coatings by micro-plasma spraying. J. Therm. Spray Technol. 2018. [Google Scholar] [CrossRef]

| Current | Voltage | Flow Rate of Argon | Spraying Distance |

|---|---|---|---|

| 20–50 A | 25 V | 1.3 L/min | 60–110 mm |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, X.; He, D.; Zhou, Z.; Wang, Z.; Wang, G. The Influence of Process Parameters on the Structure, Phase Composition, and Texture of Micro-Plasma Sprayed Hydroxyapatite Coatings. Coatings 2018, 8, 106. https://doi.org/10.3390/coatings8030106

Liu X, He D, Zhou Z, Wang Z, Wang G. The Influence of Process Parameters on the Structure, Phase Composition, and Texture of Micro-Plasma Sprayed Hydroxyapatite Coatings. Coatings. 2018; 8(3):106. https://doi.org/10.3390/coatings8030106

Chicago/Turabian StyleLiu, Xiaomei, Dingyong He, Zheng Zhou, Zengjie Wang, and Guohong Wang. 2018. "The Influence of Process Parameters on the Structure, Phase Composition, and Texture of Micro-Plasma Sprayed Hydroxyapatite Coatings" Coatings 8, no. 3: 106. https://doi.org/10.3390/coatings8030106

APA StyleLiu, X., He, D., Zhou, Z., Wang, Z., & Wang, G. (2018). The Influence of Process Parameters on the Structure, Phase Composition, and Texture of Micro-Plasma Sprayed Hydroxyapatite Coatings. Coatings, 8(3), 106. https://doi.org/10.3390/coatings8030106