Experimental Evaluation and Modeling of the Damping Properties of Multi-Layer Coated Composites

Abstract

:1. Introduction

2. Damping-Oriented Coating Solutions

2.1. GP Solution

2.2. APM and ZPM Solutions

2.3. Specimens Preparation

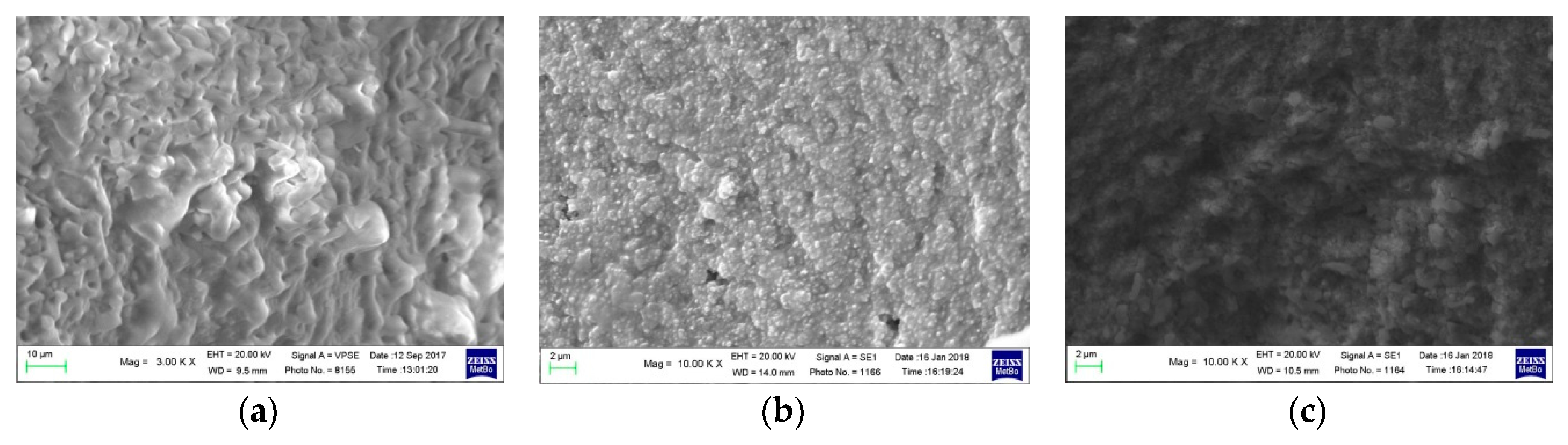

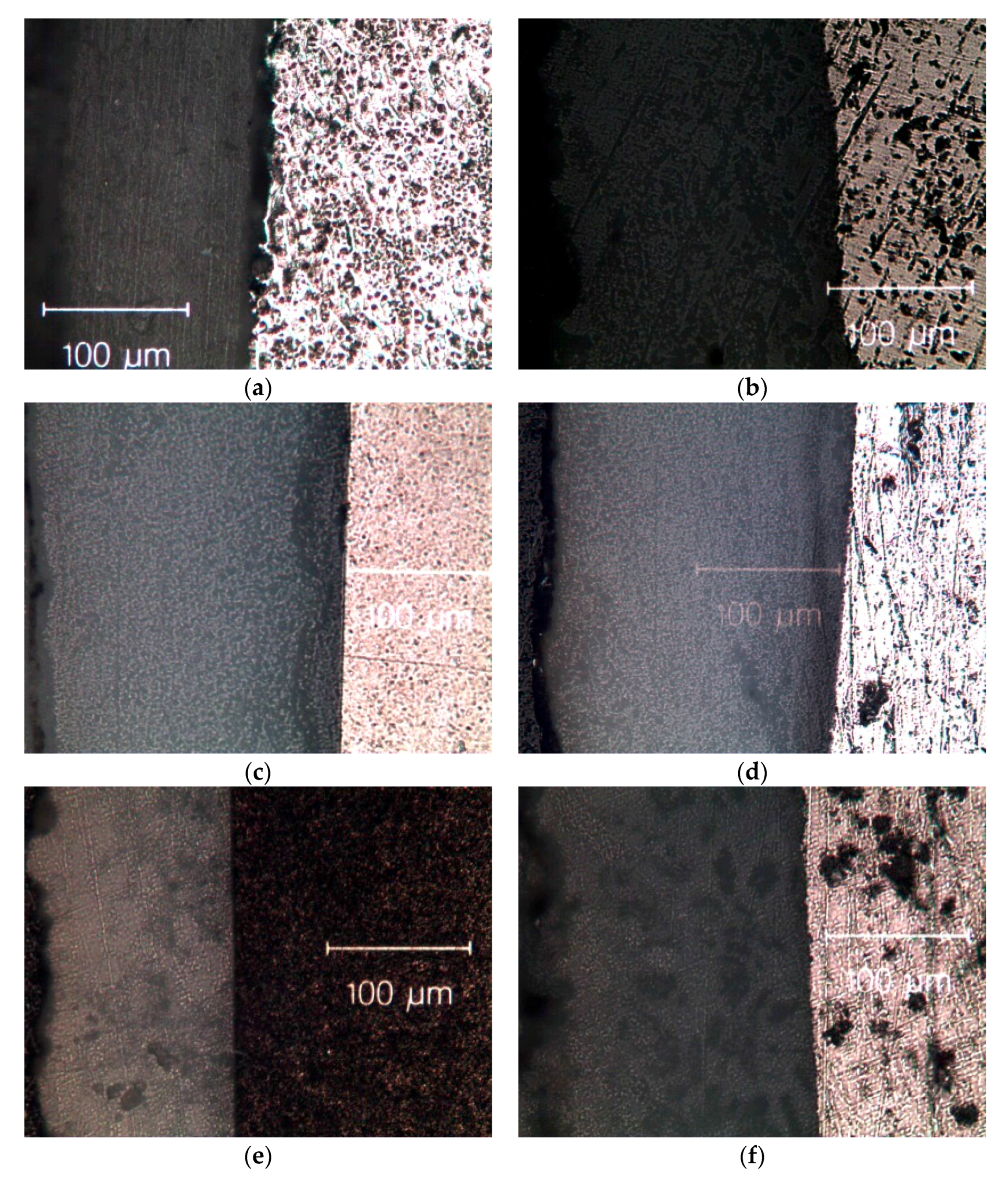

2.4. Optical and SEM Specimen Structural Characterization

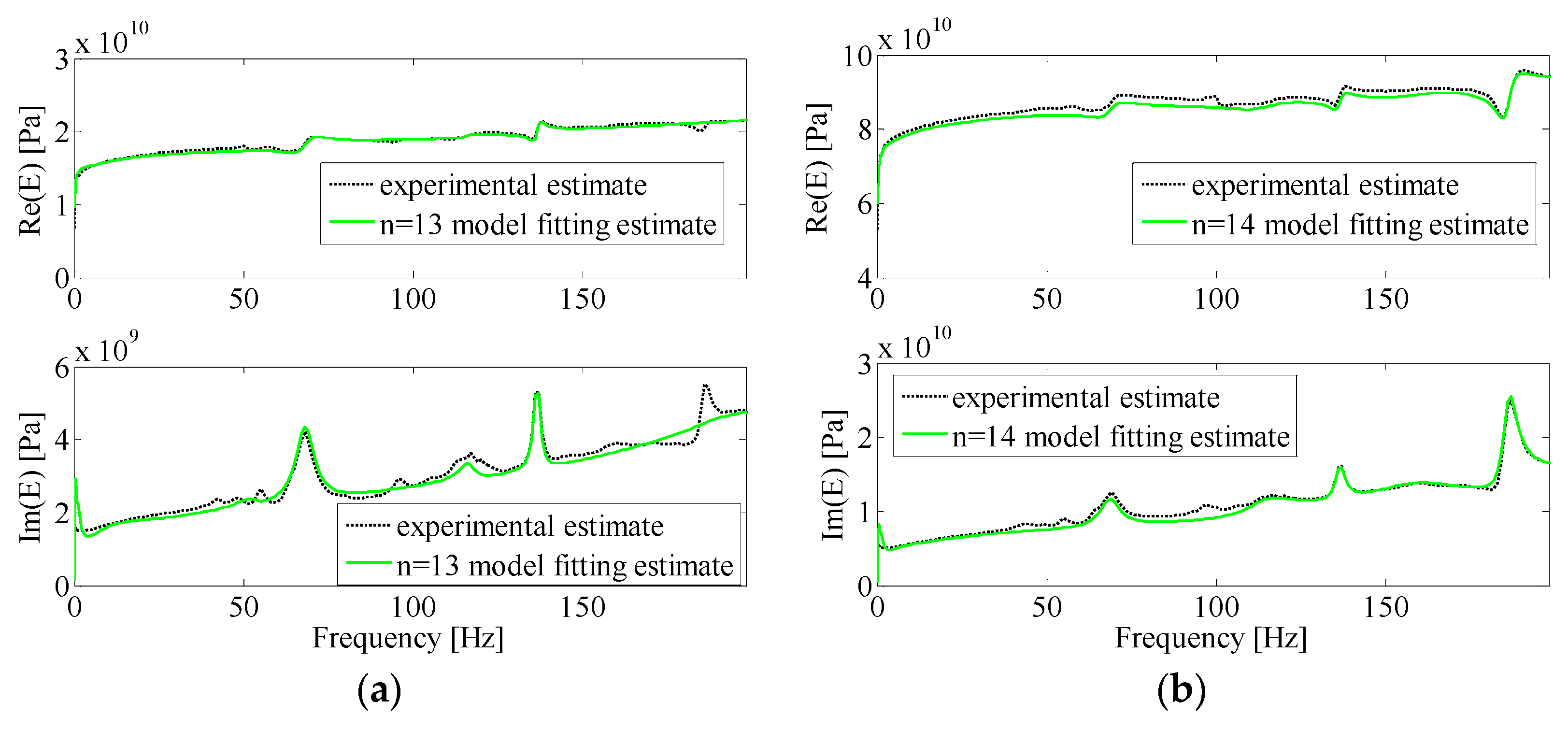

3. Identification Procedure

4. Experimental Set-Up, Measurement and Discussion

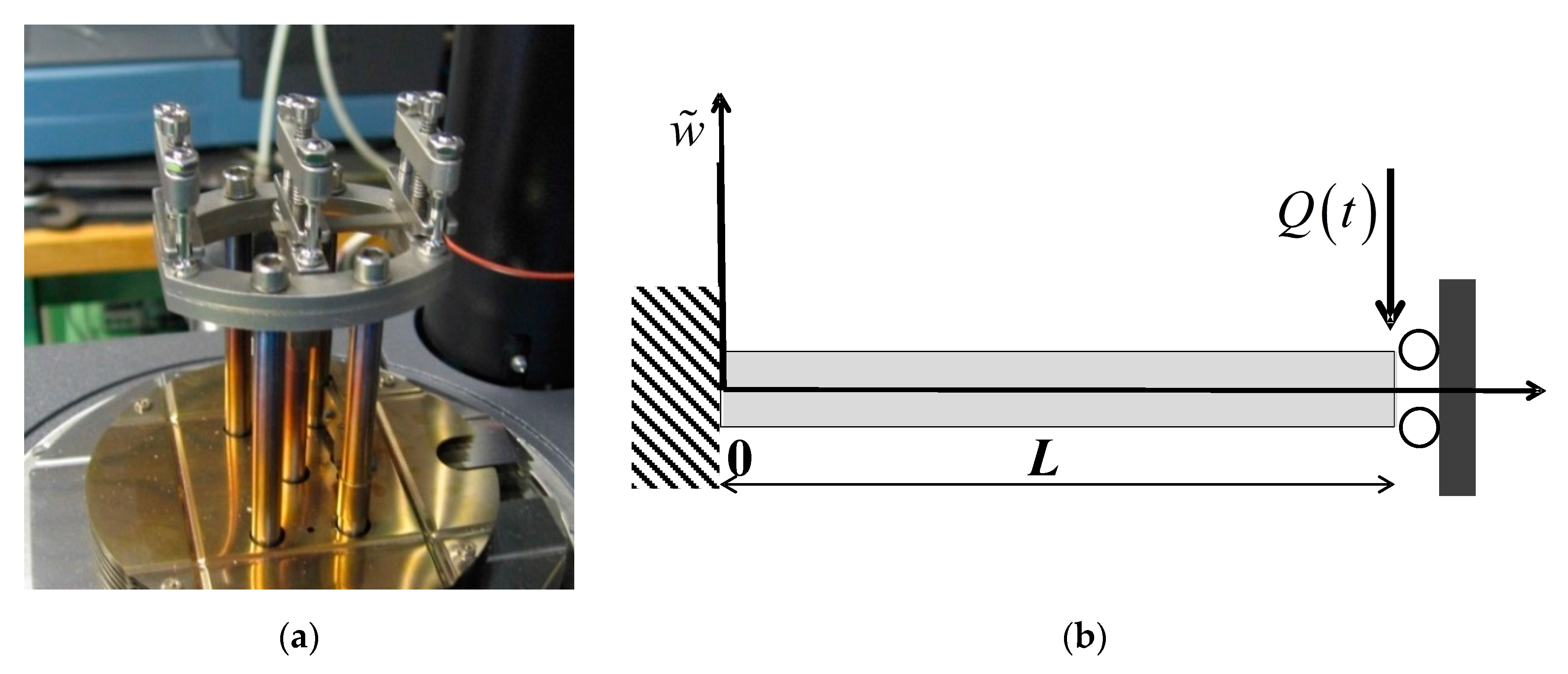

4.1. Experimental Set-Up

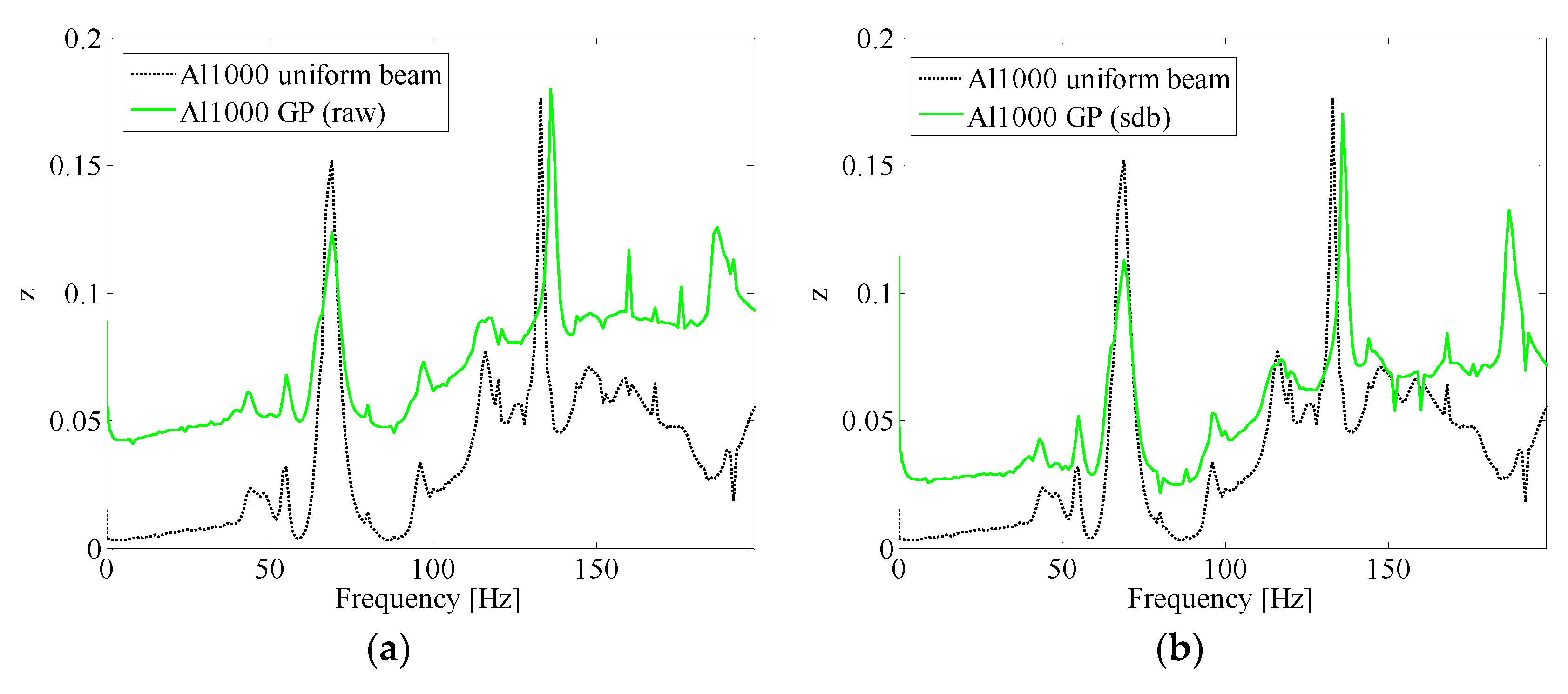

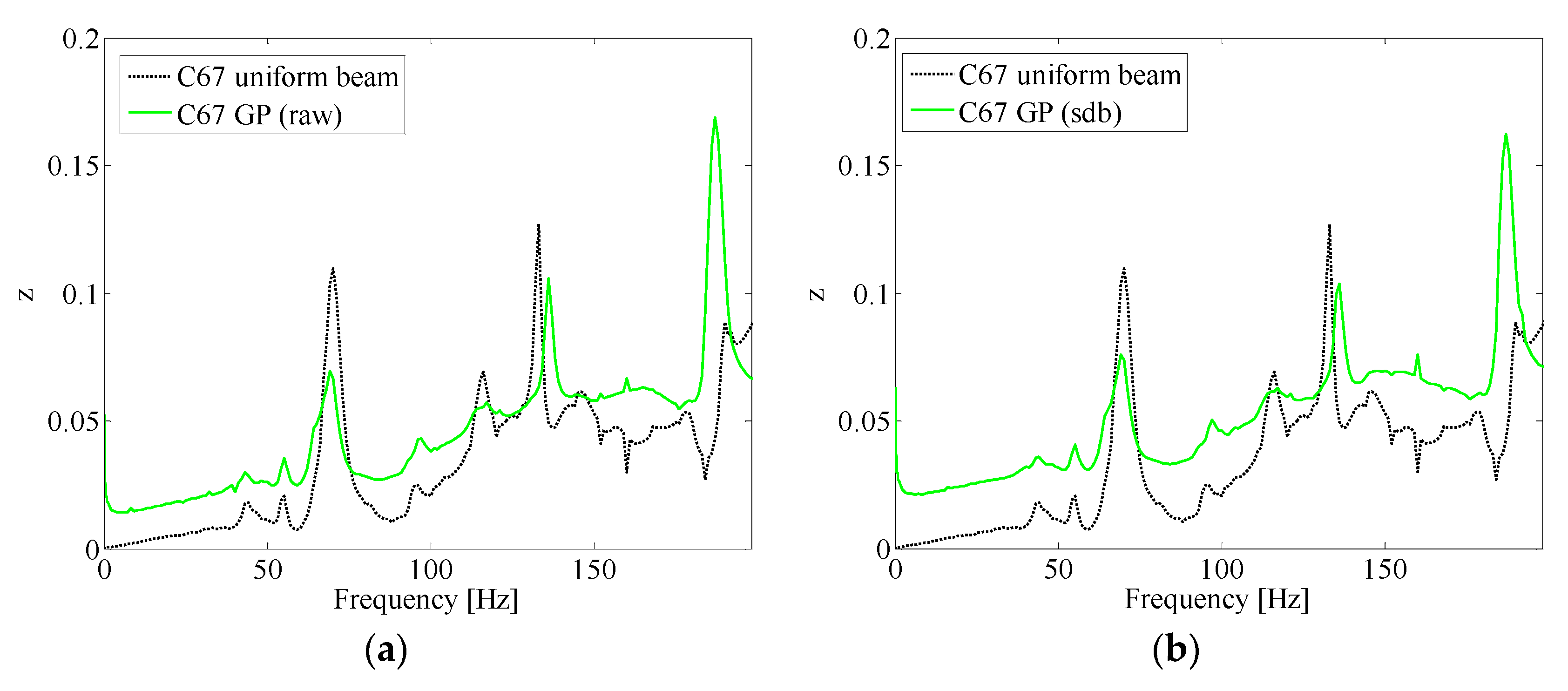

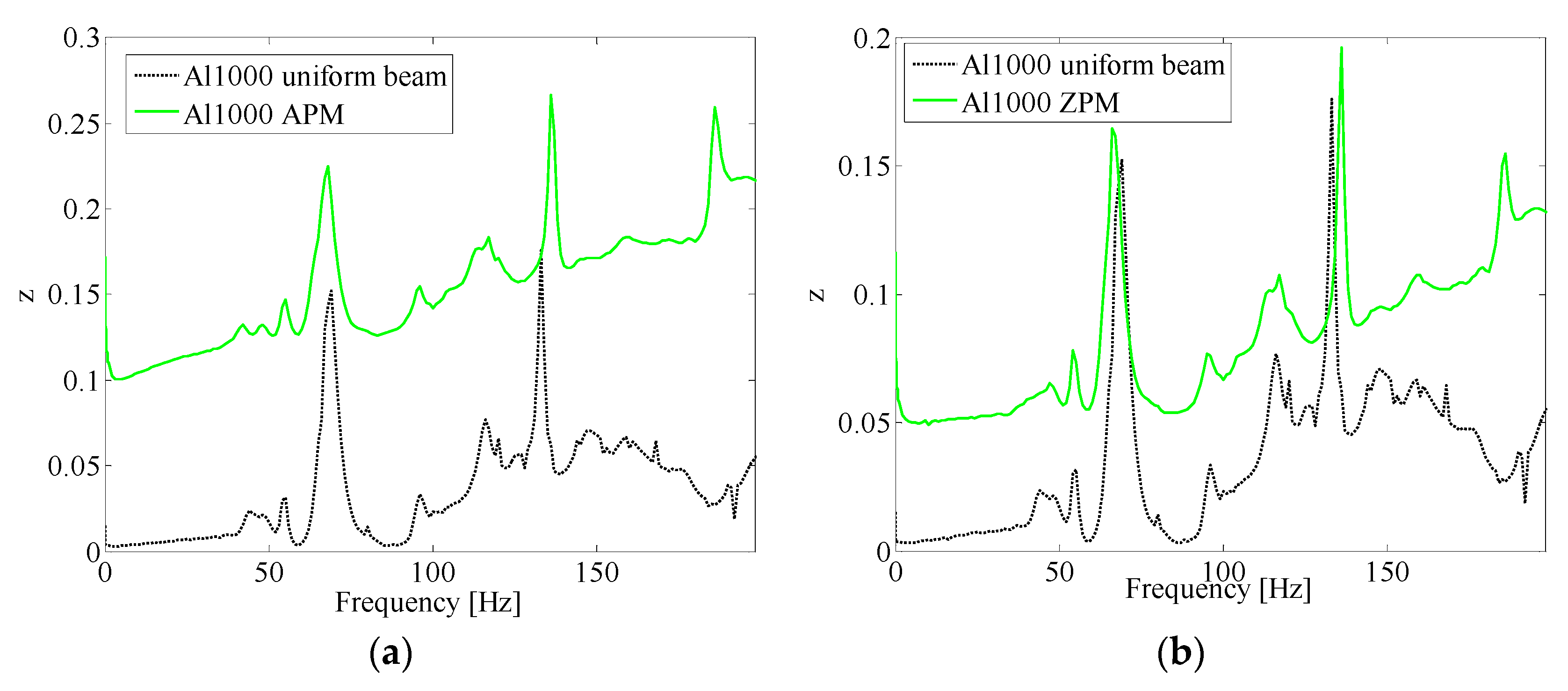

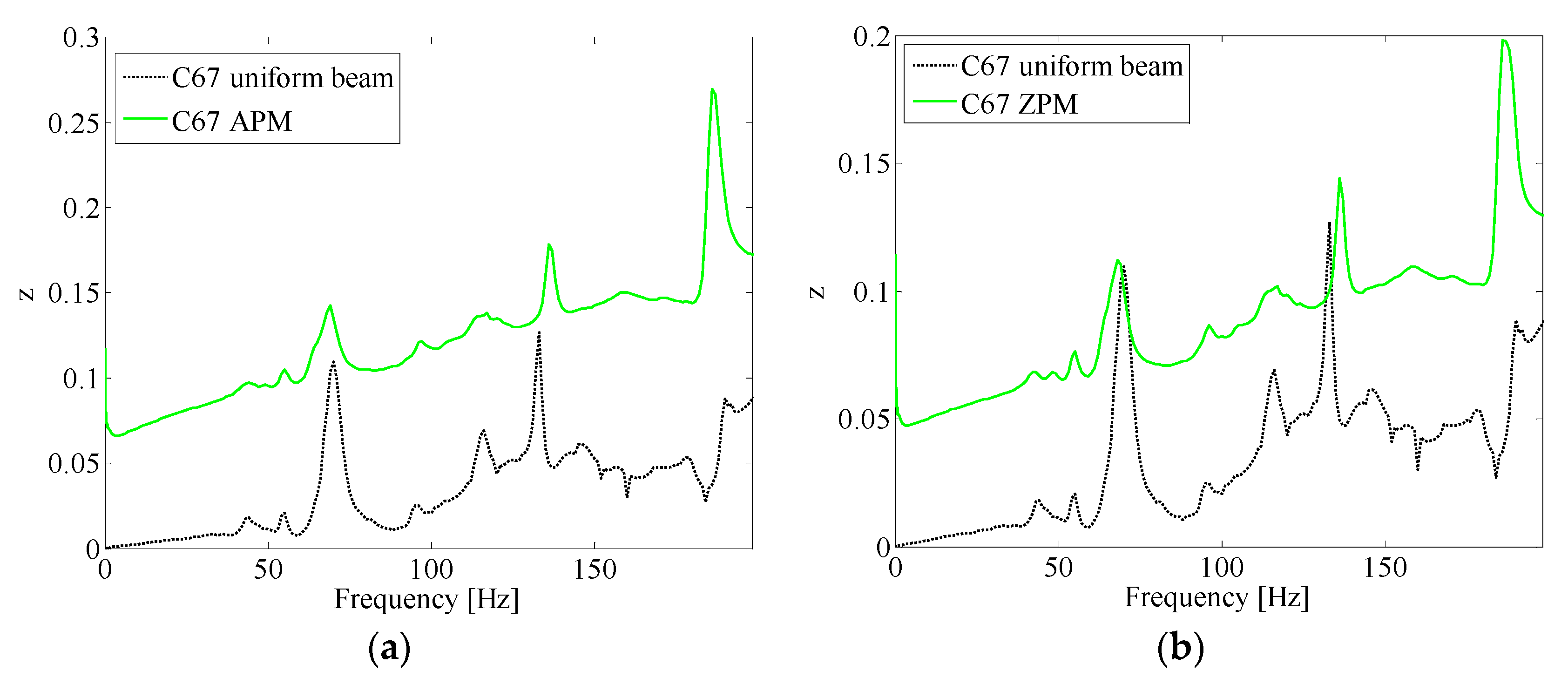

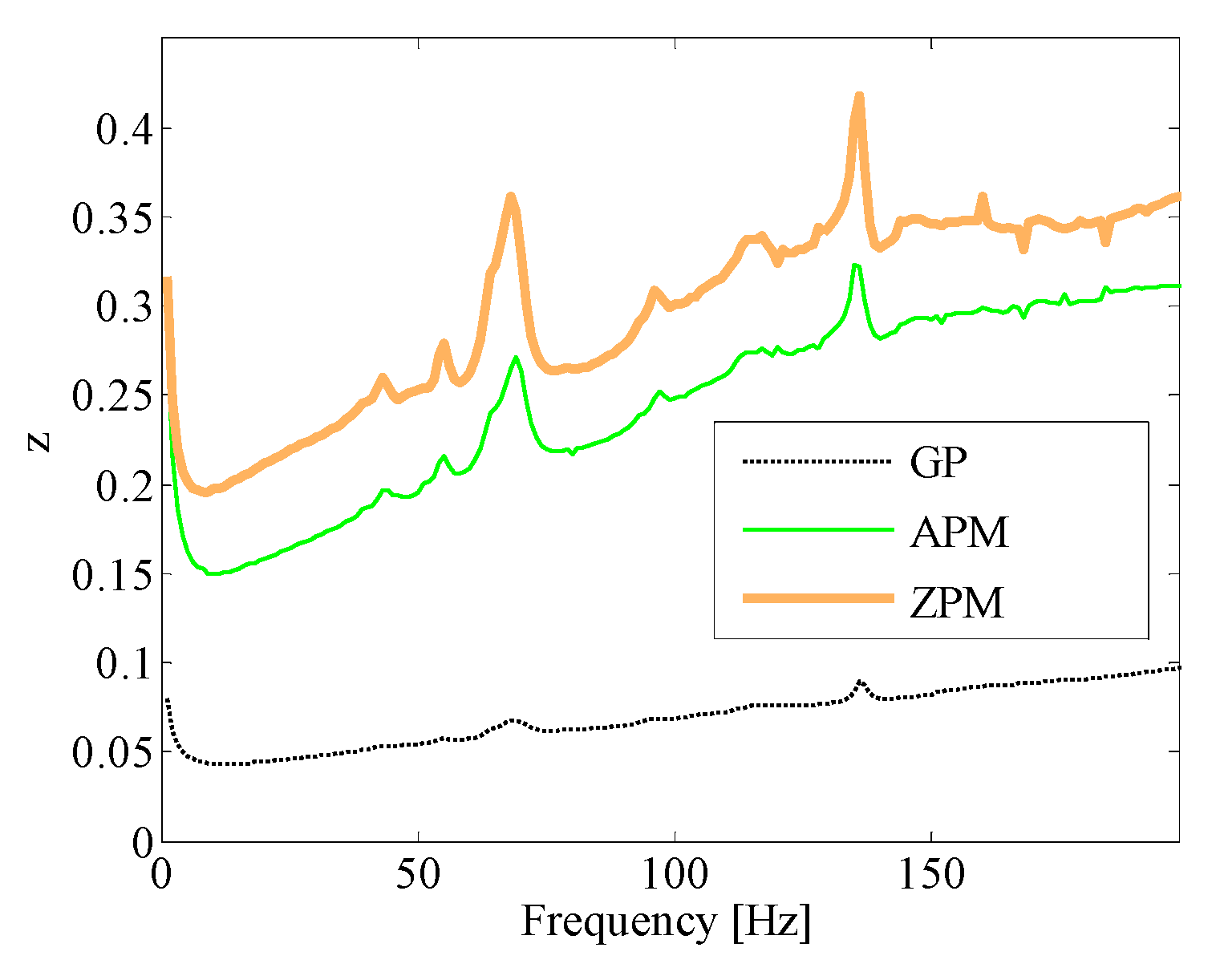

4.2. Experimental Results and Discussion

5. Modeling of Multi-Layer Coated Beam Composites

5.1. Motivations

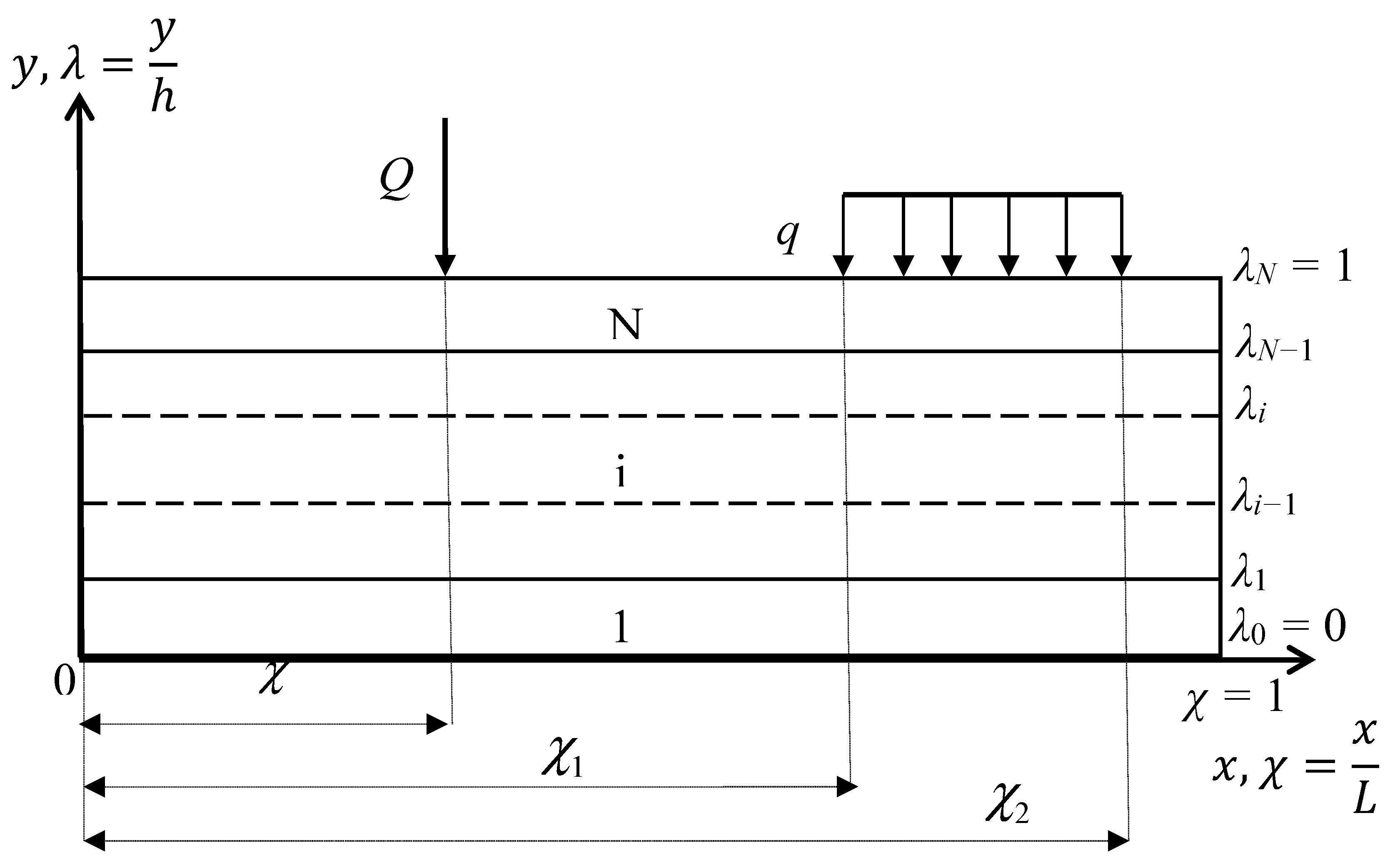

5.2. Multi-Layer Beam Flexural Model

5.3. Equation of Motion

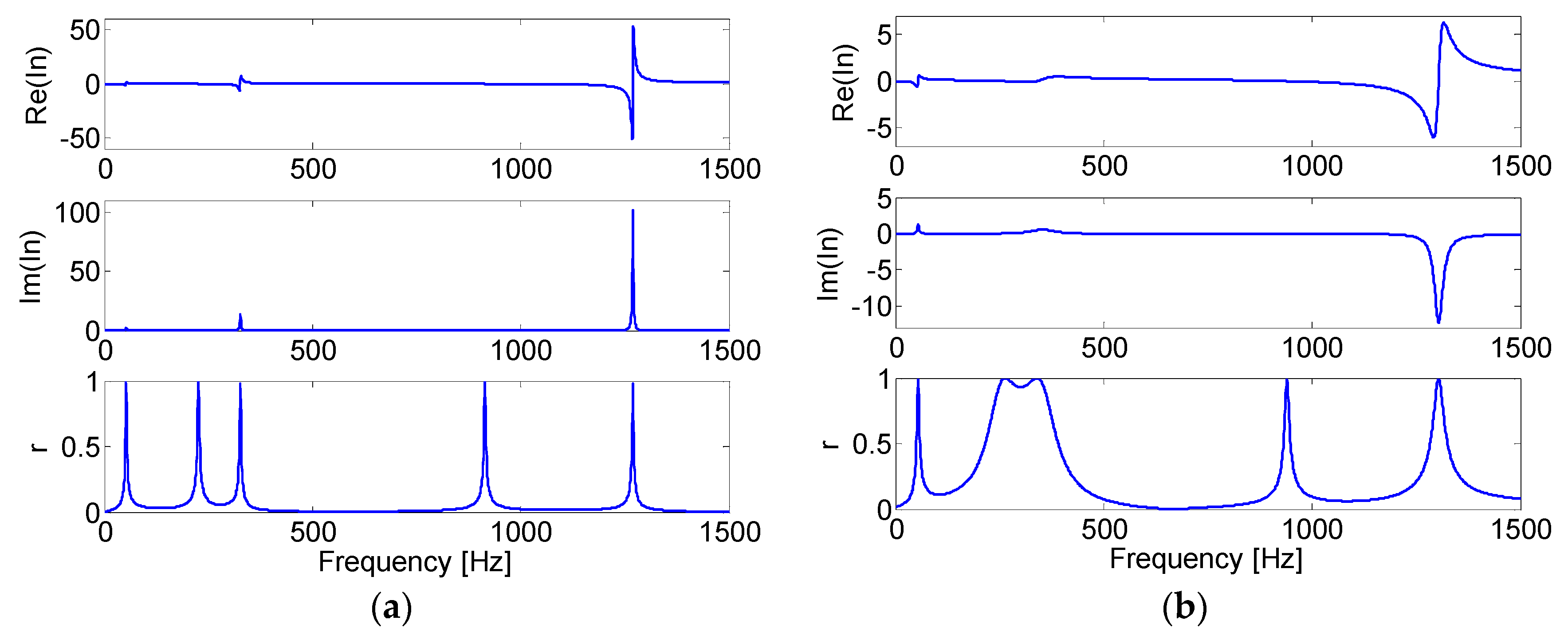

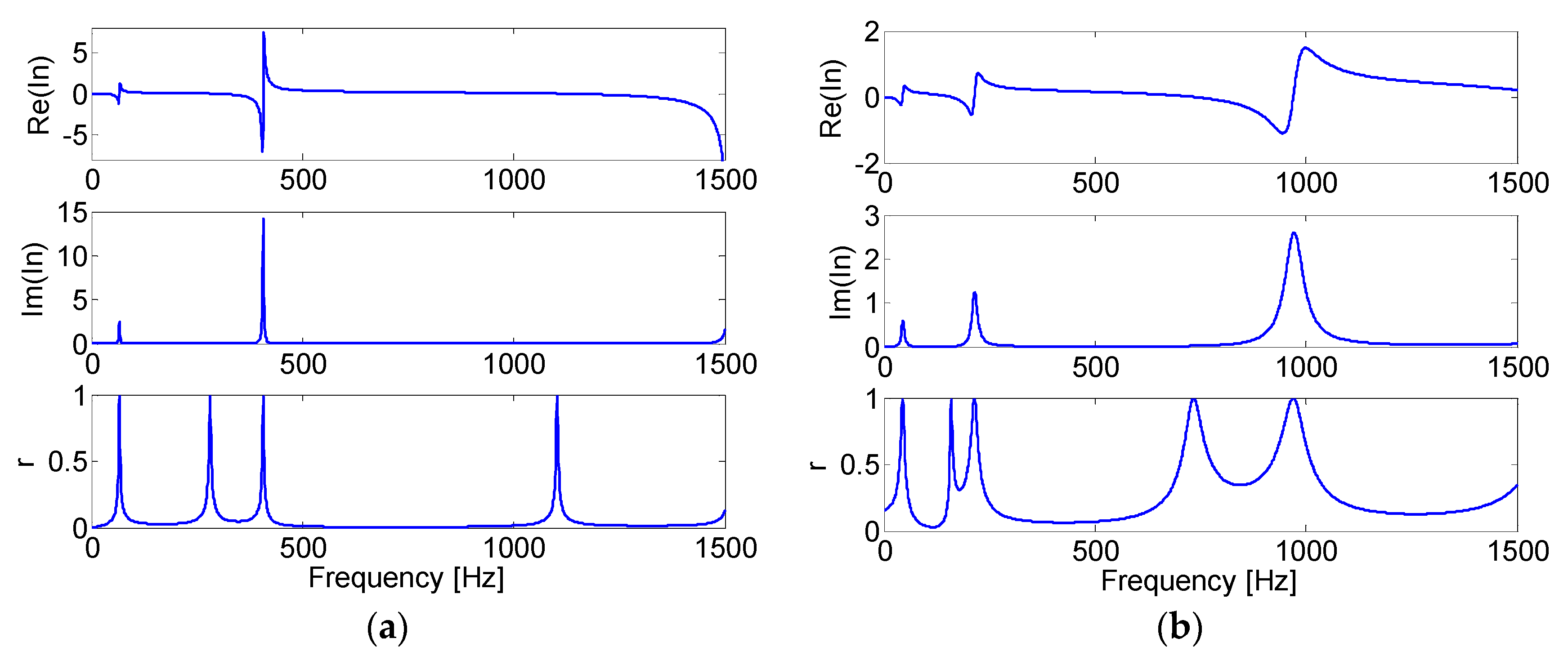

5.4. Model Application Examples

6. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Lopez de Lacalle, L.N.; Gutierrez, A.; Lamikiz, A.; Fernandes, M.H.; Sanchez, J.A. Turning of Thick Thermal Spray Coatings. J. Therm. Spray Technol. 2001, 10, 249–254. [Google Scholar] [CrossRef]

- Fernández-Abia, A.I.; Barreiro, J.; Lopez de Lacalle, L.N.; González-Madruga, D. Effect of mechanical pre-treatments in the behavior of nanostructured PVD-coated tools in turning. Int. J. Adv. Manuf. Technol. 2014, 73, 1119–1132. [Google Scholar] [CrossRef]

- Rodríguez-Barrero, S.; Fernández-Larrinoa, J.; Azkona, I.; López de Lacalle, L.N.; Polvorosa, R. Enhanced Performance of Nanostructured Coatings for Drilling by Droplet Elimination. Mater. Manuf. Process. 2016, 31, 593–602. [Google Scholar] [CrossRef]

- Fernandez-Valdivielso, A.; Lopez de Lacalle, LN.; Urbikain, G.; Rodriguez, A. Detecting the key geometrical features and grades of carbide inserts for the turning of nickel-based alloys concerning surface integrity. J. Mech. Eng. Sci. 2016, 230, 3725–3742. [Google Scholar] [CrossRef]

- Polvorosab, R.; Suáreza, A.; Lopez de Lacalle, L.N.; Cerrill, I.; Wretlandc, A.; Veigaa, F. Tool wear on nickel alloys with different coolant pressures: Comparison of Alloy 718 and Waspaloy. J. Manuf. Process. 2017, 26, 44–56. [Google Scholar] [CrossRef]

- Elosegui, I.; Alonso, U.; Lopez de Lacalle, L.N. PVD coatings for thread tapping of austempered ductile iron. Int. J. Adv. Manuf. Technol. 2017, 91, 2663–2672. [Google Scholar] [CrossRef]

- Ghidelli, M.; Sebastiani, M.; Collet, C.; Guillemet, R. Determination of the elasticmoduli and residual stresses of freestanding Au-TiW bilayer thin films by nanoindentation. Mater. Des. 2016, 106, 436–445. [Google Scholar] [CrossRef]

- Nix, W.D. Mechanical properties of thin films. Metall. Trans. A 1989, 20, 2217–2245. [Google Scholar] [CrossRef]

- Oliver, W.C.; Pharr, G.M. Measurement of hardness and elastic modulus by instrumented indentation: Advances in understanding and refinements to methodology. J. Mater. Res. 2003, 19, 3–20. [Google Scholar] [CrossRef]

- Tassini, N.; Pastias, S.; Lambrinou, K. Ceramic coatings: A phenomenological modeling for damping behavior related to microstructural features. Mater. Sci. Eng. A 2006, 442, 509–513. [Google Scholar] [CrossRef]

- Yu, L.; Ma, Y.; Zhou, C.; Xu, H. Damping efficiency of the coating structure. Int. J. Solids Struct. 2005, 42, 3045–3058. [Google Scholar] [CrossRef]

- Ustinov, A.I.; Movchan, B.A. A study of damping ability of tin-and yttrium-coated flat specimens of Ti-6%Al-4%V titanium alloy. Strength Mater. 2001, 33, 339–343. [Google Scholar] [CrossRef]

- Rongong, J.A.; Goruppa, A.A.; Buravalla, V.R.; Tomlinson, G.R.; Jones, F.R. Plasma deposition of constrained layer damping coating. J. Mech. Eng. Sci. 2004, 218, 669–680. [Google Scholar] [CrossRef]

- Blackwell, C.; Palazzotto, A.; George, T.J.; Cross, C.J. The evaluation of the damping characteristics of hard coating on titanium. Shock Vib. 2007, 14, 37–51. [Google Scholar] [CrossRef]

- Casadei, F.; Bertoldi, K.; Clarke, D.R. Vibration damping of thermal barrier coatings containing ductile metallic layers. ASME J. Appl. Mech. 2014, 81, 101001. [Google Scholar] [CrossRef]

- Du, G.; Tan, Z.; Ba, D.; Liu, K.; Sun, W.; Han, Q. Damping properties of a novel porous Mg-Al alloy coating prepared by arc ion plating. Surf. Coat. Technol. 2014, 238, 139–142. [Google Scholar] [CrossRef]

- Ustinov, A.I.; Skorodzievskii, V.S. A study of the dissipative properties of homogeneous materials deposited as coatings part 2. Copper condensates with different microstructural characteristics. Strength Mater. 2008, 40, 275–277. [Google Scholar] [CrossRef]

- Colorado, H.A.; Velez, J.; Salva, H.R.; Ghilarducci, A.A. Damping behavior of physical vapor-deposited TiN coatings on AISI 304 stainless steel and adhesion determination. Mater. Sci. Eng. A 2006, 442, 514–518. [Google Scholar] [CrossRef]

- Khor, K.A.; Chia, C.T.; Gu, Y.W.; Boey, F.Y.C. High temperature damping behavior of plasma sprayed NiCoCrAlY coatings. J. Therm. Spray Technol. 2002, 11, 359–364. [Google Scholar] [CrossRef]

- Wang, X.; Pei, Y.; Ma, Y. The effect of microstructure at interface between coating and substrate on damping capacity of coating systems. Appl. Surf. Sci. 2013, 282, 60–66. [Google Scholar] [CrossRef]

- Kiretseu, M.; Hui, D.; Tomlinson, G. Advanced shock-resistant and vibration damping of nanoparticle-reinforced composite material. Compos. Part B 2008, 39, 128–138. [Google Scholar] [CrossRef]

- Amadori, S.; Catania, G. Damping contributions of coatings to the viscoelastic behaviour of mechanical components. In Proceedings of the Surveillance 9 International Conference, Fez, Morocco, 22–24 May 2017; pp. 1–13. [Google Scholar]

- Amadori, S.; Catania, G. Experimental evaluation of the damping properties and optimal modeling of coatings made by plasma-deposition techniques. In Proceedings of the 7th International Conference on Mechanics and Materials in Design Albufeira, Algarve, Portugal, 11–15 June 2017; INEGI/FEUP: Porto, Portugal, 2017; pp. 313–324. [Google Scholar]

- Buravalla, V.R.; Remillat, C.; Rongrong, J.A.; Tomlinson, G.A. Advances in damping materials and technology. Smart Mater. Bull. 2001, 8, 10–13. [Google Scholar] [CrossRef]

- Reed, S.A.; Palazzotto, A.N.; Baker, W.P. An experimental technique for the evaluation of strain dependent material properties of hard coatings. Shock Vib. 2008, 15, 697712. [Google Scholar] [CrossRef]

- Pastias, S.; Saxton, C.; Shipton, M. Hard damping coatings: An experimental procedure for extraction of damping characteristics and modulus of elasticity. Mater. Sci. Eng. A 2004, 370, 412–416. [Google Scholar] [CrossRef]

- Torvik, P.J. Determination of mechanical properties of non-linear coatings from measurements with coated beams. Int. J. Solids Struct. 2009, 46, 1066–1077. [Google Scholar] [CrossRef]

- Averill, R.C.; Yip, Y.C. Development of simple robust finite elements based on refined theories for thick laminated beams. Comput. Struct. 1996, 59, 529546. [Google Scholar] [CrossRef]

- Di Sciuva, M.; Gherlone, M.; Librescu, L. Implications of damaged interfaces and of other non-classical effects on the load carrying capacity of multilayered composite shallow shells. Int. J. Non-Linear Mech. 2002, 37, 851–867. [Google Scholar] [CrossRef]

- Iurlaro, L.; Gherlone, M.; di Sciuva, M.; Tessler, A. Refined Zigzag Theory for laminated composite and sandwich plated derived from Reissner’s Mixed Variational Theorem. Compos. Struct. 2015, 133, 809–817. [Google Scholar] [CrossRef]

- Liu, D.; Li, X. An overall view of laminate theories based on the displacement hypothesis. J. Compos. Mater. 1996, 30, 1539–1561. [Google Scholar] [CrossRef]

- Yong, S.L.; Feng, D.W.; Lukey, G.C.; van Deventer, J.S.J. Chemical characterization of the steel-geopolymeric gel interface. Colloids Surf. A Physicochem. Eng. Asp. 2007, 302, 411–423. [Google Scholar] [CrossRef]

- Prud’Homme, E.; Michaud, P.; Joussein, E.; Clacens, J.; Arii-Clacens, S.; Sobrados, I.; Peyratout, C.; Smith, A.; Sanz, J.; Rossignol, S. Structural characterization of geomaterial foams—Thermal behavior. J. Non-Cryst. Solids 2011, 357, 3637–3647. [Google Scholar] [CrossRef]

- Temuujin, J.; Minjihmaa, A.; Rickard, W.; Lee, M.; Williams, I.; van Riessen, A. Preparation of metacaolin based geopolymer coatings on metal substrates as thermal barriers. Appl. Clay Sci. 2009, 46, 265–270. [Google Scholar] [CrossRef]

- He, J.; Zhang, J.; Yu, Y.; Zhang, G. The strength and microstructure of two geopolymers derived from metakaolin and red mud-fly ash admixture: A comparative study. Constr. Build. Mater. 2012, 30, 80–91. [Google Scholar] [CrossRef]

- Rovnaník, P. Effect of curing temperature on the development of hard structure of metakaolin-based geopolymer. Constr. Build. Mater. 2010, 24, 1176–1183. [Google Scholar] [CrossRef]

- Amadori, S.; Catania, G. Robust identification of the mechanical properties of viscoelatic non-standard materials by means of time and frequency domain experimental measurements. Compos. Struct. 2017, 169, 79–89. [Google Scholar] [CrossRef]

- Nowick, A.S.; Berry, B.S. Anelastic Relaxation in Crystalline Solids; Academic Press Inc.: Cambridge, MA, USA, 1972. [Google Scholar]

- Di Sciuva, M. Multilayered anisotropic plate models with continuous interlaminar stresses. Compos. Struct. 1992, 22, 149–167. [Google Scholar] [CrossRef]

- Librescu, L.; Schmidt, R. A general linear theory of laminated composite shells featuring interlaminar bonding imperfections. Int. J. Solid Struct. 2001, 38, 3355–3375. [Google Scholar] [CrossRef]

- Reddy, J.N. On refined theories of composite laminates. Meccanica 1990, 25, 230–238. [Google Scholar] [CrossRef]

- Sun, C.T.; Whitney, J.M. Theory for the Dynamic Response of Laminated Plates. AIAA J. 1973, 11, 178–183. [Google Scholar] [CrossRef]

- Sun, W.; Liu, Y.; Du, G. Analytical Modeling of Hard-Coating Cantilever Composite Plate considering the Material Nonlinearity of Hard Coating. Math. Probl. Eng. 2015, 2015, 978392. [Google Scholar] [CrossRef]

- Wang, G.; Unal, A.; Zuo, Q.H. Modelling and Analysis of Multilayered Elastic Beam Using Spectral Finite Element Method. J. Vib. Acoust. 2016, 138, 041013. [Google Scholar] [CrossRef]

- Ewins, D.J. Modal Testing: Theory, Practice and Applications, 2nd ed.; Research Studies Press, University of Michigan: Ann Arbor, MI, USA, 2000. [Google Scholar]

| Base (Metakaolin) | Activator | ||

|---|---|---|---|

| Components | Weight Fraction [%] | Components | Molar Fraction |

| SiO2 | 55 | H2O | 73.7 |

| Al2O3 | 39 | ||

| K2O + Na2O | 1 | KOH | 11.7 |

| Fe2O3 | 1.8 | ||

| TiO2 | 1.5 | SiO2 | 14.6 |

| CaO + MgO | 0.6 | ||

| Specimen | Substrate | Coating Layer |

|---|---|---|

| A1 | Al1000 (raw) | GP |

| A2 | Al1000 (sdb) | GP |

| A3 | Al1000 (raw) | APM |

| A4 | Al1000 (raw) | ZPM |

| S1 | Steel C67 (raw) | GP |

| S2 | Steel C67 (sdb) | GP |

| S3 | Steel C67 (raw) | APM |

| S4 | Steel C67 (raw) | ZPM |

| Beam Layer Data | ||||||

| Beam | hi (mm) | Ei (GPa) | Gi (GPa) | ρi (103 kg/m3) | ||

| B1 | {25, 50, 25} | {9, 210, 9} | {3.5, 80, 3.5} | {1.9, 7.85, 1.9} | ||

| B2 | {10, 5, 10, 50, 10, 5, 10} | {9, 210, 9, 210, 9, 210, 9} | {3.5, 80, 3.5, 80, 3.5, 80, 3.5} | {1.9, 7.85, 1.9, 7.85, 1.9, 7.85, 1.9} | ||

| Constrain Parameters | ||||||

| Beam | (1015 N/m4) | (1015 N/m4) | (105 N·s/m4) | (105 N·s/m4) | (105 N·s/m4) | (105 N·s/m4) |

| B1 | 1 | 10 | 8 | 2 | 1.2 | 0.01 |

| B2 | 1 | 10 | 8 | 2 | 1.4 | 0.2 |

| Interface Parameters | ||||||

| Beam | φi (108 N/m3) | ηi (1010 N/m3) | ||||

| B1 | {6, 6} | {3, 3} | ||||

| B2 | {8, 8, 8, 8, 8,8} | {5, 5, 5, 5, 5,5} | ||||

| Beam | Natural Frequency (Hz) | Damping Ratio (%) | ||||

|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 1 | 2 | 3 | |

| B10 | 52.41 | 326.74 | 1269.16 | 2.32 | 0.43 | 0.109 |

| B1 | 54.04 | 352.48 | 1303.83 | 4.48 | 10.3 | 0.931 |

| B20 | 65.84 | 406.45 | 1291.1 | 1.95 | 0.36 | 0.0178 |

| B2 | 44.64 | 214.77 | 971.34 | 8.88 | 3.6 | 2.77 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Amadori, S.; Catania, G.; Casagrande, A. Experimental Evaluation and Modeling of the Damping Properties of Multi-Layer Coated Composites. Coatings 2018, 8, 53. https://doi.org/10.3390/coatings8020053

Amadori S, Catania G, Casagrande A. Experimental Evaluation and Modeling of the Damping Properties of Multi-Layer Coated Composites. Coatings. 2018; 8(2):53. https://doi.org/10.3390/coatings8020053

Chicago/Turabian StyleAmadori, Stefano, Giuseppe Catania, and Angelo Casagrande. 2018. "Experimental Evaluation and Modeling of the Damping Properties of Multi-Layer Coated Composites" Coatings 8, no. 2: 53. https://doi.org/10.3390/coatings8020053

APA StyleAmadori, S., Catania, G., & Casagrande, A. (2018). Experimental Evaluation and Modeling of the Damping Properties of Multi-Layer Coated Composites. Coatings, 8(2), 53. https://doi.org/10.3390/coatings8020053