Curve-Correction Factor for Characterization of the Output of a Three-Dimensional Curved Photovoltaic Module on a Car Roof

Abstract

1. Introduction

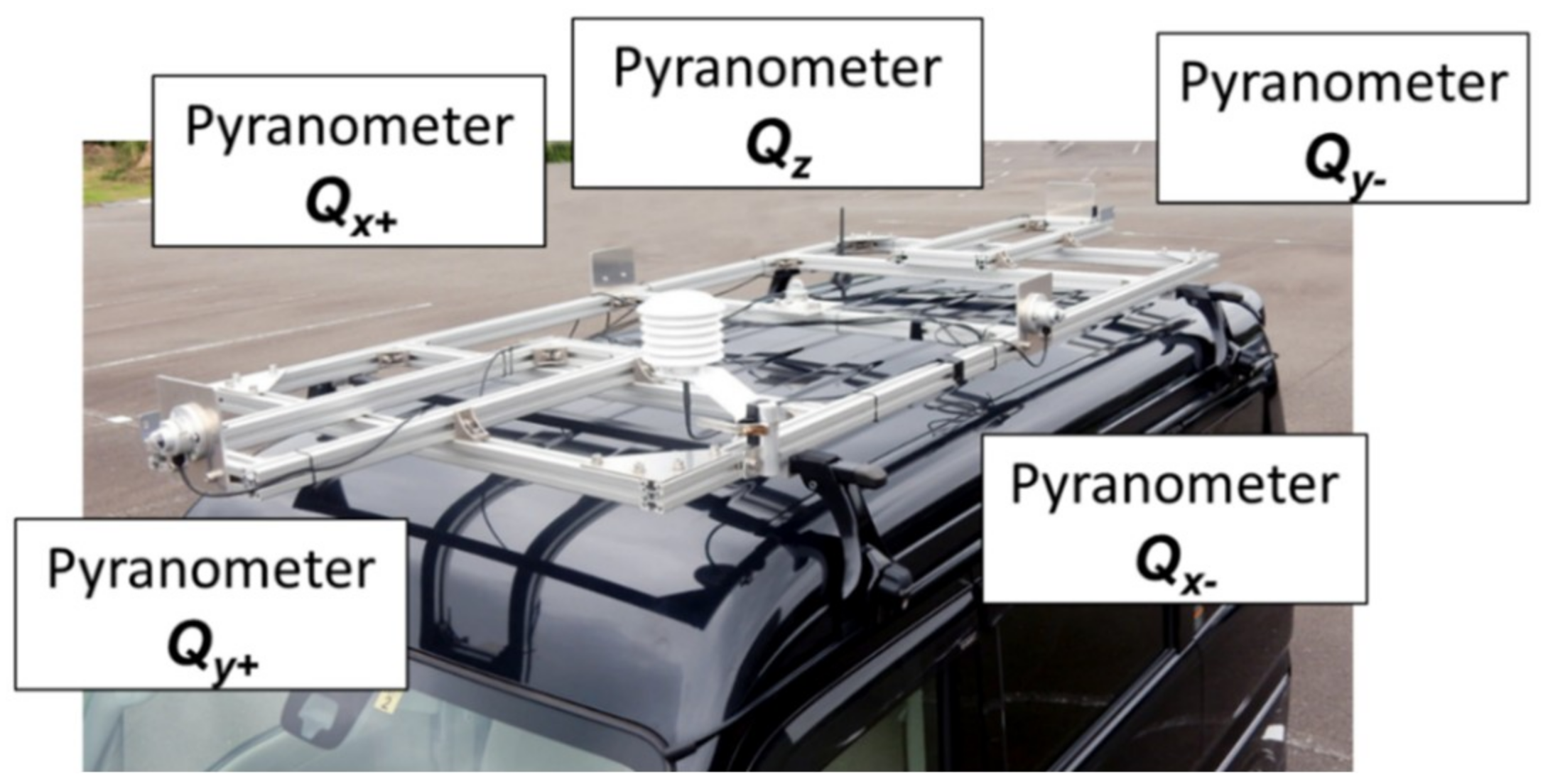

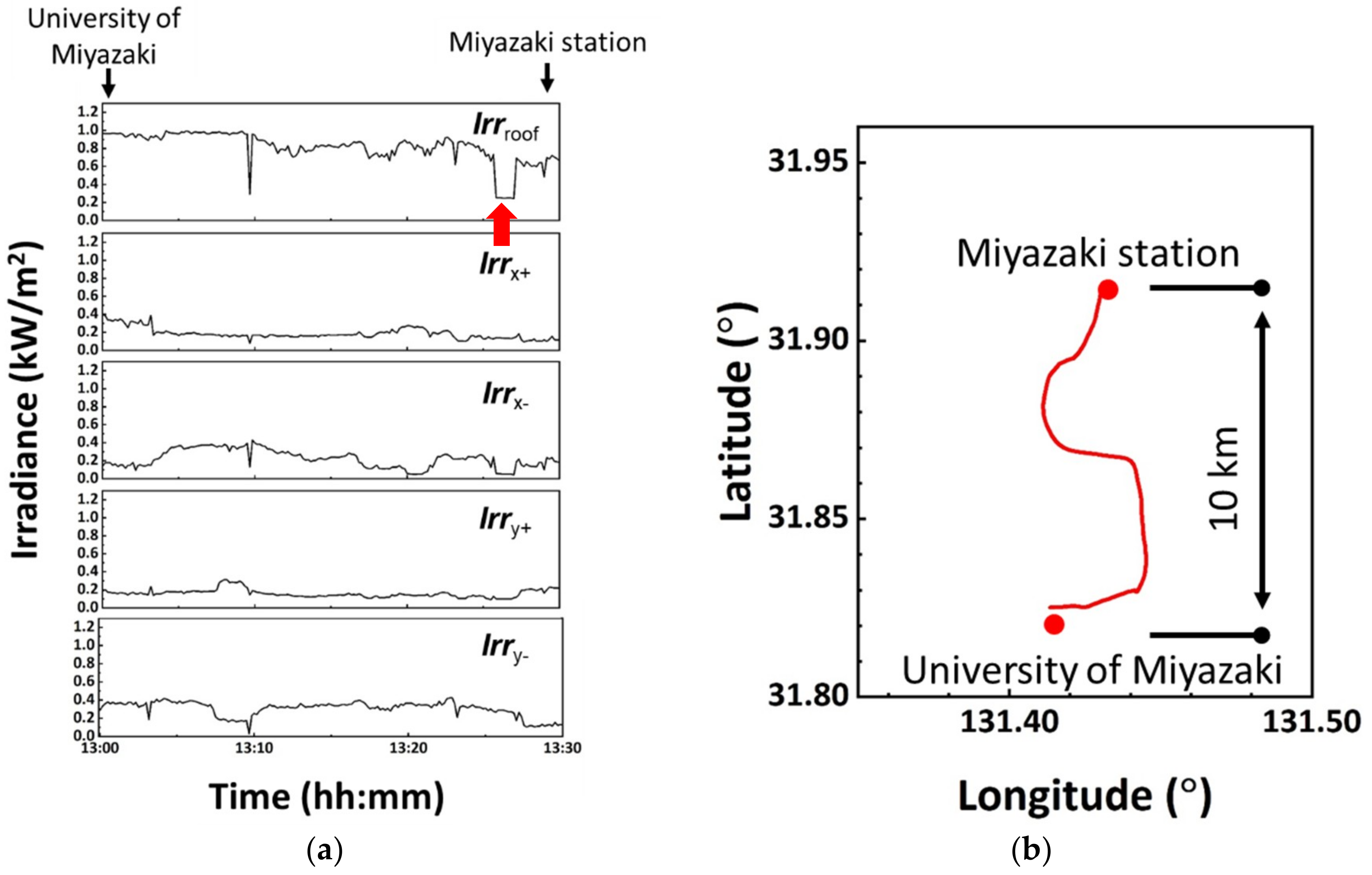

2. Evaluation of Annual Irradiance

3. Optical Simulation Procedure

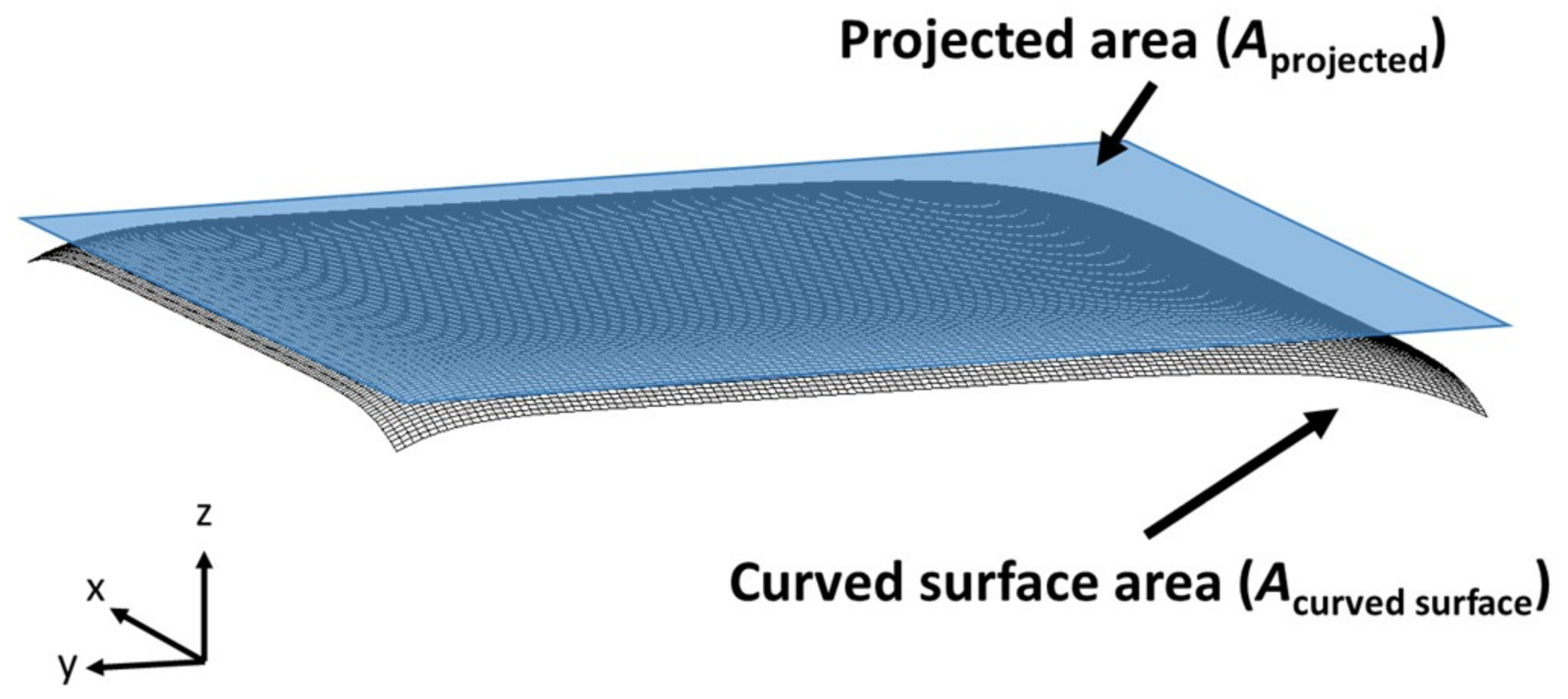

3.1. Introduction of the Curve-Correction Factor

3.2. The Optical Model

4. Results

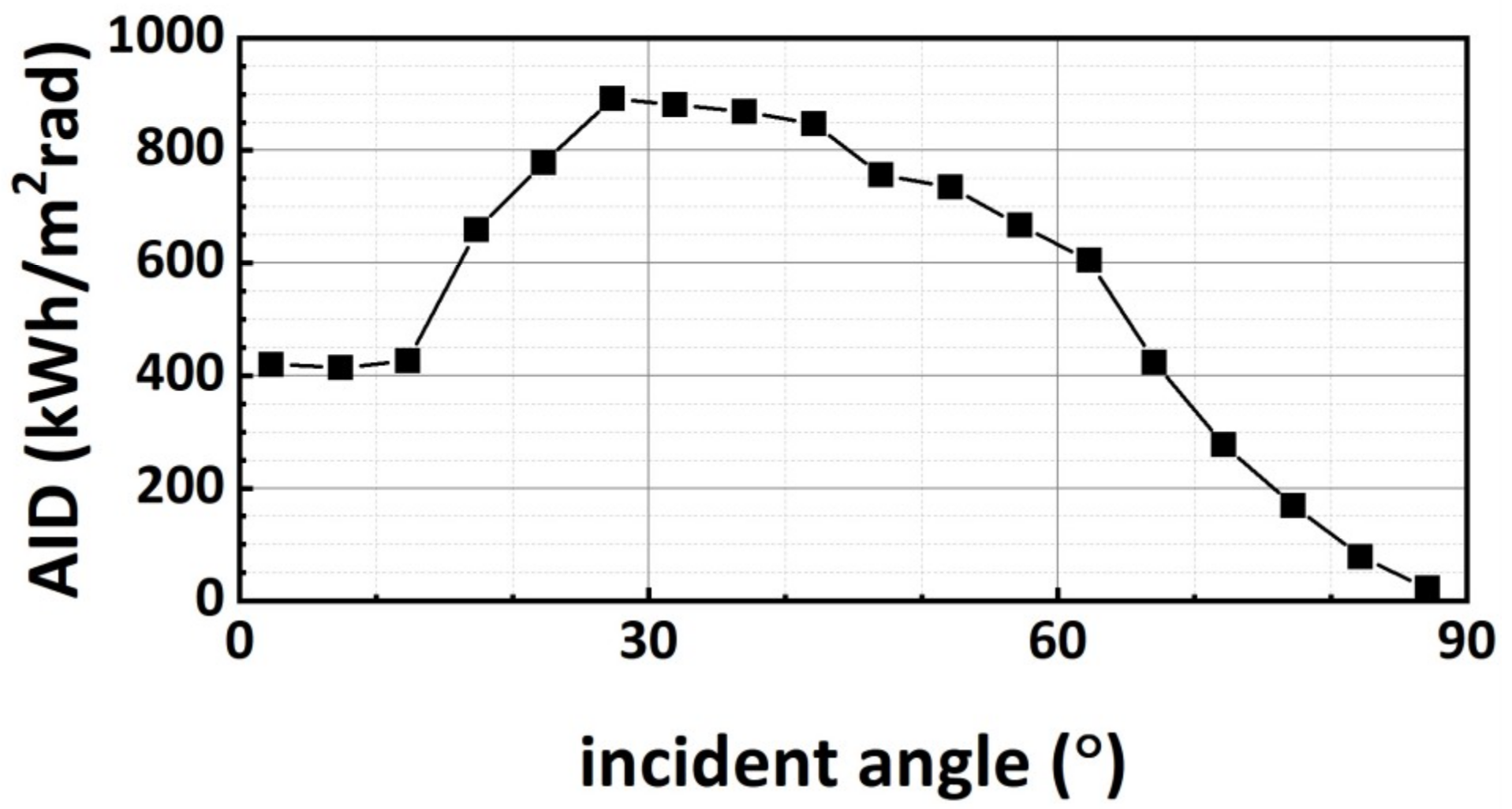

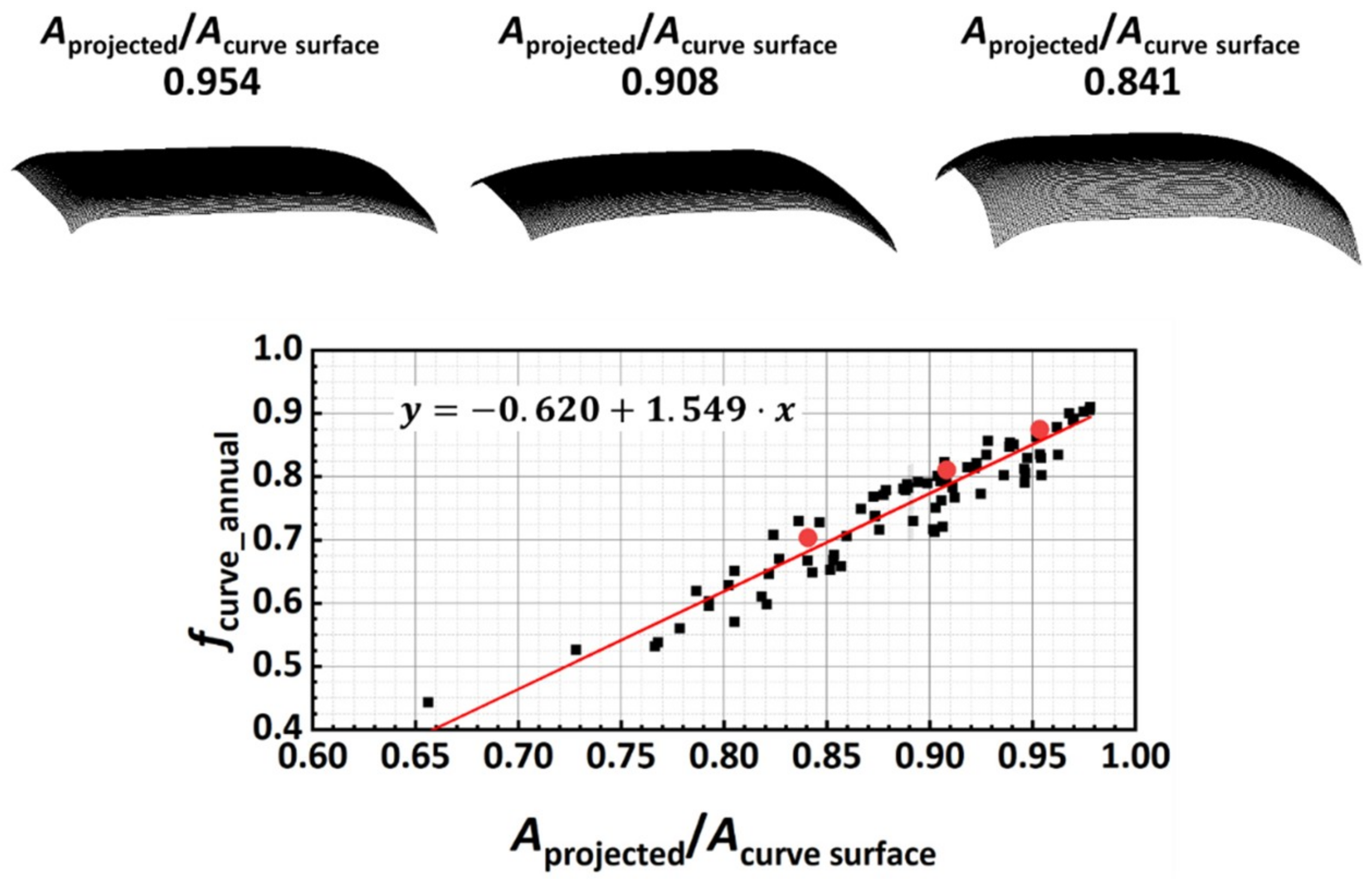

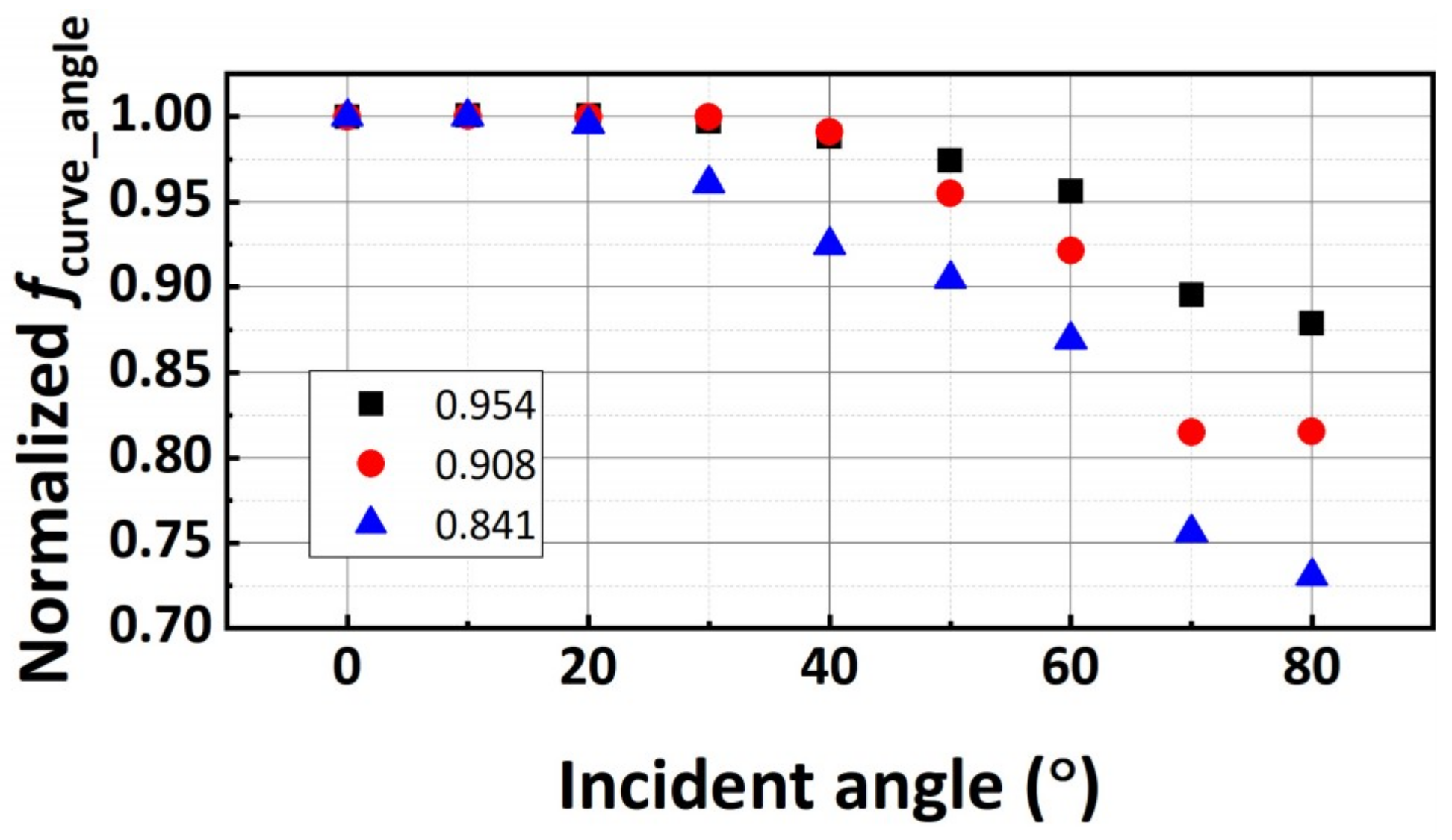

4.1. Annual Irradiance

4.2. Curve-Correction Factor

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Birnie, D.P. Solar-to-vehicle (S2V) systems for powering commuters of the future. J. Power Sour. 2009, 186, 539–542. [Google Scholar] [CrossRef]

- Pantoš, M. Stochastic optimal charging of electric-drive vehicles with renewable energy. Energy 2011, 36, 6567–6576. [Google Scholar] [CrossRef]

- Denholm, P.; Kuss, M.; Margolis, R.M. Co-benefits of large scale plug-in hybrid electric vehicle and solar PV deployment. J. Power Sour. 2013, 236, 350–356. [Google Scholar] [CrossRef]

- Nguyen, T.-T.; Kim, H.W.; Lee, G.H.; Choi, W. Design and implementation of the low cost and fast solar charger with the rooftop PV array of the vehicle. Sol. Energy 2013, 96, 83–95. [Google Scholar] [CrossRef]

- Birnie, D.P. Analysis of energy capture by vehicle solar roofs in conjunction with workplace plug-in charging. Sol. Energy 2016, 125, 219–226. [Google Scholar] [CrossRef]

- Saitoh, T.S.; Yamada, N.; Ando, D.; Kurata, K. A grand design of future electric vehicle to reduce urban warming and CO2 emissions in urban area. Renew. Energy 2005, 30, 1847–1860. [Google Scholar] [CrossRef]

- Masuda, T.; Araki, K.; Okumura, K.; Urabe, S.; Kudo, Y.; Kimura, K.; Nakado, T.; Sato, A.; Yamaguchi, M. Static concentrator photovoltaics for automotive applications. Sol. Energy 2017, 146, 523–531. [Google Scholar] [CrossRef]

- Automotive News, Next-Generation Toyota Prius Has Solar Roof for Europe, Japan. Available online: http://www.autonews.com/article/20160616/OEM05/160619900/next-generation-toyota-prius-has-solar-roof-for-europe-japan (accessed on 30 August 2018).

- Green, M.A.; Hishikawa, Y.; Dunlop, E.D.; Levi, D.H.; Hohl-Ebinger, J.; Ho-Baillie, A.W.Y. Solar cell efficiency tables (version 52). Prog. Photovolt. 2018, 26, 427–436. [Google Scholar] [CrossRef]

- Yang, W.S.; Noh, J.H.; Jeon, N.J.; Kim, Y.C.; Ryu, S.; Seo, J.; Seok, S.I. High-performance photovoltaic perovskite layers fabricated through intramolecular exchange. Science 2015, 348, 1234–1237. [Google Scholar] [CrossRef] [PubMed]

- Chirila, A.; Reinhard, P.; Pianezzi, F.; Bloesch, P.; Uhl, A.R.; Fella, C.; Kranz, L.; Keller, D.; Gretener, C.; Hagendorfer, H.; et al. Potassium-induced surface modification of Cu(In,Ga)Se2 thin films for high-efficiency solar cells. Nat. Mater. 2013, 12, 1107–1111. [Google Scholar] [CrossRef] [PubMed]

- Zortea, L.; Nishiwaki, S.; Weiss, T.P.; Haass, S.; Perrenoud, J.; Greuter, L.; Feurer, T.; Palaniswamy, G.; Buecheler, S.; Tiwari, A.N. Cu(In,Ga)Se2 solar cells on low cost mild steel substrates. Sol. Energy 2018, in press. [Google Scholar] [CrossRef]

- Takamoto, T.; Washio, H.; Juso, H. Application of InGaP/GaAs/InGaAs triple junction solar cells to space use and concentrator photovoltaic. In Proceedings of the 2014 IEEE 40th Photovoltaic Specialist Conference (PVSC), Denver, CO, USA, 8–13 June 2014; pp. 1–5. [Google Scholar] [CrossRef]

- Sasaki, K.; Agui, T.; Nakaido, K.; Takahashi, N.; Onitsuka, R.; Takamoto, T. Development of InGaP/GaAs/InGaAs inverted triple junction concentrator solar cells. AIP Conf. Proc. 2013, 1556, 22–25. [Google Scholar]

- Ota, Y.; Ueda, K.; Takamoto, T.; Nishioka, K. Output evaluation of a world’s highest efficiency flat sub module with InGaP/GaAs/InGaAs inverted triple-junction solar cell under outdoor operation. Jpn. J. Appl. Phys. 2018, 57, 08RD08. [Google Scholar] [CrossRef]

- Imaizumi, M.; Takamoto, T.; Kaneko, N.; Nozaki, Y.; Ohshima, T. Qualification test results of IMM triple-junction solar cells, space solar sheets, and lightweight&compact solar paddle. E3S Web Conf. 2017, 16, 03012. [Google Scholar] [CrossRef]

- Petter Jelle, B.; Breivik, C.; Drolsum Røkenes, H. Building integrated photovoltaic products: A state-of-the-art review and future research opportunities. Sol. Energy Mater. Sol. Cells 2012, 100, 69–96. [Google Scholar] [CrossRef]

- Azadian, F.; Radzi, M.A.M. A general approach toward building integrated photovoltaic systems and its implementation barriers: A review. Renew. Sustain. Energy Rev. 2013, 22, 527–538. [Google Scholar] [CrossRef]

- Ota, Y.; Masuda, T.; Araki, K.; Yamaguchi, M. A mobile multipyranometer array for the assessment of solar irradiance incident on a photovoltaic-powered vehicle. Sol. Energy 2018. submitted for publication. [Google Scholar]

- ISO 9060 Solar Energy—Specification and Classification of Instruments for Measuring Hemispherical Solar and Direct Solar Radiation; International Organization for Standardizaiton (ISO): Geneva, Switzerland, 1990.

- Itagaki, A.; Okamura, H.; Yamada, M. Preparation of meteorological data set throughout japan for suitable design of PV systems. In Proceedings of the 3rd World Conference on Photovoltaic Energy Conversion, Osaka, Japan, 11–18 May 2003; Volume 2, pp. 2074–2077. [Google Scholar]

| Specifications | SR03 | MS-602 |

|---|---|---|

| ISO classification (ISO 9060:1990 [20]) | Second class | Second class |

| Response time (95%) | <3 s | <17 s |

| Non-linearity (100 to 1000 W m−2) | < ±1% | < ±1.5% |

| Spectral selectivity (0.35 to 1.5 × 10−6 m) | < ±5% | < ±1% |

| Temperature response (−10 to +40 °C) | < ±3% | <2% |

| Tilt response (0 to 90° at 1000 W m−2) | < ±2% | < ±2% |

| Surface | Average Daily Irradiance (kWh m−2/day) |

|---|---|

| Car roof | 3.61 |

| Car side (Irrx+, Irrx−) | 3.28 |

| Car front and rear (Irry+, Irry−) | 3.03 |

| Horizontal (for comparison) | 3.90 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ota, Y.; Masuda, T.; Araki, K.; Yamaguchi, M. Curve-Correction Factor for Characterization of the Output of a Three-Dimensional Curved Photovoltaic Module on a Car Roof. Coatings 2018, 8, 432. https://doi.org/10.3390/coatings8120432

Ota Y, Masuda T, Araki K, Yamaguchi M. Curve-Correction Factor for Characterization of the Output of a Three-Dimensional Curved Photovoltaic Module on a Car Roof. Coatings. 2018; 8(12):432. https://doi.org/10.3390/coatings8120432

Chicago/Turabian StyleOta, Yasuyuki, Taizo Masuda, Kenji Araki, and Masafumi Yamaguchi. 2018. "Curve-Correction Factor for Characterization of the Output of a Three-Dimensional Curved Photovoltaic Module on a Car Roof" Coatings 8, no. 12: 432. https://doi.org/10.3390/coatings8120432

APA StyleOta, Y., Masuda, T., Araki, K., & Yamaguchi, M. (2018). Curve-Correction Factor for Characterization of the Output of a Three-Dimensional Curved Photovoltaic Module on a Car Roof. Coatings, 8(12), 432. https://doi.org/10.3390/coatings8120432