Anti-Fouling Ceramic Coating for Improving the Energy Efficiency of Steel Boiler Systems

Abstract

:1. Introduction

2. Material and Methods

2.1. Starting Materials and Ceramic Coating Preparation

2.2. Fly Ash and Coating Characterization

2.3. Adhesion and Thermal Shock Testings

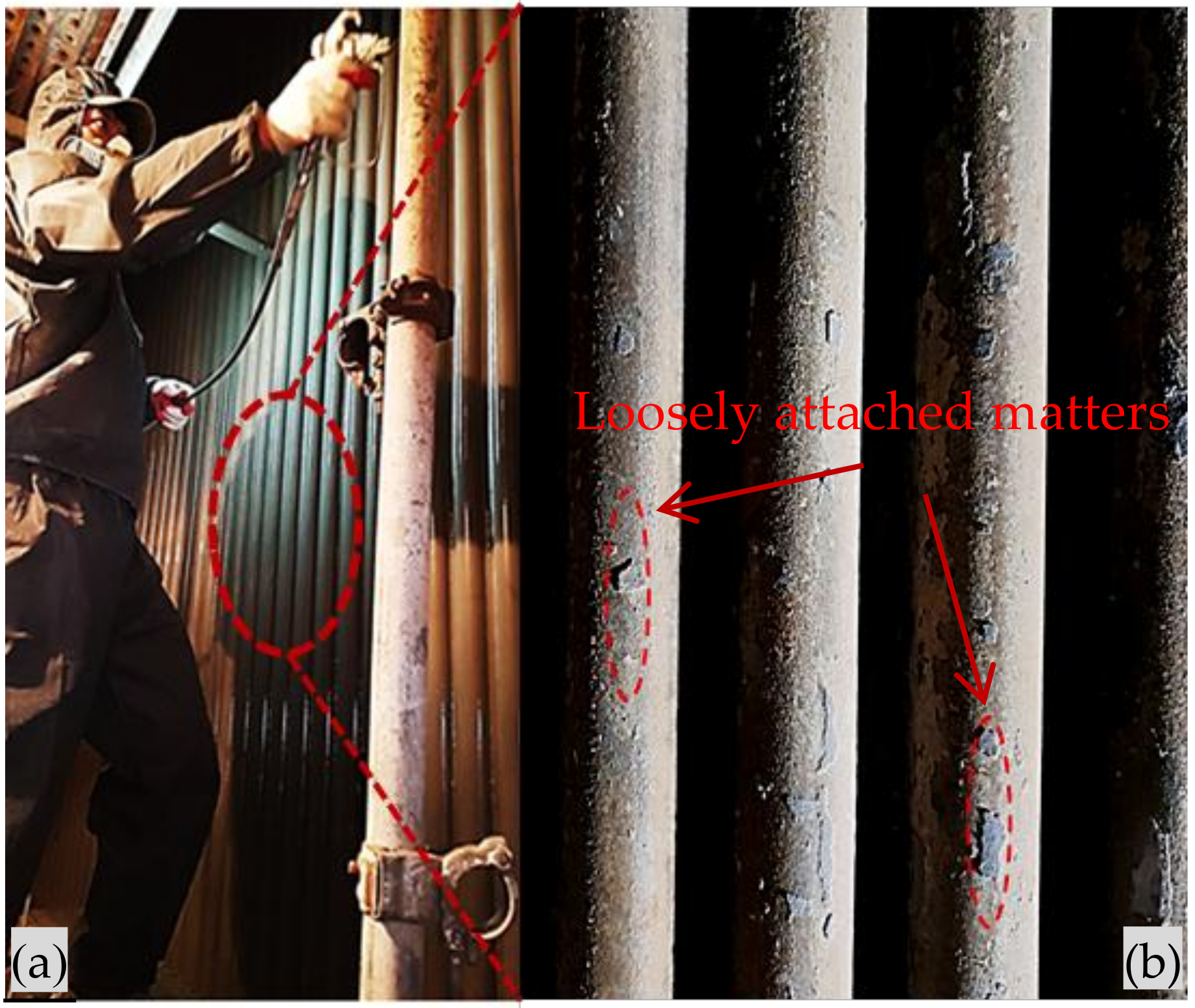

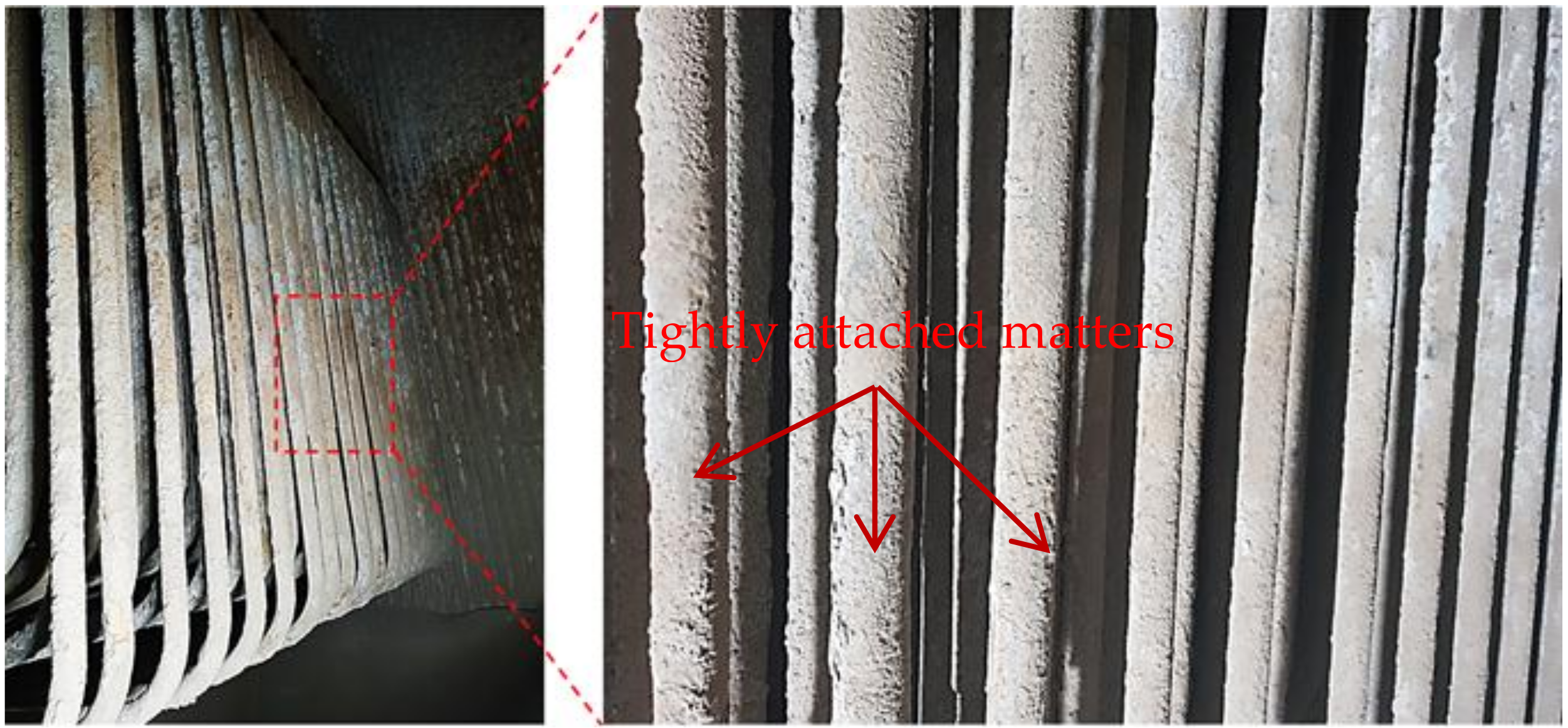

2.4. Anti-Fouling Testing

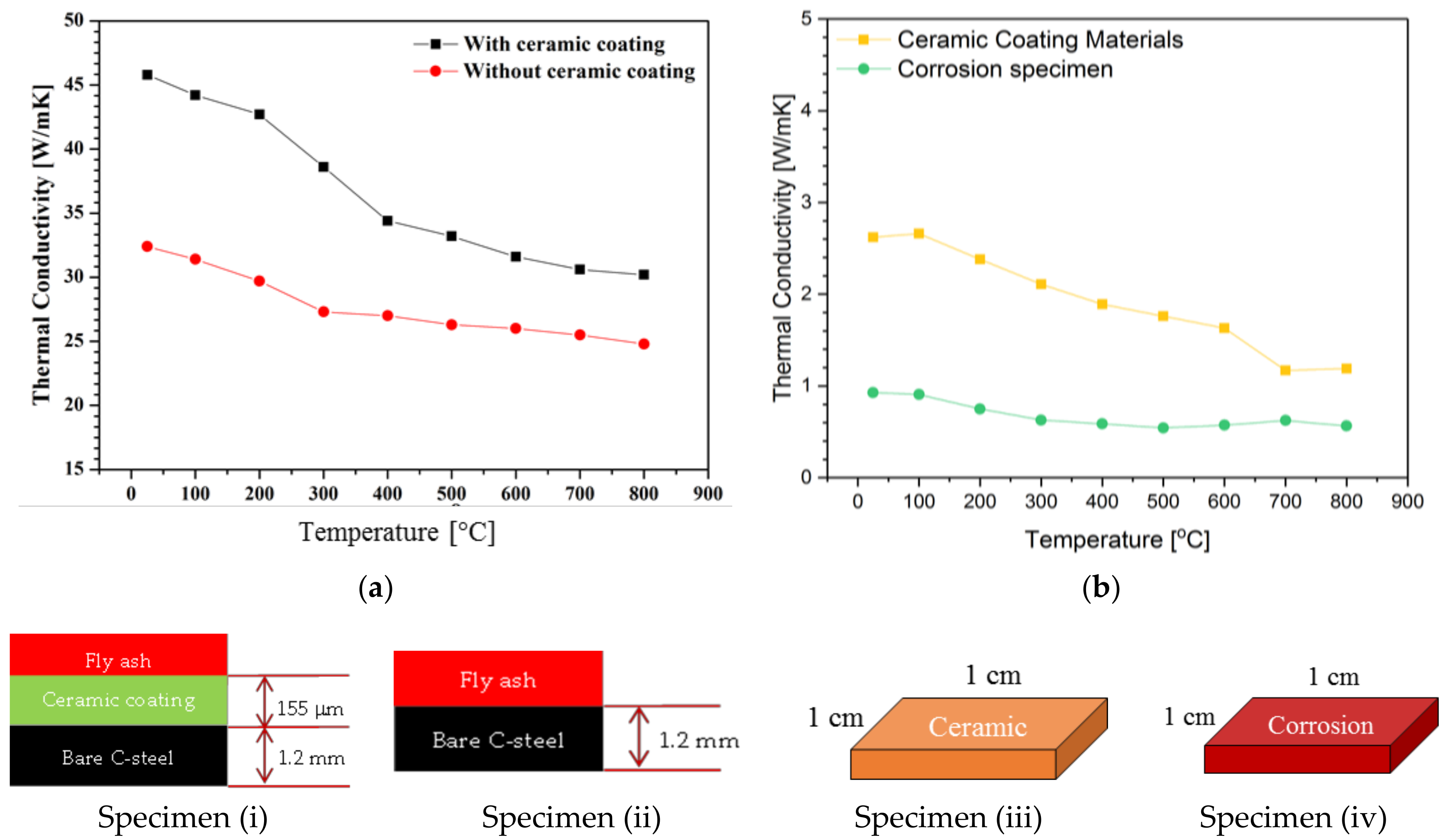

2.5. Thermal Conductivity Measurement

3. Results and Discussion

3.1. Properties of Fly Ashes

3.2. Microstructure and Morphology of Ceramic Coating

3.3. Adhesion and Thermal Shock Properties

3.4. Anti-Fouling

3.5. Thermal Conductivity

3.6. Application of the Coating

4. Conclusions

- A ceramic coating with a thickness of 150–160 µm was successfully developed and applied to carbon steel.

- Fly ash with high concentrations of sodium and chlorine was selected as the fouling matter. In the anti-fouling testing, the developed ceramic coating with a dense structure performed well at preventing fly ash fouling. In comparison, the bare steel without coating was severely fouled.

- The ceramic coating showed a significant improvement in the thermal conductivity of the boiler at high temperature (800 °C). Hence, it can help increase the overall energy efficiency for actual application to real boiler systems in WTE facilities.

Supplementary Materials

Author Contributions

Funding

Acknowledgement

Conflicts of Interest

References

- Hansen, J.; Sato, M.; Ruedy, R.; Lacis, A.; Oinas, V. Global warming in the twenty first century: An alternative scenario. Proc. Natl. Acad. Sci. U.S.A. 2000, 97, 9875–9880. [Google Scholar] [CrossRef] [PubMed]

- Xu, S.; He, H.; Luo, L. Status and prospects of municipal solid waste to energy technologies in China. In Recycling of Solid Waste for Biofuels and Bio-chemicals; Karthikeyan, O.P., Heimann, K., Muthu, S.S., Eds.; Springer: Berlin, Germany, 2016; pp. 31–54. [Google Scholar]

- Ibrahim, H.A. Fouling in heat exchangers. In MATLAB—A Fundamental Tool for Scientific Computing and Engineering Applications; Katsikis, V., Ed.; InTechopen: London, UK, 2012; Volume 3, pp. 57–96. [Google Scholar]

- Regueiro, A.; Patiño, D.; Granada, E.; Porteiro, J. Experimental study on the fouling behaviour of an underfeed fixed-bed biomass combustor. Appl. Therm. Eng. 2017, 112, 523–533. [Google Scholar] [CrossRef]

- Energy Efficiency Benchmarking Study of Food Manufacturing Plants in Singapore. Available online: http://www.e2singapore.gov.sg/DATA/0/docs/Resources/Industry/FMBS%20Final%20Report%20v1.1.pdf (accessed on 18 February 2018).

- Barma, M.C.; Saidur, R.; Raham, S.M.A.; Allouhi, A.; Akash, B.A.; Sadiq, M.S. A review on boilers energy use, energy savings, and emissions reductions. Renew. Sustain. Energy Rev. 2017, 79, 970–983. [Google Scholar] [CrossRef]

- Gupta, R.D.; Ghai, S.; Jain, A. Energy efficiency improvement strategies for industrial boilers: A case study. J. Eng. Technol. 2011, 1, 52–56. [Google Scholar] [CrossRef]

- Nussbaumer, T. Combustion and co-combustion of biomass: Fundamentals, technologies, and primary measures for emission reduction. Energy Fuels 2003, 17, 1510–1521. [Google Scholar] [CrossRef]

- Gao, X.; Jiang, Z.; Gao, J.; Xu, D.; Wang, Y.; Pan, H. Boiler maintenance robot with multi-operational schema. In Proceedings of the 2008 IEEE International Conference on Mechatronics and Automation, Takamatsu, Japan, 5–8 August 2008. [Google Scholar]

- Karell, M. Energy Saving Tips: Boiler Maintenance. Available online: http://www.energymanagertoday.com/energy-saving-tipsboiler-maintenance-091900 (accessed on 18 February 2018).

- Nguyen, M.D.; Bang, J.W.; Kim, Y.H.; Bin, A.S.; Hwang, K.H.; Pham, V.H.; Kwon, W.T. Slurry spray coating of carbon steel for use in oxidizing and humid environments. Ceram. Int. 2018, 44, 8306–8313. [Google Scholar] [CrossRef]

- Milad, F.; Amin, R.B.; Hossein, E.; Mahdi, S. Study on high-temperature oxidation behaviors of plasma-sprayed TiB2-Co composite coatings. J. Korean Ceram. Soc. 2018, 55, 178–184. [Google Scholar]

- Nguyen, M.D.; Bang, J.W.; Bin, A.S.; Kim, S.R.; Kim, Y.H.; Hwang, K.H.; Pham, V.H.; Kwon, W.T. Novel polymer-derived ceramic environmental barrier coating system for carbon steel in oxidizing environments. J. Eur. Ceram. Soc. 2017, 37, 2001–2010. [Google Scholar] [CrossRef]

- Wang, K.; Unger, J.; Torrey, J.D.; Flinn, B.D.; Bordia, R.K. Corrosion resistant polymer derived ceramic composite environmental barrier coatings. J. Eur. Ceram. Soc. 2014, 34, 3597–3606. [Google Scholar] [CrossRef]

- Günthner, M.; Kraus, T.; Dierdorf, A.; Decker, D.; Krenkel, W.; Motz, G. Advanced coatings on the basis of Si(C)N precursors for protection of steel against oxidation. J. Eur. Ceram. Soc. 2009, 29, 2061–2068. [Google Scholar] [CrossRef]

- Chen, M.; Li, W.; Shen, M.; Zhu, S.; Wang, F. Glass-ceramic coatings on titanium alloys for high temperature oxidation protection: Oxidation kinetics and microstructure. Corros. Sci. 2013, 74, 178–186. [Google Scholar] [CrossRef]

- Li, W.; Chen, M.; Wang, C.; Zhu, S.; Wang, F. Preparation and oxidation behavior of SiO2-Al2O3-glass composite coating on Ti-47Al-2Cr-2Nb alloy. Surf. Coat. Technol. 2013, 218, 30–38. [Google Scholar] [CrossRef]

- Günthner, M.; Schütz, A.; Glatzel, U.; Wang, K.; Bordia, R.K.; Greißl, O.; Krenke, W.; Motz, G. High performance environmental barrier coatings, Part I: Passive filler loaded SiCN system for steel. J. Eur. Ceram. Soc. 2011, 31, 3003–3010. [Google Scholar] [CrossRef]

- Moreau, F.; Durán, A.; Munoz, F. Structure and properties of high Li2O-containing aluminophosphate glasses. J. Eur. Ceram. Soc. 2009, 29, 1895–1902. [Google Scholar] [CrossRef]

- Shan, X.; Wei, L.Q.; Liu, P.; Zhang, X.M.; Tang, W.X.; Qian, P.; He, Y.; Ye, S.F. Influence of CoO glass–ceramic coating on the anti-oxidation behavior and thermal shock resistance of 200 stainless steel at elevated temperature. Ceram. Int. 2014, 40, 12327–12335. [Google Scholar] [CrossRef]

- ASTM D3359 Standard Test Methods for Measuring Adhesion by Tape Test; ASTM International: West Conshohocken, PA, USA, 2017.

- ASTM D4541 Standard Test Method for Pull-Off Strength of Coatings Using Portable Adhesion Testers; ASTM International: West Conshohocken, PA, USA, 2017.

- Wibberley, L.J.; Wall, T.F. Alkali-ash reactions and deposit formation in pulverized-coal-fired boilers: The thermodynamic aspects involving silica, sodium, sulphur and chlorine. Fuel 1982, 61, 87–92. [Google Scholar] [CrossRef]

- Lee, S.H.; Themelis, N.J.; Castaldi, M.J. High-temperature corrosion in waste-to-energy boilers. J. Therm. Spray Technol. 2007, 16, 104–110. [Google Scholar] [CrossRef]

- Melissari, B. Ash related problems with high alkali biomass and its mitigation experimental evaluation. Memoria Investigaciones en Ingeniería 2014, 12, 31–44. [Google Scholar]

- Nielsen, H.P.; Frandsen, F.J.; Dam-Johansen, K.; Baxter, L.L. The implications of chlorine-associated corrosion on the operation of biomass-fired boilers. Prog. Energy Combust. Sci. 2000, 26, 283–298. [Google Scholar] [CrossRef]

- Yan, Z.Q.; Xiong, X.; Xiao, P.; Chen, F.; Zhang, H.B.; Huang, B.Y. Si–Mo–SiO2 oxidation protective coatings prepared by slurry painting for C/C–SiC composites. Surf. Coat. Technol. 2008, 202, 4734–4740. [Google Scholar] [CrossRef]

- Barker, M.G.; Wood, D.J. The corrosion of chromium, iron, and stainless steel in liquid sodium. J. Less Common Met. 1974, 35, 315–323. [Google Scholar] [CrossRef]

- Wall, T.F.; Bhattacharya, S.P.; Zhang, D.K.; Gupta, R.P.; He, X. The properties and thermal effects of ash deposits in coal-fired furnaces. Prog. Energy Combust. Sci. 1993, 19, 487–504. [Google Scholar] [CrossRef]

- Baxter, L.L. Influence of ash deposit chemistry and structure on physical and transport properties. Fuel Proc. Technol. 1998, 56, 81–88. [Google Scholar] [CrossRef]

| C | Si | Mn | P | S | Cr | Ni | Cu | Fe |

|---|---|---|---|---|---|---|---|---|

| 0.42–0.48 | 0.15–0.35 | 0.6-0.9 | <0.03 | <0.035 | <0.2 | <0.2 | <0.3 | 96.61−97.17 |

| Binder and Fillers | Average Particle Size (µm) | SiO2–K2O Molar Ratio | Viscosity (MPa·s) at 20 °C | Softening Temperature |

|---|---|---|---|---|

| Potassium silicate (PS) | − | 3.2‒3.4 | Low (50) | 640–680 °C |

| Flake Al | 25 | − | − | − |

| Al2O3 | 11 | − | − | − |

| SiO2 | 12.5 | − | − | − |

| NiO | 1.7 | − | − | − |

| CoO | 3.6 | − | − | − |

| PS | Al2O3 | Al | NiO | CoO | SiO2 |

|---|---|---|---|---|---|

| 66.1 | 6.6 | 0.8 | 3.3 | 3.3 | 19.8 |

| Fly Ash | SiO2 | Al2O3 | Fe2O3 | CaO | Na2O | Cl | K2O | MgO | SO3 | P2O5 |

|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 24.9 | 13.2 | 2.56 | 17.1 | 13.1 | 12.8 | 2.36 | 1.82 | 1.29 | 2.96 |

| 2 | 85.0 | 2.90 | 0.87 | 7.27 | 1.01 | 0.20 | 0.35 | 0.50 | 0.18 | 0.94 |

| 3 | 19.7 | 9.06 | 16.6 | 25.3 | 1.91 | 2.88 | 0.89 | 11.2 | 11.1 | 0.15 |

| 4 | 20.9 | 5.19 | 12.9 | 23.1 | 1.28 | 0.86 | 0.61 | 7.94 | 24.7 | 0.13 |

| Fly Ash | Pb | Cd | As | Hg | Cu |

|---|---|---|---|---|---|

| 1 | 785 | 33 | N.D | N.D | 5620 |

| 2 | 74 | N.D | N.D | N.D | 2240 |

| 3 | N.D | N.D | N.D | N.D | 265 |

| 4 | N.D | N.D | N.D | N.D | 149 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nguyen, M.D.; Bang, J.W.; Kim, Y.H.; Bin, A.S.; Hwang, K.H.; Pham, V.-H.; Kwon, W.-T. Anti-Fouling Ceramic Coating for Improving the Energy Efficiency of Steel Boiler Systems. Coatings 2018, 8, 353. https://doi.org/10.3390/coatings8100353

Nguyen MD, Bang JW, Kim YH, Bin AS, Hwang KH, Pham V-H, Kwon W-T. Anti-Fouling Ceramic Coating for Improving the Energy Efficiency of Steel Boiler Systems. Coatings. 2018; 8(10):353. https://doi.org/10.3390/coatings8100353

Chicago/Turabian StyleNguyen, Minh Dat, Jung Won Bang, Young Hee Kim, An Su Bin, Kyu Hong Hwang, Vuong-Hung Pham, and Woo-Teck Kwon. 2018. "Anti-Fouling Ceramic Coating for Improving the Energy Efficiency of Steel Boiler Systems" Coatings 8, no. 10: 353. https://doi.org/10.3390/coatings8100353

APA StyleNguyen, M. D., Bang, J. W., Kim, Y. H., Bin, A. S., Hwang, K. H., Pham, V.-H., & Kwon, W.-T. (2018). Anti-Fouling Ceramic Coating for Improving the Energy Efficiency of Steel Boiler Systems. Coatings, 8(10), 353. https://doi.org/10.3390/coatings8100353