Impact Wear of Structural Steel with Yield Strength of 235 MPa in Various Liquids

Abstract

:1. Introduction

2. Experimental

2.1. Material Preparation

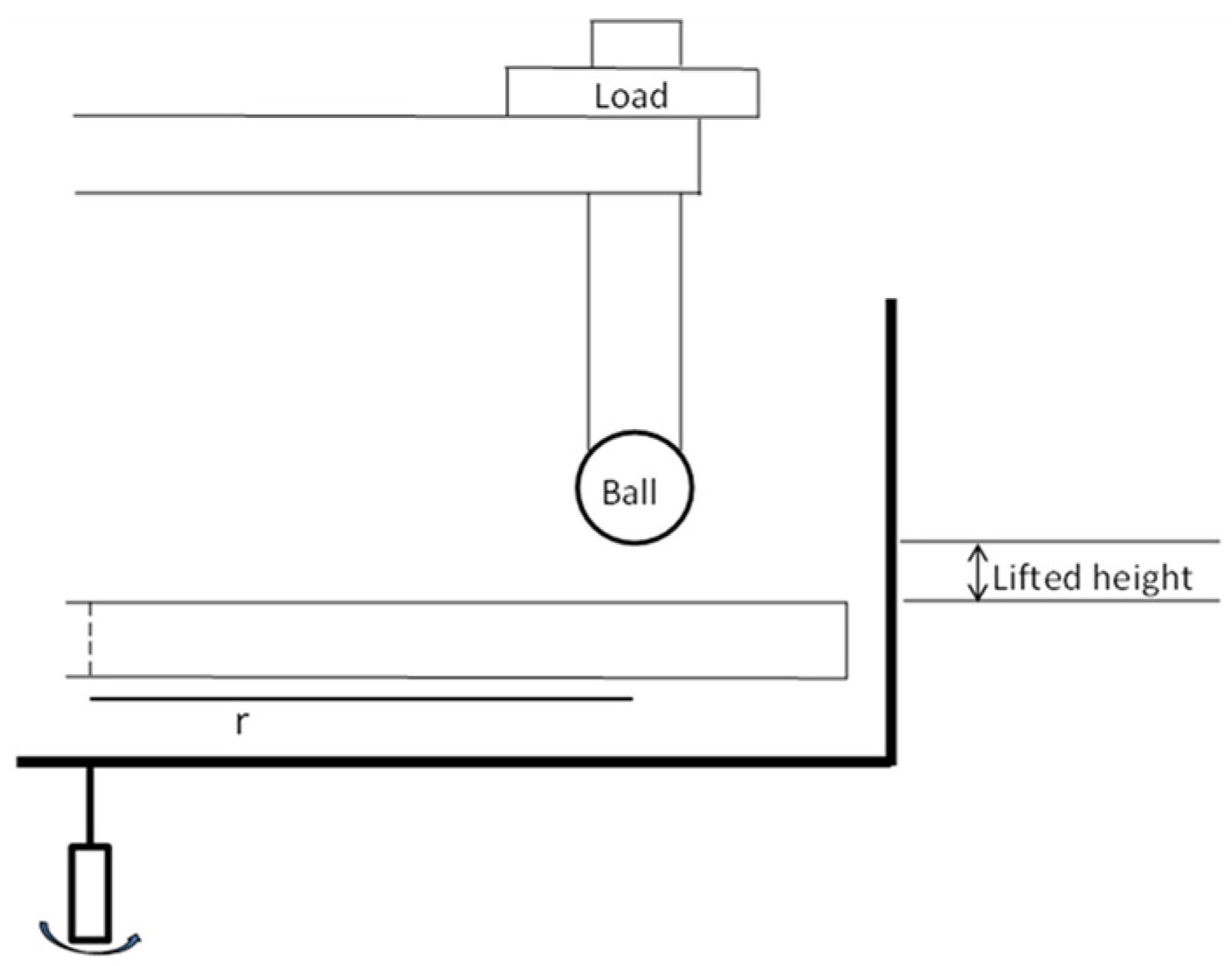

2.2. Experimental Procedure with a Hammering Pin on Disc

2.3. Characterization

3. Results

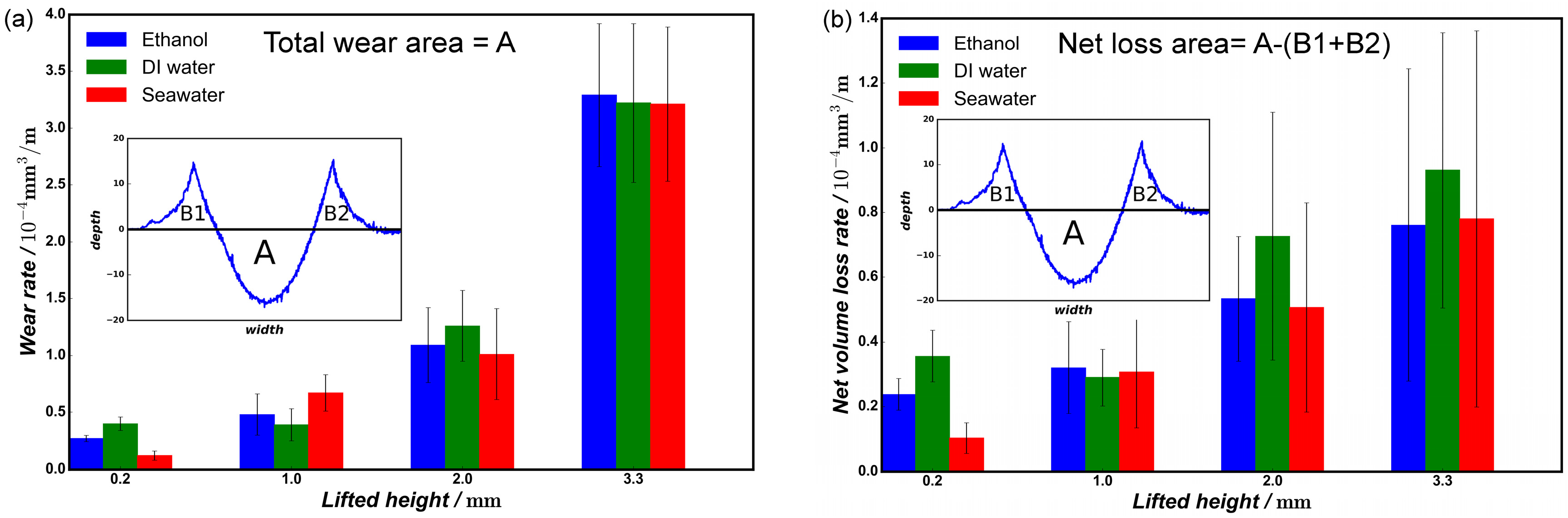

3.1. Wear Rate Comparison

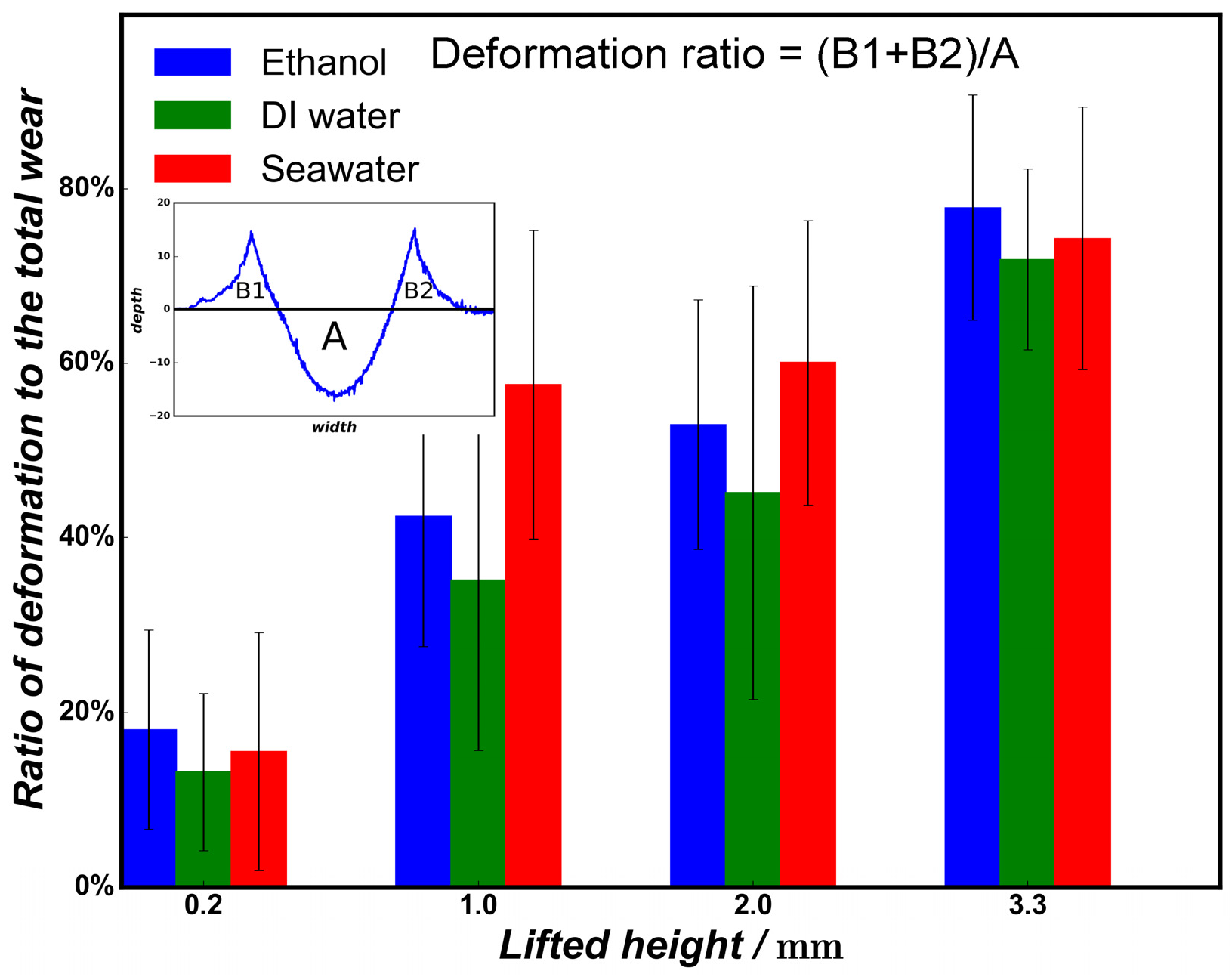

3.2. Wear Track Analysis

4. Discussion

5. Conclusions

Supplementary Materials

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Wilson, K.C.; Addie, G.R.; Sellgren, A.; Clift, R. Slurry Transport Using Centrifugal Pumps, 3rd ed.; Springer: Boston, MA, USA, 2006. [Google Scholar]

- Roco, M.C.; Addie, G.R. Erosion wear in slurry pumps and pipes. Powder Technol. 1987, 50, 35–46. [Google Scholar] [CrossRef]

- Jones, M.; Llewellyn, R.J. Erosion-corrosion assessment of materials for use in the resources industry. Wear 2009, 267, 2003–2009. [Google Scholar] [CrossRef]

- Shivamurthy, R.C.; Kamaraj, M.; Nagarajan, R.; Shariff, S.M.; Padmanabham, G. Influence of microstructure on slurry erosive wear characteristics of laser surface alloyed 13Cr-4Ni steel. Wear 2009, 267, 204–212. [Google Scholar] [CrossRef]

- Ramesh, C.S.; Keshavamurthy, R.; Channabasappa, B.H.; Pramod, S. Influence of heat treatment on slurry erosive wear resistance of Al6061 alloy. Mater. Des. 2009, 30, 3713–3722. [Google Scholar] [CrossRef]

- Bross, S.; Addie, G. Prediction of impeller nose wear behavior in centrifugal slurry pumps. Exp. Therm. Fluid Sci. 2002, 26, 841–849. [Google Scholar] [CrossRef]

- Dube, N.M.; Dube, A.; Veeregowda, D.H.; Iyer, S.B. Experimental technique to analyze the slurry erosion wear due to turbulence. Wear 2009, 267, 259–263. [Google Scholar] [CrossRef]

- Tupper, G.B.; Govender, I.; Mainza, A.N.; Plint, N. A mechanistic model for slurry transport in tumbling mills. Miner. Eng. 2013, 43–44, 102–104. [Google Scholar] [CrossRef]

- Ojala, N.; Valtonen, K.; Antikainen, A.; Kemppainen, A.; Minkkinen, J.; Oja, O.; Kuokkala, V.-T. Wear performance of quenched wear resistant steels in abrasive slurry erosion. Wear 2016, 354–355, 21–31. [Google Scholar] [CrossRef]

- Rajahram, S.S.; Harvey, T.J.; Wood, R.J.K. Erosion-corrosion resistance of engineering materials in various test conditions. Wear 2009, 267, 244–254. [Google Scholar] [CrossRef]

- Truscott, G.F. A literature survey on abrasive wear in hydraulic machinery. Wear 1972, 20, 29–50. [Google Scholar] [CrossRef]

- Deng, T.; Bingley, M.S.; Bradley, M.S.A.; de Silva, S.R. A comparison of the gas-blast and centrifugal-accelerator erosion testers: The influence of particle dynamics. Wear 2008, 265, 945–955. [Google Scholar] [CrossRef]

- Kotzur, B.A.; Berry, R.J.; Bradley, M.S.; Farnish, R.J. Quantifying the influence of secondary impacts within centrifugal impact testers. In Proceedings of the 12th International Conference on Bulk Materials Storage, Handling and Transportation (ICBMH 2016), Darwin, Austrilia, 11–14 July 2016; pp. 373–382. [Google Scholar]

- Liu, Y.; Mol, J.M.C.; Janssen, G.C.A.M. Corrosion reduces wet abrasive wear of structural steel. Scr. Mater. 2015, 107, 92–95. [Google Scholar] [CrossRef]

- European Standard EN 10025-2:2004 Hot Rolled Products of Structural Steels—Part 2: Technical Delivery Conditions for Non-Alloy Structural Steels; British Standard Institution: London, UK, 2004.

- Rabinowicz, E.; Tanner, R.I. Friction and wear of materials. J. Appl. Mech. 1966, 33, 479. [Google Scholar] [CrossRef]

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Y.; Janssen, G.C.A.M. Impact Wear of Structural Steel with Yield Strength of 235 MPa in Various Liquids. Coatings 2017, 7, 237. https://doi.org/10.3390/coatings7120237

Liu Y, Janssen GCAM. Impact Wear of Structural Steel with Yield Strength of 235 MPa in Various Liquids. Coatings. 2017; 7(12):237. https://doi.org/10.3390/coatings7120237

Chicago/Turabian StyleLiu, Yueting, and G.C.A.M. Janssen. 2017. "Impact Wear of Structural Steel with Yield Strength of 235 MPa in Various Liquids" Coatings 7, no. 12: 237. https://doi.org/10.3390/coatings7120237

APA StyleLiu, Y., & Janssen, G. C. A. M. (2017). Impact Wear of Structural Steel with Yield Strength of 235 MPa in Various Liquids. Coatings, 7(12), 237. https://doi.org/10.3390/coatings7120237