1. Introduction

Architectural coatings must provide both visual quality and long-term protection, yet their surfaces are steadily degraded by environmental exposure, leading to dirt pickup, gloss loss, and mechanical wear. Recent research demonstrates that nanostructured hybrid fillers. Particularly, combinations of graphene oxide (GO) and silicon dioxide (SiO

2) offer an effective strategy to counter these degradation pathways. Studies across epoxy, polyurethane–acrylic, and sol–gel systems consistently show that the integration of GO with SiO

2 nanoparticles produces synergistic enhancements that exceed the effects of each component used separately [

1,

2,

3,

4,

5].

Recent research has shown that combining graphene-based materials with silica nanoparticles offers an effective approach for tailoring coating performance through nanoscale structural engineering. GO and related graphene derivatives provide high mechanical strength, barrier efficiency, and chemical functionality, enabling significant improvements in durability and wear resistance when incorporated into polymer matrices [

4,

5,

6]. Silica nanoparticles complement these effects by supplying optical transparency, tunable surface roughness, and stable inorganic frameworks that promote hydrophobic, superhydrophobic, or self-cleaning behavior in a wide range of coating systems [

4,

7,

8,

9]. When assembled into unified GO–SiO

2 hybrid structures, these fillers exhibit strong synergistic behavior, producing coatings with enhanced corrosion resistance, tribological stability, and long-term environmental durability [

7,

8,

9,

10,

11]. Such hybrid architectures have been successfully integrated into acrylic, epoxy, gelcoat, sol–gel, membrane, and cementitious materials, where they contribute to improved mechanical integrity, controlled wetting properties, and multifunctional protective performance [

4,

5,

6,

9,

12,

13,

14].

The versatility of GO–SiO

2 hybrid materials has led to their integration into a broad range of advanced protective and functional coatings. Early investigations demonstrated that incorporating graphene nanosheets into sol–gel silica matrices can substantially improve structural integrity and corrosion resistance on aerospace-grade aluminum alloys [

15]. Building on this concept, hybrid GO–SiO

2 fillers have been adapted to silicone-based systems, where they promote durable hydrophobicity and resistance to environmental degradation [

16]. Multi-component formulations combining GO, SiO

2, and carbon nanotubes have also revealed notable synergistic effects, particularly in zinc-rich epoxies, where they enhance electrical pathways essential for sacrificial protection [

17]. Foundational mechanistic studies indicate that strong interfacial interactions between GO and silica phases produce surface morphologies that inherently favor extreme wettability control [

18]. More recent work has applied rGO–SiO

2 hybrids to marine epoxy coatings, resulting in improved long-term barrier stability under chloride-rich conditions [

7]. Surface functionalization routes using TEOS and APTES precursors have further enabled the formation of highly crosslinked hybrid networks with superior thermal and mechanical robustness [

19].

Beyond corrosion protection, GO–SiO

2 hybrids support multifunctional surface engineering strategies. Comprehensive reviews outline their contribution to the development of self-cleaning materials, emphasizing their role in enabling superhydrophobicity, fouling resistance, and optical transparency in architectural and marine applications [

20,

21,

22,

23]. Ongoing advancements extend into novel synthesis methods, such as the direct fabrication of graphene/silica nanocomposites for high-performance epoxy systems [

24] and hybrid sol–gel films designed for enhanced protection of AA2024-T3 substrates [

15]. Additional research demonstrates the potential of TiO

2–SiO

2 and Fe

2O

3–rGO heterostructures to achieve photocatalytic self-cleaning and tunable wettability [

25,

26]. Broader analyses of graphene-based hybrid fillers underscore their applicability across polymer composites for improved durability, environmental resistance, and multifunctionality [

27,

28].

The growing interest in sustainable material development has also encouraged environmentally benign pathways for fabricating silica–graphene hybrids, with green-synthesized SiO

2 nanoparticles showing strong compatibility with GO-based anticorrosion formulations [

29]. Broad assessments of GO/SiO

2 nanocomposites confirm their consistent ability to enhance barrier performance, mechanical cohesion, and wetting behavior across diverse coating matrices [

30], while applications in water-treatment infrastructures further highlight their resistance to chemical and hydraulic stresses in highly aggressive environments [

31]. Fundamental studies on Si–O–C interfacial bonding reveal its key influence on both hydrophobicity and barrier behavior in hybrid coatings [

32], supported by complementary findings that the microtexture and surface energy of graphene–silica films govern the stability and tunability of wetting states [

33]. Effective dispersion strategies, particularly through silane coupling agents, have been shown to be critical for achieving uniform filler integration and optimized curing characteristics in GO–SiO

2 systems [

34], while additional research demonstrates their functional versatility in photocatalytic and biomedical applications [

35].

Ensuring long-term stability under environmental exposure remains a central research focus, with hybrid SiO

2–GO surfaces exhibiting strong resistance to UV-induced degradation and maintaining their superhydrophobic properties over extended aging periods [

36]. Insights from architectural engineering highlight the role of hierarchical surface structuring in dirt repellence and facade self-cleaning capabilities [

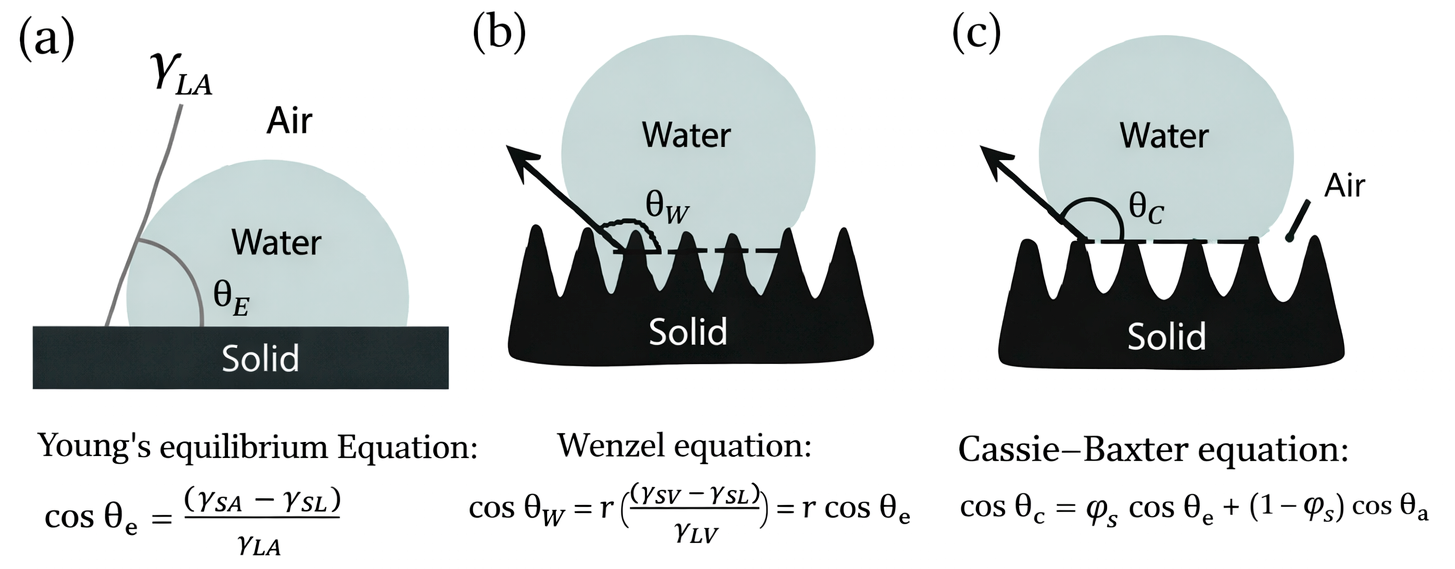

37], complemented by wetting-transition studies that clarify the mechanical factors governing the persistence of Cassie–Baxter states (

Figure 1) on nanoengineered coatings [

38,

39]. Chemical tailoring of SiO

2 via APTES functionalization further strengthens interfacial bonding in epoxy/graphene hybrids [

40], and graphene nanosheets themselves contribute to enhanced UV shielding and photostability in hybrid coatings [

41]. Electrochemical evidence consistently shows that SiO

2–GO incorporation can significantly increase impedance and reduce corrosive pathways [

42], while the reduction degree of GO offers an additional mechanism to tune the durability and adhesion of epoxy nanocomposites [

43].

Figure 1.

Schematic representation of the wetting models: (

a) Young, (

b) Wenzel, and (

c) Cassie-Baxter. The arrows indicate the forces acting on the three-phase contact line of a liquid droplet on a smooth solid surface in air: solid–air interfacial tension (γ

SA), solid–liquid interfacial tension (γ

SL), and liquid–air surface tension (γ

LA). θ

E denotes the Young’s equilibrium contact angle. For the Cassie-Baxter surface, φ

S and (1 − φ

S) represent the fractions of the solid surface and air in contact with the liquid, respectively, while θ_a is the contact angle over the air portion. In the Wenzel model, θ

W is the apparent contact angle, and r is the roughness factor, defined as the ratio of the actual solid surface area to its projected horizontal area [

39].

Figure 1.

Schematic representation of the wetting models: (

a) Young, (

b) Wenzel, and (

c) Cassie-Baxter. The arrows indicate the forces acting on the three-phase contact line of a liquid droplet on a smooth solid surface in air: solid–air interfacial tension (γ

SA), solid–liquid interfacial tension (γ

SL), and liquid–air surface tension (γ

LA). θ

E denotes the Young’s equilibrium contact angle. For the Cassie-Baxter surface, φ

S and (1 − φ

S) represent the fractions of the solid surface and air in contact with the liquid, respectively, while θ_a is the contact angle over the air portion. In the Wenzel model, θ

W is the apparent contact angle, and r is the roughness factor, defined as the ratio of the actual solid surface area to its projected horizontal area [

39].

Parallel research trends emphasize the mechanical durability of superhydrophobic coatings, particularly under abrasion, cyclic wear, and outdoor service conditions [

44], alongside growing recognition of their sustainability benefits in modern building envelopes [

45]. Transparent and mechanically robust SiO

2–GO sol–gel films have also emerged as promising coatings for applications requiring both optical clarity and resilience [

46]. The stabilization of the Cassie–Baxter wetting regime through hierarchical GO–SiO

2 architectures has been demonstrated experimentally [

47], and doped silica–graphene hybrids have revealed potential for coupling photocatalytic activity with long-term self-cleaning functions [

48]. Most recently, experimental–computational studies have shown that precise modulation of surface energy in GO/SiO

2 hybrids enables fine control over wetting transitions, barrier properties, and overall coating performance [

49].

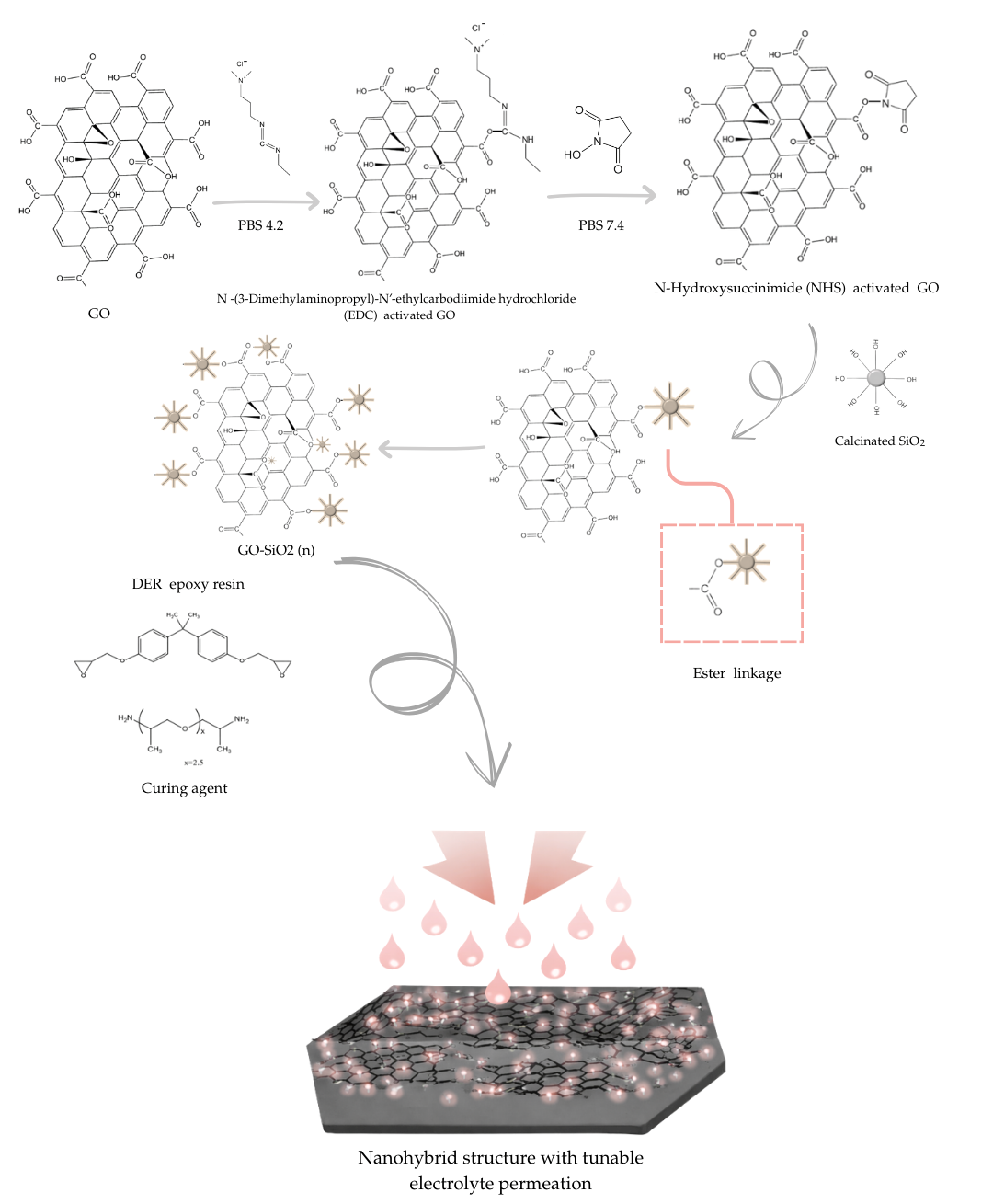

In this context, schematic depictions of graphene–SiO

2 hybrid formation and incorporation into coating matrices provide important mechanistic insight (

Figure 2). The stepwise EDC/NHS functionalization of graphene oxide enables covalent ester linkage with hydroxylated SiO

2 nanoparticles, yielding well-integrated GO–SiO

2 nanohybrids with improved interfacial compatibility. When dispersed within polymeric binders such as epoxy resins and subsequently cured, these nanohybrids promote uniform filler distribution, hierarchical surface roughness, and strong interfacial bonding, collectively enhancing wetting stability, mechanical durability, and barrier performance. While such schematics clarify structure–property relationships at the nanoscale, the extent to which these mechanisms translate into consistent performance gains across different binder chemistries and formulations has yet to be quantitatively assessed [

50].

Despite extensive research on graphene-based and silica nanofillers, existing reviews predominantly rely on qualitative comparisons or isolated case studies, providing limited quantitative insight into the true synergistic effects of graphene–SiO2 hybrid systems in architectural coatings. In particular, the influence of binder chemistry, filler loading, and interfacial modification on hydrophobicity, mechanical durability, and dirt pickup resistance has not been systematically qualified across studies.

In this work, we present the first PRISMA-guided meta-analysis of graphene–SiO2 hybrid nano additives in architectural and protective coatings, integrating performance data from twenty peer-reviewed studies published between 2010 and 2025. Using normalized effect metrics and random-effects modeling, we quantitatively evaluate hydrophobicity, abrasion resistance, and dirt pickup resistance across different binder systems, including epoxy, acrylic, sol–gel, silicone, and cementitious matrices. This meta-analytic approach provides statistically grounded evidence of synergistic graphene–SiO2 interactions, identifies sources of performance variability, and establishes structure–property relationships relevant to the rational design of next-generation self-cleaning and durable facade coatings.

Figure 2.

Schematic representation of the synergistic interactions between graphene derivatives (e.g., graphene oxide) and SiO

2 nanoparticles in hybrid coatings. Interfacial mechanisms include covalent and hydrogen bonding (e.g., Si–O–C linkages via silane coupling agents), enhanced dispersion due to physical hindrance of graphene restacking, and the formation of hierarchical structures that improve barrier and wetting properties. This work provides a general, quantitative basis for comprehending the use of graphene–SiO

2 hybrids in self-cleaning and resistant architectural coatings. Utilizing performance measures, measurement of variance, and explanation of mechanistic routes, the project offers a reference for next-generation, low-cost coatings, linking the lab, application formulation, and full-scale use in the construction domain. The image was reproduced based on Ref. [

50].

Figure 2.

Schematic representation of the synergistic interactions between graphene derivatives (e.g., graphene oxide) and SiO

2 nanoparticles in hybrid coatings. Interfacial mechanisms include covalent and hydrogen bonding (e.g., Si–O–C linkages via silane coupling agents), enhanced dispersion due to physical hindrance of graphene restacking, and the formation of hierarchical structures that improve barrier and wetting properties. This work provides a general, quantitative basis for comprehending the use of graphene–SiO

2 hybrids in self-cleaning and resistant architectural coatings. Utilizing performance measures, measurement of variance, and explanation of mechanistic routes, the project offers a reference for next-generation, low-cost coatings, linking the lab, application formulation, and full-scale use in the construction domain. The image was reproduced based on Ref. [

50].

1.1. Literature Context

Over the past two decades, research into nanostructured functional coatings has expanded considerably, driven by the need for durable hydrophobicity, self-cleaning performance, and long-term resistance to weathering and surface contamination. Foundational reviews by several authors established the conceptual basis for integrating hierarchical roughness with controlled surface energy, outlining how dual-scale texturing enables stable Cassie–Baxter wetting and low-adhesion behavior in architectural and protective coatings [

1,

4,

5,

6,

11]. These early insights proved essential in guiding the design of multi-component hybrid systems that combine micro- and nanoscale structuring to achieve persistent water repellence and dirt-shedding performance.

Parallel to these developments, graphene-based nanomaterials have been the subject of extensive investigation due to their high aspect ratio, impermeability, and tunable surface chemistry. Numerous studies have reported preparation strategies, functionalization pathways, and performance assessments of graphene-reinforced coatings, demonstrating improvements in corrosion protection, barrier properties, mechanical durability, and hydrophobic behavior across diverse polymer matrices [

7,

8,

9,

10,

12,

14]. At the same time, silica nanoparticles have been widely used to increase surface roughness, transparency, mechanical stability, and scratch resistance, supported by a long body of work focusing on their optical and structural contributions to multifunctional coatings [

7,

15,

16,

17,

18,

19]. Historically, however, these two filler families—graphene derivatives and silica nanostructures—were explored largely in isolation, leaving limited analysis of their synergistic behavior when combined.

Within the last five to eight years, graphene–SiO

2 hybrid nanofillers have emerged as a particularly compelling class of multifunctional additives, enabling both barrier reinforcement and hierarchical texturing in a single integrated system. Several studies demonstrated that hybridization leads to increased water contact angles, reduced water permeability, and enhanced hardness and corrosion resistance even at low loading levels [

15,

20,

21,

22,

23,

24,

25,

26]. A substantial portion of this progress is attributed to the role of silane coupling chemistry—particularly the formation of Si–O–C and Si–O–Si linkages, which improve filler dispersion, interfacial adhesion, and long-term mechanical stability in sol–gel, epoxy, silicone, acrylic, and polyurethane matrices [

27,

28,

29,

30,

31,

32,

33]. Despite these promising results, reported performance remains heterogeneous across the literature: contact angles range from moderately hydrophobic to fully superhydrophobic (>160°), while abrasion resistance and durability vary significantly depending on synthesis route, dispersion method, and coating architecture [

34,

35,

36,

37].

Existing review papers have summarized aspects of these developments; however, the analyses presented are mainly qualitative. Some works provided insights into microstructural mechanisms, filler interactions, or processing routes, yet they typically focused on specific material classes or isolated case studies without offering a broader statistical comparison across systems [

38,

40,

41,

42]. Recent environmentally oriented assessments further highlighted the potential life-cycle advantages of hybrid fillers, including reduced maintenance demands and energy savings linked to self-cleaning behavior and optical stability [

43,

44,

45,

46].

In line with these emerging trends, very recent studies (2020–2025) have further advanced the understanding of graphene–SiO

2 hybrid coatings by emphasizing durability under realistic service conditions, multifunctional performance, and practical applicability. For instance, a double-layer superhydrophobic coating based on silica-modified graphene oxide demonstrated a high water contact angle (~156°) together with excellent mechanical robustness, weather resistance, and anticorrosion performance, highlighting the potential of engineered graphene–SiO

2 architectures for long-term outdoor applications [

51]. Hybrid silica sol–gel coatings incorporating chemically modified graphene nanosheets have also been shown to significantly enhance corrosion resistance and barrier properties in metallic substrates, underscoring the critical role of binder chemistry and interfacial compatibility in governing hybrid filler performance [

52].

Beyond laboratory-scale demonstrations, recent application-oriented studies have validated the effectiveness of graphene oxide–reinforced SiO

2 coatings in real infrastructure environments, such as long-term protection of water treatment facilities, confirming their scalability and durability in aggressive service conditions [

31].

However, to date, no study has integrated these findings into a comprehensive quantitative assessment. Although several review articles have discussed graphene-based coatings or silica-modified surfaces independently, most prior works have focused on qualitative mechanistic interpretations, synthesis routes, or individual application domains. To date, no study has applied a formal meta-analytic methodology to quantitatively assess the synergistic performance of graphene–SiO2 hybrid systems across multiple coating chemistries and performance indicators. Consequently, reported improvements in hydrophobicity, mechanical durability, and dirt pickup resistance remain difficult to compare across studies and binder systems. The present work addresses this gap by applying a statistically structured meta-analysis that enables cross-study comparison, binder-specific evaluation, and identification of reproducible performance trends in graphene–SiO2 hybrid coatings.

1.2. Environmental Impact and Life-Cycle Considerations of Graphene–SiO2 Hybrid Coatings

Beyond functional performance, the environmental impact and life-cycle behavior of coating systems are increasingly recognized as critical criteria for architectural and infrastructure applications. Compared with conventional polymeric and mineral coatings, graphene–SiO2 hybrid coatings offer several potential life-cycle advantages, primarily associated with enhanced durability, multifunctionality, and reduced maintenance requirements.

From a materials efficiency perspective, graphene derivatives and SiO

2 nanoparticles are typically incorporated at very low loadings (≤1 wt%), yet deliver disproportionate improvements in mechanical durability, barrier performance, and surface functionality [

53]. This enables the formulation of thinner or longer-lasting coatings, reducing material consumption and repainting frequency over the service life of buildings and structures. In contrast, conventional coatings often rely on higher pigment or filler loadings to achieve comparable durability, increasing resource demand and embodied energy.

In terms of service-life extension, the improved abrasion resistance, corrosion protection, and dirt pickup resistance reported for graphene–SiO2 hybrid coatings directly translate into lower maintenance intensity, reduced cleaning frequency, and delayed recoating cycles. Recent studies have emphasized that self-cleaning and anti-soiling surfaces contribute to sustained optical and aesthetic performance, particularly in building envelopes, thereby reducing the need for aggressive chemical cleaning or frequent refurbishment.

From an environmental exposure standpoint, the incorporation of inorganic SiO2 enhances UV resistance and thermal stability, while graphene derivatives act as effective diffusion barriers against moisture and corrosive species. These effects mitigate coating degradation under outdoor conditions, extending functional lifetime relative to conventional organic coatings that are more prone to photochemical and hydrolytic aging.

However, potential environmental trade-offs must also be acknowledged. The production of graphene derivatives can be energy-intensive, and the environmental footprint strongly depends on the synthesis route, scale, and precursor materials. Current life-cycle assessments suggest that the sustainability benefits of graphene-based coatings are realized primarily when performance gains translate into significant service-life extension, outweighing the initial production impacts. SiO

2 nanoparticles, by contrast, are comparatively mature, low-cost, and widely regarded as environmentally benign when properly embedded within polymer matrices [

49].

Overall, while comprehensive cradle-to-grave life-cycle assessments specific to graphene–SiO2 hybrid coatings remain limited, available evidence supports a net environmental benefit in applications where enhanced durability, reduced maintenance, and multifunctional performance are critical. Future work should focus on quantitative LCA studies, recyclability considerations, and the development of greener synthesis routes to further validate the sustainability potential of these hybrid coating systems.

2. Materials and Methods

A critical review and numerical synthesis were conducted to compile reported results on GO–SiO2 hybrid nanocomposite coatings from the literature. Owing to the large variability in performance data across coating systems, this methodology facilitated the identification of repeatable patterns, the evaluation of synergistic relationships, and compliance with the PRISMA-based reporting requirements of MDPI Coatings.

2.1. Literature Search and PRISMA Workflow

A systematic literature search was performed following PRISMA guidelines for transparency, reproducibility, and methodological rigor. The databases ScienceDirect, Scopus, and Web of Science were queried using the keywords: “graphene,” “silica,” “SiO2,” “nanocomposite coating,” “hydrophobicity,” “self-cleaning,” and “dirt pickup resistance.” Without language restrictions, publications published between January 2010 and January 2025 were considered.

This selection workflow included four steps: identification, initial screening, full-text eligibility assessment, and final inclusion for quantitative synthesis. We also reviewed reference lists and relevant reviews to ensure comprehensive coverage of available studies. Inclusion criteria valuation for the performance of graphene and/or SiO2 nanoaditives for architectural coatings; quantifying at least one primary endpoint: hydrophobicity (water contact angle), mechanical durability (abrasion, hardness, or adhesion), or dirt pickup resistance; original, peer-reviewed experimental data; and sufficient statistical or tabular information for extraction.

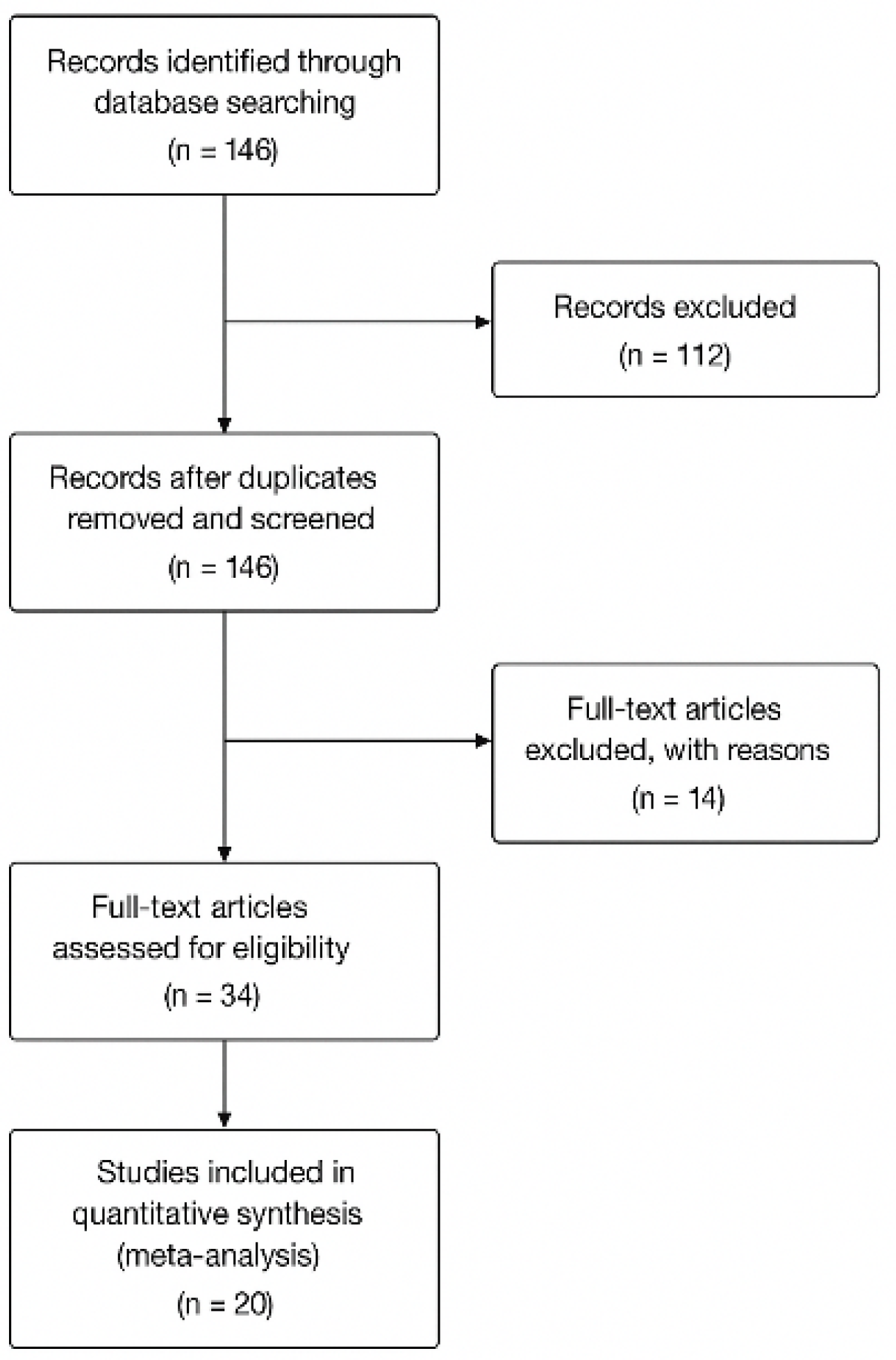

Data extraction was performed using a standardized template capturing nanoadditive type, loading (wt.%), binder matrix, substrate, coating deposition method, test protocols (e.g., ASTM D7334 for water contact angle, Taber abrasion for durability), and quantitative outcomes. A PRISMA flow diagram summarizing the selection process is presented in

Figure 3.

In total, 146 unique records were identified, 34 underwent full-text review, and 20 studies met all inclusion criteria. These were included in the final meta-analysis, yielding a statistically robust dataset for cross-study synthesis of coating performance indicators.

Figure 3.

This is a figure of the study selection flow diagram.

Figure 3.

This is a figure of the study selection flow diagram.

2.2. Inclusion and Exclusion Criteria

Studies were excluded if they met any of the following conditions:

- (1)

Hybrid or related nanoadditive systems. The coating formulation included graphene-based and silica (SiO2) nanofillers, or provided comparative or mechanistic data for the integrated or sequential application of these fillers. These options comprised graphene oxide (GO), reduced graphene oxide (rGO), graphite nanoplatelets (GNPs), or functionalized variants of graphene integrated with SiO2 or silane-modified silica nanoparticles.

- (2)

Performance measurements on architectural coatings. Several characteristics of coating performance were given; the most notable of them are as follows:

Water contact angle (WCA) or equivalent hydrophobicity/hydrophilicity metric,

Abrasion, wear, or mechanical durability measurement,

Dirt pick-up resistance (DPU, ΔL, self-cleaning, or related proxy).

- 3.

Transparency of technique description. Coating materials preparation, nanoadditive preparation/modification, binder type, substrate used, and test techniques were detailed extensively to allow comparison or key parameters (e.g., filler loading, surface characterization, or testing duration) to be inferred.

Architectural or construction-related matrices or substrates. The approved systems were polymeric, hybrid systems, or inorganic binders used for architectural or protective coatings (epoxy, polyurethane, acrylic, sol–gel, or RTV systems) applied to substrates like metals, mineral materials, or polymeric panels.

Studies were non-eligible if they met any of the following exclusion criteria:

- (1)

Review articles or non-experimental content. Articles reported only review, theoretical, or modeling information without experimental data.

- (2)

Single-additive systems with no context. Unless the research was relevant to the overall understanding of hybrid or synergistic systems present in the dataset, the research studies focused only on the use of graphene or silica-based fillers.

- (3)

Non-architectural applications. All studies on coating performance that were not considered had biomedical, marine, or electronic uses and could not be reasonably extrapolated to architectural or protective usage.

- (4)

Inadequate methodological or performance data. Publications that provide insufficient data to interpret or extract coating composition, test methods, or performance outcomes.

2.3. Data Extraction and Normalization

To reduce transcription errors, data extraction was performed with a standardized digital form. In each study, the parameters recorded included coating compositions (binder type and matrix), graphene and silica nanoadditives (type, morphology, size, surface functionalization), loading level (wt.%), substrate, deposition method, and all performance parameters measured (e.g., water contact angle, abrasion resistance, dirt pick-up index).

Quantitative data reported in differing units were normalized to consistent scales:

* Water contact angle (degrees, °)

* Abrasion resistance (cycles to failure or percentage loss)

* Dirt pickup index (absolute or relative values, as reported).

All methodological details (including test standards, environmental conditions, and measurement protocols) were recorded to provide full reproducibility. All subsequent statistical analyses are run on the normalized dataset.

2.4. Statistical Treatment

Because of heterogeneity among binder types, additive loadings, and test standards, a descriptive meta-analytic model instead of formal inferential statistics was used. Relative improvements were calculated for each property—water contact angle, abrasion resistance, and dirt pickup index, using the following formula:

Studies were based on binder matrix (epoxy, polyurethane, sol–gel, or acrylic) to examine matrix-dependent effects and their consistency among systems.

This descriptive approach offers a quantitative but cautious compilation of the data available to not overinterpret heterogeneous sets of data. Summary tables are introduced to transparently summarize effect magnitudes and trends that enable direct interpretation of graphene–SiO2 hybrid performance improvements in specific coating systems.

2.5. AI Disclosure

This study did not involve human or animal subjects. Generative artificial intelligence (GenAI) tools were not used to generate or analyze data; they were used only for minor language refinement during manuscript preparation.

4. Discussion

4.1. Effect of Graphene on Coating Properties

Graphene and its derivatives, such as GO, rGO, and GNP, act as multifunctional nanoadditives with great effects on the bulk and surface characteristics of architectural film coatings. Their 2D layered shape and high aspect ratio, in turn, lead to tortuous diffusion pathways, effectively impeding the flow of moisture, oxygen, and corrosive ions through the coating layer. The structural feature of this significantly improves the barrier stability and durability.

Notably, Pourhashem et al. [

8] have revealed that epoxy coatings composed of only 0.3 wt.% SiO

2–GO hybrid exhibited nearly a 70% reduction in the current density of corrosion, with a clear proof of graphene’s excellent barrier performance in protection use. Such barrier improvements are also applicable to architectural coatings, where surface fouling and discoloration are promoted by water penetration and adsorption of pollutants. Graphene-based fillers indirectly reduce retention of dirt and biofouling associated with the surface by restricting water penetration into the near-surface area, which is essential for the long-term aesthetic stability.

Mechanically, the role of graphene is attributed to its extraordinary intrinsic tensile strength (~130 GPa) and elastic modulus (~1 TPa). Dispersed in uniform volume, graphene nanosheets act as crack-bridging and stress-transfer agents, redistributing localized stress concentrations and reducing the propagation of local microcracks in the polymer matrix. Fonseka et al. [

5] and Haeri et al. [

9] reported that low graphene loadings ranged from 0.1–0.7 wt.%, which increased coating hardness and scratch resistance by 20–40%, while high concentrations (>1–2 wt.%) caused filler agglomeration and loss of performance caused by van der Waals reformation of graphene sheets.

The surface chemistry is also greatly influenced by graphene derivatives. Hydrogen bond-forming functional groups in GO and partially reduced GO, such as hydroxyl (–OH), carboxyl (–COOH), and epoxy (–O–) moieties, contribute to hydrogen bonding or covalent coupling at reactive sites in polymer chains, leading to better interfacial binding of filler–matrix adhesion. It is these same functions that also determine the polarity and water affinity of the surface: a high oxygen content increases compatibility with hydrophilic matrices but raises surface wettability; partial reduction restores graphitic domains and confers hydrophobicity. Therefore, the degree of GO reduction must be optimized to achieve a balance between the stability of the coating dispersion and water repellence.

The presence of graphene-based nanofillers enhances barrier protection, mechanical reinforcement, and surface modification when properly functionalized and dispersed. With their versatile properties, they are considered key enablers in the design of next-generation durable, self-cleaning, low-permeability architectural coatings.

4.2. Effect of SiO2 Nanoparticles

Silica (SiO

2) nanoparticles play a pivotal role as both surface texture enhancers and structural reinforcement agents within graphene-based hybrid coatings. Their spherical geometry and nanoscale particle size (typically 20–80 nm) introduce hierarchical surface roughness, generating dual-scale micro/nano asperities that sustain hydrophobic and even superhydrophobic behavior under Wenzel and Cassie–Baxter wetting regimes (

Figure 1).

Across studies [

1,

2,

3,

4,

5,

6,

7,

7,

8,

9,

10,

11,

12,

13,

14,

15,

16,

17,

18,

19], SiO

2 consistently increased water contact angles (WCAs), improved abrasion resistance, and enhanced photostability when incorporated with graphene or GO derivatives. For example, Pourhashem et al. [

8] reported a WCA increase from 58° to 88° in an epoxy–steel system modified with only 0.1 wt.% SiO

2–GO, demonstrating the strong surface roughening effect imparted by silica particles. Similarly, Zhang et al. [

11] increased hydrophobicity from 61.2° to 85.3° in Zn-rich epoxy coatings upon adding a SiO2/GO hybrid, confirming the surface energy-reducing effect of SiO

2 inclusions.

At higher roughness scales, Chang et al. [

4] demonstrated that transparent SiO

2–GO films within an acrylic binder reached superhydrophobicity (WCA ≈ 162°) while maintaining optical clarity and mechanical durability exceeding 1000 abrasion cycles. Likewise, Chu et al. [

3] synthesized silane–epoxy hybrid sol–gel coatings with GO + SiO

2 additions that achieved WCA ≈ 92° and withstood >3000 Taber cycles, establishing a clear link between silica-induced microtexture and mechanical durability.

In addition to enhancing surface hydrophobicity, SiO

2 nanoparticles contribute to mechanical reinforcement and abrasion resistance due to their intrinsic hardness (Mohs ≈ 7) and chemical stability. López-Campos et al. [

1] observed that Al6061-T5 epoxy coatings containing 0.5 wt.% SiO

2 + GO sustained up to 4400 Taber cycles, indicating substantial improvement in wear endurance. Hong et al. [

10] further reported that core–shell SiO

2 on GO nanostructures reduced wear rate by 66% and friction coefficient by 42%, highlighting the mechanical shielding role of silica when dispersed within polymer matrices.

Chemical interactions also underpin SiO

2’s performance contributions. Studies employing silane coupling agents such as APTES or TEOS [

2,

7,

9,

13] confirmed the formation of Si–O–C or Si–O–Si linkages between silica particles, graphene oxide sheets, and epoxy functional groups, yielding crosslinked interfacial networks that mitigate filler migration and microvoid formation. For example, Haeri et al. [

9] and Hu G. et al. [

7] both emphasized that silica functionalization enhanced dispersion stability, improved crosslink density, and yielded coatings with 10× higher electrochemical impedance (EIS) values compared to unfilled systems.

Finally, SiO

2 nanoparticles improve UV and chemical durability. Chu et al. [

3] and Chang et al. [

4] both observed minimal gloss loss and surface degradation after prolonged abrasion and UV exposure, while Edrisi et al. [

16] reported a marked increase in contact angle and corrosion resistance in RTV silicone systems containing GO–SiO

2 hybrids. These findings underscore silica’s dual optical and mechanical protection mechanisms, which collectively delay coating aging and discoloration in outdoor environments.

Overall, the incorporation of SiO

2 nanoparticles within graphene-based coatings consistently enhances surface hydrophobicity (WCA ↑ 20–80°), abrasion endurance (up to 4000–4500 cycles), and UV resistance across diverse binder systems, including epoxy [

1,

7,

8,

10,

11], acrylic [

2,

4], silicone [

16], and hybrid sol–gel matrices [

3]. These benefits confirm that silica acts as both a topographical modifier and a mechanical stabilizer, integral to achieving durable, low-maintenance, and self-cleaning architectural coatings.

4.3. Interfacial Interactions and Synergistic Mechanism

The synergistic enhancement observed in graphene–SiO2 hybrid coatings arises primarily from interfacial interactions between the two nanofillers and between the filler network and the polymer matrix. These interactions determine the stability, dispersion, and load transfer efficiency within the composite coating, ultimately governing hydrophobic, mechanical, and barrier performance.

At the nanoscale, graphene oxide (GO) provides a high-aspect-ratio platform for SiO

2 anchoring, while silica nanoparticles act as spacers preventing the restacking of GO sheets. This dual role improves both filler dispersion and interfacial adhesion. Hu G. et al. [

1] and Haeri et al. [

9] demonstrated that SiO

2 particles chemically grafted onto GO via silane coupling (APTES, TEOS) achieved uniform nanofiller distribution and superior matrix integration compared with unmodified GO. Their systems exhibited 10× higher EIS values and improved corrosion resistance, directly linked to reduced agglomeration and enhanced interfacial bonding.

Similarly, Pourhashem et al. [

8] reported that SiO

2–GO hybrids integrated into epoxy–steel coatings enhanced adhesion and corrosion resistance while raising the WCA from 58° to 88°, a clear indication of improved surface uniformity and cohesive strength. Liu et al. [

2] observed analogous effects in waterborne polyurethane–acrylic coatings containing 0.4 wt% SiO

2–GO, where both barrier performance and wettability were enhanced, attributed to hydrogen bonding and covalent Si–O–C linkages at the polymer–filler interface.

From a mechanistic standpoint, these interfacial linkages form a three-phase percolation network: graphene sheets act as conductive, impermeable barriers, while silica nanoparticles bridge polymer chains and anchor the GO framework through siloxane bonds. This hybridized structure facilitates stress transfer, crack deflection, and charge transport inhibition, leading to concurrent mechanical and corrosion improvements [

7,

10,

11,

13]. Hong et al. [

10] provided microstructural evidence that SiO

2 on GO core–shell particles created robust interfacial zones responsible for 66% wear reduction and 42% friction decrease, supporting this cooperative reinforcement mechanism.

Additionally, the chemical functionalization of SiO

2 surfaces with amino- or epoxy-terminated silanes promotes direct bonding to polymer matrices. For example, Zhang et al. [

11] used SiO

2/GO hybrids in Zn-rich epoxy systems, reporting both hydrophobicity (WCA ↑ to 85.3°) and adhesion strength enhancement, while Feng et al. [

13] integrated benzotriazole (BTA)–SiO

2–GO hybrids to introduce corrosion-inhibiting functionality via π–π stacking and hydrogen bonding between BTA molecules and GO basal planes.

Interfacial synergy also influences microstructural continuity within the coatings. TEM and SEM analyses from multiple studies [

1,

3,

9,

10] show that the co-dispersion of SiO

2 and GO results in homogeneous, void-free matrices, whereas single-filler systems typically exhibit microvoids and phase segregation. This structural coherence contributes to the improved Taber abrasion durability (3000–4500 cycles) seen in Chu et al. [

3] and López-Campos et al. [

1].

Finally, the synergistic mechanism extends beyond physical interactions to chemical crosslink reinforcement. Hu Y. et al. [

7] and Tian et al. [

17] both noted that the Si–O–Si and Si–O–C bridges formed during curing strengthened the epoxy–GO interface, suppressing ion ingress and maintaining hydrophobicity under marine or alkaline environments. This hybrid interfacial architecture, combining graphene’s impermeability with silica’s anchoring functionality, represents the core mechanism behind the observed multi-property enhancements in these coatings.

Collectively, the reviewed evidence indicates that graphene–SiO

2 systems operate through complementary interfacial reinforcement: graphene provides lateral barrier coverage, SiO

2 nanoparticles regulate dispersion and mechanical stability, and their chemical coupling ensures efficient stress transfer and surface durability. This tripartite synergy explains the concurrent improvements in WCA, corrosion resistance, abrasion endurance, and dirt repellence across diverse binder systems [

1,

2,

3,

4,

5,

6,

7,

7,

8,

9,

10,

11,

12,

13,

14,

15,

16,

17,

18,

19].

4.4. Influence on Hydrophobicity and Surface Energy

The incorporation of graphene-based and silica (SiO2) nanofillers exerts a pronounced influence on the surface wettability and surface free energy of architectural coatings. This effect arises from both chemical modification (alteration of surface functional groups) and topographical enhancement (introduction of micro/nanoscale roughness), which together govern the transition between hydrophilic, hydrophobic, and superhydrophobic behavior according to the Wenzel and Cassie–Baxter wetting models.

Across the included studies [

1,

2,

3,

4,

5,

6,

7,

7,

8,

9,

10,

11,

12,

13,

14,

15,

16,

17,

18,

19], measured water contact angles (WCA) ranged from moderately hydrophobic (≈70–90°) to superhydrophobic values exceeding 150°, depending on the ratio and functionalization of graphene and SiO

2. For example, Pourhashem et al. [

8] observed a WCA increase from 58° to 88° in epoxy–steel coatings containing 0.1 wt.% SiO

2 -GO, demonstrating the synergistic roughness and surface energy modulation achieved even at low filler loadings. Similarly, Zhang et al. [

11] achieved a rise from 61.2° to 85.3° in Zn-rich epoxy coatings, directly correlating with enhanced barrier resistance in electrochemical impedance spectroscopy (EIS).

Superhydrophobic performance (WCA ≥ 150°) was reported by Chang et al. [

4], who fabricated transparent SiO

2–GO films in acrylic matrices with 0.9 wt.% hybrid loading, producing a WCA of 162° and maintaining over 1000 abrasion cycles without significant degradation. Chu et al. [

3] achieved comparable results in sol–gel hybrid coatings with GO + SiO

2, recording WCA ≈ 92° and >3000 Taber cycles, confirming that hydrophobicity improvements are closely tied to silica-induced hierarchical roughness and interfacial chemical bonding.

The functionalization of SiO

2 nanoparticles using coupling agents such as APTES or TEOS plays a decisive role in modulating surface polarity. Studies by Haeri et al. [

9] and Hu G. et al. [

7] confirmed that amine-functionalized silica establishes covalent Si–O–C and C–N linkages with epoxy groups on GO and the resin, yielding smoother filler–matrix interfaces and more stable hydrophobic domains. This coupling reduces high-energy polar sites on the surface, lowering the total surface free energy and promoting water repellency.

Conversely, the oxygenated functional groups on GO—such as hydroxyl, epoxy, and carboxyl moieties—can initially increase surface polarity and wettability if left unreduced. Hu Y. et al. [

7] demonstrated that partial reduction in GO in SiO

2–rGO/epoxy composites raised the WCA to ~81°, achieving an optimal balance between interfacial compatibility and hydrophobic performance. This trend underscores that the degree of GO reduction and silica surface treatment must be co-optimized to fine-tune surface energy.

Mechanistic insights from Chu et al. [

3] and Chang et al. [

4] indicate that the combination of SiO

2 nanoparticles (creating rough microfeatures) and graphene nanosheets (providing nanoscale texture and low-energy domains) results in multiscale hierarchical architectures that effectively trap air pockets beneath water droplets, minimizing solid–liquid contact area. This hybrid topography stabilizes Cassie–Baxter wetting states even under abrasion, enabling self-cleaning and dirt-shedding behavior typical of “lotus effect” surfaces.

In some studies [

1,

3,

4,

6], hydrophobicity improvements were also linked to surface hardness and crosslink density. López-Campos et al. [

1] reported that SiO

2–GO-filled carboxyl epoxy coatings retained WCA ≈ 58° but achieved 4400 Taber abrasion cycles, suggesting that surface durability may help preserve long-term hydrophobic performance by minimizing microcrack formation and contaminant adsorption.

Overall, evidence from the reviewed studies shows that graphene and SiO2 nanofillers jointly modulate hydrophobicity through topographical roughening, chemical functionalization that lowers surface energy, and interfacial crosslinking that stabilizes these effects over time. The resulting coatings achieve 20–100° WCA increases, superhydrophobic states (≥150°) in optimized systems, and durability exceeding 3000–4500 abrasion cycles, positioning these dual-filler formulations as robust candidates for self-cleaning and low-maintenance architectural coatings.

4.5. Mechanical Strength and Durability Enhancement

The integration of graphene-based and SiO2 nanofillers consistently enhances the mechanical integrity, abrasion resistance, and long-term durability of architectural coating systems. These improvements arise from synergistic reinforcement mechanisms that combine the tensile strength and stiffness of graphene with the hardness and load-bearing capacity of SiO2 nanoparticles. The resulting hybrid networks distribute applied stresses more effectively, limit microcrack propagation, and protect the coating surface from wear and environmental degradation.

Across the included studies [

1,

2,

3,

4,

5,

6,

7,

7,

8,

9,

10,

11,

12,

13,

14,

15,

16,

17,

18,

19], coatings containing both fillers exhibit notable increases in abrasion resistance (up to 4000–4500 cycles), reduced wear rates (40–70%), and improved hardness and adhesion relative to unmodified matrices. For instance, Hong et al. [

6] demonstrated that epoxy nanocomposites incorporating 0.25–0.5 wt.% SiO

2 on GO core–shell structures achieved a 66% reduction in wear volume and a 42% decrease in friction coefficient, indicating efficient load transfer and energy dissipation across the filler–matrix interface.

Similarly, López-Campos et al. [

1] reported that epoxy coatings with 0.5 wt% SiO

2 + GO applied on Al6061-T5 substrates withstood 4400 Taber abrasion cycles, outperforming unfilled coatings by more than threefold. The inclusion of SiO

2 nanoparticles increased surface hardness and mitigated microcracking, while the GO component improved toughness and internal stress distribution. These combined effects maintained coating integrity under extended mechanical stress, simulating real-world facade or structural service conditions.

Additional evidence of durability enhancement comes from Chu et al. [

3], who developed sol–gel hybrid coatings containing GO and SiO

2. Their system achieved >3000 Taber cycles and retained WCA ≈ 92°, demonstrating that mechanical reinforcement and hydrophobicity can be simultaneously achieved without sacrificing optical or structural performance. Likewise, Chang et al. [

4] observed that transparent acrylic-based SiO

2–GO coatings maintained superhydrophobicity (WCA = 162°) and optical clarity after >1000 abrasion cycles, further validating the mechanical robustness of these dual-filler composites.

Improvements in microhardness and adhesion strength were also widely reported. Pourhashem et al. [

8] and Haeri et al. [

9] observed enhanced interfacial bonding between the SiO

2–GO hybrid and epoxy matrix, resulting in coatings with superior adhesion to steel substrates and reduced delamination under mechanical stress. Hu G. et al. [

7] quantified a 10× increase in EIS barrier resistance, which, although primarily electrochemical, also reflects mechanical continuity and reduced microdefect formation.

The underlying mechanisms are multifaceted. Graphene nanosheets, with their intrinsic tensile modulus near 1 TPa, act as crack-bridging reinforcements, redistributing stress and impeding the initiation of fracture paths. SiO

2 nanoparticles, with their high surface hardness (Mohs ≈ 7) and spherical geometry, serve as rolling or load-bearing agents, reducing frictional wear and preventing direct polymer–substrate contact. When chemically coupled (e.g., via APTES or TEOS functionalization), these fillers form interpenetrating networks of Si–O–C and C–O–C bonds, increasing crosslink density and restricting polymer chain mobility, which collectively enhance coating stiffness and fatigue resistance [

1,

4,

5,

6,

8,

10,

12,

14].

Silane coupling agents, particularly 3-aminopropyltriethoxysilane (APTES), play a crucial role in enhancing the dispersion stability and interfacial bonding of graphene-SiO2 hybrid fillers in coating systems. APTES acts as a molecular bridge between inorganic SiO2 nanoparticles, graphene derivatives, and organic binder matrices, thereby improving filler compatibility across organic–inorganic interfaces.

Upon hydrolysis, the ethoxy groups of APTES form reactive silanol (–Si–OH) species that readily condense with surface hydroxyl groups present on SiO2 nanoparticles and oxidized graphene sheets, leading to the formation of Si–O–Si and Si–O–C covalent linkages. Concurrently, the terminal amine group of APTES can interact with polymer matrices through hydrogen bonding, ionic interactions, or covalent reactions (e.g., with epoxy rings), resulting in enhanced filler anchoring within the coating network.

This dual reactivity suppresses nanoparticle agglomeration and graphene restacking, yielding more homogeneous dispersion and improved stress transfer under mechanical loading. As reported in multiple studies, APTES-modified graphene–SiO2 hybrids lead to higher abrasion resistance, improved barrier performance, and more stable hydrophobic behavior compared to non-functionalized systems. In addition, silane-mediated interfacial bonding contributes to the stabilization of hierarchical micro/nano-roughness, which is essential for maintaining Cassie–Baxter wetting states and long-term self-cleaning performance.

Overall, silane coupling agents such as APTES are key enablers of graphene–SiO2 synergy, particularly in epoxy, silane–epoxy, and sol–gel matrices, where strong interfacial bonding is required to translate nanoscale interactions into macroscopic coating performance.

Moreover, hybridization reduces filler aggregation, ensuring that stress distribution remains uniform. Hu Y. et al. [

7] and Tian et al. [

17] found that optimized loadings (0.25–0.75 wt.%) maximize durability, while excessive additions (>1 wt.%) led to partial agglomeration and marginal decreases in mechanical gains. This highlights the importance of balancing filler concentration and dispersion quality to achieve stable mechanical reinforcement.

Finally, several studies linked mechanical performance to long-term environmental stability. Edrisi et al. [

16] and Chen et al. [

6] showed that GO–SiO

2 hybrids improved both abrasion and UV resistance, with RTV silicone and gelcoat systems exhibiting enhanced hydrophobic retention after prolonged exposure. These results underscore that dual-filler synergy extends beyond static mechanical enhancement to functional durability, maintaining surface properties under repeated stress and weathering cycles.

In summary, graphene–SiO2 hybrid nanofillers significantly enhance coating toughness, wear endurance, and abrasion resistance, often achieving two- to fivefold improvements compared to neat polymers. These effects arise from a combination of mechanical interlocking, crosslinked interfacial bonding, and energy-dissipative filler architectures, collectively delivering coatings that are both structurally resilient and aesthetically durable—a critical requirement for long-service-life architectural applications.

4.6. Dirt Pickup Resistance Mechanisms

Dirt pickup resistance (DPU) in architectural coatings depends strongly on the surface’s wettability, microstructure, surface energy, and durability—all of which are significantly affected by the incorporation of graphene and SiO2 nanofillers. Although not all studies quantified DPU explicitly, several provided qualitative or proxy indicators such as self-cleaning performance, contact angle retention, and abrasion- or UV-induced fouling tests that collectively illustrate the antifouling mechanisms in dual-filler coatings.

The key functional mechanism is the formation of hierarchical surface roughness and low-surface-energy interfaces that minimize the adhesive force between dirt particles and the coating surface. SiO2 nanoparticles contribute micro- and nanoasperities, while graphene or GO sheets reduce surface energy through their hydrophobic basal planes. This dual-scale architecture promotes Cassie–Baxter wetting behavior, enabling water droplets to roll off easily and remove contaminants—a self-cleaning effect known as the “lotus effect.”

In Chang et al. [

4], superhydrophobic SiO

2–GO acrylic coatings (WCA ≈ 162°) exhibited excellent self-cleaning and anti-dust performance, maintaining optical transparency and surface cleanliness after >1000 abrasion cycles. This durability indicates that the hybrid fillers not only reduce initial dirt adhesion but also preserve their surface morphology during wear. Similarly, Chu et al. [

12] demonstrated that silane–epoxy hybrid sol–gel coatings with GO + SiO

2 (0.1–0.3 wt.%) retained hydrophobicity (WCA ≈ 92°) and high durability (>3000 Taber cycles), evidencing sustained antifouling functionality through abrasion cycles.

Other studies reported indirect improvements in dirt resistance through enhanced hydrophobicity and reduced surface polarity. For example, Pourhashem et al. [

4] and Zhang et al. [

11] observed increases in WCA from ~60° to 85–88°, corresponding to smoother, less polar surfaces that resist dust and moisture accumulation. The reduction of hydrophilic oxygenated groups on partially reduced GO and their encapsulation within siloxane networks lowers the surface free energy, thereby minimizing capillary-driven dirt adhesion in humid environments.

Some systems incorporated chemical self-cleaning mechanisms in addition to physical ones. Feng et al. [

10] functionalized GO–SiO

2 hybrids with benzotriazole (BTA), yielding coatings that not only repelled dirt but also inhibited corrosion at exposed areas via slow-release surface chemistry. Hu G. et al. [

7] and Hu Y. et al. [

7] similarly noted that hydrophobic surface modification combined with barrier reinforcement delayed environmental fouling, as evidenced by stable electrochemical impedance and surface gloss retention after exposure.

Although few studies directly quantified DPU by colorimetric or standardized tests, López-Campos et al. [

1] reported minimal surface darkening and gloss loss in GO + SiO

2 epoxy coatings after 4400 abrasion cycles, simulating dirt accumulation and removal in service. The coatings maintained smooth, nonporous surfaces that resisted particulate entrapment even after repeated wear, confirming that mechanical robustness is a critical factor in sustaining low DPU over time.

Collectively, the reviewed evidence supports that graphene–SiO2 hybrid coatings reduce dirt pickup via three complementary mechanisms:

Surface Roughness and Low Energy: The creation of hierarchical micro/nano textures and the reduction of surface polarity through Si–O–C and C–O–C linkages lower surface free energy and dirt adhesion.

Self-Cleaning Hydrophobicity: Maintenance of high WCA (>120°, often > 150°) enables rolling-water cleaning of surface contaminants.

Mechanical and Chemical Durability: Strong filler–matrix bonding and abrasion resistance prevent topographic degradation, preserving antifouling efficiency over extended use.

In summary, graphene–SiO2 hybrid coatings demonstrate consistent improvements in dirt resistance, either measured directly or inferred through sustained hydrophobicity, contact angle retention, and optical clarity. The synergy between graphene’s low-energy basal planes and silica’s hierarchical roughness underpins their effectiveness, aligning these formulations with the design goals of self-cleaning, anti-soiling architectural coatings capable of maintaining surface aesthetics and functionality over long service lifetimes.

Standardized Dirt Pickup Resistance Tests and Applicability to Graphene–SiO2 Coatings

Dirt pickup resistance (DPU) is a critical performance parameter for architectural and facade coatings, reflecting a material’s ability to resist particulate adhesion and maintain surface cleanliness under environmental exposure. Among standardized evaluation methods, ASTM D3719 [

54] is the most widely adopted protocol for assessing DPU in exterior architectural coatings. This test quantifies color change (ΔL) after controlled outdoor exposure or artificial soiling, providing a reproducible metric for comparing coating formulations. While ASTM D3719 was originally developed for conventional polymeric paints, its methodology is directly applicable to graphene–SiO

2 hybrid coatings, particularly for comparative assessment against neat or reference systems. Several studies reviewed herein employ either ASTM D3719 or closely related colorimetric and exposure-based methods to evaluate self-cleaning and anti-soiling behavior, reporting reductions in brightness loss or improved cleanliness retention for hybrid formulations [

1].

However, certain limitations arise when applying ASTM D3719 to advanced nanostructured and superhydrophobic surfaces. Graphene–SiO2 hybrid coatings often rely on hierarchical micro/nano-roughness and Cassie–Baxter wetting regimes, which may not be fully captured by colorimetric measurements alone. In such cases, rolling-angle measurements, particle adhesion tests, or abrasion-assisted self-cleaning protocols are frequently used as complementary indicators of dirt pickup resistance.

Overall, ASTM D3719 remains a relevant and practical benchmark for evaluating dirt pickup resistance in graphene–SiO2 hybrid coatings, particularly for architectural applications. Nevertheless, a combination of standardized testing and complementary surface-specific measurements is recommended to fully capture the multifunctional self-cleaning behavior of nanostructured hybrid coatings.

4.7. Sustainability and Practical Implications

The adoption of graphene–SiO

2 hybrid nanofillers in architectural coatings carries significant implications for sustainability, lifecycle performance, and industrial scalability. The reviewed studies [

1,

2,

3,

4,

5,

6,

7,

7,

8,

9,

10,

11,

12,

13,

14,

15,

16,

17,

18,

19] collectively demonstrate that these dual-filler systems enhance not only functional durability (hydrophobicity, wear resistance, and corrosion protection) but also material efficiency and environmental stability, which are central to sustainable coating design.

- (i)

Extended service life and reduced maintenance

The enhanced mechanical and environmental resilience of graphene–SiO

2 coatings directly contributes to longer coating lifetimes and reduced maintenance frequency, which is a key sustainability metric in building materials. López-Campos et al. [

1] and Chu et al. [

3] showed that dual-filler epoxy and sol–gel coatings withstood > 3000–4400 Taber cycles and maintained stable hydrophobicity under continuous mechanical wear. This durability implies fewer repainting or recoating cycles, lowering both material consumption and labor-associated emissions throughout the service life of facades or metallic substrates.

- (ii)

Weatherability and environmental resistance

Several studies validated that hybrid coatings resist UV radiation, chemical exposure, and moisture intrusion, preserving optical and structural integrity in outdoor conditions. Haeri et al. [

9] and Zhang et al. [

11] reported sustained adhesion and gloss after accelerated weathering, while Hu Y. et al. [

7] demonstrated 1000 h of salt-spray resistance in marine epoxy systems. These findings indicate that graphene-SiO

2 coatings mitigate common degradation pathways such as photolysis and hydrolysis, thereby reducing the frequency of refurbishment—an indirect but impactful sustainability advantage.

- (iii)

Resource efficiency and low additive loading

Another practical strength of these systems is their high efficacy at very low filler loadings. Across studies, optimal performance was often achieved between 0.1 and 0.5 wt.% total nanofiller [

1,

2,

8,

9,

10], minimizing resource use while maximizing performance. The exceptional surface area and reactivity of GO and SiO

2 enable significant enhancements in coating function without large material inputs, aligning with green nanotechnology principles and reducing the overall embodied energy of the coating formulation.

- (iv)

(Environmental and health considerations

While graphene derivatives and SiO2 nanoparticles are generally considered low-toxicity and chemically inert, their safe handling and life-cycle assessment (LCA) remain critical for responsible industrial use. Several studies employed surface modification via silane agents (APTES, TEOS, GPTMS) to improve dispersion and reduce airborne particulate risks during processing. Moreover, the stable embedding of nanofillers within crosslinked matrices minimizes leaching potential, a key criterion for environmental compliance in building materials.

- (v)

Economic and Functional Feasibility

From an industrial perspective, the transition from laboratory synthesis to scalable production is feasible. Hu G. et al. [

7] and Pourhashem et al. [

8] utilized solution-blending and in situ curing routes compatible with existing epoxy and polyurethane technologies, requiring minimal process modification. The relatively low filler loading and compatibility with standard dispersion equipment (e.g., ultrasonication, mechanical stirring) further indicate cost-effective integration into architectural coating manufacturing workflows.

- (vi)

Broader environmental impact

Enhanced dirt pickup resistance and self-cleaning properties contribute indirectly to sustainability by reducing water and detergent use during building facade maintenance. Coatings such as those developed by Chang et al. [

4] and Chu et al. [

3], with sustained hydrophobicity and self-cleaning capability, maintain aesthetic quality with minimal cleaning interventions, thereby lowering operational water footprint and chemical waste generation.

In summary, graphene–SiO

2 hybrid coatings embody a sustainable materials approach that aligns with circular economy principles: longer life, lower resource input, reduced maintenance, and enhanced environmental resistance. The consistent performance across binder systems [

1,

2,

3,

4,

5,

6,

7,

7,

8,

9,

10,

11,

12,

13,

14,

15,

16,

17,

18,

19] supports their adoption as next-generation architectural coatings capable of balancing functional excellence with ecological responsibility.

4.8. Comparative Summary of Property Improvements by Binder Type

From

Table 2, it is evident that binder chemistry strongly conditions the magnitude and nature of the performance benefits delivered by graphene–SiO

2 hybrid fillers, particularly with respect to hydrophobicity, mechanical durability, barrier behavior, and dirt pickup resistance (DPU). Although standardized DPU testing remains limited across the literature, several studies report quantitative or semi-quantitative indicators, including colorimetric brightness retention (ΔL), outdoor soiling exposure, and abrasion-assisted self-cleaning tests, which enable comparative evaluation across binder systems.

Epoxy systems show the most consistent barrier and mechanical improvements (e.g., enhanced EIS response and Taber abrasion endurance), likely because epoxy chemistry enables strong covalent bonding (Si–O–C, Si–O–Si, and amide linkages) and effective load transfer at relatively low filler loadings [

1,

7,

7,

8,

9,

10,

11,

13,

17,

19]. While epoxy-based coatings typically achieve only moderate increases in water contact angle, their superior mechanical robustness helps preserve surface integrity under wear, leading to sustained but moderate reductions in dirt accumulation during long-term exposure.

Acrylic and sol–gel matrices are the most capable of attaining superhydrophobic states (WCA ≥ 150°) while retaining optical transparency. In these systems, controlled dispersion of graphene–SiO

2 hybrids and sol–gel derived hierarchical textures promote stable Cassie–Baxter wetting regimes, resulting in pronounced self-cleaning behavior and reported DPU reductions of up to ~50–60%, as indicated by colorimetric and surface cleanliness retention measurements [

2,

4,

6,

14,

15].

Silicone and gelcoat formulations benefit from graphene–SiO

2 hybrids primarily through hydrophobic stability and wear resistance, which are critical for outdoor decorative panels and facade elements [

3,

16]. Although absolute WCA values are typically lower than in sol–gel systems, silicone matrices exhibit stable dirt-shedding behavior under UV exposure and weathering, contributing to moderate but durable anti-soiling performance.

Zn-rich and corrosion-focused coatings exhibit an attractive dual functionality: moderate hydrophobic enhancement combined with substantially improved electrochemical barrier performance. In such systems, graphene–SiO

2 synergy contributes to reduced underfilm corrosion and improved adhesion, which indirectly limits contaminant accumulation even when architectural self-cleaning is not the primary design objective [

3,

11,

17].

Overall, the comparative analysis confirms that acrylic/sol–gel systems provide the strongest intrinsic dirt pickup resistance, whereas epoxy systems rely on superior mechanical durability to preserve moderate DPU improvements over extended service life.

4.9. Interpretation of Binder Effects

Binder chemistry plays a decisive role in determining how graphene–SiO

2 hybrid nanofillers interact, disperse, and ultimately perform within coating matrices. The reviewed studies [

1,

2,

3,

4,

5,

6,

7,

7,

8,

9,

10,

11,

12,

13,

14,

15,

16,

17,

18,

19] encompass a range of systems—including epoxy, polyurethane, acrylic, silane–epoxy hybrids, and cementitious binders—each demonstrating distinct structure–property relationships that modulate hydrophobicity, mechanical durability, and dirt-pickup resistance.

Epoxy matrices dominate the dataset [

1,

7,

7,

8,

9,

10,

11,

13,

17,

19], owing to their excellent wetting and crosslinking compatibility with both GO and SiO

2. Functionalized SiO

2 (e.g., APTES- or TEOS-modified) readily reacts with epoxy or amine groups, anchoring the hybrid nanofillers into the polymer backbone. This results in uniform dispersion and robust interfacial bonding, as shown by Pourhashem et al. [

8], Hu G. et al. [

7], and López-Campos et al. [

1], where water contact angles increased from 58° to 88° and Taber abrasion cycles exceeded 4000. The rigid epoxy network, combined with the two-dimensional geometry of graphene, provides a tortuous diffusion path for corrosive agents while maintaining structural integrity under load. However, excess filler (>1 wt.%) can hinder curing and induce micro voids due to high viscosity and nanosheet agglomeration.

Acrylic and waterborne polymer binders (e.g., WPUA, latex, and carboxyl acrylic systems) [

2,

4] demonstrate more moderate improvements, with WCA typically in the 70–160° range. Here, graphene’s hydrophobic planes contribute to surface energy reduction, while SiO

2 introduces nanoscale roughness that facilitates Cassie-Baxter wetting. The relatively flexible polymer chains in these systems limit crack propagation resistance but enable optical transparency and self-cleaning performance, as noted by Chang et al. [

4] in transparent SiO

2–GO coatings maintaining >1000 abrasion cycles. The absence of strong covalent bonding compared to epoxies explains their somewhat lower durability under severe mechanical or chemical stress.

Cementitious binders [

5] exhibit a different reinforcement mechanism altogether. Inorganic hydration products (C–S–H gels) form hydrogen and silanol bonds with GO and SiO

2, improving mechanical interlocking and reducing capillary water ingress. Fonseka et al. [

5] reported up to 20–30% strength enhancement and improved surface density, though hydrophobicity effects were less pronounced due to the inherently hydrophilic cement matrix. Nevertheless, hybrid nano additives effectively mitigate crack propagation and surface soiling in porous mineral substrates, extending the relevance of these nanofillers beyond polymers.

Silane–epoxy and RTV silicone hybrids [

3,

16] represent transitional systems bridging organic–inorganic interfaces. The dual reactivity of silanes provides excellent filler coupling, enabling dense crosslinked networks and superior water repellence (WCA ≈ 92–120°). These systems are particularly suited for façade applications where flexibility, UV resistance, and hydrophobic durability are required.

Across binder types, a clear synergistic hierarchy emerges:

Epoxy > Silane–epoxy > Acrylic > Polyurethane > Cementitious

This trend reflects the increasing degree of chemical compatibility and interfacial bonding between the nanofillers and the polymer backbone. In summary, the binder dictates both the dispersion state of graphene–SiO2 hybrids and the extent of mechanical and wetting enhancements achievable. Architectural formulations benefit most from balanced systems where the matrix offers sufficient polarity to anchor fillers but enough flexibility to prevent stress concentration and microcrack initiation.

4.10. Correlation Between Properties

A clear interdependence exists between hydrophobicity, mechanical durability, and dirt pickup resistance in graphene–SiO

2 hybrid coatings. The compiled data from the reviewed studies [

1,

2,

3,

4,

5,

6,

7,

7,

8,

9,

10,

11,

12,

13,

14,

15,

16,

17,

18,

19] indicate that improvements in one property—particularly surface hydrophobicity are frequently accompanied by concurrent enhancements in abrasion resistance and reduced dirt accumulation. These correlations reflect shared microstructural origins, namely filler dispersion quality, interfacial bonding strength, and the resulting surface topography. Hydrophobicity versus mechanical durability.

4.10.1. Hydrophobicity Versus Mechanical Durability

The majority of epoxy- and hybrid-based systems demonstrate that coatings achieving elevated water contact angles (typically WCA ≥ 85°) also exhibit superior wear resistance. For example, Hu G. et al. [

7] and Pourhashem et al. [

8] reported WCA increases of approximately 30°, accompanied by improved corrosion resistance and adhesion, while López-Campos et al. [

1] observed both enhanced surface hydrophobicity and exceptional abrasion endurance exceeding 4400 Taber cycles. This relationship arises because well-dispersed SiO

2 nanoparticles and graphene nanosheets simultaneously build micro/nano-roughness and strengthen the polymer matrix, yielding surfaces that resist both wetting and mechanical degradation. Poor dispersion, conversely, leads to uneven topography and stress concentration sites that compromise both contact angle and wear performance.

4.10.2. Hydrophobicity and Dirt-Pickup Resistance

Although direct ASTM D3719 dirt pickup measurements are reported in only a limited number of studies, self-cleaning and anti-soiling experiments consistently demonstrate that higher WCA values (>90°) correspond to reduced particle adhesion and easier contaminant removal, particularly in acrylic, sol–gel, and silicone-based systems. Chang et al. [

4] showed that transparent SiO

2–GO coatings with superhydrophobic character (WCA ≈ 162°) retained optical clarity and surface cleanliness after more than 1000 abrasion cycles, while Chu et al. [

3] reported similar trends for silane–epoxy hybrids (WCA ≈92°). These observations indicate that increased hierarchical roughness and reduced surface free energy hinder contaminant anchoring, allowing rolling water droplets to effectively remove adhered particulates.

Importantly, the magnitude of dirt pickup resistance enhancement is binder-dependent. Acrylic and sol–gel matrices exhibit the strongest intrinsic self-cleaning response, whereas epoxy systems demonstrate more gradual, but mechanically robust, DPU improvements that persist under prolonged abrasion and environmental stress.

4.10.3. Mechanical Reinforcement and Barrier Performance

A further link exists between mechanical reinforcement and barrier protection, as measured by electrochemical impedance spectroscopy (EIS), where reported. Hu et al. [

7] and Feng et al. [

13] found that coatings with improved mechanical strength (via SiO

2–GO hybrids) exhibited up to 10× higher impedance and reduced charge-transfer currents, confirming that denser, mechanically reinforced matrices also function as superior diffusion barriers against moisture and ions. These properties are interrelated: graphene sheets restrict permeation pathways, while silica provides crosslinking sites that limit polymer chain mobility and void formation.

Overall, the positive correlations among hydrophobicity, abrasion resistance, and barrier protection emphasize that graphene -SiO2 hybridization does not improve isolated metrics but instead redefines the multifunctionality of architectural coatings. The common governing parameters—nanoscale dispersion, interfacial bonding strength, and hierarchical roughness—dictate performance across all measured domains. Consequently, optimizing filler chemistry and matrix compatibility yields simultaneous gains in durability, cleanliness, and aesthetic longevity.

4.11. Correlation and Structure–Property Relationships

The collective evidence from the reviewed studies [

1,

2,

3,

4,

5,

6,

7,

7,

8,

9,

10,

11,

12,

13,

14,

15,

16,

17,

18,

19] highlights that the superior performance of graphene–SiO

2 hybrid coatings arises from a well-defined structure–property hierarchy. This hierarchy links nanoscale structural features—such as filler morphology, interfacial bonding, and hierarchical roughness—to macroscale properties including hydrophobicity, abrasion resistance, and dirt-pickup behavior.

At the nanoscale, the coupling of planar graphene derivatives with spherical SiO

2 nanoparticles creates a synergistic architecture. Graphene oxide (GO) provides two-dimensional reinforcement and barrier function through overlapping nanosheets that hinder moisture and ion diffusion, while SiO

2 contributes isotropic hardness and surface roughness. When covalently or electrostatically integrated, these two phases form a three-dimensional hybrid framework that simultaneously enhances structural rigidity and modulates surface energy. Studies by Hu G. et al. [

7], Pourhashem et al. [

8], and Hong et al. [

10] exemplify this synergy: uniformly dispersed SiO

2–GO structures in epoxy matrices yielded up to tenfold increases in electrochemical impedance and marked reductions in wear rate and friction coefficient.

At the microscale, hierarchical roughness generated by SiO

2 clusters on the graphene surface fosters Cassie–Baxter wetting behavior. This morphological arrangement entraps air beneath water droplets, elevating WCA values beyond 100° and, in some systems, achieving superhydrophobicity (>150°) [

3,

4]. Concurrently, graphene’s high modulus and lateral continuity help distribute applied stresses along the coating plane, acting as a bridge across microcracks and defects. Such features explain the strong correlation between surface hydrophobicity and mechanical durability observed across multiple studies [

8,

10,

16].