Analysis and Conservation of Glazed Decoration in Ancient Buildings in Shanxi, China

Abstract

1. Introduction

2. Research Locations

3. Methods

- (1)

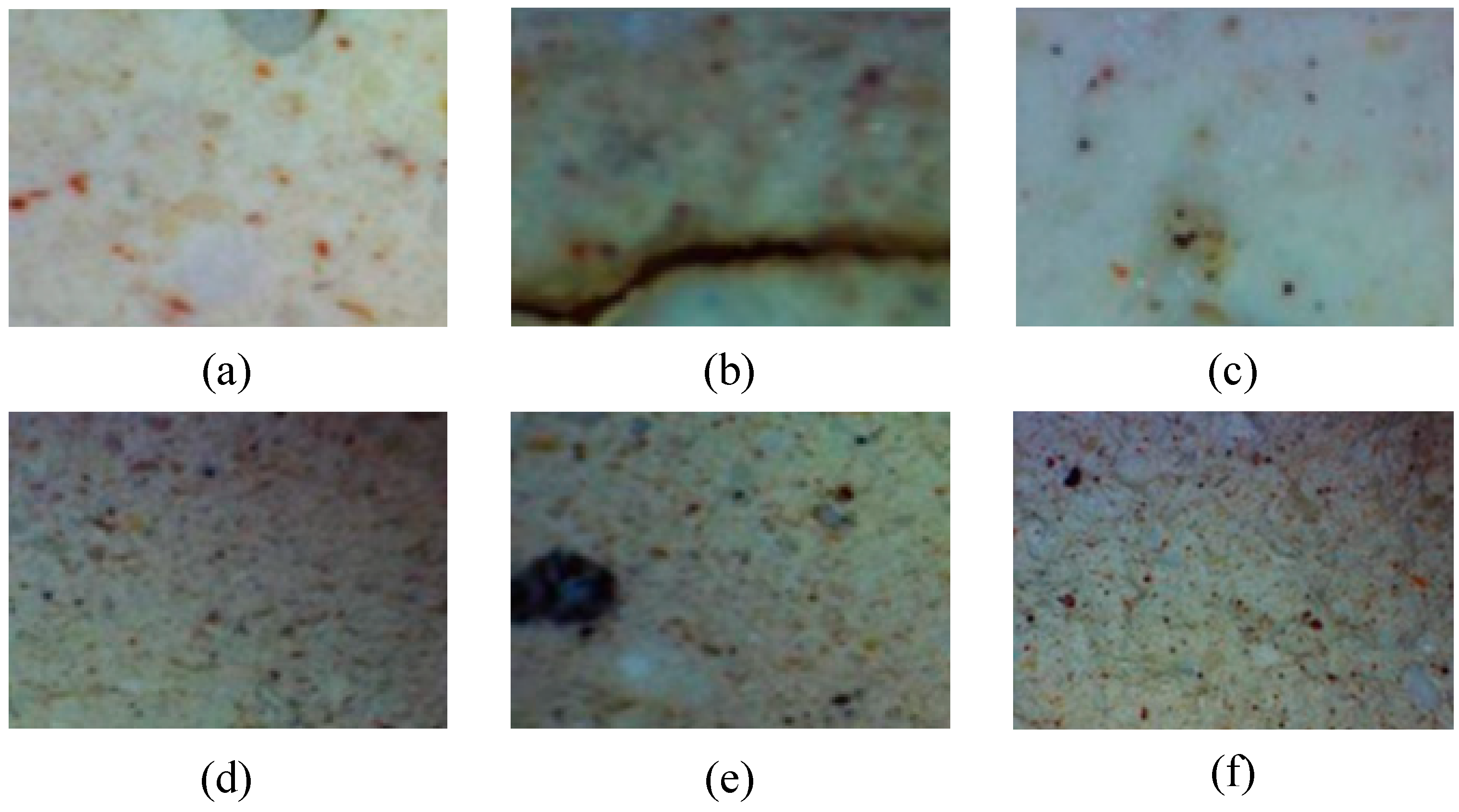

- The colorful glaze was examined with a Dino-Lite AM3111 handheld microscope. With a magnification of tens to hundreds of times, this equipment is perfect for on-site inspection and enables close examination of glazing fractures and other deterioration events.

- (2)

- An environmental scanning electron microscope (Thermo Fisher Scientific Quattro S) fitted with a Bruker QUANTAX EDS X-ray energy dispersive spectrometer was used to examine the materials’ microstructure and chemical makeup. The working distance was roughly 10 mm, the low vacuum was 50 Pa, and the accelerating voltage was set between 15 and 20 kV. The CBS backscattered electron mode was used to capture the images. After being immersed in epoxy resin, the cross-sectional sample was polished and ground.

- (3)

- A Renesas Vavia laser micro-focusing Raman spectrometer was used to examine the materials’ physical phase composition. A research-grade Leica microscope with a spatial resolution of less than 0.5 μm is attached to this device. An excitation wavelength of 532 nm, a laser power of 280 mW, a laser power density of 1.0%, a scan period of 10 s, and ten scans in total were the experimental parameters.

- (4)

- A Leeb hardness tester was used to gauge the hardness of the exposed body and the pigmented glaze. Despite the colored glaze’s relative hardness, caution must be used during the test to prevent additional damage. The test must be continuously monitored, and if damage is found, it must be halted right away.

- (5)

- A gloss meter was used to gauge the colored glaze’s gloss. A smaller measurement aperture is advised since some colored glazes may have curved surfaces. Additionally, a test angle of 60° is typically adequate because different gloss levels can result in some regions having good shine and others having absolutely no sheen at all [16].

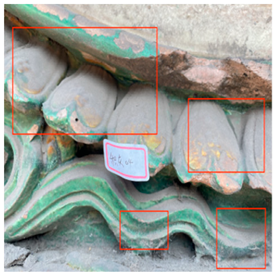

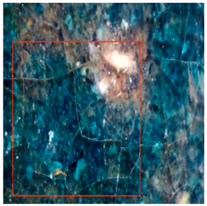

4. On-Site Damage to the Glazed Tile Enamel

4.1. Inferior Glass Glaze Due to Production Process

4.2. The Glass Glaze Used Naturally Is of Inferior Quality

5. Analysis of the Causes of Degradation

5.1. Data and Environment

5.2. The Effects of Temperature and Humidity Changes

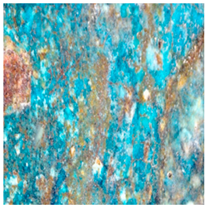

5.3. Changes in Glaze Morphology Before and After Acid Rain Corrosion

6. Coating Materials of Glazed Tile Matrix by PDMS–OH/TEOS

6.1. Color Difference Compatibility Analysis

6.2. Hardness

6.3. Fetal Permeability Analysis

6.4. Micromorphological Analysis

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Klesner, C.E. The Regional Production, Consumption, and Trade of Glazed Ceramics in Medieval Central Asia. Doctoral Dissertation, The University of Arizona, Tucson, AZ, USA, 2021. [Google Scholar]

- Kaliyannan, G.V.; Rathanasamy, R.; Gunasekaran, R.; Sivaraj, S.; Kandasamy, S.; Rao, S.K.; Ceramics, P.O. Defects Engineering in Electroceramics for Energy Applications; Springer: Singapore, 2024; pp. 53–86. [Google Scholar]

- Zhao, L.; Xu, J.; Zhang, Y.; Zhang, Z.; Li, M.; Li, H.; Shang, S.; Wang, X.; Hu, X.; Zhang, X.; et al. Non-firing Synthesis for Oxides: From Natural to Synthetic Forms with Energy-Efficient and Sustainable Processes. J. Mater. Eng. Perform. 2024, 33, 11411–11437. [Google Scholar]

- Zhang, D.; Hu, S.; Peng, Z.; Liu, Z.; Yu, J.; Yuan, L. Thermal shock resistance of WC–Cr3C2–Ni coatings deposited via high-velocity air fuel spraying. Surf. Coat. Technol. 2024, 487, 131034. [Google Scholar] [CrossRef]

- Li, Q.; Zhang, F.; Jia, W.; Guo, Y. Study on the Surface Coating Techniques of Furniture in the Long’en Hall of Qing Changling Mausoleum. Coatings 2025, 15, 712. [Google Scholar] [CrossRef]

- Ping, M.; Jin, H.; Zhang, Z.; Zhang, L.; Sun, M.; Cao, M.; Cui, J. Application of smalt in building glazed tiles from Yuanmingyuan Park, Beijing’in Qing dynasty. npj Herit. Sci. 2025, 13, 282. [Google Scholar]

- Bai, X.; Zhang, H.; Tu, Y.; Sun, S.; Li, Y.; Ding, H.; Bai, M.; Chang, L.; Zhang, J. Preparation and Application of Apatite–TiO2 Composite Opacifier: Preventing Titanium Glaze Yellowing through Pre-Combination. Materials 2024, 17, 1056. [Google Scholar] [CrossRef]

- Bulut, H.A.; Şahin, R. Radon, concrete, buildings and human health—A review study. Buildings 2024, 14, 510. [Google Scholar] [CrossRef]

- Tan, J.; Esteves, A.C.C.; Yang, J.; Zhou, S. Zwitterion-bearing silica sol for enhancing antifouling performance and mechanical strength of transparent PDMS coatings. Prog. Org. Coat. 2024, 191, 108415. [Google Scholar]

- Song, H.; Chen, Y.; Zheng, L. The Non-Destructive Testing of Architectural Heritage Surfaces via Machine Learning: A Case Study of Flat Tiles in the Jiangnan Region. Coatings 2025, 15, 761. [Google Scholar] [CrossRef]

- Malet-Damour, B.; Bigot, D.; Rivière, G. Experimental and Numerical Analysis on a Thermal Barrier Coating with Nano-Ceramic Base: A Potential Solution to Reduce Urban Heat Islands? Eng 2023, 4, 2421–2442. [Google Scholar] [CrossRef]

- Francke, B.; Kula, D.; Koda, E. Analysis of the Durability of Thermal Insulation Properties in Inverted Foundation Slab Systems of Single-Family Buildings in Poland. Buildings 2025, 15, 3579. [Google Scholar] [CrossRef]

- Wei, K.; Wang, Z.; He, Y.; Wang, Z. Deciphering and Preserving the Landscape Genes of Handicraft Villages from the Perspective of Production–Living–Ecology Spaces (PLESs): A Case Study of YaoTou Village, Shaanxi Province. Sustainability 2024, 16, 10742. [Google Scholar] [CrossRef]

- GB/T 3810.12-2016; Test Methods of Ceramic Tiles—Part 12: Determination of Frost Resistance. Standardization Administration of the People’s Republic of China: Beijing, China, 2016.

- Abdelmoniem, A.M. Preserving the wooden heritage of the National Police Museum: Challenges and conservation strategies. J. Infrastruct. Preserv. Resil. 2025, 6, 14. [Google Scholar] [CrossRef]

- Khalid, S.; Azad, M.M.; Kim, H.S.; Yoon, Y.; Lee, H.; Choi, K.S.; Yang, Y. A review on traditional and artificial intelligence-based preservation techniques for oil painting artworks. Gels 2024, 10, 517. [Google Scholar] [CrossRef]

- Pradell, T.; Molera, J. Ceramic technology. How to characterise ceramic glazes. Archaeol. Anthropol. Sci. 2020, 12, 189. [Google Scholar] [CrossRef]

- Ribeiro, M.J.; Tulyaganov, D. Traditional ceramics manufacturing. In Ceramics, Glass and Glass-Ceramics: From Early Manufacturing Steps Towards Modern Frontiers; Springer: Cham, Switzerland, 2021; pp. 75–118. [Google Scholar]

- Youssef, E.; Mostafa, N.; Khoury, J.; Merhej, T.; Lteif, R. Glaze surface defects causes and prevention controls. J. Ceram. Sci. Technol. 2023, 14, 1–10. [Google Scholar]

- Mourou, C.; Zamorano, M.; Ruiz, D.P.; Martín-Morales, M. Characterization of ceramic tiles coated with recycled waste glass particles to be used for cool roof applications. Constr. Build. Mater. 2023, 398, 132489. [Google Scholar] [CrossRef]

- Balliana, E.; Caveri, E.M.C.; Falchi, L.; Zendri, E. Tiles from Aosta: A peculiar glaze roof covering. Colorants 2023, 2, 533–551. [Google Scholar] [CrossRef]

- Vijerathne, D.T.; Wahala, S.B.; Asmone, A.S. Advancing environmental sustainability of ceramic tile production: A cradle-to-gate life cycle assessment case study from Sri Lanka. Front. Built Environ. 2025, 11, 1654253. [Google Scholar] [CrossRef]

- Hawryluk, M.; Marzec, J. Problems related to the operation of machines and devices for the production of ceramic roof tiles with a special consideration of the durability of tools for band extrusion. Arch. Civ. Mech. Eng. 2024, 25, 60. [Google Scholar] [CrossRef]

- Corregidor, V.; Ruvalcaba-Sil, J.L.; Prudêncio, M.I.; Dias, M.I.; Alves, L.C. Ion Beam-Induced Luminescence (IBIL) for Studying Manufacturing Conditions in Ceramics: An Application to Ceramic Body Tiles. Materials 2024, 17, 5075. [Google Scholar] [CrossRef]

- Gritti, N.; Power, R.M.; Graves, A.; Huisken, J. Image restoration of degraded time-lapse microscopy data mediated by near-infrared imaging. Nat. Methods 2024, 21, 311–321. [Google Scholar]

- Ju, S.; Luo, Q.; Lu, Z.; Wang, F.; Shi, J.; Wang, L.; Liu, Z.; Jiang, J. A novel thermal-tailored strategy to mitigate thermal cracking of cement-based materials by carbon fibers and liquid-metal-based microencapsulated phase change materials. Constr. Build. Mater. 2024, 428, 136338. [Google Scholar] [CrossRef]

- Es-Soufi, H.; Berdimurodov, E.; Sayyed, M.; Bih, L. Nanoceramic-based coatings for corrosion protection: A review on synthesis, mechanisms, and applications. Environ. Sci. Pollut. Res. 2025, 32, 16978–17004. [Google Scholar]

- Lin, C.; Li, K.; Li, M.; Dopphoopha, B.; Zheng, J.; Wang, J.; Du, S.; Li, Y.; Huang, B. Pushing radiative cooling technology to real applications. Adv. Mater. 2025, 37, 2409738. [Google Scholar]

- Zhou, B.; Ma, Q.; Li, Z.; Zhang, Z.; Li, N.; Song, S. Corrosion of glaze in the marine environment: Study on the green-glazed pottery from the Southern Song “Nanhai I” shipwreck (1127–1279 AD). Herit. Sci. 2023, 11, 134. [Google Scholar]

- Macedo, M.F.; Vilarigues, M.G.; Coutinho, M.L. Biodeterioration of glass-based historical building materials: An overview of the heritage literature from the 21st century. Appl. Sci. 2021, 11, 9552. [Google Scholar] [CrossRef]

- Stanaszek-Tomal, E. Microorganisms in Red Ceramic Building Materials—A Review. Coatings 2024, 14, 985. [Google Scholar] [CrossRef]

- Oliwa, K.; Kozub, B.; Łoś, K.; Łoś, P.; Korniejenko, K. Assessment of durability and degradation resistance of geopolymer composites in water environments. Materials 2025, 18, 3892. [Google Scholar] [CrossRef]

- Wu, Z.; Xu, J.; Ji, Y.; Fan, H.; Li, L.; Meng, M. Tensile strength and deformation properties of fiber-reinforced loess: Laboratory and numerical investigation. Acta Geotech. 2025, 1–23. [Google Scholar] [CrossRef]

- Bakar, N.H.A.; Ismail, W.N.W.; Yusop, H.M.; Zulkifli, N.F.M. Synthesis of a water-based TEOS–PDMS sol–gel coating for hydrophobic cotton and polyester fabrics. New J. Chem. 2024, 48, 933–950. [Google Scholar]

- Sadeghi, M.A.; Aghighi, M.; Barralet, J.; Gostick, J.T. Pore network modeling of reaction-diffusion in hierarchical porous particles: The effects of microstructure. Chem. Eng. J. 2017, 330, 1002–1011. [Google Scholar] [CrossRef]

- Njindam, O.; Njoya, D.; Mache, J.; Mouafon, M.; Messan, A.; Njopwouo, D. Effect of glass powder on the technological properties and microstructure of clay mixture for porcelain stoneware tiles manufacture. Constr. Build. Mater. 2018, 170, 512–519. [Google Scholar] [CrossRef]

| Number | Building Name | Coloured Glaze Component Position | Location | Construction Time |

|---|---|---|---|---|

| 1 | Chongshan Temple | Glazed tile | Taiyuan City | 1391 |

| 2 | Houtu Temple | Glazed tile | Jiexiu city | 457 |

| 3 | Taihe rock colored glass memorial archway | Coloured glaze archway | Jiexiu city | 1897 |

| 4 | XianshenTemple | Glass wall | Jiexiu city | 1055 |

| 5 | Shousheng Temple and the colored glass tower | Coloured glaze tile | Yangcheng County | 1608 |

| 6 | HaiHuitwo towers | Coloured glaze tile | Yangcheng County | 894 |

| 7 | Guqinglian Temple | Glazed tiles | Jincheng city | 559 |

| 8 | Shanhua Temple | Glass wall | Datong City | 1445 |

| 9 | Datong House Confucian Temple | Glass wall | Datong City | 1375 |

| 10 | Guanyin TANG | Glass wall | Datong City | Qing dynasty |

| Guanyin Tang | Guqinglian Temple | Chongshan Temple |

|---|---|---|

|  |  |

| Chongshan Temple | Guanyin Tang | Jiexiu Houtu Temple |

|---|---|---|

|  |  |

| Shousheng Temple and the colored glass tower | Guqinglian Temple | Taihe rock colored glass memorial archway |

|  |  |

| Camera Shooting | Hand-Held Microscopy | Camera Shooting | Hand-Held Microscopy | Area | |

|---|---|---|---|---|---|

| 1 |  |  |  |  | Datong City Guanyin temple Shanhua Temple |

| 2 |  |  |  |  | Taiyuan City Goodness advocating Temple |

| 3 |  |  |  |  | Jiexiu city After the temple |

| 4 |  |  |  |  | Jiexiu city Taihe rock colored glass memorial archway Zoroastrians |

|  |  |  | Yangcheng County The sea will two towers Shousheng Temple and the colored glass tower |

| Sample Number | Sample Composition | Ethanol Addition (wt%) | Penetration Depth (mm) |

|---|---|---|---|

| TEOS | TEOS | 0 | 3 |

| E-0 | PDMS–OH/TEOS | 0 | 6 |

| E-5 | PDMS–OH/TEOS | 5 | 7.5 |

| E-10 | PDMS–OH/TEOS | 10 | 9.5 |

| E-15 | PDMS–OH/TEOS | 15 | 7 |

| E-20 | PDMS–OH/TEOS | 20 | 4.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, Y.; Wang, N.; Yu, L.; Qian, L.; Zhou, S. Analysis and Conservation of Glazed Decoration in Ancient Buildings in Shanxi, China. Coatings 2026, 16, 14. https://doi.org/10.3390/coatings16010014

Chen Y, Wang N, Yu L, Qian L, Zhou S. Analysis and Conservation of Glazed Decoration in Ancient Buildings in Shanxi, China. Coatings. 2026; 16(1):14. https://doi.org/10.3390/coatings16010014

Chicago/Turabian StyleChen, Yao, Ning Wang, Liwen Yu, Liquan Qian, and Shuanglin Zhou. 2026. "Analysis and Conservation of Glazed Decoration in Ancient Buildings in Shanxi, China" Coatings 16, no. 1: 14. https://doi.org/10.3390/coatings16010014

APA StyleChen, Y., Wang, N., Yu, L., Qian, L., & Zhou, S. (2026). Analysis and Conservation of Glazed Decoration in Ancient Buildings in Shanxi, China. Coatings, 16(1), 14. https://doi.org/10.3390/coatings16010014