Abstract

In this study, poplar boards were bleached and treated with two types of urea–formaldehyde-coated ternary system thermochromic microcapsules (UF@TS), which were mixed with UV primer. The bleached poplar boards were manually painted with two layers of primer and topcoat. Coating samples with varying microcapsule contents were prepared and evaluated based on factors such as glossiness, reflectivity, and other surface properties. The experimental results showed that bleaching treatment significantly increased the whiteness of poplar wood, with an improvement rate of up to 17%. Among the two microcapsule types, the coating containing #2 microcapsules exhibited superior surface quality compared to #1 microcapsules. As the microcapsule content increased, the coating glossiness showed an overall decreasing trend and a certain degree of fluctuation, and the #2 microcapsule showed lower reflectivity values. The addition of UF@TS microcapsules negatively affected the coating adhesion but had little effect on hardness. The #2 microcapsule enhanced the impact resistance of the coating to a certain extent and increased surface roughness. Regarding thermochromic performance, the #1 microcapsule exhibited higher color-changing temperature and larger color difference, while the #2 microcapsule showed color-changing temperature closer to room temperature. Despite a decline in thermochromic performance and glossiness during aging, the 1# microcapsule showed slightly better stability. The coating containing 10% #2 microcapsules demonstrated the best comprehensive performance on bleached poplar wood, with glossiness of 2.1 GU, reflectivity of 67.95%, adhesion grade of 1, hardness of 6 H, impact resistance grade of 4, and surface roughness of 0.681 μm. The ΔE in the range of −20 °C to 50 °C was 7.434. After aging, ΔE was 5.846, and the light loss rate was 9%, with excellent comprehensive performance.

1. Introduction

UV coatings, characterized by high solid content and low solvent usage, are fast drying and environmentally friendly during both preparation and application stages [1,2,3,4,5]. However, they also suffer from drawbacks such as high viscosity and poor leveling properties [6,7,8,9]. In order to improve the performance of UV coatings and endow them with intelligent characteristics, modified UV coatings have become an important research content in the field [10,11,12,13,14]. Li et al. [15] developed a modified organosilicon acrylate prepolymer that combined the advantages of UV curing and moisture curing. This system features a rapid curing rate and addresses issues associated with shadowed areas and thick coatings in conventional UV curing. The dual-curing mechanism of UV and moisture also overcame problems such as oxygen inhibition and poor adhesion typically found in UV-cured organosilicon materials. These UV/moisture dual-curing coatings showed promising potential in anti-fouling and anti-fingerprint applications. While improving the coating performance of UV coatings, the study had also imparted new properties to the coatings, highlighting the significance of comprehensive performance optimization in achieving multifunctional coatings [16,17,18]. Sen et al. [19] developed antimicrobial coatings without the addition of antibacterial agents by synthesizing two different quaternary imidazole compounds to modify silica nanoparticles. Based on the thioene reaction mechanism, they synthesized UV-cured coatings that exhibited certain antimicrobial properties.

Fast-growing wood species generally exhibit inferior physical and chemical properties compared to conventional hardwoods. Current research on fast-growing timber primarily focuses on wood modification techniques, among which bleaching is one of the most common wood modification treatment methods [20,21,22]. Herstedt et al. [23] investigated the bleaching effects of 11 different solutions on woods such as Honduran mahogany and found that different wood species respond differently to oxidative and reductive bleaching agents. A mixture of hydrogen peroxide and ammonia was recommended for moderate bleaching, while oxalic acid-based solutions often darkened most wood types and were therefore not recommended for routine use. The study has also shown that strong oxidative bleaching agents, such as hydrogen peroxide, sodium hydroxide, and sodium silicate, exhibit excellent whitening effects. However, their strong oxidizing nature may cause damage to wood fibers during the bleaching process, such as fiber softening, structural loosening, or surface roughening, which can negatively affect the mechanical properties and subsequent coating adhesion. Therefore, it is essential to carefully control the reaction conditions to ensure both effective bleaching and a balance between the aesthetic appearance and functional stability of the wood. Bleached poplar wood was selected as the substrate due to its advantages of abundance resources, low cost, and uniform surface color after treatment, which facilitates the observation of thermochromic effects [24,25,26,27]. Moreover, the porous structure of poplar wood promotes better penetration and adhesion of UV coatings, enabling the formation of stable composite coating systems [28,29,30]. By adding thermochromic microcapsules into wood coatings, the core material can be effectively protected from environmental influences while also reducing direct contact between the human body and the chemical components within the core material. This strategy ensures safety while imparting dynamic color-changing functionality to the substrate, thus enhancing the added value of furniture [31,32,33,34].

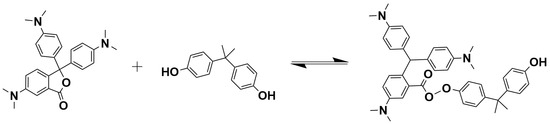

Thermochromic microcapsules are a type of functional material that can change color in response to temperature variations, widely used in smart coatings, temperature indicators, and related applications [35]. Among them, the most widely studied thermochromic systems are organic reversible color change systems based on electron gain and loss mechanism, primarily composed of color developer, leuco dye, and solvent. The color developer loses electrons to form a colored structure, determining the hue of the thermochromic response; the leuco dye acts as an electron acceptor, regulating the intensity of the color change; and the solvent serves as a medium in which the two components form a reversible complex, with its phase transition temperature determining the triggering point of color change [36]. This system offers good thermal responsiveness and a wide range of color tunability, making it highly promising for various intelligent applications. One of the most studied combinations is the thermochromic system composed of crystal violet lactone, bisphenol A, and decanol. In this system, crystal violet lactone initially exists in a closed lactone ring structure, acting as an electron donor. Bisphenol A serves as the electron acceptor and forms hydrogen bonds with crystal violet lactone. At low temperatures, the hydroxyl groups of bisphenol A interact with the central carbon of crystal violet lactone, inducing ring opening of the lactone structure and forming conjugated double bonds, which produce a distinct blue coloration. When the temperature rises, the solvent melts and alters the molecular environment, disrupting the conjugated structure (Figure 1). As a result, crystal violet lactone returns to its closed, colorless lactone form, achieving reversible color change [37,38].

Figure 1.

Color change principle diagram.

In this study, two types of urea–formaldehyde-coated ternary system thermochromic microcapsules (UF@TS) were selected and added into UV primer and UV topcoat at various ratios. Two layers of primer and topcoat were painted manually to prepare the UV coatings on the surface of bleached poplar wood. The effects of UF@TS microcapsules on the optical performance, mechanical performance, thermochromic performance, and thermal aging resistance of the UV coatings were systematically investigated. By comprehensively analyzing these performance indicators, this study aimed to elucidate the application characteristics of UF@TS microcapsules in wood substrate coating, thereby providing theoretical basis and technical support for the development of intelligent thermochromic coatings. In addition, this study provides a new perspective for the field of thermochromic wood coatings. By optimizing the UV curing coating process on the surface of bleached fast-growing wood, the thermochromic performance of the coating was enhanced, while environmental pollution and potential health hazards were reduced. This enabled the realization of low-temperature thermochromic functionality in the high-value utilization of fast-growing wood. More notably, the application scope of thermochromic UV-curable coatings on furniture surfaces was expanded. While imparting color-changing functionality, the coatings also exhibited improved phase change enthalpy and enhanced thermal aging resistance, contributing to both decorative and functional performance.

2. Materials and Methods

2.1. Materials

The raw materials are shown in Table 1. The size of the poplar wood board is 50 mm × 50 mm × 3 mm (Shanghai Lingyu Wood Industry Co., Ltd., Shanghai, China). The heartwood of poplar was selected for the test due to its higher density and better performance compared to sapwood. However, it often has darker colors and is used less in home decoration. The coatings used in this study were UV primer and topcoat, both provided by Jiangsu Haitian Technology Co., Ltd., Zhenjiang, China, with a solid content of more than 98.0%. The main components of the UV primer include epoxy acrylate resin, polyester acrylate resin, trimethylol acrylate, trimethyl acrylate, photoinitiator, defoamer, leveling agent, etc. The main components of the scratch-resistant UV topcoat include polyurethane acrylic resin, propylene glycol diacrylate, hexanediol diacrylate, photoinitiator, matting powder, defoamer, leveling agent, etc.

Table 1.

List of raw materials.

2.2. Preparation Method of Microcapsules

Preparation and dispersion of core material: According to the preliminary experimental results, the temperature of the water bath (DF-101S, Muyang Hongguanriyi E-commerce Co., Ltd., Muyang, China) was set to 50 °C. A total of 80 g of decanol was weighed into a beaker. A total of 1.6 g of crystal violet lactone and 4.8 g of bisphenol A were sequentially added at a mass ratio of 1:3. The mixture was stirred for 1.5 h at a speed of 400 rpm. After the mixture was fully fused, it was naturally cooled to room temperature. Next, 1.74 g of gum arabic and 1.02 g of Triton X-100 were weighed as emulsifiers and dissolved in 52.52 mL of distilled water. Then, 4.15 g of the core material was added to the solution. The mixture was heated to 65 °C and stirred for 30 min at a high speed. It was then subjected to ultrasonic emulsification for 5 min to improve the uniform encapsulation of the emulsifier on the core material surface.

Preparation of wall material: First, 8.00 g of urea and 8.42 g of formaldehyde solution were weighed and dissolved in 125.00 mL of distilled water. The mixture was placed in a water bath and stirred until completely dissolved. Triethanolamine was then added to adjust the pH value to 8.5. The beaker was sealed and heated in the water bath to 70 °C, followed by stirring at 300 rpm for 1 h to obtain the wall material solution.

Preparation of thermochromic microcapsules: The ultrasonically treated core material solution was placed in a water bath at 35 °C and stirred slowly. The wall material solution was added, and the stirring speed was adjusted to 500 rpm. Then, 0.58 g of silicon dioxide and 0.58 g of sodium chloride were added, followed by dropwise addition of an 8% citric acid monohydrate solution to adjust the pH value to approximately 2.5. Subsequently, the mixture was carried out for 1 h. After that, the temperature was increased to 68 °C, and the stirring speed was adjusted to 250 rpm. The reaction was continued for another 30 min to obtain the microcapsule solution.

The obtained product was sealed and stored at rest for three days. Impurities were then removed by vacuum filtration, followed by rinsing with deionized water. The sample was subsequently dried at 35 °C to yield a light blue thermochromic microcapsule powder.

2.3. Pretreatment and Coating Method of Bleached Poplar Wood Board

Bleaching treatment of poplar board: Ten pieces of poplar wood were selected for pretreatment. A total of 800 mL of 4.00 g/L sodium hydroxide solution was prepared. The fast-growing poplar boards were immersed in the solution for 15 min and then thoroughly rinsed with water. Next, a bleaching solution was prepared by mixing 290.00 g of hydrogen peroxide (7.7 wt%) and 16.00 g of sodium silicate and then diluting with deionized water to a total volume of 800 mL. The bleaching process was carried out in a magnetic stirring water bath at 65 °C. The poplar boards were immersed in the bleaching solution for 6 h. After bleaching, the boards were thoroughly rinsed and air-dried at room temperature to minimize deformation caused by rapid drying [39].

Bleached poplar board coating method: The bleached poplar boards were painted with two layers of primer and topcoat manually. The surface of the bleached poplar substrates was pretreated by sanding with 800-grit sandpaper to remove the wood burrs [40,41,42,43]. Based on the results of preliminary single-factor experiments, two UF@TS thermochromic microcapsules with superior performance (designated as #1 and #2) were selected as additives. The preparation materials for the two types of microcapsules are shown in Table 2. The microcapsules were mixed with the UV primer at mass fractions of 0% (blank control), 5%, 10%, 15%, 20%, and 25%, with the total mass of each coating system strictly controlled at 1.000 g. During the coating process, 0.500 g of the composite UV primer was evenly applied to the substrate surface. Then, curing was conducted for 60 s using a single-lamp UV curing machine (#620, Huzhou Tongxu Machinery Equipment Co., Ltd., Huzhou, China) at a conveyor speed of 0.1 m/s. The above primer coating process was repeated, followed by the application of two layers of UV topcoat. The details of the coating ratios with different UF@TS microcapsule amounts added are shown in Table 3.

Table 2.

Materials of single-factor test required for microcapsule preparation.

Table 3.

Coating ratios with UF@TS added.

2.4. Testing and Characterization

2.4.1. Morphology Analysis

Whiteness value of bleached poplar wood: The chromaticity coordinates (L, a, and b) before and after bleaching treatment were measured by colorimeter (SEGT-J, Zhuhai Tianchuang Instrument Co., Ltd., Zhuhai, China). Specifically, L represents the variation of luminosity, quantified with a scale ranging from 0 to 100. The larger the L value, the brighter the surface. The a and b values correspond to chromaticity coordinates, where a represents the green/red axis (a < 0 is green, a > 0 is red), and b represents the yellow/blue axis (b < 0 is blue, b > 0 is yellow). The initial whiteness (W0) and the whiteness (W) after treatment were calculated, respectively, and the difference ΔW represents the whiteness improvement value. The specific calculations are shown in Equations (1) and (2).

W = 100 − [(100 − L)2 + a2 + b2]1/2

ΔW = W − W0

Scanning electron microscopy (SEM) (Quanta-200, Thermo Fisher Technology Co., Ltd., Waltham, MA, USA): A small section was carefully peeled from the surface of the bleached poplar wood board as required. The sample was then fixed, sprayed gold, and placed into the instrument for vacuum operation. After vacuumization, the sample was scanned, and adjustments were made to brightness and focus for image acquisition [44,45,46].

2.4.2. Infrared Spectral Characterization

The prepared coatings were analyzed using Fourier Transform Infrared (FTIR) spectroscopy (VERTEX 80V, Brook Co., Karlsruhe, Germany) [47,48].

2.4.3. Optical Performance Testing

Glossiness: According to the standard GB/T 4893.6-2013, a gloss meter (HG268, Shenzhen Sanenshi Technology Co., Ltd., Shenzhen, China) was used to test the glossiness of the coating [49]. The glossiness of the coating at three incident angles (20°, 60° and 85°) was, respectively, recorded, and the difference was compared.

Reflectivity: The reflectivity of the coating within the visible light spectrum was measured using a UV spectrophotometer (U-3900/3900H, Hitachi Instrument Co., Ltd., Suzhou, China) equipped with an integrating sphere. The sphere diameter is 60 mm. This spherical cavity features high diffuse reflectivity on its inner surface, which uniformly distributes incident or transmitted light from the sample into the sphere. The optical detector measures total light intensity to enhance measurement accuracy. During testing, the sample is positioned at the front end of the integrating sphere while the light source shines vertically onto its surface. By analyzing the energy distribution between incident and reflected light, the reflectivity is calculated. Defined as the ratio of reflected light intensity to incident light intensity, reflectivity is typically expressed as a percentage [50,51].

2.4.4. Mechanical Performance and Roughness Testing

Impact resistance: According to the standard GB/T 4893.9-2013, the impact resistance of the coating was tested by using a coating impactor (QCJ-50, Shanghai Meiyu Instrument Technology Co., Ltd., Shanghai, China) [52]. The test sample was horizontally fixed on the test platform, and a steel ball was released from a preset height of 50 mm to strike the surface. Five different impact points were selected on each sample for testing. After the test, the impact areas were visually examined under natural light using a magnifying glass, and the damage characteristics at each point were recorded. The impact resistance was classified into five grades, with Grade 1 indicating the best resistance and Grade 5 the worst. The final impact resistance grade of the sample was determined by calculating the average damage level of the five impact points.

Hardness: According to the standard GB/T 6739-2022, the coating hardness was tested using a pencil hardness meter (HT-6510P, Shenzhen Junda Times Instrument Co., Ltd., Shenzhen, China) [53]. The front end of test pencil was ground to meet the standard shape requirements and then fixed in the hardness meter [54,55,56]. During the test, a fixed load was applied to the coating surface at a constant speed of 0.5 mm/s for scratch testing. Each sample would be tested with a pencil of different hardness from 6H to 6B in turn, with the scratch length not less than 10 mm each time. After testing, the samples were examined, and the highest pencil grade that did not leave a visible scratch was recorded as the pencil hardness of the coating.

Adhesion: According to the standard GB/T 4893.4-2013, the coating adhesion was tested with a coating adhesion grid meter (QFH-A, Shenzhen Junda Times Instrument Co., Ltd., Shenzhen, China) [57]. Two sets of orthogonal cuts were made on the leveled coating surface at a constant speed. The cuts were deep enough to penetrate through the entire coating layer to the wood substrate to form a grid pattern. Then, the tape was tightly attached to the cutting area and then quickly peeled off to observe the degree of damage. The adhesion is divided into 6 grades from 0 to 5, among which Grade 0 means no coating peeling and the adhesion is optimal. Grade 5 indicates more than 65% of the coating is removed and has the worst adhesion [58,59].

Roughness: A surface roughness tester (J8-4C, Shanghai Taiming Optical Instrument Co., Ltd., Shanghai, China) was used to measure and record the roughness values in order to obtain variation trends of roughness among different coating samples.

2.4.5. Thermochromic Performance Testing

The color change of the coating was tested using the gradient heating method. The samples were placed in environments at temperatures of −20 °C, −10 °C, 0 °C, 10 °C, 20 °C, 30 °C, 40 °C and 50 °C in turn. The chromaticity values were measured at every 10 °C interval, with each temperature maintained for 2 min to ensure measurement stability. The samples were put in a fixed-temperature oven to keep them at a constant temperature. The temperature of the sample surface was then tested using a laser induction thermometer (2003Y, Putian Hanjiang Huafeng Plastic Co., Ltd., Putian, China). During measurement, the laser induction thermometer was first used to test the coating surface temperature, and after reaching the specified temperature, the chromaticity value was measured with the tester at the same time. This temperature range covers the typical ambient conditions encountered by furniture materials in daily use [60]. Therefore, the observed color change behavior is more representative of practical applications. The turning point in color change can be considered the responsive temperature range of the microcapsules. At each temperature, the L, a, and b values were recorded, and the color difference ΔE between adjacent temperature points was calculated, where the L value represents the brightness and darkness value of the sample, the a value represents the red and green value of the sample, and the b value represents the yellow and blue value of the sample [61]. All measurements were made under a standard D65 light source and 10° observation conditions. The values of L1, a1, and b1 represent the values after the temperature of the test sample changes, and L2, a2, and b2 represent the values of the initial test temperature of the sample (−5 °C). The color difference ΔE is calculated based on Equation (3). Among them, ΔL = L1 − L2, Δa = a1 − a2, and Δb = b1 − b2. Each temperature point was measured four times, and the average value was taken to ensure the accuracy and representativeness of the data.

ΔE = [(ΔL)2 + (Δa)2 + (Δb)2]1/2

2.4.6. Aging Performance Testing

The aging performance of the coating was evaluated according to the standard GB/T 1740-2007 and the artificial accelerated aging test method [62]. The samples were placed in a drying oven maintained at 120 °C and subjected to thermal aging for 12 h. The changes in color-changing performance and glossiness of the UV coating on the bleached poplar surface were tested to characterize the changes before and after coating aging.

3. Results and Discussion

3.1. Analysis of the Morphology and Bleaching Effect of Poplar Wood Board

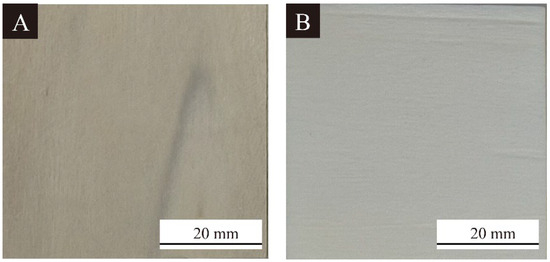

The macroscopic morphology of the poplar wood before and after bleaching is shown in Figure 2. After bleaching treatment, the wood surface became obviously whiter, with the original uneven coloration and various chromatic defects transformed into a uniform natural light tone. Whiteness measurements were conducted at 10 °C after bleaching. The initial whiteness value was 77.30, which increased to 90.53 after treatment, representing an improvement of 17%. The color difference ΔE of the board was measured several times from −20 °C to 50 °C. The maximum ΔE value of poplar wood before bleaching reached 2.92, while after bleaching, the maximum ΔE was reduced to 2.54. This showed that after bleaching, the whiteness of the wood increased significantly, and the ΔE between the colors on the surface was significantly weakened. Wood with higher whiteness and lower surface color differences was more suitable for the application of thermochromic coatings, which could better reflect the color-changing performance of the coating.

Figure 2.

Macroscopic morphology of poplar boards: (A) before bleaching; (B) after bleaching.

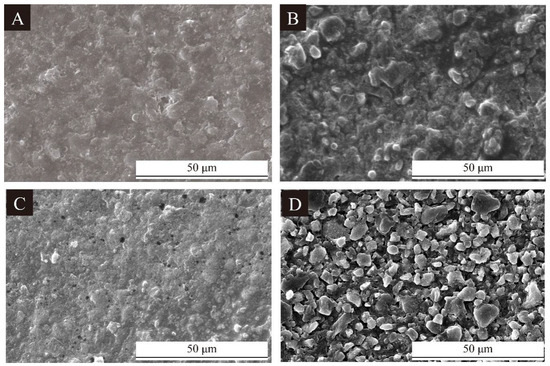

The microscopic morphology of the longitudinal section of the wood before and after bleaching is shown in Figure 3. It can be observed that the wood fibers were not significantly affected by the bleaching treatment. Partial release of lignin led to increased porosity and a looser texture in the wood structure. The unbleached wood exhibited a more regular and compact structure, whereas the bleached samples showed deformation and irregular sizes of the vessel elements, which may negatively impact the intrinsic properties of the wood. However, the loss of lignin also resulted in enlarged pores, allowing for better penetration and accommodation of coatings and microcapsules.

Figure 3.

SEM images of longitudinal cutting poplar: (A) before bleaching; (B) after bleaching.

The SEM images of the bleached poplar surface coating with the added UF@TS are shown in Figure 4. The selected matte topcoat had a high solid content, so Sample #0 exhibited a certain degree of surface roughness. When the amount of #2 microcapsules was added to 10%, irregular protrusions were found on the surface of the #2-2 coating. It could be found that spherical microcapsules that were different from the #0 coating appeared. The overall surface morphology remained consistent with that of #0, without excessive change. In contrast, spherical microcapsules were barely visible on the surface of the #2-3 coating, and dense pits appeared, suggesting aggravated aggregation of microcapsules with the increase in microcapsule content. The surface morphology of the #2-3 coating was notably different from that of #1-3. The surface of the #1-3 coating showed obvious powdering and poor curing crosslinking, and it was difficult to observe the morphology of spherical microcapsules. It could be found that the agglomeration of 1# microcapsules was relatively serious in the UV coating, and it worked together with the matting powder in the matte topcoat, which further affected the curing of the surface morphology of the coating.

Figure 4.

SEM images of the surface coatings of bleached poplar with two types of UF@TSs added: (A) #0, (B) #2-2, (C) #2-3, and (D) #1-3.

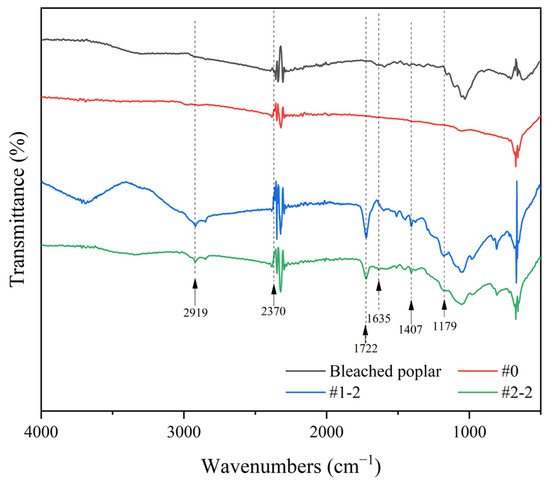

3.2. Infrared Spectral Analysis of the Surface Coating on Bleached Poplar Wood with UF@TS Added

As shown in Figure 5, the absorption peak at 2919 cm−1 corresponded to the stretching vibration of the C−CH3 bond, which was attributed to the organic components of the wood surface, the main component bisphenol A in the core material and the epoxy acrylate resin in the UV primer. This peak appeared stronger in the absorption curves of UV primers containing microcapsules. It showed that the coating contains a higher proportion of organic components characterized by −CH3. The peaks at 1179 cm−1 and 1722 cm−1 corresponded to the stretching vibrations of C−O and C=O, respectively. These were characteristic peaks of the polyester acrylate resin, trimethylolpropane triacrylate, and trimethylolpropane acrylate, which were the main components of the UV primer. It showed that the main structure of the primer system has not changed significantly. The ester carbonyl C=O absorption peak with a non-lactone ring structure appeared at 1635 cm−1, while the peak at 1407 cm−1 corresponded to the symmetric stretching absorption peak of carboxylate. After bleaching, a cluster of dense peaks appeared around 2370 cm−1. The reason for this phenomenon was that after the lignin of the wood was removed, other chemical peaks of the wood were preserved. On the right side of this peak range, the chemical composition of lignin contained in the surface before bleaching showed large fluctuations. The presence of these peaks indicated that wood bleaching had a good effect on the removal of lignin, and the coating of the UV coating with the microcapsules was completed. The introduction of microcapsules would not cause obvious chemical reactions with the UV coating or wood substrate, and the three main interactions were physical embedding and interfacial bonding.

Figure 5.

Infrared spectra of surface coatings on bleached poplar.

3.3. Optical Performance Analysis of the Surface Coating on Bleached Poplar Wood with UF@TS Added

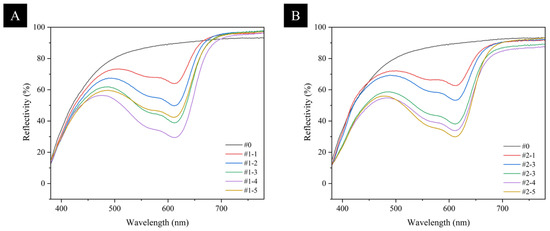

The 60° glossiness of the poplar wood surface before bleaching was 6.0 GU, which decreased to 3.9 GU after bleaching, representing a 35% gloss loss. Visually, this optical change indicates a visual transformation of the wood surface from a glossy to a matte appearance. The reflectivity of the poplar wood board before bleaching was 74.26%, and the reflectivity after bleaching was 93.60%, with a 26% improvement. The obvious color whitening could be observed with the naked eye, which was contrary to the glossiness change. This further proved the effect of bleaching from the data perspective. The effects of the two types of UF@TS microcapsules on the glossiness and reflectivity of the bleached wood surface are shown in Table 4. The coating added #1 UF@TS microcapsules exhibited an overall decreasing trend in 60° glossiness, though not strictly linear, showing a certain degree of fluctuation. This was particularly evident at the 85° gloss angle, where significant variation was observed; for example, the #1-2 coating had a gloss value of 11.2 GU, while the #1-5 coating dropped to only 1.9 GU. This suggested that higher microcapsule content may have led to aggregation or uneven distribution, which interfered with the surface reflective properties and resulted in glossiness instability. Furthermore, glossiness measured at an 85° angle was more sensitive to the microstructure of the surface, thus exhibiting greater variability. The glossiness of the coating that added #2 microcapsules tended to decrease first and then increase. This behavior could be attributed to the uneven distribution of microcapsules at low addition levels, which significantly disrupted the surface glossiness. With the increase in the amount of microcapsules with a smaller particle size, more microcapsules filled in the surface roughness caused by matting agents in the matte topcoat, leading to an increase in glossiness. Since the topcoat itself had a high solid content, excessive microcapsule addition further increased the solids content. Although the glossiness tended to increase slightly at higher loading levels, the physical and chemical properties of the coating would be affected to a certain extent.

Table 4.

Changes in glossiness and reflectivity of bleached poplar surface coatings with two types of UF@TSs added, respectively, at different amounts.

The reflectivity of the surface coating of the bleached poplar board is shown in Figure 6. As the microcapsule content increased, the overall reflectivity of the coatings tended to decrease. While the hiding power of the coating improved, the color of the coating darkened, gradually masking the underlying wood grain. At a 25% microcapsule loading, the color change of the coating at room temperature was relatively slow. The degree of color deepening was less than the speed of hiding power increase, resulting in a smaller improvement in color-rendering performance, while the wood grain was further covered by excessive microcapsules. Two of the 10% microcapsules added in the UV coating showed superior optical performance. While maintaining good color-rendering performance, the glossiness was higher, and the coverage rate was lower. By analyzing the reflectivity of longer wavelengths, it was found that the reflectivity of the coatings that added #1 microcapsules was higher in this wavelength range compared to those without microcapsules, indicating that it reflected more red light. Specifically, under normal temperature conditions, the coatings that added #1 microcapsules demonstrated superior wood grain coverage compared to the blank sample, significantly higher than the coatings with added #2 microcapsules. This was because the #1 microcapsules were more concentrated in the central area of the coating to be tested. The poor compatibility between microcapsules and UV coating led to poor leveling after coating and agglomeration in the center. The overall reflectivity of the coating with added #2 microcapsules was also lower than that with added #1 microcapsules, and the substrate coverage rate was lower, which could better retain the original texture of the substrate.

Figure 6.

Reflectivity of surface coatings on bleached poplar with UF@TS: (A) #1 added; (B) #2 added.

3.4. Mechanical Performance and Roughness Analysis of the Surface Coating on Bleached Poplar Wood with UF@TS Added

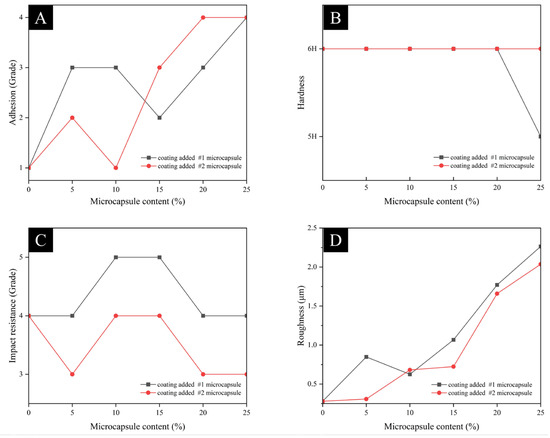

The surface roughness of the wood increased from 1.216 μm before bleaching to 1.513 μm after bleaching, consistent with the decrease in glossiness. The surface of the wood became rough due to bleaching, and the regular arrangement of the fibers themselves was affected, resulting in a loss of surface luster, thereby making subsequent coating application more necessary. The effects of two UF@TS microcapsules with different addition amounts on the mechanical properties of bleached poplar surface coating are shown in Table 5 and Figure 7. Among the coatings that added #1 microcapsules, the adhesion of the #1-3 coating was optimal at Grade 2. When the amount of UF@TS continued to increase, the adhesion became weaker, and the #1-5 coating was reduced to a minimum Grade 4. This indicated that an appropriate amount of microcapsule addition could enhance coating adhesion, as the microcapsules could play a certain anchoring role during penetration into the coating, thereby forming a tighter combination among the microcapsules, the coating, and the wood substrate. However, excessive microcapsule loading could negatively affect coating leveling, leading to poor adhesion. This is attributed to microcapsule agglomeration, which resulted in uneven distribution, weakening its resistance to mechanical peeling or cutting forces. The adhesion of the #2-1 to #2-3 coating was better than that of #1-1 to #1-3 because the particle size of #2 microcapsules was more uniform and could be better distributed in the coating at low addition amounts.

Table 5.

Mechanical properties of bleached poplar surface coatings with UF@TS added.

Figure 7.

Mechanical properties of surface coating on bleached poplar wood: (A) adhesion, (B) hardness, (C) impact resistance, and (D) roughness.

The UV topcoat used was a scratch-resistant matte coating with extremely high surface hardness, far above the standard requirement of 6H pencil hardness. However, the hardness of the #1-5 coating decreased to 5H. In contrast, the hardness of the #2 coating consistently maintained at 6H. Combined with the surface state, it could be found that the surface of UV topcoat with added #1 microcapsules appeared to have obvious powdering. This is because the UV topcoat had a high solid content and contained matte additives, namely matting agent. Due to the poor combination of #1 microcapsules and the topcoat, the high addition amount of #1 microcapsules negatively affected the curing of the UV topcoat, thus resulting in reduced surface hardness.

As the addition amount of UF@TS microcapsules increased, the impact resistance of the coating was reduced first and then increased. The impact resistance grades of the #1-2 and #2-3 coatings were the lowest, at Grade 5 and Grade 4, respectively. The inherently poor impact resistance of the coatings was attributed to the high hardness and brittleness of both the UV primer and topcoat, making the surface prone to cracking under external impact. However, the impact resistance of the UV coating with low content of #2 microcapsules was improved to some extent, while the impact resistance of the #1-2 and #1-3 coatings with #1 microcapsules was further deteriorated. These results indicated that an appropriate amount of #2 microcapsules could enhance the toughness of the coating. This conclusion was further supported by elongation at break experiments, which suggested that the combination of UF topcoat and #2 microcapsules results in lower internal stress and better interfacial compatibility.

The roughness of the samples increased, and the coating roughness increased to a maximum of 2.264 μm and 2.036 μm in the range of #1-3 to #1-5 and #2-3 to #2-5, respectively. The coating that added #2 microcapsules still remained at a low level. At low addition levels, the roughness was greatly affected by microcapsule agglomeration. For example, the roughness of the #1-1 and #1-5 coatings was higher than that of #1-2 and #2-1, mainly due to poor leveling of the coating itself.

3.5. Thermochromic Performance Analysis of the Surface Coating on Bleached Poplar Wood with UF@TS Added

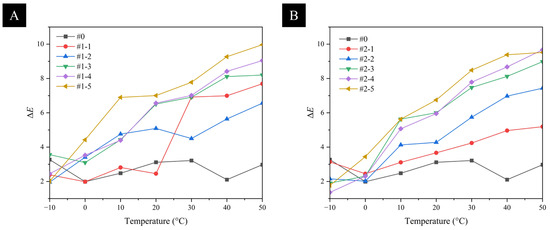

As shown in Table 6 and Figure 8, the ΔE values of the #0 coating remained around 3 across the tested temperatures. Since there was essentially no significant variation in ΔE with temperature increase, coatings with ΔE values below 3 were considered to have no thermochromic function. For coatings containing UF@TS microcapsules, ΔE increases gradually with temperature. At 50 °C, a higher ΔE was observed. With the increasing of microcapsule content, the overall ΔE value tended to increase as well. The color change of the microcapsules from blue to light blue occurred at a temperature node between 20 and 30 °C. That was, above 30 °C, the color difference of coating was small, and it could be found that most microcapsules had completed the color change process. As shown in Table 7, the ΔE value variation of the coating during cooling was further tested to verify whether there was hysteresis in the thermochromic behavior. The experimental results showed that the ΔE values of the coating were basically consistent with the heating process with the temperature drop, indicating that the thermochromic system had good reversibility and stability, but there was a certain degree of hysteresis. At the same time, limited by the test conditions, the ΔE between −20 °C and −10 °C increased rapidly, which may mean that the starting temperature node of the color change process from the basic dark blue to light blue coating may be lower than −10 °C or even lower than −20 °C. In contrast, the coating with a higher microcapsule addition amount had a higher ΔE value of 50 °C, such as the #1-3 to #1-5 coating and #2-4 to #2-5 coating, and the maximum ΔE reached 9.970. Part of the increase in color difference was concentrated in the high-temperature area, such as 40–50 °C, because the surface temperature of the coating was higher than the interior during heating and the internal microcapsule had a slow response to temperature, so the low-temperature discoloration efficiency was poor. However, such a situation was not ideal for practical applications requiring quick low-temperature responses. Considering both the response temperature range and ΔE values, the #2-3 coating demonstrated the optimal thermochromic performance, with a complete color change at 30 °C, making it well suited for decorative coatings on furniture surfaces in the −10 °C to 30 °C range. In comparison, the #1-3 coating exhibited a lower maximum ΔE at high temperatures, inefficient low-temperature response, and weaker overall physical properties. The #2-2 coating also showed significant ΔE changes between −10 °C and 30 °C, with a lower color change temperature than that of the #2-3 coating at 20 °C.

Table 6.

Chromaticity value and ΔE of coatings with temperature increase.

Figure 8.

Coating ΔE with temperature variation: (A) coatings with #1 microcapsule; (B) coatings with added #2 microcapsule.

Table 7.

Chromaticity value and ΔE of coatings with temperature decrease.

3.6. Aging Performance Analysis of the Surface Coating on Bleached Poplar Wood with UF@TS Added

As shown in Figure 9, after a short period of thermal aging, the coatings suffered visible degradation, particularly exhibiting delamination between the topcoat and the primer. This could be attributed to the difference in thermal expansion coefficients between the two UV coating layers. Among the samples, coatings that added #1 microcapsules showed more pronounced surface deterioration, including severe topcoat damage, indicating that #1 microcapsules further weakened the morphological retention ability of the topcoat in the aging process compared to #2 microcapsules. Additionally, the 2-4# and #2-5 coatings also displayed expansion cracks and serious damage, while coatings of #2-1 to #2-3 maintained relatively good surface morphology after aging. However, while the entire batch of coating primer was intact, the overall coating changed to yellow, and the color was no longer bright after cooling. Some microcapsules may lose their discoloration performance as the core solvent decanol evaporated at a high temperature. The ΔE values of the coatings after aging are shown in Table 8. It was evident that thermochromic performance declined overall. Coatings with low microcapsule content, such as #1-1, #1-2, and #2-1, did not exhibit noticeable thermochromic behavior before or after aging. In the #1-4 coating, although it contained a relatively high concentration of microcapsules, severe topcoat cracking led to substantial loss of color-changing function. Although other coatings with high addition amount lost less color-changing performance due to the large base number of microcapsules, the coating was severely damaged by thermal aging, and the topcoat could no longer be applied normally in practice. Among all samples, the #2-2 UV coating showed the least surface degradation and retained good color-changing performance, indicating the best thermal aging resistance. This is attributed to the better compatibility between #2 microcapsules and the topcoat, and the amount of microcapsules added in the #2-2 coating was moderate at 10%. Furthermore, due to the phase change nature of the microcapsules, the thermal stability of the coating system was enhanced during short-term aging, resulting in a more stable coating structure and less loss of thermochromic function.

Figure 9.

Macroscopic morphology of UV coatings with UF@TS added, before aging: (A) wood before bleaching, (B) #0, (C) #1-1, (D) #1-2, (E) #1-3, (F) #1-4, (G) #1-5, (H) #2-1, (I) #2-2, (J) #2-3, (K) #2-4, (L) #2-5; after aging: (M) wood before bleaching, (N) #0, (O) #1-1, (P) #1-2, (Q) #1-3, (R) #1-4, (S) #1-5, (T) #2-1, (U) #2-2, (V) #2-3, (W) #2-4, (X) #2-5.

Table 8.

The ΔE of coatings at high and low temperatures after aging.

According to the glossiness aging performance data analysis in Table 9, for coatings with added #1 microcapsules, as the addition amount increased from 5% to 15%, the #1-1 to #1-3 coatings maintained a glossiness of 2.3–2.5 GU after aging, and the aging gloss loss rate decreased from 11% to 8%. This indicated that appropriate addition of thermochromic microcapsules could improve the thermal stability of coatings as phase-change microcapsules. However, when the addition amount exceeded 20%, the aging loss rate suddenly increased to 25%, indicating that excessive addition would lead to a decrease in the density of the coating structure. In contrast, coatings with added #2 microcapsules exhibited greater gloss loss after aging. This may be attributed to the coating system consisting of a matte topcoat and a glossy primer. During the aging process, the topcoat layer of the coating that added #1 microcapsules cracked, exposing the glossy primer beneath, which resulted in a reverse increase in glossiness.

Table 9.

Glossiness of coatings after aging.

4. Conclusions

In this study, based on bleached poplar wood substrates, two types of UF@TS microcapsules were selected as additives. The microcapsules were mixed with the UV primer at mass fractions of 0% (blank control), 5%, 10%, 15%, 20% and 25%, and the bleached poplar boards were painted with two layers of primer and topcoat manually. The results showed that bleaching treatment significantly improved the whiteness of the poplar boards, with an increase rate of 17%, effectively reducing the uneven surface color difference with minimal impact on the microscopic morphology of wood fibers. Among the microcapsule coatings, the surface morphology of the coatings with #2 microcapsules (corresponding to Samples #2-1 to #2-5) was superior to that of those with #1 microcapsules (corresponding to Samples #1-1 to #1-5). As the microcapsule content increased, the glossiness generally decreased, and the overall reflectivity of #2 coatings was lower. While the addition of UF@TS microcapsules reduced coating adhesion, the hardness was barely affected. Among them, #1 microcapsules weakened the impact resistance, whereas #2 microcapsules enhanced it. The addition of UF@TS microcapsules also increased surface roughness. In terms of thermochromic performance, #1 microcapsules exhibited greater ΔE but required higher activation temperatures, while #2 microcapsules responded closer to room temperature, making them more suitable for practical use. However, both types showed some decline in color change performance and glossiness after aging, with #1 coatings retaining glossiness slightly better. Overall, the #2-2 coating demonstrated the best comprehensive performance. The UV coating, prepared by adding 10% of #2 microcapsules on the surface of bleached poplar wood, achieved a glossiness of 2.1 GU, reflectivity of 67.95%, adhesion rating of Grade 1, hardness of 6 H, impact resistance of Grade 4, surface roughness of 0.681 μm, and ΔE of 7.434 across −20 °C to 50 °C. After aging, ΔE remained at 5.846 with a gloss loss rate of 9%, indicating superior overall performance.

Author Contributions

Conceptualization, methodology, validation, resources, data management, supervision, and writing—review and editing, J.H.; formal analysis, Y.Z.; investigation, X.Y. and J.L. All authors have read and agreed to the published version of the manuscript.

Funding

This project was partly supported by the Natural Science Foundation of Jiangsu Province (BK20201386).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data are contained within the article.

Conflicts of Interest

The authors declare that there are no conflicts of interest.

References

- Chen, Y.; Liu, R.; Luo, J. Improvement of anti-aging property of UV-curable coatings with silica-coated TiO2. Prog. Org. Coat. 2023, 179, 107479. [Google Scholar] [CrossRef]

- Jafarifard, S.; Ebrahimi, M.; Sharif, F. Antistatic epoxy acrylate/graphene oxide UV-curable coatings with improved shrinkage and adhesion strength. Prog. Org. Coat. 2023, 182, 107595. [Google Scholar] [CrossRef]

- Bednarczyk, P.; Wróblewska, A.; Markowska-Szczupak, A.; Ossowicz-Rupniewska, P.; Nowak, M.; Kujbida, M.; Kaminska, A.; Czech, Z. UV Curable Coatings Based on Urethane Acrylates Containing Eugenol and Evaluation of Their Antimicrobial Activity. Coatings 2021, 11, 1556. [Google Scholar] [CrossRef]

- Choi, W.C.; Gavande, V.; Kim, D.Y.; Lee, W.K. Study on Press Formability and Properties of UV-Curable Polyurethane Acrylate Coatings with Different Reactive Diluents. Polymers 2023, 15, 880. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.; Liu, Y.; Wang, X.; Chen, D.M.; Ding, H. Fabrication of sericite-TiO2/HDTMS superhydrophobic self-cleaning coatings by hydrothermal method. J. Alloys Compd. 2025, 1014, 178677. [Google Scholar] [CrossRef]

- Chen, M.J.; Pan, X.Y.; Tian, Y.; Li, J.B.; Tan, Q.G.; Jin, M.; Ren, J. Synthesis of renewable isosorbide-based polyurethane acrylate resins for UV-cured coating with adjustable properties. Prog. Org. Coat. 2023, 182, 107695. [Google Scholar] [CrossRef]

- Bednarczyk, P.; Walkowiak, K.; Irska, I. Epoxy (Meth) acrylate-Based Thermally and UV Initiated Curable Coating Systems. Polymers 2023, 15, 4664. [Google Scholar] [CrossRef] [PubMed]

- Gavande, V.; Mahalingam, S.; Kim, J.; Lee, W.K. Optimization of UV-Curable Polyurethane Acrylate Coatings with Hexagonal Boron Nitride (hBN) for Improved Mechanical and Adhesive Properties. Polymers 2024, 16, 2544. [Google Scholar] [CrossRef] [PubMed]

- Zhou, M.X.; Liu, J.; Lu, P.; Huang, Y.Z.; Xiao, Y.X.; Zhang, J.Y.; Hu, Y.; Yang, Z.H. Polyfunctional phytic acid-based reactive diluent for UV-curable coating with improved flame-retardant performance and toughness. Ind. Crop. Prod. 2023, 204, 117368. [Google Scholar] [CrossRef]

- Zhu, J.L.; Fan, H.; Wan, J.T. Solvent-Free and UV-Cured Epoxy Silicone Coating with Excellent Wear Resistance and Antismudge Properties. ACS Appl. Mater. Interfaces 2024, 16, 35494–35504. [Google Scholar] [CrossRef]

- Wang, X.; Ding, H.; Xu, Z.Q.; Zhang, J.M.; Yao, Y.B. Preparation of a UV anti-aging and superhydrophobic self-cleaning coating by loading nano-rutile on sericite and being modified with HDTMS. Appl. Clay Sci. 2024, 247, 107212. [Google Scholar] [CrossRef]

- Rosu, D.; Mustata, F.R.; Rosu, L.; Varganici, C.D. Photochemical Aging of Eco-Friendly Wood Coatings Derived from Vegetable Oils. ACS Appl. Polym. Mater. 2021, 3, 6303–6314. [Google Scholar] [CrossRef]

- Yang, M.C.; Li, S.; Zhang, S.G.; Gao, B.; Tong, Z.H.; Cheng, D.D.; Chen, D.L.; Huang, R.Y.; Yang, Y.C. Dense and superhydrophobic biopolymer-coated large tablet produced with energy efficient UV-curing for controlled-release fertilizer. J. Mater. Chem. A 2022, 10, 18834–18844. [Google Scholar] [CrossRef]

- Davoudi, S.; Multigner, M.; Calvez, I.; Hermann, A.; Landry, V. Influence of Magnetic Particles and Magnetic Field on Gloss in UV Coating. Coatings 2023, 13, 1625. [Google Scholar] [CrossRef]

- Li, X.Q.; Bian, F.P.; Li, S.; Gui, X.F.; Yao, M.F.; Hu, J.W.; Lin, S.D. Preparation of siloxymethyl-modified silicone acrylate prepolymers with UV/moisture dual curability for applications in anti-smudge and anti-fingerprint coatings. Colloids Surf. A Physicochem. Eng. Asp. 2023, 658, 130669. [Google Scholar] [CrossRef]

- Yang, Z.; Liu, H.J.; Zhao, J.Y.; Wang, C.; Li, H.T.; Wang, X.H.; Yang, Y.; Wu, H.X.; Gu, Z.P.; Li, Y.W. UV absorption enhanced polydopamine coating. Mater. Horiz. 2024, 11, 2438–2448. [Google Scholar] [CrossRef]

- Noè, C.; Tonda-Turo, C.; Carmagnola, I.; Hakkarainen, M.; Sangermano, M. UV-Cured Biodegradable Methacrylated Starch-Based Coatings. Coatings 2021, 11, 127. [Google Scholar] [CrossRef]

- Zhang, Y.A.; Sheng, Y.M.; Wang, M.H.; Lu, X. UV-curable self-healing, high hardness and transparent polyurethane acrylate coating based on dynamic bonds and modified nano-silica. Prog. Org. Coat. 2022, 172, 107051. [Google Scholar] [CrossRef]

- Sen, F.; Kocatürk, E.; Çakmakçi, E.; Kahraman, M.V. Quaternary imidazolium-functionalized reactive silica nanoparticles-containing thiolene photocured antibacterial hybrid coatings. React. Funct. Polym. 2022, 170, 105149. [Google Scholar] [CrossRef]

- Cong, R.Z.; Cai, T.Y.; Ge-Zhang, S.; Yang, H.; Zhang, C. Fabrication of PVA-Silica Sol Wood Composites via Delignification and Freezing Pretreatment. Polymers 2024, 16, 1949. [Google Scholar] [CrossRef]

- Xu, J.F.; Qin, Y.; Liu, R.; Long, L.; Ma, E.N. Preparation and properties of high-performance fast-growing wood modified by exfoliated organo-montmorillonite in waterborne hyperbranched polyacrylate emulsion. Constr. Build. Mater. 2021, 298, 123868. [Google Scholar] [CrossRef]

- Zhang, Y.; Guan, P.F.; Ma, X.; Li, P.; Sun, Z.Y.; Li, X.J.; Zuo, Y.F. Study on the Effect of Acrylic Acid Emulsion on the Properties of Poplar Wood Modified by Sodium Silicate Impregnation. Forests 2023, 14, 1221. [Google Scholar] [CrossRef]

- Herstedt, L.; Herstedt, M. Chemical bleaching of wood: An investigation into the bleaching of mahogany, walnut, rosewood, padauk, and purpleheart. Stud. Conserv. 2017, 62, 162–172. [Google Scholar] [CrossRef]

- Lu, D.T.; Xiong, X.Q.; Lu, G.Z.; Gui, C.S.; Pang, X.R. Effects of NaOH/H2O2/Na2SiO3 Bleaching Pretreatment Method on Wood Dyeing Properties. Coatings 2023, 13, 233. [Google Scholar] [CrossRef]

- Ibarra, D.; Martin-Sampedro, R.; Wicklein, B.; Borrero-Lopez, A.M.; Valencia, C.; Valdehita, A.; Navas, J.M.; Eugenio, M.E. Populus alba L., an Autochthonous Species of Spain: A Source for Cellulose Nanofibers by Chemical Pretreatment. Polymers 2022, 14, 68. [Google Scholar] [CrossRef] [PubMed]

- Xu, W.; Chen, P.; Yang, Y.; Wang, X.; Liu, X. Effects of Freezing and Steam Treatments on the Permeability of Populus Tomentosa. Materialwiss. Werkst. 2021, 52, 907–915. [Google Scholar] [CrossRef]

- Wu, S.S.; Tao, X.; Xu, W. Thermal Conductivity of Poplar Wood Veneer Impregnated with Graphene/Polyvinyl Alcohol. Forests 2021, 12, 777. [Google Scholar] [CrossRef]

- Wu, G.F.; Shen, Y.L.; Fu, F.; Ren, H.Q.; Qu, W. Mechanism of the super-large deformation behavior of poplar wood under transverse compression. Ind. Crop. Prod. 2023, 205, 117510. [Google Scholar] [CrossRef]

- Ding, S.H.; Lan, Z.Y.; Fang, S.Z. Pyrolysis temperature determines the amendment effects of poplar residue-derived biochars on reducing CO2 emission. GCB Bioenergy 2023, 15, 1030–1045. [Google Scholar] [CrossRef]

- Xu, B.H.; Yu, K.B.; Wu, H.C.; Bouchaïr, A. Mechanical properties and engineering application potential of the densified poplar. Wood Mater. Sci. Eng. 2022, 17, 659–667. [Google Scholar] [CrossRef]

- Yang, Z.X.; Han, Y.; Peng, W.W.; Wang, L.; Yan, X.X. Effect of Fluorane Microcapsule Content on Properties of Thermochroic Waterborne Topcoat on Tilia europaea. Polymers 2022, 14, 3638. [Google Scholar] [CrossRef]

- Wang, L.; Han, Y.; Yan, X.X. Effects of Adding Methods of Fluorane Microcapsules and Shellac Resin Microcapsules on the Preparation and Properties of Bifunctional Waterborne Coatings for Basswood. Polymers 2022, 14, 3919. [Google Scholar] [CrossRef] [PubMed]

- Ji, Y.H.; Zhang, Y.H.; Wang, X.X.; Zhang, D.Z.; Zhang, F.D.; Huang, Y.X.; Yu, Y.L.; Yu, W.J.; Zhu, R.X. Reversible thermochromic transparent bamboo for dynamically adaptive smart windows. Ind. Crop. Prod. 2023, 197, 116593. [Google Scholar] [CrossRef]

- Cheng, Z.F.; Zhao, B.B.; Lei, L.L.; Zhu, Y.F.; Wei, Z.B.; Yu, T.; Fan, J.H.; Li, Y. Self-assembled poly (lactic acid) films with high heat resistance and multi-stage thermochromic properties prepared by blown film-annealing. Chem. Eng. J. 2024, 480, 148261. [Google Scholar] [CrossRef]

- Yang, T.J.; Yuan, D.; Liu, W.; Zhang, Z.; Wang, K.Y.; You, Y.X.; Ye, H.P.; de Haan, L.T.; Zhang, Z.; Zhou, G.F. Thermochromic Cholesteric Liquid Crystal Microcapsules with Cellulose Nanocrystals and a Melamine Resin Hybrid Shell. ACS Appl. Mater. Interfaces 2022, 14, 4588–4597. [Google Scholar] [CrossRef]

- Yu, W.D.; Liu, H.; Tan, J.L.; Wang, C.X. The reversible thermochromic fabric for the double-stage temperature monitoring. Eur. Polym. J. 2024, 206, 112769. [Google Scholar] [CrossRef]

- Liu, H.S.; Deng, Y.H.; Ye, Y.; Liu, X.Q. Reversible Thermochromic Microcapsules and Their Applications in Anticounterfeiting. Materials 2023, 16, 5150. [Google Scholar] [CrossRef] [PubMed]

- Zou, Y.M.; Yan, X.X. Preparation and Optimization of Thermochromic Microcapsules as a Ternary System of Crystal Violet Lactone: Bisphenol A: Decanol Encapsulated with Urea Formaldehyde Resin in a UV-Curable Primer. Polymers 2025, 17, 851. [Google Scholar] [CrossRef]

- Weng, M.Y.; Fu, Y.C.; Xu, W. Flame-Retardant Coating on Wood Surface by Natural Biomass Polyelectrolyte via a Layer-by-Layer Self-Assembly Approach. Forests 2024, 15, 1362. [Google Scholar] [CrossRef]

- Zhang, N.; Mao, Y.Q.; Wu, S.S.; Xu, W. Effects of the Ball Milling Process on the Particle Size of Graphene Oxide and Its Application in Enhancing the Thermal Conductivity of Wood. Forests 2022, 13, 1325. [Google Scholar] [CrossRef]

- Wang, C.; Li, J.Y.; Wang, X.W.; Chu, Q.; Wang, T.Y. Influence of Shell Structure on the Tensile Strength of Fused Filament Fabrication Models. Mater. Plast. 2024, 61, 19–26. [Google Scholar] [CrossRef]

- Xue, J.X.; Xu, W.; Zhou, J.C.; Mao, W.G.; Wu, S.S. Effects of High-Temperature Heat Treatment Modification by Impregnation on Physical and Mechanical Properties of Poplar. Materials 2022, 15, 7334. [Google Scholar] [CrossRef] [PubMed]

- Wang, C.; Li, J.Y.; Wang, T.Y.; Wang, X.W. Additive manufacturing of furniture corner guards based on thermoplastic polyurethane filament. Bioresources 2025, 20, 5398–5406. [Google Scholar] [CrossRef]

- Hu, W.; Yang, Z.; Shi, N.; Yu, X. Experimental study on effects of the selected load parameters on fatigue life of the mortise-and-tenon furniture joint. Wood Mater. Sci. Eng. 2025, 19, 1–7. [Google Scholar] [CrossRef]

- Wang, C.; Li, J.Y.; Wang, T.Y.; Chu, Q.; Wen, S.Q. Design and Rapid Prototyping of Packaging Liner for Rosewood Craft based on Gyroid Infill Structure. Bioresources 2025, 20, 842–851. [Google Scholar] [CrossRef]

- Yue, X.Y.; Xiong, X.Q.; Zhang, M.; Xu, X.T.; Yang, L.J. Multi-objective optimization for energy-efficient hybrid flow shop scheduling problem in panel furniture intelligent manufacturing with transportation constraints. Expert Syst. Appl. 2025, 274, 126830. [Google Scholar] [CrossRef]

- Hu, W.; Zhao, Y.; Xu, W.; Liu, Y. Study on withdrawal force capacity of insert nut in wood-based materials used for case furniture. Wood Mater. Sci. Eng. 2024, 18, 1–10. [Google Scholar] [CrossRef]

- Hu, W.; Zhao, Y.; Xu, W.; Liu, Y. The influences of selected factors on bending moment capacity of case furniture joints. Appl. Sci. 2024, 14, 10044. [Google Scholar] [CrossRef]

- GB/T 4893.6-2013; Test of Surface Coatings of Furniture—Part 6: Determination of Gloss Value. Standardization Administration of the People’s Republic of China: Beijing, China, 2013.

- Hu, W.; Yu, R.; Yang, P. Characterizing roughness of wooden mortise and tenon considering effects of measured position and assembly condition. Forests 2024, 15, 1584. [Google Scholar] [CrossRef]

- Wang, C.; Li, J.Y.; Wang, T.Y.; Chu, Q.; Wang, X.W. Fused deposition 3D printing of bonsai tree guiding mold based on acrylonitrile-butadiene-styrene copolymer. Bioresources 2024, 19, 5839–5846. [Google Scholar] [CrossRef]

- GB/T 4893.9-2013; Physical and Chemical Properties Test of Furniture Surface Coatings—Part 9: Determination of Impact Resistance. Standardization Administration of the People’s Republic of China: Beijing, China, 2013.

- GB/T 6739-2022; Paints and Varnishes-Determination of Coatings Hardness by Pencil Test. Standardization Administration of the People’s Republic of China: Beijing, China, 2022.

- Hu, W.; Luo, M.; Liu, Y.; Xu, W.; Konukcu, A.C. Experimental and numerical studies on the mechanical properties and behaviors of a novel wood dowel reinforced dovetail joint. Eng. Fail. Anal. 2023, 152, 107440. [Google Scholar] [CrossRef]

- Hu, W.; Yu, R. Study on the strength mechanism of the wooden round-end mortise-and-tenon joint using the digital image correlation method. Holzforschung 2024, 78, 519–530. [Google Scholar] [CrossRef]

- Hu, W.; Luo, M.; Hao, M.; Tang, B.; Wan, C. Study on the effects of selected factors on the diagonal tensile strength of oblique corner furniture joints constructed by wood dowel. Forests 2023, 14, 1149. [Google Scholar] [CrossRef]

- GB/T 4893.4-2013; Test of Surface Coatings of Furniture—Part 4: Determination of Adhesion—Cross Cut. Standardization Administration of the People’s Republic of China: Beijing, China, 2013.

- Wang, C.; Li, J.Y.; Wang, T.Y.; Wang, X.W.; Chu, Q. Effect of Optimised Infill Parameters on the Tensile Properties of MEX Co-polyester Models. Mater. Plast. 2024, 61, 129–136. [Google Scholar] [CrossRef]

- Hu, W.; Luo, M.; Yu, R.; Zhao, Y. Effects of the selected factors on cyclic load performance of T-shaped mortise-and-tenon furniture joints. Wood Mater. Sci. Eng. 2024, 18, 1–10. [Google Scholar] [CrossRef]

- Zhou, J.C.; Xu, W. Toward interface optimization of transparent wood with wood color and texture by silane coupling agent. J. Mater. Sci. 2022, 57, 5825–5838. [Google Scholar] [CrossRef]

- GB/T 11186.3-1989; Methods for Measuring the Color of Coatings. Part III: Calculation of Color Differences. Standardization Administration of the People’s Republic of China: Beijing, China, 1990.

- GB/T 1740-2007; Determination of Moisture and Heat Resistance of Coatings. Standardization Administration of the People’s Republic of China: Beijing, China, 2007.

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).