Synthesis and Characterization of Titanium Layer with Fiber-like Morphology on HDPE by Plasma Treatment

Abstract

1. Introduction

2. Materials and Methods

3. Results

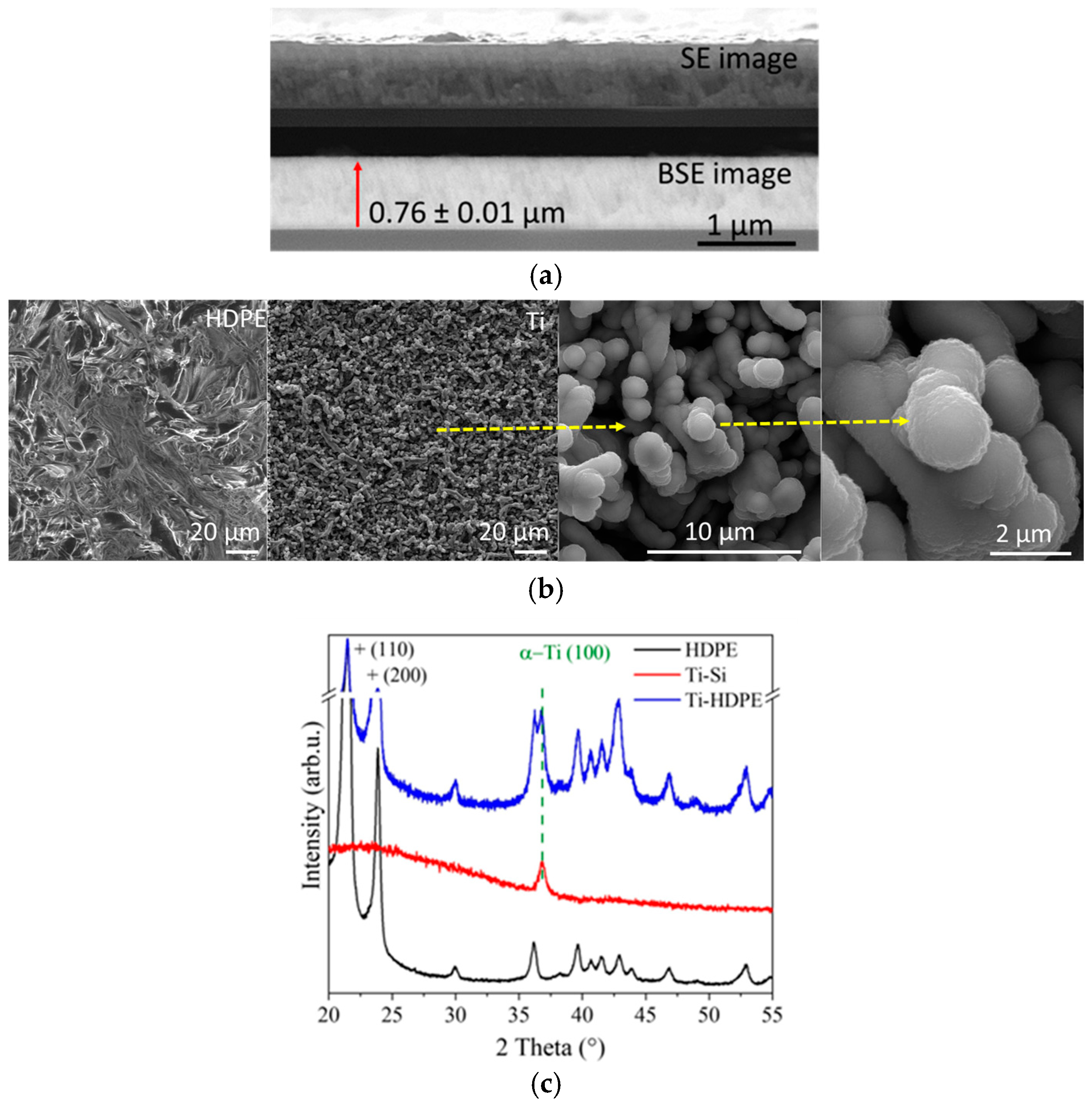

3.1. Surface Characteristics

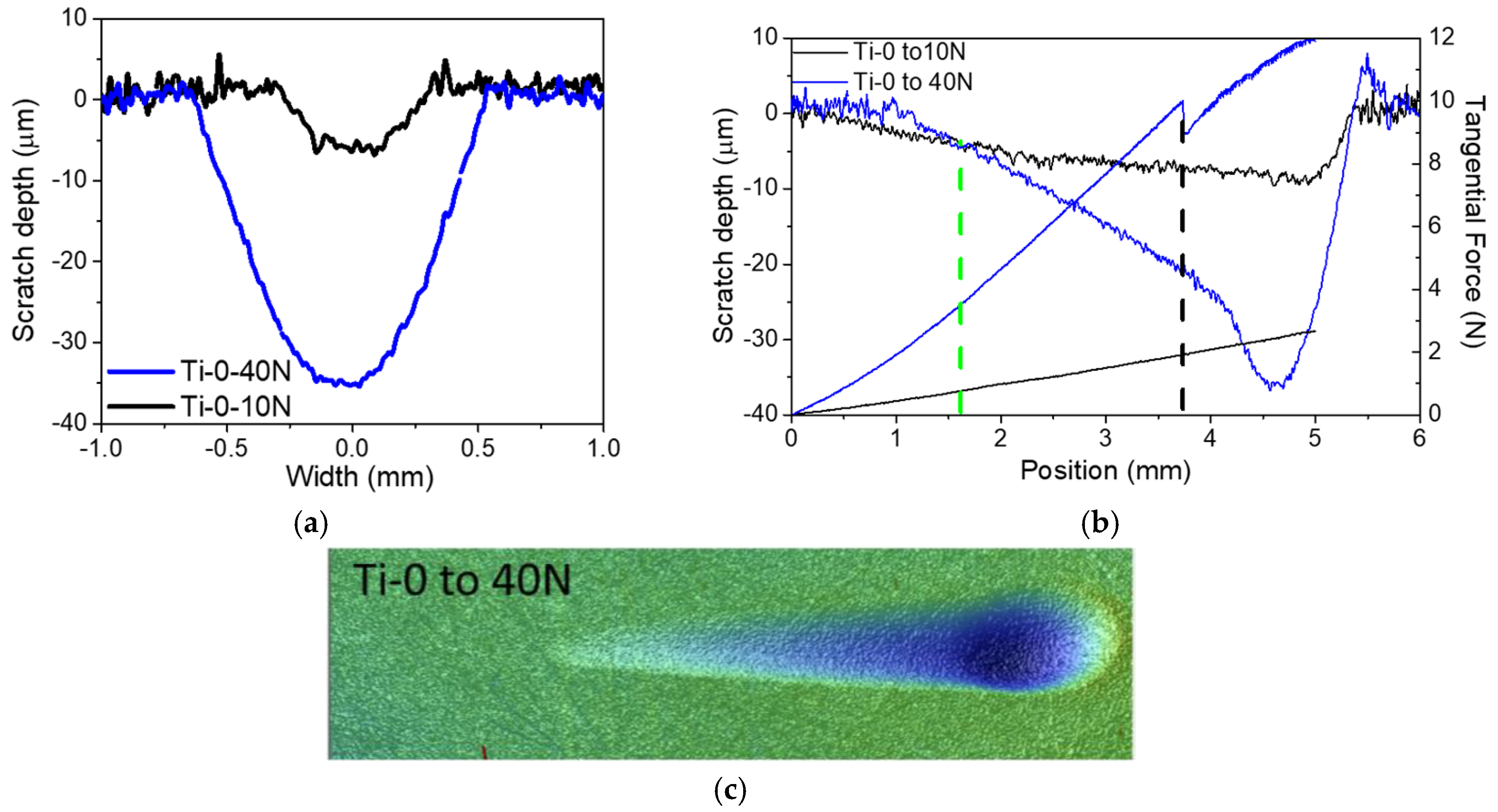

3.2. Mechanical Properties

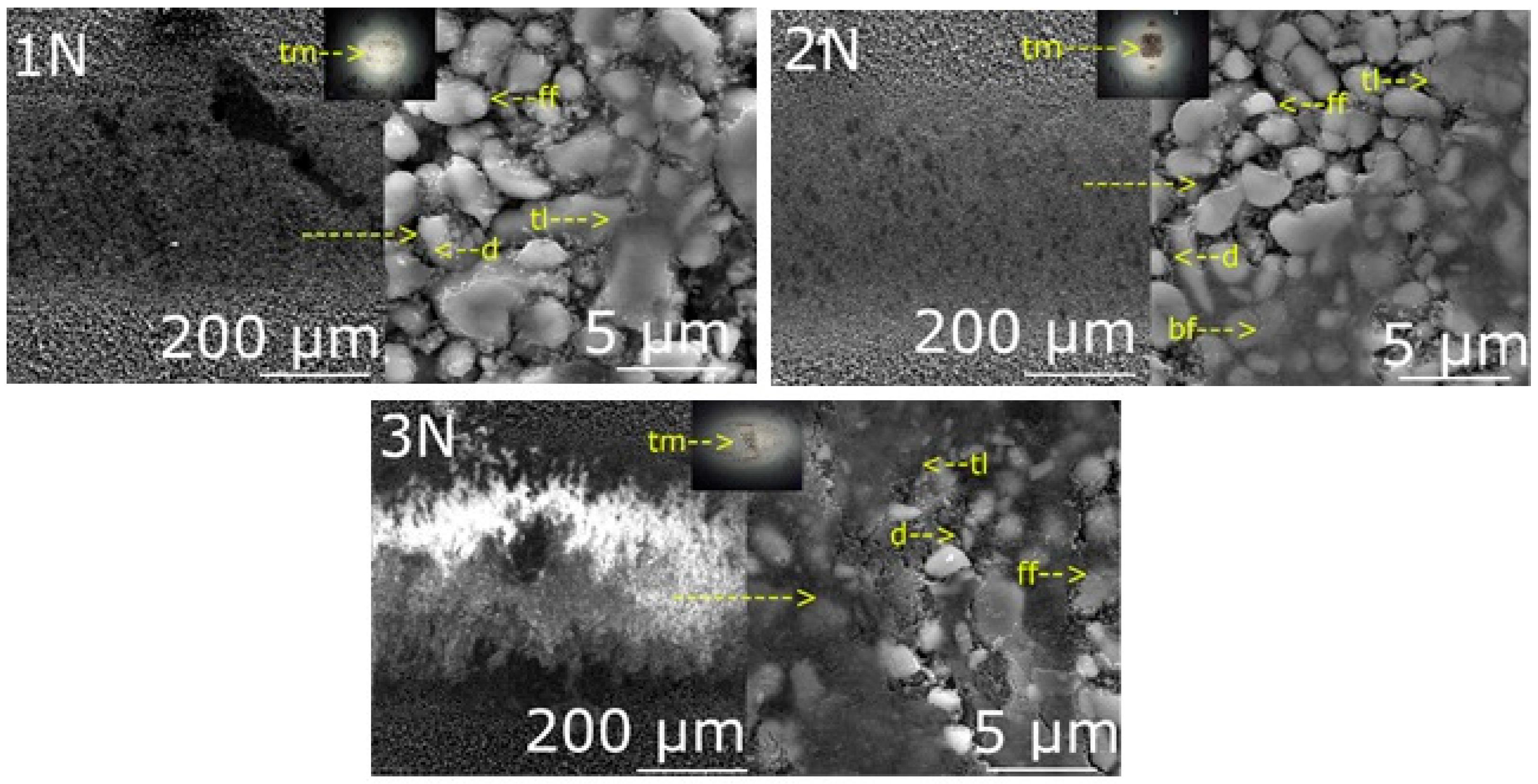

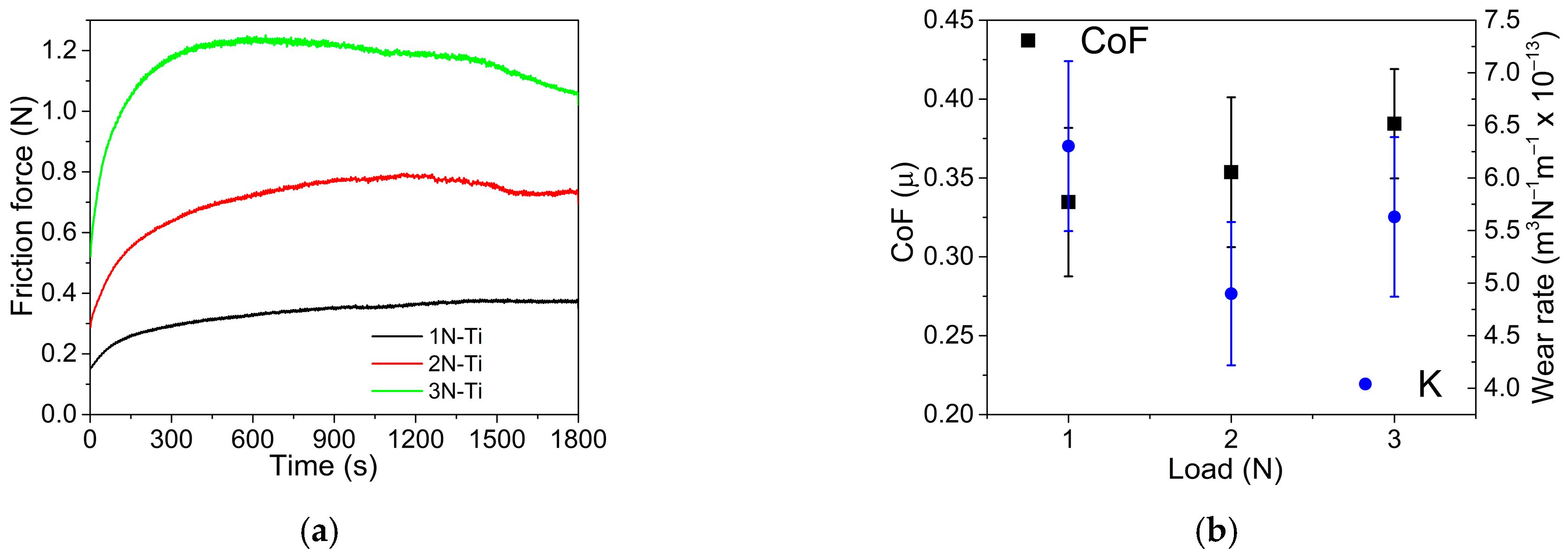

3.3. Tribological Properties

4. Discussion

5. Conclusions

- The plasma treatment successfully combined the etching effect on the HDPE that polarized the polymer surfaces, facilitating the the titanium (Ti) deposition, forming a layer with fibers-like morphology with the α-Ti phase crystalline structure.

- The Ti coating with fiber-like morphology had a good adhesion to the HDPE surfaces and load-bearing capacity, reducing the plastic deformation around the worn zones.

- The plasma treatment provided effective surface protection for the HDPE substrate by enabling plastic deformation and fiber fracture without layer detachment, leading to the formation of a tribolayer that contributed to reducing surface wear during sliding operations.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Salem, A.; Bensalah, W.; Mezlini, S. Effect of hygrothermal aging on the tribological behavior of HDPE composites for bio-implant application. Polym. Test. 2021, 94, 107050. [Google Scholar] [CrossRef]

- Chan, J.X.; Wong, J.F.; Petrů, M.; Hassan, A.; Nirmal, U.; Othman, N.; Ilyas, R.A. Effect of nanofillers on tribological properties of polymer nanocomposites: A review on recent development. Polymers 2021, 13, 2867. [Google Scholar] [CrossRef] [PubMed]

- Xu, S.; Tangpong, X.W. Review: Tribological behavior of polyethylene-based nanocomposites. J. Mater. Sci. 2013, 48, 578–597. [Google Scholar] [CrossRef]

- Wang, S.; Zhang, J.; Liu, L.; Yang, F.; Zhang, Y. Evaluation of cooling property of high density polyethylene (HDPE)/titanium dioxide (TiO2) composites after accelerated ultraviolet (UV) irradiation. Sol. Energy Mater. Sol. Cells 2015, 143, 120–127. [Google Scholar] [CrossRef]

- Balasubramanian, V.; Natarajan, K.; Rajeshkannan, V.; Perumal, P. Enhancement of in vitro high-density polyethylene (HDPE) degradation by physical, chemical, and biological treatments. Environ. Sci. Pollut. Res. 2014, 21, 12549–12562. [Google Scholar] [CrossRef] [PubMed]

- Mitroka, S.M.; Smiley, T.D.; Tanko, J.; Dietrich, A.M. Reaction mechanism for oxidation and degradation of high density polyethylene in chlorinated water. Polym. Degrad. Stab. 2013, 98, 1369–1377. [Google Scholar] [CrossRef]

- Pelto, J.; Heino, V.; Karttunen, M.; Rytöluoto, I.; Ronkainen, H. Tribological performance of high density polyethylene (HDPE) composites with low nanofiller loading. Wear 2020, 460–461, 203451. [Google Scholar] [CrossRef]

- García, E.; Louvier-Hernández, J.; Cervantes-Vallejo, F.; Flores-Martínez, M.; Hernández, R.; Alcaraz-Caracheo, L.; Hernández-Navarro, C. Mechanical, dynamic and tribological characterization of HDPE/peanut shell composites. Polym. Test. 2021, 98, 107075. [Google Scholar] [CrossRef]

- Liu, T.; Li, B.; Lively, B.; Eyler, A.; Zhong, W.-H. Enhanced wear resistance of high-density polyethylene composites reinforced by organosilane-graphitic nanoplatelets. Wear 2014, 309, 43–51. [Google Scholar] [CrossRef]

- Liu, T.; Wang, Y.; Eyler, A.; Zhong, W.-H. Synergistic effects of hybrid graphitic nanofillers on simultaneously enhanced wear and mechanical properties of polymer nanocomposites. Eur. Polym. J. 2014, 55, 210–221. [Google Scholar] [CrossRef]

- Burris, D.L.; Boesl, B.; Bourne, G.R.; Sawyer, W.G. Polymeric nanocomposites for tribological applications. Macromol. Mater. Eng. 2007, 292, 387–402. [Google Scholar] [CrossRef]

- Hsueh, H.-C.; Kim, J.H.; Orski, S.; Fairbrother, A.; Jacobs, D.; Perry, L.; Hunston, D.; White, C.; Sung, L. Micro and macroscopic mechanical behaviors of high-density polyethylene under UV irradiation and temperature. Polym. Degrad. Stab. 2020, 174, 109098. [Google Scholar] [CrossRef]

- Fadzil, A.F.B.A.; Pramanik, A.; Basak, A.K.; Prakash, C.; Shankar, S. Role of surface quality on biocompatibility of implants—A review. Ann. 3D Print. Med. 2022, 8, 100082. [Google Scholar] [CrossRef]

- Chen, S.; Cao, L.; Wu, T.; Zhao, J.; Liu, J.; An, M.; Guo, R.; Li, H.; Chen, W. Fabrication and in vitro biocompatibility of hierarchical cellulose acetate/polyvinylpyrrolidone@titania nanowire hollow microfibers. Int. J. Biol. Macromol. 2024, 280, 136095. [Google Scholar] [CrossRef]

- Abbas-Abadi, M.S.; Zayoud, A.; Kusenberg, M.; Roosen, M.; Vermeire, F.; Yazdani, P.; Van Waeyenberg, J.; Eschenbacher, A.; Hernandez, F.J.A.; Kuzmanović, M.; et al. Thermochemical recycling of end-of-life and virgin HDPE: A pilot-scale study. J. Anal. Appl. Pyrolysis 2022, 166, 105614. [Google Scholar] [CrossRef]

- Mondal, P.; Das, A.; Wazeer, A.; Karmakar, A. Biomedical porous scaffold fabrication using additive manufacturing technique: Porosity, surface roughness and process parameters optimization. Int. J. Lightweight Mater. Manuf. 2022, 5, 384–396. [Google Scholar] [CrossRef]

- Oehrlein, G.S.; Phaneuf, R.J.; Graves, D.B. Plasma-polymer interactions: A review of progress in understanding polymer resist mask durability during plasma etching for nanoscale fabrication. J. Vac. Sci. Technol. B 2011, 29, 010801. [Google Scholar] [CrossRef]

- Engoor, G.G.; Dewangan, V.K.; Latiyan, S.; Kumar, T.S.S.; Sujatha, N.; Palani, I.A.; Vasa, N.J. Synthesis and characterization of TiO2–ZnO composite thin films for biomedical applications. Biomed. Mater. 2025, 20, 025023. [Google Scholar] [CrossRef]

- Hrbek, T.; Kúš, P.; Yakovlev, Y.; Novakova, J.; Lobko, Y.; Khalakhan, I.; Matolin, V.; Matolinova, I. Sputter-etching treatment of proton-exchange membranes: Completely dry thin-film approach to low-loading catalyst-coated membranes for water electrolysis. Int. J. Hydrogen Energy 2020, 45, 20776–20786. [Google Scholar] [CrossRef]

- Tserepi, A.; Gogolides, E.; Bourkoula, A.; Kanioura, A.; Kokkoris, G.; Petrou, P.S.; Kakabakos, S.E. Plasma Nanotextured Polymeric Surfaces for Controlling Cell Attachment and Proliferation: A Short Review. Plasma Chem. Plasma Process. 2016, 36, 107–120. [Google Scholar] [CrossRef]

- Yakovlev, Y.; Nováková, J.; Kúš, P.; Dinhová, T.; Matolínová, I.; Matolín, V. Highly developed nanostructuring of polymer-electrolyte membrane supported catalysts for hydrogen fuel cell application. J. Power Sources 2019, 439, 227084. [Google Scholar] [CrossRef]

- Gravis, D.; Rigolé, G.; Yengui, M.; Knapp, W.; Coulon, J.F.; Poncin-Epaillard, F. Enhancement of metal adhesion, owing to the plasma texturing of PEEK. Plasma Process. Polym. 2021, 18, 2100009. [Google Scholar] [CrossRef]

- Lambare, C.; Tessier, P.-Y.; Poncin-Epaillard, F.; Debarnot, D. Plasma functionalization and etching for enhancing metal adhesion onto polymeric substrates. RSC Adv. 2015, 5, 62348–62357. [Google Scholar] [CrossRef]

- Yudhanto, A.; Li, X.; Tao, R.; Melentiev, R.; Lubineau, G. Identifying adhesion characteristics of metal-polymer interfaces: Recent advances in the case of electroplated acrylonitrile butadiene styrene. Mater. Today Commun. 2023, 35, 106218. [Google Scholar] [CrossRef]

- Berumen, J.; De la Mora, T.; López-Perrusquia, N.; Jiménez-Palomar, I.; Muhl, S.; Hernández-Navarro, C.; García, E. Structural, chemical and mechanical study of TiAlV film on UHMWPE produced by DC magnetron sputtering. J. Mech. Behav. Biomed. Mater. 2019, 93, 23–30. [Google Scholar] [CrossRef]

- Fumagalli, N.; de Haro Sanchez, J.C.; Bianchi, C.L.; Turri, S.; Griffini, G. Metallization of polypropylene substrates through surface functionalization and physical vapor deposition of chromium coatings. Surf. Coat. Technol. 2024, 484, 130880. [Google Scholar] [CrossRef]

- Civantos, A.; Martínez-Campos, E.; Ramos, V.; Elvira, C.; Gallardo, A.; Abarrategi, A. Titanium coatings and surface modifications: Toward clinically useful bioactive implants. ACS Biomater. Sci. Eng. 2017, 3, 1245–1261. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Zhao, Y. Biocompatibility and antibacterial performance of titanium by surface treatment. J. Coat. Technol. Res. 2012, 9, 223–228. [Google Scholar] [CrossRef]

- Yu, S.; Guo, D.; Han, J.; Sun, L.; Zhu, H.; Yu, Z.; Dargusch, M.; Wang, G. Enhancing antibacterial performance and biocompatibility of pure titanium by a two-step electrochemical surface coating. ACS Appl. Mater. Interfaces 2020, 12, 44433–44446. [Google Scholar] [CrossRef]

- Alekseeva, O.K.; Lutikova, E.K.; Markelov, V.V.; Porembsky, V.I.; Fateev, V.N. Stationary and pulsed magnetron sputtering technologies for protective/catalyst layer production for PEM systems. Int. J. Electrochem. Sci. 2018, 13, 797–811. [Google Scholar] [CrossRef]

- Saoula, N.; Djerourou, S.; Yahiaoui, K.; Henda, K.; Kesri, R.; Erasmus, R.; Comins, J. Study of the deposition of Ti/TiN multilayers by magnetron sputtering. Surf. Interface Anal. 2010, 42, 1176–1179. [Google Scholar] [CrossRef]

- Liu, Z.; Lin, H.; Wang, Z.; Chen, L.; Wu, T.; Pang, Y.; Cai, L.; He, J.; Peng, S.; Shen, H.; et al. Dual functional dopant-free contacts with titanium protecting layer: Boosting stability while balancing electron transport and recombination losses. Adv. Sci. 2022, 9, 2202240. [Google Scholar] [CrossRef]

- Wu, S.; Chen, H.; Du, X.; Liu, Z. Effect of deposition power and pressure on rate deposition and resistivity of titanium thin films grown by DC magnetron sputtering. Spectrosc. Lett. 2016, 49, 514–519. [Google Scholar] [CrossRef]

- Liu, C.; Shviro, M.; Gago, A.S.; Zaccarine, S.F.; Bender, G.; Gazdzicki, P.; Morawietz, T.; Biswas, I.; Rasinski, M.; Everwand, A.; et al. Exploring the Interface of skin-layered titanium fibers for electrochemical water splitting. Adv. Energy Mater. 2021, 11, 2002926. [Google Scholar] [CrossRef]

- Takizawa, T.; Nakayama, N.; Haniu, H.; Aoki, K.; Okamoto, M.; Nomura, H.; Tanaka, M.; Sobajima, A.; Yoshida, K.; Kamanaka, T.; et al. Titanium fiber plates for bone tissue repair. Adv. Mater. 2018, 30, 1703608. [Google Scholar] [CrossRef]

- Kotha, S.; Li, C.; McGinn, P.; Schmid, S.; Mason, J. Improved mechanical properties of acrylic bone cement with short titanium fiber reinforcement. J. Mater. Sci. Mater. Med. 2006, 17, 1403–1409. [Google Scholar] [CrossRef] [PubMed]

- Jung, M.J.; Nam, K.H.; Shaginyan, L.R.; Han, J.G. Deposition of Ti thin film using the magnetron sputtering method. Thin Solid Films 2003, 435, 145–149. [Google Scholar] [CrossRef]

- Reznickova, A.; Kolska, Z.; Hnatowicz, V.; Svorcik, V. Nano-structuring of PTFE surface by plasma treatment, etching, and sputtering with gold. J. Nanoparticle Res. 2011, 13, 2929–2938. [Google Scholar] [CrossRef]

- Fu, R.; Yang, Y.; Lu, C.; Ming, Y.; Zhao, X.; Hu, Y.; Zhao, L.; Hao, J.; Chen, W. Large-Scale Fabrication of High-Performance Ionic Polymer–Metal Composite Flexible Sensors by in Situ Plasma Etching and Magnetron Sputtering. ACS Omega 2018, 3, 9146–9154. [Google Scholar] [CrossRef]

- Du, K.; Jiang, Y.; Huang, P.-S.; Ding, J.; Gao, T.; Choi, C.-H. Self-formation of polymer nanostructures in plasma etching: Mechanisms and applications. J. Micromech. Microeng. 2017, 28, 014006. [Google Scholar] [CrossRef]

- Neděla, O.; Slepička, P.; Švorčík, V. Surface modification of polymer substrates for biomedical applications. Materials 2017, 10, 1115. [Google Scholar] [CrossRef]

- Di Mundo, R.; Troia, M.; Palumbo, F.; Trotta, M.; d’Agostino, R. Nano-texturing of Transparent Polymers with Plasma Etching: Tailoring Topography for a Low Reflectivity. Plasma Process. Polym. 2012, 9, 947–954. [Google Scholar] [CrossRef]

- Ellinas, K.; Pujari, S.P.; Dragatogiannis, D.A.; Charitidis, C.A.; Tserepi, A.; Zuilhof, H.; Gogolides, E. Plasma micro-nanotextured, scratch, water and hexadecane resistant, superhydrophobic, and superamphiphobic polymeric surfaces with perfluorinated monolayers. ACS Appl. Mater. Interfaces 2014, 6, 6510–6524. [Google Scholar] [CrossRef]

- Hrbek, T.; Kúš, P.; Kosto, Y.; Rodríguez, M.G.; Matolínová, I. Magnetron-sputtered thin-film catalyst with low-Ir-Ru content for water electrolysis: Long-term stability and degradation analysis. J. Power Sources 2023, 556, 232375. [Google Scholar] [CrossRef]

- Looijmans, S.F.; Anderson, P.D.; van Breemen, L.C. Contact mechanics of high-density polyethylene: Effect of pre-stretch on the frictional response and the onset of wear. Wear 2018, 410–411, 142–148. [Google Scholar] [CrossRef]

- Dasari, A.; Duncan, S.; Misra, R. Micro-and nano-scale deformation processes during scratch damage in high density polyethylene. Mater. Sci. Technol. 2003, 19, 239–243. [Google Scholar] [CrossRef]

- Xiang, C.; Sue, H.J.; Chu, J.; Coleman, B. Scratch behavior and material property relationship in polymers. J. Polym. Sci. Part B Polym. Phys. 2001, 39, 47–59. [Google Scholar] [CrossRef]

- Guermazi, N.; Elleuch, K.; Ayedi, H.; Zahouani, H.; Kapsa, P. Susceptibility to scratch damage of high density polyethylene coating. Mater. Sci. Eng. A 2008, 492, 400–406. [Google Scholar] [CrossRef]

- Puliyalil, H.; Cvelbar, U. Selective plasma etching of polymeric substrates for advanced applications. Nanomaterials 2016, 6, 108. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vargas-Oliva, E.Y.; Hernández-Navarro, C.; Guzman-Ayon, V.; Ceballos-Muez, M.d.P.J.; García-Bustos, E.D.; Doñu-Ruiz, M.A.; López-Perrusquia, N.; Flores-Martínez, M.; Muhl-Saunders, S. Synthesis and Characterization of Titanium Layer with Fiber-like Morphology on HDPE by Plasma Treatment. Coatings 2025, 15, 995. https://doi.org/10.3390/coatings15090995

Vargas-Oliva EY, Hernández-Navarro C, Guzman-Ayon V, Ceballos-Muez MdPJ, García-Bustos ED, Doñu-Ruiz MA, López-Perrusquia N, Flores-Martínez M, Muhl-Saunders S. Synthesis and Characterization of Titanium Layer with Fiber-like Morphology on HDPE by Plasma Treatment. Coatings. 2025; 15(9):995. https://doi.org/10.3390/coatings15090995

Chicago/Turabian StyleVargas-Oliva, Erick Yair, Carolina Hernández-Navarro, Violeta Guzman-Ayon, María del Pilar Jadige Ceballos-Muez, Ernesto David García-Bustos, Marco Antonio Doñu-Ruiz, Noé López-Perrusquia, Martin Flores-Martínez, and Stephen Muhl-Saunders. 2025. "Synthesis and Characterization of Titanium Layer with Fiber-like Morphology on HDPE by Plasma Treatment" Coatings 15, no. 9: 995. https://doi.org/10.3390/coatings15090995

APA StyleVargas-Oliva, E. Y., Hernández-Navarro, C., Guzman-Ayon, V., Ceballos-Muez, M. d. P. J., García-Bustos, E. D., Doñu-Ruiz, M. A., López-Perrusquia, N., Flores-Martínez, M., & Muhl-Saunders, S. (2025). Synthesis and Characterization of Titanium Layer with Fiber-like Morphology on HDPE by Plasma Treatment. Coatings, 15(9), 995. https://doi.org/10.3390/coatings15090995