Abstract

Bacterial nanocellulose (BNC) composite films have emerged as promising candidates for sustainable building materials, yet their practical application in building-integrated photovoltaics (BIPV) facade systems is hindered by insufficient mechanical strength, poor environmental stability, and limited energy efficiency. Here, we developed bacterial nanocellulose/zinc oxide–phenolic resin (BNC/ZnO–PF) composite films with high-strength, stability, and energy efficiency for BIPV facade system through a simple strategy. Specifically, we first prepared BNC films, then in-situ grew ZnO nanoparticles on BNC films via ultrasound assistance, and finally hot-pressed the BNC/ZnO films with PF resin. The BNC/–PF composite films exhibit high mechanical strength (tensile strength of 93.8 MPa), exceptional sturdiness (wet strength of 92.3 MPa), and thermal properties, demonstrating their durability for long-term outdoor applications. Furthermore, the BNC/ZnO–PF composite films show high transparency (86.47%) and haze (82.02%) in the visible light range, enabling effective light propagation and scattering, as well as soft, uniform, and large-area light distribution. Meanwhile, a low thermal conductivity of 21.7 mW·m−1·K−1 can effectively impede the transfer of high outdoor temperatures into the room, significantly reducing the energy consumption demands of heating and cooling systems. Coupled with its ability to en-hance the photovoltaic conversion efficiency of solar cells by 12.9%, this material can serve as the core encapsulation layer for BIPV facades. While enabling build-ing-integrated photovoltaic power generation, through the synergistic effect of light management and thermal insulation, it is expected to reduce comprehensive building energy consumption, providing a new solution for building energy efficiency under carbon neutrality goals.

1. Introduction

Optical management films with high transmittance and light diffusivity are widely used in organic light-emitting diodes (OLEDs) [1,2], solar cells [3,4,5], transistors [6], touchscreen electrodes [7], optical sensors [8,9,10], and energy-efficient buildings [11,12,13]. BIPV utilize photovoltaic cells embedded in window, exterior wall, or roof materials to capture solar energy and convert it into electrical energy. This method not only provides renewable energy generation but also minimizes reliance on electricity from the traditional power grid, thereby reducing the carbon footprint of buildings. BIPV encapsulation materials require a synergistic combination of high transmittance, mechanical robustness, environmental stability, and sustainability [11,14,15]. For instance, solar cell substrates demand not only optical efficiency but also thermal stability to withstand outdoor conditions [16,17], while building-integrated films need wet strength retention to resist humidity [18]. However, BIPV encapsulation materials use traditional substrates made from non-biodegradable and non-renewable petroleum-based polymers (polyethylene terephthalate (PET) [19] and polycarbonate (PC) [20] etc.) and heavy, fragile glass, leading to high energy consumption and severe environmental pollution [21,22]. More importantly, such materials have poor light management capabilities, causing uneven illumination and uncomfortable glare [11]. Thus, the growing global energy demand and heightened environmental awareness necessitate the development of efficient and sustainable energy-saving optical management films to reduce energy consumption and carbon emissions.

Cellulose, a key component of biomass, can be processed into various cellulose nanomaterials. These nanomaterials have attracted extensive attention in sustainable material science due to their excellent mechanical properties, biodegradability, and renewability, and have been widely developed for light management materials, such as transparent wood/bamboo (a wood-based material with high optical transmittance prepared by removing lignin and impregnating the wood matrix with a transparent polymer [23,24,25,26]) and transparent paper [27,28,29,30] for light management applications. For transparent wood, the rich amounts of lignin in natural wood should be effectively removed while preserving the wood/cellulose structure. Such processes consume more energy and time, reducing production efficiency [31]. Cellulose-based transparent paper, however, typically has limited mechanical properties, insufficient to support large-scale and wide-range use [5].

Given the limitations of traditional petroleum-based polymers and glass in light management applications, this study aims to develop a high-performance, sustainable alternative. Specifically, we seek to fabricate a bacterial nanocellulose-based composite film with excellent mechanical strength, stability, and light management capabilities, which can enhance the efficiency of optoelectronic devices such as solar cells while meeting environmental sustainability requirements. BNC possesses unique physicochemical properties, including elasticity, high tensile strength, high surface area, high porosity, and a nanoscale three-dimensional network structure [32,33,34], making it an excellent substrate. However, its inherent hydrophilicity and loose structure lead to poor water stability and low tensile strength, limiting large-scale applications [35]. ZnO nanoparticles, as metal semiconductor materials, exhibit enhanced light absorption and infrared radiation scattering capabilities due to their large specific surface area and unique optical properties [36], thereby enhancing the thermal insulation performance of BNC/ZnO–PF composite films. Additionally, the incorporation of ZnO increases the surface roughness of the composite films, which reduces light reflectivity and thus enhances light absorption [37]. PF resin provides strong adhesion, thermal resistance, and hydrophobicity, which can densify porous structures and improve mechanical strength [38,39]. However, its brittleness may compromise flexibility if not properly blended with a fibrous matrix like BNC. Hot-pressing enables a dense film structure with sufficient chemical/hydrogen bonding between BNC fibers and PF resin. This structural and chemical disparity endows the designed BNC/ZnO–PF composite films with high mechanical properties and sturdiness. Additionally, the cellulose composite films exhibit other advantages, including excellent thermal stability, energy-saving, and thermal insulation properties. More importantly, as an advanced light management layer, BNC/ZnO–PF composite films significantly enhance the photoelectric conversion efficiency of photovoltaic devices. Moreover, as an advanced light management layer that enhances the photovoltaic conversion efficiency of solar devices, these composite films can synergize with BIPV systems integrated into building facades: while enabling buildings to generate renewa-ble electricity on-site, they optimize the utilization of solar energy through their optical properties, further reducing dependence on traditional power grids. Compared with conventional petroleum-based polymer or glass substrates, BNC/ZnO–PF composite films, derived from renewable bacterial nanocellulose, also align with the concept of circular economy due to their potential biodegradability, avoiding environmental pol-lution caused by non-renewable materials. Such multifunctional integra-tion—combining light management, thermal insulation, photovoltaic efficiency en-hancement, and sustainability—positions these composite films as a promising solu-tion to address the dual challenges of building energy consumption and environmental protection.

2. Experimental Section

2.1. Experimental Materials and Reagents

Acetobacter xylinum (SHBCC D80041) was provided by the Shanghai Bioresource Collection and Preservation Center (Shanghai, China). D-glucose anhydrous, yeast extract, and peptone were purchased from Shanghai Tongtian Biotechnology Co., Ltd. (Shanghai, China). The PF resin used in this study is a thermosetting resin purchased from Henan Borun New Materials Co., Ltd. (Xinxiang, China). It has a solid content of 40 wt%, a viscosity of 250–350 mPa·s, and a curing temperature range of 120–150 °C. Zinc acetate dihydrate (Zn(CH3COO)2·2H2O), absolute ethanol (CH3CH2OH), and ammonium hydroxide (NH4OH) were all purchased from Sinopharm Chemical Reagent Co., Ltd. (Shanghai, China). Other chemical reagents used in this study were of analytical grade and used without further purification.

2.2. Preparation of BNC Films

Acetobacter xylinum was taken out from −80 °C and inoculated into HS medium containing 20 g/L D-glucose anhydrous, 5 g/L yeast extract, 5 g/L peptone, 2.7 g/L disodium hydrogen phosphate, and 1.15 g/L citric acid (pH 6.0). After static activation at 30 °C for 48 h, the seed solution was prepared by expanding the culture with a 5% inoculation amount for 24 h. The medium raw materials with the same components were weighed and dissolved in distilled water. After sterilization, 10% seed solution was inoculated, and static culture was carried out at 30 °C for 7–10 days until a BNC film formed on the liquid surface. After collecting and washing the film, it was cut into small pieces (10 cm × 10 cm) using sterile tweezers in a clean bench. The cut step was performed to facilitate uniform drying and avoid uneven shrinkage during the subsequent drying process, which could lead to warping or cracking of the film. To control the film thickness by a vacuum suction filtration setup (model SHB-III, Zhengzhou Greatwall Scientific Industrial & Trade Co., Ltd., Zhengzhou, China), the BNC pieces were evenly spread on wet qualitative filter paper in the suction filtration funnel, and the vacuum pressure (0.08 MPa) and filtration time (0.5 h) were strictly controlled to ensure consistent compaction of the BNC network. After filtration, the filter cake was dried in an oven at 40 °C to constant weight, and the filter paper was peeled off to obtain BNC films.

2.3. Preparation of BNC/ZnO Composite Films

To prepare BNC/ZnO composite films, we employed an impregnation method. Zn(CH3COO)2·2H2O was used as the zinc ion precursor. Zn(CH3COO)2·2H2O (0.1 mol/21.95 g) was dissolved in 200 mL of a water–ethanol (1:9) mixture. The solution was stirred vigorously at 50 °C. After the complete dissolution of Zn(CH3COO)2·2H2O, the BNC film was immersed in the Zn(CH3COO)2·2H2O solution for 3 h. Then the Zn(CH3COO)2·2H2O-soaked BNC film was immersed in 200 mL of ammonium hydroxide solution (pH 8) equipped with a high-intensity ultrasonic bath for ultrasonic treatment for 1 h. The ultrasonic treatment was performed using an ultrasonic cleaner (SB-100D, Ningbo Xinzhi Biotechnology Co., Ltd., Ningbo, China) with a power of 100 W, a frequency of 40 kHz, and a temperature set at 30 ± 2 °C. After ultrasonic treatment, the BNC film was washed with a large amount of distilled water to prepare BNC/ZnO composite films.

2.4. Preparation of BNC/ZnO–PF Composite Films

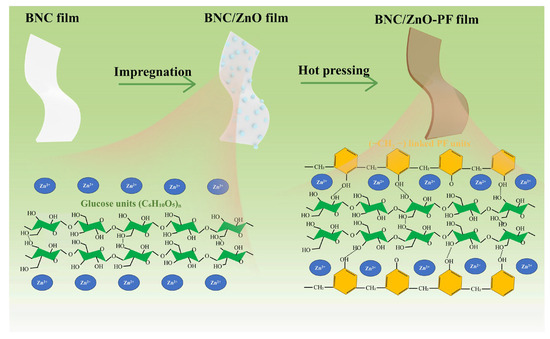

We first prepared BNC films, then in-situ grew ZnO nanoparticles on BNC films via ultrasound assistance, and finally filled PF resin into the BNC/ZnO skeleton followed by hot-pressing treatment. The prepared cellulose film was immersed in a PF solution for 20 min. Subsequently, the wet cellulose–PF material was hot-pressed (WT-LHY, Dongguan Kajiang Technology Co., Ltd., Dongguan, China) at 135 °C under a pressure of ~20 MPa for 10 min to fabricate BNC/ZnO-PF (Figure 1). In addition, we also prepared PF resin films as control samples through a similar hot-pressing process.

Figure 1.

The preparation of BNC/ZnO-PF film. Firstly, using BNC as the template, nano-ZnO was synthesized by the impregnation method. The BNC sample was immersed in a mixed solution of Zn(CH3COO)2·2H2O and NaOH to allow the Zn2+ to penetrate the cellulose network. Then, ultrasonic assistance was used to promote the in-situ synthesis of nano-ZnO. Subsequently, through a combined treatment process of filling PF resin and hot pressing, the PF is deposited on the surface of nanocellulose fibers and densifies the BNC/ZnO–PF film. Hydroxyl groups form abundant hydrogen bonds, which can enhance the bonding between nanocellulose fibers and PF resins.

2.5. Preparation of GaAs Batteries with BNC/ZnO–PF Films

The BNC/ZnO–PF film was attached onto the gallium arsenide solar cells (GaAs) (FullSuns Corporation, Shanghai, China) without any antireflection layers. Poly(vinyl alcohol) solution (200 μL, 10 wt%) was used as a binder between the BNC/ZnO–PF film and the GaAs.

2.6. Material Characterization

The morphology of the samples was examined using micrographs obtained from a scanning electron microscope (SEM, Zeiss Supra55, Carl Zeiss AG, Oberkochen, Germany). The elemental compositions were detected by energy dispersive spectroscopy (EDS) equipped on the SEM. Fourier transform infrared (FTIR) spectra were collected over the wavenumber range of 400–4000 cm−1 with a resolution of 4 cm−1. X-ray photoelectron spectroscopy (XPS) analysis was used to study the surface chemical compositions by using a Thermo Scientific K-Alpha X-ray photoelectron spectrometer (Thermo Scientific, Waltham, MA, USA). Mechanical tests were conducted by using a CMT6103 universal testing machine (Jinan Chenxin Testing Machine Manufacturing Co., Ltd., Jinan, China) with a 2000 N load cell. The rate was set to 5 mm min− 1 during stress–strain tests. The light transmittance and haze of the samples in the visible light range (390–780 nm) were tested using the light transmittance and haze tester (CMT6103, Mattel Industrial Systems (China) Co., Ltd., Shanghai, China). The thermal stability was determined by using a Thermogravimetric (TG) analyzer (TA, Q600, New Castle, DE, USA) from room temperature to 800 °C at the heating rate of 10 °C min−1 under N2 atmosphere. The thermal conductivity of the samples was tested using the German-NetzSCH-LFA 447. The thermal conductivity of the samples was tested by the PPMS (Quantum Design-MPMS37T, San Diego, CA, USA). Water contact angles for the samples were analyzed using a DSA-100 instrument (Krüss, Hamburg, Germany) by the sessile-drop method. The corresponding infrared images were recorded by a thermal infrared imager (UNI-T, Uti220A) to illustrate the surface temperature distribution. The reflectivity of the GaAs solar cell with or without BNC/ZnO–PF film for λ = 550 nm was measured using the spectrophotometer (Specord 250 Plus, Jena Analytical Instruments AG, Jena, Germany) equipped with an integral sphere. The incident light intensity was calibrated at 100 mW·cm−2 using a standard Si solar cell. To obtain the J–V curves, the linear sweep voltammetry method was employed with a Keithley 2400 source-measure unit.

3. Results and Discussion

3.1. Morphological and Chemical Characterization of BNC/ZnO–PF Films

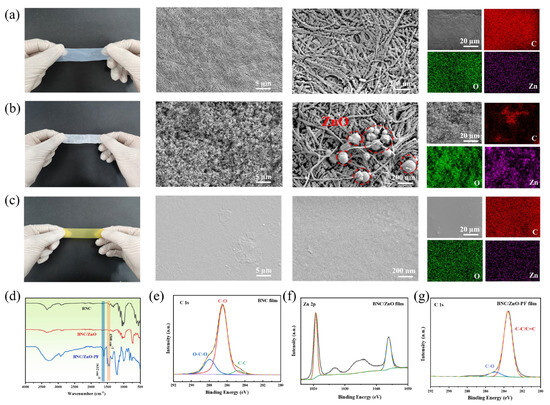

The morphological characteristics and elemental compositions of BNC, BNC/ZnO, and BNC/ZnO–PF films were determined by SEM and EDS, and the results are shown in Figure 2a–c. The fibers on the surface of the intact BNC film overlapped and closed with each other, forming a loose porous structure (Figure 2a), which may negatively affect the optical and mechanical properties (e.g., tensile strength and transparency). Elemental distribution showed that C and O elements were uniformly distributed on the surface of the BNC film, whereas the Zn element only exhibited significant background noise. The elemental content data also showed that the BNC film contained a large amount of C and O, but did not contain Zn (Table S1, Supporting Information). With the impregnation method synthesis of ZnO, ZnO nanoparticles were distributed in the bacterial cellulose network, with partial agglomeration observed due to the high surface energy of nanoscale particles (Figure 2b). The ultrasonic-assisted method has been widely used in the preparation of new nanomaterials with diverse properties, as it enables the production of nanoparticles with smaller sizes and controlled shapes [40,41]. When liquids are subjected to ultrasonic irradiation, acoustic cavitation––i.e., the formation, growth, and immediate collapse of bubbles in the liquid––induces high temperatures, high pressures, and extremely rapid cooling rates, which accelerate the hydrolysis of zinc acetate [42,43]. Meanwhile, strong shock waves and micro-jets generated by cavitation promote the nucleation and growth of ZnO crystals, limiting particle agglomeration that would otherwise occur with continuous mechanical stirring. The results show that the ZnO nanoparticles synthesized by the ultrasonic-assisted method are spherical with an average particle size in the range of 80–120 nm, which is comparable to the size of ZnO nanoparticles prepared by similar methods reported [44,45,46,47,48]. Compared with the intact BNC film, the surface roughness of the BNC/ZnO film increased significantly, thereby reducing light reflectance and enhancing light absorption. Additionally, the elemental composition of the BNC/ZnO film indicated that C, O, and Zn elements were uniformly distributed on its surface, providing further evidence for the impregnation method synthesis of ZnO nanoparticles. The element content is shown in Table S2 (Supporting Information). Through PF resin filling and hot pressing, it was clearly observed that the surface of the BNC/ZnO–PF film became flat and smooth (similar to the SEM image of the PF resin film (Figure S1, Supporting Information)), indicating a tight bonding between bacterial nanocellulose fibers and PF resin. Elemental distribution showed that the signal of Zn element almost disappeared again due to the uniform filling of PF resin (Table S3, Supporting Information). Furthermore, the cross-sectional SEM images of BNC (Thinkness: ~0.17 mm), BNC/ZnO (Thinkness: ~0.18 mm), and BNC/ZnO–PF (Thinkness: ~0.09 mm) also confirmed the above results (Figure S2, Supporting Information).

Figure 2.

The morphological characteristics and chemical compositional characterizations of the BNC/ZnO-PF film. (a–c) Picture, SEM, and EDS images of BNC, BNC/ZnO, and BNC/ZnO–PF film. (d) FT-IR spectra of BNC, BNC/ZnO, and BNC/ZnO-PF fllm. (e) The XPS high-resolution C1s spectrum of BNC film. (f,g) The XPS high-resolution Zn2p and C1s spectrum of BNC/ZnO–PF film.

The chemical structures of BNC, BNC/ZnO, and BNC/ZnO–PF films were further studied by FT-IR spectroscopy. The spectrum of the BNC film shows typical cellulose characteristic peaks: a broad and intense peak at 3320 cm−1 corresponding to the stretching vibration of hydroxyl groups (-OH) in the cellulose molecular chain, which is a key feature of the abundant hydrogen bonds in BNC [49]. The peak at 2851 cm−1 is attributed to the symmetric stretching vibration of methylene groups (-CH2) in the glucose ring [50]. Additionally, the peak at 1029 cm−1 is associated with the C–O–C stretching vibration of the pyranose ring, confirming the presence of the cellulose backbone structure [51]. Compared with the BNC film, the FTIR spectrum of the BNC/ZnO film shows no significant new peaks, but there is a slight shift in the -OH peak (from 3320 cm−1 to 3315 cm−1). This shift indicates that ZnO nanoparticles interact with the hydroxyl groups of BNC through coordination bonds or hydrogen bonds. In the BNC/ZnO–PF film, compared with PF resin FT–IR spectra (Figure S3, Supporting Information), typical characteristic peaks of PF resin functional groups were observed, including peaks at 1508 cm−1 and 1612 cm−1 belonging to the benzene ring, and characteristic peaks at 3320 cm−1, 2851 cm−1, and 1029 cm−1 belonging to -OH, -CH2 groups, and C–O–C of the pyranose ring in cellulose molecules [52,53], directly confirming the successful introduction of PF resin into the composite film. We also used XPS to analyze the chemical elements of BNC, BNC/ZnO, and BNC/ZnO–PF films (Figure S4, Supporting Information). For the high-resolution C 1s spectrum of the BNC film (Figure 2e), there were three peaks at 284.6 eV, 286.7 eV, and 288.3 eV, corresponding to C–C/C=C, C–O, and O–C–O bonds in cellulose [54,55]. For the high-resolution Zn 2p spectrum of the BNC/ZnO film (Figure 2f), the XPS peaks at 1021.8 eV and 1044.7 eV corresponded to the 2p3/2 and 2p1/2 energy peaks of Zn2+ ions (ZnO), respectively [56]. For the high-resolution C 1s spectrum of the BNC/ZnO–PF film (Figure 2g), a new peak appeared at 287.2 eV, indicating the presence of C=O bonds in the BNC/ZnO-PF film [57], which was in good agreement with the FT–IR results. The high-resolution O 1s spectrum results (Figure S5, Supporting Information) also showed that the high-resolution C 1s spectrum indicated C–O–C (530.4 eV), O–C (531.6 eV), O–H (532.4 eV), and O=C (531.0 eV) bonds in the BNC/ZnO–PF film. Also, the XPS peaks at 1021.4 eV and 1044.6 eV corresponded to the 2p3/2 and 2p1/2 energy peaks of Zn2+ ions (ZnO), respectively (Figure S6, Supporting Information).

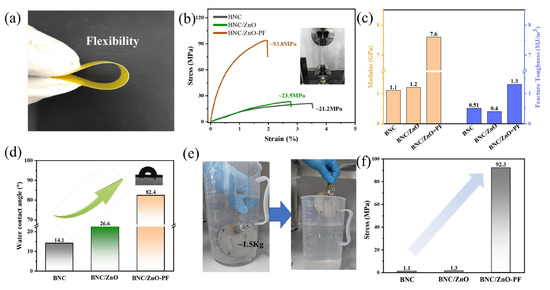

3.2. The Mechanical Properties and Water Stability of BNC/ZnO-PF Fllm

Benefiting from the high flexibility of BNC fibers and PF resin and their good bonding, the BNC/ZnO–PF film can be easily bent, demonstrating its excellent flexibility, as shown in Figure 3a. Figure 3b shows the stress–strain curves of BNC, BNC/ZnO, and BNC/ZnO–PF samples. Previous reports have indicated that ZnO nanoparticles can alter the mechanical properties of bacterial cellulose films, specifically characterized by enhanced tensile properties and reduced flexibility. Our experiment yielded similar results: due to the formation of weak coordination bonds between -OH groups in BNC and Zn2+ in ZnO, the tensile strength of the BNC/ZnO film (23.5 MPa) increased by approximately 10.6% relative to the BNC film (21.2 MPa). Additionally, as a result of increased density, the flexibility decreased, and the fracture strain dropped significantly. It is worth noting that the BNC/ZnO–PF film (~93.8 MPa) exhibited a high tensile strength, more than four times higher than that of the initial BNC film (~21.2 MPa), while the density of the BNC/ZnO–PF film was only about twice that of the BNC film (Figure S7, Supporting Information). This result outperforms some reported light-management cellulose-based films, such as cellulose/poly(m-phenylene isophthalamide) films (55.9 MPa) [58], silica acrylic emulsion/carbon dot/recycled cellulose films (~60 MPa) [59], and cellulose films prepared via nucleophilic post-modification (~80 MPa) [60]. In addition, the tensile strength of BNC/ZnO–PF films is significantly higher than that of pure PF resin films (Figure S8, Supporting Information). The excellent mechanical properties of BNC/ZnO–PF are attributed to the sufficient chemical/hydrogen bonds between BNC fibers and PF resin, as well as the dense film structure formed thereby. Additionally, the BNC/ZnO–PF film had a modulus of 7.6 GPa, while the BNC and BNC/ZnO films had approximately 1.1 GPa and 1.2 GPa, respectively. It is worth noting that although the tensile strength (165 MPa) of commercial glass materials [61] exceeds that of the BNC/ZnO–PF film, it tends to fail suddenly under load and has limited strain (only 0.004%). The fracture toughness (1.4 MJ·m−3) of the BNC/ZnO–PF film is significantly higher than that of BNC (0.5 MJ·m−3) and BNC/ZnO films (0.4 MJ·m−3), and is three orders of magnitude higher than that of commercial glass materials (0.003 MJ·m−3) [62]. This makes our BNC/ZnO–PF film less prone to breakage when used as a light management material, greatly improving its safety in use.

Figure 3.

The mechanical properties and water stability of BNC/ZnO–PF film. (a) The BNC/ZnO–PF film in the bended condition. (b) Tensile stress–strain curves of the BNC, BNC/ZnO and BNC/ZnO–PF film, where the tensile strength of the BNC/ZnO–PF fllm is much higher than the BNC and BNC/ZnO. (c) Bar charts of tensile strength and fracture toughness of B BNC, BNC/ZnO and BNC/ZnO–PF film. (d) Comparison of water contact angles of BNC, BNC/ZnO, and BNC/ZnO–PF film. (e) The underwater load-bearing test of BNC/ZnO–PF film. (f) The wet tensile strength of the BNC, BNC/ZnO, and BNC/ ZnO–PF film.

Cellulose materials are highly hydrophilic, so their unstable performance in water limits their application in various engineering and material fields. In the BNC/ZnO–PF film, a hydrophobic interface of PF resin was formed on its surface by hot pressing, effectively preventing water penetration. Through water contact angle (WCA) testing, the WCA of the BNC/ZnO–PF film (82.4°) was significantly larger than that of BNC (14.1°) and BNC/ZnO film (26.6°), as shown in Figure 3d. This enables our BNC/ZnO–PF film to have ideal stability in water environments, while BNC and BNC/ZnO films exhibit obvious hydrophilicity (Figure S9, Supporting Information). It is worth noting that the BNC/ZnO–PF film can withstand a strong load of 1.5 kg underwater (Figure 3e), which is almost impossible for the hydrophilic BNC film (Figure S10, Supporting Information). More specifically, the wet strength of the BNC/ZnO–PF film is approximately 92.3 MPa (Figure 3f), similar to its strength under dry conditions (~93.8 MPa). With the change of working conditions from dry to humid environments, the tensile strengths of BNC and BNC/ZnO films sharply decrease to about 1.1 MPa and 1.3 MPa, respectively. This is mainly because the naturally hydrophobic PF resin well covers the BNC fibers and fully fills the fiber scaffold of the BNC film, enabling it to have excellent mechanical properties in water environments.

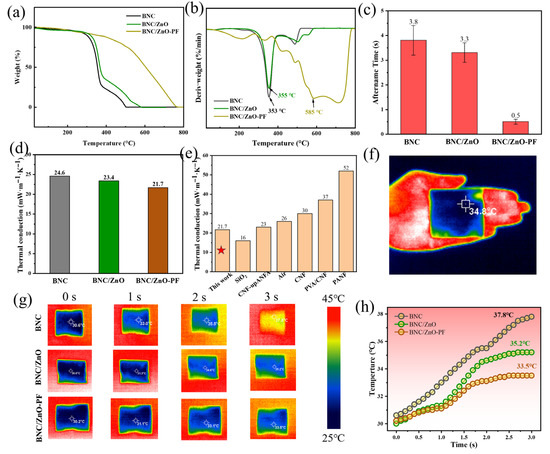

3.3. The Thermal and Thermal Insulation Performance

In addition to excellent mechanical properties, the BNC/ZnO–PF film also exhibits good thermal stability and thermal insulation performance. Figure 4a,b show the TG and Derivative Thermogravimetric (DTG) curves of BNC, BNC/ZnO, and BNC/ZnO–PF films. As observed from Figure 4a, BNC and BNC/ZnO films showed rapid weight loss due to thermal evaporation and started to decompose at around 300 °C. In contrast, the BNC/ZnO–PF film exhibited higher thermal stability due to the excellent thermal stability of PF itself, with almost no decomposition below 400 °C. The maximum decomposition temperature (Tmax) can be observed from Figure 4b. For BNC and BNC/ZnO films, the Tmax values were approximately 353 °C and 355 °C, respectively. The slight difference between them may be due to the interaction between ZnO and BNC. For BNC/ZnO–PF, the Tmax was 585°C, which was higher than that of pure PF resin (516 °C) (Figure S11, Supporting Information). The higher Tmax of BNC/ZnO-PF was attributed to the unique three-dimensional network structure of BNC, which can interweave with phenolic resin. When heated, the network structure of BNC can play a supporting role, restricting the movement of phenolic resin molecules and volume changes during pyrolysis, thereby making it more difficult for phenolic resin to undergo thermal decomposition. Such high thermal stability enables the BNC/ZnO–PF film to have excellent tolerance in a wide range of processing temperatures. The combustion performance of BNC, BNC/ZnO, and BNC/ZnO–PF films was evaluated by vertical combustion test, as shown in Figure 4c. After the flame was removed, the afterflame time of BNC was 3.8 s. By contrast, the afterflame time of BNC/ZnO was shortened to 3.4 s, which was due to the introduction of ZnO nanoparticles forming an inorganic physical barrier. This not only reduced the oxygen supply required for combustion but also catalyzed the carbonization of cellulose, promoting the formation of a dense char layer on the surface of the cryogel [63]. With the filling of PF resin, the afterflame time was significantly shortened to 0.5 s, which was caused by the inherent high thermal stability of PF resin.

Figure 4.

The thermal and thermal insulation performance of BNC/ZnO–PF film. (a) TGA and (b) DTG curves of BNC, BNC/ZnO, and BNC/ZnO–PF film. (c) The residual flame duration in the BNC, BNC/ZnO, and BNC/ ZnO–PF film combustion experiment. (d) The thermal conductivity of BNC, BNC/ZnO, and BNC/ ZnO–PF film. (e) Comparison of the thermal conductivity of BNC/ZnO–PF film with that of similar thermal insulation materials. (f) Infrared imaging of BNC/ZnO–PF film in the palm. (g) Infrared imaging and (h) time-temperature curves of BNC/ZnO–PF film under outdoor conditions without light.

The thermal insulation performance was evaluated by measuring the thermal conductivity of BNC, BNC/ZnO, and BNC/ZnO–PF films, as shown in Figure 4d. With the introduction of ZnO and PF resin, the thermal conductivity of the ZnO film decreased from 24.6 mW·m−1·K−1 to 21.7 mW·m−1·K−1. We explain this result from the micro, mesoscopic and macroscopic perspectives, respectively. First, from a microscopic perspective, the introduction of ZnO particles and PF resin significantly increased the material density. High-density structures will form a more complex microscopic interface network. When heat flows through, multiple scattering and reflection occur at the interfaces of the BNC matrix, ZnO particles and PF resin, thereby significantly extending the heat conduction path. This “path complication” effect effectively inhibits the directional transmission of phonons (the main carriers of heat conduction), resulting in a decrease in heat diffusivity and ultimately manifested as a decline in thermal conductivity. From the mesoscopic perspective, the addition of ZnO particles and PF resin constructed a multiphase composite interface of “BNC matrix—ZNO–PF”. Due to the differences in the vibration frequencies and propagation speeds of phonons in each phase, strong scattering effects occur at the interfaces of phonons during heat conduction. Especially, as an organic phase, the amorphous structure of PF resin itself has a relatively low thermal conductivity. The difference in interface matching formed with inorganic ZnO particles and the BNC matrix further enhances the dissipation of phonon energy. Finally, from a macroscopic perspective, the BNC/ZnO–PF films as a whole forms a low thermal conductivity network, making it difficult for heat to penetrate and thus creating a stable “thermal barrier” on the object’s surface. So compared with other thermal insulation materials (Figure 5e), BNC/ZnO–PF showed significant advantages due to its ultra-low thermal conductivity. When the BNC/ZnO–PF film was covered on the palm, the temperature of the BNC/ZnO–PF film increased slightly (the air temperature was approximately 32 °C), but the color of the palm-covered area tended to be consistent with the background (as shown in Figure 4f). The thermal insulation performance of the BNC/ZnO–PF film was further studied by measuring the temperature change of the sample above the heating source. During the experiment, the samples were placed in the shade without sunlight at the same time, and the surface temperature was approximately 40 °C. Figure 5g shows the infrared images of BNC, BNC/ZnO, and BNC/ZnO–PF films. The BNC film showed a consistently rapid temperature increase within 0–3s, reaching 37.8 °C at 3 s, while the BNC/ZnO film rapidly increased in the initial 0–2 s, then the heating rate gradually decreased, and finally reached 35.2 °C at 3 s. In contrast, the BNC/ZnO–PF film showed a gradual decrease in the heating rate throughout 0–3 s, finally stabilizing at only 33.5 °C at 3 s (Figure 4h). This result indicates that the high thermal conductivity of the sample leads to rapid heat transfer. The BNC/ZnO–PF film exhibited higher thermal resistance, effectively slowing down heat transfer, thus resulting in a slower temperature rise and lower steady-state temperature in the temperature–time curve. Such thermal insulation performance, when combined with its light management ca-pabilities, suggests that integrating BNC/ZnO–PF films into building exteriors could reduce the need for active heating and cooling systems, thereby lowering building en-ergy consumption. pecifically, the film’s low thermal conductivity of 21.7 mW·m−1·K−1 enables it to act as an efficient thermal barrier: in summer, it inhibits the transfer of high outdoor temper-atures into the interior, reducing the frequency and duration of air conditioning opera-tion required to maintain comfortable indoor temperatures; in winter, it slows down the loss of indoor heat to the external environment, thereby decreasing the energy in-put needed for heating systems. This dual-season thermal regulation effect directly alleviates the energy burden of the building’s core climate control systems.

Figure 5.

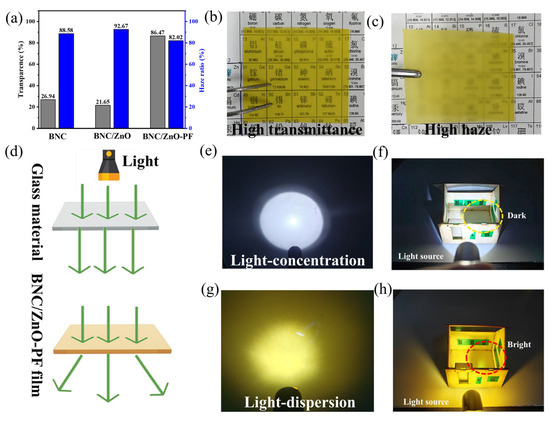

The optical characteristics of BNC/ZnO–PF fllm. (a) The transmittance and haze of BNC, BNC/ZnO, and BNC/ZnO–PF fllm in the visible light range. (b,c) Images of BNC/ ZnO–PF fllm, which enables the different readability of the letters behind the sample, demonstrating (b) high transmittance and (c) high haze. (d) Schematic diagram of light penetration of BNC/ZnO–PF fllm and commercial glass materials. Photographic evidence of the soft, uniform, and large areal lighting resulted from (g,h) our BNC/ZnO–PF fllm, in comparison to a hard and glare lighting using (e,f) glass material.

3.4. Optical Performances of BNC/ZnO–PF Fllm

BNC/ZnO–PF also exhibits excellent light management capability. Filling with PF resin significantly improves the optical transmittance of the BNC/ZnO–PF film (optical transmittance in the visible range of 390–780 nm is 86.47%), which is significantly higher than that of BNC (26.94%) and BNC/ZnO (21.65%) (Figure 5a), and it is superior to cellulose-based light-transmitting films of the same type, such as vitrimer–cellulose paper (84%) [64], benzoxazine resin/cellulose (80%) [65], and cellulose nanofibers/polymethyl methacrylate (75%–80%) [66]. High optical transmittance enables the transmission of light energy, which is crucial for the function of optoelectronic devices [67]. In addition to high transparency (Figure 5b), the BNC/ZnO–PF film also exhibits considerable light diffusion capability. As seen in Figure 5c, when the BNC/ZnO–PF film is placed 3 cm away from the background image, the underlying logo becomes visually blurred. The BNC/ZnO–PF film possesses high transparency and light scattering capability, which is considered beneficial for applications as antireflective substrates required in optoelectronic fields such as solar cells and outdoor displays. Furthermore, since ZnO is an efficient UV absorber [68], the BNC/ZnO–PF film is expected to have certain UV-shielding performance, effectively protecting human health under sunlight. Compared with commercial glass materials, which hardly scatter incident light and exhibit low haze, the light scattering capability of the BNC/ZnO–PF film caused by its high haze is beneficial for expanding the illumination area, enabling the BNC/ZnO–PF film to fully utilize sunlight (Figure 5d). This is conducive to the full utilization of solar energy, thereby achieving the goal of saving electrical energy. We further prepared downlights using the BNC/ZnO–PF film and commercial glass as transparent panels (Figure 5e,g). The downlight constructed with the BNC/ZnO–PF film emits soft, uniform, and large-area light, while the glass-assembled downlight releases harsh and glare light. Additionally, we used downlights to simulate daily sunlight to irradiate a house model. As found in Figure 5f,h, the house illuminated by the downlight with the BNC/ZnO–PF film has almost no light dead angle, and the interior of the house shows an overall bright effect, while the house model illuminated by the downlight with commercial glass as the transparent panel has large areas of dim corners. Therefore, when this material is used as building facades such as glass curtain walls, it has both light transmittance and frosted surface properties. It not only meets the building’s lighting needs while ensuring user privacy, but also effectively reduces the heat brought by direct sunlight into the building interior, thereby lowering the overall energy consumption of the building.

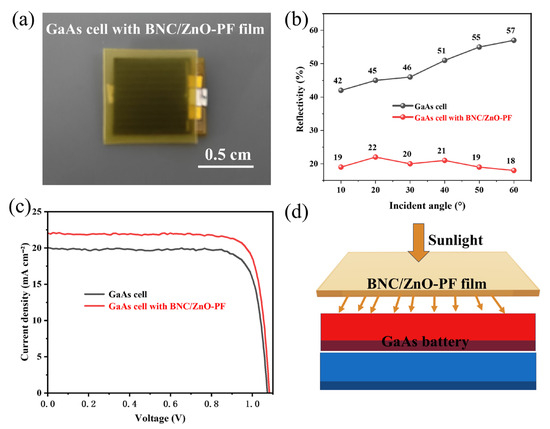

3.5. The Application of BNC/ZnO–PF Fllm in Solar Cells

The combination of high transmittance and high haze makes our BNC/ZnO–PF film a promising choice for efficient light management layers in solar cells. In this study, BNC/ZnO–PF films were used as light management layers for commercial gallium arsenide (GaAs) solar cells (Figure 6a), and their applicability was evaluated. Glass and plastics are widely used as common substrates in solar cell applications. This study demonstrates the potential of using BNC/ZnO–PF films as a viable alternative to traditional glass substrates for assembling GaAs. As shown in Figure 6b, for incident monochromatic light with a wavelength of 550 nm, the reflectance of GaAs cells on glass substrates is 42%–57%, and the reflectance generally increases with the increase of the light incident angle. By contrast, the reflectance of GaAs cells containing BNC/ZnO–PF films is significantly reduced, in the range of 19%–22%. Furthermore, their reflection is almost independent of the incident angle. The antireflective effect ultimately increases light absorption in GaAs cells. The current density–voltage (J–V) curves of GaAs cells assembled on transparent bamboo substrates or glass substrates are shown in Figure 6c. The photovoltaic characteristics of GaAs cells, such as short-circuit current density (Jsc), open-circuit voltage (Voc(V)), and fill factor (FF), are shown in Table S1. The GaAs cell prepared on a traditional glass substrate has a PCE of 17.7%, a Jsc of 20.85 mA cm−2, a Voc of 1.07 V, and an FF of 0.82 under 100 mW cm−2 AM 1.5G simulated irradiation. Cellulose substrates exhibit good optical haze but generally have low transmittance; consequently, solar cells fabricated on cellulose substrates typically show relatively low power conversion efficiency (PCE, <1.4%) [69,70]. The size of BNC fibers is much smaller than the wavelength of visible light; thus, the light-management films made from BNC achieve high transparency while exhibiting significant scattering along the light transmission direction. So, by using BNC/ZnO–PF films, the PCE achieved a significant relative increase of 12.9% (to 20.0%). Other parameters, namely Jsc, Voc, and FF, also showed higher values, reaching 22.0 mA∙cm−2, 1.08 V, and 0.85. These enhancements are attributed to the high transmittance and high haze of BNC/ZnO–PF films, which lead to an increase in the photon travel path within the PSC and improve the possibility of photon capture in the cell (Figure 6d).

Figure 6.

The application of BNC/ZnO–PF fllm in Solar Cells. (a) Attachment of BNC/ZnO–PF films onto a GaAs solar cell. (b) Reflectivity of GaAs cells with or without BNC/ZnO–PF film for λ = 550 nm. (c) Current density–voltage curves for the bare GaAs cell and the GaAs cells with BNC/ZnO–PF film. (d) Schematic of light distribution incident on a solar cell.

4. Conclusions

In this work, we developed a high-strength, stable, and energy-saving BNC/ZnO–PF composite film for BIPV encapsulation through a simple strategy. ZnO nanoparticles were in-situ grown on BNC films via ultrasound assistance, and finally, the BNC/ZnO films were hot-pressed with PF resin for bonding. This BNC/ZnO–PF composite film exhibits high transparency (86.47%) and haze (82.02%) in the visible light band, enabling effective light propagation and scattering, thus achieving soft, uniform, and large-area light transmission with energy-saving effects. Additionally, the BNC/ZnO–PF composite film possesses excellent mechanical properties, water stability, and thermal performance. Most importantly, as a light management layer, the BNC/ZnO–PF composite film can significantly improve the power conversion efficiency of GaAs solar cells. The newly developed BNC/ZnO–PF composite film, with its attractive optical properties and excellent water stability, shows great promise for next-generation green BIPV encapsulation products. Looking ahead, the application of BNC/ZnO–PF composite films in BIPV systems is expected to reduce energy consumption for building lighting, heating, and cooling through the synergistic effect of optimizing natural light utilization, enhancing photovoltaic efficiency, and improving thermal insulation per-formance, thereby promoting the development of low-energy buildings. With its raw material characteristics based on renewable biomass and degradable potential, it also aligns with the trends of green manufacturing and circular economy, providing a new path for innovation in BIPV materials under the goal of carbon neutrality.

Supplementary Materials

The following supporting information can be downloaded at: https://www.mdpi.com/article/10.3390/coatings15091063/s1, Figure S1: SEM images of PF resin fllm; Figure S2: Cross-sectional SEM image of (a) BNC, (b) BNC/ZnO and (c) BNC/ZnO-PF fllm; Figure S3: FT-IR spectra of PF resin fllm; Figure S4: The XPS spectrum of (a) BNC, (b) BNC/ZnO and (c) BNC/ZnO-PF fllm; Figure S5: The XPS high-resolution O1s spectrum of BNC/ZnO-PF fllm; Figure S6: The XPS high-resolution Zn2p spectrum of BNC/ZnO-PF fllm; Figure S7: The density of BNC, BNC/ZnO and BNC/ZnO-PF fllm; Figure S8: Tensile stress–strain curves of the PF resin film; Figure S9: The WCA of (a) BNC and (b) BNC/ZnO fllm; Figure S10: The underwater load-bearing test of BNC fllm; Figure S11: (a) TGA and (b) DTG curves of PF resin fllm; Table S1: The element content in BNC film; Table S2: The element content in BNC/ZnO film; Table S3: The element content in BNC/ZnO-PF film; Table S4: Calculated electrical properties based on the current density-voltage characteristics for the bare GaAs cell and GaAs cells with BNC/ZnO-PF fllm.

Author Contributions

Conceptualization, L.D.; Methodology, L.D.; Investigation, L.D. and Y.Z.; Data curation, Y.Z.; Writing—original draft, C.W. and L.D.; Writing—review & editing, C.W.; Visualization, C.W.; Funding acquisition, C.W. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the Natural Science Foundation of Hunan Province (2023JJ50348).

Data Availability Statement

All data needed to evaluate the conclusions in the paper are present in the paper and/or the Supplementary Materials. Additional data related to this paper may be requested from the authors.

Conflicts of Interest

Author L.D. was employed by the company Hunan Academy of Transportation Sciences Co., Ltd. Author Y.Z. was employed by the company Heshan District Garden Landscaping Co., Ltd. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Griffini, G.; Turri, S. Polymeric materials for long-term durability of photovoltaic systems. J. Appl. Polym. Sci. 2016, 133, 43080. [Google Scholar] [CrossRef]

- Anctil, A.; Beattie, M.N.; Case, C.; Chaudhary, A.; Chrysler, B.D.; Debije, M.G.; Essig, S.; Ferry, D.K.; Ferry, V.E.; Freitag, M.; et al. Status report on emerging photovoltaics. J. Photonics Energy 2023, 13, 042301. [Google Scholar] [CrossRef]

- Guo, W.; Xu, Z.; Li, T. Metal-based semiconductor nanomaterials for thin-film solar cells. In Multifunctional Photocatalytic Materials for Energy; Woodhead Publishing: Cambridge, UK, 2018; pp. 153–185. [Google Scholar]

- Huang, Y.C.; Lee, C.C.; Lee, Y.Y.; Chung, S.; Lin, H.C.; Kasimayan, U.; Li, C.F.; Liu, S.W. High-efficiency ITO-free organic solar cells through top illumination. Mater. Adv. 2024, 5, 2411–2419. [Google Scholar] [CrossRef]

- Fang, Z.; Zhu, H.; Yuan, Y.; Ha, D.; Zhu, S.; Preston, C.; Chen, Q.; Li, Y.; Han, X.; Lee, S.; et al. Novel nanostructured paper with ultrahigh transparency and ultrahigh haze for solar cells. Nano Lett. 2014, 14, 765–773. [Google Scholar] [CrossRef] [PubMed]

- Zhu, H.; Xiao, Z.; Liu, D.; Li, Y.; Weadock, N.J.; Fang, Z.; Huang, J.; Hu, L. Biodegradable transparent substrates for flexible organic-light-emitting diodes. Energy Environ. Sci. 2013, 6, 2105–2111. [Google Scholar] [CrossRef]

- Fang, Z.; Zhu, H.; Preston, C.; Han, X.; Li, Y.; Lee, S.; Chai, X.; Chen, G.; Hu, L. Highly transparent and writable wood all-cellulose hybrid nanostructured paper. J. Mater. Chem. C 2013, 1, 6191–6197. [Google Scholar] [CrossRef]

- Lin, Z.; Lin, Y.; Li, H.; Xu, M.; He, M.; Ke, W.; Tan, H.; Han, Y.; Li, Z.; Wang, D.; et al. High-performance polarization management devices based on thin-film lithium niobate. Light Sci. Appl. 2022, 11, 93. [Google Scholar] [CrossRef]

- Kim, K.J.; Lu, P.; Culp, J.T.; Ohodnicki, K.J. Metal–organic framework thin film coated optical fiber sensors: A novel waveguide-based chemical sensing platform. ACS Sens. 2018, 3, 386–394. [Google Scholar] [CrossRef]

- Kumar, V.; Raghuwanshi, S.K.; Kumar, S. Advances in nanocomposite thin-film-based optical fiber sensors for environmental health monitoring—A review. IEEE Sens. J. 2022, 22, 14696–14707. [Google Scholar] [CrossRef]

- Sun, H.; Liu, Y.; Guo, X.; Zeng, K.; Mondal, A.K.; Li, J.; Yao, Y.; Chen, L. Strong, robust cellulose composite film for efficient light management in energy efficient building. Chem. Eng. J. 2021, 425, 131469. [Google Scholar] [CrossRef]

- Gago, E.J.; Muneer, T.; Knez, M.; Köster, H. Natural light controls and guides in buildings. Energy saving for electrical lighting, reduction of cooling load. Renew. Sustain. Energy Rev. 2015, 41, 1–13. [Google Scholar] [CrossRef]

- Löber, D.; Hasan, M.K.; Liebermann, S.; Iskhandar, M.S.Q.; Baby, S.; Chen, J.; Farrag, E.; Ahmed, N.; Liu, S.; Elsaka, B.; et al. MEMS smart glass for personalized lighting and energy management in buildings: Working principles, characterization, active light steering, thermal management, energy saving considering different locations on earth, comparison of different smart glass technologies. J. Build. Des. Environ. 2023, 1, 22962. [Google Scholar]

- Wang, X.; Xu, X.; Fan, D.; Zhang, G.; Lu, Y. wood composites as sustainable energy conversion materials for efficient solar energy harvesting and light management. J. Mater. Sci. 2024, 59, 4383–4403. [Google Scholar] [CrossRef]

- Jacucci, G.; Schertel, L.; Zhang, Y.; Yang, H.; Vignolini, S. Light management with natural materials: From whiteness to transparency. Adv. Mater. 2021, 33, 2001215. [Google Scholar] [CrossRef] [PubMed]

- Subudhi, P.; Punetha, D. Progress, challenges, and perspectives on polymer substrates for emerging flexible solar cells: A holistic panoramic review. Prog. Photovolt. Res. Appl. 2023, 31, 753–789. [Google Scholar] [CrossRef]

- Cheng, P.; Zhan, X. Stability of organic solar cells: Challenges and strategies. Chem. Soc. Rev. 2016, 45, 2544–2582. [Google Scholar] [CrossRef]

- Bing, J.; Caro, L.G.; Talathi, H.P.; Chang, N.L.; McKenzie, D.R.; Ho-Baillie, A.W.Y. Perovskite solar cells for building integrated photovoltaics—Glazing applications. Joule 2022, 6, 1446–1474. [Google Scholar] [CrossRef]

- Alrefaee, S.H.; Al-Ghamdi, S.A.; Alrashdi, K.S.; Almahri, A.; Alaysuy, O.; Alatawi, N.M.; Alghasham, H.A.; El-Metwaly, N.M. Effect of titanium oxide (TiO2) nanoparticles on the opto-mechanical properties of polyethylene terephthalate (PET) fibers. Opt. Mater. 2024, 157, 116242. [Google Scholar] [CrossRef]

- Stanculescu, F.; Stanculescu, A. Polycarbonate-based blends for optical non-linear applications. Nanoscale Res. Lett. 2016, 11, 87. [Google Scholar] [CrossRef][Green Version]

- Jastaneyah, Z.; Kamar, H.M.; Alansari, A.; Al Garalleh, H. A comparative analysis of standard and nano-structured glass for enhancing heat transfer and reducing energy consumption using metal and oxide nanoparticles: A review. Sustainability 2023, 15, 9221. [Google Scholar] [CrossRef]

- Zier, M.; Stenzel, P.; Kotzur, L.; Stolten, D. A review of decarbonization options for the glass industry. Energy Convers. Manag. X 2021, 10, 100083. [Google Scholar] [CrossRef]

- Zhu, M.; Li, T.; Davis, C.S.; Yao, Y.; Dai, J.; Wang, Y.; AlQatari, F.; Gilman, J.W.; Hu, L. Transparent and haze wood composites for highly efficient broadband light management in solar cells. Nano Energy 2016, 26, 332–339. [Google Scholar] [CrossRef]

- Pandit, K.H.; Goswami, A.D.; Holkar, C.R.; Pinjari, D.V. A review on recent developments in transparent wood: Sustainable alternative to glass. Biomass Convers. Biorefinery 2025, 15, 6331–6343. [Google Scholar] [CrossRef]

- Yang, H.; Wang, H.; Cai, T.; Ge-Zhang, S.; Mu, H. Light and wood: A review of optically transparent wood for architectural applications. Ind. Crops Prod. 2023, 204, 117287. [Google Scholar]

- Wu, J.; Wu, Y.; Yang, F.; Tang, C.; Huang, Q.; Zhang, J. Impact of delignification on morphological, optical and mechanical properties of transparent wood. Compos. Part A Appl. Sci. Manuf. 2019, 117, 324–331. [Google Scholar]

- Wang, W.; Liu, Z.; Huang, Y. Research progress on preparation and application of transparent bamboo: A review. Constr. Build. Mater. 2024, 425, 136100. [Google Scholar] [CrossRef]

- Li, X.; Li, J.; Shen, X.; Cao, M.; Wang, Y.; Zhang, W.; Xu, Y.; Ling, Z.; Chen, S.; Xu, F. Transparent cellulose/lignin composite films with adjustable haze and UV-blocking performance for light management. ACS Sustain. Chem. Eng. 2024, 12, 5427–5435. [Google Scholar]

- Zhang, Y.; Wang, S.; You, S.; Wang, J.; Wang, J.; Jia, L.; Zhang, H.; Zhang, M. Fabrication of transparent and hazy cellulosic light-management film for enhancing photon utilization in photocatalytic membrane process. J. Membr. Sci. 2023, 685, 121923. [Google Scholar] [CrossRef]

- Yang, H.; Jacucci, G.; Schertel, L.; Vignolini, S. Cellulose-based scattering enhancers for light management applications. ACS Nano 2022, 16, 7373–7379. [Google Scholar] [CrossRef]

- Xia, Q.; Chen, C.; Li, T.; He, S.; Gao, J.; Wang, X.; Hu, L. Solar-assisted fabrication of large-scale, patternable transparent wood. Sci. Adv. 2021, 7, eabd7342. [Google Scholar]

- Luo, Z.; Liu, J.; Lin, H.; Ren, X.; Tian, H.; Liang, Y.; Wang, W.; Wang, Y.; Yin, M.; Huang, Y.; et al. In situ fabrication of nano ZnO/BCM biocomposite based on MA modified bacterial cellulose membrane for antibacterial and wound healing. Int. J. Nanomed. 2020, 6, 1–15. [Google Scholar] [CrossRef] [PubMed]

- Shao, W.; Wu, J.; Liu, H.; Ye, S.; Jiang, L.; Liu, X. Novel bioactive surface functionalization of bacterial cellulose membrane. Carbohydr. Polym. 2017, 178, 270276. [Google Scholar] [CrossRef] [PubMed]

- Osorio, M.; Fernández-Morales, P.; Gañán, P.; Zuluaga, R.; Kerguelen, H.; Ortiz, I.; Castro, C. Development of novel three-dimensional scaffolds based on bacterial nanocellulose for tissue engineering and regenerative medicine: Effect of processing methods, pore size, and surface area. J. Biomed. Mater. Res. Part A 2019, 107, 348–359. [Google Scholar] [CrossRef] [PubMed]

- Nabeela, K.; Thorat, M.N.; Backer, S.N.; Ramachandran, A.M.; Thomas, R.T.; Preethikumar, G.; Mohamed, A.P.; Asok, A.; Dastager, S.G.; Pillai, S. Hydrophilic 3D interconnected network of bacterial Nanocellulose/black titania photothermal foams as an efficient interfacial solar evaporator. ACS Appl. Bio Mater. 2021, 4, 4373–4383. [Google Scholar] [CrossRef]

- Wang, T.; Sun, J.; Zhang, F.; Tan, J.; Wang, C. Ultra-lightweight and reinforced ZnO/Cellulose layered cryogel for thermal insulation. Cellulose 2025, 32, 1627–1644. [Google Scholar] [CrossRef]

- Li, Y.; Fu, C.; Wang, Z.; Huang, L.; Chen, L.; Liao, G.; Zhang, Q.; Ni, Y. Novel cellulose-based films with highly efficient photothermal performance for sustainable solar evaporation and solar-thermal power generation. J. Clean. Prod. 2024, 458, 142416. [Google Scholar] [CrossRef]

- Wang, X.; Hu, Z.; Sun, C.; Li, J.; Zhang, H. Fibrous porous ceramics with devisable phenolic resin reinforcing layer. Ceram. Int. 2019, 45, 5413–5417. [Google Scholar] [CrossRef]

- Wang, L.; Liu, M.; Yang, F.; Wu, T.; Rao, W.; Liu, Y.; Wei, C.; Yu, C. Comparative study on the structure, mechanical, thermal, and tribological properties of PF composites reinforced by different kinds of mesoporous silicas. J. Inorg. Organomet. Polym. Mater. 2021, 31, 2939–2948. [Google Scholar] [CrossRef]

- Karekar, S.E.; Bhanvase, B.A.; Sonawane, S.H.; Deosarkar, M.P.; Pinjari, D.V.; Pandit, A.B. Synthesis of zinc molybdate and zinc phosphomolybdate nanopigments by an ultrasound assisted route: Advantage over conventional method. Chem. Eng. Process. Process Intensif. 2015, 87, 51–59. [Google Scholar] [CrossRef]

- Sikwal, N.R.; Sonawane, S.H.; Bhanvase, B.A.; Ramisetty, K.; Pinjari, D.V.; Gogate, P.R.; Babu, R.S. Ultrasound-assisted preparation of ZnO nanostructures: Understanding the effect of operating parameters. Green Process. Synth. 2016, 5, 163–172. [Google Scholar] [CrossRef]

- Oxley, J.D.; Prozorov, T.; Suslick, K.S. Sonochemistry and sonoluminescence of room-temperature ionic liquids. J. Am. Chem. Soc. 2003, 125, 11138–11139. [Google Scholar] [CrossRef] [PubMed]

- Peng, Y.; Ji, J.; Chen, D. Ultrasound assisted synthesis of ZnO/reduced graphene oxide composites with enhanced photocatalytic activity and anti-photocorrosion. Appl. Surf. Sci. 2015, 356, 762–768. [Google Scholar] [CrossRef]

- Aliannezhadi, M.; Doost Mohamadi, F.; Jamali, M.; Shariatmadar Tehrani, F. Ultrasound-assisted green synthesized ZnO nanoparticles with different solution pH for water treatment. Sci. Rep. 2025, 15, 7203. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.; Hu, Y.; Wang, X.; Zhang, A.; Gao, X.; Yagoub, A.E.G.A.; Ma, H.; Zhou, C. Ultrasound-assisted synthesis of potentially food-grade nano-zinc oxide in ionic liquids: A safe, green, efficient approach and its acoustics mechanism. Foods 2022, 11, 1656. [Google Scholar] [CrossRef]

- Drabczyk, A.; Ciężkowska, M.; Kałahurska, K.; Zięba, A.; Bulowski, W.; Bucka, K.; Kasza, P.; Socha, R.P. The Application of Ultrasound Pre-Treatment in Low-Temperature Synthesis of Zinc Oxide Nanorods. Materials 2024, 17, 4980. [Google Scholar] [CrossRef]

- Alammar, T.; Mudring, A.V. Facile ultrasound-assisted synthesis of ZnO nanorods in an ionic liquid. Mater. Lett. 2009, 63, 732–735. [Google Scholar]

- Bhanvase, B.A.; Patel, M.A.; Sonawane, S.H.; Pandit, A. Intensification of ultrasound-assisted process for the preparation of spindle-shape sodium zinc molybdate nanoparticles. Ultrason. Sonochem. 2016, 28, 311–318. [Google Scholar]

- Oh, S.Y.; Yoo, D.I.; Shin, Y.; Kim, H.C.; Kim, H.Y.; Chung, Y.S.; Park, W.H.; Youk, J.H. Crystalline structure analysis of cellulose treated with sodium hydroxide and carbon dioxide by means of X-ray diffraction and FTIR spectroscopy. Carbohydr. Res. 2005, 340, 2376–2391. [Google Scholar] [CrossRef]

- Rudlicka, M.; Zarski, A.; Pokora-Carzynska, M.; Kapusniak, J. Solvent-Free Lipase-Catalysed Esterification of Potato Maltodextrins. Polysaccharides 2025, 6, 29. [Google Scholar] [CrossRef]

- Yang, H.; Gong, M.; Hu, J.; Liu, B.; Chen, Y.; Xiao, J.; Li, S.; Dong, Z.; Chen, H. Cellulose pyrolysis mechanism based on functional group evolutions by two-dimensional perturbation correlation infrared spectroscopy. Energy Fuels 2020, 34, 3412–3421. [Google Scholar] [CrossRef]

- Mo, Y.; Yang, L.; Hou, W.; Zou, T.; Huang, Y.; Zheng, X.; Liao, R. Preparation of cellulose insulating paper of low dielectric constant by OAPS grafting. Cellulose 2019, 26, 7451–7468. [Google Scholar] [CrossRef]

- Di Filippo, M.F.; Dolci, L.S.; Liccardo, L.; Bigi, A.; Bonvicini, F.; Gentilomi, G.A.; Passerini, N.; Panzavolta, S.; Albertini, B. Cellulose derivatives-snail slime films: New disposable eco-friendly materials for food packaging. Food Hydrocoll. 2021, 111, 106247. [Google Scholar] [CrossRef]

- Xu, X.; Long, Y.; Li, Q.; Li, D.; Mao, D.; Chen, X.; Chen, Y. Modified cellulose membrane with good durability for effective oil-in-water emulsion treatment. J. Clean. Prod. 2019, 211, 1463–1470. [Google Scholar] [CrossRef]

- Guo, T.; Gu, L.; Zhang, Y.; Chen, H.; Jiang, B.; Zhao, H.; Jin, Y.; Xiao, H. Bioinspired self-assembled films of carboxymethyl cellulose–dopamine/montmorillonite. J. Mater. Chem. A 2019, 7, 14033–14041. [Google Scholar] [CrossRef]

- Deng, S.; Jiang, Y.; Qu, Y.; Li, A.; Zhang, R.; Xie, Z. Improving the rate and cycle performance of V-based cathodes through regulation of the Zn2+ desolvation process. Mater. Today Energy 2024, 44, 101624. [Google Scholar] [CrossRef]

- Zhou, G.; Yin, L.C.; Wang, D.W.; Li, L.; Pei, S.; Gentle, I.R.; Li, F.; Cheng, H.M. Fibrous hybrid of graphene and sulfur nanocrystals for high-performance lithium–sulfur batteries. ACS Nano 2013, 7, 5367–5375. [Google Scholar] [CrossRef]

- Xia, G.; Ji, X.; Peng, J.; Ji, X. Cellulose/poly (meta-phenylene isophthalamide) light-management films with high antiultraviolet and tunable haze performances. ACS Appl. Polym. Mater. 2022, 4, 8407–8417. [Google Scholar] [CrossRef]

- Wu, C.; Zhang, S.; He, J. A transparent and waterproof cellulose composite film with carbon quantum dots: A greener agricultural film capable of light management. Int. J. Biol. Macromol. 2025, 320, 146133. [Google Scholar] [CrossRef]

- Qi, Y.; Lin, S.; Lan, J.; Zhan, Y.; Guo, J.; Shang, J. Fabrication of super-high transparent cellulose films with multifunctional performances via postmodification strategy. Carbohydr. Polym. 2021, 260, 117760. [Google Scholar] [CrossRef]

- Wu, T.; Xu, Y.; Cui, Z.; Li, H.; Wang, K.; Kang, L.; Cai, Y.; Li, J.; Tian, D. Efficient heat shielding and ultraviolet isolating transparent wood via in situ generation of TiO2 nanoparticles. ACS Sustain. Chem. Eng. 2022, 10, 15380–15388. [Google Scholar] [CrossRef]

- Li, T.; Zhu, M.; Yang, Z.; Song, J.; Dai, J.; Yao, Y.; Luo, W.; Pastel, G.; Yang, B.; Hu, L. Wood composite as an energy efficient building material: Guided sunlight transmittance and effective thermal insulation. Adv. Energy Mater. 2016, 6, 1601122. [Google Scholar] [CrossRef]

- Liu, C.; Lyu, J.; Shi, N.; Cheng, Q.; Liu, Z.; Xiong, Y.; Zhang, X. Kevlar nanofibrous aerogel-based 3-layer tandem cloak enables highly efficient and long-lasting infrared stealth. Chem. Eng. J. 2023, 462, 142249. [Google Scholar] [CrossRef]

- Zhang, T.; Yuan, T.; Xiao, X.; Peng, H.; Fang, X.; Wang, K.; Liu, X.; Li, Y. Transparent and shape-memory cellulose paper reinforced by vitrimer polymer for efficient light management and sustainability. Cellulose 2022, 29, 8781–8795. [Google Scholar] [CrossRef]

- Li, S.; Cui, B.; Jia, X.; Wang, W.; Cui, Y.; Ding, J.; Fang, Y.; Song, Y.; Zhang, X. A cellulose-based film with self-healing performance for light management. Ind. Crops Prod. 2024, 212, 118312. [Google Scholar] [CrossRef]

- Duan, Y.; Yang, H.; Liu, K.; Xu, T.; Chen, J.; Xie, H.; Du, H.; Dai, L.; Si, C. Cellulose nanofibril aerogels reinforcing polymethyl methacrylate with high optical transparency. Adv. Compos. Hybrid Mater. 2023, 6, 123. [Google Scholar] [CrossRef]

- Zhu, H.; Fang, Z.; Preston, C.; Li, Y.; Hu, L. Transparent paper: Fabrications, properties, and device applications. Energy Environ. Sci. 2014, 7, 269–287. [Google Scholar] [CrossRef]

- Liu, W.; Wang, T.; Tao, Y.; Ling, Z.; Huang, C.; Lai, C.; Yong, Q. Fabrication of anti-bacterial, hydrophobic and UV resistant galactomannan-zinc oxide nanocomposite films. Polymer 2021, 215, 123412. [Google Scholar] [CrossRef]

- Barr, M.C.; Rowehl, J.A.; Lunt, R.R.; Xu, J.; Wang, A.; Boyce, C.M.; Im, S.G.; Bulović, V.; Gleason, K.K. Direct monolithic integration of organic photovoltaic circuits on unmodified paper. Adv. Mater. 2011, 23, 3500. [Google Scholar] [CrossRef]

- Kim, T.S.; Na, S.I.; Kim, S.S.; Yu, B.K.; Yeo, J.S.; Kim, D.Y. Solution-processible polymer solar cells fabricated on a papery substrate. Phys. Status Solidi (RRL)–Rapid Res. Lett. 2012, 6, 13–15. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).