Near-Nozzle Atomization Characteristics in Air-Assisted Spraying: Integrated VOF-DPM Modeling and Experimental Validation

Abstract

1. Introduction

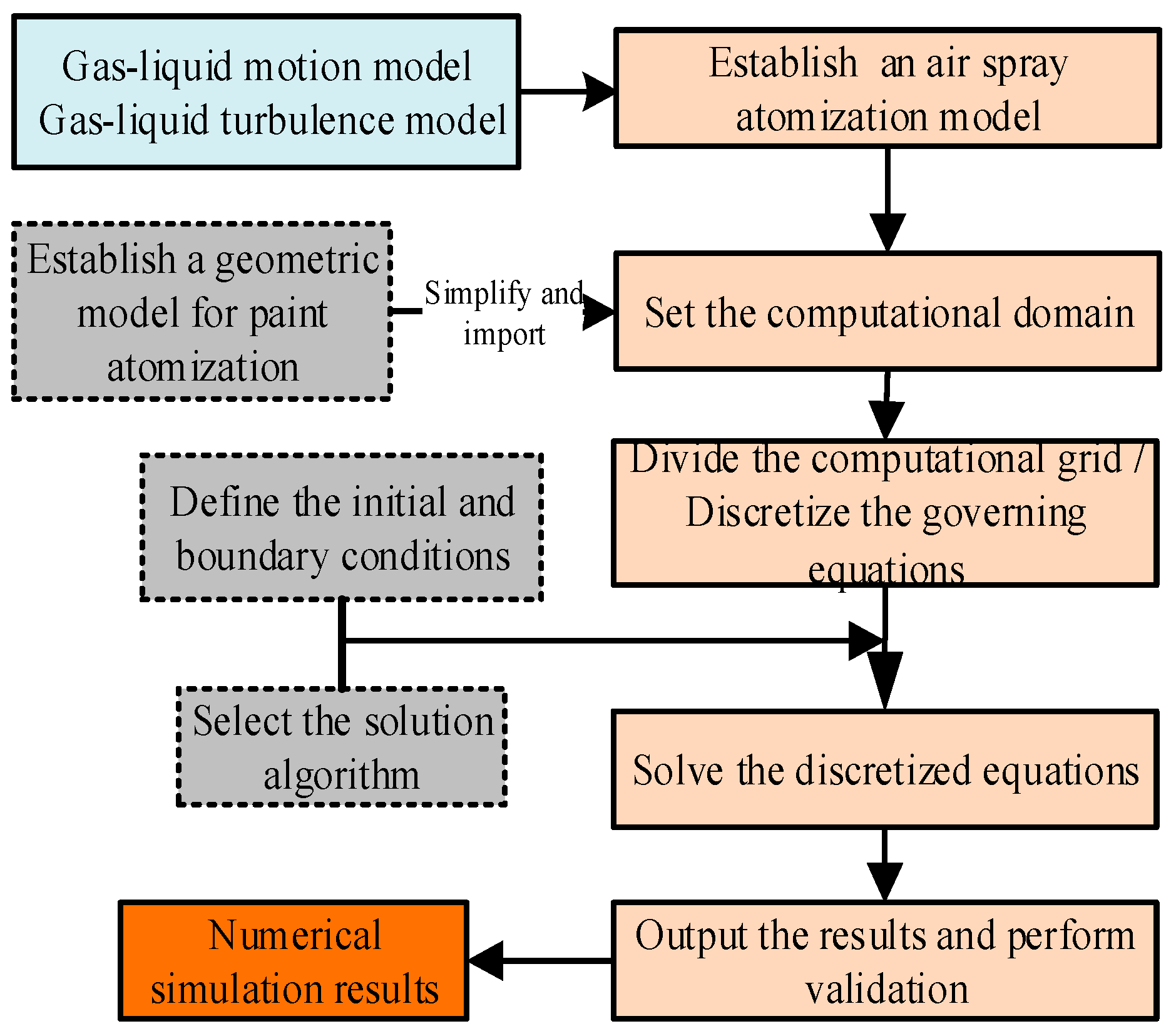

2. Multi-Scale Numerical Simulation of Paint Atomization

2.1. Mathematical Model

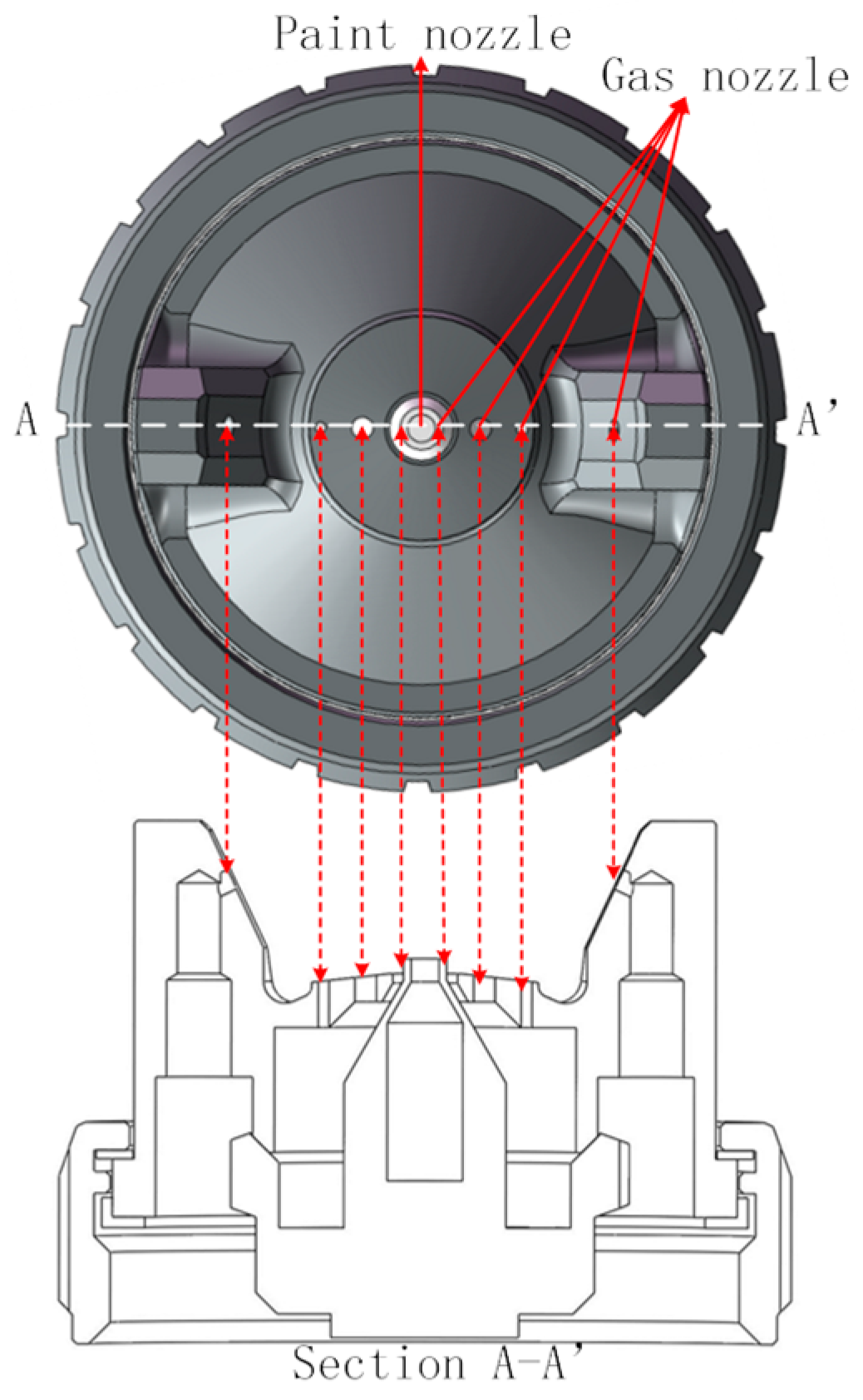

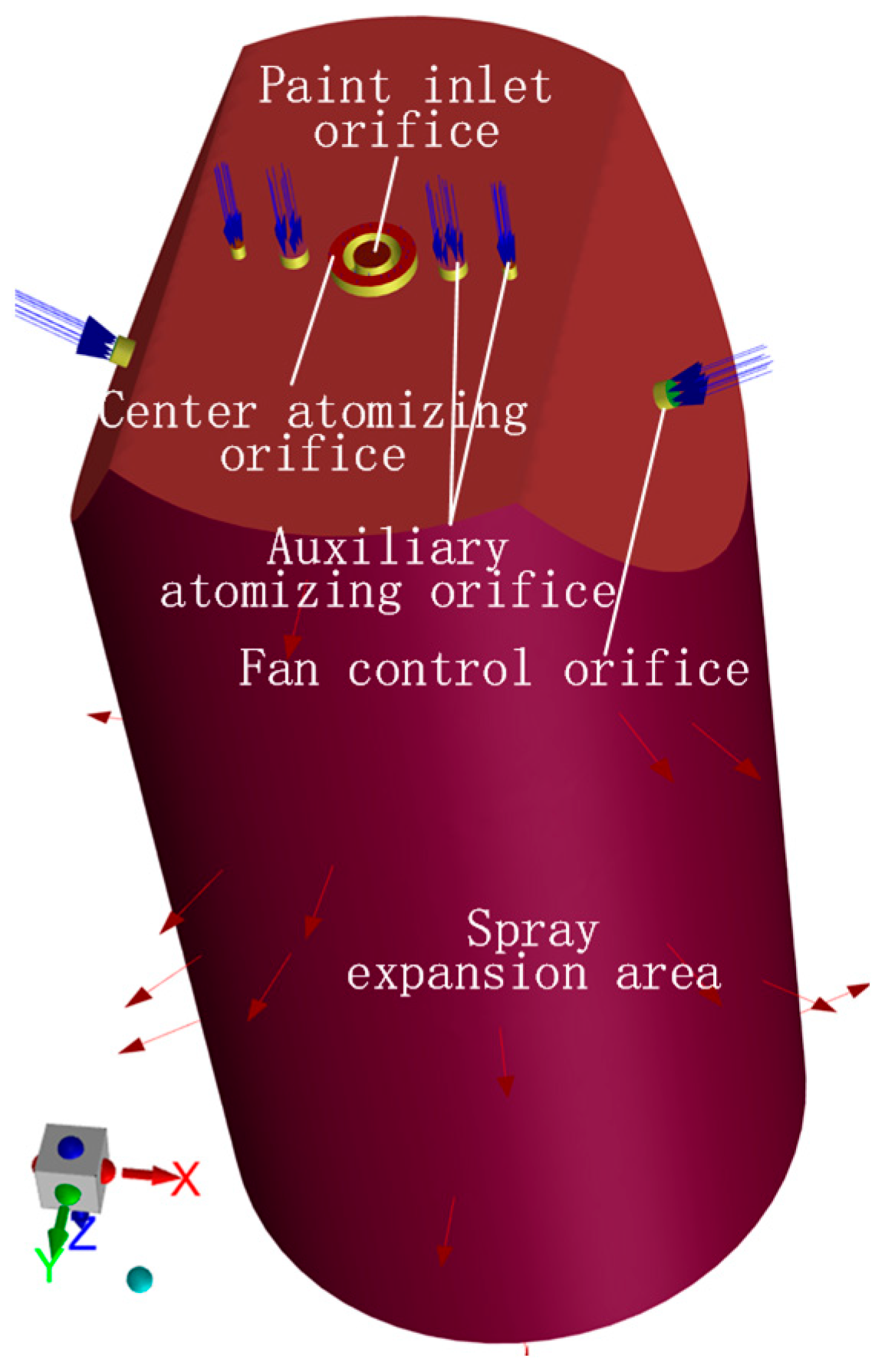

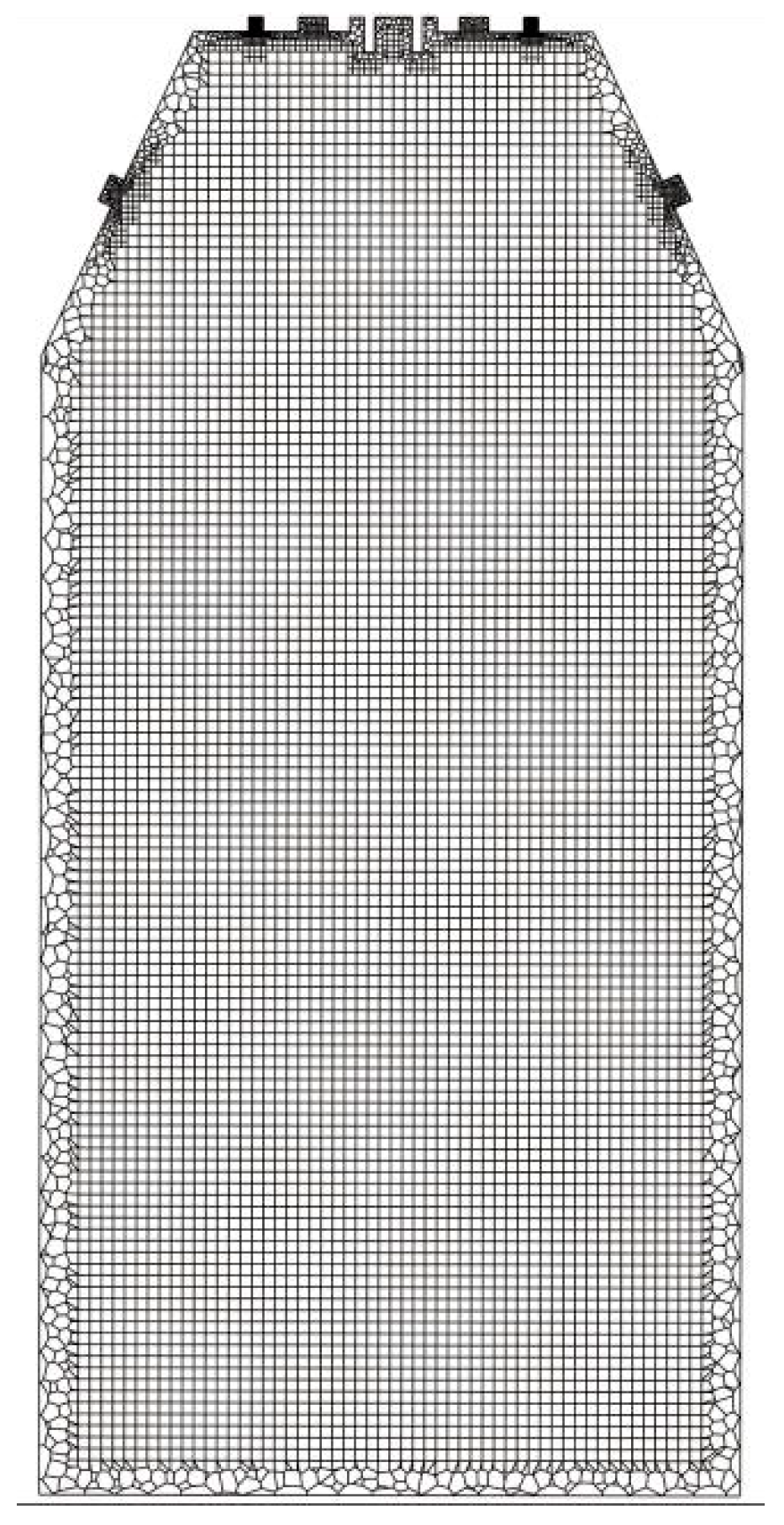

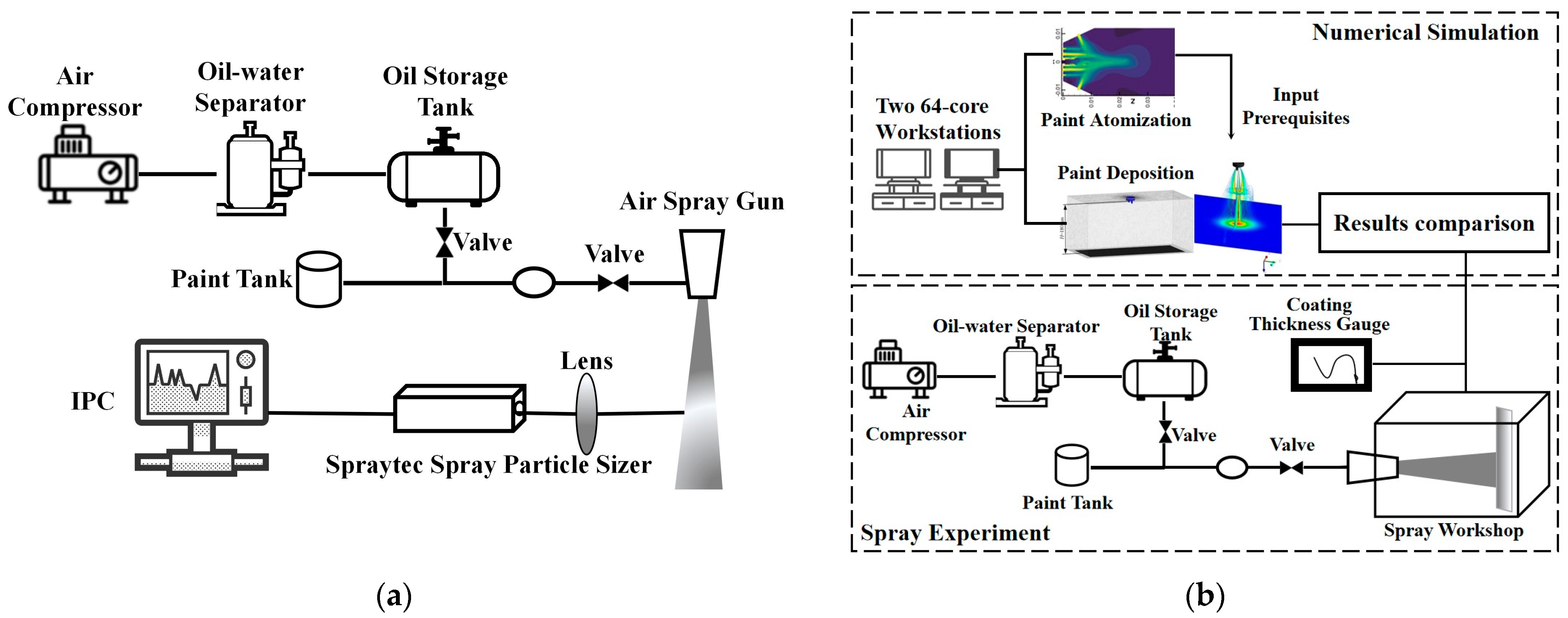

2.2. Numerical Simulation

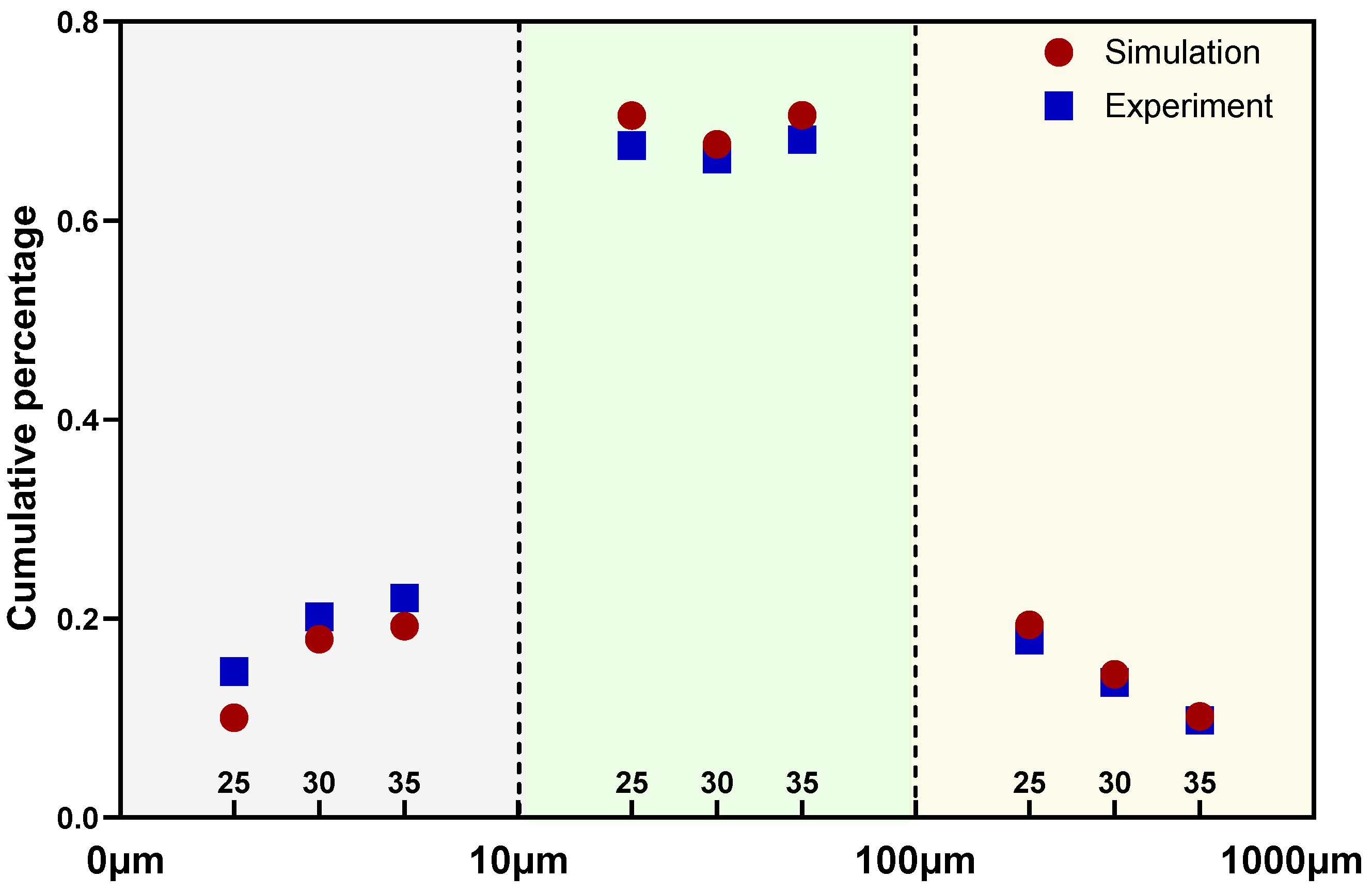

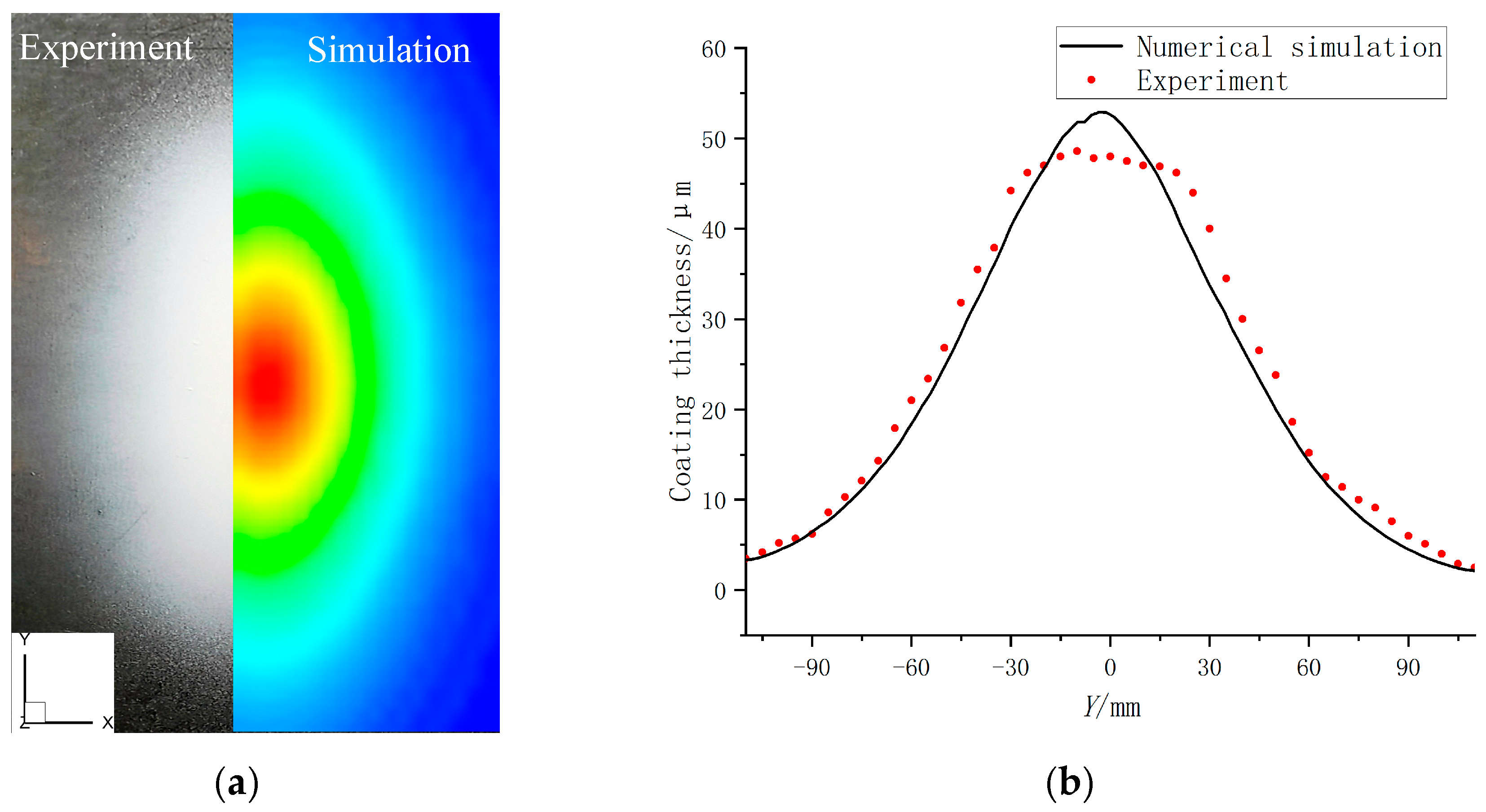

2.3. Experimental Validation

3. Results and Discussion

3.1. Characteristics of the Gas-Phase Flow Field

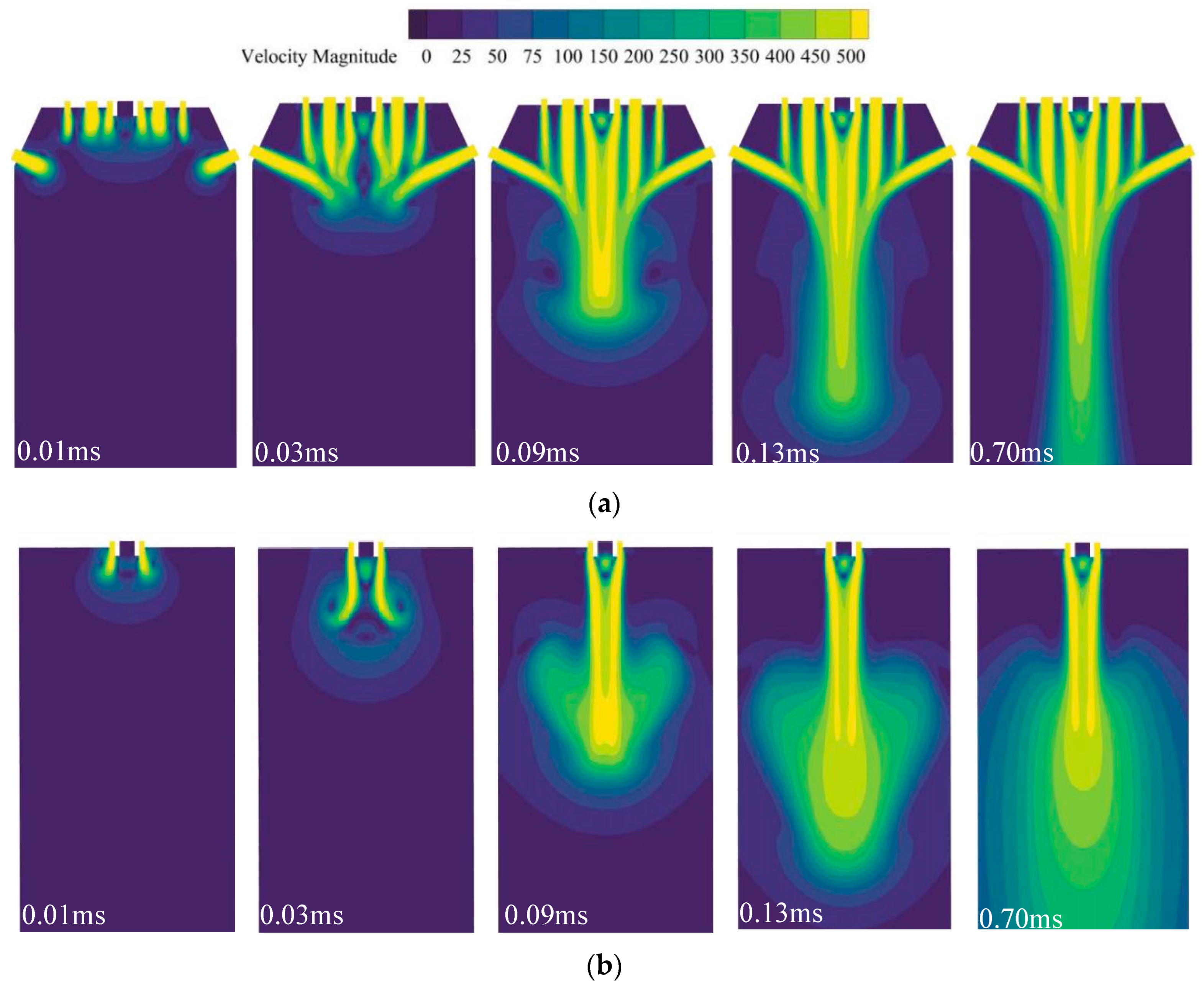

3.1.1. Gas-Phase Expansion Process

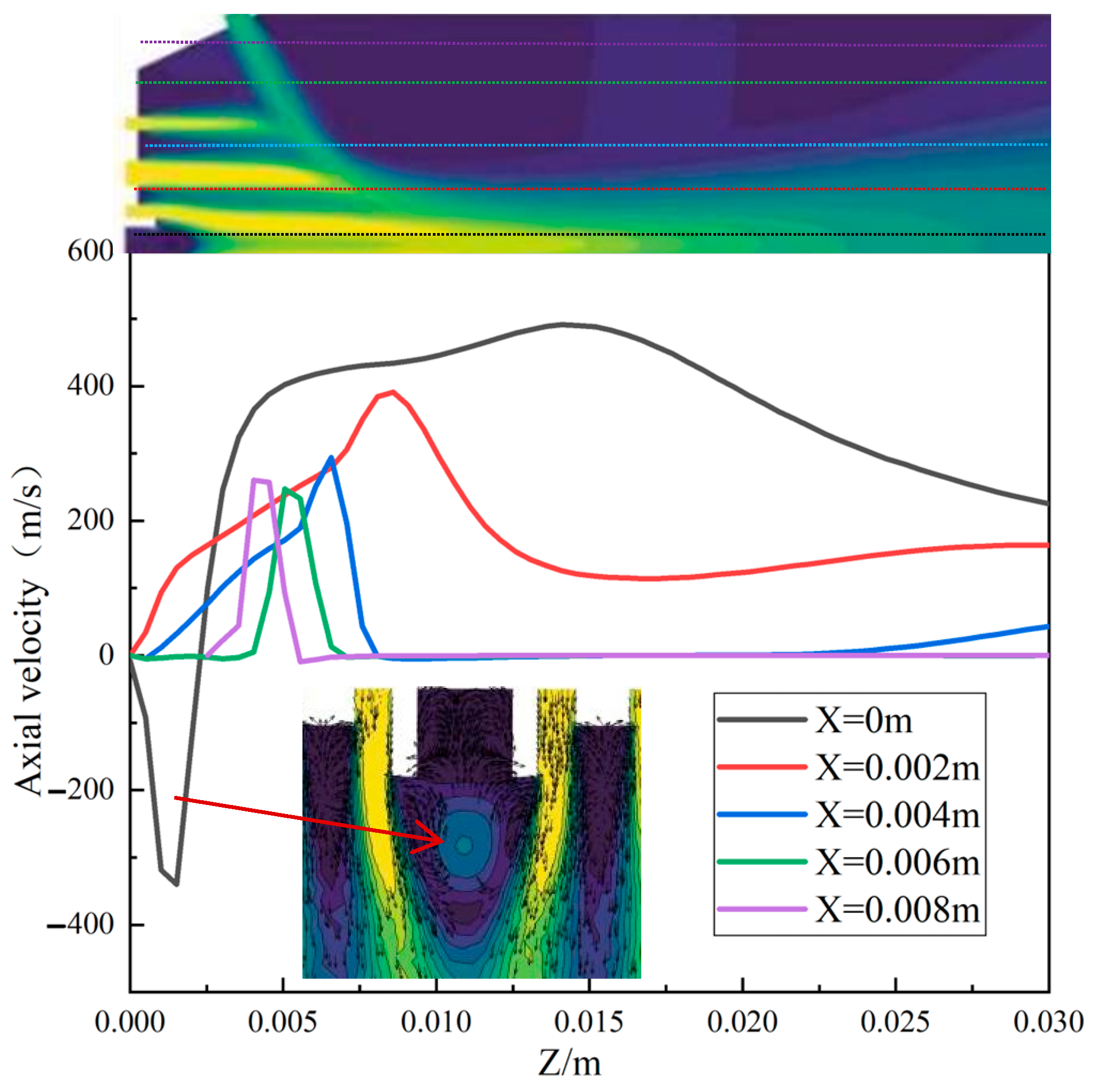

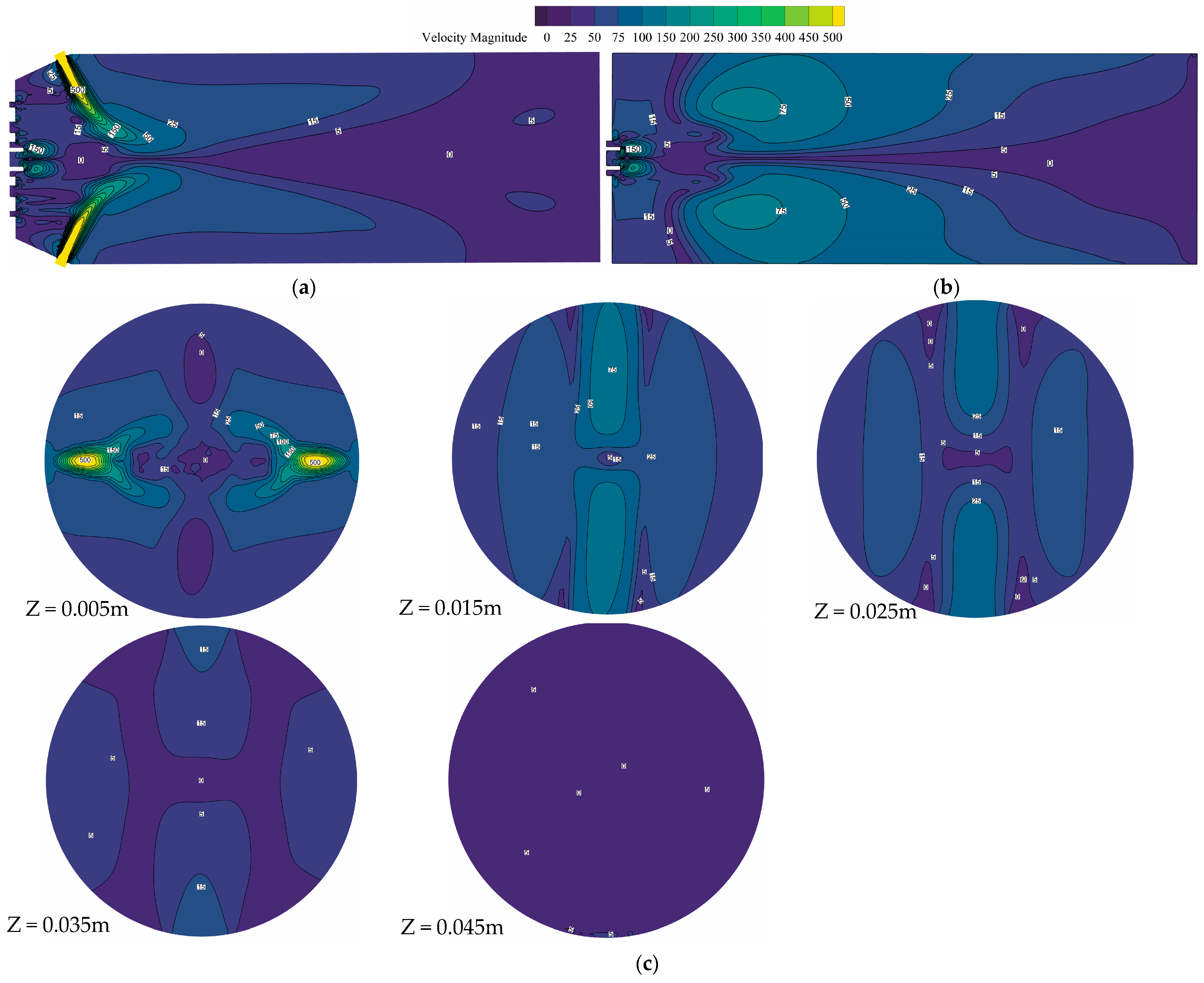

3.1.2. Velocity Distribution of the Gas-Phase Flow Field

3.2. Characteristics of the Spray Flow Field

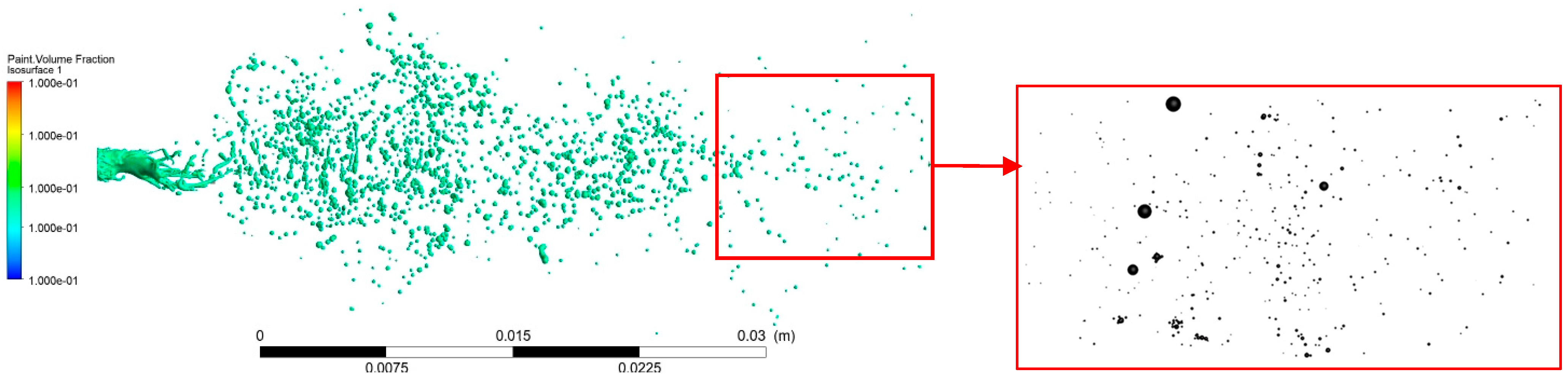

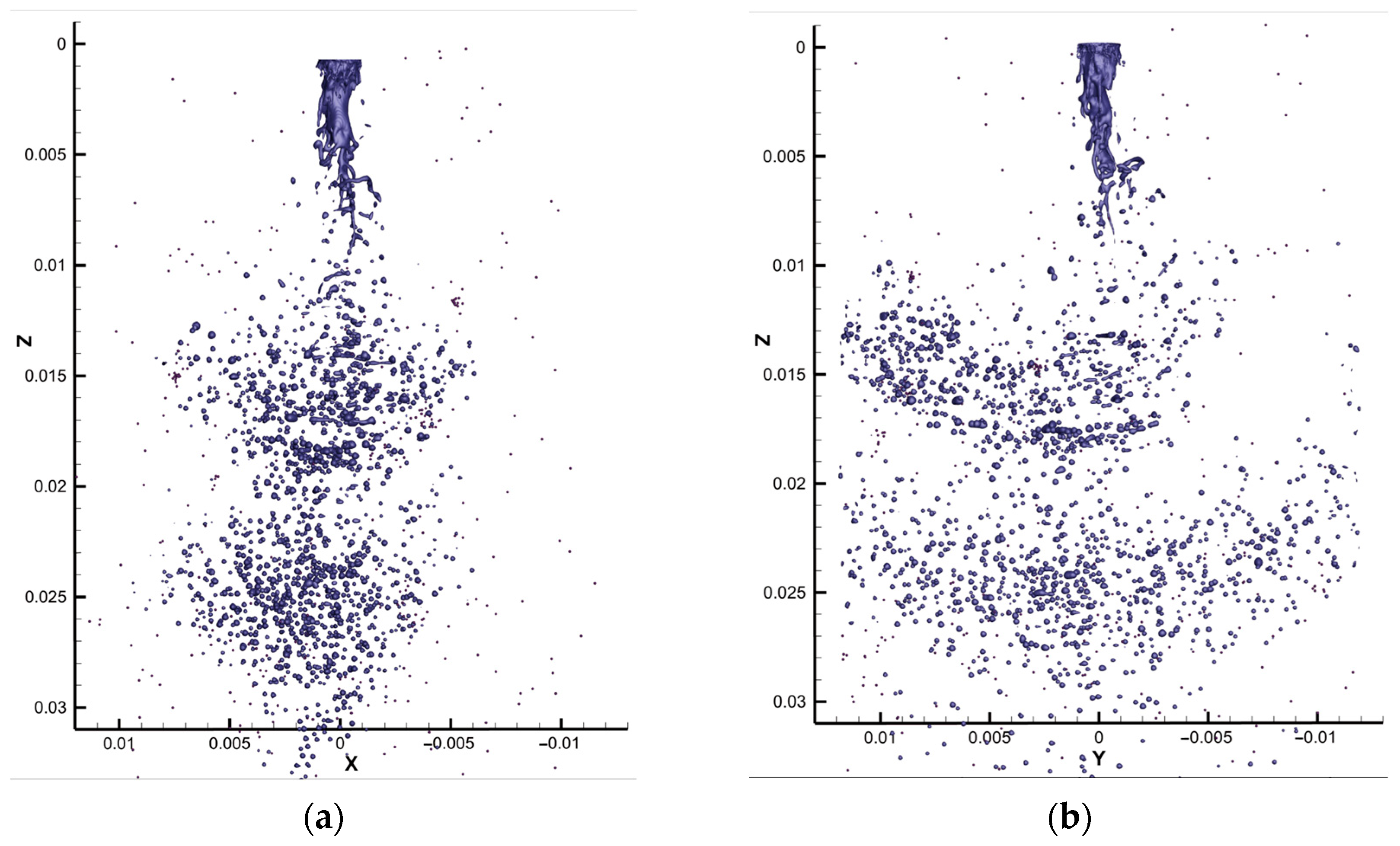

3.2.1. Spatial Distribution of the Paint Phase

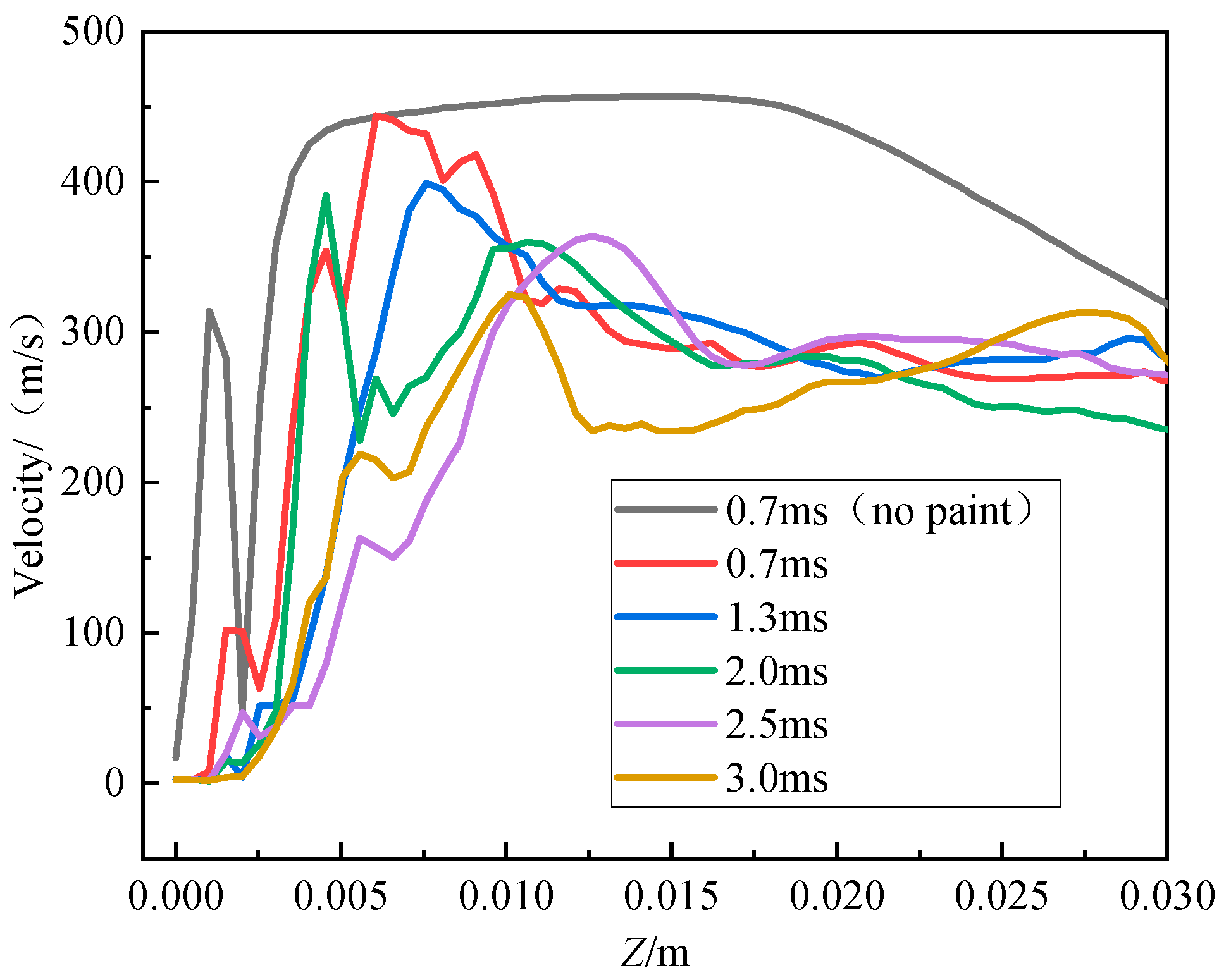

3.2.2. Axial Velocity Distribution

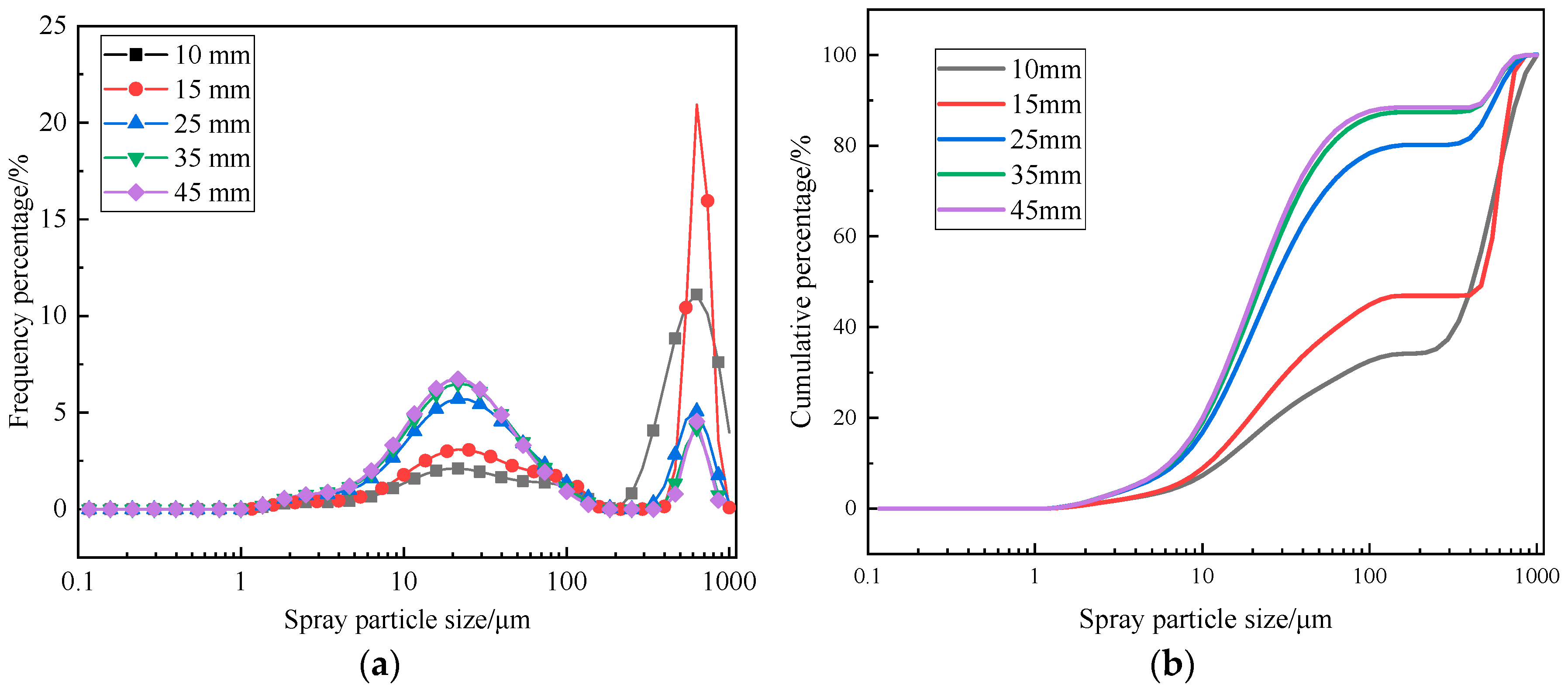

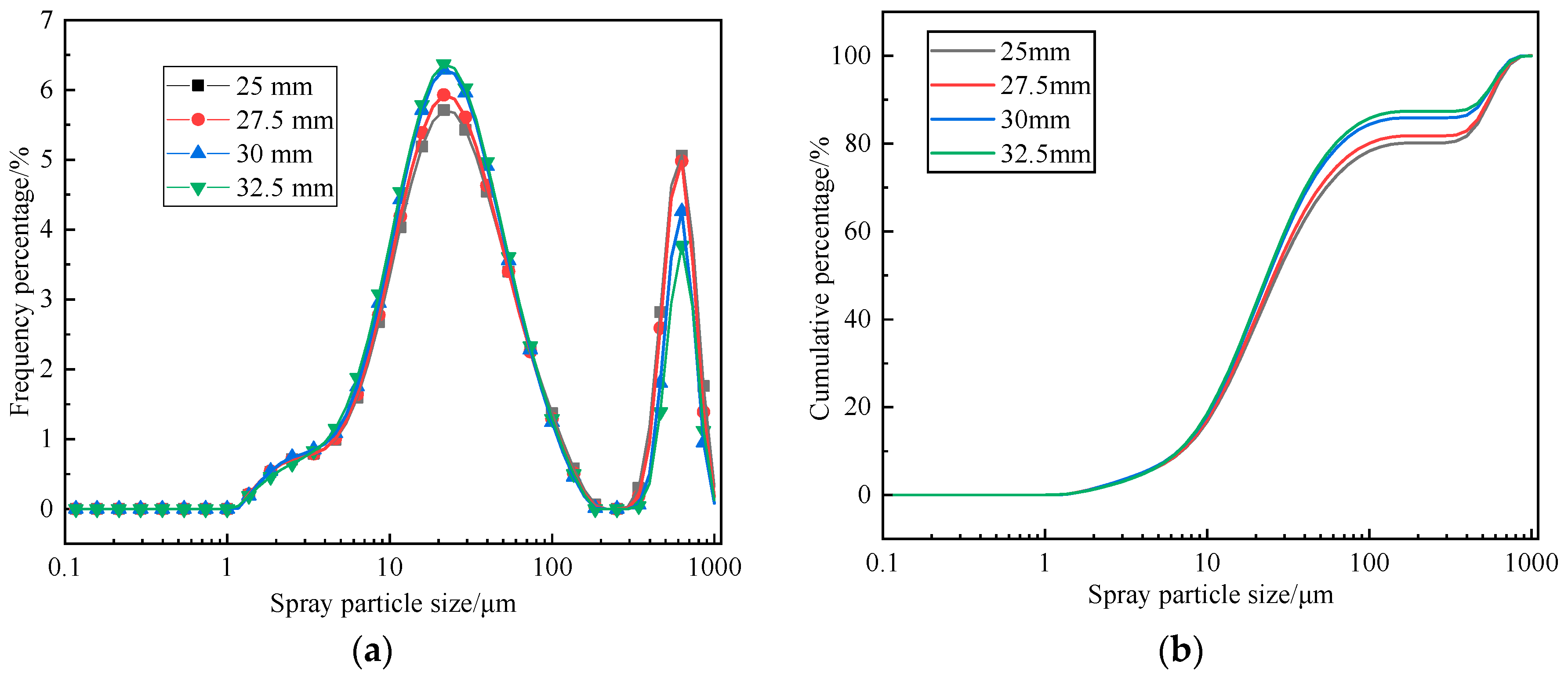

3.2.3. Spray Particle Size Distribution

3.3. Discussion

- (1)

- Nozzle Geometry Specificity: Simulations employed a single nozzle configuration (W-71). Generalizability to divergent architectures requires validation. Future studies should parameterize orifice geometry (diameter, orientation) to establish scaling laws.

- (2)

- Newtonian Fluid Assumption: Paint was modeled as an incompressible Newtonian fluid (Section 2.1), neglecting shear-thinning/thickening behaviors common in industrial coatings.

- (3)

- Parametric Range: Experiments/simulations used fixed operational parameters (e.g., 2.6 atm air pressure, 0.00495 kg/s paint flow). Comprehensive parameter–space exploration is needed to build predictive control models.

4. Conclusions

- Numerical results demonstrate that initial paint atomization occurs at 2.5 ms under the synergistic action of high-speed air jets from the central, auxiliary, and fan-shaped orifices. The spray flow field stabilizes within 30 mm downstream of the nozzle. In this near-field region, atomization yields a mixture of fine droplets and larger discontinuous ligaments/droplets, with droplet density highest along the central axis and decreasing radially.

- Radial momentum predominantly originates from the fan-shaped air jets and transverse motion induced by central air jet entrainment at the paint inlet, exhibiting higher magnitudes along fan-air expansion paths. Axial momentum is primarily governed by the central atomizing air, displaying a characteristic increase followed by a decrease with axial distance. Both auxiliary and fan-shaped flows constrain transverse airflow expansion.

- Prior to stabilization (post-2.5 ms), the position of maximum velocity along the central axis migrates downstream while its magnitude decreases. The spray comprises air-droplet mixtures, with large droplets concentrated near the central axis close to the nozzle and smaller droplets dispersed peripherally. Measured spray cone angles are 61.7° (short axis) and 99.1° (long axis), with a paint column breakup length of 8.1 mm. Full atomization (≥80% droplets ≤ 100 μm) is achieved at 27.5 mm from the nozzle.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhao, K.; Ding, Y. Investigation of dynamic characteristics of liquid nitrogen droplet impact on solid surface. Sustainability 2022, 14, 710. [Google Scholar] [CrossRef]

- Zhao, J.S.; Wei, S.T.; Zhao, D.J.; Yao, Y.B.; Wang, L.P.; Guo, L.J. Research Advancement of Coating Robot for Super Large Space. Aeronaut. Manuf. Technol. 2023, 66, 46–58. [Google Scholar]

- Wittmann, A.; Wronski, T.; Shafirovich, E.; Schönnenbeck, C.; Brillard, A.; Brilhac, J.-F.; Tschamber, V. Oxidation of magnesium particles in a fluidized bed reactor. Combust. Flame 2025, 272, 113853. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, M.L.; Wang, Y.; Wen, K.; Zhuo, K.; Guo, R.; Gao, P. Partially Coherent Illumination-based digital holographic microscopy and its applications. Laser Optoelectron 2021, 58, 1811005. [Google Scholar]

- Han, Y.C.; Bowen, D.J.; Barreto, B.L.; Zwaan, R.R.; Strachinaru, M.; van der Geest, R.J.; Hirsch, A.; van den Bosch, A.E.; Bosch, J.G.; Voorneveld, J. Validation of left ventricular high frame rate echo-particle image velocimetry against 4d flow mri in patients. Ultrasound Med. Biol. 2025, 51, 94–101. [Google Scholar] [CrossRef]

- Cholemari, M.R.; Vishnubhatla, S.H. Analysis of an accurate iterative technique with attenuation compensation in planar laser induced fluorescence. Meas. Sci. Technol. 2025, 36, 015301. [Google Scholar] [CrossRef]

- Domnick, J.; Thieme, M. Atomization characteristics of high-speed rotary bell atomizers. At. Sprays 2006, 16, 857–874. [Google Scholar] [CrossRef]

- Liu, Z.Y.; Yu, Q.B.; Ma, W.D.; Liu, J.; Tao, S. Experimental investigation on centrifugal granulation of molten yellow phosphorus slag. Chem. Eng. Res. Des. 2023, 197, 548–557. [Google Scholar] [CrossRef]

- Benmoussa, A.; Pendar, M.R.; Páscoa, J.C. Enhancing electrostatic spray-painting efficiency with modified high-voltage conductors: A numerical study on pulsed electric fields. J. Aerosol Sci. 2024, 184, 106491. [Google Scholar] [CrossRef]

- Domnick, J.; Scheibe, A.; Ye, Q. The simulation of the electrostatic spray painting process with high-speed rotary bell atomizers. Part I: Direct charging. Part. Part. Syst. Charact. 2005, 22, 141–150. [Google Scholar] [CrossRef]

- Maly, M.; Slama, J.; Sapik, M.; Jedelsky, J.; Dančová, P.; Novosad, J. 2D and 3D numerical modelling of internal flow of pressure-swirl atomizer. In Proceedings of the 13th International Conference “Experimental Fluid Mechanics 2018”, Prague, Czech Republic, 13–16 November 2018; EDP Sciences: Les Ulis, France, 2019; Volume 213, p. 02055. [Google Scholar]

- Xiang, Y. Simulation of centrifugal nozzle atomization based on LES. Mod. Manuf. Technol. Equip. 2018, 12, 104–105. [Google Scholar]

- Fogliati, M.; Fontana, D.; Garbero, M.; Vanni, M.; Baldi, G.; Dondè, R. CFD simulation of paint deposition in an air spray process. J. Coat. Technol. Res. 2006, 3, 117–125. [Google Scholar] [CrossRef]

- Wang, Y.A.; Xie, X.P.; Lu, X.H. Design of a double-nozzle air spray gun and numerical research in the interference spray flow field. Coatings 2020, 10, 475. [Google Scholar] [CrossRef]

- Ye, Q.; Shen, B.; Tiedje, O.; Bauernhansl, T.; Domnick, J. Numerical and experimental study of spray coating using air-assisted high pressure atomizers. At. Sprays 2015, 25, 643–656. [Google Scholar] [CrossRef]

- Ye, Q.; Domnick, J. Analysis of droplet impingement of different atomizers used in spray coating processes. J. Coat. Technol. Res. 2017, 14, 467–476. [Google Scholar] [CrossRef]

- Wu, Z.J.; Chen, Y.; Liu, H.S.; Hua, W.; Duan, J.; Kong, L. A review of the developments of the characteristics and mechanisms of airless spraying on complex surfaces. Coatings 2023, 13, 2095. [Google Scholar] [CrossRef]

- Yu, S.H.; Yin, B.F.; Deng, W.X.; Jia, H.; Ye, Z.; Xu, B.; Xu, H. Numerical investigation on effects of elliptical diesel nozzle on primary spray characteristics by large eddy simulation (LES). At. Sprays 2018, 28, 695–712. [Google Scholar] [CrossRef]

- Chen, Y.; Chen, S.M.; Chen, W.Z.; Hu, J.; Jiang, J. An atomization model of air spraying using the volume-of-fluid method and large eddy simulation. Coatings 2021, 11, 1400. [Google Scholar] [CrossRef]

- Ali, F.; Narasimhamurthy, S.; Hegde, S.; Usman, M. Temperature-dependent viscosity analysis of powell-eyring fluid model during a roll-over web coating process. Polymers 2024, 16, 1723. [Google Scholar] [CrossRef]

- Liu, H.T.; Ou, M.X.; Dong, X.; Zhou, W.; Dai, S.; Jia, W. Spraying performance and deposition characteristics of an improved air-assisted nozzle with induction charging. Front. Plant Sci. 2024, 15, 1309088. [Google Scholar] [CrossRef] [PubMed]

- Li, M.; Yang, H.Z.; Wang, J.J.; Li, G.; Tang, J. An Experimental Investigation of the Impact of Surface Tension and Viscosity on the Atomization Effect of a Solid Cone Nozzle. Appl. Sci. 2023, 13, 4522. [Google Scholar] [CrossRef]

- Chideme, N.; de Vaal, P. Effect of Liquid Viscosity and Surface Tension on the Spray Droplet Size and the Measurement Thereof. J. Appl. Fluid Mech. 2024, 17, 2652–2672. [Google Scholar]

| Gas-Phase Inlets | Pressure Inlet (2.6 atm Total Pressure) for All Air Orifices |

|---|---|

| Liquid-phase inlet | Mass flow inlet (0.00495 kg/s) for the paint nozzle |

| Ambient pressure | 1 atm (operating pressure) |

| Gravity | −9.8 m/s2 in the Z-direction |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, S.; Zhang, Y.; Wu, Z.; Fang, G.; Chen, Y.; Duan, J. Near-Nozzle Atomization Characteristics in Air-Assisted Spraying: Integrated VOF-DPM Modeling and Experimental Validation. Coatings 2025, 15, 939. https://doi.org/10.3390/coatings15080939

Chen S, Zhang Y, Wu Z, Fang G, Chen Y, Duan J. Near-Nozzle Atomization Characteristics in Air-Assisted Spraying: Integrated VOF-DPM Modeling and Experimental Validation. Coatings. 2025; 15(8):939. https://doi.org/10.3390/coatings15080939

Chicago/Turabian StyleChen, Shiming, Yu Zhang, Zhaojie Wu, Gang Fang, Yan Chen, and Jimiao Duan. 2025. "Near-Nozzle Atomization Characteristics in Air-Assisted Spraying: Integrated VOF-DPM Modeling and Experimental Validation" Coatings 15, no. 8: 939. https://doi.org/10.3390/coatings15080939

APA StyleChen, S., Zhang, Y., Wu, Z., Fang, G., Chen, Y., & Duan, J. (2025). Near-Nozzle Atomization Characteristics in Air-Assisted Spraying: Integrated VOF-DPM Modeling and Experimental Validation. Coatings, 15(8), 939. https://doi.org/10.3390/coatings15080939