Effect of Scanning Speed on Microstructure and Properties of Ni/B4C/TiC Coating

Abstract

1. Introduction

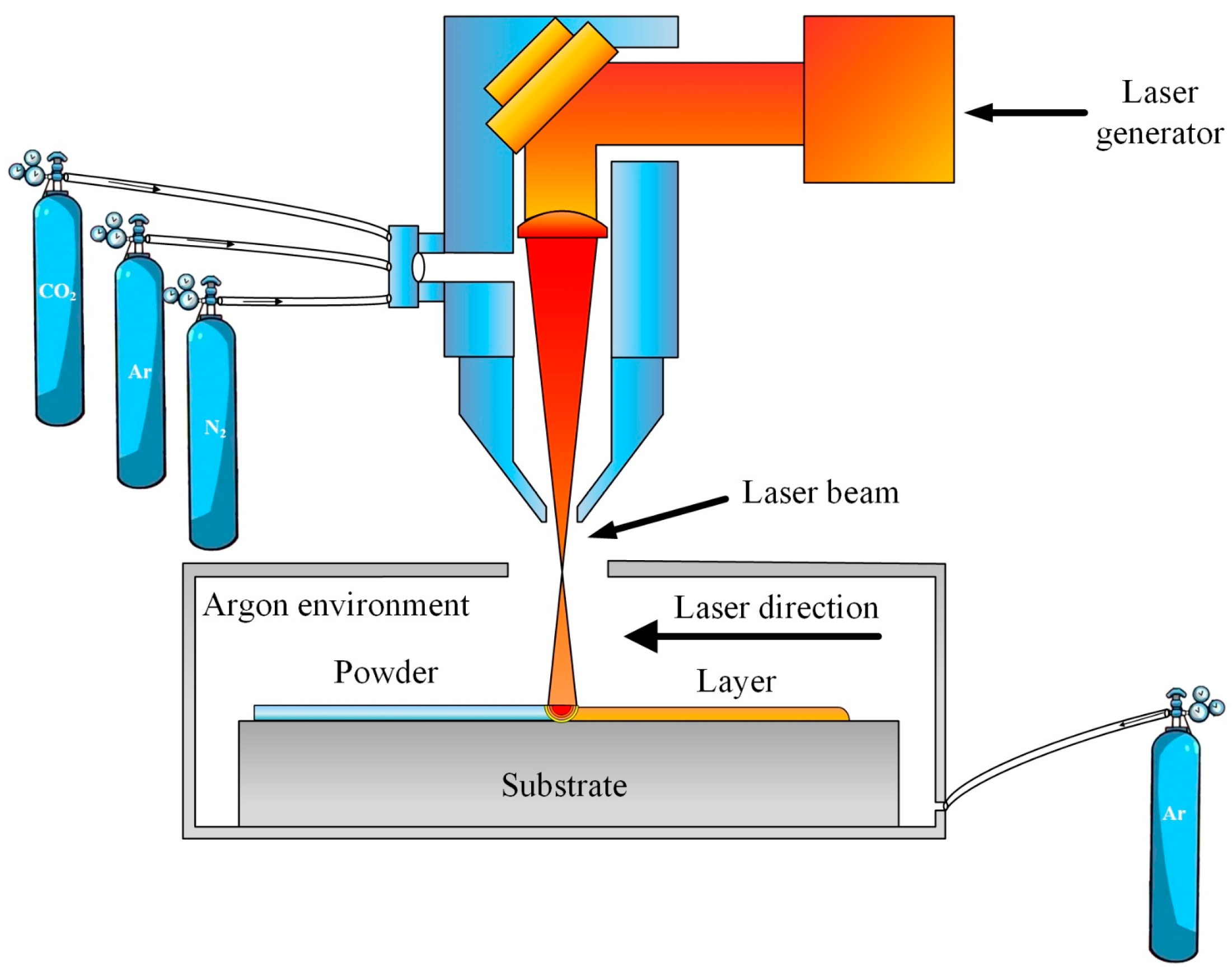

2. Materials and Methods

3. Results and Discussion

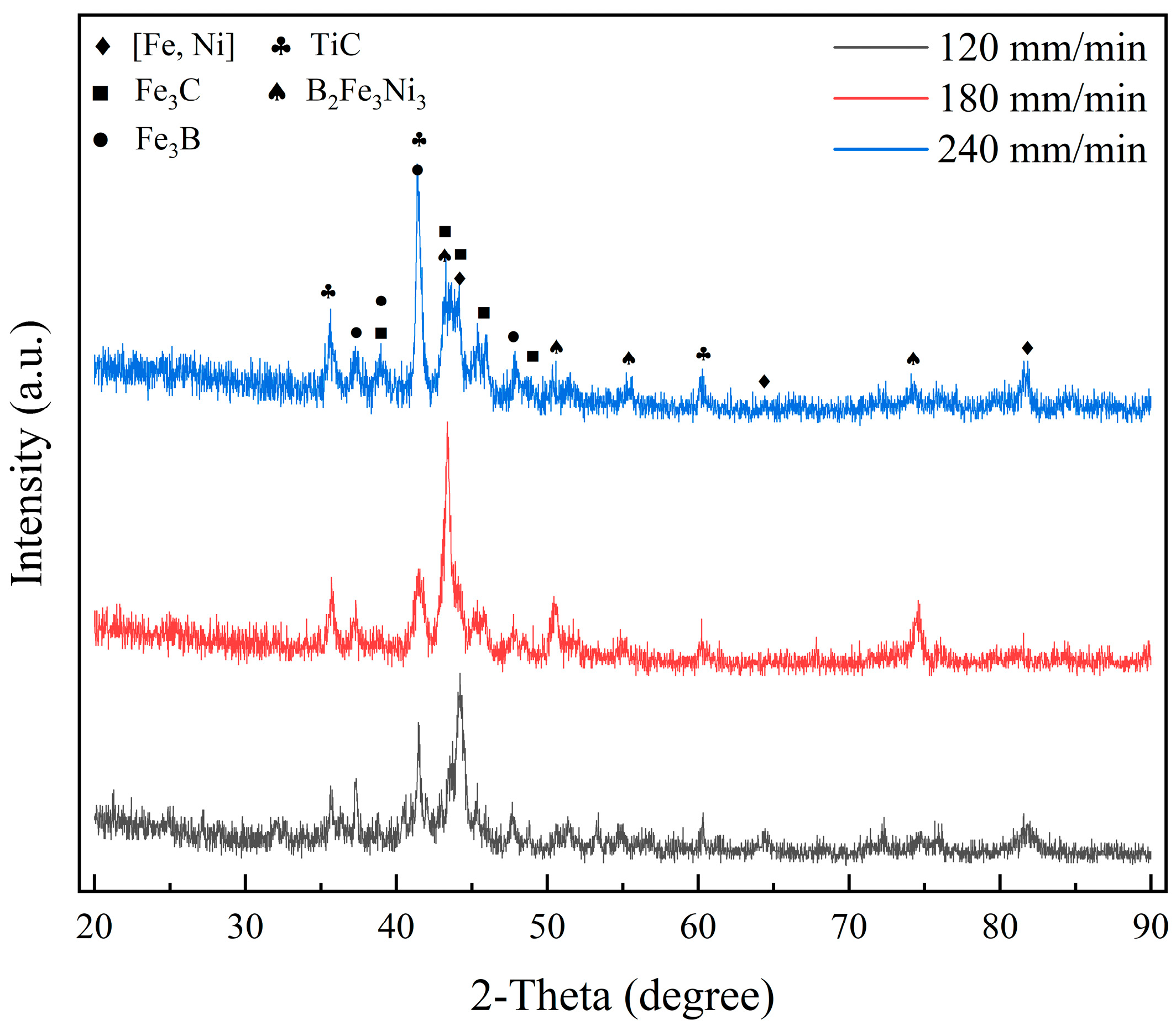

3.1. Phase Analysis

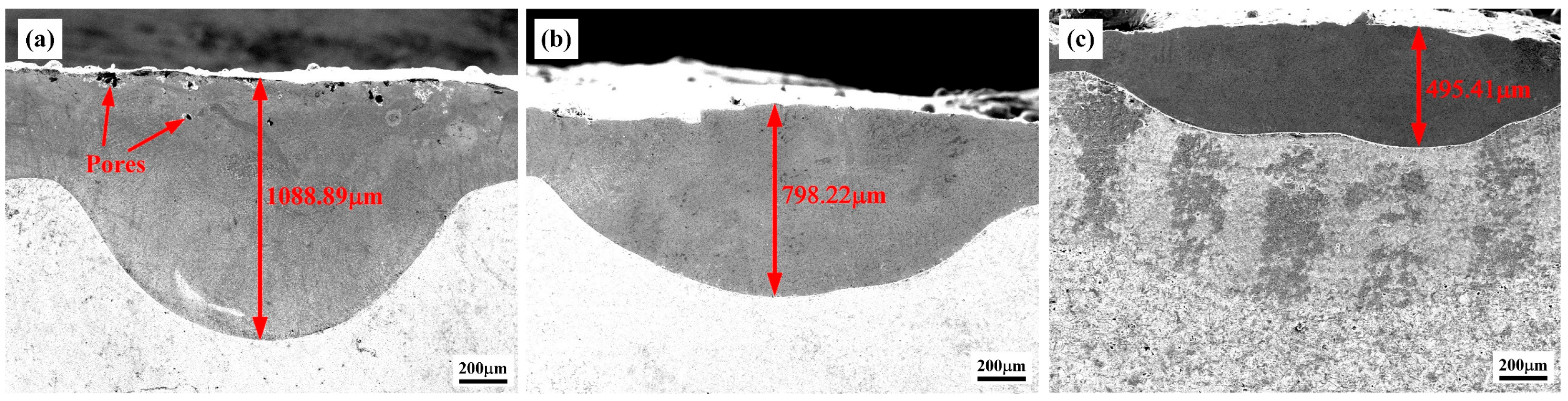

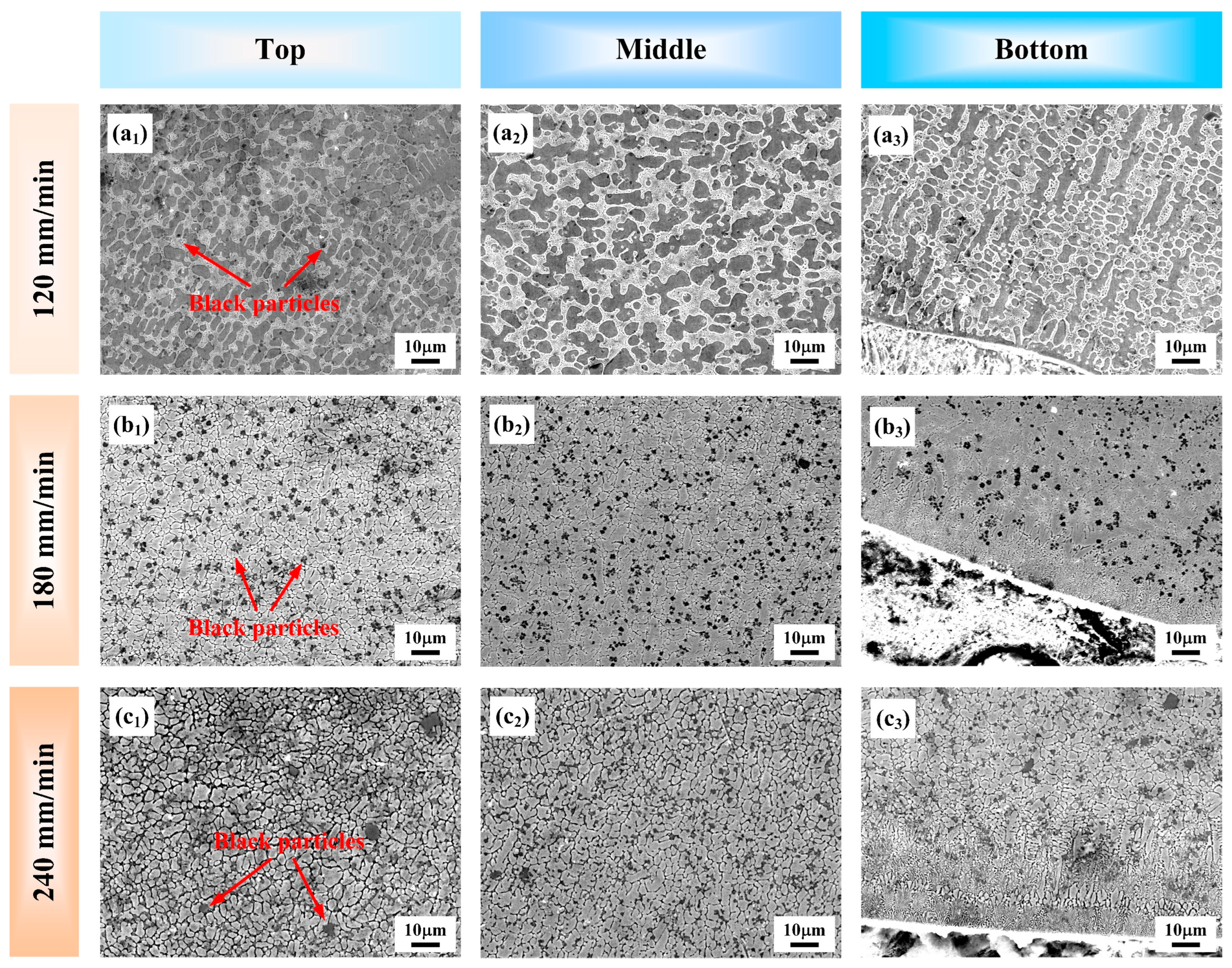

3.2. Microstructure Analysis

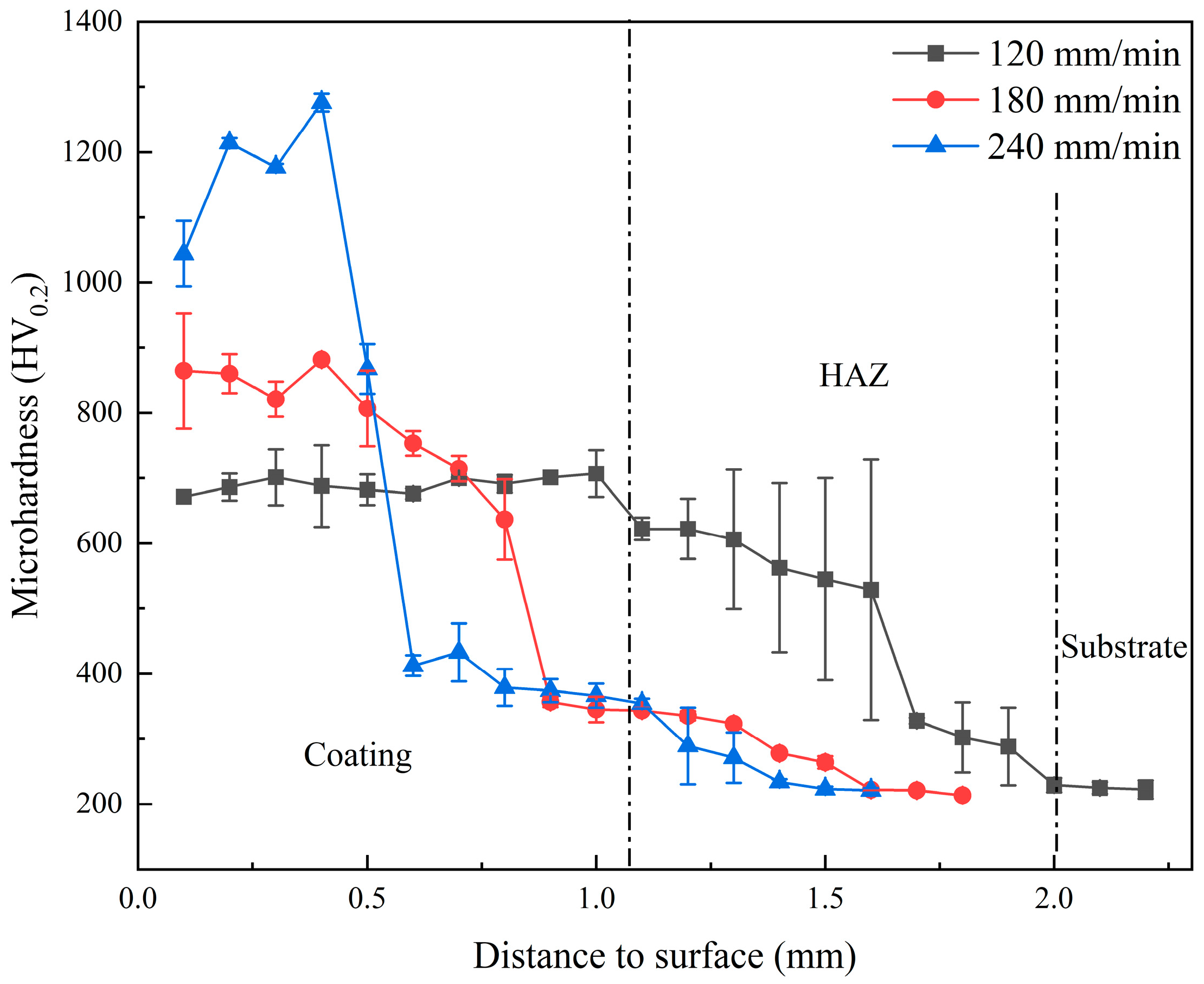

3.3. Microhardness Analysis

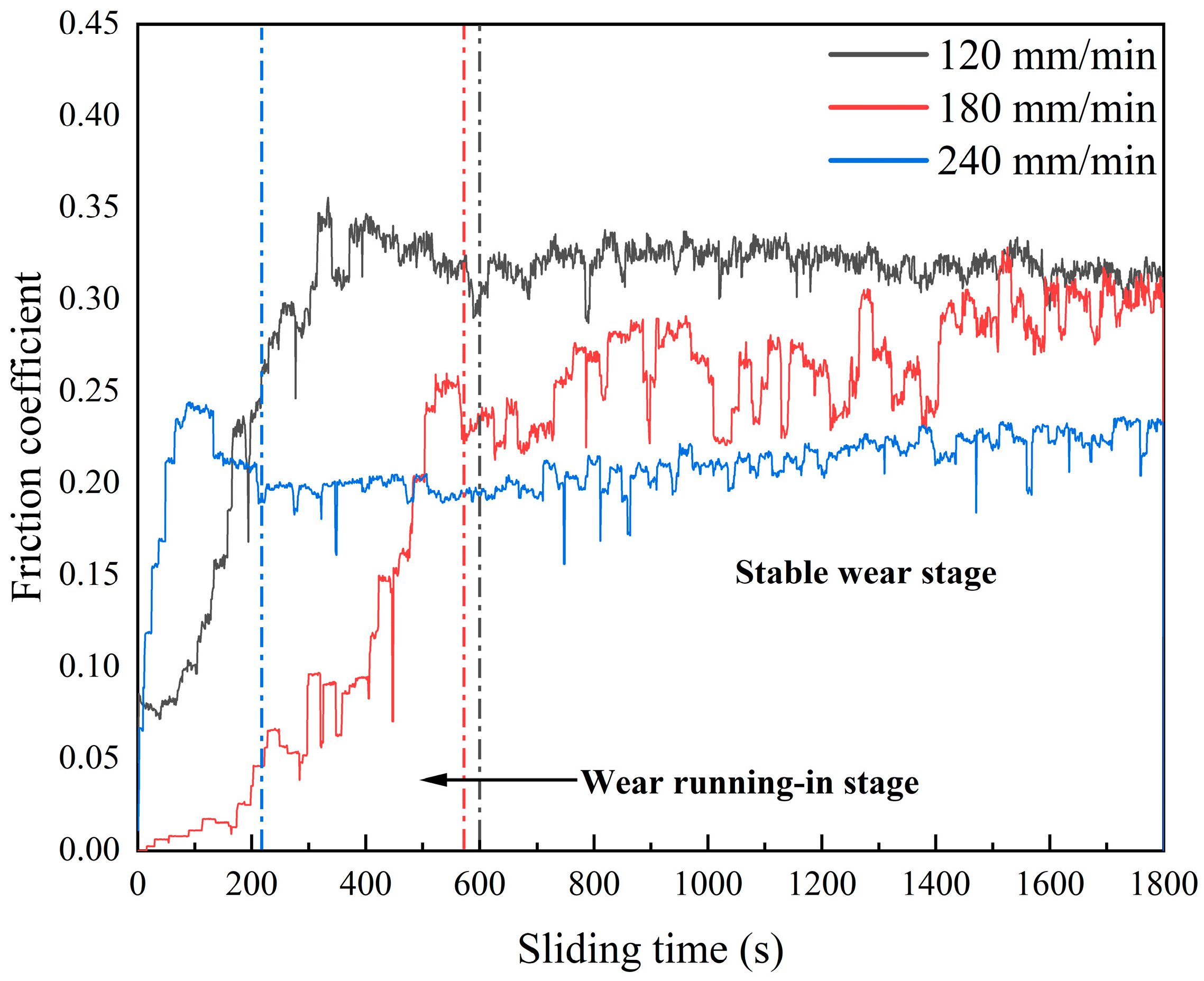

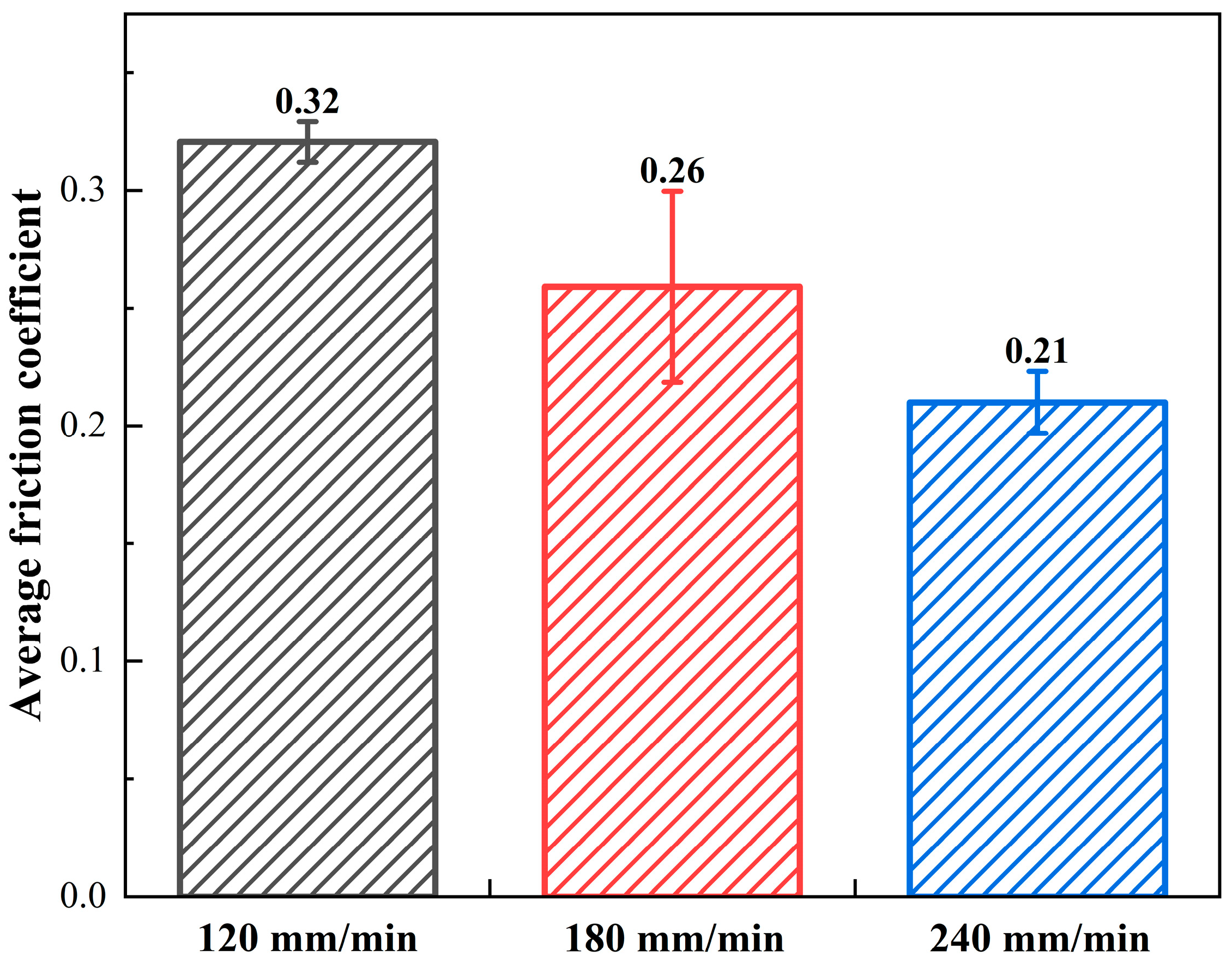

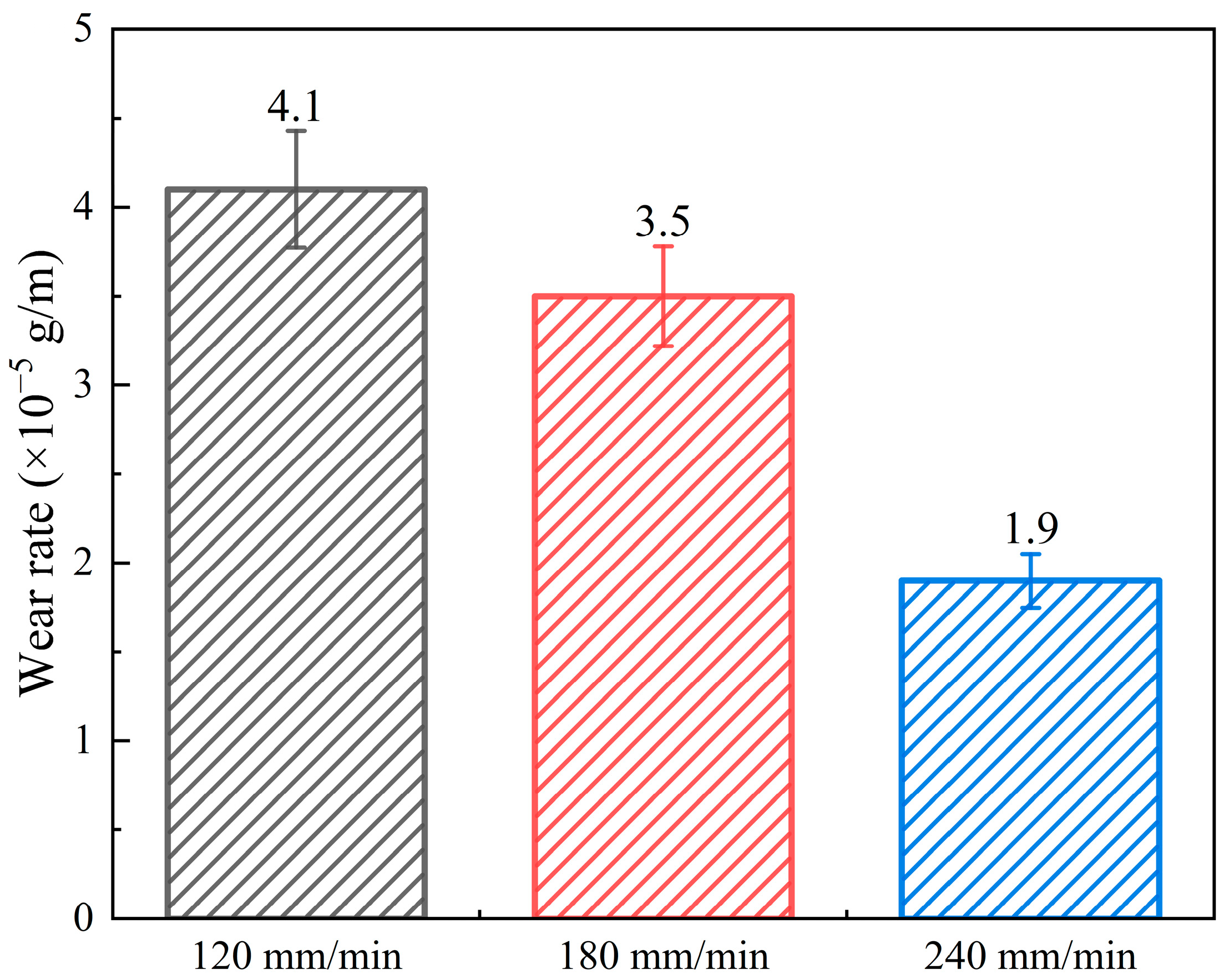

3.4. Wear Resistance Analysis

4. Conclusions

- The coating is mainly composed of Fe3B, Fe3C, B2Fe3Ni3, TiC, and solid solution [Fe, Ni]. The microstructure of the coating includes equiaxed crystals, columnar crystals, and dendritic crystals. The presence of eutectic structures at lower part of the coating was observed at scanning speeds of 180 mm/min and 240 mm/min.

- The microhardness of the coating increases as the scanning speed increases. When the scanning speed is 240 mm/min, the microhardness of the coating is 1280 Hv0.2, which is about 5.8 times that of the substrate.

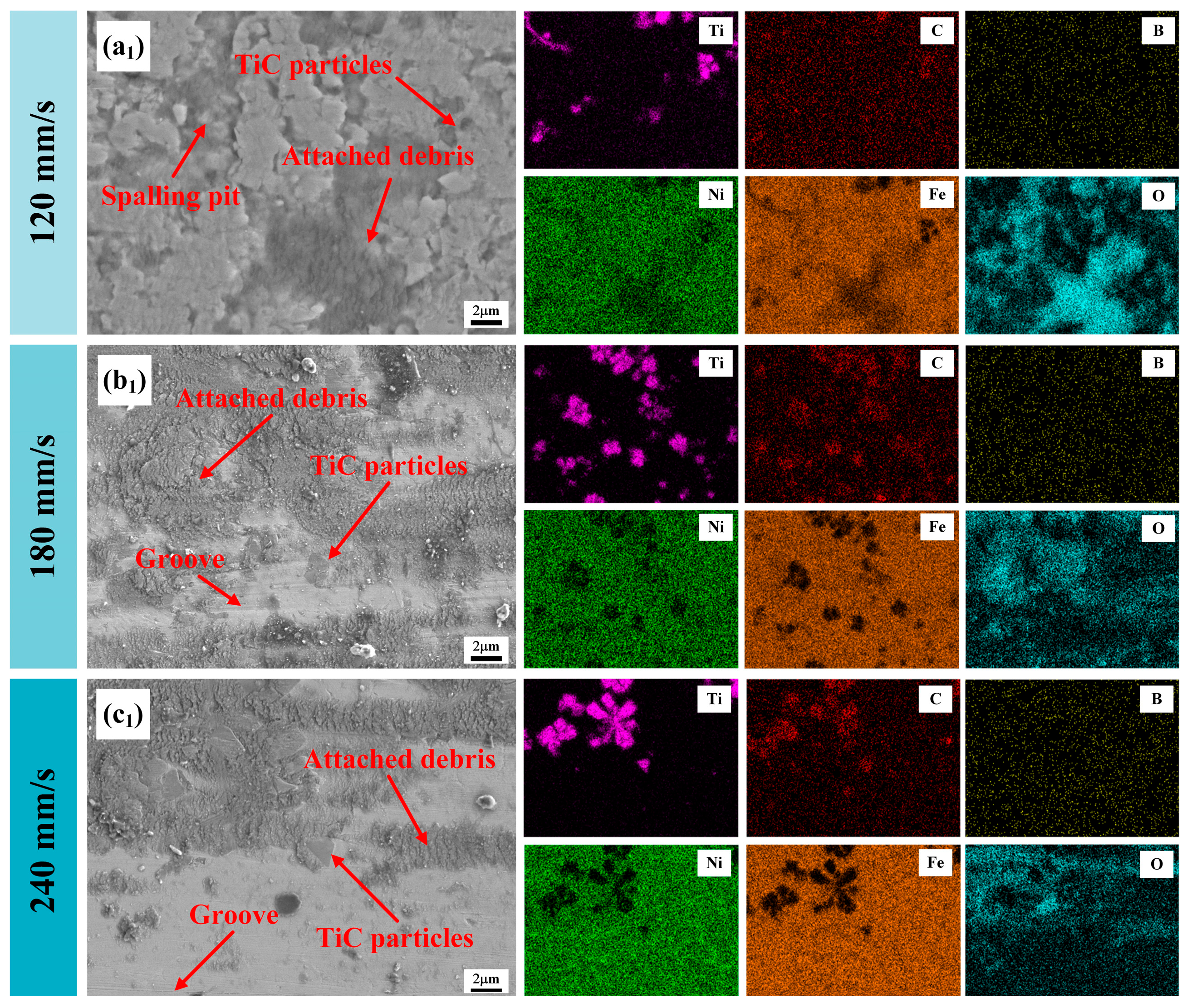

- The wear rate decreases as the scanning speed increases. When the scanning speed is 240 mm/min, the wear rate of the coating reaches the minimum value of 1.9 × 10−5 g/m and the coating shows the best wear resistance. The wear mechanism shifts from fatigue to abrasion as the scanning speed increases.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhang, Z.-Q.; Niu, W.; Lei, Y.-W.; Zheng, Y. The Effect of SiC Content on the Microstructure and Mechanical Properties of AlCoCrFeNiTi Laser Cladding High-Entropy Alloy Coatings. J. Therm. Spray Technol. 2025, 34, 1195–1207. [Google Scholar] [CrossRef]

- Liu, Q.-S.; Liu, X.-B.; Wang, G.; Liu, Y.-F.; Meng, Y.; Zhang, S.-H. Effect of Cu content on microstructure evolution and tribological behaviors of Ni60 composite coatings on 45# steel by laser cladding. Opt. Laser Technol. 2022, 156, 108549. [Google Scholar] [CrossRef]

- Huang, G.; Qu, L.; Lu, Y.; Wang, Y.; Li, H.; Qin, Z.; Lu, X. Corrosion resistance improvement of 45 steel by Fe-based amorphous coating. Vacuum 2018, 153, 39–42. [Google Scholar] [CrossRef]

- Zhao, C.; Du, W.; Yu, Z.; Zhang, Z.; Zhang, H. Effect of ultrasonic radiation on the organization and mechanical properties of laser-melted Ni-based WC coatings. Alex. Eng. J. 2024, 110, 215–233. [Google Scholar] [CrossRef]

- Chen, S.; Liu, Q.; Chen, J.; Zhang, L.; Cui, T.; Sun, X. Microstructure and tribological performance of novel Ni-based alloy cladding with excellent high temperature wear resistance and self-lubrication performance. Surf. Coat. Technol. 2024, 494, 131395. [Google Scholar] [CrossRef]

- Jiang, G.-Y.; Zhang, J.-W. The influence of laser power on the microstructure and friction performance of laser-prepared TiC-NbC composite coatings on stainless steel surfaces. Mater. Today Commun. 2024, 41, 110812. [Google Scholar] [CrossRef]

- Zheng, Y.; Lian, G.F.; Lu, H.; Chen, C.R.; Huang, X. Defects, organization, and properties of TiB2-TiC Bi-ceramic phase by laser cladding in situ synthesis. Ceram. Int. 2024, 50, 41097–41116. [Google Scholar] [CrossRef]

- Wang, P.; Zhang, Y.-H.; Pang, M.; Gao, L.-H. Research of the effects of laser power variation on the properties of laser cladding Ni45/Cr3C2/MoS2 self-lubricating wear-resistant coatings on the surface of 300M ultra-high-strength steel. J. Mater. Sci. 2024, 59, 13652–13676. [Google Scholar] [CrossRef]

- Liu, H.; Lin, X.; Zhang, X.; Yang, T.; Yi, F.; Xu, W. Influence of structure and properties for laser cladding fe based alloy on 45 steel surface. J. Phys. Conf. Ser. 2024, 2730, 012014. [Google Scholar] [CrossRef]

- Zhao, Y.; Yang, C.; Wang, L.; Wu, Y.; Liu, Y.; Xie, Z.; Fang, Q.; Feng, W.; Liu, H.; Chen, H. Enhancing strength, ductility, and thermal fatigue resistance in Stellite 21 coatings via Mn alloying and Transformation-Induced Plasticity. Mater. Sci. Eng. A 2024, 918, 147448. [Google Scholar] [CrossRef]

- Tang, B.; Tan, Y.; Xu, T.; Sun, Z.; Li, X. Effects of TiB2 Particles Content on Microstructure, Mechanical Properties and Tribo-logical Properties of Ni-Based Composite Coatings Reinforced with TiB2 Particles by Laser Cladding. Coatings 2020, 10, 813. [Google Scholar] [CrossRef]

- Ma, Q.; Zhang, H.; Lv, Y.; Song, C.; Guo, N.; Xiao, G.; Zhao, W. Microstructure and properties of W0.5Ta0.3MoNbVAlTi1-xZrx high entropy alloy coatings by laser cladding on the surface of 45# steel. Ceram. Int. 2023, 49, 36416–36428. [Google Scholar] [CrossRef]

- Qu, C.C.; He, B.; Cheng, X.; Wang, H.M. Microstructure and wear characteristics of laser-clad Ni-based self-lubricating coating incorporating MoS2/Ag for use in high temperature. J. Mater. Res. Technol. 2024, 33, 4481–4492. [Google Scholar] [CrossRef]

- Zhou, L.; Ma, G.; Wang, H.; Wang, W.; Mou, H.; XianYong, Z.; Zhao, H.; Li, Y.; Tan, N. High-speed laser cladded Ni-based cermet coating with high ceramic phase content derived from core-shell structured powder. Surf. Coat. Technol. 2024, 489, 131110. [Google Scholar] [CrossRef]

- Li, C.; Li, J.; Yao, F. In Situ Generation of TiCN Ni-Based Coatings by Laser Cladding and Study of Their Structure and Properties. Adv. Eng. Mater. 2024, 26, 2301997. [Google Scholar] [CrossRef]

- Feng, M.; Lin, T.; Lian, G.; Chen, C.; Huang, X. The influence of WC content on the microstructure and properties of laser cladding CoCrFeMnNiSi1.6 high-entropy alloy coatings. Ceram. Int. 2024, 50, 55286–55306. [Google Scholar] [CrossRef]

- Han, J.; Tang, S.; Guan, J.; Mao, Y.; Zhu, K.; Li, Y.; Li, P. Microstructure and wear property of (TiN + NbC) double ceramic phase-reinforced in FeCrNiCoAl high-entropy alloy coating fabricated by laser cladding. Ceram. Int. 2024, 50, 49066–49084. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, Z.; Lv, Z.; Cao, J.; Tong, Y.; Sun, M.; Cui, C.; Wang, X. Effect of SiC and TiC content on microstructure and wear behavior of Ni-based composite coating manufactured by laser cladding on Ti–6Al–4V. Wear 2024, 552, 205431. [Google Scholar] [CrossRef]

- Han, M.; Zhang, J.; Dong, P.; Du, K.; Zheng, Z.; Zhang, C.; Xu, B. Tribological properties and wear mechanism of Ni@Gr reinforced Ni-based alloy coatings prepared via laser cladding. J. Mater. Res. Technol. 2024, 31, 799–809. [Google Scholar] [CrossRef]

- Zhang, K.W.; Kong, D.J. High-Speed Laser Cladded Ni-Based WC Coatings: Microstructure, Friction-Wear Property and Wear Mechanism. J. Therm. Spray Technol. 2024, 33, 2367–2379. [Google Scholar]

- Zhao, Y.; Yu, T.; Chen, L.; Chen, Y.; Guan, C.; Sun, J. Microstructure and wear resistance behavior of Ti–C–B4C-reinforced composite coating. Ceram. Int. 2020, 46, 25136–25148. [Google Scholar] [CrossRef]

- Cheng, Q.; Shi, H.; Zhang, P.; Yu, Z.; Wu, D.; He, S.; Tian, Y. Microstructure, oxidation resistance and mechanical properties of stellite 12 composite coating doped with submicron TiC/B4C by laser cladding. Surf. Coat. Technol. 2020, 395, 125810. [Google Scholar] [CrossRef]

- Qi, Z.; Chen, C.; Wang, C.; Zhou, Z.; Zhou, J.; Long, Y. Effect of different laser wavelengths on laser cladding of pure copper. Surf. Coat. Technol. 2022, 454, 129181. [Google Scholar] [CrossRef]

- Nie, M.; Zhang, S.; Wang, Z.; Zhang, C.; Chen, H.; Chen, J. Effect of laser power on microstructure and interfacial bonding strength of laser cladding 17-4PH stainless steel coatings. Mater. Chem. Phys. 2022, 275, 125236. [Google Scholar] [CrossRef]

- Li, G.; Hong, B.; Song, D.; Ma, Y.; Yuan, C. Effect of pulsed current coupled ultrasonic rolling on surface fretting friction and wear properties of Ti-6Al-4V alloy. Wear 2025, 568, 205959. [Google Scholar] [CrossRef]

| Elemental | C | Si | Mn | Ni | Cr | Cu | Fe |

|---|---|---|---|---|---|---|---|

| Component Content | 0.42–0.50 | 0.17–0.37 | 0.50–0.80 | ≤0.30 | ≤0.25 | ≤0.25 | Bal. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tong, Y.; Cui, B.; Liu, Y.; Lv, Y.; Liu, Q.; Zhang, D. Effect of Scanning Speed on Microstructure and Properties of Ni/B4C/TiC Coating. Coatings 2025, 15, 932. https://doi.org/10.3390/coatings15080932

Tong Y, Cui B, Liu Y, Lv Y, Liu Q, Zhang D. Effect of Scanning Speed on Microstructure and Properties of Ni/B4C/TiC Coating. Coatings. 2025; 15(8):932. https://doi.org/10.3390/coatings15080932

Chicago/Turabian StyleTong, Yan, Bo Cui, Yu Liu, You Lv, Qimeng Liu, and Dongdong Zhang. 2025. "Effect of Scanning Speed on Microstructure and Properties of Ni/B4C/TiC Coating" Coatings 15, no. 8: 932. https://doi.org/10.3390/coatings15080932

APA StyleTong, Y., Cui, B., Liu, Y., Lv, Y., Liu, Q., & Zhang, D. (2025). Effect of Scanning Speed on Microstructure and Properties of Ni/B4C/TiC Coating. Coatings, 15(8), 932. https://doi.org/10.3390/coatings15080932