Investigation of the Microstructure and Properties of Cage-Shaped Hollow Cathode Bias Voltage Modulated Si-Doped DLC Thick Film

Abstract

1. Introduction

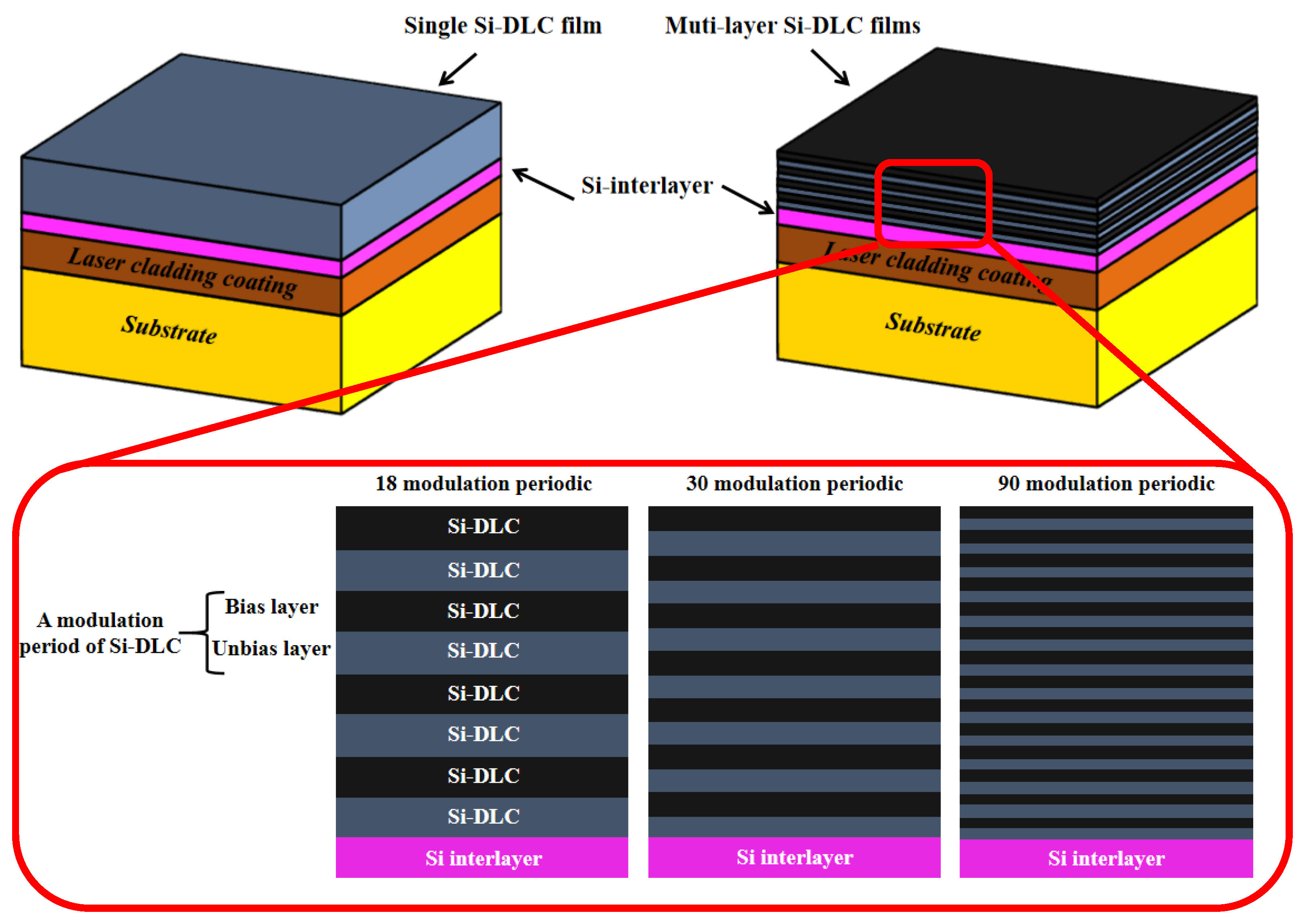

2. Materials and Methods

3. Results

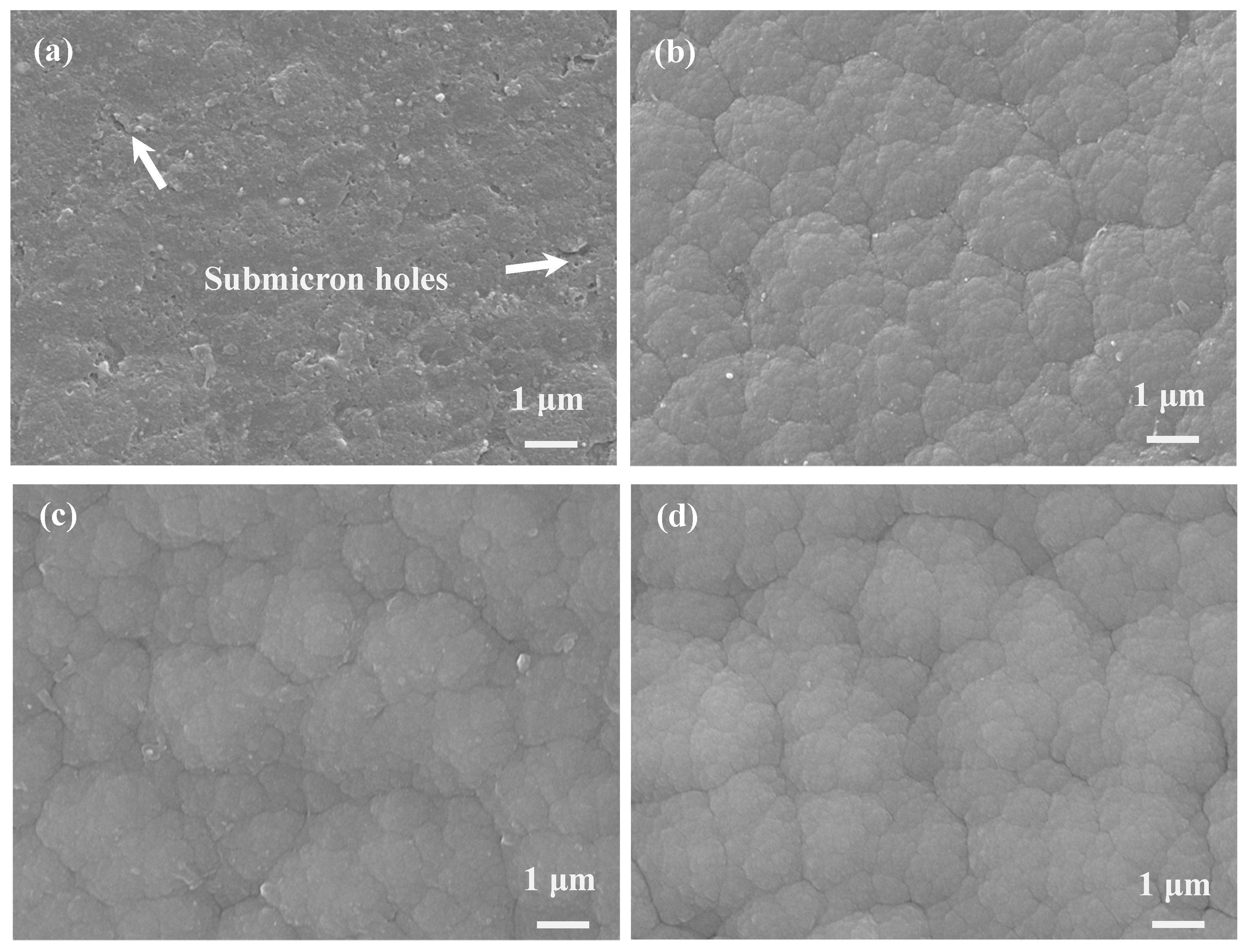

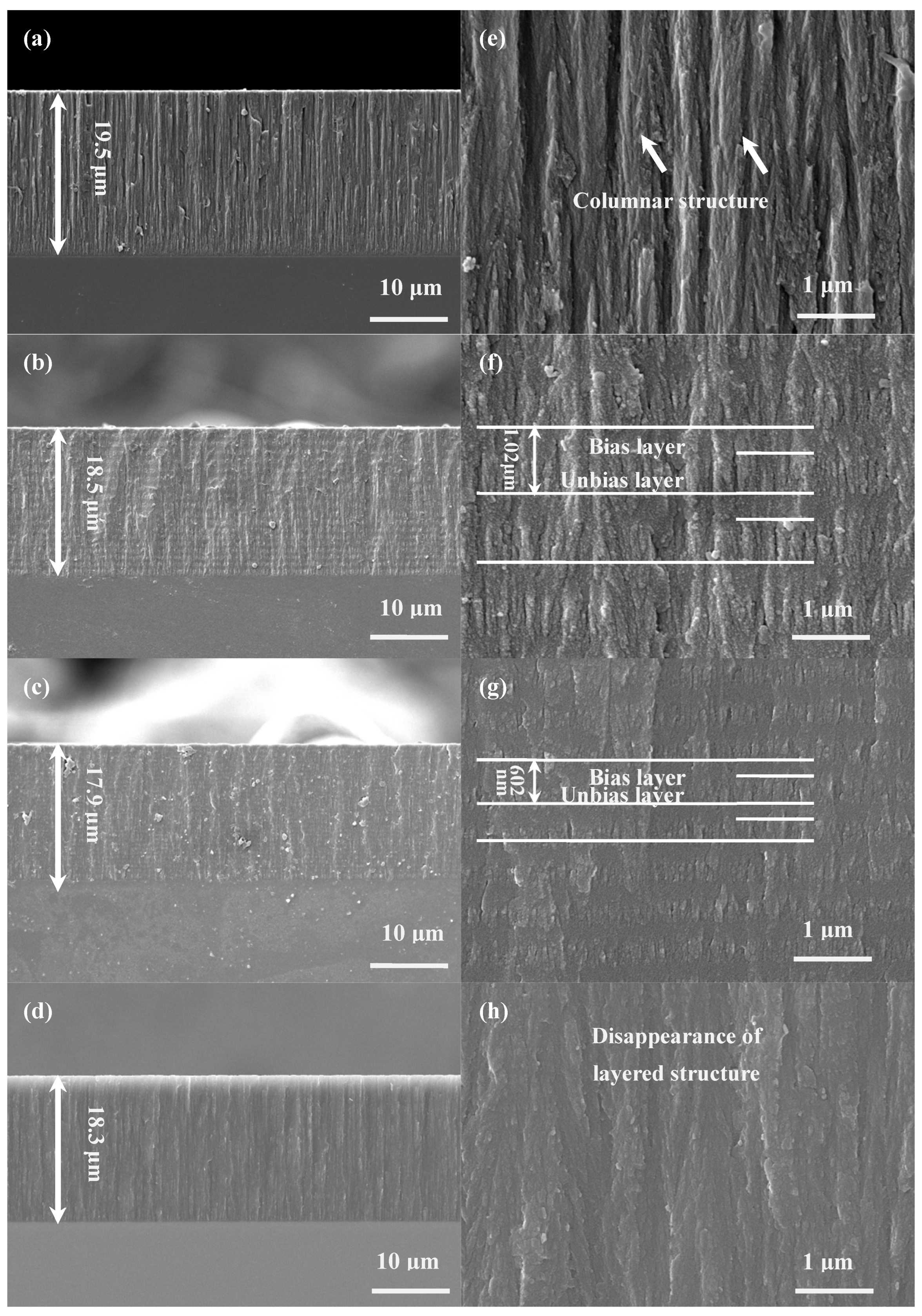

3.1. SEM Image of the Films

3.2. Surface Roughness

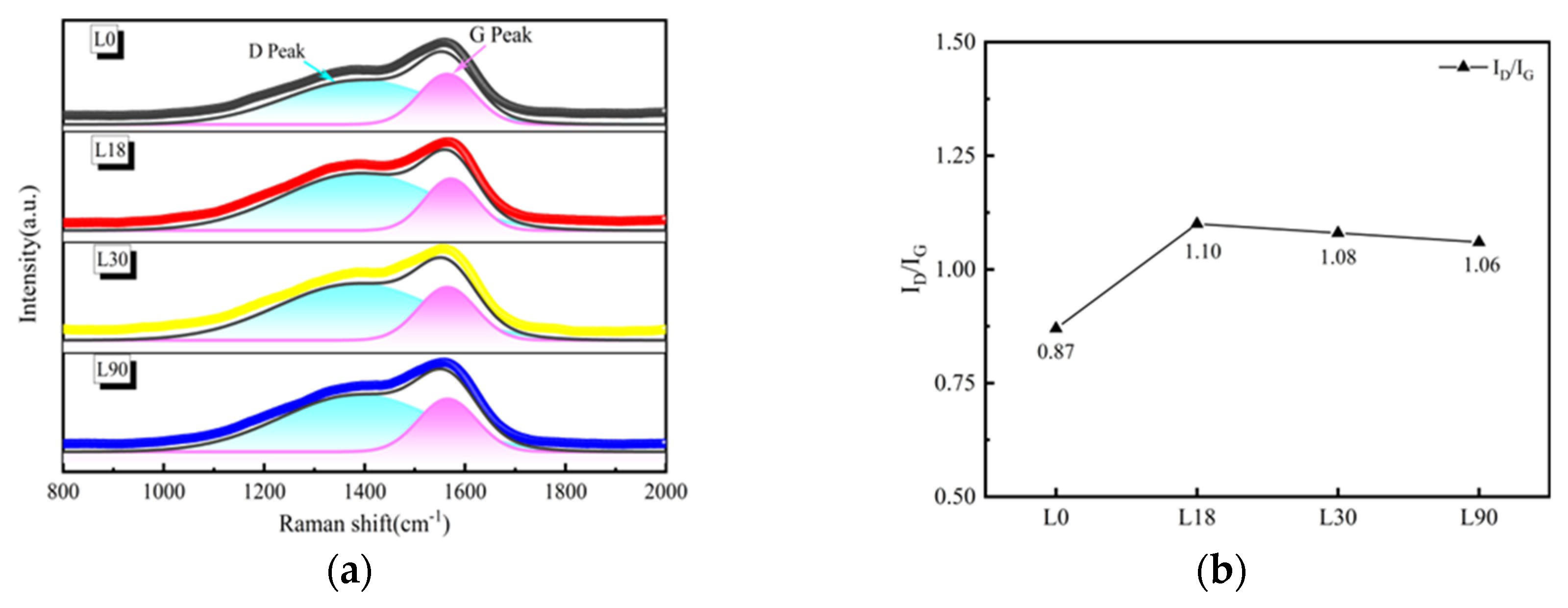

3.3. Raman Spectroscopy

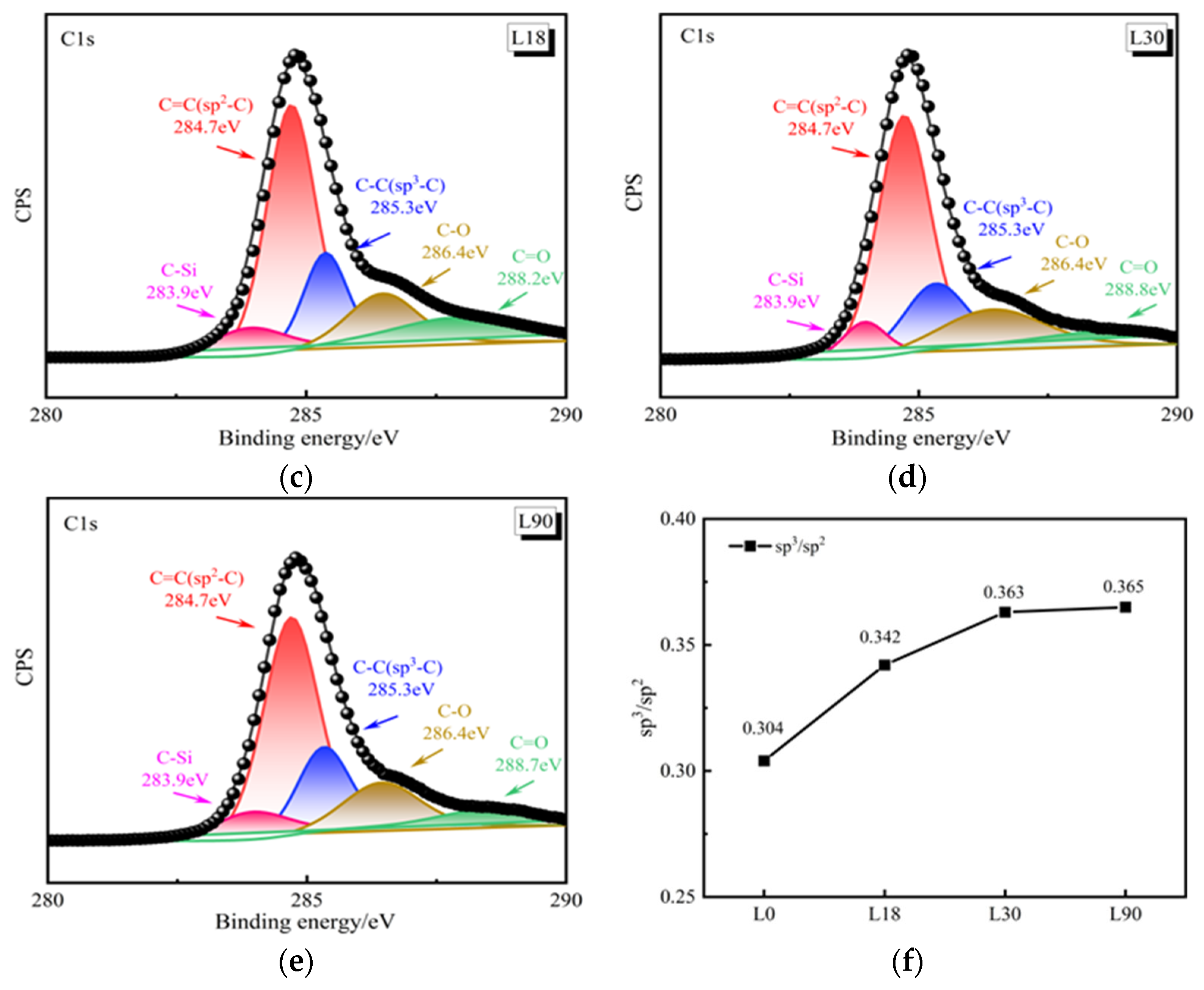

3.4. XPS

3.5. Structural Evolution Mechanism

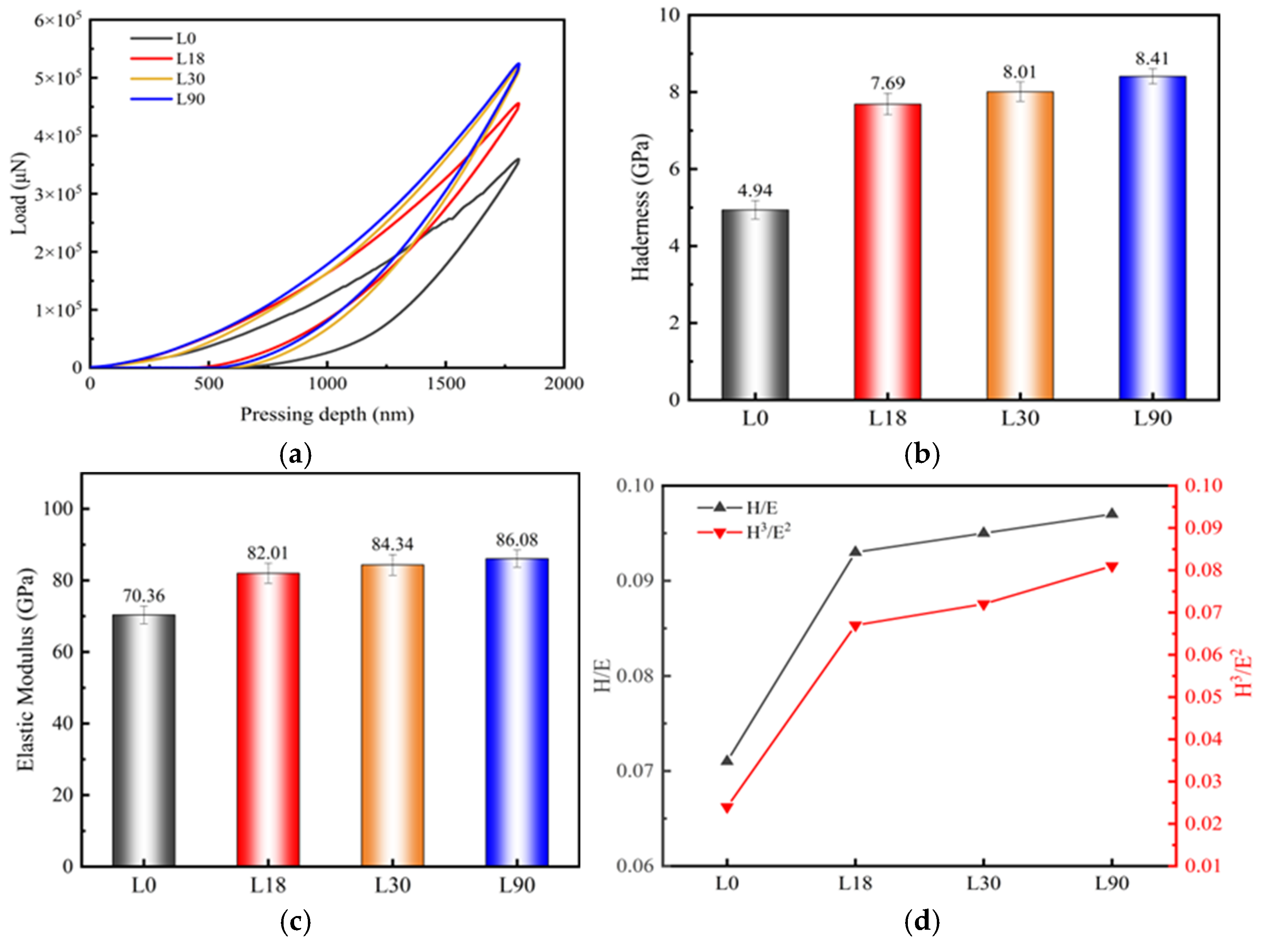

3.6. Mechanical Properties

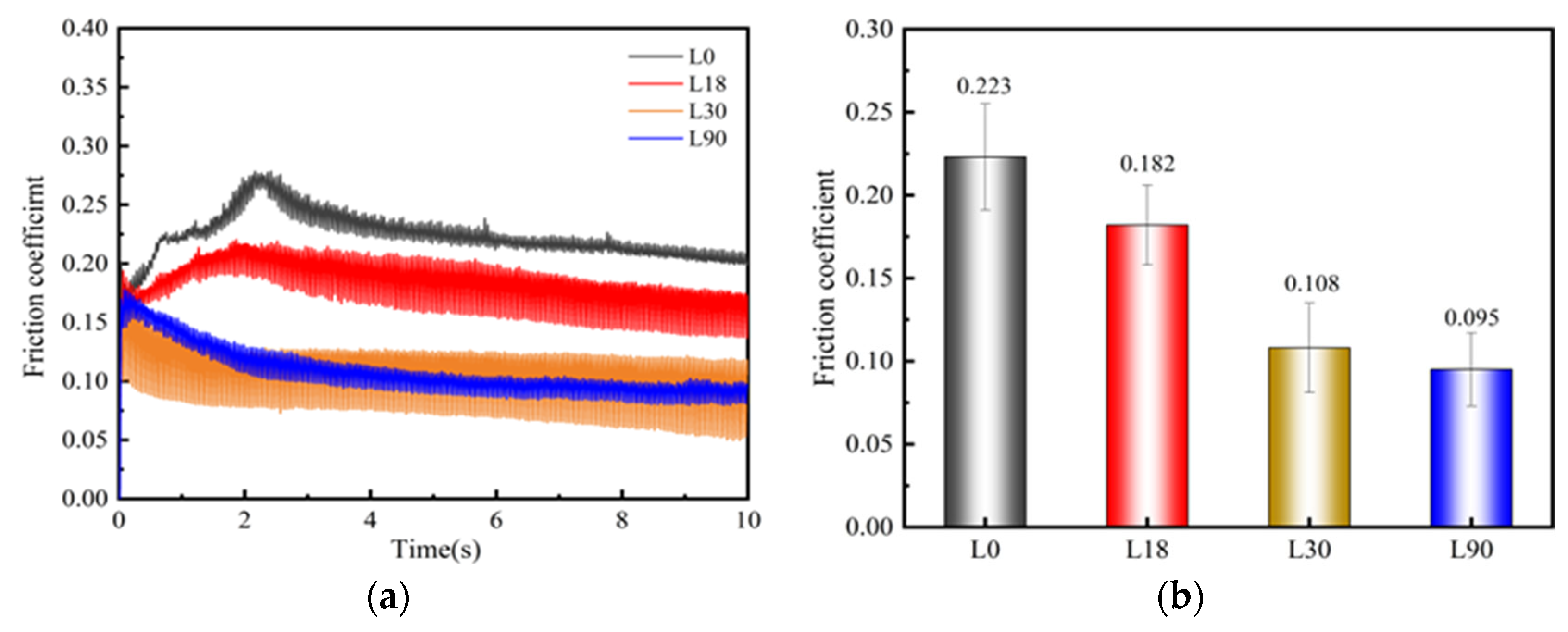

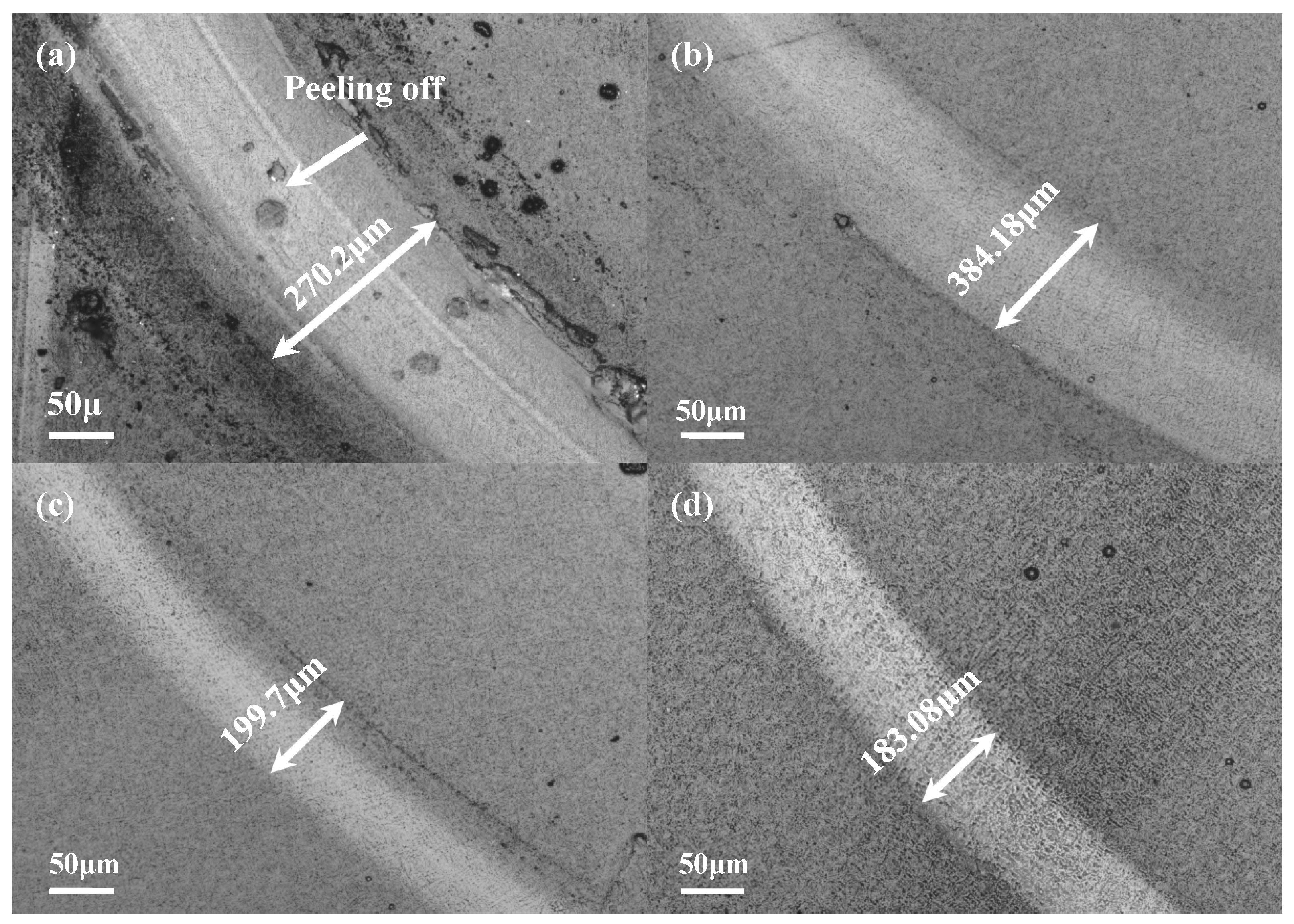

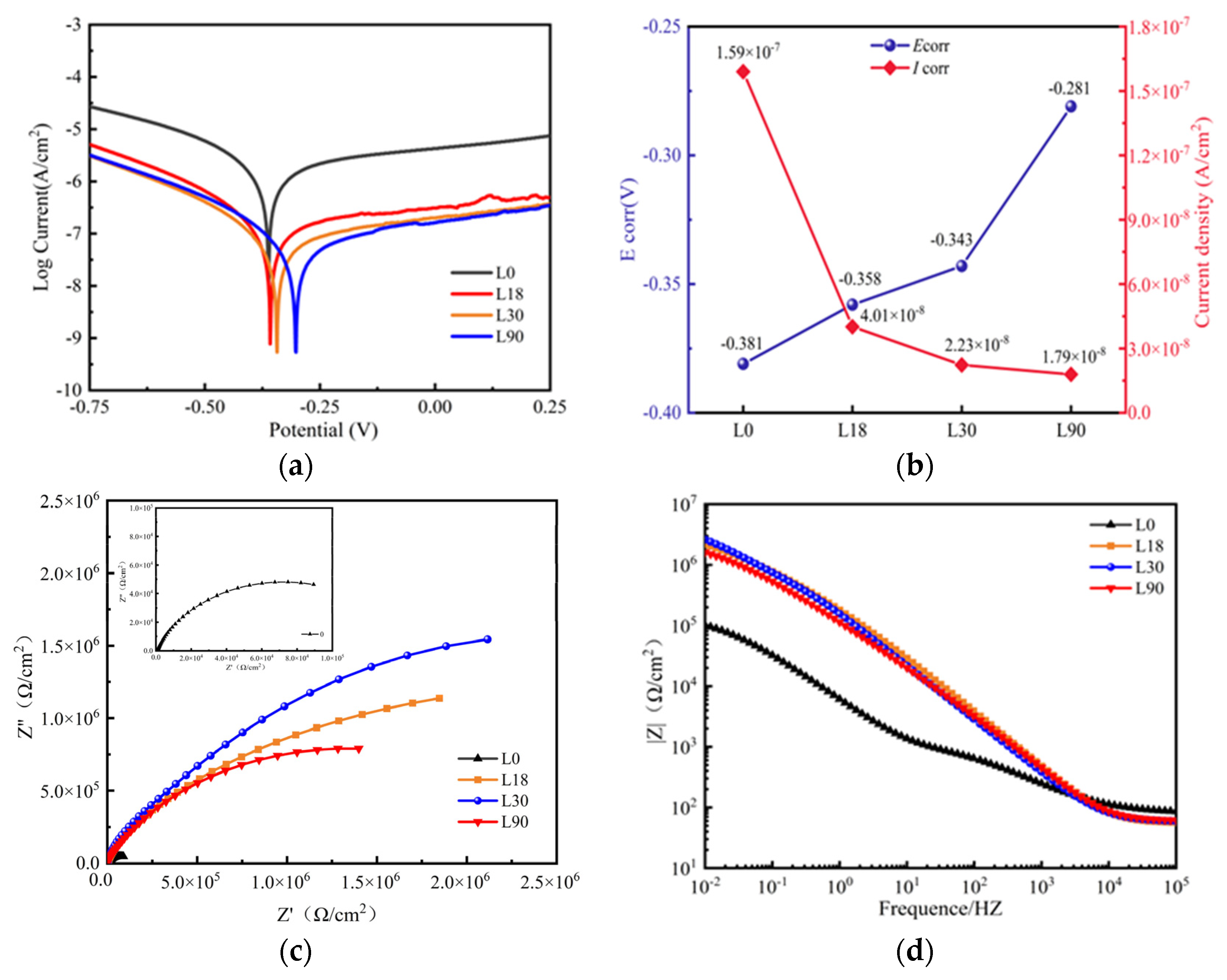

3.7. Corrosion Behavior

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Li, H.; Liu, L.; Guo, P.; Sun, L.; Wei, J.; Liu, Y.; Li, S.; Wang, S.; Lee, K.-R.; Ke, P.; et al. Long-term tribocorrosion resistance and failure tolerance of multilayer carbon-based coatings. Friction 2022, 10, 1707–1721. [Google Scholar] [CrossRef]

- Wu, Y.; Li, K.; Shi, B.; Qi, J.; Zhou, X.; Wang, Y.; Zheng, K.; Liu, Y.; Yu, S. The effect of sputtering power on the structural and tribological behaviors at elevated temperature of Ta/Si co-doped DLC films. Surf. Coat. Technol. 2024, 482, 130688. [Google Scholar] [CrossRef]

- Wei, X.; Chen, L.; Zhang, M.; Lu, Z.; Zhang, G. Effect of dopants (F, Si) material on the structure and properties of hydrogenated DLC film by plane cathode PECVD. Diam. Relat. Mater. 2020, 110, 108102. [Google Scholar] [CrossRef]

- Wang, J.; Pu, J.; Zhang, G.; Wang, L. Tailoring the structure and property of silicon-doped diamond-like carbon films by controlling the silicon content. Surf. Coat. Technol. 2013, 235, 326–332. [Google Scholar] [CrossRef]

- Wu, Y.; Shi, B.; Liu, Y.; Wang, L.; Gao, J.; Shen, Y.; Wang, Y.; Ma, Y.; Yu, S. Design of Ta gradient layer to improve adhesion strength between Cu substrate and DLC film. Vacuum 2022, 203, 111221. [Google Scholar] [CrossRef]

- Flege, S.; Hatada, R.; Ensinger, W.; Baba, K. Improved adhesion of DLC films on copper substrates by preimplantation. Surf. Coat. Technol. 2014, 256, 37–40. [Google Scholar] [CrossRef]

- Arslan, A.; Masjuki, H.H.; Varman, M.; Kalam, M.A.; Quazi, M.M.; Al Mahmud, K.; Gulzar, M.; Habibullah, M. Effects of texture diameter and depth on the tribological performance of DLC coating under lubricated sliding condition. Appl. Surf. Sci. 2015, 356, 1135–1149. [Google Scholar] [CrossRef]

- Polaki, S.R.; Kumar, N.; Ganesan, K.; Madapu, K.; Bahuguna, A.; Kamruddin, M.; Dash, S.; Tyagi, A.K. Tribological behavior of hydrogenated DLC film: Chemical and physical transformations at nano-scale. Wear 2015, 338–339, 105–113. [Google Scholar] [CrossRef]

- Modabberasl, A.; Kameli, P.; Ranjbar, M.; Salamati, H.; Ashiri, R. Fabrication of DLC thin films with improved diamond-like carbon character by the application of external magnetic field. Carbon 2015, 94, 485–493. [Google Scholar] [CrossRef]

- Forsich, C.; Dipolt, C.; Heim, D.; Mueller, T.; Gebeshuber, A.; Holecek, R.; Lugmair, C. Potential of thick a-C:H:Si films as substitute for chromium plating. Surf. Coat. Technol. 2014, 241, 86–92. [Google Scholar] [CrossRef]

- He, D.; Feng, Z.; Liang, R.; Wang, Q.; Shang, L. Effect of Cr3C2 content on the tribo-corrosion behaviors of Cr3C2-NiCr/DLC duplex coatings. Surf. Coat. Technol. 2024, 489, 131134. [Google Scholar] [CrossRef]

- He, D.; Liang, R.; Wang, Q.; Shang, L. Impact damage behaviors of Cr3C2-NiCr/DLC duplex coatings. Tribol. Inter. 2024, 200, 110086. [Google Scholar] [CrossRef]

- Liang, S.; He, D.; Shang, L.; Li, W.; Zhang, C.; Shao, L.; Seniuts, U.; Viktor, Z. Effect of cermet interlayer on the electrochemical behavior of Cr3C2-NiCr/DLC duplex coating. Surf. Coat. Technol. 2023, 469, 129813. [Google Scholar] [CrossRef]

- Wei, R. Development of new technologies and practical applications of plasma immersion ion deposition (PIID). Surf. Coat. Technol. 2010, 204, 2869–2874. [Google Scholar] [CrossRef]

- Azzi, M.; Amirault, P.; Paquette, M.; Klemberg-Sapieha, J.E.; Martinu, L. Corrosion performance and mechanical stability of 316L/DLC coating system: Role of interlayers. Surf. Coat. Technol. 2010, 204, 3986–3994. [Google Scholar] [CrossRef]

- Chicot, D.; Puchi-Cabrera, E.S.; Decoopman, X.; Roudet, F.; Lesage, J.; Staia, M.H. Diamond-like carbon film deposited on nitrided 316L stainless steel substrate: A hardness depth-profile modeling. Diam. Relat. Mater. 2011, 20, 1344–1352. [Google Scholar] [CrossRef]

- Jellesen, M.S.; Christiansen, T.L.; Hilbert, L.R.; Møller, P. Erosion–corrosion and corrosion properties of DLC coated low temperature gas-nitrided austenitic stainless steel. Wear 2009, 267, 1709–1714. [Google Scholar] [CrossRef]

- Dalibón, E.L.; Heim, D.; Forsich, C.; Rosenkranz, A.; Guitar, M.A.; Brühl, S.P. Characterization of thick and soft DLC coatings deposited on plasma nitrided austenitic stainless steel. Diam. Relat. Mater. 2015, 59, 73–79. [Google Scholar] [CrossRef]

- Sun, W.; Li, M.; Wu, M.; Hu, J. Uniformity of Si-containing diamond-like carbon films deposited at different positions by mesh hollow cathode discharge. Results Phys. 2019, 14, 102480. [Google Scholar] [CrossRef]

- Li, F.; Zhang, S.; Kong, J.; Zhang, Y.; Zhang, W. Multilayer DLC coatings via alternating bias during magnetron sputtering. Thin Solid Films 2011, 519, 4910–4916. [Google Scholar] [CrossRef]

- Kardar, M.; Parisi, G.; Zhang, Y.C. Dynamic Scaling of Growing Interfaces. Phys. Rev. Lett. 1986, 56, 889–892. [Google Scholar] [CrossRef]

- Bendavid, A.; Martin, P.J.; Comte, C.; Preston, E.W.; Haq, A.; Ismail, F.M.; Singh, R. The mechanical and biocompatibility properties of DLC-Si films prepared by pulsed DC plasma activated chemical vapor deposition. Diam. Relat. Mater. 2007, 16, 1616–1622. [Google Scholar] [CrossRef]

- Cui, W.G.; Lai, Q.B.; Zhang, L.; Wang, F.M. Quantitative measurements of sp3 content in DLC films with Raman spectroscopy. Surf. Coat. Technol. 2010, 205, 1995–1999. [Google Scholar] [CrossRef]

- Catherine, Y.; Zamouche, A. Glow discharge deposition of tetramethylsilane films. Plasma Chem. Plasma Process. 1985, 5, 353–368. [Google Scholar] [CrossRef]

- Ahmed, M.H.; Byrne, J.A.; McLaughlin, J.A.D.; Elhissi, A.; Ahmed, W. Comparison between FTIR and XPS characterization of amino acid glycine adsorption onto diamond-like carbon (DLC) and silicon doped DLC. Appl. Surf. Sci. 2013, 273, 507–514. [Google Scholar] [CrossRef]

- Irmer, G.; Dorner-Reisel, A. Micro-Raman Studies on DLC coatings. Adv. Eng. Mater. 2005, 7, 694–705. [Google Scholar] [CrossRef]

- Lifshitz, Y.; Kasi, S.R.; Rabalais, J.W.; Eckstein, W. Subplantation model for film growth from hyperthermal species. Phys. Rev. B 1990, 41, 10468–10480. [Google Scholar] [CrossRef]

- Müller, I.C.; Sharp, J.; Rainforth, W.M.; Hovsepian, P.; Ehiasarian, A. Tribological response and characterization of Mo–W doped DLC coating. Wear 2017, 376–377, 1622–1629. [Google Scholar] [CrossRef]

- Li, H.; Xu, T.; Wang, C.; Chen, J.; Zhou, H.; Liu, H. Tribochemical effects on the friction and wear behaviors of diamond-like carbon film under high relative humidity condition. Tribol. Lett. 2005, 19, 231–238. [Google Scholar] [CrossRef]

- Liu, Y.; Erdemir, A.; Meletis, E.I. An investigation of the relationship between graphitization and frictional behavior of DLC coatings. Surf. Coat. Technol. 1996, 86–87, 564–568. [Google Scholar] [CrossRef]

- Wang, L.; Li, L.; Kuang, X. Effect of substrate bias on microstructure and mechanical properties of WC-DLC coatings deposited by HiPIMS. Surf. Coat. Technol. 2018, 352, 33–41. [Google Scholar] [CrossRef]

- Leyland, A.; Matthews, A. On the significance of the H/E ratio in wear control: A nanocomposite coating approach to optimised tribological behaviour. Wear 2000, 246, 1–11. [Google Scholar] [CrossRef]

- Zhang, X.; Xiao, G.; Jiang, C.; Liu, B. Influence of process parameters on microstructure and corrosion properties of hopeite coating on stainless steel. Corros. Sci. 2015, 94, 428–437. [Google Scholar] [CrossRef]

- Li, H.T.; Sun, P.F.; Cheng, D.H.; Liu, Z.M. Effects of deposition temperature on structure, residual stress and corrosion behavior of Cr/TiN/Ti/TiN films. Ceram. Int. 2021, 47, 34909–34917. [Google Scholar] [CrossRef]

- Wang, Z.M.; Zhang, J.; Han, X.; Li, Q.F.; Wang, Z.L.; Wei, R. Corrosion and salt scale resistance of multilayered diamond-like carbon film in CO2 saturated solutions. Corros. Sci. 2014, 86, 261–267. [Google Scholar] [CrossRef]

| Element | C | B | Si | Cr | Ni | Mn | Mo | WC | Fe |

|---|---|---|---|---|---|---|---|---|---|

| Content | 0.18 | 0.84 | 0.90 | 18.37 | 4.25 | 0.54 | 4.34 | 0.54 | Bal |

| Film | Process | Ar | TMS | C2H2 | Voltage | Current | Bias | Time | Modulation Period |

|---|---|---|---|---|---|---|---|---|---|

| Sccm | V | A | V | Min | |||||

| L0 | Clean | 200 | / | / | 1400 | 45 | −200 | 30 | 0 |

| Si-interlayer | 200 | 20 | / | 1400 | 60 | 0 | 10 | ||

| Si-DLC | 70 | 10 | 130 | 1350 | 80 | 0/−200 | 180 | ||

| L18 | Clean | 200 | / | / | 1400 | 45 | −200 | 30 | 18 |

| Si-interlayer | 200 | 20 | / | 1400 | 60 | 0 | 10 | ||

| Si-DLC | 70 | 10 | 130 | 1350 | 80 | 0/−200 | 180 | ||

| L30 | Clean | 200 | / | / | 1400 | 45 | −200 | 30 | 30 |

| Si-interlayer | 200 | 20 | / | 1400 | 60 | 0 | 10 | ||

| Si-DLC | 70 | 10 | 130 | 1350 | 80 | 0/−200 | 180 | ||

| L90 | Clean | 200 | / | / | 1400 | 45 | −200 | 30 | 90 |

| Si-interlayer | 200 | 20 | / | 1400 | 60 | 0 | 10 | ||

| Si-DLC | 70 | 10 | 130 | 1350 | 80 | 0/−200 | 180 | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gong, M.; Li, H.; Wu, M.; Lv, P. Investigation of the Microstructure and Properties of Cage-Shaped Hollow Cathode Bias Voltage Modulated Si-Doped DLC Thick Film. Coatings 2025, 15, 930. https://doi.org/10.3390/coatings15080930

Gong M, Li H, Wu M, Lv P. Investigation of the Microstructure and Properties of Cage-Shaped Hollow Cathode Bias Voltage Modulated Si-Doped DLC Thick Film. Coatings. 2025; 15(8):930. https://doi.org/10.3390/coatings15080930

Chicago/Turabian StyleGong, Ming, Haitao Li, Mingzhong Wu, and Peng Lv. 2025. "Investigation of the Microstructure and Properties of Cage-Shaped Hollow Cathode Bias Voltage Modulated Si-Doped DLC Thick Film" Coatings 15, no. 8: 930. https://doi.org/10.3390/coatings15080930

APA StyleGong, M., Li, H., Wu, M., & Lv, P. (2025). Investigation of the Microstructure and Properties of Cage-Shaped Hollow Cathode Bias Voltage Modulated Si-Doped DLC Thick Film. Coatings, 15(8), 930. https://doi.org/10.3390/coatings15080930