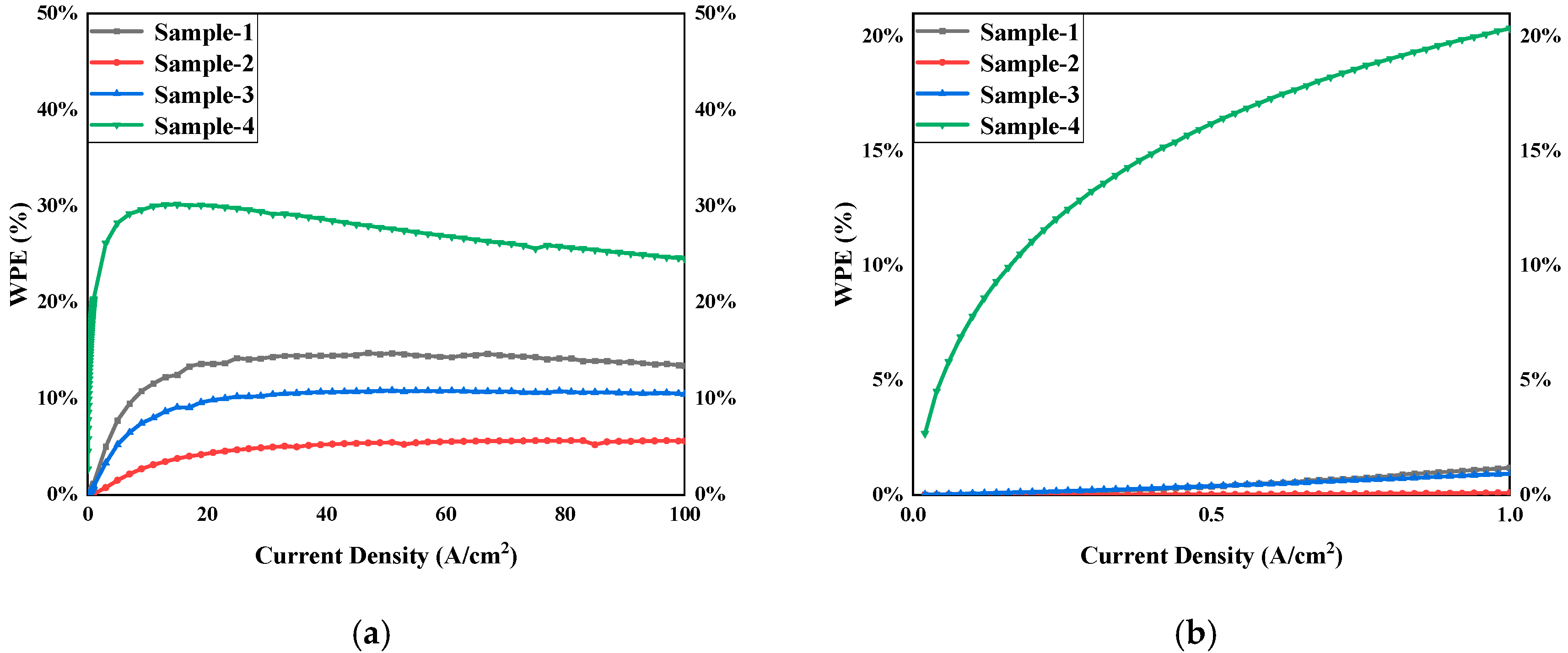

385 nm AlGaN Near-Ultraviolet Micro Light-Emitting Diode Arrays with WPE 30.18% Realized Using an AlN-Inserted Hole Spreading Enhancement S Electron Blocking Layer

Abstract

1. Introduction

- Material limitations: High Al composition in AlGaN barriers and electron-blocking layers (EBLs) improves CIE but introduces spontaneous/piezoelectric polarization effects in p-AlGaN. These effects increase Mg-H activation energy, hindering hole concentration enhancement compared to p-GaN [6,15,16,17].

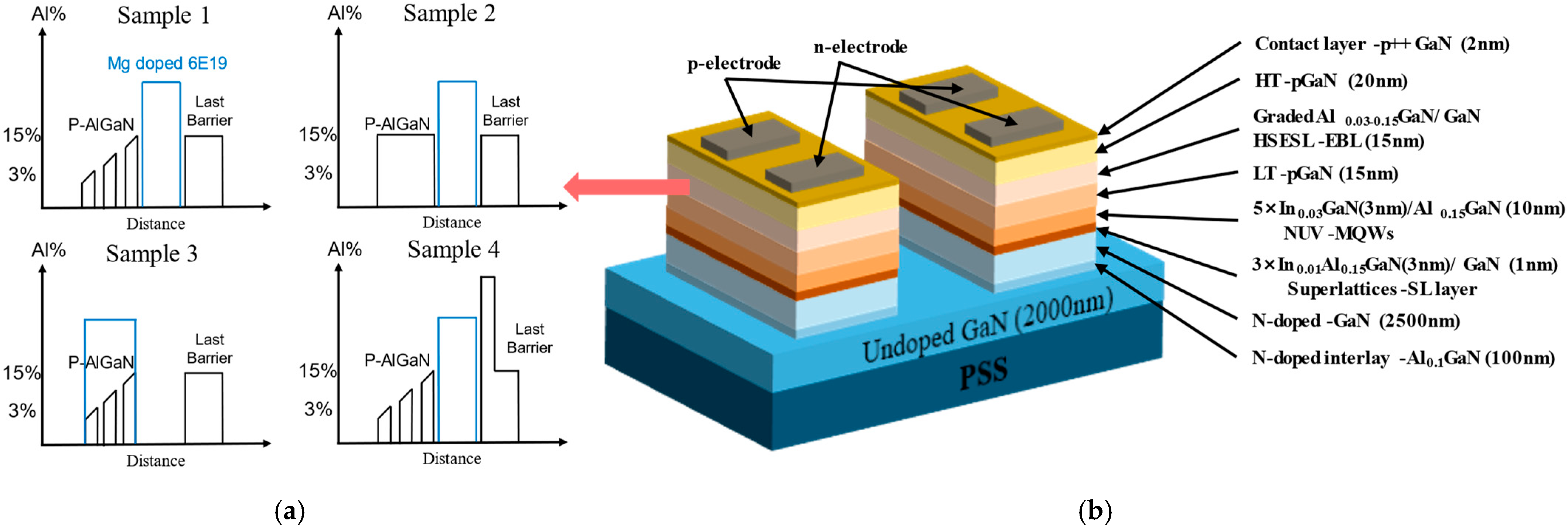

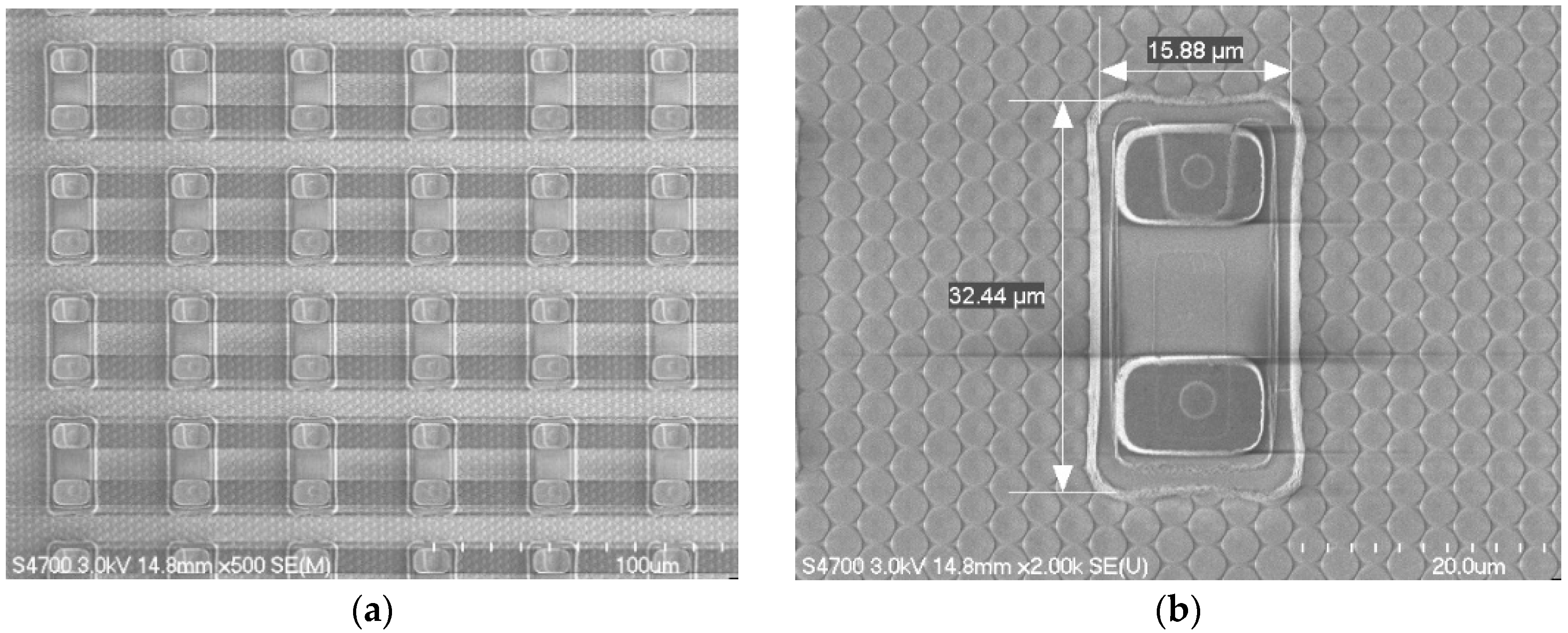

2. Device Structures and Parameters

- The substrate was cleaned in H2 ambient at a temperature of 1080 °C for 8 min to remove any impurities and oxygen.

- A 3 μm thick n-type GaN layer with a silicon doping concentration of 2 × 1019 cm−3; grown at 1070 °C with a V/III ratio of 4000.

- There was a 9 Loops period active region, and each pair was composed of 3 nm In0.02GaN quantum wells (QWs) + 12 nm Al0.15GaN barrier layer (N-type doping 2 × 1017 cm−3) with Al composition equal to 15%, grown at 900 °C with an identical V/II ratio of 33,000 to prevent fluctuations of the temperature during the growth of active layers.

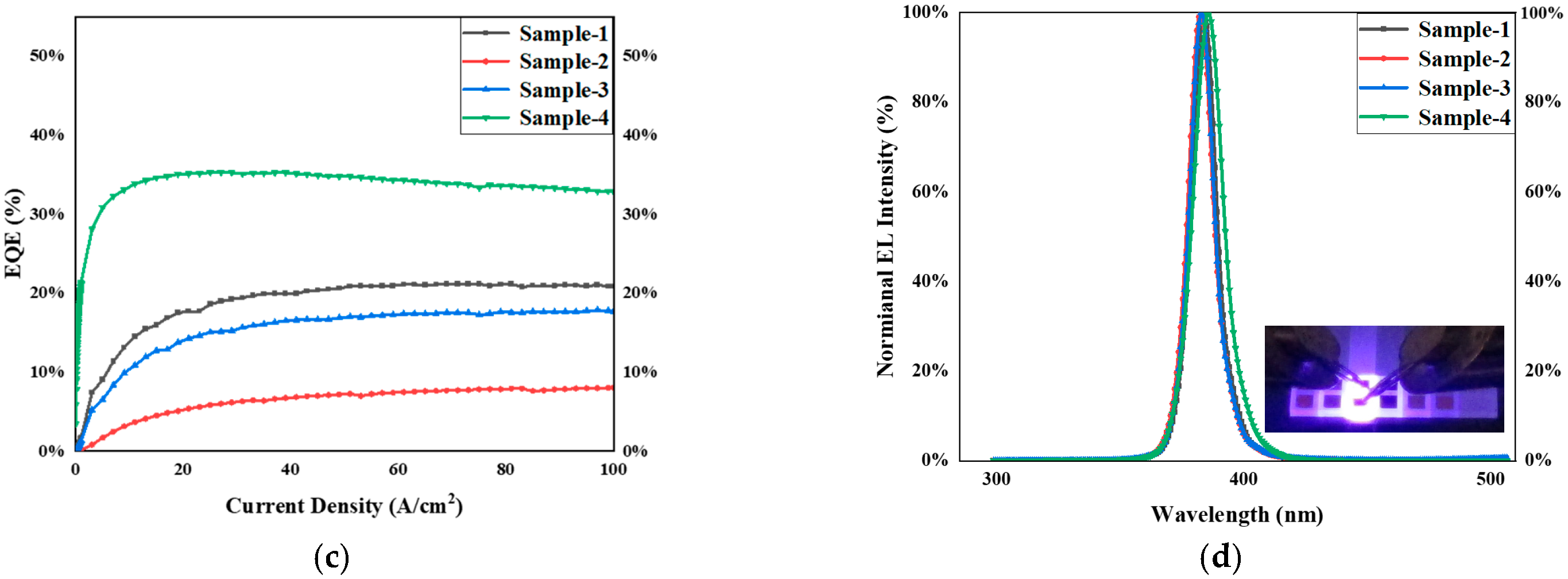

- A 20 nm p-type Al0.15GaN EBL (Mg: 2 × 1018 cm−3) grown at 930 °C with a V/III ratio of 800 and four different EBL structures, namely sample 1, 2, 3, and 4, to investigate the effect of EBL on the structure of NUV-LEDs.

- A 20 nm p-type GaN HSESL (Mg: 6 × 1019 cm−3) followed with a V/III ratio of 5000 at 950 °C.

- A 2 nm p-type GaN contact layer (Mg: 2.5 × 1020 cm−3) with the same growth condition of the p-type GaN HSESL layer.

- Sample 1: Graded Al EBL (3%→15%, linear) + dual Mg doping peaks.

- Sample 2: Uniform Al EBL (15%) + dual Mg peaks.

- Sample 3: Graded Al EBL + single Mg peak with polarization doping for enhanced hole concentration.

- Sample 4: AlN-inserted HSESL-EBL composite (graded Al + dual Mg peaks).

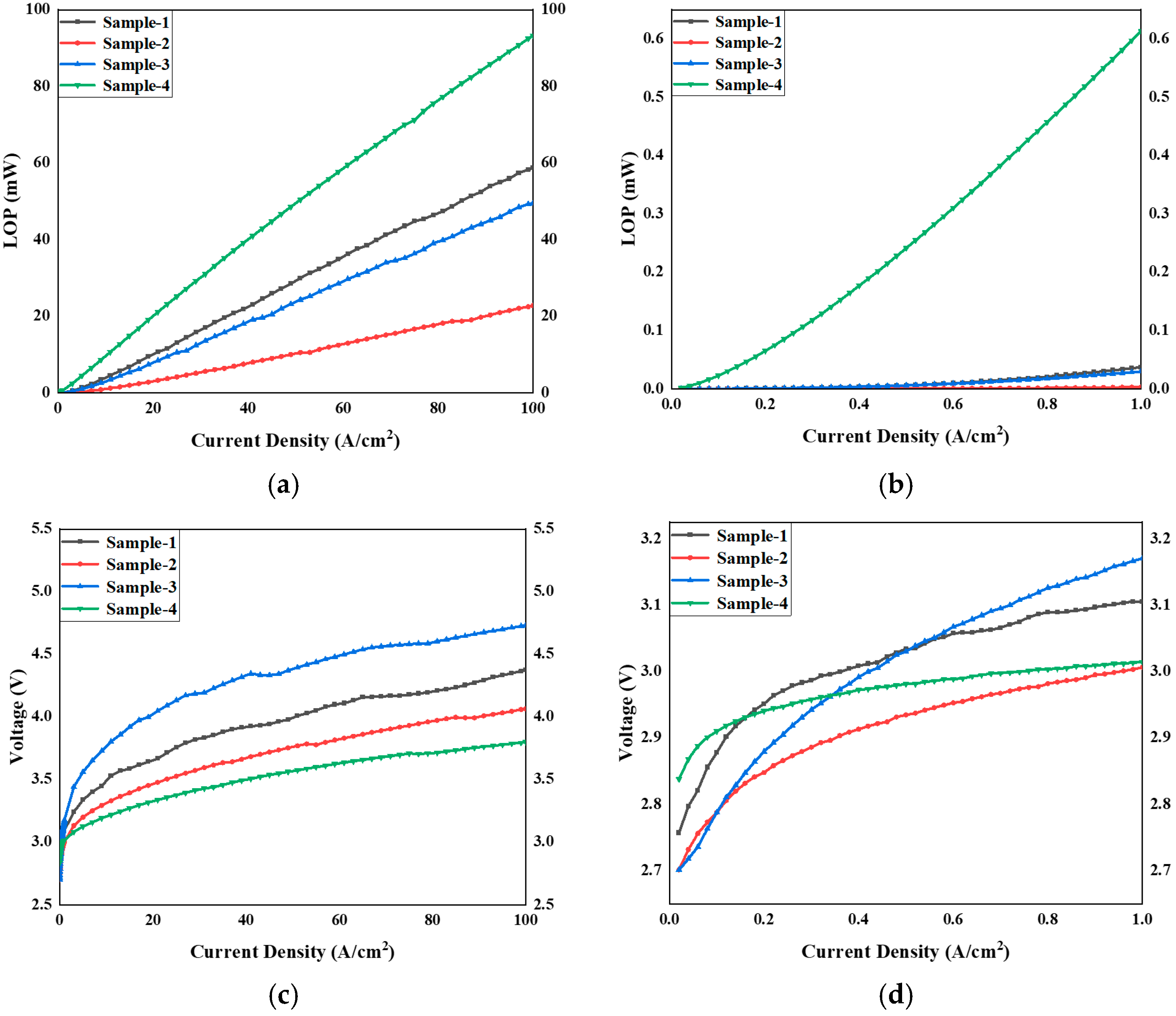

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Pernot, C.; Fukahori, S.; Inazu, T.; Fujita, T.; Kim, M.; Nagasawa, Y.; Hirano, A.; Ippommatsu, M.; Iwaya, M.; Kamiyama, S.; et al. Development of high efficiency 255–355nm AlGaN-based light-emitting diodes. Phys. Status Solidi A-Appl. Mater. Sci. 2011, 208, 1594–1596. [Google Scholar] [CrossRef]

- Khan, A.; Balakrishman, K.; Katona, T. Ultraviolet light-emitting diodes based on group three nitrides. Nat. Photonics 2008, 2, 77–84. [Google Scholar] [CrossRef]

- Mori, M.; Hamamoto, A.; Takahashi, A.; Nakano, M.; Wakikawa, N.; Tachibana, S.; Ikehara, T.; Nakaya, Y.; Akutagawa, M.; Kinouchi, Y. Development of a new water sterilization device with a 365nm UV-LED. Med. Biol. Eng. Comput. 2007, 45, 1237–1241. [Google Scholar] [CrossRef]

- Hirayama, H.; Maeda, N.; Fujikawa, S.; Toyoda, S.; Kamata, N. Recent progress and future prospects of AlGaN-based high efficiency deep-ultraviolet light-emitting diodes. Jpn. J. Appl. Phys. 2014, 53, 100209. [Google Scholar] [CrossRef]

- Lin, W.Y.; Wang, T.Y.; Ou, S.L.; Liang, J.H.; Wuu, D.S. Improved performance of 365nm LEDs by inserting an un-doped electron blocking layer. IEEE Electron. Device Lett. 2014, 35, 467–469. [Google Scholar] [CrossRef]

- Won, W.S.; Tran, L.G.; Park, W.T.; Kim, K.K.; Shin, C.S.; Kim, N.; Kim, Y.J.; Yoon, Y.J. UV-LEDs for the disinfection and Bio-Sensing applications. Int. J. Precis. Eng. Manuf. 2018, 19, 1901–1915. [Google Scholar] [CrossRef]

- Hirayama, H.; Yatabe, T.; Noguchi, N.; Ohashi, T.; Kamata, N. 231–261nm AlGaN deep-ultraviolet light-emitting diodes fabricated on AlN multilayer buffers grown by ammonia pulse-flow method on sapphire. Appl. Phys. Lett. 2007, 91, 071901. [Google Scholar] [CrossRef]

- Hai, X.; Rashid, R.; Sadaf, S.; Mi, Z.; Zhao, S. Effect of low hole mobility on the efficiency droop of AlGaN nanowire deep ultraviolet light emitting diodes. Appl. Phys. Lett. 2019, 114, 101104. [Google Scholar] [CrossRef]

- Kneissl, M.; Kolbe, T.; Chua, C.; Kueller, V.; Lobo, N.; Stellmach, J.; Knauer, A.; Rodriguez, H.; Einfeldt, S.; Yang, Z.; et al. Advances in group III-nitride-based deep UV light-emitting diode technology. Semicond. Sci. Technol. 2011, 26, 014036. [Google Scholar] [CrossRef]

- Yao, Y.; Li, H.; Wang, M.; Li, P.; Lam, M.; Iza, M.; Speck, J.S.; Denbaars, S.P.; Nakamura, S. High external quantum efficiency (6.8%) UV-A LEDs on AlN templates with quantum barrier optimization. Opt. Express 2023, 31, 28649. [Google Scholar] [CrossRef] [PubMed]

- Tamulaitis, G. Ultraviolet Light emitting diodes. Lith. J. Phys. 2011, 51, 177–193. [Google Scholar] [CrossRef]

- Delaney, K.T.; Rinke, P.; Van de Walle, C.G. Auger recombination rates in nitrides from first principles. Appl. Phys. Lett. 2009, 94, 141101. [Google Scholar] [CrossRef]

- Li, J.; Oder, T.N.; Nakarmi, M.L.; Lin, J.Y.; Jiang, H.X. Optical and electrical properties of Mg-doped p-type AlxGa1-xN. Appl. Phys. Lett. 2002, 80, 1210. [Google Scholar] [CrossRef]

- Hirayama, H.; Tsukada, Y.; Maeda, T.; Kamata, N. 227nm AlGaN Light-Emitting Diode with 0.15mW Output Power Realized using a Thin quantum Well and AlN Buffer with Reduced threading dislocation Density. Appl. Phys. Express 2008, 1, 051101. [Google Scholar] [CrossRef]

- Nam, K.B.; Li, J.; Nakarmi, M.L.; Lin, J.Y.; Jiang, H.X. Unique optical properties of AlGaN alloys and related ultraviolet emitters. Appl. Phys. Lett. 2004, 84, 25. [Google Scholar] [CrossRef]

- Zhou, S.; XU, H.; HU, H.; Gui, C.; Liu, S. High quality GaN buffer layer by isoelectric doping and its application to 365 nm InGaN/AlGaN ultraviolet light-emitting diodes. Appl. Surf. Sci. 2019, 471, 231–238. [Google Scholar] [CrossRef]

- Hirayama, H.; Fujikawa, S.; Noguchi, N.; Norimatsu, J.; Takano, T.; Tsubaki, K.; Kamata, N. 222–282nm AlGaN and InAlGaN-based deep-UV LEDs fabricated on high-quality AlN on sapphire. Phys. Status Solidi A 2009, 206, 1176. [Google Scholar] [CrossRef]

- Mondal, R.K.; Chatterjee, V.; Pal, S. Efficient Carrier Transport for AlGaN-Based Deep-UV LEDs with Graded Superlattice p-AlGaN. IEEE Trans. Electron. Devices 2020, 67, 1674–1679. [Google Scholar] [CrossRef]

- Fiorentini, V.; Bernardini, F.; Sala, F.D.; Carlo, A.D.; Lugli, P. Effects of macroscopic polarization in III-V nitride multi-quantum-wells. Physics 1999, 60, 8849. [Google Scholar] [CrossRef]

- Wang, L.; Li, G.; Song, W.; Wang, H.; Luo, X.; Sun, Y.; Zhang, B.; Jiang, J.; Li, S. Improved performance of AlGaN-based near ultraviolet light-emitting diodes with convex quantum barrier. Superlattices Microstruct. 2018, 122, 608–613. [Google Scholar] [CrossRef]

- Lu, L.; Wan, Z.; Xu, F.; Wang, X.; Lv, C.; Shen, B.; Jiang, M.; Chen, Q. Performance improvement of AlGaN-based deep-ultraviolet light-emitting diodes via asymmetric step-like AlGaN quantum wells. Superlattices Microstruct. 2017, 104, 240–246. [Google Scholar] [CrossRef]

- Kuo, Y.K.; Chen, Y.H.; Chang, J.Y.; Tsai, M.C. Numerical analysis on the effects of bandgap energy and polarization of electron blocking layer in near-ultraviolet light-emitting diodes. Appl. Phys. Lett. 2012, 100, 043513. [Google Scholar] [CrossRef]

- Rasheed, S.; Usman, M.; Ali, S.; Mustafa, L.; Ali, H. Designing p-region of AlGaN ultraviolet light-emitting diodes for the improved performance. Phys. B 2023, 659, 414865. [Google Scholar] [CrossRef]

- Tian, W.; Feng, Z.H.; Liu, B.; Xiong, H.; Zhang, J.B.; Dai, J.N.; Cai, S.J.; Chen, C.Q. Numerical study of the advantages of ultraviolet light-emitting diodes with a single step quantum well as the electron blocking layer. Opt. Quantum Electron. 2013, 45, 381–387. [Google Scholar] [CrossRef]

- Chen, Y.; Song, H.; Li, D.; Sun, X.; Jiang, H.; Li, Z.; Miao, G.; Zhang, Z.; Zhou, Y. Influence of the growth temperature of AlN nucleation layer on AlN template grown by high-temperature MOCVD. Mater. Lett. 2014, 114, 26–28. [Google Scholar] [CrossRef]

- Hirayama, H.; Tsukada, Y.; Maeda, T.; Kamata, N. Marked enhancement in the efficiency of Deep-Ultraviolet AlGaN Light-Emitting Diodes by Using a Multiquantum-Barrier Electron Blocking layer. Appl. Phys. Express 2010, 3, 031002. [Google Scholar] [CrossRef]

- He, C.; Zhao, W.; Zhang, K.; He, L.; Wu, H.; Liu, N.G.; Zhang, S.; Liu, X.; Chen, Z. High-Quality GaN Epilayers Achieved by Facet-Controlled Epitaxial Lateral Overgrowth on Sputtered AlN/PSS Templates. ACS Appl. Mater. Interfaces 2017, 9, 43386–43392. [Google Scholar] [CrossRef]

- Jiang, Z.; Zhu, Y.; Xia, C.; Sheng, Y.; Li, Y. Enhanced characteristics in AlGaN-based deep ultraviolet light-emitting diodes with interval-graded barrier superlattice electron blocking layers. Micro Nanostruct. 2024, 191, 207869. [Google Scholar] [CrossRef]

- Khan, M.A.; Maeda, N.; Rangaraju, H.; Jo, M.; Iimura, K.; Hirayama, H. Efficiency droop in AlGaN crystal-based UVB LEDs in the context of electron blocking mechanism. J. Cryst. Growth 2023, 604, 127032. [Google Scholar] [CrossRef]

- Shi, L.; Du, P.; Tao, G.; Liu, Z.; Luo, W.; Liu, S.; Zhou, S. High efficiency electron-blocking-layer-free ultraviolet LEDs with graded Al-content AlGaN insertion layer. Superlattices Microstruct. 2021, 158, 107020. [Google Scholar] [CrossRef]

- Wang, W.; Chu, C.; Che, J.; Hang, S.; Shao, H.; Tian, K.; Zhang, Y.; Zhang, Z. Is a thin p-GaN layer possible for making high-efficiency AlGaN-based deep-ultraviolet light-emitting diodes? Opt. Express 2021, 29, 29651. [Google Scholar] [CrossRef] [PubMed]

- Li, G.; Song, W.; Wang, H.; Luo, X.; Li, S. Performance improvement of UV light-emitting diodes with triangular quantum barriers. IEEE Photonics Technol. Lett. 2018, 30, 1071–1074. [Google Scholar] [CrossRef]

- Wang, X.; Sun, H.Q.; Yang, X.; Yi, X.Y.; Sun, J.; Zhang, X.; Liu, T.Y.; Guo, Z.Y.; Zhao, L.Z. Performance enhancement of AlGaN-based UV-LEDs inserted with a pin-doped AlGaN layer between the active region and electron-blocking layer. Mater. Sci. Semicond. Process. 2018, 83, 133–138. [Google Scholar] [CrossRef]

- Liu, N.; Gu, H.; Wei, Y.; Zheng, S. Performance enhancement of AlGaN-based Deep Ultraviolet Light-Emitting Diodes by using stepped and super lattice N-type confinement layer. Superlattices Microstruct. 2020, 141, 106492. [Google Scholar] [CrossRef]

- Mondal, R.K.; Chatterjee, V.; Pal, S. Effect of step-graded superlattice electron blocking layer on performance of AlGaN based deep-UV light emitting diodes. Phys. E Low-Dimens. Syst. Nanostruct. 2019, 108, 233–237. [Google Scholar] [CrossRef]

- Bao, X.; Sun, P.; Liu, S.; Ye, C.; Li, S.; Kan, J.Y. Performance improvements for AlGaN-based deep ultraviolet light-emitting diodes with the P-type and thickened last quantum barrier. IEEE Photonics J. 2015, 7, 1–10. [Google Scholar] [CrossRef]

- Liu, S.; Ye, C.; Cai, X.; Li, S.; Lin, W.; Kang, J. Performance enhancement of AlGaN deep-ultraviolet light-emitting diodes with varied superlattice barrier electron blocking layer. Appl. Phys. A 2016, 122, 527. [Google Scholar] [CrossRef]

- Fan, X.; Sun, H.; Li, X.; Sun, H.; Zhang, C.; Zhang, Z. Efficiency improvements in AlGaN-based deep ultraviolet light-emitting diodes using inverted-V-shaped graded Al composition electron blocking layer. Superlattices Microstruct. 2015, 88, 467–473. [Google Scholar] [CrossRef]

- Tsai, M.C.; Yen, S.H.; Kuo, Y.K. Deep-ultraviolet light-emitting diodes with gradually increased barrier thickness from n-layers to p-layers. Appl. Phys. Lett. 2011, 98, 111114. [Google Scholar] [CrossRef]

- Yin, Y.A.; Wang, N.; Fan, G.; Zhang, Y. Investigation of AlGaN-based deep-ultraviolet light-emitting diodes with composition-varying AlGaN multilayer barriers. Superlattices Microstruct. 2014, 76, 149–155. [Google Scholar] [CrossRef]

- Wang, C.K.; Wang, Y.W.; Chiou, Y.Z.; Chang, S.H.; Jheng, J.S.; Chang, S.P.; Chang, S.J. Suppression of electron overflow in 370-nm InGaN/AlGaN ultraviolet light emitting diodes with different insertion layer thickness. J. Cryst. Growth 2017, 468, 585–589. [Google Scholar] [CrossRef]

- Toure, A.; Halidou, I.; Benzarti, Z.; Fouzri, A.; Bchetnia, A.; El Jani, B. Characterization of low Al content AlxGa1−xN epitaxial films grown by atmospheric-pressure MOVPE. Phys. Status Solidi A 2012, 209, 977–983. [Google Scholar] [CrossRef]

- Liu, Z.; Lu, Y.; Wang, Y.; Lin, R.; Xiong, C.; Li, X. Polarization modulation at last quantum barrier for high efficiency AlGaN-Based UV LED. IEEE Photonics J. 2022, 14, 1–8. [Google Scholar] [CrossRef]

- Sahar, M.A.A.Z.M.; Hassan, Z.; Ng, S.S.; Hamzah, N.A. Highly efficient near ultraviolet LEDs using InGaN/GaN/AlxGa1-xN/GaN multiple quantum wells at high temperature on sapphire substrate. Mater. Sci. Semicond. Process. 2023, 156, 107298. [Google Scholar] [CrossRef]

- Xu, C.I.; Cai, L.; Zheng, J.; Line, H.; Chen, Z.; Niu, K.; Cheng, Z.; Xiong, F. The effect of different AlGaN insertion layer thickness on the photoelectric properties of InGaN/AlGaN near UV light emitting diodes. Results Phys. 2023, 55, 107111. [Google Scholar] [CrossRef]

- Hirayama, H.; Yatabe, T.; Noguchi, N.; Kamata, N. Development of 230–270nm AlGaN-Based Deep-UV LEDs. Electron. Commun. Jpn. 2010, 93, 24–33. [Google Scholar] [CrossRef]

- Liao, Z.; Lv, Z.; Sun, K.; Zhou, S. Improved efficiency of AlGaN-based flip-chip deep-ultraviolet LEDs using a Ni/Rh/Ni/Au p-type electrode. Opt. Lett. 2023, 48, 4229–4232. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nan, Q.; Zhang, S.; Yao, J.; Zhang, Y.; Ding, H.; Fan, Q.; Ni, X.; Gu, X. 385 nm AlGaN Near-Ultraviolet Micro Light-Emitting Diode Arrays with WPE 30.18% Realized Using an AlN-Inserted Hole Spreading Enhancement S Electron Blocking Layer. Coatings 2025, 15, 910. https://doi.org/10.3390/coatings15080910

Nan Q, Zhang S, Yao J, Zhang Y, Ding H, Fan Q, Ni X, Gu X. 385 nm AlGaN Near-Ultraviolet Micro Light-Emitting Diode Arrays with WPE 30.18% Realized Using an AlN-Inserted Hole Spreading Enhancement S Electron Blocking Layer. Coatings. 2025; 15(8):910. https://doi.org/10.3390/coatings15080910

Chicago/Turabian StyleNan, Qi, Shuhan Zhang, Jiahao Yao, Yun Zhang, Hui Ding, Qian Fan, Xianfeng Ni, and Xing Gu. 2025. "385 nm AlGaN Near-Ultraviolet Micro Light-Emitting Diode Arrays with WPE 30.18% Realized Using an AlN-Inserted Hole Spreading Enhancement S Electron Blocking Layer" Coatings 15, no. 8: 910. https://doi.org/10.3390/coatings15080910

APA StyleNan, Q., Zhang, S., Yao, J., Zhang, Y., Ding, H., Fan, Q., Ni, X., & Gu, X. (2025). 385 nm AlGaN Near-Ultraviolet Micro Light-Emitting Diode Arrays with WPE 30.18% Realized Using an AlN-Inserted Hole Spreading Enhancement S Electron Blocking Layer. Coatings, 15(8), 910. https://doi.org/10.3390/coatings15080910