Properties of Diamond-like Coatings in Tribological Systems Lubricated with Ionic Liquid

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Research Methodology

3. Results

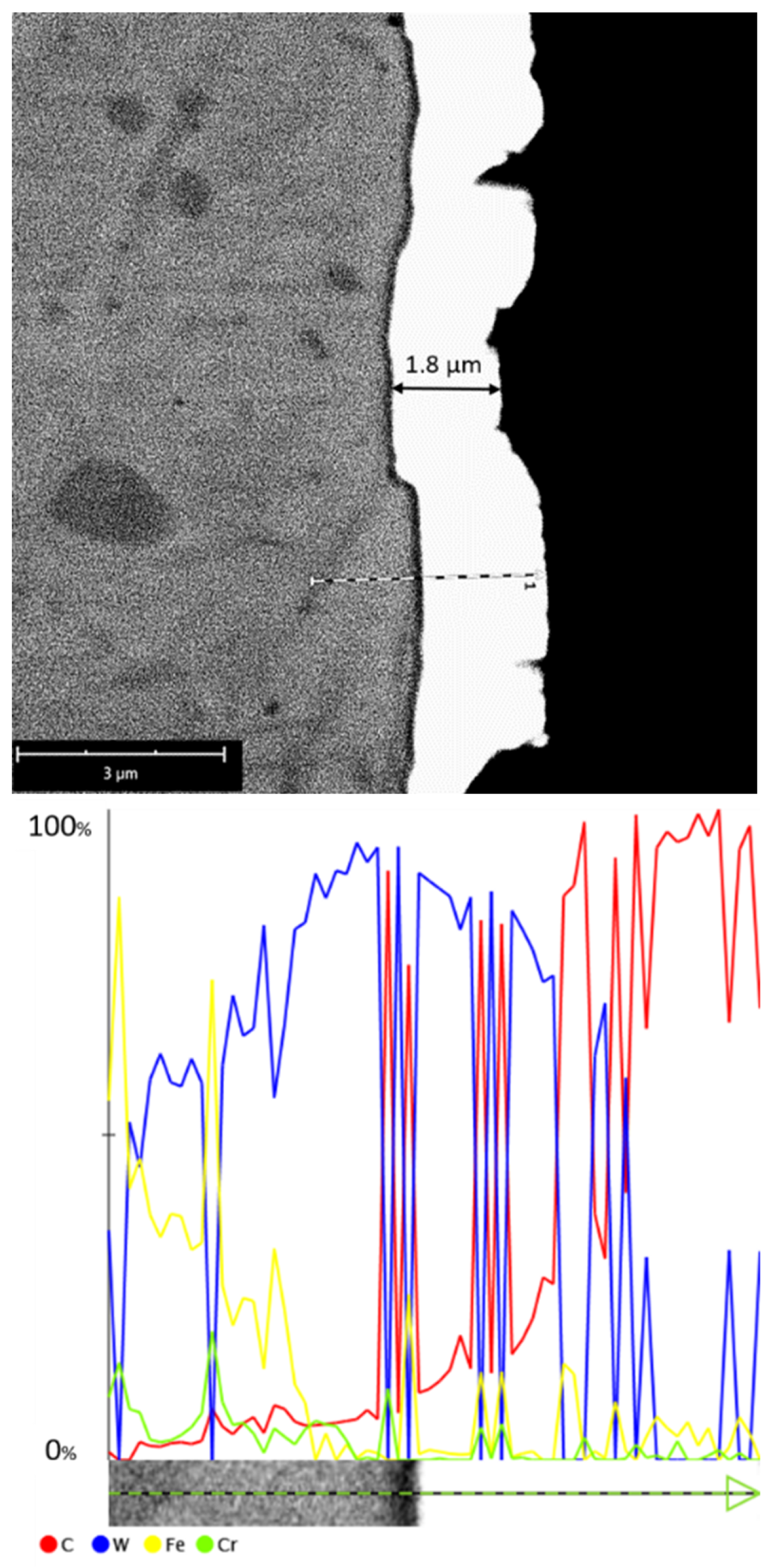

3.1. Coating Thickness

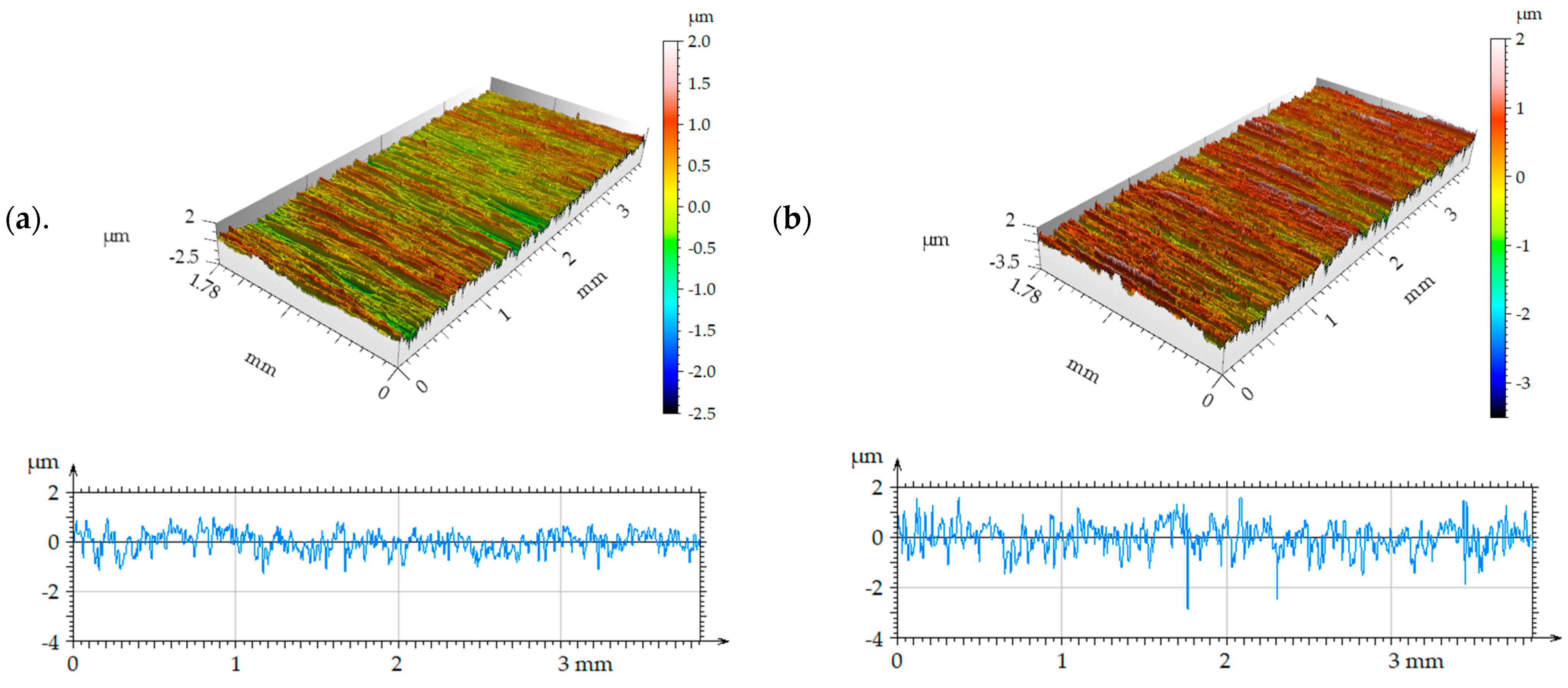

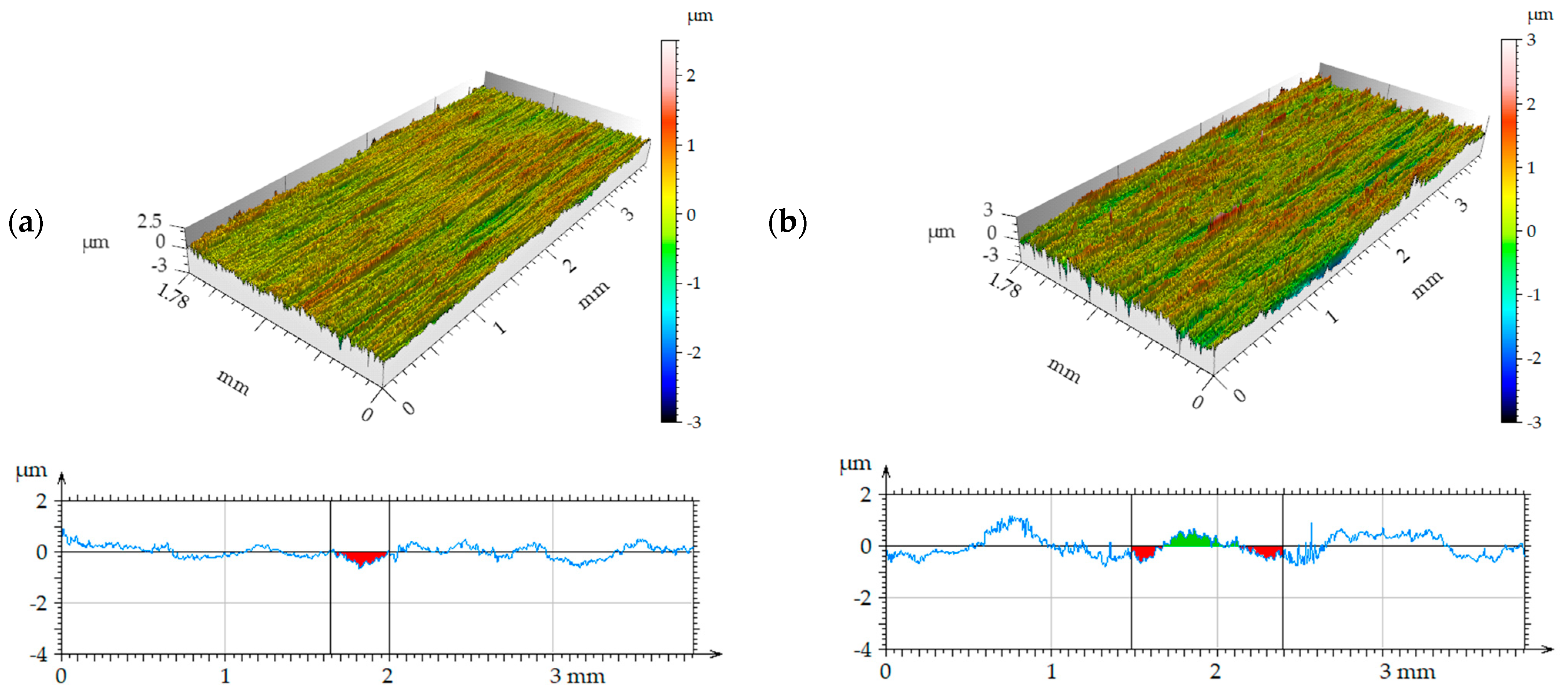

3.2. Geometric Structure

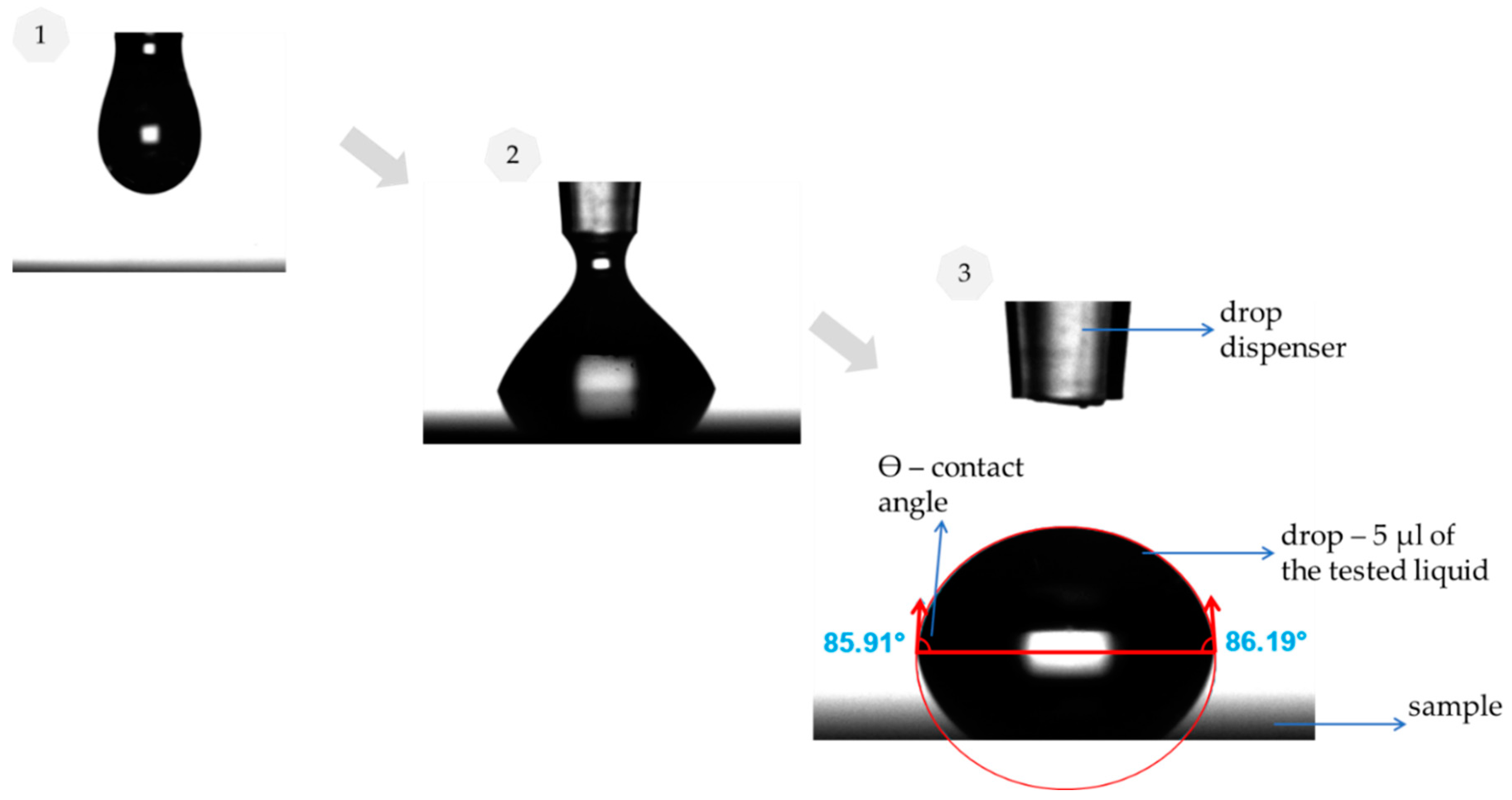

3.3. Contact Angle

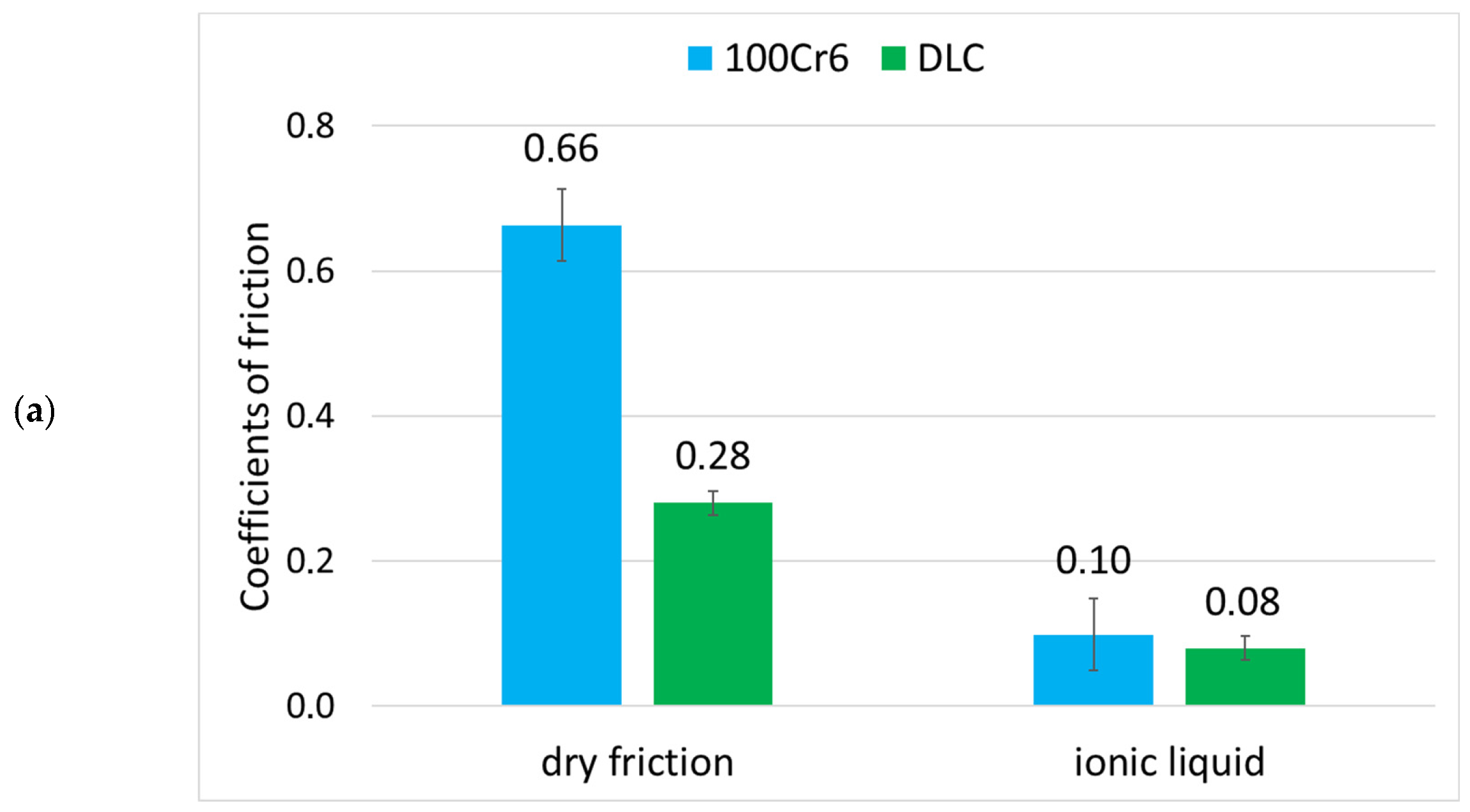

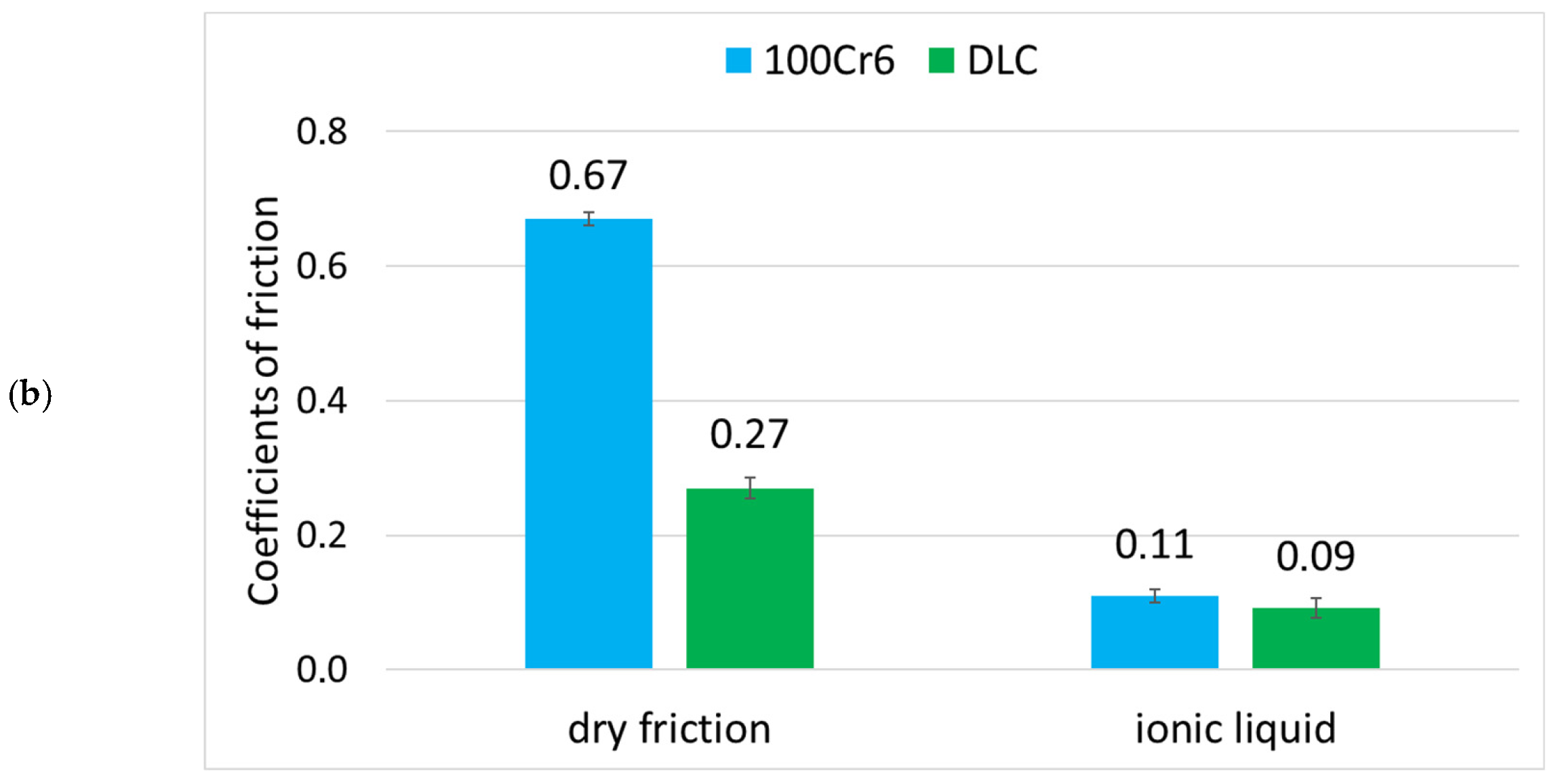

3.4. Tribological Tests

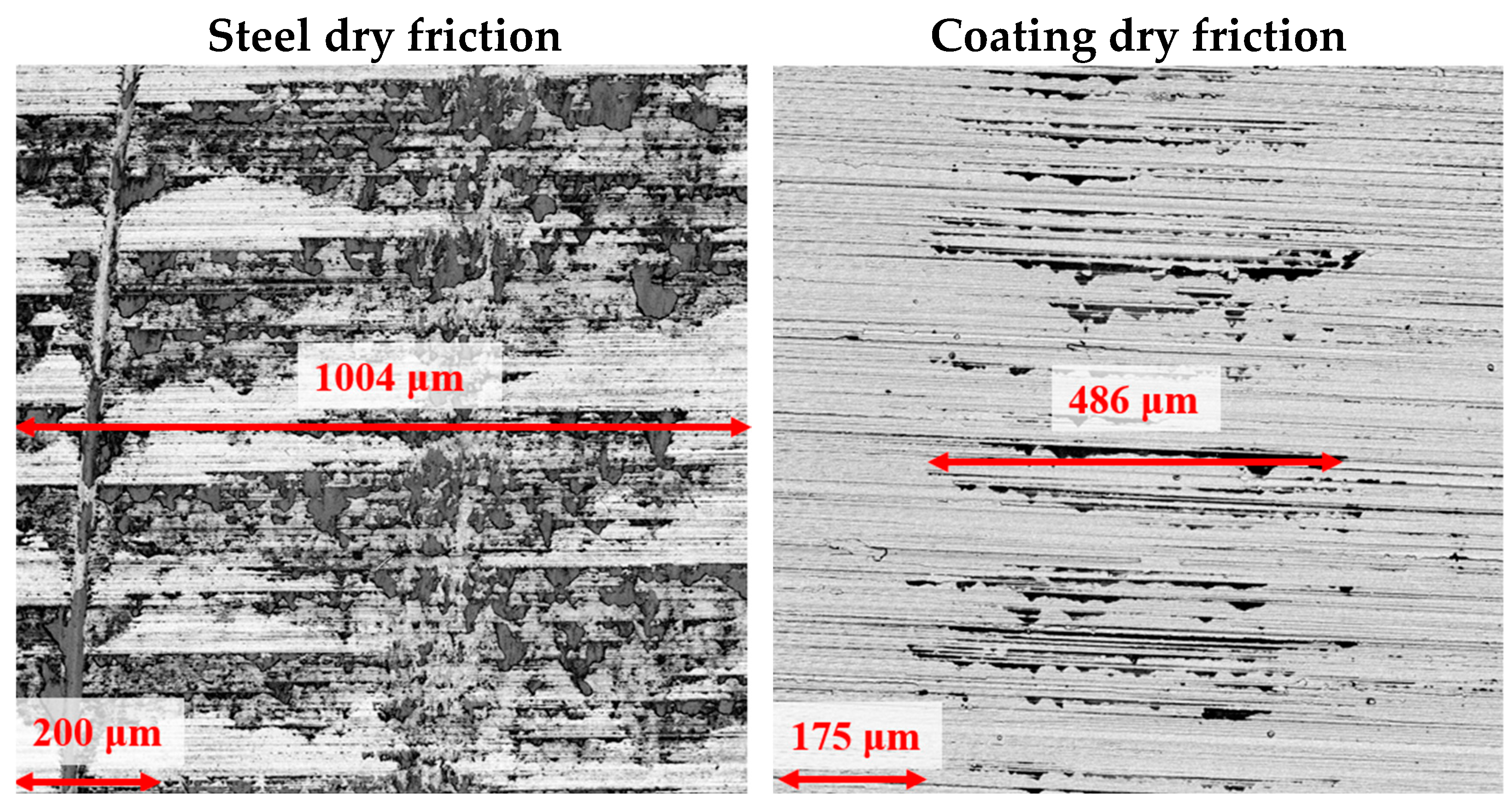

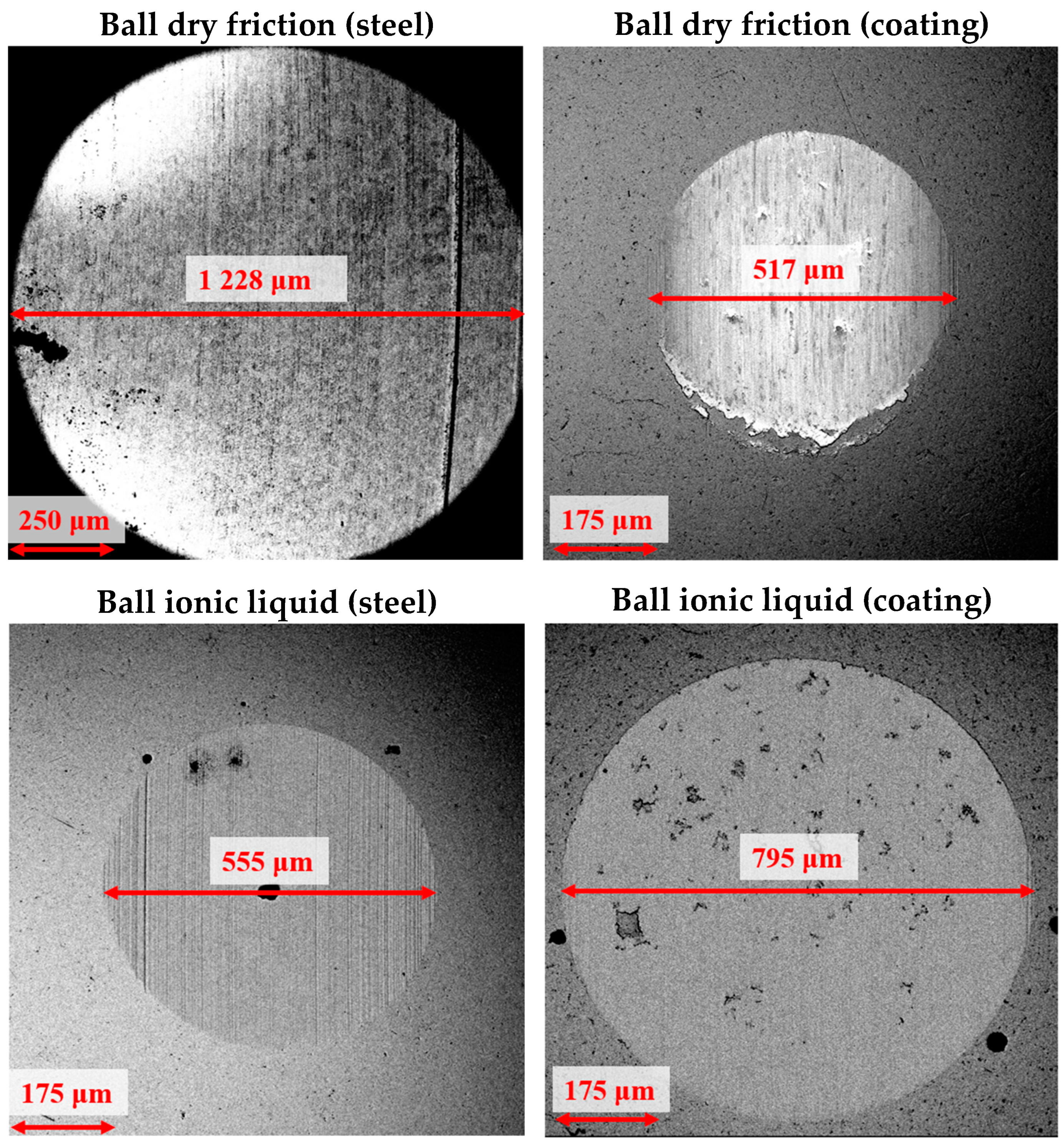

3.5. Assessment of Surface Geometric Structure of Samples

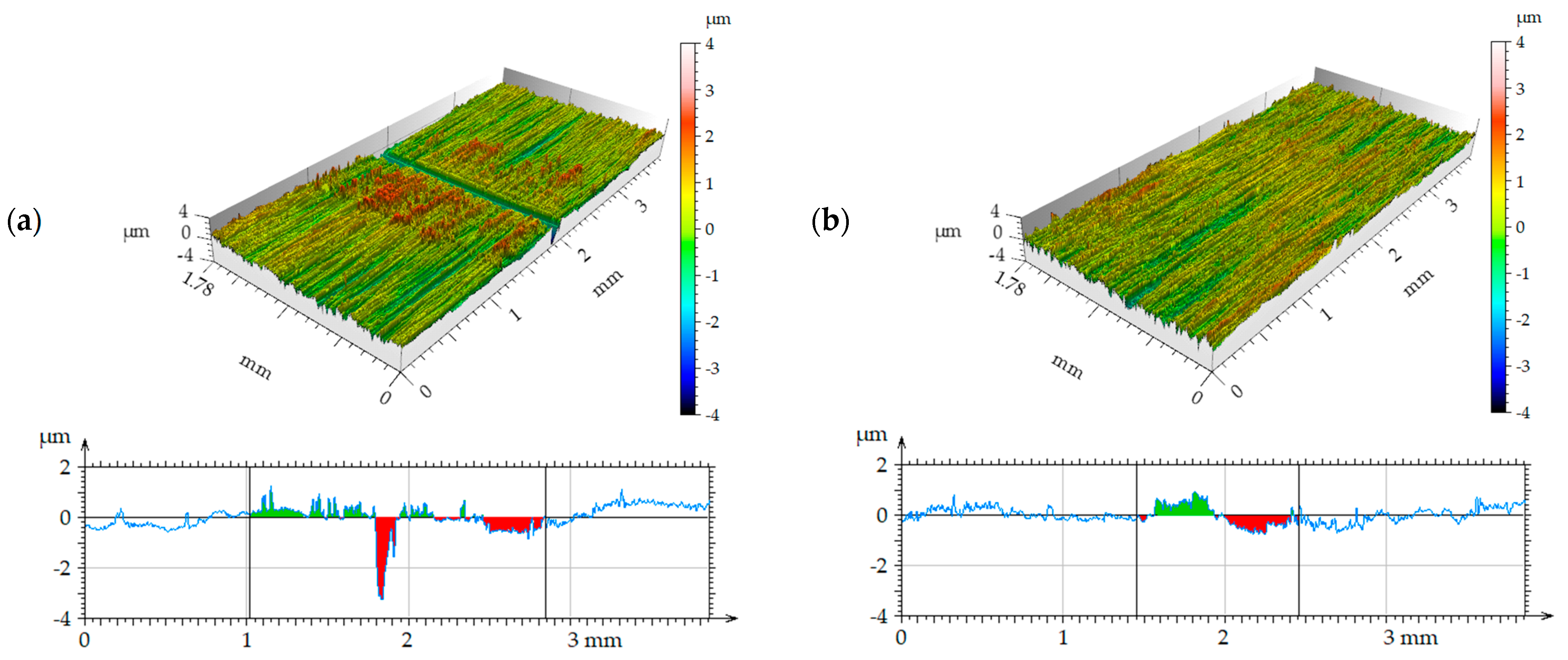

3.5.1. Load 10 N—Dry Friction

3.5.2. Load 15 N—Dry Friction

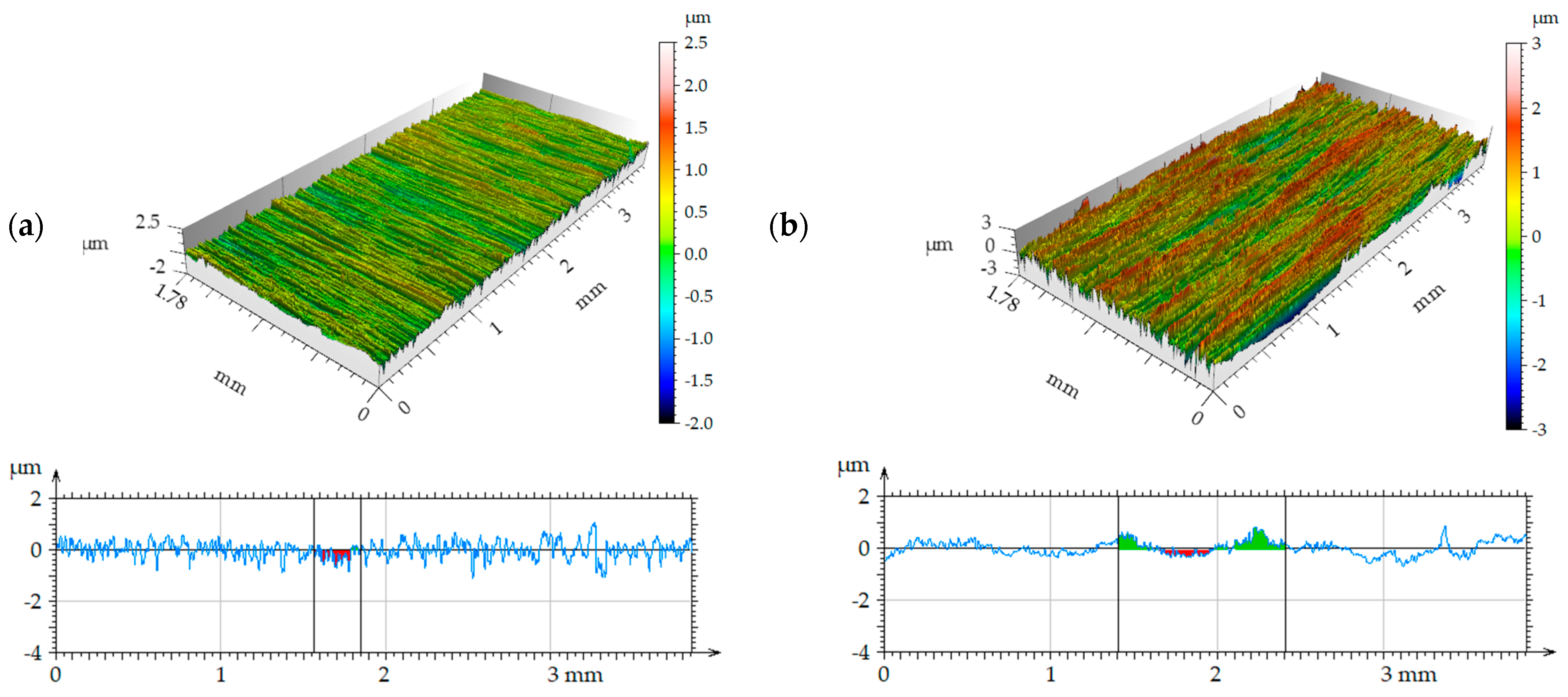

3.5.3. Load 10 N—Lubrication

3.5.4. Load 15 N—Lubrication

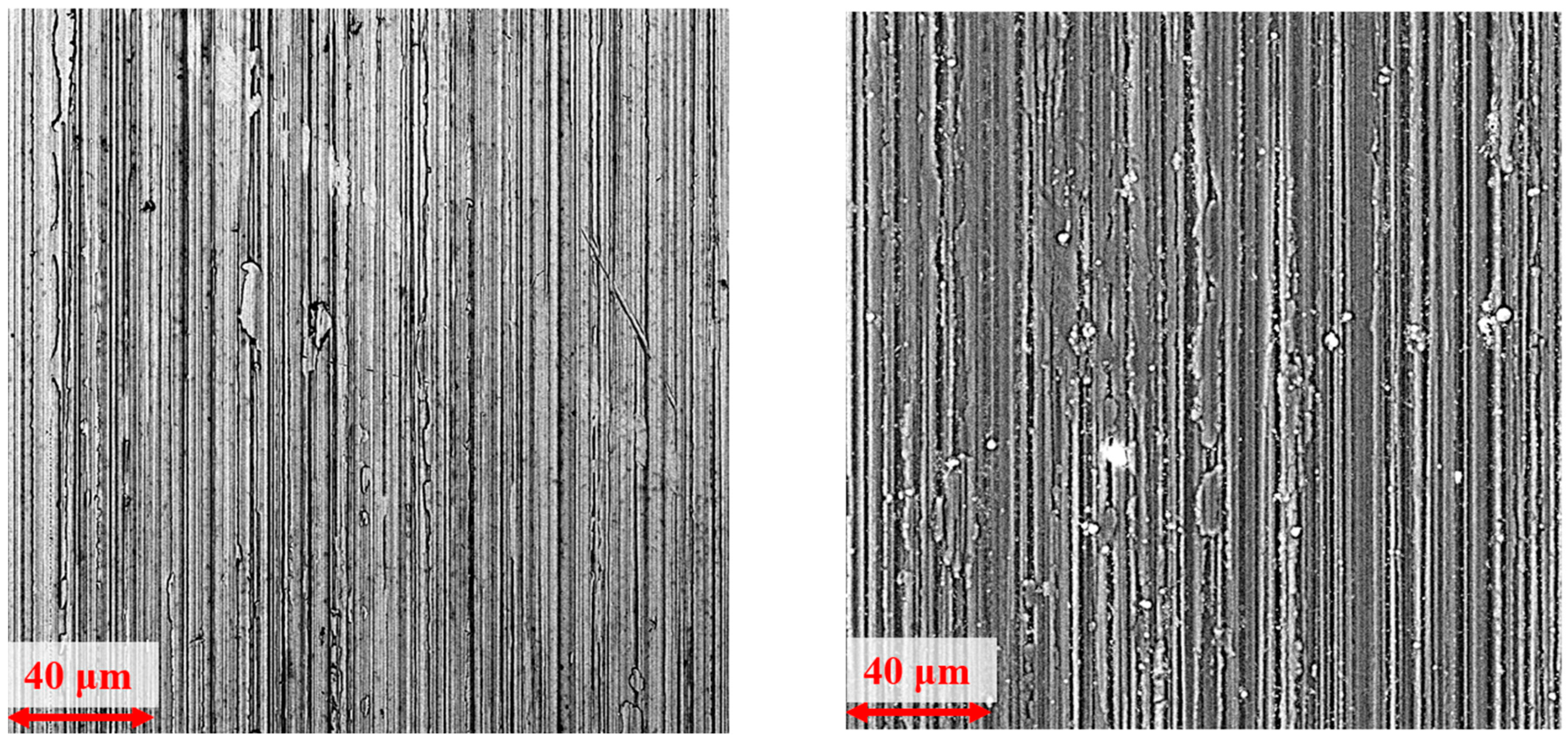

3.6. Surface Morphology After Tribological Tests

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Aisenberg, S.; Chabot, R. Ion Beam Deposition of Thin Films of Diamond-like Carbon. Appl. Phys. 1971, 42, 2953–2958. [Google Scholar] [CrossRef]

- Madej, M. Właściwości Systemów Tribologicznych z Powłokami Diamentopodobnymi; Wydawnictwo Politechniki Świętokrzyskiej: Kielce, Polska, 2013. [Google Scholar]

- Piotrowska, K.; Madej, M.; Kowalczyk, J.; Radoń-Kobus, K. Surface Roughness Effects on the Properties of Silicon-Doped Diamond-like Carbon Coatings. Coatings 2023, 13, 1629. [Google Scholar] [CrossRef]

- Sadeghi, M.; Omiya, T.; Fernandes, F.; Vilhena, L.; Ramalho, A.; Ferreira, F. Tribological Behavior of Doped DLC Coatings in the Presence of Ionic Liquid Additive Under Different Lubrication Regimes. Coatings 2023, 13, 891. [Google Scholar] [CrossRef]

- Vicen, M.; Bronček, J.; Bokůvka, O.; Nikolić, R.; Radek, N. Tribological Behaviour of the Sucaslide Diamond-like Carbon Coating. Trans. FAMENA 2021, 45, 31–40. [Google Scholar] [CrossRef]

- Madej, M.; Marczewska-Boczkowska, K.; Ozimina, D. Effect of Tungsten on the Durability of Diamond-like Carbon Coatings in the Chemical Industry. Przemysł Chem. 2014, 93, 500–505. [Google Scholar]

- Savvides, N.; Bell, T.J. Hardness and Elastic Modulus of Diamond and Diamond-like Carbon Films. Thin Solid Film. 1993, 228, 289–292. [Google Scholar] [CrossRef]

- Mano, H.; Ohana, T. Evaluation of Anti-Adhesion Characteristics of Diamond-like Carbon Film by Combining Friction and Wear Test with Step Loading and Weibull Analysis. Materials 2021, 14, 2746. [Google Scholar] [CrossRef]

- Xiao, Y. Residual Stress and Its Effect on Failure in a DLC Coating on a Steel Substrate with Rough Surfaces. Diam. Relat. Mater. 2016, 66, 23–35. [Google Scholar] [CrossRef]

- Ronkainen, H. Differentiating the Tribological Performance of Hydrogenated and Hydrogen-Free DLC Coatings. Wear 2001, 249, 260–266. [Google Scholar] [CrossRef]

- Zeng, O.; Ning, Z. High-Temperature Tribological Properties of Diamond-like Carbon Films: A Review. Rev. Adv. Mater. Sci. 2021, 60, 276–292. [Google Scholar] [CrossRef]

- Podsvirov, O.A.; Karasetov, P.A.; Vinogradov, A.Y.; Azarov, A.Y.; Karasev, N.N.; Smirnov, A.S.; Titov, A.I.; Karabeshkin, K.V. Residual Stress in Diamond-like Carbon Films: Role of Growth Conditions and Ion Irradiation. J. Surf. Investig. X-Ray Synchrotron Neutron Tech. 2010, 4, 241–244. [Google Scholar] [CrossRef]

- Świątek, I.; Olejnik, O.; Grabarczyk, J. Wpływ Warstw DLC i DLC-Si Na Zmiany Zachodzące Na Powierzchni Implantów Podczas Współpracy z Kością. Inżynieria Biomateriałów 2016, 19, 2–12. [Google Scholar]

- Dobrzański, L.A.; Dobrzańska-Danikiewicz, A.D. Obróbka Powierzchni Materiałów Inżynierskich; Politechnika Śląska: Gliwice, Poland, 2011. [Google Scholar]

- Biel-Gołaska, M. Zastosowanie Warstw Diamentowych Oraz Powłok Diamentopodobnych Na Narzędziach Medycznych i Implantach. Pr. Inst. Odlew. 2008, 48, 5–18. [Google Scholar]

- Haibo, S.; Yang, L.; Wu, H.; Zhao, L. Effects of Element Doping on the Structure and Properties of Diamond-like Carbon Films: A Review. Lubricants 2023, 11, 186. [Google Scholar] [CrossRef]

- Sun, Y.; Wang, C.; Yu, X.; Tian, Z.; Guo, Z.; Liu, Y. Using Wolfram-Doped Diamond-like Carbon Film to Extend Lifetime of Spinneret Punching Needle in Production Line. J. Phys. Conf. Ser. 2020, 1637, 012054. [Google Scholar] [CrossRef]

- Yue, W.; Liu, C.; Fu, Z.; Wang, C.; Huang, H.; Liu, J. Effects of Tungsten Doping Contents on Tribological Behaviors of Tungsten-Doped Diamond-like Carbon Coatings Lubricated by MoDTC. Tribol. Lett. 2015, 58, 31. [Google Scholar] [CrossRef]

- Madej, M.; Kowalczyk, J.; Kowalski, M.; Grabowski, P.; Wernik, J. Tribological Properties of Selected Ionic Liquids in Lubricated Friction Nodes. Materials 2024, 18, 18. [Google Scholar] [CrossRef]

- Li, C.; Wang, G.; Han, Q.; Feng, G.; Wang, L.; Wang, S. Effects of Current-Carrying Conditions on Lubrication and Tribological Performance of Ionic Liquid. J. Mol. Liq. 2022, 367, 120471. [Google Scholar] [CrossRef]

- Shaikh, S.; Sadeghi, M.; Cruz, S.; Ferreira, F. Recent Progress on the Tribology of Pure/Doped Diamond-like Carbon Coatings and Ionic Liquids. Coatings 2024, 14, 71. [Google Scholar] [CrossRef]

- Luo, X.; Wang, F.; Wang, G.; Hui, L. Exploring the Mechanism of Ionic Liquids to Improve the Extraction Efficiency of Essential Oils Based on Density Functional Theory and Molecular Dynamics Simulation. Molecules 2022, 27, 5515. [Google Scholar] [CrossRef]

- Liu, M.; Ni, J.; Zhang, C.; Wang, R.; Cheng, Q.; Liang, W.; Liu, Z. The Application of Ionic Liquids in the Lubrication Field: Their Design, Mechanisms, and Behaviors. Lubricants 2024, 12, 24. [Google Scholar] [CrossRef]

- Pernak, J. Ciecze Jonowe. Związki Na Miarę XXI Wieku. Przemysł Chem. 2003, 82, 8–9. [Google Scholar]

- Sułek, M.W.; Wasilewski, T.; Ogorzałek, M.; Bąk, A.; Pernak, J.; Walkiewicz, F. Charakterystyki Tribologiczne Cieczy Jonowych Zawierających Kation Amoniowy. Tribologia 2009, 4, 207–214. [Google Scholar]

- Sułek, M.W.; Wasilewski, T.; Ogorzałek, M.; Pernak, J.; Walkiewicz, F. Wpływ Rodzaju Anionu w Imidazoliowych Cieczach Jonowych Na Ich Właściwości Tribologiczne. Tribologia 2010, 6, 107–115. [Google Scholar]

- Kałdoński, T.J.; Stańczyk, M.; Gryglewicz, Ł.; Kałdoński, T. Wstępne Badania Właściwości Smarnościowych i Powierzchniowych Wybranych Cieczy Jonowych. Biuletyn WAT 2012, 61, 279–297. [Google Scholar]

- Minami, I. Ionic Liquids in Tribology. Molecules 2009, 14, 2286–2305. [Google Scholar] [CrossRef]

- Kałdoński, T.J.; Kałdoński, T. Ecotoxicity of Ionic Liquids as Lubricants. J. KONES 2015, 22, 135–142. [Google Scholar] [CrossRef]

- Marczewska-Boczkowska, K. Badania Procesu Korozji Stali w Niskotemperaturowych Cieczach Jonowych. Przemysł Chem. 2011, 90, 1207–1211. [Google Scholar]

- Kumar, B.; Verma, D.K.; Rastogi, R.B. Tribological Activity of Ionic Liquid Stabilized Calcium-Doped Ceria Nanoparticles. Proc. Inst. Mech. Part J J. Eng. Tribol. 2021, 235, 989–996. [Google Scholar] [CrossRef]

- Palacio, M.; Bhushan, B. A Review of Ionic Liquids for Green Molecular Lubrication in Nanotechnology. Tribol. Lett. 2010, 40, 247–268. [Google Scholar] [CrossRef]

- Omiya, T. Tribological Performance of Gd-DLC and Eu-DLC Coatings in the Presence of Synthetic Oils Containing Ionic Liquid Additives. Tribol. Lett. 2023, 71, 65. [Google Scholar] [CrossRef]

- Somers, A.E.; Howlett, P.C.; Sun, J.; MacFarlane, D.R.; Forsyth, M. Transition in Wear Performance for Ionic Liquid Lubricants Under Increasing Load. Tribol. Lett. 2010, 40, 279–284. [Google Scholar] [CrossRef]

- Azhagar, S.; Murugesan, B.; Chinnaalagu, D.; Arumugam, M.; Mahalingam, S. BMIM-PF6 Ionic Liquid Mediated Polyol Synthesis of Praseodymium (III) Oxide Nanoparticles: Physicochemical Investigation and Its Interaction with Bacterial and Cancer Cells. Ceram. Int. 2022, 48, 35386–35397. [Google Scholar] [CrossRef]

- Gatti, F.J.; Cai, W.; Herzog, R.; Gharavian, A.; Kailer, A.; Baltes, N.; Rabenecker, P.; Mörchel, P.; Balzer, B.N.; Amann, T.; et al. Investigation of Programmable Friction with Ionic Liquid Mixtures at the Nano- and Macroscales. Lubricants 2023, 11, 376. [Google Scholar] [CrossRef]

- 100CR6, W. NR 1.3505, EN ISO 683-17 Wysokowęglowa Stal Łożyskowa 2025. Available online: https://akrostal.pl/stale/lh15-100cr61-3505/ (accessed on day month year).

- Ionic Liquid. 2025. Available online: https://www.sigmaaldrich.com/PL/pl/product/aldrich/70956 (accessed on 7 July 2025).

- Radoń-Kobus, K.; Madej, M.; Kowalczyk, J.; Piotrowska, K. Properties of Diamond-like Tungsten-Doped Carbon Coatings Lubricated with Cutting Fluid. Coatings 2024, 14, 342. [Google Scholar] [CrossRef]

| 100Cr6 [% Content] | ||||||||

|---|---|---|---|---|---|---|---|---|

| Fe | C | Mn | Si | P | S | Cr | Ni | Cu |

| 95.8–96.7 | 0.95–1.1 | 0.25–0.45 | 0.15–0.35 | max. 0.025 | 0.025 | 1.3–1.65 | max. 0.3 | max. 0.3 |

| Parameter | Value |

|---|---|

| color | colorless |

| melting point | −8 °C |

| density at 20 °C | 1.38 g/mL |

| viscosity at 20 °C | 300–400 cP |

| Sample Discs | Ø 42 mm—100Cr6 Steel Ø 42 mm—100Cr6 Steel with DLC Coating |

|---|---|

| Counter-sample ball | Ø 6 mm—steel 100Cr6 |

| Type of friction | Rotation |

| Lubricant | Ionic liquid BMIM-PF6 |

| Radius | 14 mm |

| Load | 10 N, 15 N |

| Sliding speed | 0.1 m/s |

| Sliding distance | 1000 m |

| Test duration | 10,000 s |

| Ambient temperature | 22 ± 1 °C |

| Parameters | 100Cr6 Steel | DLC Coating |

|---|---|---|

| Sa [µm] | 0.33 | 0.44 |

| Sp [µm] | 1.61 | 1.61 |

| Sv [µm] | 2.20 | 3.20 |

| Sz [µm] | 3.81 | 4.80 |

| Ssk | −0.32 | −0.54 |

| Sku | 3.03 | 3.76 |

| Parameters | Value | 100Cr6–10 N | DLC–10 N | 100Cr6–15 N | DLC–15 N |

|---|---|---|---|---|---|

| Maximum depth | µm | 3.39 | 0.73 | 3.51 | 0.82 |

| Wear area | µm2 | 494.5 | 145.3 | 694.4 | 182.41 |

| Parameters | Value | 100Cr6–10 N | DLC–10 N | 100Cr6–15 N | DLC–15 N |

|---|---|---|---|---|---|

| Maximum depth | µm | 0.82 | 0.19 | 0.12 | 0.11 |

| Wear area | µm2 | 55.73 | 17.15 | 12.21 | 12.89 |

| Material Parameter | Sa [µm] | Sp [µm] | Sv [µm] | Sz [µm] | Ssk | Sku |

|---|---|---|---|---|---|---|

| Dry friction 10 N | ||||||

| 100Cr6 | 0.50 | 3.47 | 3.78 | 7.25 | −1.20 | 8.72 |

| DLC | 0.49 | 2.06 | 3.09 | 5.15 | −0.48 | 3.37 |

| Dry friction 15 N | ||||||

| 100Cr6 | 0.40 | 2.63 | 3.87 | 6.49 | 0.09 | 6.38 |

| DLC | 0.60 | 2.27 | 3.94 | 6.21 | −0.67 | 3.84 |

| Ionic liquid lubricated 10 N | ||||||

| 100Cr6 | 0.26 | 1.86 | 1.74 | 3.59 | −0.51 | 3.75 |

| DLC | 0.64 | 2.37 | 4.35 | 6.72 | −0.44 | 3.19 |

| Ionic liquid lubricated 15 N | ||||||

| 100Cr6 | 0.29 | 1.23 | 2.18 | 3.41 | −0.45 | 3.59 |

| DLC | 0.46 | 2.89 | 4.65 | 7.53 | −0.49 | 4.09 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Radoń-Kobus, K.; Madej, M. Properties of Diamond-like Coatings in Tribological Systems Lubricated with Ionic Liquid. Coatings 2025, 15, 799. https://doi.org/10.3390/coatings15070799

Radoń-Kobus K, Madej M. Properties of Diamond-like Coatings in Tribological Systems Lubricated with Ionic Liquid. Coatings. 2025; 15(7):799. https://doi.org/10.3390/coatings15070799

Chicago/Turabian StyleRadoń-Kobus, Krystyna, and Monika Madej. 2025. "Properties of Diamond-like Coatings in Tribological Systems Lubricated with Ionic Liquid" Coatings 15, no. 7: 799. https://doi.org/10.3390/coatings15070799

APA StyleRadoń-Kobus, K., & Madej, M. (2025). Properties of Diamond-like Coatings in Tribological Systems Lubricated with Ionic Liquid. Coatings, 15(7), 799. https://doi.org/10.3390/coatings15070799