Quasi-Static Indentation and Compression Behaviors of Hybrid Woven Composite Laminates

Abstract

1. Introduction

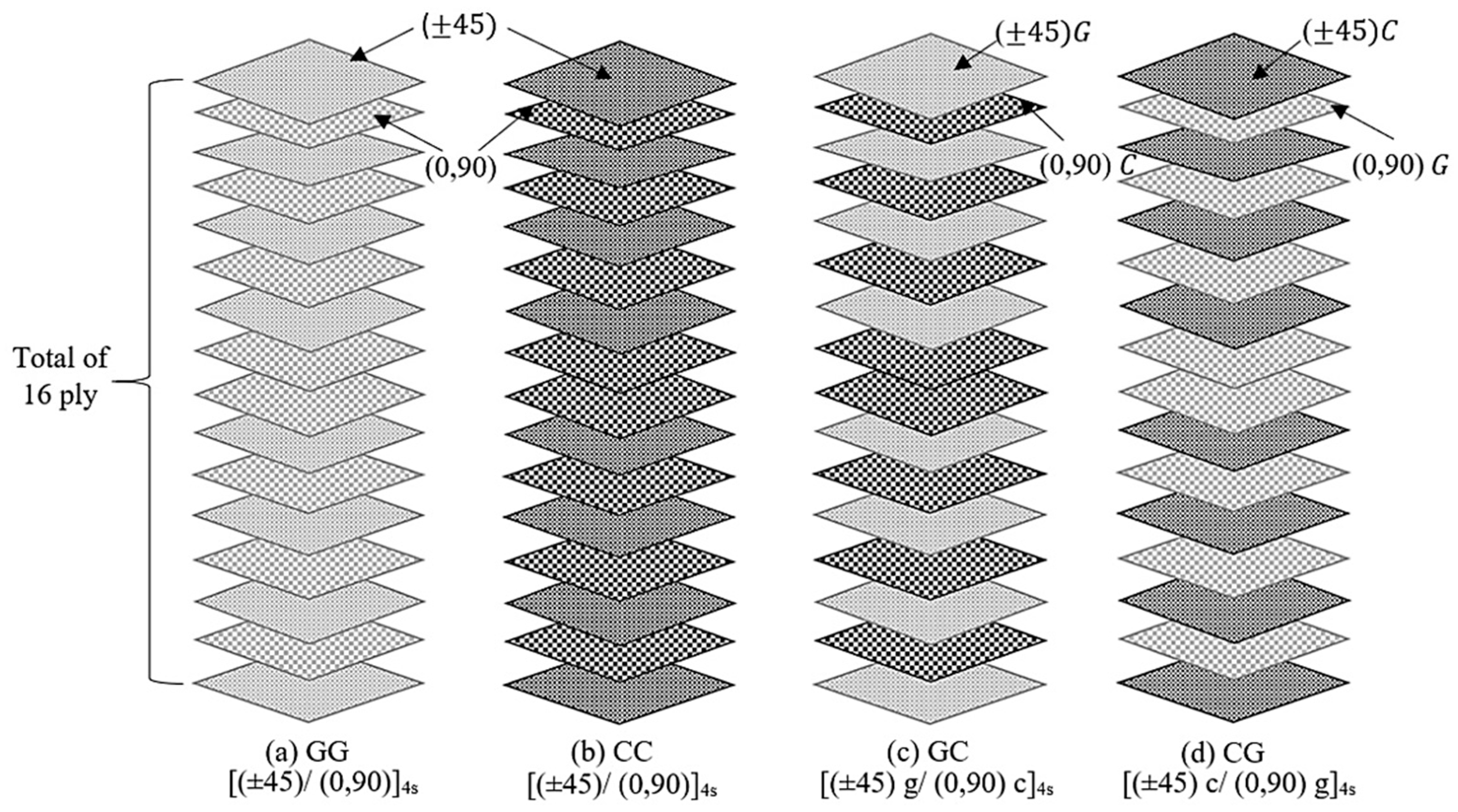

2. Materials and Methods

2.1. Materials

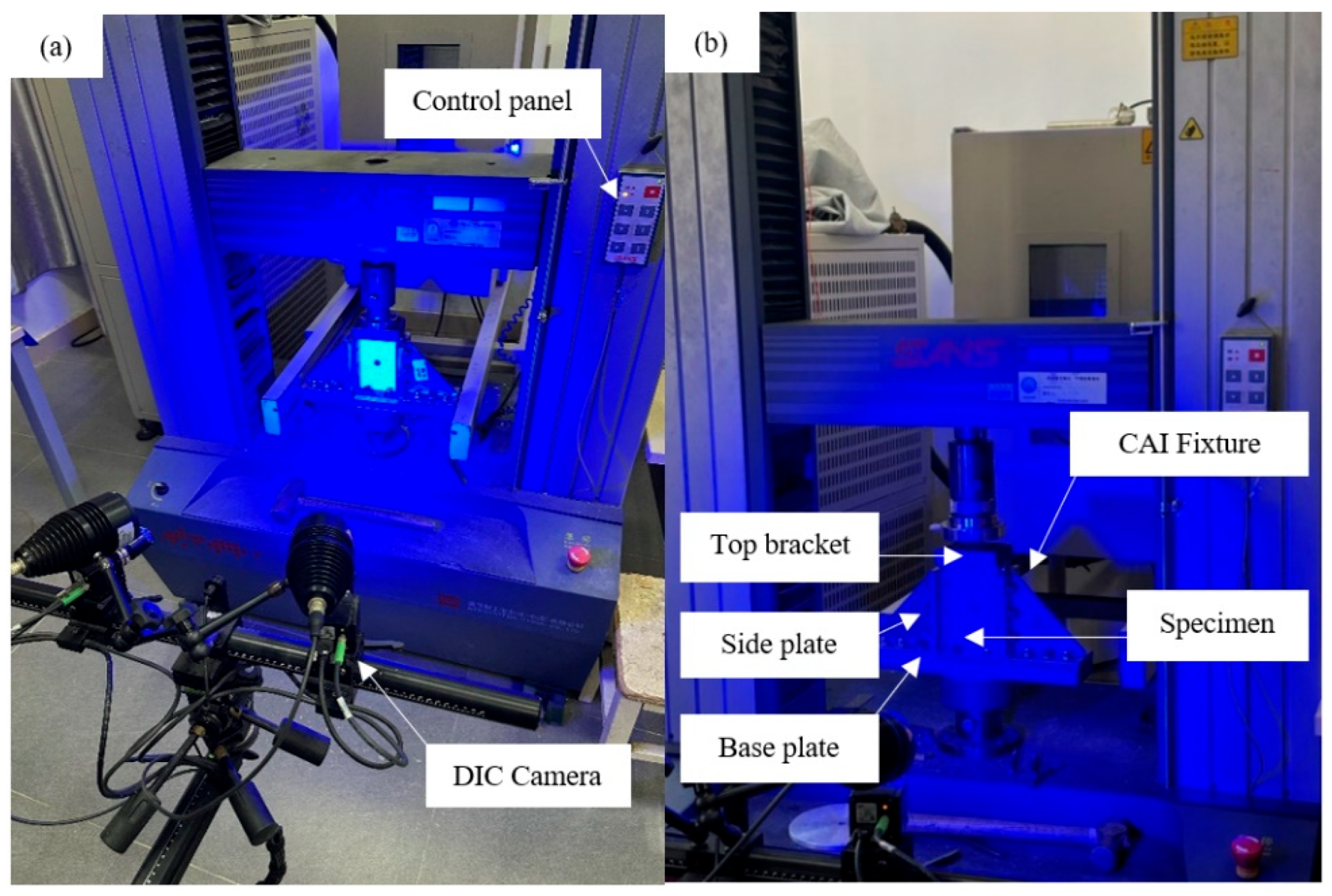

2.2. Quasi-Static Indentation Test

2.3. Compression After Indentation Test

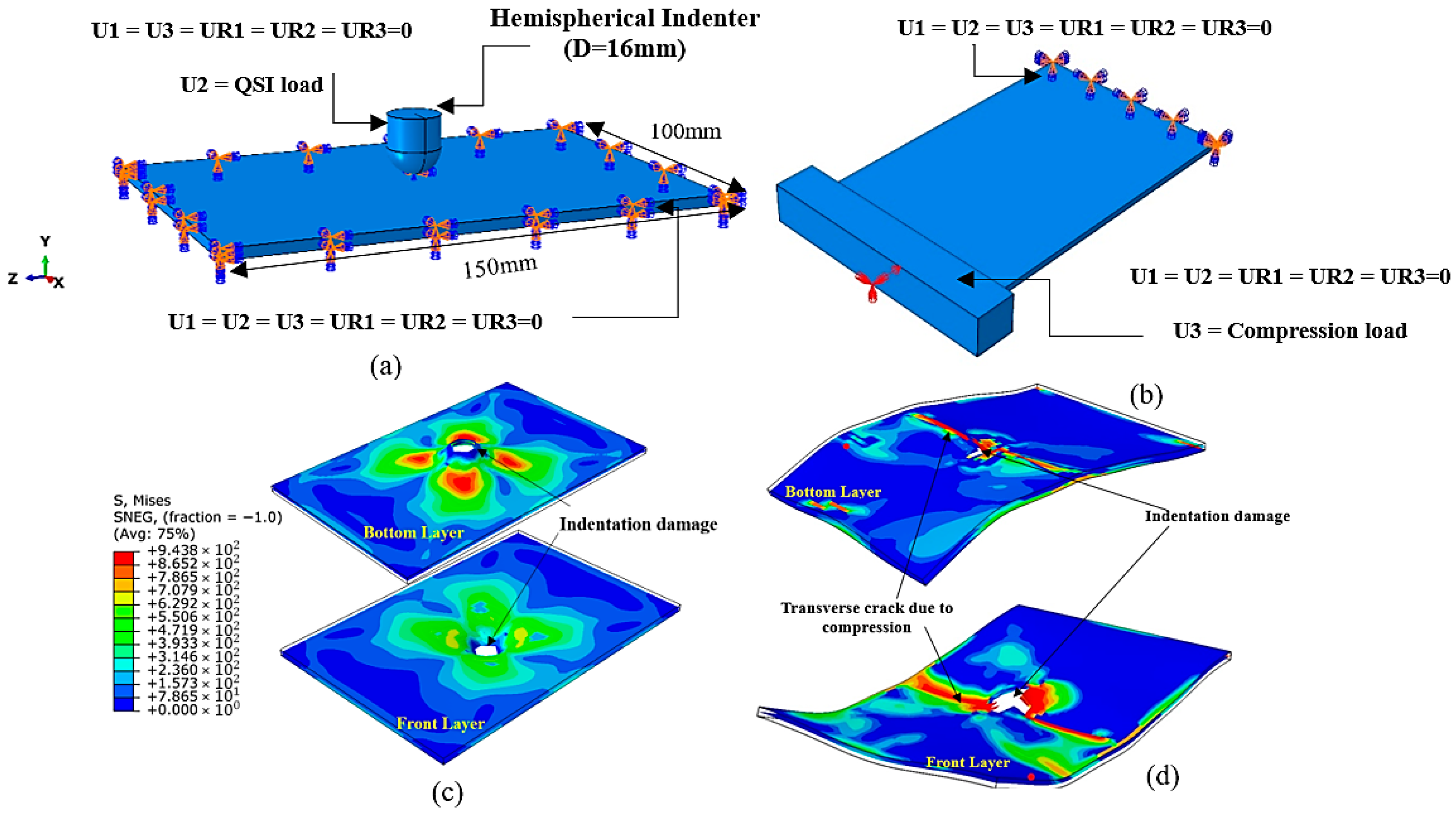

2.4. Numerical Modeling

3. Results and Discussion

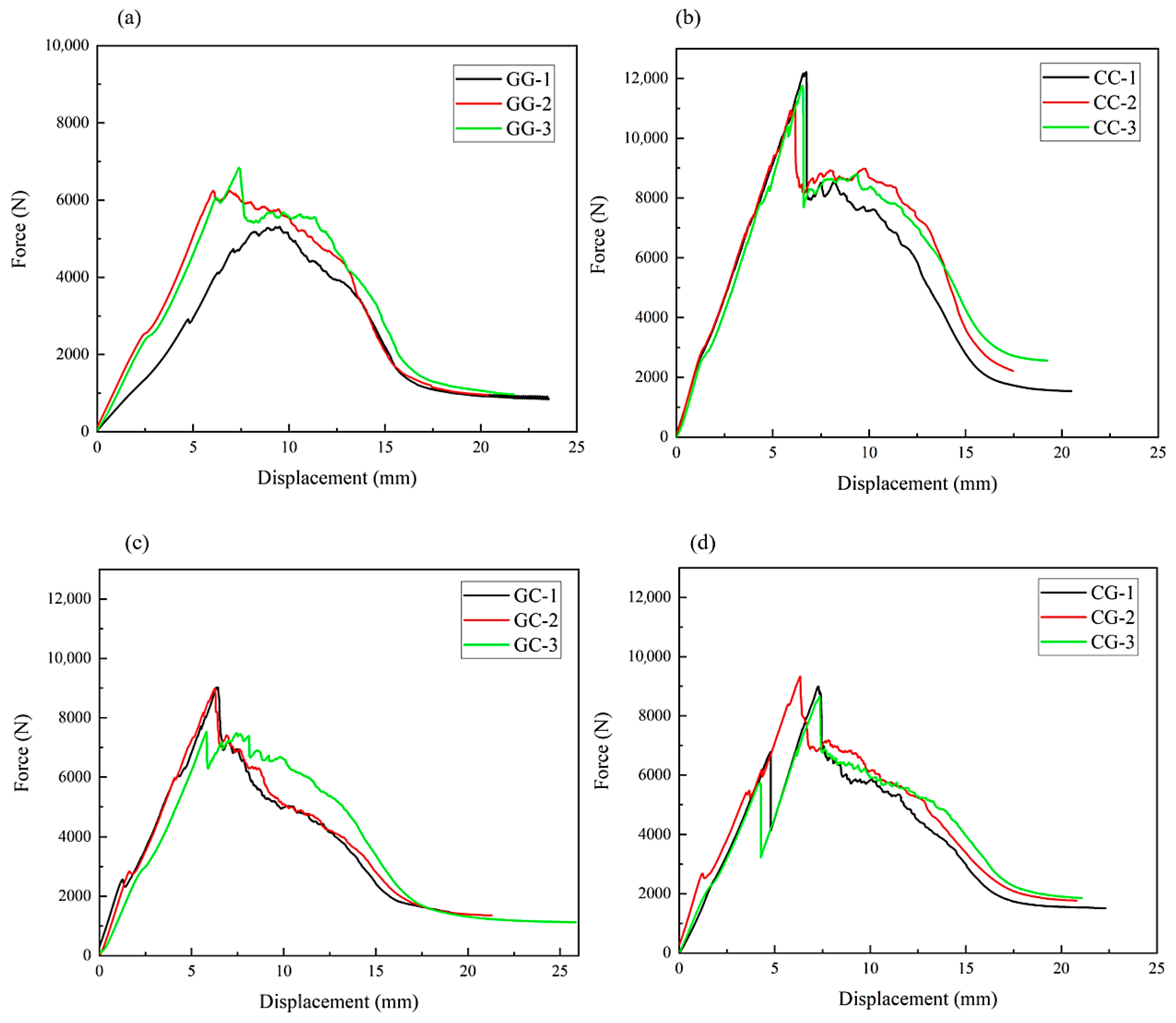

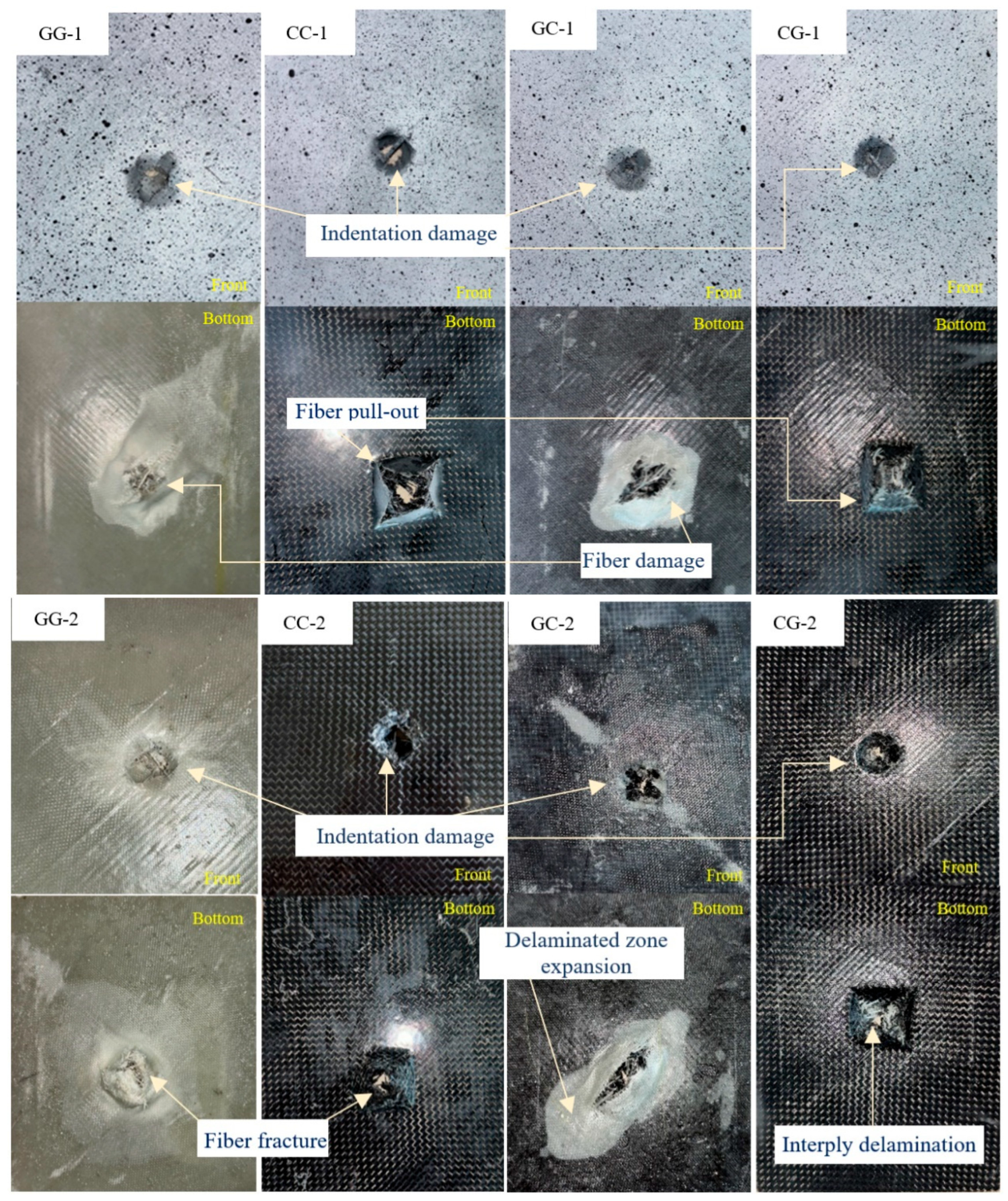

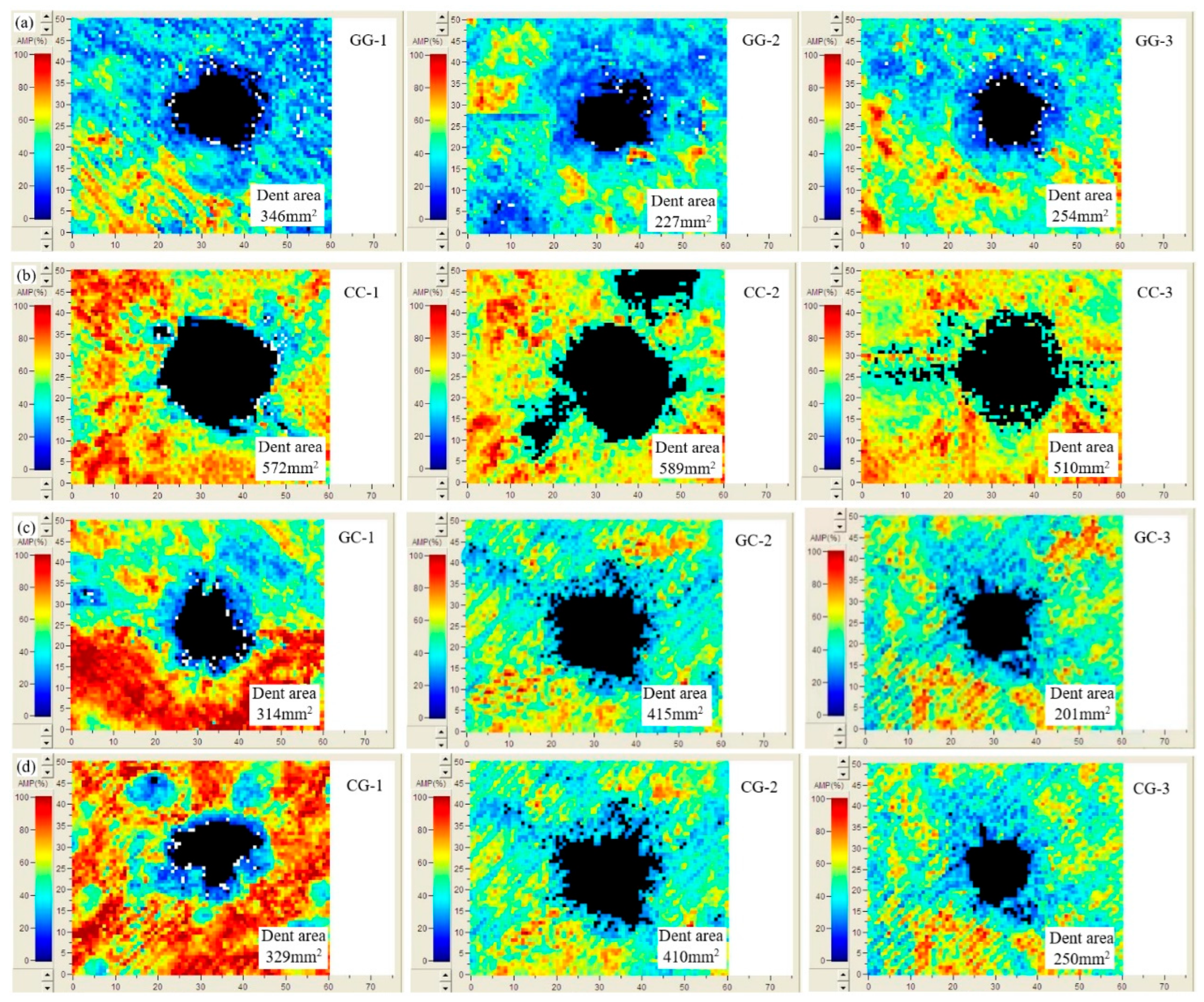

3.1. QSI of Hybrid and Non-Hybrid Woven Composite Laminates

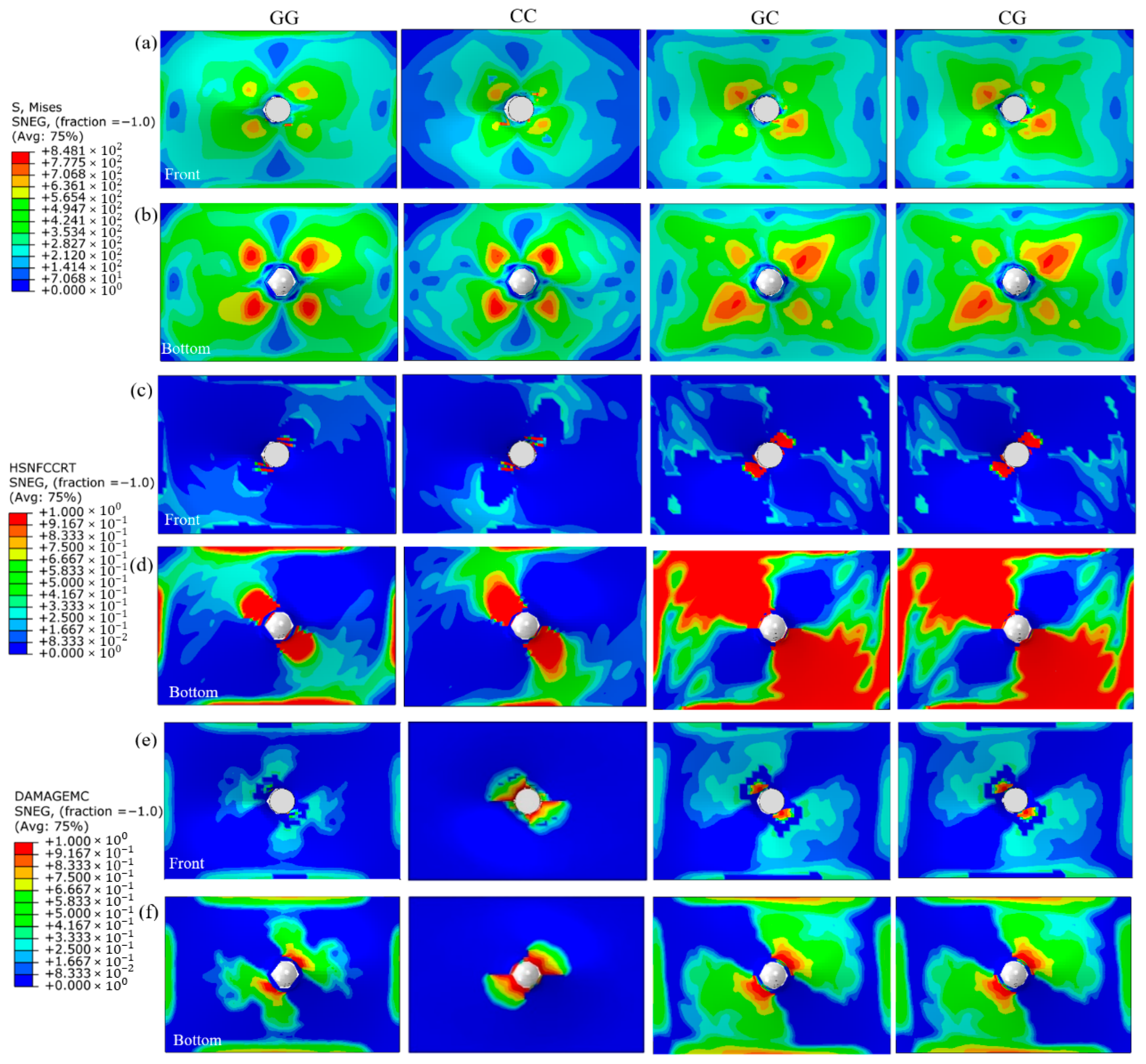

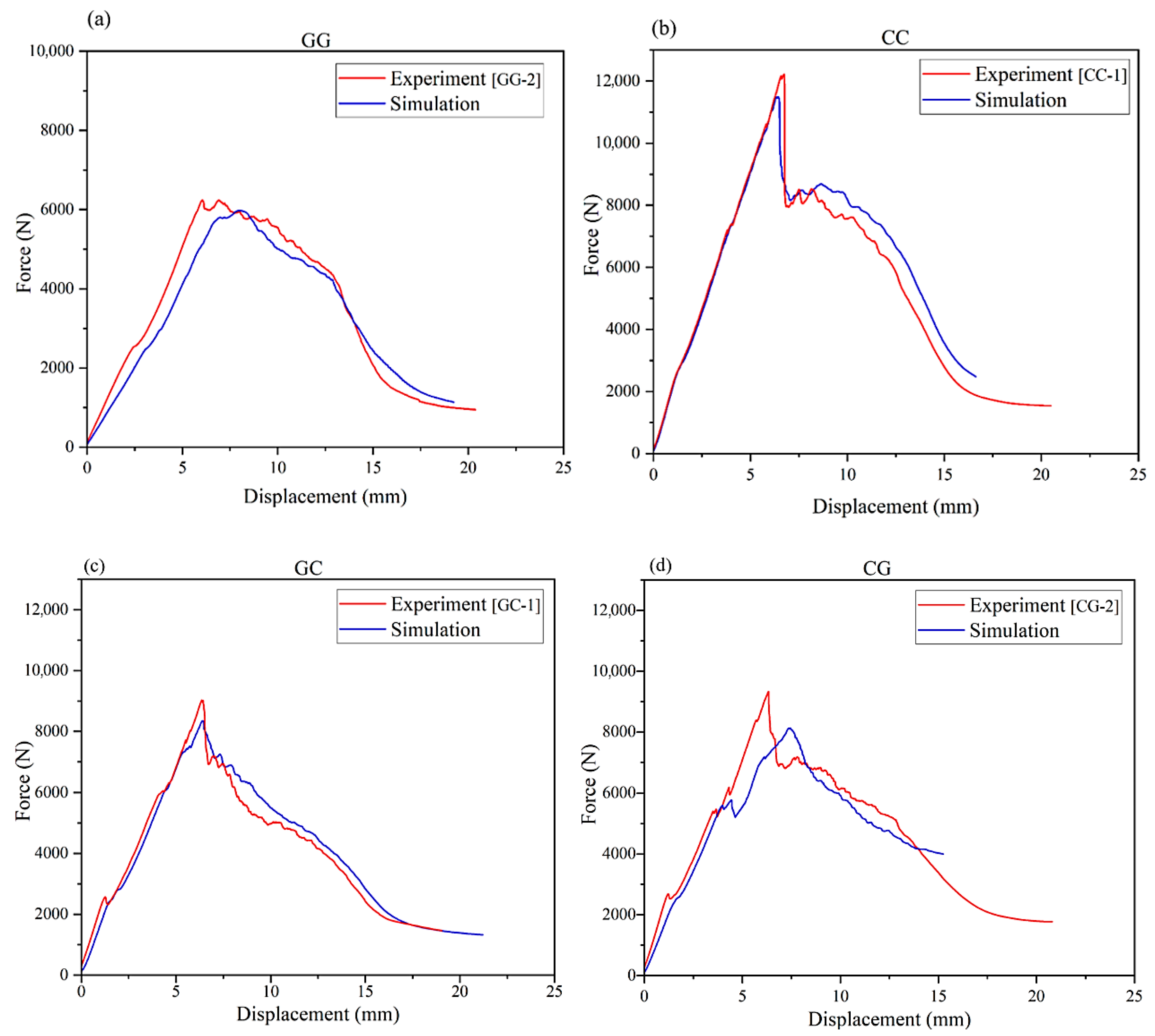

3.2. Numerical Analysis of the QSI Test

3.3. CAI Behavior of Hybrid and Non-Hybrid Woven Composite Laminates

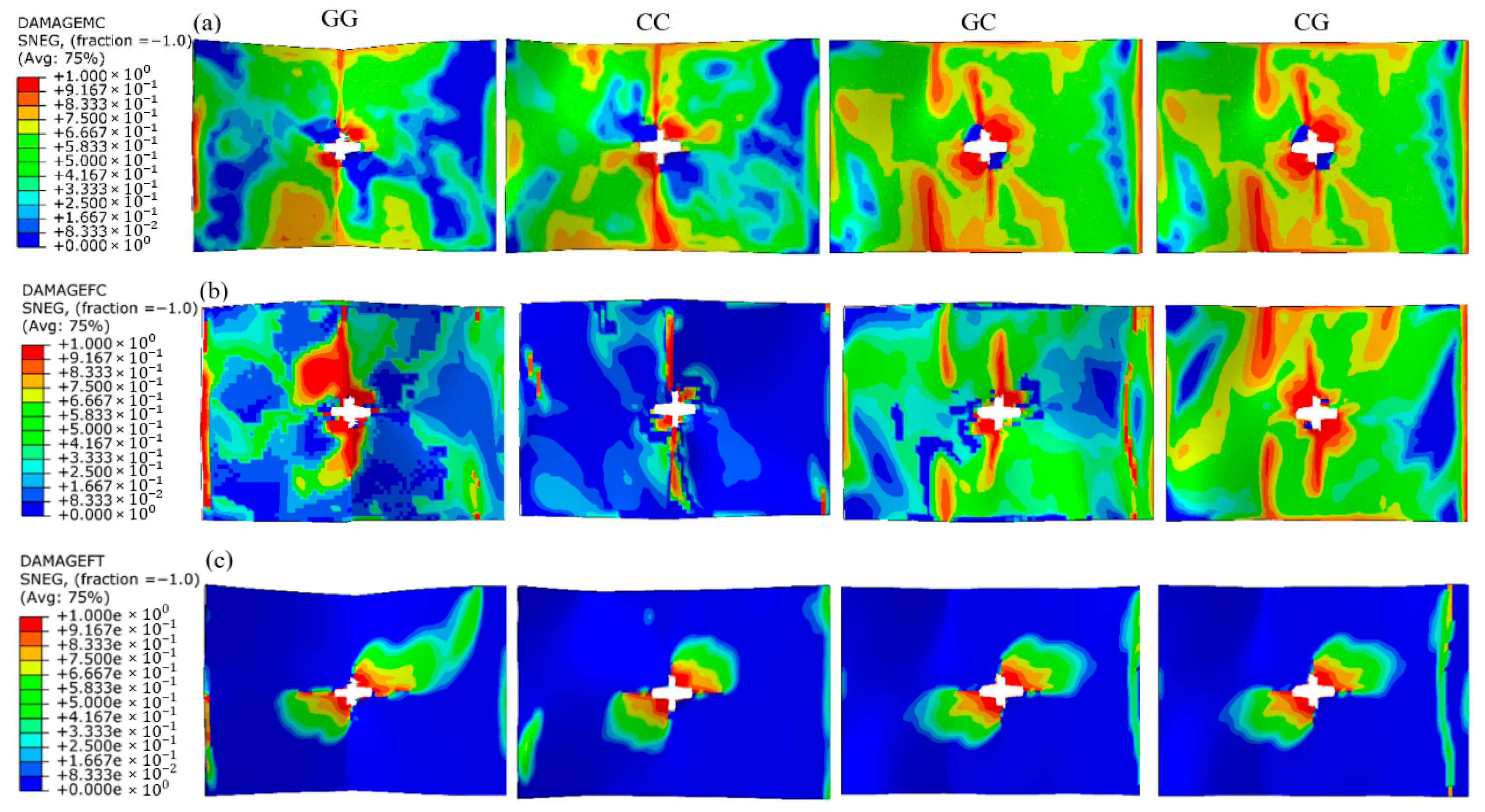

3.4. Numerical Analysis of the CAI Test

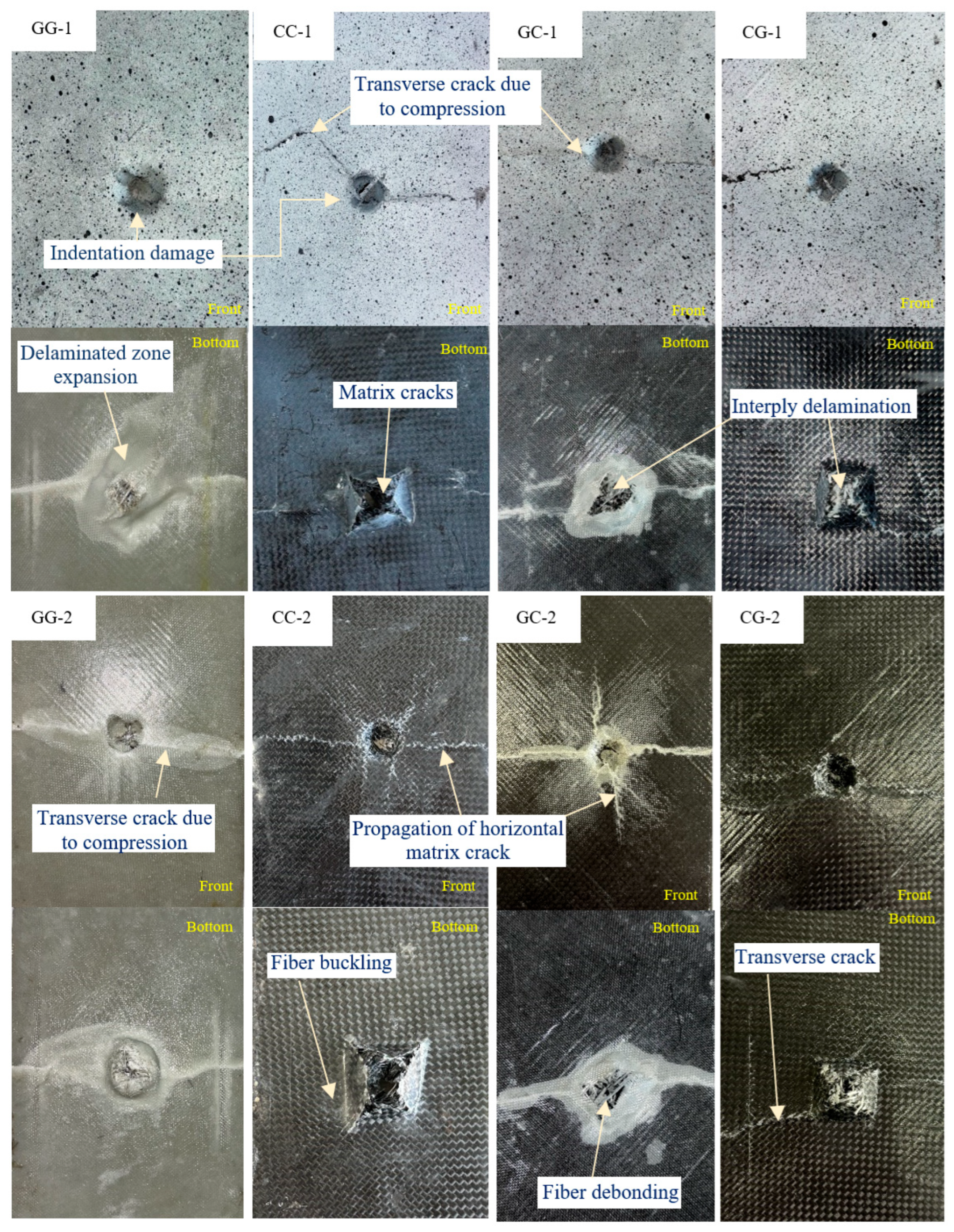

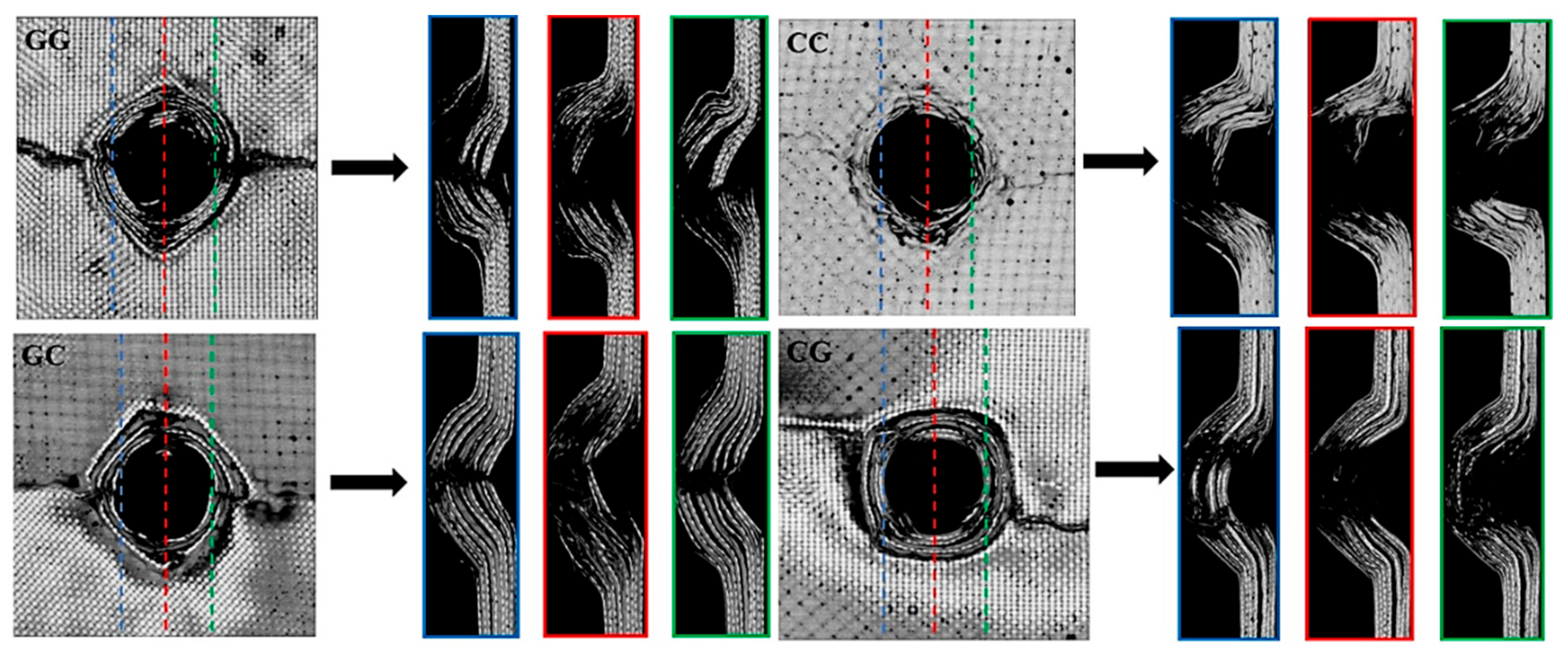

3.5. QSI and CAI Damage Mechanism

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ravishankar, B.; Nayak, S.K.; Kader, M.A. Hybrid composites for automotive applications—A review. J. Reinf. Plast. Compos. 2019, 38, 835–845. [Google Scholar] [CrossRef]

- Zhang, K.; Shi, D.; Wang, W.; Wang, Q. Mechanical characterization of hybrid lattice-to-steel joint with pyramidal CFRP truss for marine application. Compos. Struct. 2017, 160, 1198–1204. [Google Scholar] [CrossRef]

- Thibault, P.A.; Hernandez, A.R.; Mills, H. Shear driven deformation and damage mechanisms in High-performance carbon Fibre-reinforced thermoplastic and toughened thermoset composites subjected to high strain loading. Compos. Struct. 2021, 261, 13289. [Google Scholar]

- Liu, H.; Du, W.; Nezhad, H.Y.; Starr, A.; Zhao, Y. A dissection and enhancement technique for combined damage characterization in composite laminates using laser-line scanning thermography. Compos. Struct. 2021, 271, 114168. [Google Scholar] [CrossRef]

- Piscitelli, F.; Palo, R.D.; Volpe, A. Enhancing Coating Adhesion on Fibre-Reinforced Composite by Femtosecond Laser Texturing. Coatings 2023, 13, 928. [Google Scholar] [CrossRef]

- Nayak, S.; Nayak, R.K.; Panigrahi, I. Effect of Nano-fillers on low-velocity impact properties of synthetic and natural fiber reinforced polymer composites—A review. Adv. Mater. Process. Technol. 2021, 8, 1–24. [Google Scholar]

- Jesthi, D.; Nayak, R. Influence of glass/carbon fiber stacking sequence on mechanical and three-body abrasive wear resistance of hybrid composites. Mater. Res. 2020, 7, 015106. [Google Scholar] [CrossRef]

- Chen, D.; Sun, X.; Xiao, S.; Deng, J.; Yang, G.; Yang, B.; Wang, M. Investigation on flexural properties of intra-layer hybrid composite laminates reinforced with carbon and glass fibers. Fiber Polym. 2023, 24, 1119–1130. [Google Scholar] [CrossRef]

- Li, C.; Cao, Q.; Zhou, G.; Shao, M.; Chai, P.; Cai, D. Design and study of a new broadband RCS carbon-glass fiber hybrid metamaterial. Compos. Struct. 2022, 301, 116207. [Google Scholar] [CrossRef]

- Hiremath, S.; Zhang, Y.; Kim, T.W. Low-velocity impact behavior in multi-layered structures and hybrid composites via sandwich stacking techniques. Polym Compos 2024, 45, 7439–7454. [Google Scholar] [CrossRef]

- Li, Y.; Jin, Y.; Chang, X.; Shang, Y.; Cai, D. On low-velocity impact response and compression after impact of hybrid woven composite laminates. Coatings 2024, 14, 986. [Google Scholar] [CrossRef]

- Czél, G.; Wisnom, M.R. Demonstration of pseudo-ductility in high-performance glass/epoxy composites by hybridization with thin-ply carbon prepreg. Compos. Part A 2013, 52, 23–30. [Google Scholar] [CrossRef]

- Song, J.H. Pairing effect and tensile properties of laminated high-performance hybrid composites prepared using carbon/glass and carbon/aramid fibers. Compos. Part B Eng. 2015, 79, 61–66. [Google Scholar] [CrossRef]

- Zhang, J.; Chaisombat, K.; He, S.; Wang, C.H. Hybrid composite laminates reinforced with glass/carbon woven fabrics for lightweight load bearing structures. Mater. Des. 2012, 36, 75–80. [Google Scholar] [CrossRef]

- Wang, Q.; Wu, W.; Li, W. Compression properties of interlayer and intralayer carbon/glass hybrid composites. Polymers 2018, 10, 343. [Google Scholar] [CrossRef]

- Wang, Q.; Wu, W.; Li, W. Flexural progressive failure of carbon/glass interlayer and intralayer hybrid composites. Materials 2018, 11, 619. [Google Scholar] [CrossRef]

- Zweben, C. Tensile strength of hybrid composites. J. Mater. Sci. 1977, 12, 1325–1337. [Google Scholar] [CrossRef]

- Swolfs, Y.; Gorbatikh, L.; Verpoest, I. Stress concentrations in hybrid unidirectional fiber-reinforced composites with random fibre packings. Compos. Sci. Technol. 2013, 85, 10–16. [Google Scholar] [CrossRef]

- Phillips, M.G. Composition parameters for hybrid composite materials. Composites 1981, 12, 113–116. [Google Scholar] [CrossRef]

- Manders, P.; Bader, M.G. The strength of hybrid glass/carbon fibre composites. J. Mater. Sci. 1981, 16, 2233–2245. [Google Scholar] [CrossRef]

- Bunsell, A.R.; Harris, B. Hybrid carbon glass fibre composites. Composites 1974, 5, 157–164. [Google Scholar] [CrossRef]

- Dong, C. Development of a model for predicting the transverse coefficients of thermal expansion of unidirectional carbon fibre reinforced composites. Appl. Compos. Mater. 2008, 15, 171–182. [Google Scholar] [CrossRef]

- Peng, J.; Cai, D.; Zhang, N.; Zhou, G. Experimental investigation on the mechanical behavior of 3D integrated woven spacer composites under quasi-static indentation and compression after indentation: Effect of indenter shapes. Thin-Walled Struct. 2023, 182, 110213. [Google Scholar] [CrossRef]

- Dixit, M.A.; Misra, R.K. Finite element analysis of quasi-static indentation of woven fabric textile composites using different nose shape indenters. Mater. Und Werkst. 2015, 46, 1014–1028. [Google Scholar] [CrossRef]

- An, H.; Chen, S.; Huang, H. Stacking sequence optimization and blending design of laminated composite structures. Struct. Multidiscip. Optim. 2019, 59, 1–19. [Google Scholar] [CrossRef]

- Hassan, S.A.; Binoj, J.S.; Goh, K.L.; Mansingh, B.B.; Varaprasad, K.C.; Yahya, M.Y.; Ermala, C.O.F.; Ahmed, U.; Nurhadiyanto, D.; Wulandari, A.P.; et al. Effect of fiber stacking sequence and orientation on quasi-static indentation properties of sustainable hybrid carbon/ramie fiber epoxy composites. Curr. Res. Green Sustain. Chem. 2022, 5, 100284. [Google Scholar] [CrossRef]

- Jesthi, D.K.; Nayak, A.; Mohanty, S.S.; Rout, A.K.; Nayak, R.K. Evaluation of mechanical properties of hybrid composite laminates reinforced with glass/carbon woven fabrics. IOP Conf. Ser. Mater. Sci. Eng. 2018, 377, 012157. [Google Scholar] [CrossRef]

- Dehkordi, M.T.; Nosraty, H.; Shokrieh, M.; Minak, G.; Ghelli, D. The influence of hybridization on impact damage behavior and residual compression strength of intraply basalt/nylon hybrid composites. Mater. Des. 2013, 43, 283–290. [Google Scholar] [CrossRef]

- Onal, L.; Adanur, S. Effect of Stacking Sequence on the Mechanical Properties of Glass–Carbon Hybrid Composites Before and After Impact. J. Ind. Text. 2002, 31, 255–271. [Google Scholar] [CrossRef]

- Pegoretti, A.; Fabbri, E.; Migliaresi, C.; Pilati, F. Intraply and interply hybrid composites based on E-glass and poly (vinyl alcohol) woven fabrics: Tensile and impact properties. Polym. Int. 2004, 53, 1290–1297. [Google Scholar] [CrossRef]

- Naik, N.K.; Ramasimha, R.; Arya, H.; Prabhu, S.V.; ShamaRao, N. Impact response and damage tolerance characteristics of glass-carbon/epoxy hybrid composite plates. Compos. Part B Eng. 2001, 32, 565–574. [Google Scholar] [CrossRef]

- Long, X.; Li, Y.; Shen, Z.; Su, Y.; Gu, T.; Siow, K.S. Review of uniqueness challenge in inverse analysis of nanoindentation. J. Manuf. Process. 2024, 131, 1526–6125. [Google Scholar] [CrossRef]

- Sutherland, L.S.; Soares, C.G. The use of quasi-static testing to obtain the low-velocity impact damage resistance of marine GRP laminates. Compos. Part B 2012, 43, 1459–1467. [Google Scholar] [CrossRef]

- Azlin, M.N.M.; Sapuan, S.M.; Zuhri, M.Y.M.; Zainudin, E. Effect of stacking sequence and fiber content on mechanical and morphological properties of woven kenaf/polyester fiber reinforced polylactic acid (PLA) hybrid laminated composites. J. Mater. Res. Technol. 2022, 16, 1190–1201. [Google Scholar] [CrossRef]

- Anuse, V.S.; Shankar, K.; Velmurugan, R.; Ha, S.K. Compression-After-Impact analysis of carbon/epoxy and glass/epoxy hybrid composite laminate with different ply orientation sequences. Thin-Walled Struct. 2023, 185, 110608. [Google Scholar] [CrossRef]

- Caminero, M.A.; Moreno, I.G.; Rodríguez, G.P. Experimental study of the influence of thickness and ply-stacking sequence on the compression after impact strength of carbon fibre reinforced epoxy laminates. Polym. Test. 2018, 66, 360–370. [Google Scholar] [CrossRef]

- Hwang, S.F.; Mao, C.P. Failure of delaminated interply hybrid composite plates under compression. Compos. Sci. Technol. 2001, 61, 1513–1527. [Google Scholar] [CrossRef]

- Huo, L.; Alderliesten, R.; Sadighi, M. Delamination initiation in fully clamped rectangular CFRP laminates subjected to out-of-plane quasi-static indentation loading. Compos. Struct. 2022, 303, 116316. [Google Scholar] [CrossRef]

- Lyu, Q.; Wang, B.; Zhao, Z.; Guo, Z. Damage and failure analysis of hybrid laminates with different ply-stacking sequences under low-velocity impact and post-impact compression. Thin-Walled Struct. 2022, 180, 0263–8231. [Google Scholar] [CrossRef]

- Sarasini, F.; Tirillo, J.; Valente, T.; Santulli, C.; Touchard, F.; Chocinski-Arnault, L.; Mellier, D.; Lampani, L.; Gaudenzi, P. Damage tolerance of carbon/flax hybrid composites subjected to low velocity impact. Compos. Part B Eng. 2016, 91, 144–153. [Google Scholar] [CrossRef]

- ASTM-D7137/D7137M-12; Standard Test Method for Compressive Residual Strength Properties of Damaged Polymer Matrix Composite Plates. ASTM International: West Conshohocken, PA, USA, 2012.

- Attia, M.A.; Abd El-baky, M.A.; Alshorbagy, A.E. Mechanical performance of intraply and inter-intraply hybrid composites based on e-glass and polypropylene unidirectional fibers. J. Compos. Mater. 2017, 51, 381–394. [Google Scholar] [CrossRef]

- Mallick, P.K. Fiber-Reinforced Composites: Materials, Manufacturing, and Design, 3rd ed.; CRC Press: Boca Raton, FL, USA, 2007. [Google Scholar]

- Djele, A.; Karakuzu, R. An experimental study on quasi-static indentation, low-velocity impact and damage behaviors of laminated composites at high temperatures. Polym. Polym. Compos. 2021, 29, S969–S977. [Google Scholar] [CrossRef]

- Christensen, R. The numbers of elastic properties and failure parameters for fiber composites. J. Eng. Mater. Technol. 1998, 120, 110–113. [Google Scholar] [CrossRef]

- Quaresimin, M.; Ricotta, M.; Martello, L.; Mian, S. Energy absorption in composite laminates under impact loading. Compos. Part B Eng. 2013, 44, 133–140. [Google Scholar] [CrossRef]

- Liu, H.; Falzon, B.G.; Tan, W. Experimental and numerical studies on the impact response of damage-tolerant hybrid unidirectional/woven carbon-fibre reinforced composite laminates. Compos. Part B Eng. 2018, 136, 101–118. [Google Scholar] [CrossRef]

- Freitas, M.D.; Silva, A.; Reis, L. Numerical evaluation of failure mechanisms on composite specimens subjected to impact loading. Compos. Part B Eng. 2000, 31, 199–207. [Google Scholar] [CrossRef]

- Yan, H.; Oskay, C.; Krishnan, A.; Xu, L.R. Compression-after-impact response of woven fiber reinforced composites. Compos. Sci. Technol. 2010, 70, 2128–2136. [Google Scholar] [CrossRef]

| Material | E1 (GPa) | E2 (GPa) | E3 (GPa) | v12 | v13 | v23 |

|---|---|---|---|---|---|---|

| Glass fiber woven laminate | 19.03 | 19.03 | 5.63 | 0.11 | 0.32 | 0.32 |

| Carbon fiber woven laminate | 57.74 | 57.74 | 7.7 | 0.07 | 0.27 | 0.27 |

| Material | G12 (GPa) | G13 (GPa) | G23 (GPa) | S12 (MPa) | S13 (MPa) | S23 (MPa) |

|---|---|---|---|---|---|---|

| Glass fiber woven laminate | 3.42 | 2 | 2 | 69.76 | 15.53 | 15.53 |

| Carbon fiber woven laminate | 9.66 | 6.4 | 6.4 | 141.72 | 70 | 70 |

| Material | XT (MPa) | XC (MPa) | YT (MPa) | YC (MPa) | ZT (MPa) | ZC (MPa) |

|---|---|---|---|---|---|---|

| Glass fiber woven laminate | 188.72 | 74.85 | 188.72 | 74.85 | 15.15 | 42.6 |

| Carbon fiber woven laminate | 609.67 | 533.59 | 609.67 | 533.59 | 50 | 150 |

| Sample Label | Peak Force (N) | Displacement (mm) | Critical Load (N) | Avg Displacement (mm) |

|---|---|---|---|---|

| GG-1 | 5311.5 | 9.50 | ||

| GG-2 | 6241.2 | 6.92 | 6128.5 (±761.7) | 7.94 (±1.32) |

| GG-3 | 6832.7 | 7.40 | ||

| CC-1 | 12,219.5 | 6.74 | ||

| CC-2 | 11,126.9 | 6.16 | 11,705.7 (±554.5) | 6.48 (±0.29) |

| CC-3 | 11,770.8 | 6.54 | ||

| GC-1 | 9027.5 | 6.35 | ||

| GC-2 | 9001.8 | 6.27 | 8517.1 (±866.9) | 6.14 (±0.29) |

| GC-3 | 7521.9 | 5.80 | ||

| CG-1 | 8999.5 | 7.28 | ||

| CG-2 | 9328.0 | 6.33 | 8994.5 (±336.1) | 6.99 (±0.56) |

| CG-3 | 8656.0 | 7.35 |

| Specimen Label | Damage Area (mm2) | Energy (J) | Avg Damage Area (mm2) | Avg Energy (J) | SAE (J/g) |

|---|---|---|---|---|---|

| GG-1 | 346 | 25.2 | 275.7 (±61.2) | 24.1 (±2.1) | 0.3314 |

| GG-2 | 227 | 21.6 | |||

| GG-3 | 254 | 25.3 | |||

| CC-1 | 572 | 41.1 | 557.0 (±41.1) | 37.9 (±3.5) | 0.5790 |

| CC-2 | 589 | 34.3 | |||

| CC-3 | 510 | 38.5 | |||

| GC-1 | 314 | 28.7 | 310.0 (±107.5) | 26.3 (±3.8) | 0.3808 |

| GC-2 | 415 | 28.2 | |||

| GC-3 | 201 | 21.8 | |||

| CG-1 | 329 | 32.8 | 329.7 (±80.6) | 31.3 (±1.6) | 0.4530 |

| CG-2 | 410 | 29.5 | |||

| CG-3 | 250 | 31.8 |

| Material | Avg Peak Load (kN) | Displacement (mm) | Bearing Efficiency (N/g) | Residual Compressive Strength (MPa) |

|---|---|---|---|---|

| Glass laminates | 22.13 (±3.24) | 1.85 (±0.29) | 304.32 | 69.14 |

| Carbon laminates | 36.44 (±3.71) | 1.88 (±0.25) | 556.69 | 113.57 |

| Glass-Carbon laminates | 29.11 (±1.95) | 1.57 (±0.13) | 421.25 | 91.04 |

| Carbon-Glass laminates | 27.90 (±4.13) | 3.11 (±1.68) | 403.85 | 87.16 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Herath, H.U.; Cai, D.; Inusha, L.; Luna Macias, P.; Wang, X. Quasi-Static Indentation and Compression Behaviors of Hybrid Woven Composite Laminates. Coatings 2025, 15, 791. https://doi.org/10.3390/coatings15070791

Herath HU, Cai D, Inusha L, Luna Macias P, Wang X. Quasi-Static Indentation and Compression Behaviors of Hybrid Woven Composite Laminates. Coatings. 2025; 15(7):791. https://doi.org/10.3390/coatings15070791

Chicago/Turabian StyleHerath, Hiranya Uthpali, Deng’an Cai, Leshan Inusha, Paloma Luna Macias, and Xinwei Wang. 2025. "Quasi-Static Indentation and Compression Behaviors of Hybrid Woven Composite Laminates" Coatings 15, no. 7: 791. https://doi.org/10.3390/coatings15070791

APA StyleHerath, H. U., Cai, D., Inusha, L., Luna Macias, P., & Wang, X. (2025). Quasi-Static Indentation and Compression Behaviors of Hybrid Woven Composite Laminates. Coatings, 15(7), 791. https://doi.org/10.3390/coatings15070791