Abstract

Fresh-cut potatoes are highly perishable, requiring effective preservation strategies to maintain quality and extend shelf life. This study evaluated the use of edible coatings and the combination of osmotic dehydration and ohmic heating (OH-OD), both integrated with modified atmosphere packaging (MAP), to enhance microbial stability and reduce quality deterioration. Key quality parameters—including color stability, browning index, weight loss, microbial activity, and sensory attributes—were assessed. Results showed that coated samples (E-FP) had the lowest browning index (59.71) by day 8, compared to a value of 62.69 in control samples (C-FP). OH-OD-treated samples exhibited the least weight loss (6.73%) versus 17.75% in C-FP. Microbial analysis showed that E-FP samples maintained the lowest total viable count by day 8 (3.98 ± 0.02 log CFU/g), compared to OH-OD-FP (4.43 ± 0.13 log CFU/g) and C-FP (4.79 ± 0.06 log CFU/g), confirming the antimicrobial efficacy of the edible coating enriched with rosemary essential oil and ascorbic acid. Sensory evaluation further confirmed that coated samples retained superior sensory qualities, receiving the highest overall acceptance score of 8.86 ± 0.80, compared to values of 7.80 ± 0.98 for control samples (C-FP) and 2.80 ± 0.69 for OH-OD-FP samples, highlighting their enhanced consumer appeal. These findings highlight that combining advanced preservation techniques with MAP can significantly reduce moisture loss and microbial spoilage while maintaining freshness and sensory appeal. This integrated approach offers a promising solution for extending shelf life, reducing food waste, and supporting sustainability in response to consumer demand for minimally processed, high-quality fresh products.

1. Introduction

Fresh-cut potatoes are a convenient and minimally processed product but are highly perishable due to their susceptibility to enzymatic browning, microbial contamination, and physical deterioration [1]. The cutting process disrupts the protective epidermis, exposing the internal tissue to oxidative processes and moisture loss, which accelerates spoilage and negatively impacts quality [2]. These challenges significantly limit the shelf life of fresh-cut potatoes, reduce consumer acceptance, and contribute to economic losses and food waste. As global demand for minimally processed foods grows, the need for advanced preservation strategies that extend shelf life while maintaining sensory and nutritional attributes is becoming increasingly critical [3,4].

To address these challenges, various preservation techniques have been explored, each with unique advantages. Osmotic dehydration (OD), which involves the removal of water by immersing produce in hypertonic solutions, has proven effective in reducing enzymatic browning, microbial activity, and moisture loss while preserving firmness and texture [5,6,7,8]. Recent advancements have further enhanced OD’s effectiveness through pre-treatment methods such as ohmic heating [9], ultrasound-assisted OD [10], and pulsed electric field and high-pressure treatments [11] prior to the osmotic dehydration of fresh-cut potatoes. Ohmic heating (OH), in particular, has emerged as a promising thermal pre-treatment method that improves the efficiency of OD by enhancing water loss and solute uptake while preserving the sensory and nutritional qualities of the product. By providing uniform heating, minimizing thermal damage and reducing processing time, ohmic heating ensures optimal conditions for fragile products like fresh-cut potatoes, thereby improving their overall quality and stability [12].

Edible coatings, particularly those enriched with antimicrobial and antioxidant agents, have shown immense potential in providing a protective barrier to reduce microbial growth, oxidative degradation, and moisture loss [13,14,15]. These coatings have shown significant potential in maintaining the sensory attributes and extending the shelf life of fresh-cut produce, making them a versatile addition to preservation strategies [16]. Coatings developed from potato peel-extracted polysaccharides combined with rosemary essential oil and ascorbic acid, encapsulated via spray drying and electrospinning, significantly reduced browning, weight loss, and microbial load over 14 days of storage. These coatings not only enhanced appearance and texture but also demonstrated the potential of sustainable, bio-based solutions for fresh-cut preservation [17].

Modified atmosphere packaging (MAP) is a widely used technique that alters the gaseous environment surrounding fresh-cut produce to slow down microbial growth, enzymatic browning, and oxidative degradation [18]. It has consistently shown effectiveness in preserving color, texture, and overall quality while extending shelf life in minimally processed fruits and vegetables [19]. While traditional MAP applications often rely on passive packaging strategies with limited gas monitoring, emerging studies emphasize the importance of active gas regulation and novel barrier materials to optimize preservation outcomes. In particular, the integration of MAP with other preservation strategies, such as edible coatings and osmotic or thermal pre-treatments, has been suggested as a promising synergy to further reduce enzymatic browning and microbial load [20].

Despite progress in preservation technologies, the combined application of multiple innovative techniques—such as osmotic dehydration, ohmic heating, edible coatings, and modified atmosphere packaging (MAP)—for fresh-cut potato preservation remains largely unexplored. Most existing research isolates these methods, overlooking their potential synergistic benefits. Notably, the use of rigorously validated MAP with controlled gas composition and high-barrier packaging has rarely been integrated with advanced pre-treatments.

This study addresses this gap by evaluating a multi-hurdle approach that incorporates edible coatings and ohmic heating-assisted osmotic dehydration (OH-OD) with actively controlled MAP (70% N2, 30% CO2), which is verified using gas analyzers to ensure atmospheric stability. Key quality indicators—including color retention, browning index, weight loss, and microbial stability—were monitored to assess performance. This integrated strategy aims to deliver a robust and sustainable solution for extending the shelf life of fresh-cut potatoes, meeting consumer demand for minimally processed, high-quality foods while reducing postharvest waste.

2. Materials and Methods

2.1. Materials

The potatoes used in this study were of the Spunta variety, provided by Monolithos Agrofood and Renewables GP, a potato processing company in Naxos, Greece. Potato cubes were cut into uniform dimensions of 40 mm (length) × 12 mm (width) × 12 mm (height) to ensure geometric consistency across all experimental samples. Osmotic solutions were made using glycerol, glucose, and sodium chloride (NaCl), all of which were sourced from local suppliers. Edible coatings were prepared with potato starch, pectin, and glycerol, also procured from local markets. Whey protein isolate powder (WPI) was obtained from Agropur Ingredients Inc. (La Crosse, WI, USA). The active ingredients, ascorbic acid and rosemary essential oil, were obtained from Sigma-Aldrich (Steinheim, Germany) and VIORYL (Athens, Greece), respectively.

2.2. Edible Coatings

The edible coatings were prepared using separate solutions of potato starch and pectin based on our previous study [17]. A 2% (w/v) potato starch solution was heated at 90 °C for 3 h to achieve complete gelatinization and also to ensure sufficient molecular breakdown and homogeneity for optimal film-forming properties in the edible coating system. A 4% (w/v) pectin solution was heated at 50 °C until fully dissolved. Glycerol (1.5% w/v) was added as a plasticizer, and the two solutions were mixed in a 1:2 ratio to obtain the final coating solution (1% w/v starch and 2% w/v pectin). For the enriched coating, ascorbic acid (0.5% w/v) was dissolved into the matrix, and a pre-emulsion was prepared by homogenizing a 1.5% (w/v) WPI solution (pH 3) with rosemary essential oil (5% w/w) at 10,500 rpm for 5 min. The matrix and pre-emulsion were combined at a 95:5 (v/v) ratio. Fresh-cut potato cubes (40 mm × 12 mm × 12 mm) were immersed in the coating solution for 2 min, with enriched samples further dipped in a 2% (w/v) calcium chloride solution for 2 min. The coated samples were air-dried for 15 min to stabilize the coating film.

2.3. Combination of Ohmic Heating and Osmotic Dehydration

Fresh potatoes were peeled and sliced into uniform pieces and then immersed in a 1.5% (w/w) sodium chloride solution to provide sufficient conductivity for the ohmic heating process. The ohmic heating setup included a power supply, electrodes, and a sample chamber, and was operated between 30 and 100 °C. Potato slices were placed inside the chamber, and an electric field strength of 20 V/cm was applied for 7 min based on optimal conditions previously determined [4]. After heating, the samples were cooled to room temperature to halt further thermal effects. The treated potato slices were subsequently osmotic-dehydrated in a solution comprising 70% (w/w) glycerol and 10% (w/w) sodium chloride at 45 °C for 6 h. The potato-to-solution weight ratio was consistently maintained at 1:5 (w/w) to ensure uniform mass transfer. Both the potato slices and osmotic solution were placed into sealed tubes and immersed in a temperature-controlled water bath to maintain stable and consistent conditions throughout the process.

2.4. Modified Atmosphere Packaging (MAP) of Fresh-Cut Potato Samples

The fresh-cut potato samples, including control (C-FP), edible-coated (E-FP), and ohmic-heated–osmotically dehydrated (OH-OD-FP) treatments, were packaged using a Benchtop Vacuum Packing Machine (SU-310GP, Sammic, Termoli, Italy) under modified atmosphere conditions. A gas mixture of 70% N2 and 30% CO2 was used. High-barrier, food-grade plastic bags were used to prevent gas exchange and moisture loss. A gas analyzer was used to verify the accuracy of the gas composition, ensuring consistency across all samples. The packaged potato samples were stored at 4 °C for 8 days to assess their shelf life and key quality parameters, including color stability and browning index, weight loss, and microbial load.

2.5. Characterization of Fresh-Cut Potato Samples

2.5.1. Color Measurement and Browning Index Determination

The color of the potato samples was evaluated using a colorimeter (MiniScan XE, Hunter Associates Laboratory Inc., Reston, Virginia) equipped with a 4 mm measuring head. The measurements were conducted in reflectance mode using the CIE Lab* color scale [21]. Color parameters (L*, a*, and b*) were recorded at three different points on the cut surface of each sample. These parameters were then used to calculate the browning index (BI) according to Equation (1).

2.5.2. Weight Loss

The weight loss of the samples was determined by weighing them initially at day 0 and subsequently at specific time intervals during storage at 4 °C. Weight loss was calculated using Equation (2).

where Wi is the initial weight of the sample at day 0 (g), and Wt is the weight of the sample at the measured time interval (g) [22].

2.5.3. Hardness

The hardness of the potato samples was measured using a universal testing machine (model Z2.5/TN1S, Zwick, Ulm, Germany) equipped with parallel plates for uniaxial compression and a 2 kN load cell. Compression was carried out at a constant deformation rate of 5 mm/min. Before each measurement, the dimensions of the potato cubes were carefully recorded using a digital Vernier caliper. All tests were conducted at room temperature (25 °C) and were repeated four times to ensure reliable data. From these compression tests, the Elastic Modulus (E-modulus) of the potatoes was determined.

2.5.4. Microbial Load

The microbial load of C-FP, E-FP, and OH-OD-FP samples was assessed using a modified serial dilution technique (Kumari and Nikhanj, 2022 [23]; Tsakiri-Mantzorou et al., 2024 [17]). Samples were weighed, cut into smaller pieces, and homogenized in sterile filter bags containing Ringer serum (1:9 ratio) prepared with Ringer tablets (Merck, Darmstadt, Germany). A 10−1 dilution was obtained by homogenizing 10 g of each sample in 90 mL of sterile distilled water. Sequential tenfold dilutions were prepared up to 10⁷. Microbial enumeration was performed on nutrient agar for total plate count (TPC). For each dilution, 1 mL of the homogenate was plated using the pour plate method with molten sterile agar. Plates were incubated at 37 ± 2 °C for 24–48 h. Microbial colonies were counted, and results were expressed as CFU/g using Equation (3).

The results for each sample group were expressed as log (CFU/g) on a fresh weight basis to evaluate microbial growth over the storage period [24].

2.5.5. Sensory Evaluation

A sensory evaluation was conducted to determine the overall acceptability of the fresh-cut potato samples. A panel of 10 trained individuals, comprising both male and female participants aged between 22 and 45 years, took part in the assessment. All panelists were experienced in food evaluation and trained in sensory analysis. Prior to evaluation, the potato samples were fried in corn oil at 180 °C for 6 min using a deep fryer (SFR 7200SS, Sencor, 2200 W, Athens, Greece) to produce crisp, golden fries. Each panelist received coded samples: one coated with an edible coating (E-FP), one treated with osmotic dehydration and ohmic heating (OH-OD-FP), and an untreated fresh-cut control (C-FP). To eliminate order bias, the serving sequence of the samples was randomized. Panelists were provided with water as a palate cleanser between samples to prevent flavor carryover. The evaluation was conducted in a sensory laboratory under controlled lighting and temperature to ensure consistency. Panelists assessed the samples based on flavor, texture, color, and overall acceptability using a 9-point hedonic scale, where 1 indicated “dislike extremely” and 9 indicated “like extremely.” The data collected from the evaluations were statistically analyzed to determine the effects of the preservation treatments on the sensory quality of the fresh-cut potato samples.

2.6. Statistical Analysis

The data were analyzed using one-way and factorial analysis of variance (ANOVA) to identify significant differences among the treatments. Tukey’s post hoc test was applied at a significance level of α = 0.05 for multiple comparisons. All statistical analyses were conducted using SPSS 23.0 software (IBM SPSS Statistics, Chicago, IL, USA).

3. Results

3.1. Optical Observation

Table 1 presents the visual changes in C-FP, E-FP, and OH-OD-FP samples during 8 days of storage at 4 °C under MAP conditions. Among the treatments, the E-FP exhibited the best visual quality, with minimal browning, surface shrinkage, and a consistent yellow color throughout storage. The application of an edible coating, enriched with ascorbic acid and rosemary essential oil in conjunction with MAP effectively mitigated enzymatic browning and oxidative reactions by reducing oxygen availability while providing a protective barrier against moisture loss [25].

Table 1.

Optical observation of C-FP, E-FP, and OH-OD-FP samples during storage for 8 days at 4 °C.

Similarly, the OH-OD-FP sample exhibited notable improvements in visual quality, with reduced browning, although it was slightly less effective compared to the E-FP samples. In contrast, the untreated control sample (C-FP), despite being packaged under MAP conditions, showed visible deterioration as early as day 4, with noticeable browning and surface shrinkage. By day 8, the control samples exhibited significant discoloration and a loss of firmness, indicating that MAP alone was insufficient to prevent quality loss without additional treatments.

These results highlight the synergistic potential of integrating MAP with complementary preservation technologies such as edible coatings and ohmic heating-osmotic dehydration. The combined treatments markedly enhanced color stability, suppressed enzymatic browning, and minimized moisture migration, ultimately extending the visual and sensory shelf life of fresh-cut potatoes. This integrated approach provides an effective strategy for maintaining the commercial quality of minimally processed products.

3.2. Browning Index

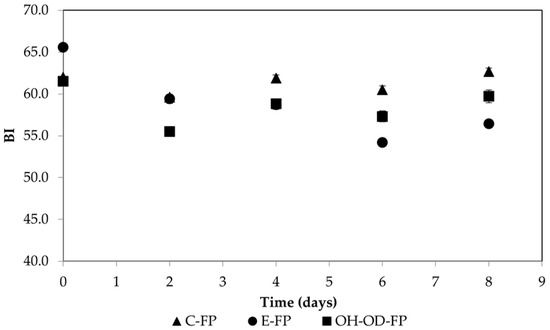

The browning index (BI) values of C-FP, OH-OD-FP, and E-FP samples during 8 days of storage at 4 °C are shown in Figure 1.

Figure 1.

Browning index of C-FP, E-FP, and OH-OD-FP samples during storage for 8 days at 4 °C.

The browning index (BI) is a key indicator of visual quality in fresh-cut produce, directly reflecting the extent of enzymatic browning—a major factor influencing consumer acceptance and marketability. In this study, BI served as a critical metric to evaluate the effectiveness of various preservation treatments.

The C-FP samples exhibited relatively stable but higher consistently browning index (BI) values throughout the storage period, indicating enzymatic browning due to the lack of additional protective treatments [26]. In contrast, the OH-OD-FP samples demonstrated a significant reduction in BI compared to the control, particularly during the initial days of storage. This suggests that the application of ohmic heating in combination with osmotic dehydration effectively suppressed browning by reducing enzymatic activity and limiting the availability of free moisture—a critical factor in enzymatic oxidation processes. Similar findings were reported where pulsed electric fields and high-pressure pre-treatments enhanced osmotic dehydration’s effectiveness in reducing browning and improving the shelf life of fresh-cut potatoes [11].

The E-FP samples consistently recorded the lowest BI values across the entire storage duration. This superior performance is attributed to the multifunctional role of the edible coating, which not only served as a physical barrier to oxygen but also leveraged the antioxidant activity of ascorbic acid and the antimicrobial properties of rosemary essential oil to inhibit polyphenol oxidase activity and maintain color stability [17,27]. Recent research has confirmed the value of similar coatings—especially those incorporating essential oils and encapsulated active agents—in significantly reducing browning in fresh-cut potatoes during storage [8,9,14]. In addition, novel strategies such as the integration of natural extracts (e.g., Flos Sophorae Immaturus) and thermal treatments have also shown promise in reducing oxidative browning in fresh-cut potatoes by modulating reactive oxygen species and nitric oxide levels [18].

Collectively, these findings demonstrate a clear hierarchy in browning inhibition efficacy, with E-FP offering the most pronounced protective effect, followed by OH-OD-FP, and C-FP showing the least resistance to browning. The results further substantiate the advantages of integrating MAP with functional edible coatings or pre-treatment strategies such as ohmic heating–osmotic dehydration, reinforcing their role in extending shelf life and preserving the visual appeal of fresh-cut potatoes.

3.3. Weight Loss

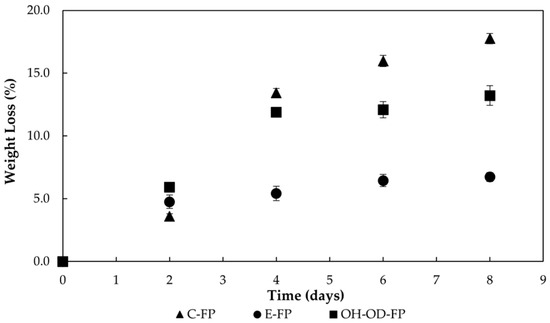

The weight loss of C-FP, OH-OD-FP, and E-FP samples during 8 days of storage at 4 °C, presented in Figure 2, reveals the effectiveness of the applied treatments.

Figure 2.

Weight loss of C-FP, E-FP, and OH-OD-FP samples during storage for 8 days at 4 °C.

The C-FP samples exhibited the highest weight loss over the storage period, a phenomenon primarily attributed to the absence of any protective treatment. This lack of intervention facilitated moisture evaporation through exposed cut surfaces, leading to accelerated dehydration—a well-documented occurrence in untreated fresh-cut produce [28]. In contrast, the OH-OD-FP samples consistently demonstrated the lowest weight loss. This can be attributed to the synergistic effects of ohmic heating and osmotic dehydration, which effectively reduce water activity by partially removing free water and creating a protective barrier that limits moisture migration [29]. Studies confirm that ohmic heating promotes uniform heating and cell membrane modification, which enhances mass transfer and water loss during osmotic dehydration [7,19].

The E-FP samples displayed intermediate weight loss, indicating that the edible coating effectively reduced moisture loss by acting as a semipermeable barrier. The inclusion of glycerol as a plasticizer likely enhanced the film’s flexibility and water-holding capacity, although the overall efficacy in minimizing dehydration was slightly lower than that observed in OH-OD-FP-treated samples [9]. Similar findings have been reported in studies using polysaccharide-based coatings enriched with natural extracts, which reduced dehydration in fresh-cut potatoes during cold storage [9].

In summary, these findings underscore the importance of incorporating targeted pre-treatments such as ohmic heating–osmotic dehydration and edible coatings to effectively mitigate weight loss in fresh-cut potatoes stored under MAP conditions. Among the treatments studied, OH-OD-FP proved most effective in preserving moisture content, while the C-FP samples, lacking supplementary protective measures, experienced the most pronounced dehydration.

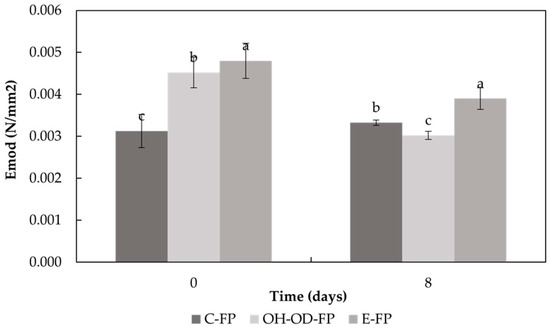

3.4. Hardness

The modulus of elasticity (Emod) of C-FP, OH-OD-FP, and E-FP samples was assessed at the beginning (day 0) and after 8 days of storage at 4 °C. The results are presented in Figure 3.

Figure 3.

Modulus of elasticity (Emod) of C-FP, E-FP and OH-OD-FP samples on day 0 and day 8 of storage at 4 °C. Different letters indicate statistically significant differences (p < 0.05).

The data reveal significant differences (p < 0.05) in the Emod values across the different potato treatments. On day 0, the E-FP samples exhibited the highest Emod, indicating enhanced structural integrity due to the edible coating treatment. The OD-OH-FP samples had an intermediate Emod, while the control (C-FP) potatoes had the lowest value. This trend suggests that both the edible coating and the osmotic dehydration with ohmic heating process significantly increased the hardness of the potato samples compared to the control.

After 8 days of storage at 4 °C, a general decrease in Emod was observed across all samples, reflecting the natural softening of potato tissue over time due to cellular degradation and moisture redistribution. Despite this decline, the E-FP samples consistently maintained the highest Emod, even on day 8, significantly differing from the control samples. This demonstrates the superior structural preservation imparted by edible coatings, likely due to their ability to reduce moisture loss, inhibit enzymatic activity, and act as effective barriers to gas and water exchange [30].

Conversely, the OD-OH-FP samples showed the moderate but significant retention of firmness compared to the control group. This suggests that the osmotic dehydration combined with ohmic heating treatments contributed to partial preservation of textural integrity. These treatments likely reduced water activity within the potato tissue and stabilized cellular components by inducing structural rearrangements, slowing down tissue softening and moisture migration [31,32].

Overall, the results demonstrate that edible coatings not only provide the highest initial Emod values but also ensure the superior retention of potato firmness during refrigerated storage. Meanwhile, osmotic dehydration combined with ohmic heating offers additional benefits by partially mitigating structural degradation, thereby improving the shelf life and textural stability of processed potato products. These findings underscore the potential of combining edible coatings and mild processing technologies to enhance and maintain the mechanical properties of potatoes during cold storage, supporting future applications in minimally processed vegetable products.

3.5. Microbial Load

Table 2 presents the total microbial load of C-FP, E-FP, and OH-OD-FP during 8 days of storage at 4 °C.

Table 2.

Total microbial load (log (cfu/g sample) of C-FP, E-FP, and OH-OD-FP samples.

The E-FP samples demonstrated the lowest microbial load at both the onset of storage (2.56 ± 0.08 log CFU/g on day 0) and after eight days of refrigerated storage (3.98 ± 0.02 log CFU/g), indicating superior microbial stability over time compared to C-FP and OH-OD-FP treatments. Although an increase in microbial load was observed across all treatments during storage—a common trend in minimally processed produce—the extent of microbial proliferation varied significantly depending on the applied preservation strategy [27].

The C-FP samples, which lacked any additional protective treatment beyond MAP, exhibited the highest microbial count by day 8 (4.79 ± 0.06 log CFU/g), underscoring the limited efficacy of MAP alone in suppressing microbial growth. Similar conclusions were drawn by Rashid et al. (2021), who found that MAP alone did not significantly inhibit microbial growth in fresh-cut potatoes beyond 5–7 days of storage, especially in the absence of antimicrobial agents [15]. In contrast, the E-FP treatment, incorporating an edible coating enriched with ascorbic acid and rosemary essential oil, effectively inhibited microbial development. The antimicrobial properties of rosemary essential oil, combined with the physical barrier function of the coating, likely contributed to this enhanced microbial control. Similarly, Sarengaowa et al. (2022) [33] observed that edible coatings enriched with essential oils like cinnamon and thyme effectively suppressed microbial growth in minimally processed vegetables. These coatings acted as both oxygen barriers and carriers for bioactive compounds, thus creating a dual defense against spoilage organisms [8,14].

The OH-OD-FP samples displayed intermediate microbial loads, suggesting that while ohmic heating and osmotic dehydration imparted some degree of microbial inhibition, this was likely due to a combination of thermal effects and reduced water activity. However, their antimicrobial efficacy was not as pronounced as that of the bioactive edible coating used in the E-FP samples [34]. These findings are supported by studies demonstrating that ohmic heating can partially inactivate microbial populations through membrane disruption and localized heating effects. For example, Müller et al. (2020) highlighted that ohmic heating reduces microbial loads primarily through rapid internal heating, which compromises microbial cell integrity, although the effect is not always sufficient to eliminate spoilage organisms when used alone [14]. Moreover, Dermesonlouoglou et al. (2025) demonstrated that pre-treating fresh-cut potatoes with pulsed electric fields and osmotic dehydration was found to promote the retention of key quality attributes such as texture and color, while also enhancing the overall shelf life stability of the potato strips [14]. In contrast, edible coatings enriched with antimicrobial compounds such as rosemary essential oil and ascorbic acid, as used in E-FP, have been shown to actively inhibit microbial metabolism and replication. Tsakiri-Mantzorou et al. (2024) and Sarengaowa et al. (2022) reported that such coatings not only delayed microbial growth more effectively than physical treatments, but also preserved overall sensory and microbial quality over longer storage durations [9,14].

Overall, these findings highlight the effectiveness of integrating bioactive edible coatings with MAP in extending microbial shelf life. The E-FP treatment emerged as the most effective approach for preserving microbial quality in fresh-cut potatoes during cold storage.

3.6. Sensory Evaluation

Table 3 presents the sensory evaluation of C-FP, E-FP, and OH-OD-FP on day 0 and Figure 4 presents a visual representation of the samples after frying.

Table 3.

Sensory evaluation of C-FP, E-FP and OH-OD-FP samples.

Figure 4.

Photos of (a) C-FP, (b) E-FP, and (c) OH-OD-FP samples after deep frying in corn oil at 180 °C for 6 min (day 0).

The sensory evaluation results reveal notable differences in the consumer perception of fresh-cut potatoes subjected to different treatments. Among the evaluated samples, E-FP consistently received the highest scores across most sensory attributes, indicating enhanced overall quality and consumer acceptance, while OH-OD-FP generally scored the lowest.

In terms of color and uniformity, E-FP samples were rated significantly higher (8.50 ± 0.64 and 9.00 ± 1.94, respectively) than OH-OD-FP, reflecting the visual appeal maintained by the edible coating. This suggests that the incorporation of ascorbic acid and rosemary essential oil effectively preserved color integrity and minimized visual defects. C-FP samples also scored relatively high in these categories but were not significantly different from E-FP, indicating that MAP alone contributed to partial maintenance of appearance. These results are consistent with previous research by Sarengaowa et al. (2022) and Gaowa et al. (2023), who demonstrated that essential oil-based coatings enhance both aroma and flavor perceptions in fresh-cut produce [8,14].

Crunchiness and interior quality followed a similar trend, with E-FP again achieving superior scores (7.71 ± 0.49 and 8.90 ± 1.36, respectively). The textural integrity of E-FP samples was well-preserved, likely due to the moisture-retentive properties of the edible coating. In contrast, OH-OD-FP samples were perceived as significantly less crunchy (4.07 ± 1.02) and had the lowest interior quality score (2.78 ± 0.88), possibly due to structural softening from the combined thermal and osmotic pre-treatment.

Regarding taste intensity, aroma intensity, and aroma acceptance, E-FP again outperformed other treatments, receiving the highest ratings (7.80 ± 0.40, 7.52 ± 1.72, and 8.69 ± 1.59, respectively), suggesting that the active compounds in the edible coating positively influenced flavor perception and olfactory appeal.

All treatments received similarly low scores for bitter taste, indicating no substantial bitterness was imparted by any of the preservation methods. Sweet taste scores remained moderate across samples with no statistically significant differences. Meanwhile, OH-OD-FP samples had a higher salty taste score (8.20 ± 0.75), likely due to salt uptake during osmotic dehydration, which may have contributed to their lower total acceptance score (2.80 ± 0.69).

Aftertaste was least favorable in OH-OD-FP (2.40 ± 0.59). This was likely affected by residual salt or treatment-induced off-flavors, whereas E-FP was rated highest (4.25 ± 0.26), suggesting a more pleasant lingering flavor. Overall, total acceptance scores highlighted the superior sensory appeal of E-FP samples (8.86 ± 0.80), followed by C-FP (7.80 ± 0.98), with OH-OD-FP scoring the lowest. These findings reinforce the benefits of edible coatings enriched with bioactive compounds in enhancing the sensory qualities and consumer acceptability of fresh-cut potatoes stored under MAP.

In summary, E-FP samples showed the best sensory performance, confirming the effectiveness of edible coatings in preserving quality and enhancing consumer acceptance of fresh-cut potatoes under MAP.

4. Conclusions

This study highlights the efficacy of combining modified atmosphere packaging (MAP) with innovative pre-treatments—namely edible coatings enriched with bioactive compounds, and the sequential application of ohmic heating and osmotic dehydration—in extending the shelf life and preserving the quality of fresh-cut potatoes. These integrated approaches effectively minimized weight loss, inhibited enzymatic browning, suppressed microbial growth, and maintained desirable sensory characteristics throughout cold storage. Among the treatments, the edible coating (E-FP), enriched with ascorbic acid and rosemary essential oil, consistently outperformed others in preserving visual quality, maintaining color stability, and enhancing sensory appeal. Conversely, the ohmic heating-osmotic dehydration treatment (OH-OD-FP) most effectively reduced moisture loss, reflecting its role in structural water removal and barrier formation. Control samples (C-FP), treated with only MAP, exhibited accelerated quality degradation, underscoring the limited efficacy of MAP alone. These findings underscore the value of combining MAP with targeted pre-treatment technologies to develop robust, sustainable preservation systems for fresh-cut produce. Future work may further explore additional functional benefits, such as oil absorption reduction during frying, to broaden application potential.

Author Contributions

Conceptualization, C.D. and M.K.; methodology, A.M., C.D., C.V. and M.K.; software, A.M., C.D. and K.T.L.; validation, A.M., C.D., K.T.L., C.V. and M.K.; formal analysis, A.M., C.D., K.T.L. and C.V.; investigation, A.M., C.D., C.V. and M.K.; resources, M.K.; data curation, A.M., C.D., K.T.L. and C.V.; writing—original draft preparation, A.M., C.D., K.T.L. and C.V.; writing—review and editing, A.M., C.D., K.T.L. and M.K.; visualization, A.M., C.D., K.T.L. and C.V.; supervision, C.D. and M.K.; project administration, M.K.; funding acquisition, M.K. All authors have read and agreed to the published version of the manuscript.

Funding

This study was funded by the European Union-NextGenerationEU in the framework of the National Recovery and Resilience Plan (Greece 2.0) under the call ID 16971 “RESEARCH—CREATE—INNOVATE” [project code Τ2ΕΔΚ-03121—project acronym: Fresh4ever].

Institutional Review Board Statement

Ethical review and approval were waived for this study because the sensory evaluation involved minimal risk to participants, and no personally identifiable information was collected. The study adhered to institutional guidelines for research involving human participants.

Informed Consent Statement

Informed consent was obtained from all subjects involved in the study.

Data Availability Statement

Data are contained within the article.

Conflicts of Interest

The authors declare no conflicts of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| C-FP | Control Fresh-cut Potato |

| E-FP | Edible-coated Fresh-cut Potato |

| OH-OD-FP | Ohmic Heated–Osmotically Dehydrated Fresh-cut Potato |

| OD | Osmotic Dehydration |

| OH | Ohmic Heating |

| WPI | Whey Protein Isolate |

| MAP | Modified Atmosphere Packaging |

| TPC | Total Plate Count |

| CFU | Colony Forming Units |

| BI | Browning Index |

| SPSS | Statistical Package for the Social Sciences |

| ANOVA | Factorial Analysis of Variance |

References

- Navina, B.; Keshav Huthaash, K.; Velmurugan, N.K.; Korumilli, T. Insights into Recent Innovations in Anti Browning Strategies for Fruit and Vegetable Preservation. Trends Food Sci. Technol. 2023, 139, 104128. [Google Scholar] [CrossRef]

- Drosou, C.; Sklirakis, I.; Polyzou, E.; Yakoumis, I.; Boukouvalas, C.J.; Krokida, M. Processing Fresh-Cut Potatoes Using Non-Thermal Technologies and Edible Coatings. Appl. Sci. 2024, 14, 11039. [Google Scholar] [CrossRef]

- Levaj, B.; Pelaić, Z.; Galić, K.; Kurek, M.; Ščetar, M.; Poljak, M.; Dite Hunjek, D.; Pedisić, S.; Balbino, S.; Čošić, Z.; et al. Maintaining the Quality and Safety of Fresh-Cut Potatoes (Solanum Tuberosum): Overview of Recent Findings and Approaches. Agronomy 2023, 13, 2002. [Google Scholar] [CrossRef]

- Liu, X.; Yang, Q.; Lu, Y.; Li, Y.; Li, T.; Zhou, B.; Qiao, L. Effect of Purslane (Portulaca oleracea L.) Extract on Anti-Browning of Fresh-Cut Potato Slices during Storage. Food Chem. 2019, 283, 445–453. [Google Scholar] [CrossRef]

- Pattanapa, K.; Therdthai, N.; Chantrapornchai, W.; Zhou, W. Original Article: Effect of Sucrose and Glycerol Mixtures in the Osmotic Solution on Characteristics of Osmotically Dehydrated Mandarin Cv. (Sai-Namphaung). Int. J. Food Sci. Technol. 2010, 45, 1918–1924. [Google Scholar] [CrossRef]

- Hawa, L.C.; Khoirunnida, F.L.; Sumarlan, S.H. Drying Kinetics and Physical Changes of Osmotically Pretreated Potato (Solanum Tuberosum L.) Slice. IOP Conf. Ser. Earth Environ. Sci. 2020, 475, 012007. [Google Scholar] [CrossRef]

- Lech, K.; Michalska, A.; Wojdyło, A.; Nowicka, P.; Figiel, A. The Influence of the Osmotic Dehydration Process on Physicochemical Properties of Osmotic Solution. Molecules 2017, 22, 2246. [Google Scholar] [CrossRef]

- Lerici, C.R.; Pinnavaia, G.; Rosa, M.D.; Bartolucci, L. Osmotic Dehydration of Fruit: Influence of Osmotic Agents on Drying Behavior and Product Quality. J. Food Sci. 1985, 50, 1217–1219. [Google Scholar] [CrossRef]

- Mari, A.; Andriotis, P.; Drosou, C.; Laina, K.; Panagiotou, N.; Krokida, M. Enhancing Shelf-life Stability of Refrigerated Potatoes through Osmotic Dehydration and Ohmic Heating Optimization: A Strategy to Mitigate Enzymatic Browning. Potato Res. 2024. [Google Scholar] [CrossRef]

- Goula, A.M.; Kokolaki, M.; Daftsiou, E. Use of Ultrasound for Osmotic Dehydration. The Case of Potatoes. Food Bioprod. Process. 2017, 105, 157–170. [Google Scholar] [CrossRef]

- Katsouli, M.; Dermesonlouoglou, E.; Dimopoulos, G.; Karafantalou, E.; Giannakourou, M.; Taoukis, P. Shelf-Life Enhancement Applying Pulsed Electric Field and High-Pressure Treatments Prior to Osmotic Dehydration of Fresh-Cut Potatoes. Foods 2024, 13, 171. [Google Scholar] [CrossRef] [PubMed]

- Sain, M.; Minz, P.S.; John, H.; Singh, A. Effect of Ohmic Heating on Food Products: An In-Depth Review Approach Associated with Quality Attributes. J. Food Process. Preserv. 2024, 2024, 2025937. [Google Scholar] [CrossRef]

- Han, J.H. Edible Films and Coatings: A Review. In Innovations in Food Packaging; Elsevier BV: Amsterdam, The Netherlands, 2014; pp. 213–255. [Google Scholar] [CrossRef]

- Baldwin, E.A.; Nisperos-Carriedo, M.O.; Baker, R.A. Edible Coatings for Lightly Processed Fruitsand Vegetables. HortScience 1995, 30, 35–38. [Google Scholar] [CrossRef]

- Bourtoom, T. Edible Films and Coatings: Characteristics and Properties. Int. Food Res. J. 2008, 15, 237–248. [Google Scholar]

- Gaowa, S.; Feng, K.; Li, Y.; Long, Y.; Hu, W. Effect of Alginate-Based Edible Coating Containing Thyme Essential Oil on Quality and Microbial Safety of Fresh-Cut Potatoes. Horticulturae 2023, 9, 543. [Google Scholar] [CrossRef]

- Tsakiri-Mantzorou, Z.; Drosou, C.; Mari, A.; Stramarkou, M.; Laina, K.T.; Krokida, M. Edible Coating with Encapsulated Antimicrobial and Antibrowning Agents via the Emerging Electrospinning Process and the Conventional Spray Drying: Effect on Quality and Shelf Life of Fresh-Cut Potatoes. Potato Res. 2024, 68, 587–619. [Google Scholar] [CrossRef]

- Tudela, J.A.; Gil, M.I. Tubers: Fresh-Cut Potatoes. In Controlled and Modified Atmospheres for Fresh and Fresh-Cut Produce; Elsevier: Amsterdam, The Netherlands, 2020; pp. 625–628. [Google Scholar]

- Paulsen, E.; Moreno, D.A.; Lema, P. Modified Atmosphere Packaging Using Cellulose-Based Film (NatureFlexTM) Preserved Quality and Bioactive Compounds of Fresh-Cut Broccolis. Postharvest Biol. Technol. 2024, 217, 113092. [Google Scholar] [CrossRef]

- Giannakourou, M.C.; Tsironi, T.N. Application of Processing and Packaging Hurdles for Fresh-Cut Fruits and Vegetables Preservation. Foods 2021, 10, 830. [Google Scholar] [CrossRef]

- Drosou, C.; Krokida, M. A Comparative Study of Encapsulation of β-Carotene via Spray-Drying and Freeze-Drying Techniques Using Pullulan and Whey Protein Isolate as Wall Material. Foods 2024, 13, 1933. [Google Scholar] [CrossRef]

- Zhang, Z.; Wang, J.; Zhang, X.; Shi, Q.; Xin, L.; Fu, H.; Wang, Y. Effects of Radio Frequency Assisted Blanching on Polyphenol Oxidase, Weight Loss, Texture, Color and Microstructure of Potato. Food Chem. 2018, 248, 173–182. [Google Scholar] [CrossRef]

- Kumari, J.; Nikhanj, P. Evaluation of edible coatings for microbiological and physicochemical quality maintenance of fresh cut papaya. J. Food Process. Preserv. 2022, 46. [Google Scholar] [CrossRef]

- Müller, W.A.; Ferreira Marczak, L.D.; Sarkis, J.R. Microbial Inactivation by Ohmic Heating: Literature Review and Influence of Different Process Variables. Trends Food Sci. Technol. 2020, 99, 650–659. [Google Scholar] [CrossRef]

- Sarengaowa; Wang, L.; Liu, Y.; Yang, C.; Feng, K.; Hu, W. Screening of Essential Oils and Effect of a Chitosan-Based Edible Coating Containing Cinnamon Oil on the Quality and Microbial Safety of Fresh-Cut Potatoes. Coatings 2022, 12, 1492. [Google Scholar] [CrossRef]

- Rashid, M.H.; Khan, M.R.; Roobab, U.; Rajoka, M.S.R.; Inam-ur-Raheem, M.; Anwar, R.; Ahmed, W.; Jahan, M.; Ijaz, M.R.A.; Asghar, M.M.; et al. Enhancing the Shelf Stability of Fresh-cut Potatoes via Chemical and Nonthermal Treatments. J. Food Process. Preserv. 2021, 45, e15582. [Google Scholar] [CrossRef]

- Rizzo, V.; Amoroso, L.; Licciardello, F.; Mazzaglia, A.; Muratore, G.; Restuccia, C.; Lombardo, S.; Pandino, G.; Strano, M.G.; Mauromicale, G. The Effect of Sous Vide Packaging with Rosemary Essential Oil on Storage Quality of Fresh-Cut Potato. LWT 2018, 94, 111–118. [Google Scholar] [CrossRef]

- Qiao, L.; Liu, Y.; Deng, X.; Yu, W.; Wang, Y.; Li, X.; Lu, L.; Liu, X. A New Strategy for Browning Regulation: Flos Sophorae Immaturus Extract and Thermal Treatment Modulates Nitric Oxide and Reactive Oxygen Species Network in Fresh-cut Potatoes. J. Food Sci. 2023, 88, 4574–4590. [Google Scholar] [CrossRef] [PubMed]

- Asghari, A.; Zongo, P.A.; Osse, E.F.; Aghajanzadeh, S.; Raghavan, V.; Khalloufi, S. Review of Osmotic Dehydration: Promising Technologies for Enhancing Products’ Attributes, Opportunities, and Challenges for the Food Industries. Compr. Rev. Food Sci. Food Saf. 2024, 23, e13346. [Google Scholar] [CrossRef]

- Nurliasari, D.; Dewantoro, A.I.; Mardawati, E.; Rahmah, D.M.; Kastaman, R.; Lubis, M.A.R.; Abdullah, A.H.D.; Djali, M.; Nurhasanah, S.; Zaini, L.H. An Evaluation on Physical Characteristics of Konjac Polysaccharides-Based Film Coating and Its Application for Strawberries Preservation. J. Renew. Mater. 2025, 13, 181–197. [Google Scholar] [CrossRef]

- Pandiselvam, R.; Tak, Y.; Olum, E.; Sujayasree, O.J.; Tekgül, Y.; Çalışkan Koç, G.; Kaur, M.; Nayi, P.; Kothakota, A.; Kumar, M. Advanced Osmotic Dehydration Techniques Combined with Emerging Drying Methods for Sustainable Food Production: Impact on Bioactive Components, Texture, Color, and Sensory Properties of Food. J. Texture Stud. 2022, 53, 737–762. [Google Scholar] [CrossRef]

- Xu, A.; Lai, W.; Chen, P.; Awasthi, M.K.; Chen, X.; Wang, Y.; Xu, P. A Comprehensive Review on Polysaccharide Conjugates Derived from Tea Leaves: Composition, Structure, Function and Application. Trends Food Sci. Technol. 2021, 114, 83–99. [Google Scholar] [CrossRef]

- Sarengaowa; Wang, L.; Liu, Y.; Yang, C.; Feng, K.; Hu, W. Effect of Ascorbic Acid Combined with Modified Atmosphere Packaging for Browning of Fresh-Cut Eggplant. Coatings 2022, 12, 1580. [Google Scholar]

- Dermesonlouoglou, E.; Seretis, G.; Katsouli, M.; Katsimichas, A.; Taoukis, P.; Giannakourou, M. Effect of Pulsed Electric Fields and Osmotic Dehydration on the Quality of Modified-Atmosphere-Packaged Fresh-Cut and Fried Potatoes. Foods 2025, 14, 420. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).