Hybrid Surface Treatment Technologies Based on the Electrospark Alloying Method: A Review

Abstract

1. Introduction

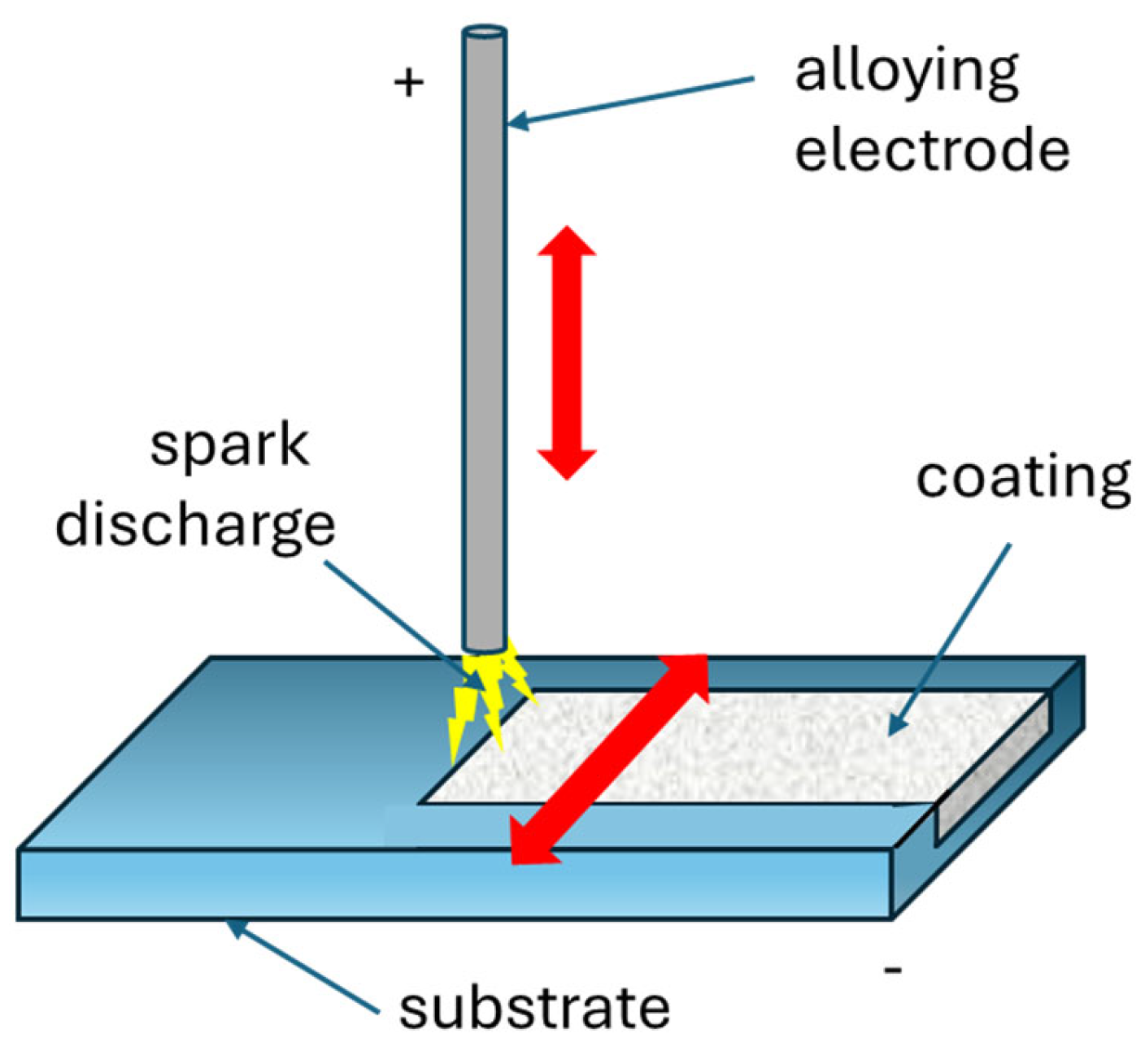

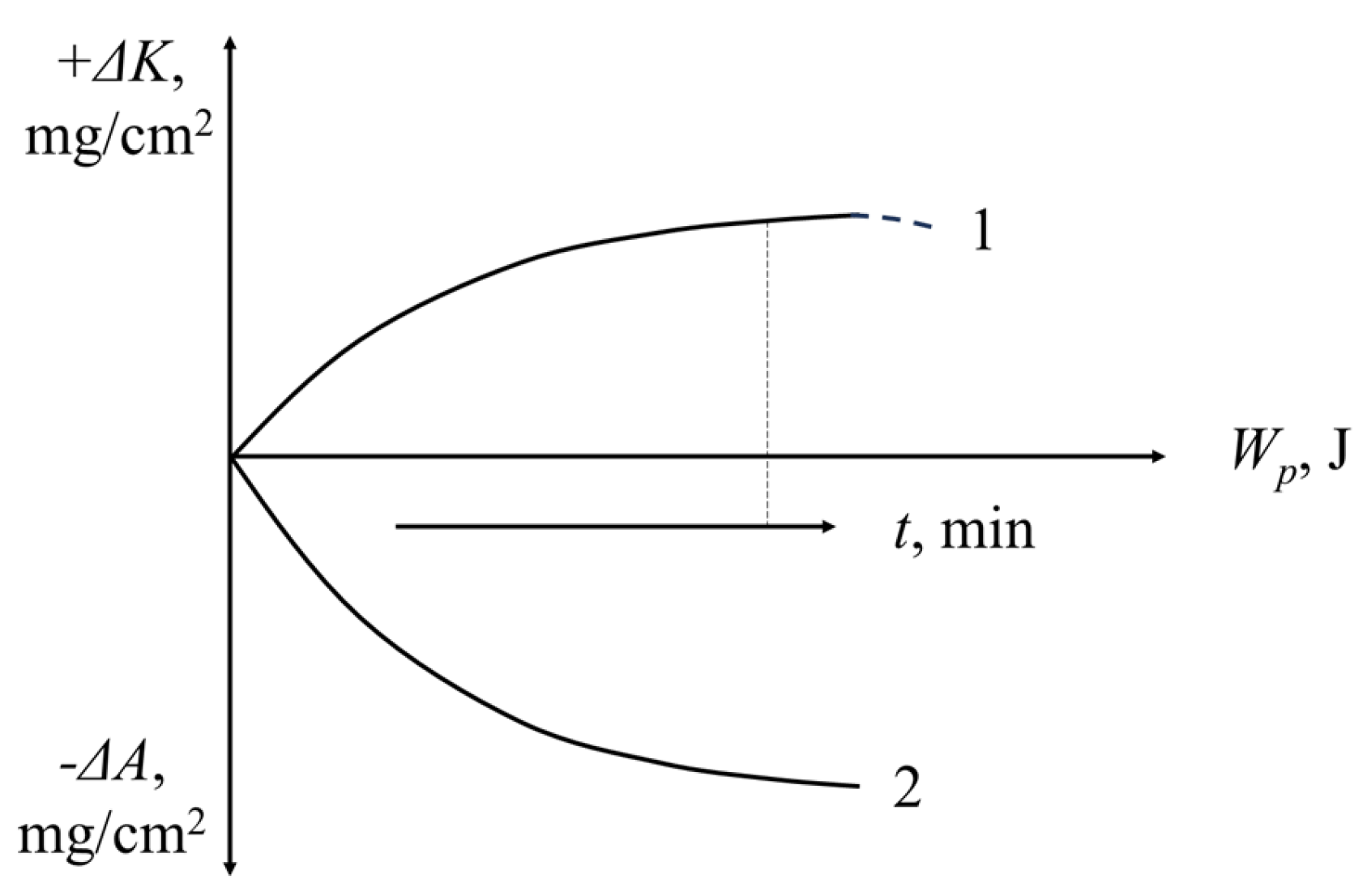

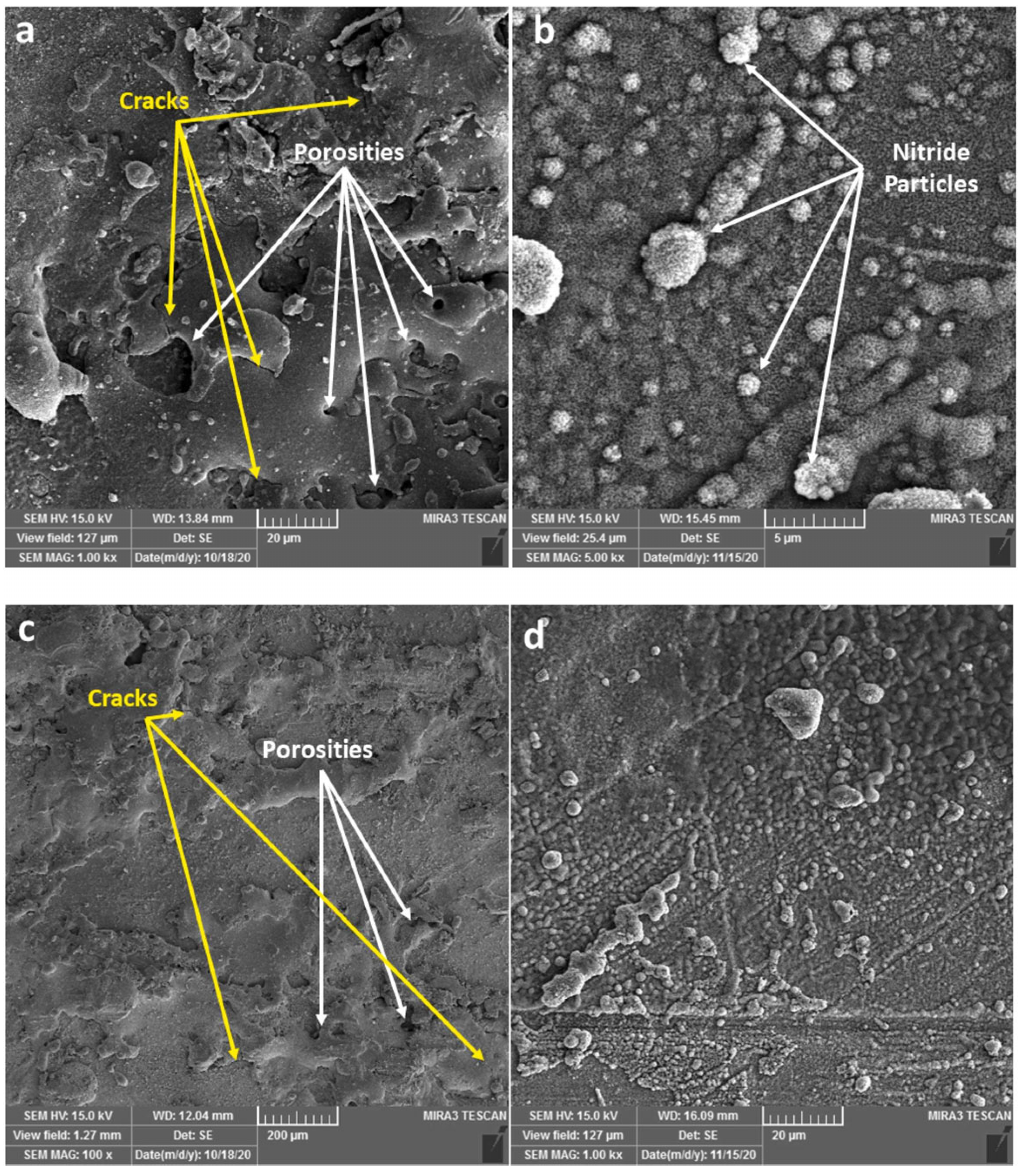

2. Electrospark Alloying Technology

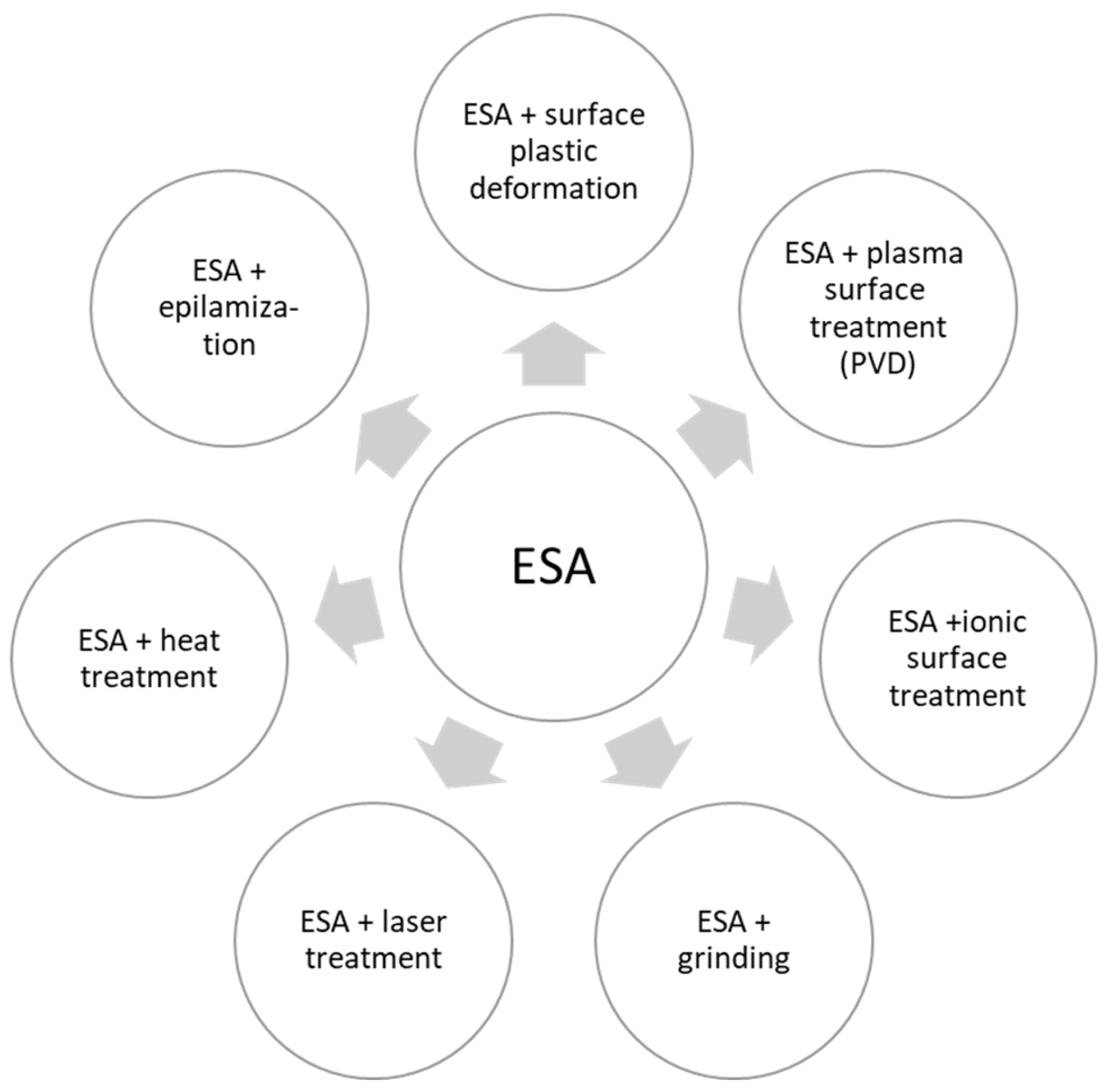

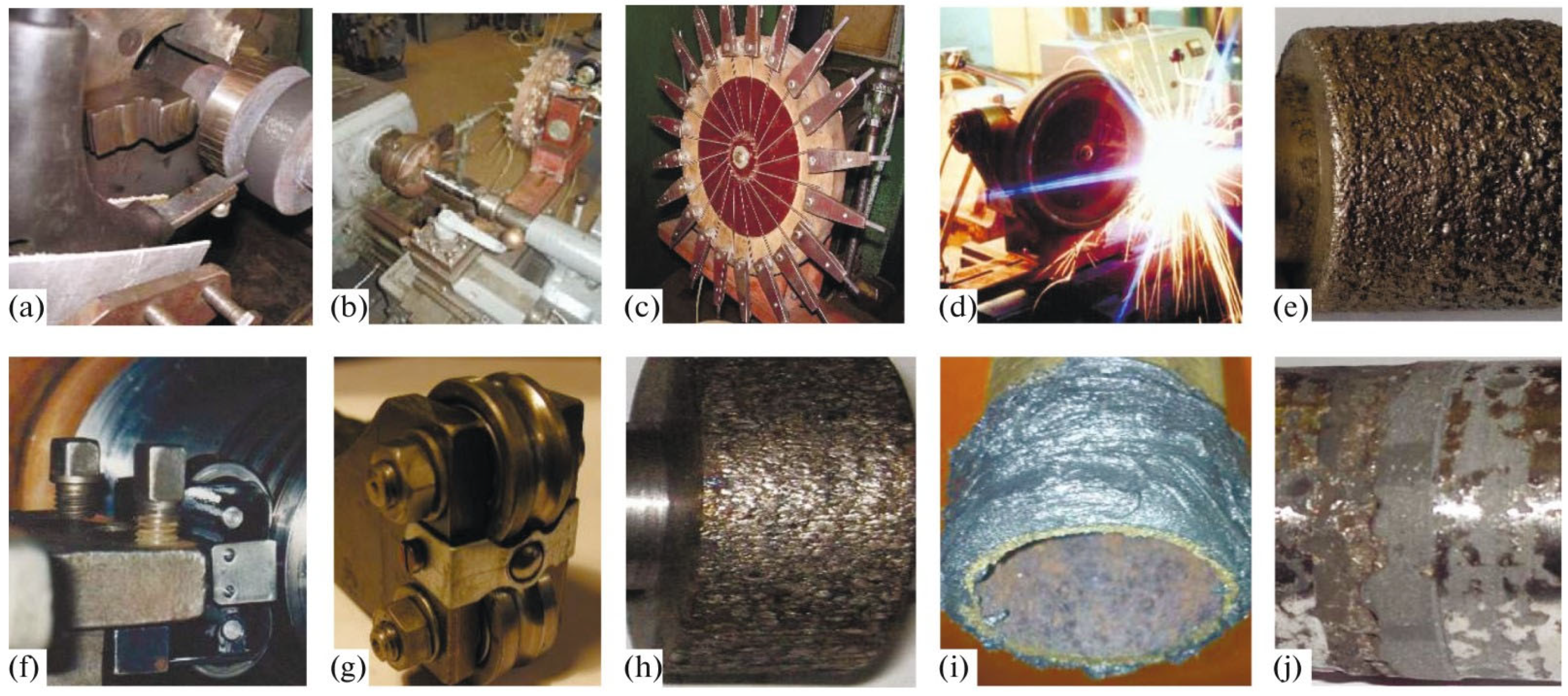

3. Hybrid ESA Technologies

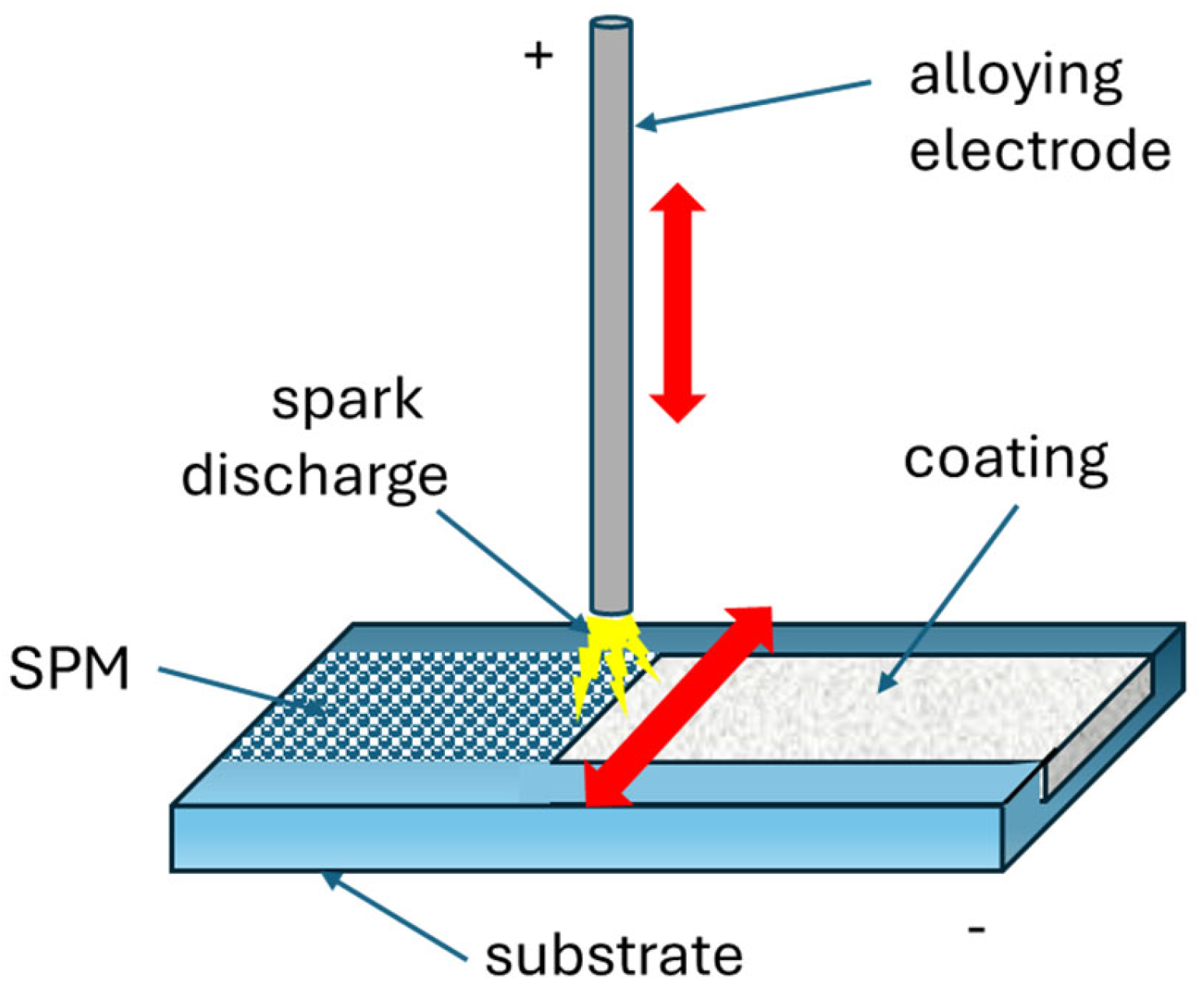

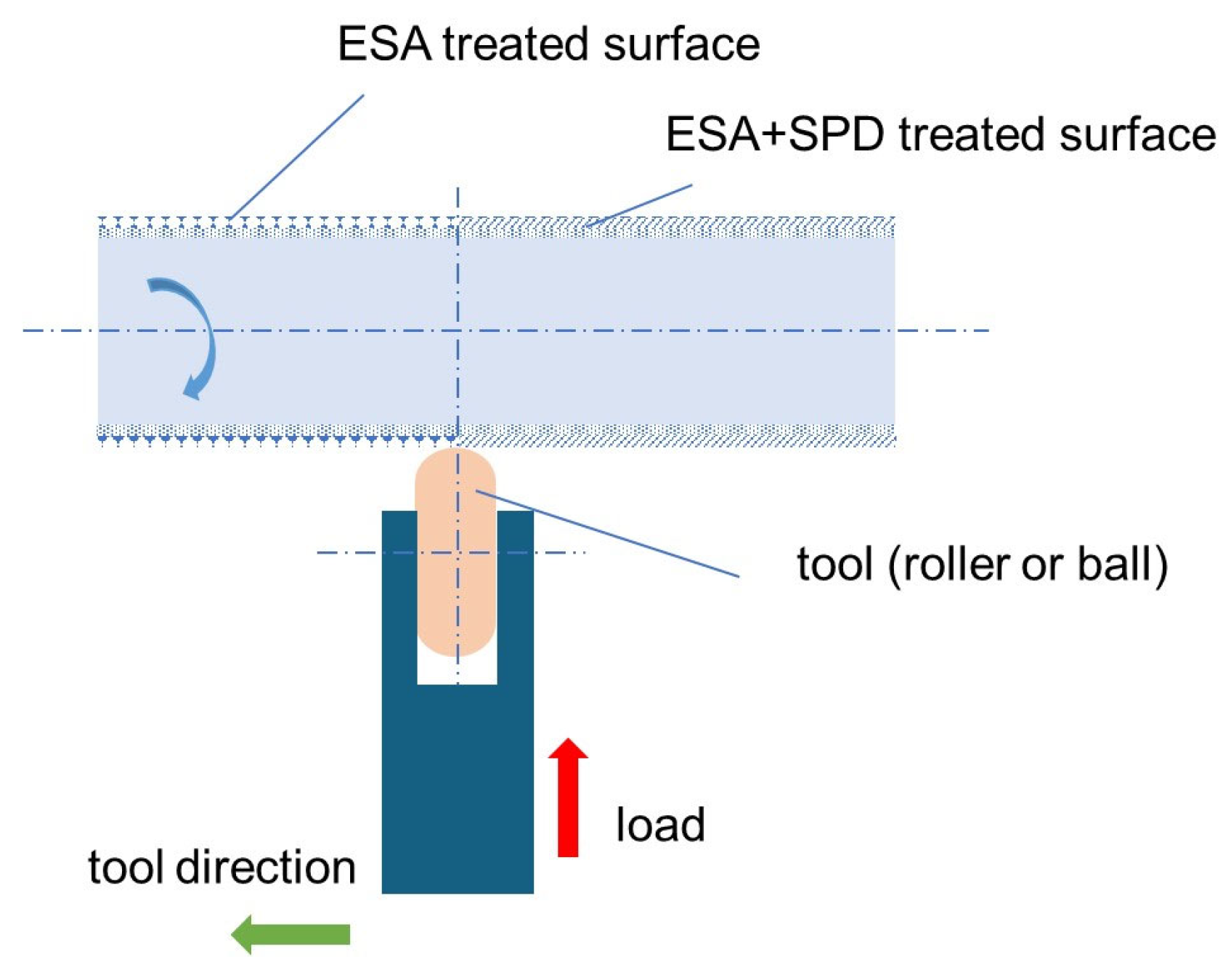

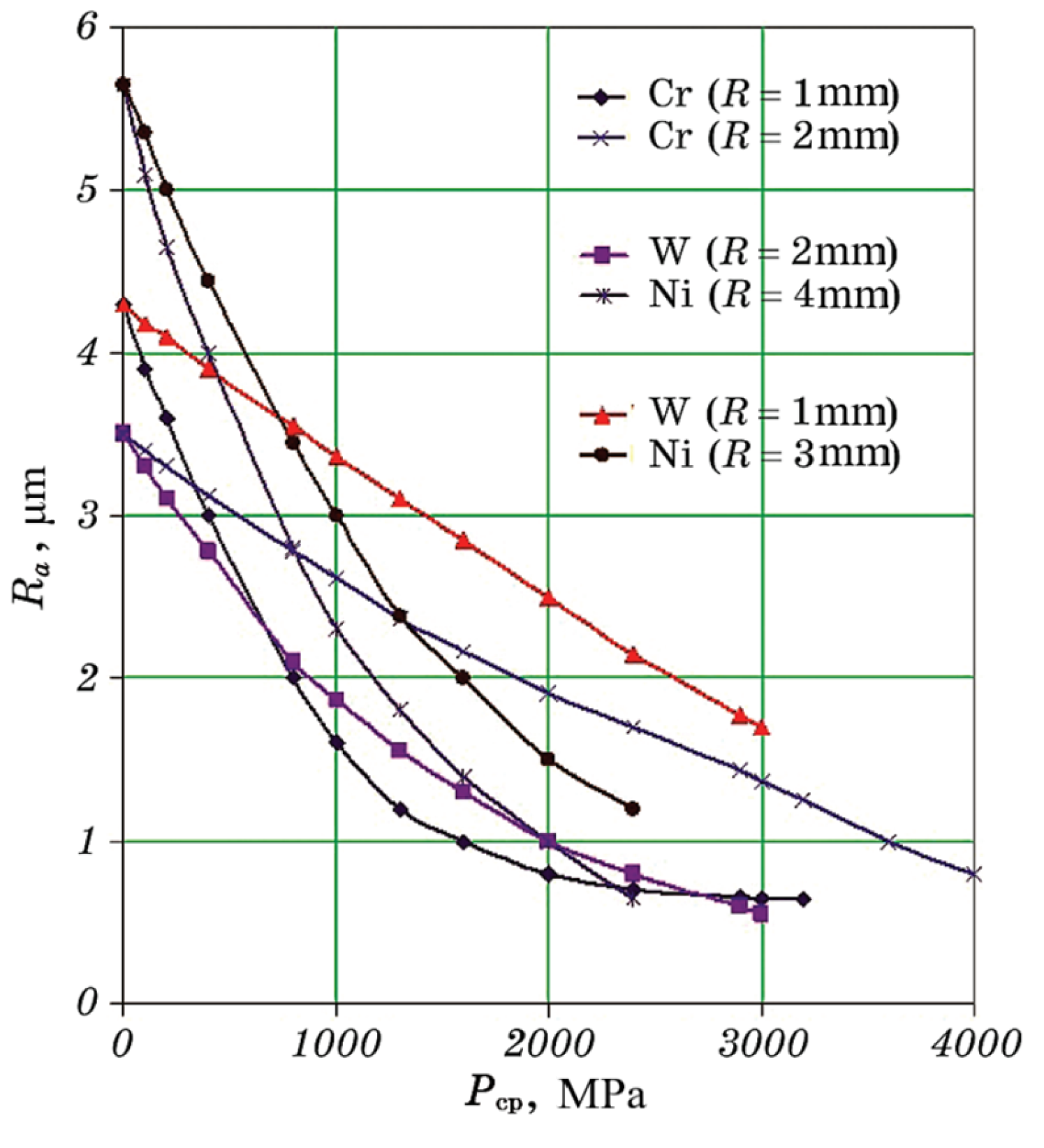

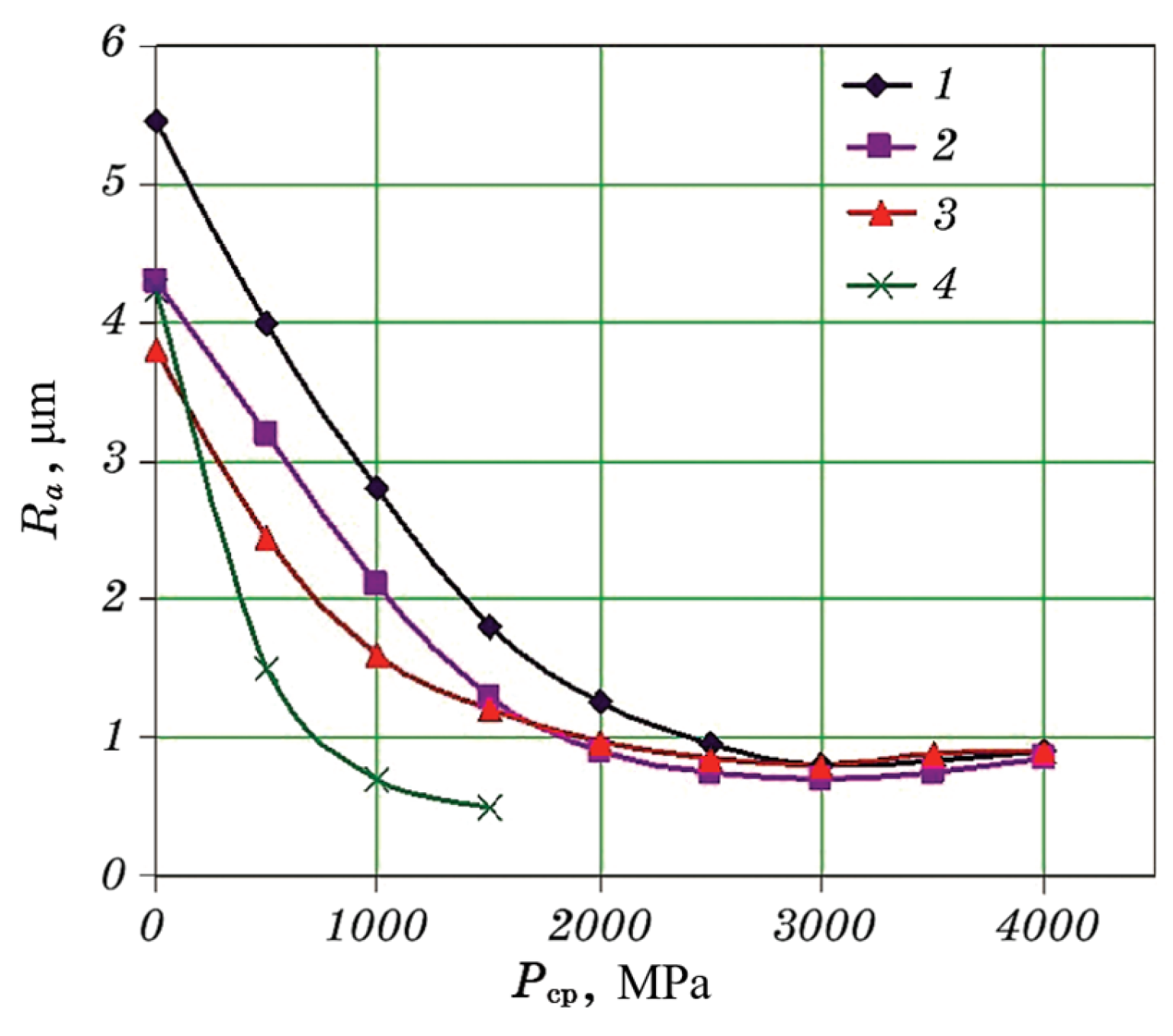

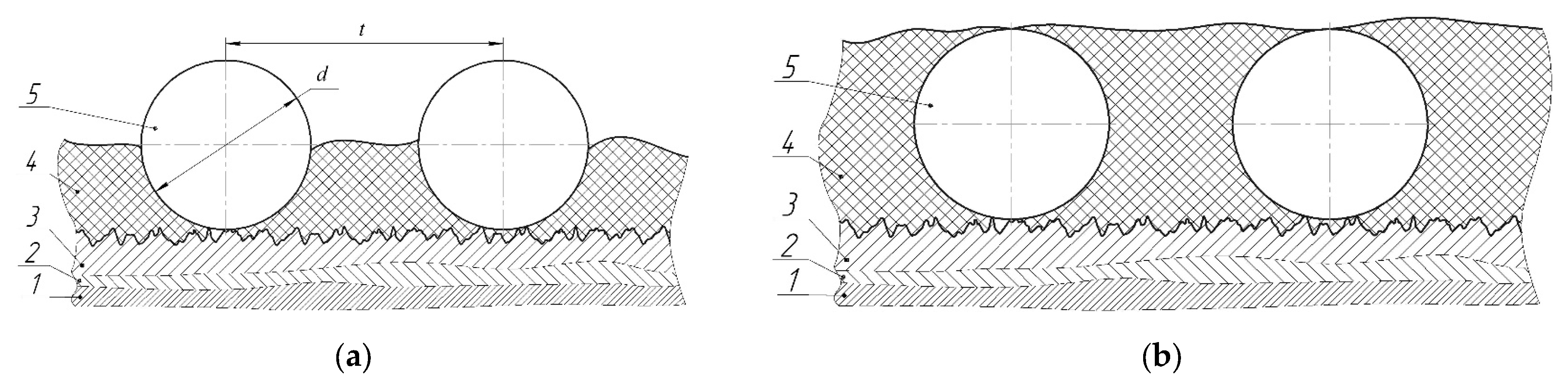

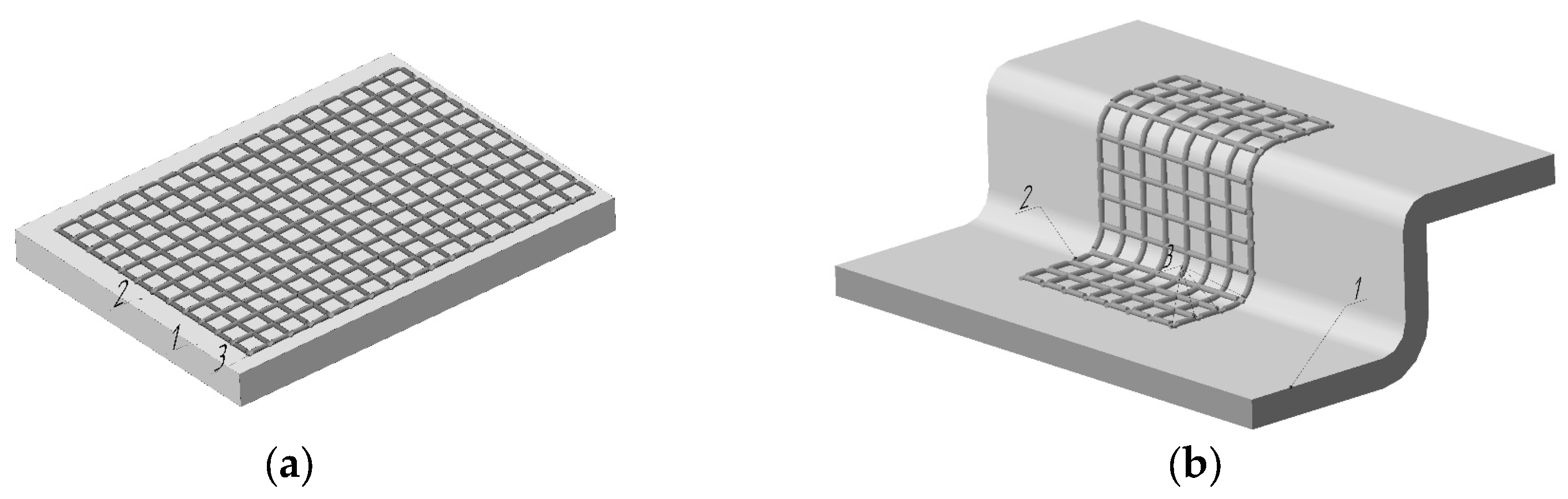

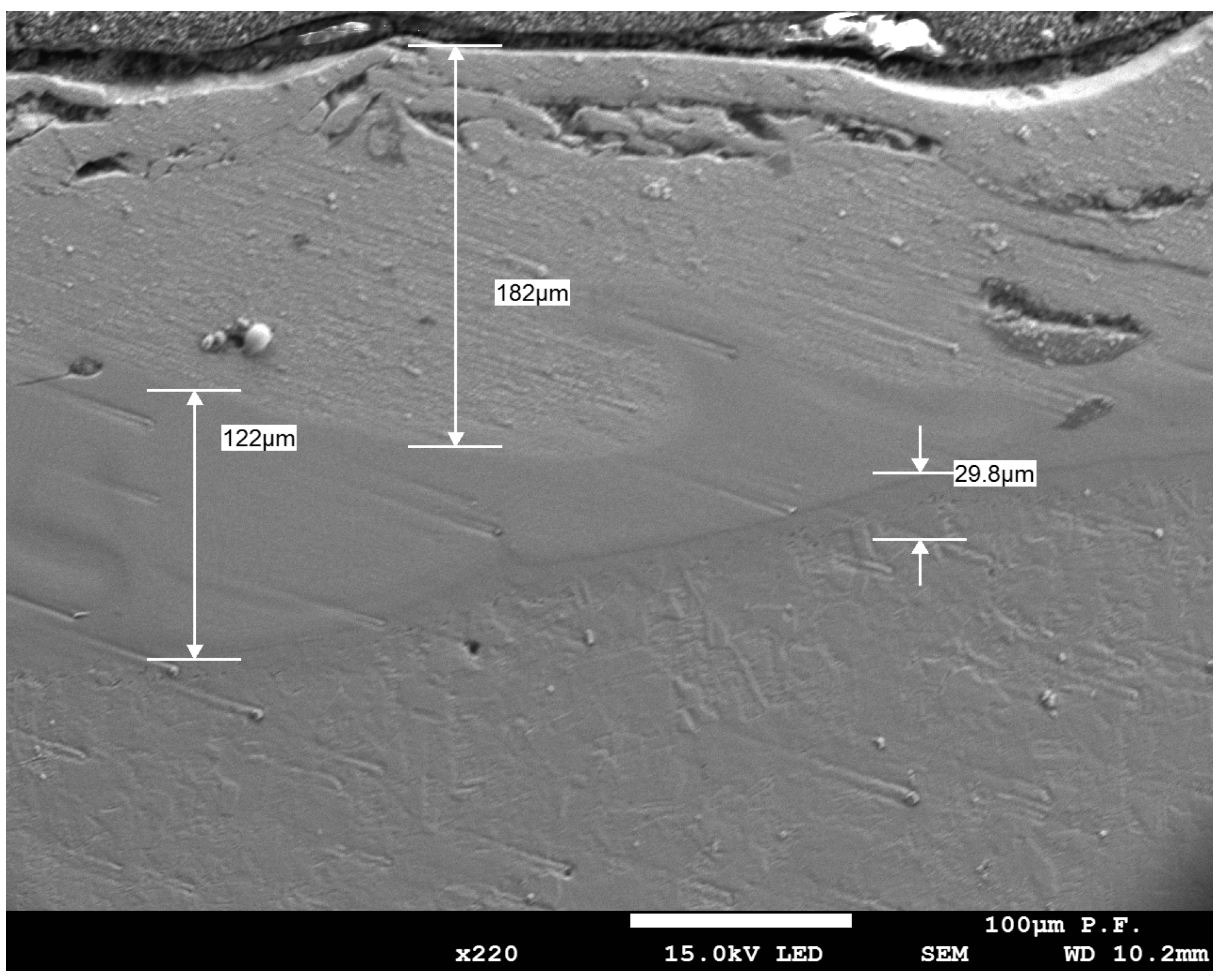

3.1. Improvement in Combined ESA and SPD Processing Methods

3.2. Improvement in Combined ESA and LT Methods

3.3. Improvement in the Technology of Restoring Worn Surfaces of Parts Using the ESA Method with Subsequent Application of Metal–Polymer Materials

- −

- reduction in the hardness and strength of the formed surface layer, consisting only of MPM, which is located above the coating applied by the ESA method;

- −

- MPM performs well in compression and much worse in shear, which negatively affects their use in friction surface restoration [77].

3.4. Combined ESA Processing and Vapor Phase Deposition (VPD)

4. Industrial Application of Hybrid Technologies

5. Summary and Outlook

- −

- Quantitative optimization of hybrid treatment parameters through experimental–computational synergy;

- −

- Development of physical–mathematical models to predict coating behavior based on process inputs;

- −

- Application of machine learning for intelligent selection of processing modes to balance performance and coating quality;

- −

- In-depth studies on residual stresses, adhesion strength, and long-term performance in operational conditions.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hahn, D.W.; Omenetto, N. Laser-induced breakdown spectroscopy (LIBS), Part II: Review of instrumental and methodological approaches to material analysis and applications to different fields. Appl. Spectrosc. 2012, 66, 347–419. [Google Scholar] [CrossRef]

- Tracton, A.A. Coatings Technology Handbook; Taylor & Francis Publishing: Boca Raton, FL, USA, 2006; 828p. [Google Scholar]

- Gaponova, O.; Kundera, C.; Kirik, G.; Tarelnyk, V.; Martsynkovskyy, V.; Konoplianchenko, I.; Dovzhyk, M.; Belous, A.; Vasilenko, O. Estimating Qualitative Parameters of Aluminized Coating Obtained by Electric Spark Alloying Method. In Advances in Thin Films, Nanostructured Materials, and Coatings. Lecture Notes in Mechanical Engineering; Springer: Singapore, 2019; pp. 249–266. [Google Scholar] [CrossRef]

- Martsinkovsky, V.; Yurko, V.; Tarelnik, V.; Filonenko, Y. Designing Thrust Sliding Bearings of High Bearing Capacity. Procedia Eng. 2012, 39, 148–156. [Google Scholar] [CrossRef]

- Martsinkovsky, V.; Yurko, V.; Tarelnik, V.; Filonenko, Y. Designing Radial Sliding Bearing Equipped with Hydrostatically Suspended Pads. Procedia Eng. 2012, 39, 157–167. [Google Scholar] [CrossRef]

- Shimizu, M.; Sakakura, M.; Ohnishi, M.; Shimotsuma, Y.; Nakaya, T.; Miura, K.; Hirao, K. Mechanism of heat-modification inside a glass after irradiation with high-repetition rate femtosecond laser pulses. J. Appl. Phys. 2010, 108, 073533. [Google Scholar] [CrossRef]

- Pogrebnjak, A.D.; Bagdasaryan, A.A.; Horodek, P.; Tarelnyk, V.; Buranich, V.V.; Amekura, H.; Okubo, N.; Ishikawa, N.; Beresnev, V.M. Positron annihilation studies of defect structure of (TiZrHfNbV)N nitride coatings under Xe14+ 200 MeV ion irradiation. Mater. Lett. 2021, 303, 130548. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, S.; Shao, W.; Wang, Z.; Qu, J.; Zhou, W.; Zhang, S. Research on the Influence of Magnetic Field Assistance on the Quality of an Electro-Spark Deposition Layer. Coatings 2025, 15, 88. [Google Scholar] [CrossRef]

- Antoszewski, B.; Tofil, S.; Scendo, M.; Tarelnik, W. Utilization of the UV laser with picosecond pulses for the formation of surface microstructures on elastomeric plastics. IOP Conf. Ser. Mater. Sci. Eng. 2017, 233, 012036. [Google Scholar] [CrossRef]

- Tarelnyk, V.B.; Gaponova, O.P.; Loboda, V.B.; Konoplyanchenko, E.V.; Martsinkovskii, V.S.; Semirnenko, Y.I.; Tarelnyk, N.V.; Mikulina, M.A.; Sarzhanov, B.A. Improving Ecological Safety when Forming Wear-Resistant Coatings on the Surfaces of Rotation Body Parts of 12Kh18N10T Steel Using a Combined Technology Based on Electrospark Alloying. Surf. Eng. Appl. Electrochem. 2021, 57, 173–184. [Google Scholar] [CrossRef]

- Antoszewski, B.; Gaponova, O.P.; Tarelnyk, V.B.; Myslyvchenko, O.M.; Kurp, P.; Zhylenko, T.I.; Konoplianchenko, I. Assessment of Technological Capabilities for Forming Al-C-B System Coatings on Steel Surfaces by Electrospark Alloying Method. Materials 2021, 14, 739. [Google Scholar] [CrossRef]

- Gaponova, O.; Tarelnyk, V.; Tarelnyk, N.; Myslyvchenko, M. Nanostructuring of Metallic Surfaces by Electrospark Alloying Method. J. Miner. 2023, 75, 3400–3412. [Google Scholar] [CrossRef]

- Penyashki, T.; Kostadinov, G.D.; Kandeva, M.K. Improvement of the Surface Properties of Carbon Steel Through Electrospark Coatings from Multicomponent Hard Alloys. Materials 2025, 18(10), 2211. [Google Scholar] [CrossRef] [PubMed]

- Rukanskis, M. Control of Metal Surface Mechanical and Tribological Characteristics Using Cost Effective Electro-Spark Deposition. Surf. Engin. Appl. Electrochem. 2019, 55, 607–619. [Google Scholar] [CrossRef]

- Barile, C.; Casavola, C.; Pappalettera, G.; Renna, G. Advancements in Electrospark Deposition (ESD) Technique: A Short Review. Coatings 2022, 12, 1536. [Google Scholar] [CrossRef]

- Rukanskis, M.; Padgurskas, J.; Mihailov, V.; Rukuiža, R.; Žunda, A.; Baltakys, K.; Tučkutė, S. Investigation of the Lubricated Tribo-System of Modified Electrospark Coatings. Coatings 2023, 13, 825. [Google Scholar] [CrossRef]

- Mihailov, V.; Kazak, N.; Ivashcu, S.; Ovchinnikov, E.; Baciu, C.; Ianachevici, A.; Rukuiza, R.; Zunda, A. Synthesis of Multicomponent Coatings by Electrospark Alloying with Powder Materials. Coatings 2023, 13, 651. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, M.; Dai, S.; Zhu, L. Research Progress in Electrospark Deposition Coatings on Titanium Alloy Surfaces: A Short Review. Coatings 2023, 13, 1473. [Google Scholar] [CrossRef]

- Gaponova, O.P.; Tarelnyk, V.B.; Antoszewski, B.; Radek, N.; Tarelnyk, N.V.; Kurp, P.; Myslyvchenko, O.M.; Hoffman, J. Technological Features for Controlling Steel Part Quality Parameters by the Method of Electrospark Alloying Using Carburezer Containing Nitrogen—Carbon Components. Materials 2022, 15, 6085. [Google Scholar] [CrossRef]

- Gaponova, O.P.; Antoszewski, B.; Tarelnyk, V.B.; Kurp, P.; Myslyvchenko, O.M.; Tarelnyk, N.V. Analysis of the Quality of Sulfomolybdenum Coatings Obtained by Electrospark Alloying Methods. Materials 2021, 14, 6332. [Google Scholar] [CrossRef]

- Al-Quraan, T.M.A.; Tokaruk, V.V.; Mikosianchyk, O.A.; Mnatsakanov, R.G.; Kichata, N.M.; Kuzin, N.O. Influence of Continuity of Electric Spark Coatings on Wear Resistance of Aluminum Alloy. Tribol. Ind. 2021, 43, 603–614. [Google Scholar] [CrossRef]

- Lu, K.; Zhu, J.; Ge, W.; Hui, X. Progress on New Preparation Methods, Microstructures, and Protective Properties of High-Entropy Alloy Coatings. Coatings 2022, 12, 1472. [Google Scholar] [CrossRef]

- Tarel’nik, V.B.; Konoplyanchenko, E.V.; Kosenko, P.V.; Martsinkovskii, V.S. Problems and Solutions in Renovation of the Rotors of Screw Compressors by Combined Technologies. Chem Pet. Eng. 2017, 53, 540–546. [Google Scholar] [CrossRef]

- Sidorenko, S.I.; Ivashchenko, E.V.; Lobachova, G.G.; Mazanko, V.F. The Influence of Ti and Zr on the Diffusion of Isotope Ni in the Iron Surface Layer at Electric-Spark Alloying in Carbon Containing Environment. Defect Diffus. Forum 2008, 277, 87–90. [Google Scholar] [CrossRef]

- Tarelnyk, V.B.; Paustovskii, A.V.; Tkachenko, Y.G.; Konoplianchenko, E.V.; Martsynkovskyi, V.S.; Antoszewski, B. Electrode Materials for Composite and Multilayer Electrospark-Deposited Coatings from Ni–Cr and WC–Co Alloys and Metals. Powder Met. Met. Ceram 2017, 55, 585–595. [Google Scholar] [CrossRef]

- Umanskyi, O.; Storozhenko, M.; Baglyuk, G.; Melnyk, O.; Brazhevsky, V.; Chernyshov, O.; Terentiev, O.; Gubin, Y.; Kostenko, O.; Martsenyuk, I. Structure and Wear Resistance of Plasma-Sprayed NiCrBSiC–TiCrC Composite Powder Coatings Powder Metall. Met. Ceram. 2020, 59, 434–444. [Google Scholar] [CrossRef]

- Tarel’nik, V.B.; Martsinkovskii, V.S.; Zhukov, A.N. Increase in the Reliability and Durability of Metal Impulse End Seals. Part 1. Chem. Petrol. Eng. 2017, 53, 114–120. [Google Scholar] [CrossRef]

- Tarelnyk, V.B.; Gaponova, O.P.; Konoplianchenko, Y.V.; Martsynkovskyy, V.S.; Tarelnyk, N.V.; Vasylenko, O.O. Improvement of quality of the surface electroerosive alloyed layers by the combined coatings and the surface plastic deformation. I. Features of formation of the combined electroerosive coatings on special steels and alloys. Metallofiz. I Noveishie Tekhnol. 2019, 41, 47–69. [Google Scholar] [CrossRef]

- Tarelnyk, V.B.; Gaponova, O.P.; Konoplyanchenko Ye, V.; Yevtushenko, N.S.; Herasymenko, V.O. The Analysis of a Structural State of Surface Layer after Electroerosive Alloying. II. Features of Formation of Electroerosive Coatings on Special Steels and Alloys by Hard Wear-Resistant and Soft Antifriction Materials. Metallofiz. Noveishie Tekhnol. 2018, 40, 795–815. [Google Scholar] [CrossRef]

- Reynold, J.L.; Holdren, R.L.; Brown, L.E. Electro-Spark Deposition. Adv. Mater. Process 2003, 161, 35–37. [Google Scholar]

- Gould, J. Application of electro-spark deposition as a joining technology. Weld J. 2011, 90, 191–197. [Google Scholar]

- Gaponova, O.; Tarel’nyk, N.V. Improvement of the quality parameters of the surface layers of steel parts after alitization by the electrospark alloying method Part 3. Mathematical model of forecasting quality parameters of coatings taking into account the performance of surface treatment. Metallofiz. I Noveishie Tekhnol. 2024, 46, 771–795. [Google Scholar] [CrossRef]

- Johnson, R.N.; Sheldon, G.L. Advances in the electrospark deposition coating process. J. Vac. Sci. Technol. A 1986, 4, 2740–2746. [Google Scholar] [CrossRef]

- Cadney, S.; Brochu, M. Formation of amorphous Zr41.2Ti13.8Ni10Cu12.5Be22.5 coatings via the ElectroSpark Deposition process. Intermetallics 2008, 16, 518–523. [Google Scholar] [CrossRef]

- Gaponova, O.P.; Tarelnyk, N.V. Properties of Surfaces Parts from X10CrNiTi18-10 Steel Operating in Conditions of Radiation Exposure Retailored by Electrospark Alloying. Pt. 2. Features of the Structural State of the Retailored Surfaces. Metallofiz. Noveishie Tekhnol. 2022, 44, 1103–1115. [Google Scholar] [CrossRef]

- Oppong, B.G.; Geambazu, L.E.; Ormsdottir, A.M.; Gunnarsson, B.G.; Csaki, I.; Fanicchia, F.; Kovalov, D.; Karlsdottir, S.N. Microstructural Properties and Wear Resistance of Fe-Cr-Co-Ni-Mo-Based High Entropy Alloy Coatings Deposited with Different Coating Techniques. Appl. Sci. 2022, 12, 3156. [Google Scholar] [CrossRef]

- Kalinina, N.E.; Hlushkova, D.B.; Hrinchenko, O.D.; Kalinin, V.T.; Voronkov, A.I.; Kostina, L.L.; Nikitchenko, I.N.; Nosova, T.V.; Reznikov, A.A. Hardening of leading edges of turbine blades by electrospark alloying. Probl. At. Sci. Technol. 2019, 2, 151–154. [Google Scholar] [CrossRef]

- Cao, G.; Zhang, X.; Tang, G.; Ma, X. Microstructure and Corrosion Behavior of Cr Coating on M50 Steel Fabricated by Electrospark Deposition. J. Mater. Eng. Perform. 2019, 28, 4086–4094. [Google Scholar] [CrossRef]

- Kuptsov, K.A.; Sheveyko, A.N.; Zamulaeva, E.I.; Sidorenko, D.A.; Shtansky, D.V. Two-layer nanocomposite WC/a-C coatings produced by a combination of pulsed arc evaporation and electro-spark deposition in vacuum. Mater. Des. 2019, 167, 107645. [Google Scholar] [CrossRef]

- Topală, P.; Slătineanu, L.; Dodun, O.; Coteaţă, M.; Pınzaru, N. Electrospark Deposition by Using Powder Materials. Mater. Manuf. Process. 2010, 25, 932–938. [Google Scholar] [CrossRef]

- Paustovskii, A.V.; Tkachenko, Y.G.; Alfintseva, R.A.; Kirilenko, S.N.; Yurchenko, D.Z. Optimization of the composition, structure, and properties of electrode materials and electrospark coatings for strengthening and reconditioningof metal surfaces. Surf. Engin. Appl. Electrochem. 2013, 49, 4–12. [Google Scholar] [CrossRef]

- Haponova, O.; Tarelnyk, V.; Mościcki, T.; Tarelnyk, N.; Półrolniczak, J.; Myslyvchenko, O.; Adamczyk-Cieślak, B.; Sulej-Chojnacka, J. Investigation of the Structure and Properties of MoS2 Coatings Obtained by Electrospark Alloying. Coatings 2024, 14, 563. [Google Scholar] [CrossRef]

- Tarelnyk, V.B.; Gaponova, O.P.; Tarelnyk, N.V.; Myslyvchenko, O.M. Aluminizing of Metal Surfaces by Electric-Spark Alloying. Prog. Phys. Met. 2023, 24, 282–318. [Google Scholar] [CrossRef]

- Tarelnik, V.B.; Paustovskii, A.V.; Tkachenko, Y.G.; Martsinkovskii, V.S.; Belous, A.V.; Konoplyanchenko, E.V.; Gaponova, O.P. Electrospark Graphite Alloying of Steel Surfaces: Technology, Properties, and Application. Surf. Eng. Appl. Electrochem. 2018, 54, 147–156. [Google Scholar] [CrossRef]

- Tarelnyk, V.; Gaponova, O.; Martsynkovskyy, V.; Kutakh, A.; Golovchenko, G. New Process for Nitriding Steel Parts. In Proceedings of the 2021 IEEE 11th International Conference “Nanomaterials: Applications and Properties”, Odessa, Ukraine, 5–11 September 2021. [Google Scholar] [CrossRef]

- Tarelnyk, V.; Martsynkovskyy, V.; Gaponova, O.; Konoplianchenko, I.; Dovzyk, M.; Tarelnyk, N.; Gorovoy, S. New sulphiding method for steel and cast iron parts. IOP Conf. Ser. Mater. Sci. Eng. 2017, 233, 012049. [Google Scholar] [CrossRef]

- Gritsenko, V.G.; Lazarenko, A.D.; Lyubchenko, K.Y.; Martsinkovskii, V.S.; Tarel’nik, V.B. Increasing the Life of the Slider Bearings of the Turbines of High-Speed Compressors. Chem. Petrol. Eng. 2020, 55, 821–828. [Google Scholar] [CrossRef]

- Umanskyi, O.P.; Storozhenko, M.S.; Tarelnyk, V.B.; Koval, O.Y.; Gubin, Y.V.; Tarelnyk, N.V.; Kurinna, T.V. Electrospark Deposition of Fenicrbsic–Meb2 Coatings on Steel. Powder Metall. Met. Ceram. 2020, 59, 57–67. [Google Scholar] [CrossRef]

- Gaponova, O.P.; Tarelnyk, V.B.; Martsynkovskyy, V.S.; Kirik, G.V.; Batalova, A.B. Combined electrospark running-in coatings of bronze parts. Part 1. structure and mechanical properties. Metallofiz. I Noveishie Tekhnol. 2021, 43, 1121–1138. [Google Scholar] [CrossRef]

- Gaponova, O.P.; Tarelnyk, V.B.; Martsynkovskyy, V.S.; Konoplianchenko, I.; Melnyk, V.; Vlasovets, V.; Tarelnyk, N.V.; Gerasimenko, V.O.; Bondarev, S.G.; Batalova, A.B.; et al. Combined electrospark running-in coatings of bronze parts. Part 2. distribution of elements in a surface layer. Metallofiz. I Noveishie Tekhnol. 2021, 43, 1155–1166. [Google Scholar] [CrossRef]

- Gaponova, O.P.; Tarelnyk, V.B.; Martsynkovskyy, V.S.; Konoplianchenko, I.; Melnyk, V.; Vlasovets, V.; Kirik, G.V.; Tarelnyk, N.V.; Mikulina, M.O.; Kutakh, A.A.; et al. Combined Electrospark Running-in Coatings of Bronze Parts. Part 3. Tribological Properties. Metallofiz. I Noveishie Tekhnol. 2021, 43, 1325–1334. [Google Scholar] [CrossRef]

- Zhang, Z.; Konoplianchenko, I.; Tarelnyk, V.; Liu, G.; Du, X.; Yu, H. The Characterization of Running-In Coatings on the Surface of Tin Bronze by Electro-Spark Deposition. Coatings 2022, 12, 930. [Google Scholar] [CrossRef]

- Penyashki, T.; Kostadinov, G.; Kandeva, M.; Nikolov, A.; Dimitrova, R.; Kamburov, V.; Danailov, P.; Bozhkov, S. Study of the Influence of Coating Roughness on the Properties and Wear Resistance of Electrospark Deposited Ti6Al4V Titanium Alloy. Tribol. Ind. 2023, 46, 13–28. [Google Scholar] [CrossRef]

- Radek, N.; Pietraszek, J.; Gądek-Moszczak, A.; Orman, Ł.J.; Szczotok, A. The Morphology and Mechanical Properties of ESD Coatings before and after Laser Beam Machining. Materials 2020, 13, 2331. [Google Scholar] [CrossRef] [PubMed]

- Radek, N.; Kalinowski, A.; Pietraszek, J.; Orman, Ł.; Szczepaniak, M.; Januszko, A.; Kamiński, J.; Broncek, J.; Paraska, O. Formation of coatings with technologies using concentrated energy stream. Prod. Eng. Arch. 2022, 28, 117–122. [Google Scholar] [CrossRef]

- Baghjari, S.H.; Malek Ghaini, F.; Shahverdi, H.R.; Ebrahimnia, M.; Mapelli, C.; Barella, S. Characteristics of electrospark deposition of a nickel-based alloy on 410 stainless steel for purpose of facilitating dissimilar metal welding by laser. Int. J. Adv. Manuf. Technol. 2016, 87, 2821–2828. [Google Scholar] [CrossRef]

- Zhao, P.; Zhu, J.; Yang, K.; Li, M.; Shao, G.; Lu, H.; Ma, Z.; Wang, H.; He, J. Outstanding wear resistance of plasma sprayed high-entropy monoboride composite coating by inducing phase structural cooperative mechanism. Appl. Surf. Sci. 2023, 616, 156516. [Google Scholar] [CrossRef]

- Li, Z.-X.; Liu, Y.-H.; Liu, H.-J.; Wu, L.-K.; Cao, F.-H. Effect of magnetron sputtered Al coating and anodization on the hot corrosion performance of Ti48Al2Nb2Cr alloy. Mater. Commun. 2023, 36, 106524. [Google Scholar] [CrossRef]

- Tarelnyk, V.B. Kombinirowannyje Technologii Elektroerozionnogo Liegirowania; Tekhnika: Kyiv, Ukraine, 1997; 127p. [Google Scholar]

- Tarelnyk, V.B.; Gaponova, O.P.; Konoplianchenko, Y.V. Electric-Spark Alloying of Metal Surfaces with Graphite. Prog. Phys. Met. 2022, 23, 27–58. [Google Scholar] [CrossRef]

- Tarel’nik, V.B.; Martsinkovskii, V.S.; Zhukov, A.N. Increase in the Reliability and Durability of Metal Impulse End Seals. Part 2. Chem. Petrol. Eng. 2017, 53, 266–272. [Google Scholar] [CrossRef]

- Tarelnyk, V.B.; Gaponova, O.P.; Konoplianchenko, Y.V.; Martsynkovskyy, V.S.; Tarelnyk, N.V.; Vasylenko, O.O. Improvement of Quality of the Surface Electroerosive Alloyed Layers by the Combined Coatings and the Surface Plastic Deformation. II. The Analysis of a Stressedly-Deformed State of Surface Layer after a Surface Plastic Deformation of Electroerosive Coatings. Metallofiz. Noveishie Tekhnol. 2019, 41, 173–192. [Google Scholar]

- Tarelnyk, V.B.; Gaponova, O.P.; Konoplianchenko, Y.V.; Martsynkovskyy, V.S.; Tarelnyk, N.V.; Vasylenko, O.O. Improvement of Quality of the Surface Electroerosive Alloyed Layers by the Combined Coatings and the Surface Plastic Deformation. III. The Influence of the Main Technological Parameters on Microgeometry, Structure and Properties of Electrolytic Erosion Coatings. Metallofiz. Noveishie Tekhnol. 2019, 41, 313–335. [Google Scholar] [CrossRef]

- Tarelnik, V.B.; Antoshevsky, B.; Martsinkovsky, V.S.; Konoplyanchenko, E.V.; Belous, A.V. Tsementatsiya Ehlektroehrozionnym Legirovaniem: Monografiya [Cementation by Electroerosive Alloying: A Monograph]; Tarelnik, V.B., Ed.; University Book: Sumy, Ukraine, 2015; ISBN 978-966-680-740-6. [Google Scholar]

- Radek, N.; Bartkowiak, K. Performance properties of electro-spark deposited carbide-ceramic coatings modified by laser beam. Phys. Procedia 2010, 5, 417–423. [Google Scholar] [CrossRef]

- Antoszewski, B.; Tarelnyk, V. Laser texturing of sliding surfaces of bearings and pump seals. Appl. Mechan. Mater. 2014, 630, 301–307. [Google Scholar] [CrossRef]

- Radek, N.; Bronček, J.; Fabian, P.; Pietraszek, J.; Antoszewski, K. Properties of the Electro-Spark Deposited Coatings-Technology and Applications. Mater. Sci. Forum. 2015, 818, 61–64. [Google Scholar] [CrossRef]

- Radek, N.; Antoszewski, B. The influence of laser treatment on the properties of electro-spark deposited coatings. Kov. Mater. 2009, 47, 31–38. [Google Scholar]

- Verbitchi, V.; Ciuca, C.; Cojocaru, R. Electro-spark coating with special materials. Nonconvent. Technol. Rev. 2011, 1, 57–62. [Google Scholar]

- Myslyvchenko, O.; Lytvyn, R.; Grinkevich, K.; Zgalat-Lozynskyy, O.; Bondar, A.; Shyrokov, O.; Ivanchenko, S.; Bloschanevich, O.; Stegniy, A. Laser Treatment of Electrospark-Deposited Ti0.8W0.25Cr0.5FeCo1.75Ni3AlB0.6 High-Entropy Coatings. JOM 2024, 76, 3960–3968. [Google Scholar] [CrossRef]

- Paustovskii, A.V.; Botvinko, V.P. Phase composition of the surface layers of high-speed cutting steel after electrospark alloying and laser treatment. Mater. Sci. 2000, 36, 100–103. [Google Scholar] [CrossRef]

- Lytvyn, R.V.; Grinkevich, K.E.; Myslyvchenko, O.M.; Trachenko, I.V.; Bloschanevych, O.M.; Ivanchenko, S.E.; Derev’yanko, O.V.; Stegniy, A.I.; Belik, V.D.; Zgalat-Lozynskyy, O.B. Wear-Resistant Coatings Produced from TiN–TiB2 and TiN–Si3N4 Composites by Electrospark Deposition and Laser Processing. Powder. Metall. Met. Ceram. 2024, 62, 611–620. [Google Scholar] [CrossRef]

- Feldshtein, E.E.; Kardapolova, M.A.; Gaida, R.; Khorodyski, B.; Kaval’chuk, O.V. Tribological properties of electrospark-deposited and further laser-hardened coatings. J. Frict. Wear. 2013, 34, 137–141. [Google Scholar] [CrossRef]

- Lešnjak, A.; Tušek, J. Processes and properties of deposits in electrospark deposition. Sci. Technol. Weld. Join. 2002, 7, 391–396. [Google Scholar] [CrossRef]

- Martsinkovskyy, V.S.; Tarelnyk, V.B.; Pavlov, O.G.; Ischenko, A.O. The Method for Restoration of Worn Surfaces of Metal Parts (Variants). Patent for Invention UA 104664 Bul. 4 p. 3. Available online: https://iprop-ua.com/inv/pdf/ep4z7c9e-pub-description.pdf (accessed on 15 April 2025).

- Tarelnik, V.B.; Martsinkovsky, V.S.; Pavlov, O.G.; Sarzhanov, B.O. The Method of Restoring Worn Surfaces of Metal Parts. Patent of Ukraine No.117980 UA, MPK B23H 1/00, B23H 5/02 (2006.01), B23H 5/04 (2006.01), B23P 6/00, C23C 28/00; appl. 10.04.2017; Publ. 25.10.2018, Bull. No. 20. 2018. Available online: https://iprop-ua.com/inv/pdf/2squcp00-pub-description.pdf (accessed on 15 April 2025).

- Ishchenko, O.O. Tekhnolohichni Zasady Vidnovlennia Promyslovoho Obladnannia Suchasnymy Polimernymy Materialamy; Vydavnytstvo, PDTU: Mariupol, Ukraine, 2007; 247p. [Google Scholar]

- Tarelnyk, V.; Martsynkovskyy, V.; Sarzhanov, A.; Pavlov, A.; Gerasimenko, V.; Sarzhanov, B. Improvement of integrated technology for restoring surfaces of steel and iron parts. IOP Conf. Ser. Mater. Sci. Eng. 2017, 233, 012050. [Google Scholar] [CrossRef]

- Tarelnik, V.B.; Martsinkovsky, V.S.; Pavlov, O.G.; Sarzhanov, B.O. The Method for Restoring Worn Surfaces of Metal Parts. Patent of Ukraine No. 118892. u201703446; Appl. 10.04.2017; Publ. 28.08.2017, Bull. No. 16. Available online: https://iprop-ua.com/inv/pdf/ioppl3rm-pub-description.pdf (accessed on 15 April 2025).

- Tarelnyk, V.; Konoplianchenko, I.; Gaponova, O.; Tarelnyk, N.V.; Martsynkovskyy, V.S.; Sarzhanov, B.O.; Sarzhanov, O.A.; Antoszewski, B. Effect of Laser Processing on the Qualitative Parameters of Protective Abrasion-Resistant Coatings. Powder. Metall. Met. Ceram. 2020, 58, 703–713. [Google Scholar] [CrossRef]

- Tarelnik, V.B.; Martsynkovsky, V.S.; Gaponova, O.P.; Konoplyanchenko, E.V.; Tarelnik, N.V.; Pavlov, O.G.; Sarzhanov, B.O.; Antoshevsky, B. The Method for Restoring Worn Surfaces of Machine Parts Made of Stainless Steel. Patent of Ukraine No.121614. u201809310; appl. 12.09.2018; publ. 25.06.2020, Bull. No. 12. Available online: https://sis.nipo.gov.ua/uk/search/detail/1440749/ (accessed on 15 April 2025).

- El-Eskandarany, M.S. Mechanical Alloying, 3rd ed.; William Andrew Publishing: Norwich, NY, USA, 2020; 484p. [Google Scholar] [CrossRef]

- Berladir, K.; Hovorun, T.; Botko, F.; Radchenko, S.; Oleshko, O. Thin Modified Nitrided Layers of High-Speed Steels. Materials 2025, 18, 2434. [Google Scholar] [CrossRef] [PubMed]

- Tekin, T.; Ischia, G.; Naclerio, F.; Ipek, R.; Bandini, M.; Molinari, A.; Benedetti, M. Unveiling the impact of nitriding and PVD coating on the fatigue properties of L-PBF maraging steel. Mater. Sci. Eng. A 2025, 935, 148365. [Google Scholar] [CrossRef]

- Bermejo, J.M.B.; Lindvall, R.; Saatçi, B.; Ståhl, J.-E.; Åberg, L.M.; Bohlin, O.; Windmark, C. Wear behaviour of PVD (Ti,Si)N-(Ti,Al)N coated cemented carbide in down milling pearlitic compacted graphite iron. Wear 2025, 570, 205891. [Google Scholar] [CrossRef]

- Tabrizi, A.T.; Aghajani, H. Study through Diverse Synthesis Methods of Chromium Nitride Thin Layers: A Review. J. Surf. Investig. 2021, 15, 1217–1224. [Google Scholar] [CrossRef]

- Wang, X.; Wang, Y.; Ling, Z.; Yuan, Z.; Shi, J.; Qin, J.; Sun, H.; Pan, K.; Geng, Z.; Ma, H.; et al. Strategies for superhard tool coating materials: Focus on preparation methods and properties. J. Iron Steel Res. Int. 2025. [Google Scholar] [CrossRef]

- Staszuk, M.; Pakuła, D.; Reimann, Ł.; Musztyfaga-Staszuk, M.; Socha, R.; Tański, T. Investigation of Ti/Al2O3+TiO2 and Ti+TiO2/Al2O3+TiO2 hybrid coatings as protection of ultra-light Mg–(Li)–Al–RE alloys against corrosion. Sci. Rep. 2022, 12, 19363. [Google Scholar] [CrossRef]

- Béjar, M.A.; Schnake, W.; Saavedra, W.; Vildósola, J.P. Surface hardening of metallic alloys by electrospark deposition followed by plasma nitriding. J. Mater. Process. Technol. 2006, 176, 210–213. [Google Scholar] [CrossRef]

- Tarelnyk, V.B.; Konoplianchenko, I.; Gaponova, O.P.; Radionov, O.; Antoszewski, B.; Kundera, C.; Tarelnyk, N.V.; Voloshko, T.; Bondarev, S.G.; Gerasimenko, V.O.; et al. Application of Wear-Resistant Nanostructures Formed by Ion Nitridizing & Electrospark Alloying for Protection of Rolling Bearing Seat Surfaces. In Proceedings of the IEEE 12th International Conference Nanomaterials: Applications & Properties (NAP) 2022, Krakow, Poland, 11–16 September 2022; pp. 1–8. [Google Scholar] [CrossRef]

- Marcinkovsky, V.S.; Tarelnik, V.B. The Method of Strengthening the Surface of Steel Parts Subjected to Heat Treatment. Patent of Ukraine for Invention No. 103701: MPK 23N 5/00. Publ. 11.11.2013. Dull. No. 21. Available online: https://iprop-ua.com/inv/pdf/2y6qkr4h-pub-description.pdf (accessed on 15 April 2025).

- Abdi, F.; Aghajani, H.; Tabrizi, A.T.; Nasimi, L.; Shokouhi, F.F. Study on the effect of the crack closing of AlCoCrFeMnNi high entropy alloy electro-spark deposited coating by plasma nitriding on the corrosion resistance. J. Alloys Compd. 2023, 966, 171629. [Google Scholar] [CrossRef]

- Abdi, F.; Aghajani, H.; Asl, S.K. Evaluation of the corrosion resistance of AlCoCrFeMnNi high entropy alloy hard coating applied by electro spark deposition. Surf. Coat. Technol. 2023, 454, 129156. [Google Scholar] [CrossRef]

- Zamulaeva, E.I.; Kudryashov, A.E.; Kiryukhantsev-Korneev, P.V.; Bashkirov, E.; Mukanov, S.; Pogozhev, Y.S.; Levashov, E.A. Protective Heterophase Coatings Produced by Electrospark Deposition and High-Power Impulse Magnetron Sputtering. Surf. Engin. Appl. Electrochem. 2024, 60, 607–617. [Google Scholar] [CrossRef]

- Smirnov, I.V.; Glukhovskyy, V.Y.; Kopylov, V.I. Multicomponent coatings created by combination of magnetron deposition and electrospark alloying. Nauk. Visti NTUU-KPI 2007, 6, 86–91. Available online: http://www.irbis-nbuv.gov.ua/publ/REF-0000185012 (accessed on 15 April 2025).

- Radek, N.; Konstanty, J.; Pietraszek, J.; Orman, Ł.J.; Szczepaniak, M.; Przestacki, D. The Effect of Laser Beam Processing on the Properties of WC-Co Coatings Deposited on Steel. Materials 2021, 14, 538. [Google Scholar] [CrossRef] [PubMed]

- Tarelnyk, V.; Martsynkovskyy, V. Upgrading of pump and compressor rotor shafts using combined technology of electroerosive alloying. Appl. Mech. Mater. 2014, 630, 397–412. [Google Scholar] [CrossRef]

| Discharge Energy of ESA, J | Method of Treatment * | Total Layer Depth After Treatment, µm | Microhardness **, MPa | Roughness Ra, µm |

|---|---|---|---|---|

| 0.6 | CESA | 48 | 10,130 | 0.9–1.0 |

| CESA + AFUF | 50 | 8800 | 0.2 | |

| CESA + AFUF + grinding | 48 | 8410 | 0.6 | |

| CESA + Grinding | 18 | 7230 | 0.6 | |

| CESA + BR | 30 | 9500 | 0.11–0.21 | |

| 2.83 | CESA | 200 | 9740 | 5.8-6.7 |

| CESA + AFUF | 210 | 9700 | 0.8 | |

| CESA + AFUF + grinding | 195 | 9500 | 0.8 | |

| CESA + Grinding | 130 | 7900 | 0.8 | |

| CESA + BR | 96 | 8400 | 0.53–0.71 | |

| 6.8 | CESA | 250 | 11,000 | 10.0–14.5 |

| CESA + AFUF | 244 | 9850 | 0.8 | |

| CESA + AFUF + grinding | 220 | 8750 | 0.8 | |

| CESA + Grinding | 110 | 6700 | 0.8 | |

| CESA + BR | 115 | 9000 | 1.23–1.58 |

| LT Mode | Thickness, µm | Microhardness, MPa | Continuity, % | Surface Roughness, Ra, µm |

|---|---|---|---|---|

| Mode 1 (supply 120 mm/min, voltage 500 V, laser pulse 0.3 × 10−3 s, frequency 100 Hz) | 10/100 * | 6110/2650 * | 65/100 * | 2.1 |

| Mode 2 (supply 120 mm/min, voltage 500 V, laser pulse 0.3 × 10−3 s, frequency 50 Hz) | 40/130 | 7200/4500 | 90–95/100 | 3.3 |

| Mode 3 (supply 120 mm/min, voltage 500 V, laser pulse 1 × 10−3 s, frequency 50 Hz) | 50/190 | 8900/6500 | 90–95/100 | 6.2 |

| Mode 4 (supply 120 mm/min, voltage 550 V, laser pulse 1 × 10−3 s, frequency 50 Hz) | 100/230 | 9250/7250 | 100/100 | 8.1 |

| Mode 5 (supply 120 mm/min, voltage 600 V, laser pulse 1 × 10−3 s, frequency 50 Hz) | 420/260 | 10,000/7300 | 100/100 | 9.0 |

| Method of Treatment * | Treatment Regimes | Materials | Coating Parameters | ||

|---|---|---|---|---|---|

| Thickness, μm | Hardness, MPa | Roughness, Ra, μm | |||

| ESA [59,64] | Discharge energy Wp = 0.6 J | Substrate—carbon steel with 0.45% C, alloying electrode–graphite | 48 | 1013 | 0.9–1.0 |

| Wp = 2.83 J | 200 | 974 | 5.8–6.7 | ||

| Wp = 6.8 J | 250 | 1100 | 10.0–14.5 | ||

| ESA + AFUF [59,64] | ESA: Wp = 0.6 J; AFUF: frequency 18–22 kHz, running-in speed 50 m/min, feed rate—no more than 0.2 mm/rev, number of passes—1 | 50 | 880 | 0.2 | |

| ESA: Wp = 2.83 J; AFUF: same | 210 | 970 | 0.8 | ||

| ESA: Wp = 6.8 J; AFUF: same | 244 | 985 | 0.8 | ||

| ESA [70] | Consistently at Wp = 1.1 J, mode of 7 min/cm2 and Wp = 0.24 J, mode of 1.5 min/cm2 | Substrate—AISI 1020 carbon steel, alloying electrode–Ti0.8W0.25Cr0.5FeCo1.75Ni3AlB0.6 | 30−35 | 10,500 ± 500 | – |

| ESA + LT [70] | ESA—consistently at Wp = 1.1 J, mode of 7 min/cm2 and Wp = 0.24 J, mode of 1.5 min/cm2; LT—irradiation wavelength 1.06 μm, laser pulse duration 5 ms, focal length of the system 100 cm, pulse frequency 10 Hz, spot diameter 1.25 mm, voltage 550 V, radiation energy 3.9 J, power density 0.65 × 105 W/cm2 | 25−30 | 11,500 ± 500 | – | |

| ESA [96] | Voltage 230 V, capacitor 300 μF, current 2.1 A, deposition time 2 min/cm2 | Substrate—carbon steel with 0.45% C, alloying electrode–WC-Co alloy (95 wt % WC–5 wt % Co) | 25−35 | 1013 | 2.64−3.16 |

| ESA + LT [96] | ESA: same; LT: pulse duration time 0.5 ms, frequency 45 Hz, stroke of laser beam 0.35 mm, speed of movement 230 mm/min | 30–40 | 953 | 9.87–10.57 | |

| ESA [80] | Consistently at Wp = 0.55 J and Wp = 0.90 J | Substrate—12Kh18N10T, alloying electrode–hard alloy T15K6; MPM—VK6 hard alloy powder in two-component epoxy system filled with Loctite 3478 ferrosilicon | 50 | 5000–5400 | 37 |

| ESA + MPM + LT [80] | ESA: same; LT: supply 120 mm/min, voltage 500 V, laser pulse 0.3 · 10−3 s, frequency 50 Hz | ‘Dark’ layer | |||

| 40 | 7200 | 3.3 | |||

| ‘Light’ layer | |||||

| 130 | 4500 | – | |||

| ESA + MPM + LT [80] | ESA: same; LT: supply 120 mm/min, voltage 600 V, laser pulse duration 1 · 10−3 s, frequency 50 Hz | ‘Dark’ layer | |||

| 420 | 10,000 | 9.0 | |||

| ‘Light’ layer | |||||

| 260 | 7300 | – | |||

| ESA [94] | ESA: discharge current 120 A, pulse frequency 3200 Hz, pulse duration of 20 μs | Substrate—molybdenum; ESA medium–argon; alloying electrode–HfSi2–MoSi2–HfB2 ceramics; HIPIMS medium–argon | 6 | 23,200 ± 400 | 2.9 |

| ESA + MS (HIPIMS) [94] | ESA: same; HIPIMS: average power 1 kW, peak power 50 kW, peak current 50 A, frequency 1 kHz, pulse duration 50 μs | 6÷12 | – | 5.5 | |

| ESA [59] | ESA: consistently Cu (current 0.5–0.6 A; voltage 38.5–56.1 V; capacitance 20 µF) and hard alloy VK8 (current 2.0–2.2 A; voltage 68.7 V; capacitance 300 µF) | Substrate—carbon steel with 0.45% C, alloying electrode–Cu and hard alloy VK8; plasma nitriding medium–mixture of ammonia and nitrogen | 20 | 7600–9500 | 0.9 |

| ESA + ion–plasma nitriding [59] | ESA: same; ion–plasma nitriding; temperature 520 °C, 12 h. | 70 | 2800–5750 | 0.6 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Haponova, O.; Tarelnyk, V.; Mościcki, T.; Tarelnyk, N. Hybrid Surface Treatment Technologies Based on the Electrospark Alloying Method: A Review. Coatings 2025, 15, 721. https://doi.org/10.3390/coatings15060721

Haponova O, Tarelnyk V, Mościcki T, Tarelnyk N. Hybrid Surface Treatment Technologies Based on the Electrospark Alloying Method: A Review. Coatings. 2025; 15(6):721. https://doi.org/10.3390/coatings15060721

Chicago/Turabian StyleHaponova, Oksana, Viacheslav Tarelnyk, Tomasz Mościcki, and Nataliia Tarelnyk. 2025. "Hybrid Surface Treatment Technologies Based on the Electrospark Alloying Method: A Review" Coatings 15, no. 6: 721. https://doi.org/10.3390/coatings15060721

APA StyleHaponova, O., Tarelnyk, V., Mościcki, T., & Tarelnyk, N. (2025). Hybrid Surface Treatment Technologies Based on the Electrospark Alloying Method: A Review. Coatings, 15(6), 721. https://doi.org/10.3390/coatings15060721