Coated High-Performance Paper from Bacterial Cellulose Residue and Eucalyptus Pulp: Enhanced Mechanical Strength, Water Resistance, and Air Barrier Properties

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Bacterial Cellulose (BC) and Eucalyptus Pulp (EP)

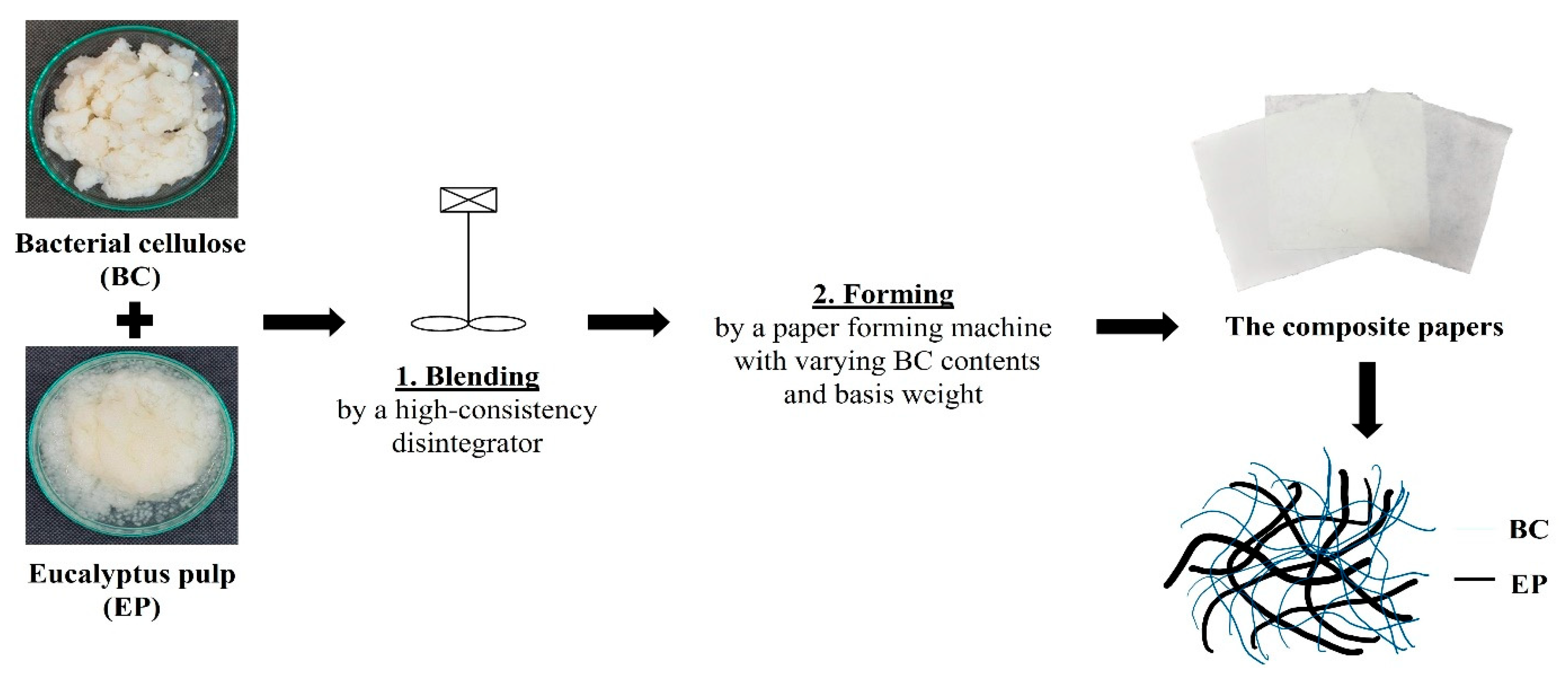

2.3. Preparation of Paper from Bacterial Cellulose (BC) and Eucalyptus Pulp (EP)

2.4. Surface Paper Coating of Cationic Modified Starch

2.5. Physical Characterization

2.5.1. Basis Weight and Thickness

2.5.2. Coating Weight

2.6. Mechanical Characterization

2.6.1. Tensile Index

2.6.2. Tear Index

2.7. Surface Morphology

2.8. Water Absorption Testing

2.9. Contact Angle Measurement

2.10. Air Permeability

2.11. Statistical Analysis

3. Results

3.1. Physico-Mechanical Properties

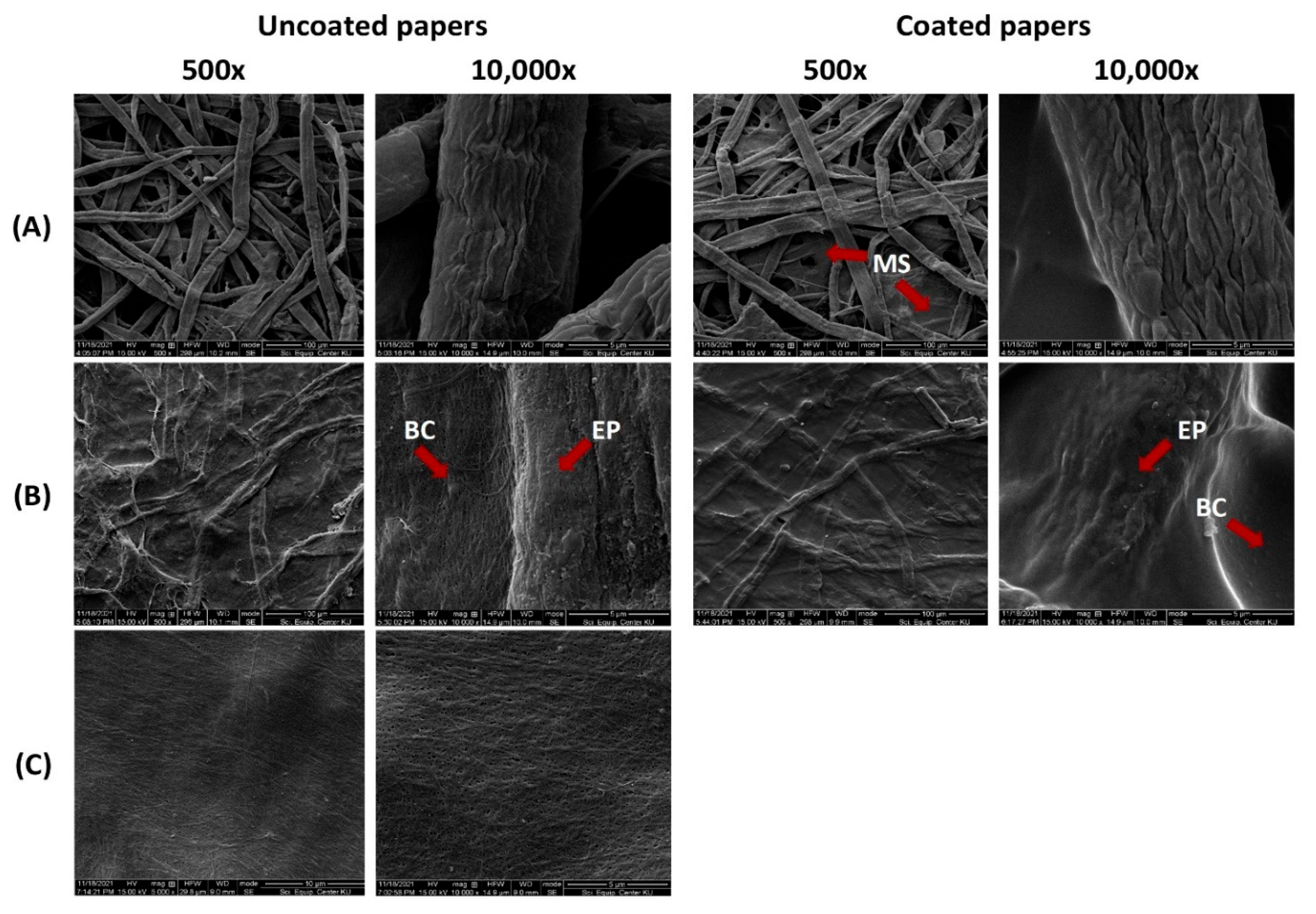

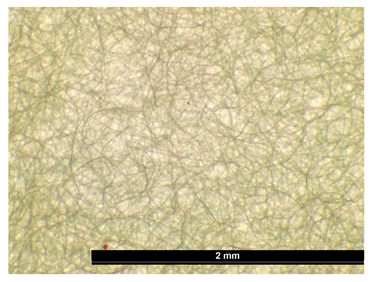

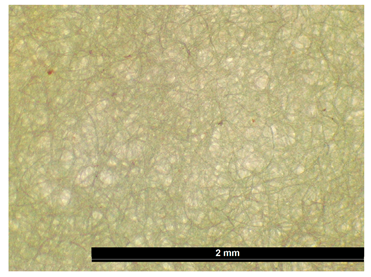

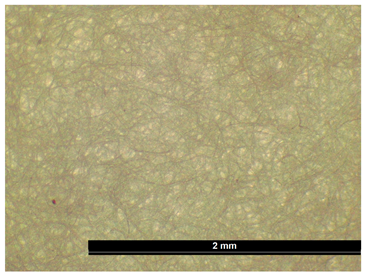

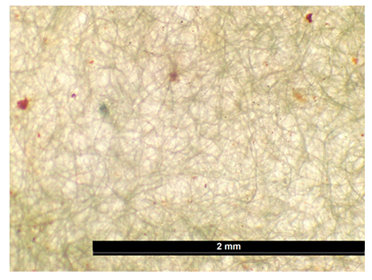

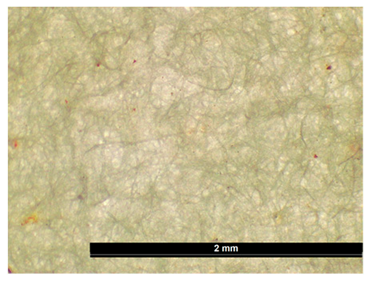

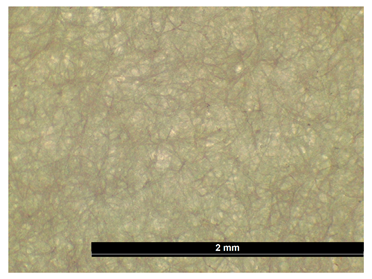

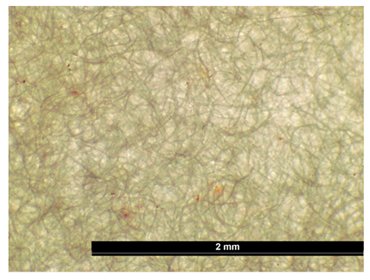

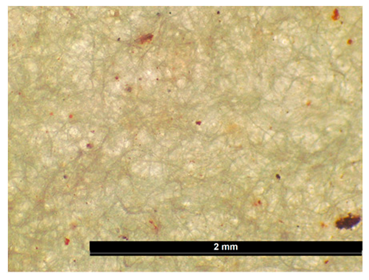

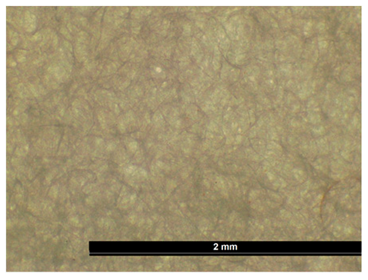

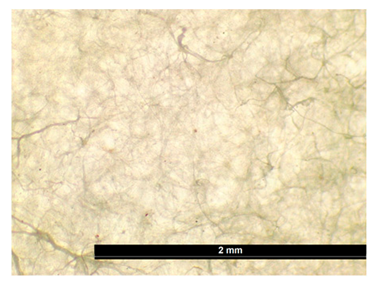

3.2. Surface Morphology

3.3. Water Absorption

3.4. Surface Wettability

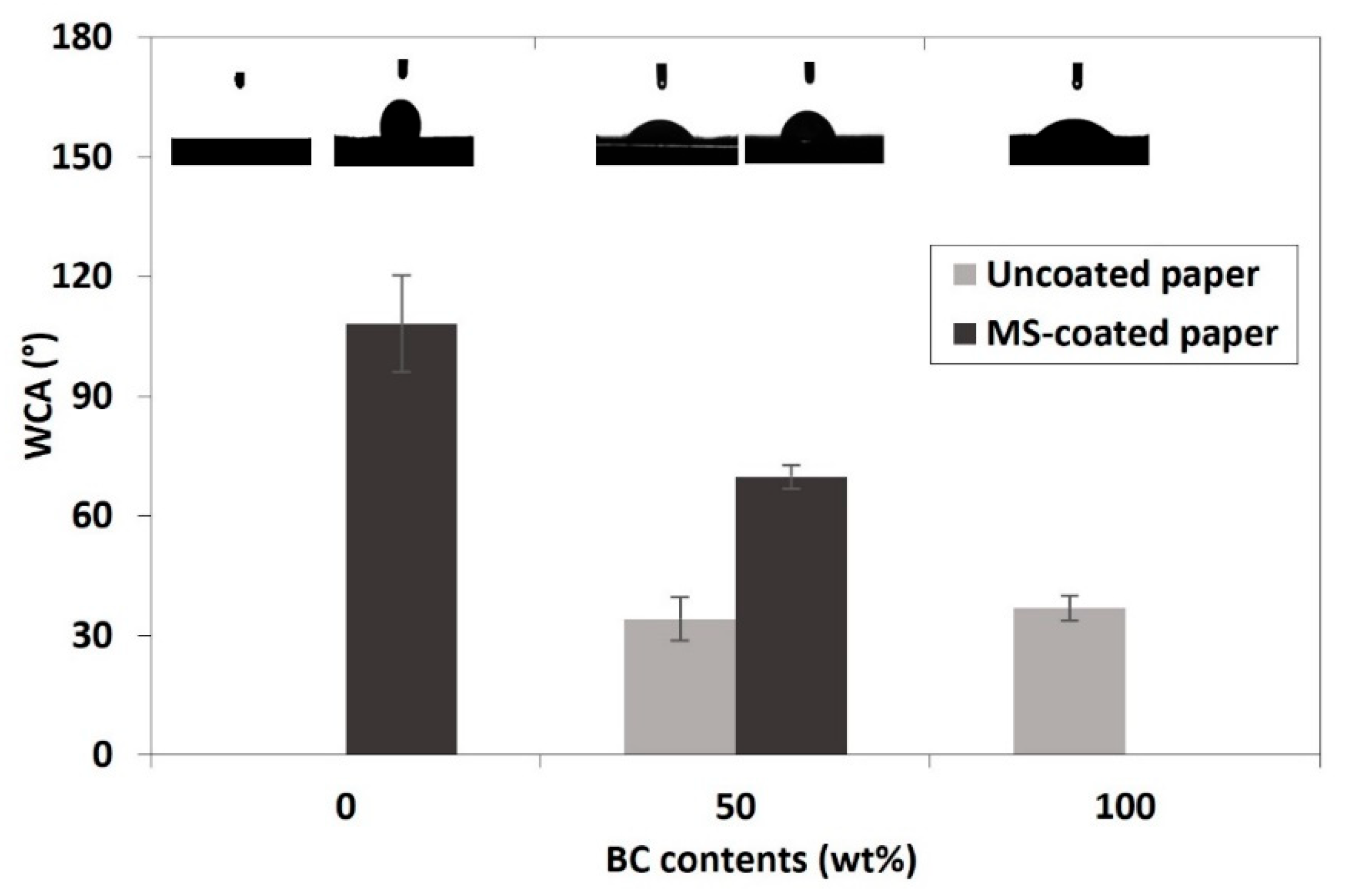

3.5. Air Permeability

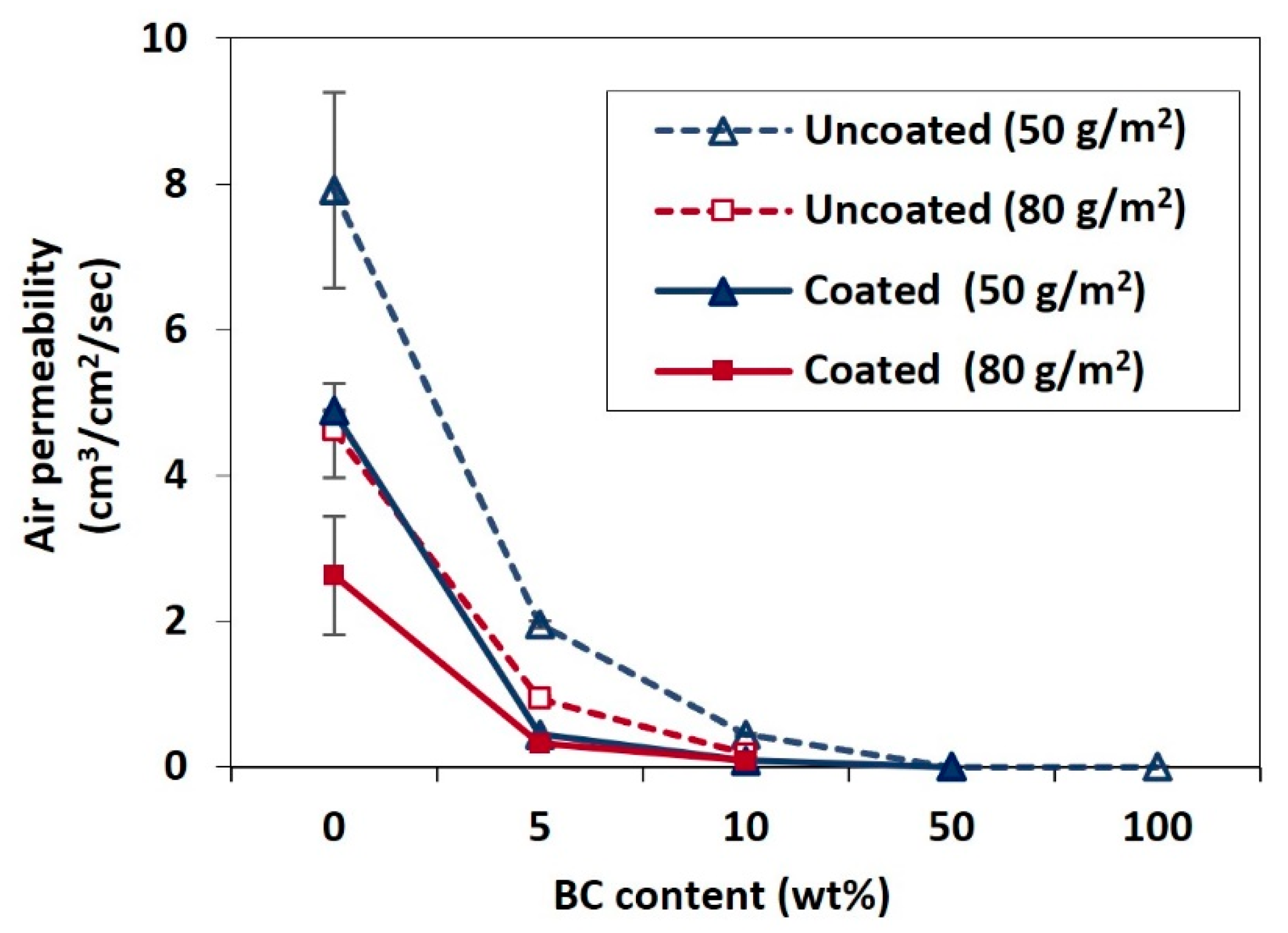

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Fillat, A.; Martínez, J.; Valls, C.; Cusola, O.; Roncero, M.B.; Vidal, T.; Valenzuela, S.V.; Diaz, P.; Pastor, F.I.J. Bacterial cellulose for increasing barrier properties of paper products. Cellulose 2018, 25, 6093–6105. [Google Scholar] [CrossRef]

- Shaghaleh, H.; Xu, X.; Wang, S. Current progress in production of biopolymeric materials based on cellulose, cellulose nanofibers, and cellulose derivatives. RSC Adv. 2018, 8, 825–842. [Google Scholar] [CrossRef] [PubMed]

- Torgbo, S.; Quan, V.M.; Sukyai, P. Cellulosic value-added products from sugarcane bagasse. Cellulose 2021, 28, 5219–5240. [Google Scholar] [CrossRef]

- Basta, A.H.; El-Saied, H. Performance of improved bacterial cellulose application in the production of functional paper. J. Appl. Microbiol. 2009, 107, 2098–2107. [Google Scholar] [CrossRef]

- Torgbo, S.; Sukyai, P. Biodegradation and thermal stability of bacterial cellulose as biomaterial: The relevance in biomedical applications. Polym. Degrad. Stab. 2020, 179, 109232. [Google Scholar] [CrossRef]

- Shah, N.; Ul-Islam, M.; Khattak, W.A.; Park, J.K. Overview of bacterial cellulose composites: A multipurpose advanced material. Carbohydr. Polym. 2013, 98, 1585–1598. [Google Scholar] [CrossRef]

- Xiang, Z.; Jin, X.; Liu, Q.; Chen, Y.; Li, J.; Lu, F. The reinforcement mechanism of bacterial cellulose on paper made from woody and non-woody fiber sources. Cellulose 2017, 24, 5147–5156. [Google Scholar] [CrossRef]

- Campano, C.; Merayo, N.; Negro, C.; Blanco, Á. Low-fibrillated bacterial cellulose nanofibers as a sustainable additive to enhance recycled paper quality. Int. J. Biol. Macromol. 2018, 114, 1077–1083. [Google Scholar] [CrossRef] [PubMed]

- Kalyoncu, E.E.; Pesman, E. Bacterial cellulose as reinforcement in paper made from recycled office waste pulp. BioResources 2020, 15, 8496. [Google Scholar] [CrossRef]

- Pradipasena, P.; Chollakup, R.; Tantratian, S. Formation and characterization of BC and BC-paper pulp films for packaging application. J. Thermoplast. Compos. Mater. 2018, 31, 500–513. [Google Scholar] [CrossRef]

- Tabarsa, T.; Sheykhnazari, S.; Ashori, A.; Mashkour, M.; Khazaeian, A. Preparation and characterization of reinforced papers using nano bacterial cellulose. Int. J. Biol. Macromol. 2017, 101, 334–340. [Google Scholar] [CrossRef]

- Zhao, Y.; Yang, Z.; Zhou, R.; Zheng, B.; Chen, M.; Liu, F.; Miao, W.; Zhou, R.; Cullen, P.; Xia, Z. Bacterial nanocellulose assembly into super-strong and humidity-responsive macrofibers. J. Bioresour. Bioprod. 2024, 9, 369–378. [Google Scholar] [CrossRef]

- Wu, A.; Hu, X.; Ao, H.; Chen, Z.; Chu, Z.; Jiang, T.; Deng, X.; Wan, Y. Rational design of bacterial cellulose-based air filter with antibacterial activity for highly efficient particulate matters removal. Nano Sel. 2022, 3, 201–211. [Google Scholar] [CrossRef]

- Stanislas, T.T.; Bilba, K.; de Oliveira Santos, R.P.; Onésippe-Potiron, C.; Savastano Junior, H.; Arsène, M.-A. Nanocellulose-based membrane as a potential material for high performance biodegradable aerosol respirators for SARS-CoV-2 prevention: A review. Cellulose 2022, 29, 8001–8024. [Google Scholar] [CrossRef]

- Sharma, P.; Mittal, M.; Yadav, A.; Aggarwal, N.K. Bacterial cellulose: Nano-biomaterial for biodegradable face masks–a greener approach towards environment. Environ. Nanotechnol. Monit. Manag. 2023, 19, 100759. [Google Scholar] [CrossRef] [PubMed]

- Jonsirivilai, B.; Torgbo, S.; Sukyai, P. Multifunctional filter membrane for face mask using bacterial cellulose for highly efficient particulate matter removal. Cellulose 2022, 29, 6205–6218. [Google Scholar] [CrossRef] [PubMed]

- French, V.; Du, C.; Foster, E.J. Mycelium as a self-growing biobased material for the fabrication of single-layer masks. J. Bioresour. Bioprod. 2023, 8, 399–407. [Google Scholar] [CrossRef]

- Li, H.; Qi, Y.; Zhao, Y.; Chi, J.; Cheng, S. Starch and its derivatives for paper coatings: A review. Prog. Org. Coat. 2019, 135, 213–227. [Google Scholar] [CrossRef]

- Sharma, M.; Aguado, R.; Murtinho, D.; Valente, A.J.M.; De Sousa, A.P.M.; Ferreira, P.J.T. A review on cationic starch and nanocellulose as paper coating components. Int. J. Biol. Macromol. 2020, 162, 578–598. [Google Scholar] [CrossRef]

- Sothornvit, R. Effect of hydroxypropyl methylcellulose and lipid on mechanical properties and water vapor permeability of coated paper. Food Res. Int. 2009, 42, 307–311. [Google Scholar] [CrossRef]

- Vaithanomsat, P.; Kongsin, K.; Trakunjae, C.; Boonyarit, J.; Jarerat, A.; Sudesh, K.; Chollakup, R. Biosynthesized Poly (3-Hydroxybutyrate) on coated pineapple leaf fiber papers for biodegradable packaging application. Polymers 2021, 13, 1733. [Google Scholar] [CrossRef] [PubMed]

- Srichola, P.; Boonyarit, J.; Kongtud, W.; Chollakup, R. Utilization of pineapple leaf fiber mixed with banana or cattail stem fibers and their paper physical properties for application in packaging. Agric. Nat. Resour. 2022, 56, 1103–1112. [Google Scholar]

- Dal, A.E.B.; Hubbe, M.A.; Pal, L.; Gule, M.E. Crude wood rosin and its derivatives as hydrophobic surface treatment additives for paper and packaging. ACS Omega 2020, 5, 31559–31566. [Google Scholar] [CrossRef] [PubMed]

- Guillaume, C.; Pinte, J.; Gontard, N.; Gastaldi, E. Wheat gluten-coated papers for bio-based food packaging: Structure, surface and transfer properties. Food Res. Int. 2010, 43, 1395–1401. [Google Scholar] [CrossRef]

- Chollakup, R.; Kongtud, W.; Sukatta, U.; Premchookiat, M.; Piriyasatits, K.; Nimitkeatkai, H.; Jarerat, A. Eco-friendly rice straw paper coated with longan (Dimocarpus Longan) peel extract as bio-based and antibacterial packaging. Polymers 2021, 13, 3096. [Google Scholar] [CrossRef]

- Tanpichai, S.; Witayakran, S.; Srimarut, Y.; Woraprayote, W.; Malila, Y. Porosity, density and mechanical properties of the paper of steam exploded bamboo microfibers controlled by nanofibrillated cellulose. J. Mater. Res. Technol. 2019, 8, 3612–3622. [Google Scholar] [CrossRef]

- Gülsoy, S.; Hürfikir, Z.; Turgut, B. Effects of decreasing grammage on the handsheet properties of unbeaten and beaten kraft pulps. Turk. J. For. 2016, 17, 56–60. [Google Scholar]

- Hassan, E.A.; Hassan, M.L.; Oksman, K. Improving bagasse pulp paper sheet properties with microfibrillated cellulose isolated from xylanase-treated bagasse. Wood Fiber Sci. 2011, 43, 76–82. [Google Scholar]

- Xiang, Z.; Zhang, J.; Liu, Q.; Chen, Y.; Li, J.; Lu, F. Improved dispersion of bacterial cellulose fibers for the reinforcement of paper made from recycled fibers. Nanomaterials 2019, 9, 58. [Google Scholar] [CrossRef]

- Yuan, J.; Wang, T.; Huang, X.; Wei, W. Dispersion and beating of bacterial cellulose and their influence on paper properties. BioResources 2016, 11, 9290–9301. [Google Scholar] [CrossRef]

- Gao, W.-H.; Chen, K.-F.; Yang, R.-D.; Yang, F.; Han, W.-J. Properties of bacterial cellulose and its influence on the physical properties of paper. BioResources 2011, 6, 144–153. [Google Scholar] [CrossRef]

- Kopacic, S.; Walzl, A.; Zankel, A.; Leitner, E.; Bauer, W. Alginate and chitosan as a functional barrier for paper-based packaging materials. Coatings 2018, 8, 235. [Google Scholar] [CrossRef]

- Ybañez, M.G.; Camacho, D.H. Designing hydrophobic bacterial cellulose film composites assisted by sound waves. RSC Adv. 2021, 11, 32873–32883. [Google Scholar] [CrossRef] [PubMed]

- Xiang, Z.; Liu, Q.; Chen, Y.; Lu, F. Effects of physical and chemical structures of bacterial cellulose on its enhancement to paper physical properties. Cellulose 2017, 24, 3513–3523. [Google Scholar] [CrossRef]

- Liu, X.; Souzandeh, H.; Zheng, Y.; Xie, Y.; Zhong, W.-H.; Wang, C. Soy protein isolate/bacterial cellulose composite membranes for high efficiency particulate air filtration. Compos. Sci. Technol. 2017, 138, 124–133. [Google Scholar] [CrossRef]

| BC Content (%) | Paper Sheet Forming Time (min) | Thickness (mm) | Basis Weight (g/m2) | Coat Weight (g/m2) | Tensile Index (N·m/g) | Tear Index (mN·m2/g) | Cobb (g/m2) | |

|---|---|---|---|---|---|---|---|---|

| Uncoated paper | 0 | 3–5 | 0.24 ± 0.03 a | 52.27 ± 0.82 ns | - | 6.09 ± 0.32 e | 0 c | 56.62 ± 0.97 b |

| 5 | ≤30 | 0.14 ± 0.02 a | 53.73 ± 2.99 ns | - | 11.40 ± 0.00 d | 0 c | 68.97 ± 0.62 a | |

| 10 | ≤30 | 0.17 ± 0.03 a | 55.98 ± 1.56 ns | - | 17.27 ± 0.00 c | 3.72 ± 0.26 b | 66.52 ± 3.26 a | |

| 50 | ≤60 | 0.11 ± 0.03 b | 51.84 ± 1.22 ns | - | 51.30 ± 0.64 b | 5.49 ± 0.56 a | 29.06 ± 2.02 c | |

| 100 | 60–75 | 0.08 ± 0.03 b | 74.24 ± 15.58 ns | - | 63.57 ± 3.33 a | 3.61 ± 0.00 b | 19.57 ± 2.68 d | |

| MS-coated paper | 0 | 3–5 | 0.17 ± 0.01 c | 54.70 ± 0.78 b | 3.79 ± 0.32 c | 31.36 ± 2.51 b | 5.60 ± 0.21 b | 51.65 ± 1.42 a |

| 5 | ≤30 | 0.24 ± 0.03 a | 56.09 ± 4.06 b | 6.54 ± 0.11 a | 27.62 ± 1.71 b | 4.86 ± 0.15 c | 60.45 ±10.99 a | |

| 10 | ≤30 | 0.20 ± 0.02 b | 65.03 ± 0.69 a | 6.05 ± 0.09 a | 29.15 ± 1.47 b | 5.59 ± 0.01 b | 57.90 ± 0.31 a | |

| 50 | ≤60 | 0.07 ± 0.01 d | 56.83 ± 1.97 b | 4.44 ± 0.10 b | 46.88 ± 0.41 a | 6.15 ± 0.26 a | 25.04 ± 4.20 b | |

| 100 | 60–75 | N/A | ||||||

| BC Content (%) | Paper Sheet Forming Time (min) | Thickness (mm) | Basis Weight (g/m2) | Coat Weight (g/m2) | Tensile Index (N·m/g) | Tear Index (mN·m2/g) | Cobb (g/m2) | |

|---|---|---|---|---|---|---|---|---|

| Uncoated paper | 0 | 3–5 | 0.24 ± 0.03 a | 75.01 ± 7.96 ns | - | 6.87 ± 0.26 b | 0 b | 99.58 ± 15.01 ns |

| 5 | ≤30 | 0.24 ± 0.03 a | 81.49 ± 3.19 ns | - | 12.17 ± 0.62 a | 3.11 ± 0.14 a | 97.09 ± 4.21 ns | |

| 10 | ≤30 | 0.17 ± 0.04 b | 89.17 ± 1.22 ns | - | 11.41 ± 0.59 a | 4.09 ± 0.68 a | 91.70 ± 10.94 ns | |

| MS-coated paper | 0 | 3–5 | 0.25 ± 0.03 a | 75.01 ± 7.96 b | 2.36 ± 1.01 ns | 27.52 ± 0.64 a | 4.70 ± 0.59 ns | 72.40 ± 7.80 ns |

| 5 | ≤30 | 0.24 ± 0.02 ab | 81.49 ± 3.19 a | 4.27 ± 3.19 ns | 20.35 ± 0.10 b | 5.20 ± 0.45 ns | 78.24 ± 14.62 ns | |

| 10 | ≤30 | 0.22 ± 0.01 b | 89.17 ± 1.70 a | 5.24 ± 2.18 ns | 26.58 ± 0.22 a | 5.63 ± 0.53 ns | 80.83 ± 2.95 ns |

| BC Content (%) | Uncoated Filter Paper | MS-Coated Filter Paper | ||

|---|---|---|---|---|

| 50 g/m2 | 80 g/m2 | 50 g/m2 | 80 g/m2 | |

| 0 |  |  |  |  |

| 5 |  |  |  |  |

| 10 |  |  |  |  |

| 50 |  | N/A |  | N/A |

| 100 |  | N/A | N/A | N/A |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Srichola, P.; Kongsin, K.; Apipatpapha, T.; Boonyarit, J.; Ounu, P.; Chollakup, R. Coated High-Performance Paper from Bacterial Cellulose Residue and Eucalyptus Pulp: Enhanced Mechanical Strength, Water Resistance, and Air Barrier Properties. Coatings 2025, 15, 720. https://doi.org/10.3390/coatings15060720

Srichola P, Kongsin K, Apipatpapha T, Boonyarit J, Ounu P, Chollakup R. Coated High-Performance Paper from Bacterial Cellulose Residue and Eucalyptus Pulp: Enhanced Mechanical Strength, Water Resistance, and Air Barrier Properties. Coatings. 2025; 15(6):720. https://doi.org/10.3390/coatings15060720

Chicago/Turabian StyleSrichola, Preeyanuch, Kunat Kongsin, Thanyachol Apipatpapha, Jirachaya Boonyarit, Peeraya Ounu, and Rungsima Chollakup. 2025. "Coated High-Performance Paper from Bacterial Cellulose Residue and Eucalyptus Pulp: Enhanced Mechanical Strength, Water Resistance, and Air Barrier Properties" Coatings 15, no. 6: 720. https://doi.org/10.3390/coatings15060720

APA StyleSrichola, P., Kongsin, K., Apipatpapha, T., Boonyarit, J., Ounu, P., & Chollakup, R. (2025). Coated High-Performance Paper from Bacterial Cellulose Residue and Eucalyptus Pulp: Enhanced Mechanical Strength, Water Resistance, and Air Barrier Properties. Coatings, 15(6), 720. https://doi.org/10.3390/coatings15060720