Abstract

Enhanced hard coatings with exceptional mechanical and thermal qualities have prompted substantial study into multicomponent nitride systems. TiAl(Si)N coatings have emerged as viable possibilities owing to their remarkable hardness, thermal stability, and oxidation resistance. This work involved the fabrication of thickness-varied TiAl(Si)N gradient coatings using reactive magnetron sputtering, employing a controlled modulation of aluminum and silicon content across the film thickness. Three samples, with thicknesses of ~400 nm, ~600 nm, and ~800 nm, were deposited under uniform Ar/N2 gas flow ratios, and their microstructural, mechanical, and tribological characteristics were rigorously examined. SEM investigation demonstrated a significant change across thicknesses. XRD results validated the emergence of a predominant cubic TiAl(Si)N phase alongside a secondary hexagonal AlN phase, signifying partial phase segregation. The nanoindentation results indicated that Sample 2 exhibited the maximum hardness (~38 GPa) and Young’s modulus (~550 GPa) due to an optimized equilibrium between solid solution strengthening and nanocomposite production. Tribological testing revealed that Sample 1 displayed the lowest and most consistent friction coefficient, corresponding to its superior H/E and H3/E2 ratios, which signify improved elasticity and resistance to plastic deformation. The findings emphasize that the implementation of a compositional gradient, especially in the distribution of Si and Al, markedly affects the microstructure and performance of TiAl(Si)N coatings. Gradient structures enhance the microstructure, optimize hardness, and increase the friction coefficient. Ongoing refinement of gradient profiles and deposition parameters may further improve the characteristics of TiAl(Si)N coatings, facilitating their wider industrial use.

1. Introduction

Because of several conceivable uses in the contemporary aerospace sector, manufacturing, medicine, and so forth [1,2,3,4,5,6], multilayer nitride coatings have been extensively researched since the final quarter of the 20th century. Researchers have gathered knowledge on the deposition methods, structure, characteristics, and many application points of view from the time of the first mention of these structures to the present [1]. Binary metal nitrides were shown to have better qualities than traditional metals. Moreover, multilayer nitride coatings show great durability, wear, corrosion resistance, and mechanical, optical, electrical, and magnetic qualities [7]. The particular qualities of nitride materials directly rely on their structure and the kinds of chemical connections created between their constituent components [7,8]. This has resulted in the creation of multicomponent systems such as titanium aluminum silicon nitride (TiAl(Si)N), which show better qualities than their binary equivalents [9].

Due to their outstanding qualities—high hardness, good chemical stability, and extraordinary wear and corrosion resistance—aluminum nitride (AlN) coatings have been widely used to protect metal substrates against both corrosion and wear [10,11,12]. Using magnetron sputtering, Altun et al. [10] applied single-layer AlN coatings on several Mg alloy substrates (AZ31, AZ61, AZ63, and AZ91). The findings showed that these AlN coatings really strengthened the corrosion resistance of the substrates. The anti-corrosion efficacy of the coatings, however, was much compromised by structural flaws like pinholes and fractures. Using magnetron sputtering on AZ31 Mg alloy, Wu et al. [12] created a multilayer coating made up of DLC/AlN/Al, which reduced the corrosion current density of the alloy tenfold. Using filtered cathodic vacuum arc deposition, Xie et al. [13] created composite coatings made of Al and AlN on an AZ31 Mg alloy, so significantly improving substrate hardness and corrosion resistance with a hardness of 512 HV and a corrosion current density of 1.913 × 10−6 A/cm2. Shi et al. [14], meanwhile, created a seven-structural-color AlN/Si/Al coating for a Mg alloy; nevertheless, its corrosion resistance was less remarkable because of AlN layer thickness constraints. Therefore, the creation of color-tunable AlN-based hard coatings with better anti-corrosive qualities has been a constant difficulty up until now.

Designing multilayer structures is a good way to improve the corrosion resistance of coatings [15]. Of the many design techniques at hand, the trend of inserting many thin layers inside a monolayer coating to produce multilayer structural coatings has become more common [16]. The inclusion of an amorphous thin layer might hinder the development of the columnar structure in the coating, hence lowering surface flaws including pinholes and coarse clusters [16]. Zhang et al. [17], for example, deposited monolayer Hf and Hf/Si3N4 multilayer coatings on the AZ91D Mg alloy. The results showed that the implanted Si3N4 thin layers efficiently controlled the columnar development of the Hf sublayer, hence lowering coating porosity and so preventing the entrance of the corrosive medium, which increased the corrosion resistance of the Hf coating. Given the above results, including several thin layers of Si inside the AlN monolayer coating provides two advantages. The Si thin layers can reduce the columnar development of the AlN coating and lower growth-related flaws, hence improving its corrosion resistance [17]. Conversely, the Si thin layer can act as a light-reflecting surface, generating a thin film interference effect with the AlN top layer and hence generating a structural color effect [14].

Especially at high electron density, the great incompressibility of transition metal atoms from group IVB to VIB allows them to create very orientated covalent compounds with lighter elements including C or N. When applied as coatings, such materials show remarkable mechanical qualities with great bond strength, hardness, and wear resistance [18]. While adding carbon lowers friction coefficients, introducing aluminum into ceramic TiN coatings improves thermal stability and corrosion resistance. Quaternary composite coatings produced by adding both aluminum and carbon to the TiN system outperform in wear resistance, corrosion resistance, and tribological characteristics [19,20,21,22].

Adding aluminum (Al) to TiN creates TiAlN, which enhances oxidation resistance by generating a protective Al2O3 layer at higher temperatures. Adding more silicon (Si) causes a nanocomposite structure in which nanocrystalline (Ti, Al)N grains are buried inside an amorphous Si3N4 matrix. The coating’s improved hardness and thermal stability come from its unusual design. Research has shown that TiAl(Si)N coatings with an ideal Si concentration may approach 40 GPa in hardness, far more than TiN or TiAlN coatings by itself [9].

Researchers have looked at the idea of compositional gradients inside the coating to improve even more the performance of TiAl(Si)N coatings. Functionally graded materials (FGMs) are defined by a progressive change in composition and structure across their volume, therefore producing commensurate variations in their characteristics. Regarding TiAl(Si)N coatings, a gradient in Si content may be designed to maximize the distribution of hardness, residual stress, and thermal stability over the coating thickness [23,24,25].

Compared to their homogeneous equivalents, gradient TiAl(Si)N coatings have shown better mechanical qualities. Coatings with a Si content gradient, for example, show better substrate adherence, lower residual stresses, and higher fracture propagation resistance. In applications with cyclic loads and high-temperature settings, such as cutting tools and aerospace components, these qualities are especially advantageous [26,27].

Usually, gradient TiAl(Si)N coatings are deposited using sophisticated physical vapor deposition (PVD) methods like reactive magnetron sputtering. The coating’s composition throughout its thickness may be tailored by exactly regulating the power given to the Ti, Al, and Si targets during the deposition process. Coatings with a regulated gradient in Si concentration may be made using this method, hence optimizing their thermal and mechanical qualities. Recent research has underlined the benefits of gradient TiAl(Si)N coatings in several uses. Coatings with a Si content gradient, for instance, have demonstrated improved performance in high-speed machining processes where they offer longer tool life and greater wear resistance than traditional coatings. These coatings also show better oxidation resistance at high temperatures, which qualifies them for usage in severe conditions [25,28,29].

Reactive magnetron sputtering was used for the deposition of TiAl(Si)N gradient coatings with different thicknesses, hence showing the effect of compositional gradients on coatings’ performance. Previous studies on TiAl(Si)N gradient coatings have primarily focused on enhancing mechanical properties through adjustments in annealing parameters, gradient architecture, and chemical composition [9,24,26,27,28]. To the best of our knowledge, this is the first study that systematically explores the effect of coating thickness on the structural and mechanical characteristics of TiAl(Si)N gradient coatings, and we aim to address this gap.

2. Materials and Methods

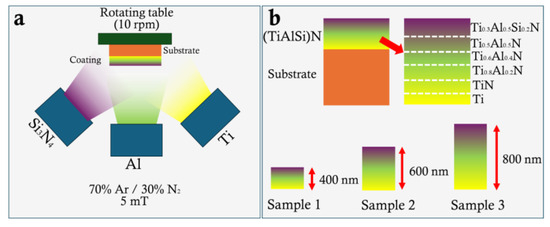

Magnetron sputtering. Reactive magnetron sputtering produced TiAl(Si)N gradient coatings with the experimental configuration and consequent multilayer structure shown in Figure 1. Under a 70% Ar/30% N2 environment at 5 mTorr, three sputtering targets with 2” in diameter—Si3N4, Al, and Ti—are arranged around a rotating substrate holder (10 rpm) in Figure 1a. Al and Ti targets were set to DC, while the Si3N4 target was set to RF sources. The base pressure was <10−9 Torr. The sputtering targets were pre-cleaned by pre-sputtering in a pure Ar atmosphere for 120 s with closed individual shutters to remove surface contaminants. Pure Ar was used to deposit an initially pure Ti layer. Rotational motion guarantees consistent exposure to the fluxes from every target, hence producing a steady compositional change inside the coating. Varying power supplied to magnetrons produced the gradient structure. The color variations in the diagram correlate to changes in composition and phase. Table 1 provides the comprehensive information.

Figure 1.

The schematic illustration of the reactive magnetron sputtering process (a), and composition of the thickness-varied TiAl(Si)N gradient thin films (b).

Table 1.

Deposition parameters.

Starting with the substrate (AISI 316L steel disks, Ø16 mm and 1 mm thick) with pure Ti, followed by TiN, and going via a progressive rise in Al content, the schematic structure of the multilayer coating is depicted in Figure 1b, ultimately reaching TiAlSiN at the top. To investigate how film thickness and gradient architecture affect coating performance, three samples with total thicknesses of 400 nm, 600 nm, and 800 nm were created. The thickness range was chosen based on prior experimental results, focused on nanocomposite TiAlN and TiAlSiN coatings [9,27].

Thin film characterization. Dual-beam scanning electron microscopy (Helios 5 CX, ThermoFisher, Waltham, MA, USA) with an energy dispersive X-ray spectroscopy (EDS) equipment from EDAX (Mahwah, NJ, USA) for elemental analysis was used to investigate the morphology and nanostructure of the produced sensors. Using a Rigaku SmartLab diffractometer with a Cu K\u03b1 radiation source (Tokyo, Japan), low-angle X-ray diffraction (XRD) was used to examine the phase composition of thickness-varied TiAl(Si)N gradient thin films.

Under the following conditions—a radius of 3.00 mm, a sliding speed of 5.00 cm/s, and an applied normal load of 1.00 N—the tribological characteristics were assessed using a “ball–disk” setup on a TRB3 tribometer (Anton Paar Srl, Buchs, Switzerland). Using a “Fischerscope HM2000 S” device (Helmut Fischer GmbH, Sindelfingen, Germany), the microhardness and elastic modulus were calculated under the following conditions: load ramp-up to 10.000 mN over 15 s and a creep duration of 5.0 s at the maximum load.

3. Results and Discussion

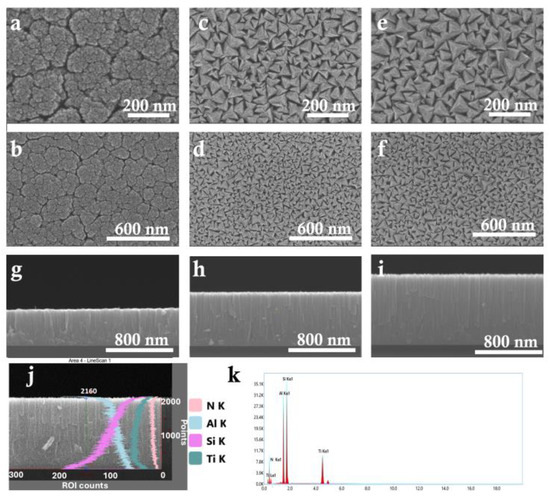

The SEM pictures in Figure 2 provide information on the microstructure and morphology of TiAl(Si)N gradient thin films produced by reactive magnetron sputtering. The gradient design was accomplished by progressively raising the aluminum content and adding silicon in the top layers throughout three samples (Sample 1: a, b, and g; Sample 2: c, d, and h; Sample 3: e, f, and i). The surface SEM (Figure 2a–f) show an obvious topographical evolution: Sample 1 displays microcracks and fine-grained nanocrystalline islands. By comparison, Sample 2 has faceted grains and better homogeneity ascribed to higher Al concentration and longer deposition durations. With big pyramidal grains and a dense, organized surface structure, Sample 3 has the most sophisticated morphology, benefiting from longer deposition durations and a high Al/Si composition. The distinct microstructure of Sample 1 is primarily due to a shorter deposition time, which limits grain growth and results in fine-grained, microcracked morphology. Additionally, the underlying TiN seed layer, being proportionally thicker in Sample 1 relative to the total film thickness, likely influenced nucleation behavior and suppressed the development of columnar grains observed in thicker samples.

Figure 2.

The surface and cross-sectional morphology of the thickness-varied TiAl(Si)N gradient thin films (Sample 1: (a,b,g); Sample 2: (c,d,h); Sample 3: (e,f,i)); (j) the cross-section with element distribution by line and EDS spectra for Sample 3 (k).

From around 500 nm to about 800 nm, the cross-sectional SEM Figure 2g–i reveal thick, densely well-adhered columnar formations for all coatings. While Samples 2 (h) and 2 (i) exhibit more obvious columnar development with somewhat broader columns, suggesting a shift towards a more textured microstructure, Sample 2 (g) shows a finer and more compact columnar morphology. The compositional gradient and customized sputtering settings mostly drive the observed microstructural change. Higher Si concentration in the higher layers helps to create a nanocomposite structure—TiAlN nanocrystals set in an amorphous Si3N4 matrix—which impedes grain development. At the same time, larger nanocrystals contain more aluminum. While steady nitridation is guaranteed by continuous gas flow ratios (30% N2 and 70% Ar), longer deposition times allow thicker, more ordered layers.

Illustrating the elements’ distribution of nitrogen (N), aluminum (Al), silicon (Si), and titanium (Ti) over the film thickness, Figure 2j presents the cross-sectional SEM picture of Sample 3 with a matching EDS line scan. All elements’ smooth and continuous profiles verify a uniform distribution over the film, suggestive of steady co-sputtering deposition circumstances. The slight elemental gradients imply that the film is chemically homogenous without clear layering or phase separation.

The EDS quantification backed by the spectrum in Figure 2k reveals once more the existence of the four essential components. With matching weight percentages of 27.2 wt.%, 25.0 wt.%, 28.2 wt.%, and 19.6 wt.%, respectively, Sample 2’s atomic concentrations—most likely depicted in this figure—are around 45.4 at.% N, 21.7 at.% Al, 23.4 at.% Si, and 9.5 at.% Ti. The EDS analysis result in Table 2 is integrative and corresponds to the full cross-sectional thickness of each coating (~400–800 nm). These results indicate a gradient change in element content. However, it should be noted that the reported values are integrative and do not correspond to specific localized points.

Table 2.

The element composition assessed by EDS.

A purposeful change in sputtering power or target design to provide compositional tailoring is suggested by the rising nitrogen and silicon concentration from Sample 1 to Sample 3 and falling titanium content. Such changes immediately affect characteristics including heat stability, stress relaxation, and hardness. The EDS measurements’ modest error margins—mostly under 10% confirm the dependability of the compositional data.

All things considered, the EDS quantification and Figure 2j,k together confirm the successful production of a chemically homogeneous and compositionally tailored TiAlSiN coating. These findings support the morphological data (Figure 2g–i), suggesting that the exact elemental composition of the films strongly links microstructural development.

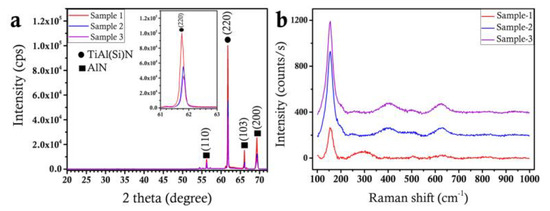

Across all three samples, the X-ray diffraction (XRD) patterns (Figure 3a) of Samples 1, 2, and 3 verify the development of a multiphase structure comprising a primary cubic TiAl(Si)N phase and a secondary hexagonal w-AlN (ICDD card No. 00-025-1133). As described by Ji et al. in [9], the TiAl(Si)N solid solution’s (220) reflection corresponds to the dominant peak at about 61° 2θ. Extra peaks matching the (110), (103), and (200) planes of the hexagonal AlN point to phase segregation, in which excess aluminum crystallizes independently. The uniform XRD patterns for every sample indicate comparable phase compositions with different structural refinements. The shift of XRD peaks to the right (higher 2θ angles) corresponds to a decrease in lattice parameters, which may be caused by the substitution of smaller atoms into the crystal lattice, such as the incorporation of Al and Si into TiN, leading to the accumulation of residual compressive stresses in the film. This shift indicates structural changes due to doping and stress development during film growth [28,30]. No distinct peaks related to TiO2 polymorphs (e.g., anatase at 25.3° and rutile at 27.4°) are observed, suggesting either the absence of crystalline TiO2 or its presence below the detection threshold of conventional XRD.

The Rietveld refinement was applied to assess the approximate phase ratio. All samples exhibit a dominant cubic TiAl(Si)N phase with a relatively stable fraction of the hexagonal AlN phase: ~32.5% in Sample 1, ~29.0% in Sample 2, and ~30.4% in Sample 3. These slight variations suggest that the AlN content decreases slightly at an intermediate thickness (Sample 2), which corresponds to the highest hardness and elastic modulus. This indicates that minimizing excess AlN segregation through controlled thickness can impact mechanical performance, as AlN may act as a softer secondary phase that reduces overall hardness and structural cohesion [9,28].

Figure 3.

The structural and mechanical characterization of the thickness-varied TiAl(Si)N gradient thin films: (a) XRD patterns; (b) Raman spectra of the thin films.

The Raman spectra of the TiAlSiN gradient coatings (Figure 3b) exhibit a dominant peak centered at approximately 155 cm−1 with a full width at half maximum (FWHM) of ~30 cm−1, which can be attributed to the Eg mode of anatase TiO2. This mode, typically located at ~144 cm−1 in bulk anatase, is known to shift toward higher wavenumbers and broaden in response to nanoscale crystallite size, strain, or dopant incorporation, such as Al or Si, which distort the Ti–O lattice environment, as was discussed by Oshaka et al. in [31]. The increasing intensity of this peak from Sample 1 to Sample 3 suggests a progressive enhancement of the anatase phase, likely due to surface oxidation during deposition or post-deposition processes. It should be noted that the anatase dominant XRD peak at 2θ~27.4° was not observed, possibly due to occurring at the surface only. The broader shoulder observed in the 500–650 cm−1 range may correspond to optical modes from the cubic TiAl(Si)N lattice, which becomes Raman-active due to compositional disorder and nanocrystallinity as was discussed by Barshilia et al. in [32].

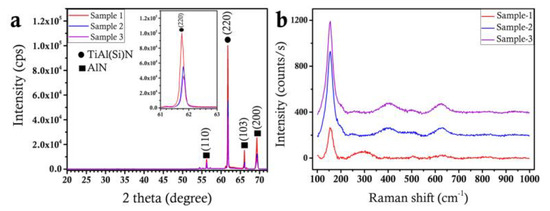

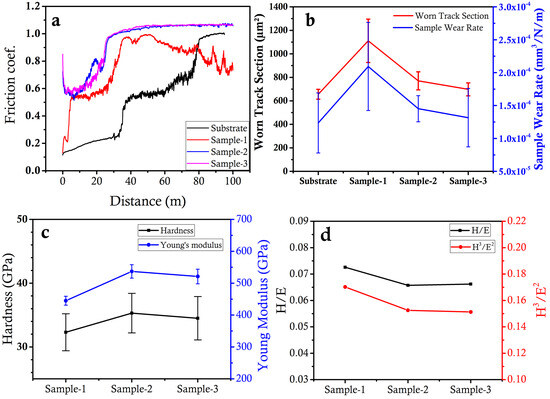

Presented in Figure 4a, the tribological behavior reveals the change in friction coefficients as a function of sliding distance. The coatings generally exhibited higher friction coefficients than the substrate. However, Sample 1 demonstrated a low and stable coefficient of friction, possibly due to the presence of finely distributed microcracks. These may act as stress-relief zones, reducing localized deformation and aiding energy dissipation during sliding. Although microcracks typically reduce wear resistance, their controlled formation in this case may contribute to enhanced friction stability [33]. By comparison, Samples 2 and 3 have more variable and greater friction coefficients, implying a progressive tribolayer deterioration during sliding. These findings draw attention to the fact that the tribological performance is closely related to the structural integrity and mechanical properties of the coating.

Figure 4.

The mechanical characterization of the thickness-varied TiAl(Si)N gradient thin films. (a) Tribological testing; (b) worn track section and wear resistance; (c) hardness and Young’s modulus; (d) H/E and H3/E2.

Figure 4b presents the worn track cross-sectional area and wear rate of the substrate and TiAl(Si)N gradient coatings, revealing distinct differences in wear resistance among the samples. Sample 1 exhibits the highest wear track area and wear rate, despite showing the lowest and most stable friction coefficient in earlier tribological data. This apparent contradiction can be attributed to the fine-grained, microcracked structure of Sample 1, which enhances elasticity (high H/E and H3/E2 ratios) but may also reduce load-bearing capacity and resistance to material removal under prolonged sliding [33].

In contrast, Samples 2 and 3 show reduced wear track area and lower wear rates, with Sample 3 demonstrating the best wear resistance overall. This improvement correlates with increased film thickness, better crystallinity, and more continuous nanocomposite structures, which provide improved mechanical stability and resistance to abrasive wear [26,34]. Additionally, thicker coatings help to delay substrate influence, which becomes increasingly significant in thin films like Sample 1 during high-load wear tests.

The observed trend emphasizes that optimal tribological performance depends not only on friction behavior but also on microstructural integrity, thickness, and phase stability—all of which play a crucial role in wear resistance under real contact conditions.

Figure 4c illustrates the mechanical characteristics assessed by nanoindentation. Among the tested coatings, Sample 2 shows the greatest hardness (~38 GPa) and Young’s modulus (~550 GPa); Samples 1 and 3 show marginally lower values. An optimal mix between solid solution strengthening from Al and Si doping and microstructural refinement could explain Sample 2’s increase in hardness and stiffness. Excessive Al or Si segregation could cause Sample 3 to have a relatively lower hardness as it would produce a softer composite structure.

While Sample 2 has the highest hardness and Young’s modulus, wear resistance in practical applications also depends on elasticity and the ability to resist plastic deformation. Figure 4d shows the ratios of H/E and H3/E2, which, respectively, indicate a coating’s resistance to elastic strain and plastic deformation. Sample 1, which is in line with its better friction performance, shows the highest H/E and H3/E2 values implying the best mix of elasticity and resistance to plastic deformation. Lower H/E and H3/E2 ratios are seen in Samples 2 and 3, which correspond to their greater friction coefficients and imply that although they have higher hardness, they are more susceptible to brittle failure under mechanical stress. All things considered, the total structural, tribological, and mechanical findings show that among the three samples, Sample 1 offers the greatest balance between hardness, elasticity, and wear resistance.

4. Conclusions

This study systematically investigated the influence of coating thickness on the microstructure, mechanical, and tribological performance of TiAl(Si)N gradient coatings synthesized by reactive magnetron sputtering. The coatings, fabricated with controlled compositional gradients and varying thicknesses (400, 600, and 800 nm), revealed significant structural and functional differences.

SEM and EDS analyses confirmed the formation of dense, well-adhered coatings with microstructural evolution from fine-grained and microcracked (Sample 1) to large, faceted pyramidal grains (Sample 3) as the thickness increased. XRD patterns showed a dominant cubic TiAl(Si)N solid solution phase and a minor hexagonal AlN phase, with slight variations in their ratio across samples. Raman spectroscopy additionally indicated the presence of surface-localized TiO2 (anatase) signatures in the thinner films.

Nanoindentation tests revealed that Sample 2 (600 nm) achieved the highest hardness (~38 GPa) and Young’s modulus (~550 GPa) due to an optimal balance between nanocrystalline grain formation and amorphous Si3N4 dispersion. Despite having a slightly lower hardness, Sample 1 (400 nm) demonstrated the best tribological performance, with the lowest and most stable friction coefficient and the highest H/E and H3/E2 ratios, indicating enhanced elasticity and resistance to plastic deformation. Wear rate analysis confirmed that thicker coatings (Sample 3) exhibited better resistance to material loss, while Sample 1’s fine microstructure contributed to friction stability but also higher wear depth under load.

The findings underline that by customizing thickness and microstructure, engineering compositional gradients inside TiAl(Si)N coatings can greatly improve mechanical stability and wear performance. Particularly in settings needing high hardness, these results open the way for the further evolution of functionally graded TiAl(Si)N coatings for demanding industrial uses.

Author Contributions

Conceptualization, A.K., A.M. and R.K.; methodology, A.S.; investigation, A.K., A.M., R.K. and A.S.; writing—original draft preparation, A.K., A.M. and R.K.; editing, G.U. and F.B. All authors have read and agreed to the published version of the manuscript.

Funding

This research has been funded by the Science Committee of the Ministry of Science and Higher Education of the Republic of Kazakhstan (Grant No. AP22684071 “Novel high hardness, corrosion- and wear-resistant TiAlN/Si multilayer coatings”).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data sets supporting the results of this article are included with-in the article.

Acknowledgments

The authors would like to express their sincere gratitude to Alexander Pogrebnjak, Amanzhol Turlybekuly, and Nazgul Yerdybayeva for their valuable guidance, scientific insight, and continuous support throughout this research. Their expertise and dedication significantly contributed to the successful completion of this work.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Zhang, X.; Zeng, Z.; Zeng, X.; Pelenovich, V.; Wan, Q.; Pogrebnjak, A.; Xue, L.; Chen, Y.; Yang, B. Hardening Mechanism and Plastic Deformation Behavior in Super-Hard AlCrNbSiTiN High-Entropy Nitride Nanocomposite Coatings. Mater. Res. Lett. 2025, 13, 103–112. [Google Scholar] [CrossRef]

- Kasymbaev, A.; Smirnova, K.; Pogrebnyak, A. Physical Patterns of Obtaining WN/ZrN Composite Coatings by the Method of Vacuum Arc Deposition. Bull. Shakarim University Tech. Sci. 2024, 1, 462–470. [Google Scholar] [CrossRef]

- Rakhadilov, B.K.; Kenesbekov, A.B.; Kowalevski, P.; Ocheredko, Y.A.; Sagdoldina, Z.B. Development of Air-Plasma Technology for Hardening Cutting Tools by Applying Wear-Resistant Coatings. NEWS Natl. Acad. Sci. Repub. Kazakhstan 2020, 3, 54–62. [Google Scholar] [CrossRef]

- Sagdoldina, Z.; Rakhadilov, B.; Kurbanbekov, S.; Kozhanova, R.; Kengesbekov, A. Effect of Irradiation with Si+ Ions on Phase Transformations in Ti–Al System during Thermal Annealing. Coatings 2021, 11, 205. [Google Scholar] [CrossRef]

- Azamatov, B.; Dzhes, A.; Borisov, A.; Kaliyev, D.; Maratuly, B.; Sagidugumar, A.; Alexandr, M.; Turlybekuly, A.; Plotnikov, S. Antibacterial Properties of Copper-Tantalum Thin Films: The Impact of Copper Content and Thermal Treatment on Implant Coatings. Heliyon 2025, 11, e41130. [Google Scholar] [CrossRef]

- Pogrebnyak, A.D.; Ivashchenko, V.I.; Erdybaeva, N.K.; Kupchishin, A.I.; Lisovenko, M.A. Microstructure and Mechanical Properties of Multilayer α-AlN/α-BCN Coating as Functions of the Current Density during Sputtering of a B4C Target. Phys. Solid State 2018, 60, 2030–2033. [Google Scholar] [CrossRef]

- Vereschaka, A.; Tabakov, V.; Grigoriev, S.; Sitnikov, N.; Oganyan, G.; Andreev, N.; Milovich, F. Investigation of Wear Dynamics for Cutting Tools with Multilayer Composite Nanostructured Coatings in Turning Constructional Steel. Wear 2019, 420–421, 17–37. [Google Scholar] [CrossRef]

- Maksakova, O.V.; Simoẽs, S.; Pogrebnjak, A.D.; Bondar, O.V.; Kravchenko, Y.O.; Koltunowicz, T.N.; Shaimardanov, Z.K. Multilayered ZrN/CrN Coatings with Enhanced Thermal and Mechanical Properties. J. Alloys Compd. 2019, 776, 679–690. [Google Scholar] [CrossRef]

- Ji, L.; Liu, H.; Huang, C.; Li, S.; Yin, M.; Liu, Z.; Zhao, J.; Xu, L. Effect of TiAlSiN Gradient Structure Design on Mechanical Properties and Microstructure of Coatings. Surf. Coat. Technol. 2025, 496, 131617. [Google Scholar] [CrossRef]

- Altun, H.; Sen, S. The Effect of DC Magnetron Sputtering AlN Coatings on the Corrosion Behaviour of Magnesium Alloys. Surf. Coat. Technol. 2005, 197, 193–200. [Google Scholar] [CrossRef]

- Altun, H.; Sen, S. The Effect of PVD Coatings on the Corrosion Behaviour of AZ91 Magnesium Alloy. Mater. Des. 2006, 27, 1174–1179. [Google Scholar] [CrossRef]

- Wu, G.; Dai, W.; Zheng, H.; Wang, A. Improving Wear Resistance and Corrosion Resistance of AZ31 Magnesium Alloy by DLC/AlN/Al Coating. Surf. Coat. Technol. 2010, 205, 2067–2073. [Google Scholar] [CrossRef]

- Xie, W.; Zhao, Y.; Liao, B.; Pang, P.; Wuu, D.; Zhang, S. Al–AlN Composite Coatings on AZ31 Magnesium Alloy for Surface Hardening and Corrosion Resistance. Vacuum 2021, 188, 110146. [Google Scholar] [CrossRef]

- Shi, X.; Zhang, S.; You, Y.; Sun, D.; Yu, X.; Wang, J.; Du, H.; Li, F. Enhancing Color Tunability, Corrosion Resistance, and Hardness of AlN/Al Coatings on Magnesium Alloys via Sputtering a Si Interlayer. Vacuum 2023, 209, 111772. [Google Scholar] [CrossRef]

- Wan, Z.; Zhang, T.F.; Lee, H.-B.-R.; Yang, J.H.; Choi, W.C.; Han, B.; Kim, K.H.; Kwon, S.-H. Improved Corrosion Resistance and Mechanical Properties of CrN Hard Coatings with an Atomic Layer Deposited Al2O3 Interlayer. ACS Appl. Mater. Interfaces 2015, 7, 26716–26725. [Google Scholar] [CrossRef]

- Zhang, D.; Qi, Z.; Wei, B.; Shen, H.; Wang, Z. Microstructure and Corrosion Behaviors of Conductive Hf/HfN Multilayer Coatings on Magnesium Alloys. Ceram. Int. 2018, 44, 9958–9966. [Google Scholar] [CrossRef]

- Zhang, D.; Qi, Z.; Wei, B.; Wu, Z.; Wang, Z. Anticorrosive yet Conductive Hf/Si 3 N 4 Multilayer Coatings on AZ91D Magnesium Alloy by Magnetron Sputtering. Surf. Coat. Technol. 2017, 309, 12–20. [Google Scholar] [CrossRef]

- Zhou, B.; Wang, Y.; Liu, Z.; Zhi, J.; Sun, H.; Wang, Y.; Wu, Y.; Hei, H.; Yu, S. Effect of Modulation Ratio on Microstructure and Tribological Properties of TiAlN/TiAlCN Multilayer Coatings Prepared by Multi-Excitation Source Plasma. Vacuum 2023, 211, 111917. [Google Scholar] [CrossRef]

- Tillmann, W.; Grisales, D.; Marin Tovar, C.; Contreras, E.; Apel, D.; Nienhaus, A.; Stangier, D.; Lopes Dias, N.F. Tribological Behaviour of Low Carbon-Containing TiAlCN Coatings Deposited by Hybrid (DCMS/HiPIMS) Technique. Tribol. Int. 2020, 151, 106528. [Google Scholar] [CrossRef]

- Liu, K.; Ma, F.; Lou, M.; Dong, M.; Zhu, Y.; Wang, Y.; Wu, X.; Liu, X.; Li, J. Structure and Tribocorrosion Behavior of TiAlCN Coatings with Different Al Contents in Artificial Seawater by Multi-Arc Ion Plating. Surf. Topogr. 2021, 9, 045004. [Google Scholar] [CrossRef]

- Zeng, Y.; Qiu, Y.; Mao, X.; Tan, S.; Tan, Z.; Zhang, X.; Chen, J.; Jiang, J. Superhard TiAlCN Coatings Prepared by Radio Frequency Magnetron Sputtering. Thin Solid Film. 2015, 584, 283–288. [Google Scholar] [CrossRef]

- Yeung, M.T.; Lei, J.; Mohammadi, R.; Turner, C.L.; Wang, Y.; Tolbert, S.H.; Kaner, R.B. Superhard Monoborides: Hardness Enhancement through Alloying in W1−xTaxB. Adv. Mater. 2016, 28, 6993–6998. [Google Scholar] [CrossRef] [PubMed]

- Qin, B.; Sun, Q.; Yu, J.; Wen, T. Strength Variation and Cracking Behavior of Corundum Bricks with Modified Hydrated Magnesium Chloride Binders. Ceram. Int. 2024, 50, 23568–23576. [Google Scholar] [CrossRef]

- Lungu, M.V.; Tălpeanu, D.; Ciobanu, R.C.; Cojocaru, A.; Pătroi, D.; Marinescu, V.; Caramitu, A.R. Evaluation of Magnetron Sputtered TiAlSiN-Based Thin Films as Protective Coatings for Tool Steel Surfaces. Coatings 2024, 14, 1184. [Google Scholar] [CrossRef]

- Oda, A.; Kinoshita, K.; Yoda, S.; Katsumata, H.; Uekusa, S. Growth of Si0.5Ge0.5 Single Crystals by the Traveling Liquidus-Zone Method and Their Structural Characterization. Procedia Eng. 2012, 36, 404–410. [Google Scholar] [CrossRef][Green Version]

- Lü, W.; Li, G.; Zhou, Y.; Liu, S.; Wang, K.; Wang, Q. Effect of High Hardness and Adhesion of Gradient TiAlSiN Coating on Cutting Performance of Titanium Alloy. J. Alloys Compd. 2020, 820, 153137. [Google Scholar] [CrossRef]

- Su, K.; Liu, D.; Shao, T. Microstructure and Mechanical Properties of TiAlSiN Nano-Composite Coatings Deposited by Ion Beam Assisted Deposition. Sci. China Technol. Sci. 2015, 58, 1682–1688. [Google Scholar] [CrossRef]

- Zhou, Q.; Huang, B.; Zhang, E.; Peng, Z.; Chen, Q.; Liang, D. Improving the Mechanical and Tribological Properties of TiAlSiN Coatings by Annealing. Vacuum 2023, 214, 112249. [Google Scholar] [CrossRef]

- Dauphas, S.; Ababou-Girard, S.; Girard, A.; Le Bihan, F.; Mohammed-Brahim, T.; Vié, V.; Corlu, A.; Guguen-Guillouzo, C.; Lavastre, O.; Geneste, F. Stepwise Functionalization of SiNx Surfaces for Covalent Immobilization of Antibodies. Thin Solid Film. 2009, 517, 6016–6022. [Google Scholar] [CrossRef]

- Musil, J. Hard and Superhard Nanocomposite Coatings. Surf. Coat. Technol. 2000, 125, 322–330. [Google Scholar] [CrossRef]

- Ohsaka, T.; Izumi, F.; Fujiki, Y. Raman Spectrum of Anatase, TiO2. J. Raman Spectrosc. 1978, 7, 321–324. [Google Scholar] [CrossRef]

- Barshilia, H.C.; Rajam, K.S. A Raman-Scattering Study on the Interface Structure of Nanolayered TiAlN∕TiN and TiN∕NbN Multilayer Thin Films Grown by Reactive Dc Magnetron Sputtering. J. Appl. Phys. 2005, 98, 014311. [Google Scholar] [CrossRef]

- Leyland, A.; Matthews, A. On the Significance of the H/E Ratio in Wear Control: A Nanocomposite Coating Approach to Optimised Tribological Behaviour. Wear 2000, 246, 1–11. [Google Scholar] [CrossRef]

- Pogrebnjak, A.; Smyrnova, K.; Bondar, O. Nanocomposite Multilayer Binary Nitride Coatings Based on Transition and Refractory Metals: Structure and Properties. Coatings 2019, 9, 155. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).