1. Introduction

Electrolytic copper foil is one of the most important materials in lithium-ion batteries (LIB), printed circuit boards (PCB), and chip packaging substrates (CPS) [

1,

2,

3,

4]. Currently, according to the different production methods of copper foil, it can generally be divided into two major categories: rolled copper foil and electrolytic copper foil. Rolled copper foil is an ingot formed by melting and casting pure copper. Subsequently, the base material is prepared through a series of processes such as hot pressing and cold pressing in a high-precision pressing mill to obtain the required copper foil thickness and quality. Electrolytic copper foil is manufactured through the electrochemical deposition of copper ions in an electrolyte solution [

5,

6]. Compared with the disadvantages of rolled copper foil, such as the complex production process, stringent equipment requirements, low production efficiency, and high cost, electrolytic copper foil has the following advantages: a simple production process, a minimal equipment cost, easy control of the foil thickness, high production efficiency, and a reduced total cost.

With the rapid development of downstream technologies, the demand for upstream electrolytic copper foil has increased year by year. In particular, the requirements for the quality and performance of copper foil are growing continuously. The cathode roller, a key piece of equipment in copper foil manufacturing, enables the electrode positioning of copper foil on its surface—a process that essentially extends the microstructure of the roller’s substrate [

7,

8]. The microstructure of the cathode roller is closely related to the grade and quality of the copper foil, thus playing a decisive role in producing high-quality copper foil.

At present, there are two main methods for the manufacturing of cathode rollers, which are spinning (seamless) and welding (seamed) [

9,

10]. Compared with the welding manufacturing method, the production cycle of the spinning method is much longer, and the costs are much higher. Moreover, the spinning equipment and molds for the manufacturing of cylinder sleeves with large diameters are more costly or even impossible to obtain. Meanwhile, the preparation of titanium cylinder sleeves for cathode rollers via the welding method has the advantages of a lower cost, higher production efficiency, and no limitation on the diameter of the titanium cylinder sleeves. Therefore, in the manufacturing of titanium cathode rollers with large diameters, the welding manufacturing method provides outstanding advantages [

11,

12]. However, there typically exists a longitudinal weld on the surface of the cathode roller’s titanium cylinder sleeve when using the welding method. This brings about a bright band at the corresponding position on the copper foil material, resulting from the presence of the longitudinal weld, which seriously affects the quality of the copper foil and restricts the production efficiency. This is because the grain boundaries on the surface have a great influence on the electrode positioning of copper ions, mainly due to their inherent defect characteristics [

13,

14]. Therefore, a key solution in the production of welded cathode rollers is to develop an appropriate method to regulate the microstructure of the weld-related zone and obtain a microstructure with almost the same grain size as the base material, thus avoiding the bright band at the corresponding position of the longitudinal weld.

Due to the above problem of the bright band, strict requirements have been put forward regarding the grain size and uniformity of cathode rollers manufactured via the welding method in the industrial production of electrolytic copper foil. In order to meet these high requirements, many studies have been conducted to refine the microstructure in the weld zone, and the goal is to solve the problem of the bright band existing at the corresponding position of the copper foil material [

15,

16]. Sun et al. [

17] introduced a large number of martensite structures to the surface of the titanium cathode through selective laser melting, thereby increasing the density of the grain boundaries. Won-Bin [

18] selected appropriate ranges for the welding process parameters for the cathode roller through thermoelastic–plastic analysis and used a series of welding variables obtained from an analysis of optimization algorithms. However, his research has almost no practical value in the real production of cathode rollers, since too few welding variables were considered and it was not based on engineering applications. Wu [

19] proposed a novel fast-frequency pulsed tungsten inert gas (FFP-TIG) welding technology, which introduces a high-frequency pulsed current into TIG welding to achieve the goal of refining the microstructure of Ti-6Al-4V welds. However, this method is not popular and has a relatively high production cost; thus, it is challenging to promote and apply. Zongshi Hou [

20] reported a method that involves repeatedly heating, forging, and hammering the cathode roller weld seam and heat-affected zone to modify the microstructure in the weld zone, resulting in an equiaxed structure similar to that of the base material. However, while heating the weld zone, it is necessary to keep the base material cool; thus, this method is complex and challenging to apply in cathode rollers with large diameters. Xu [

21] adopted post-welding annealing and sandblasting treatment, which was beneficial in refining the microstructure in the weld zone, but the sandblasting treatment only refined the grains on the surface layer of the cathode roller.

Therefore, the reported and existing technologies cannot effectively and conveniently solve the problem of the bright band resulting from the longitudinal weld due to the presence of microstructures with large grain sizes [

11,

12]. In this study, in order to promote the application of the welding method for the manufacturing of cathode roller titanium cylinder sleeves, different welding variables, including the welding groove, energy, and pass, are adopted. Moreover, severe deformation in the weld zone caused by different deforming methods followed by annealing is primarily explored in this study. The research goal is to develop a novel technology to effectively regulate the microstructure of the weld zone and heat-affected zone of a TA1 titanium plate, obtain a microstructure close to that of the base material, and thus promote the application of the welding method in the manufacturing of cathode rollers.

2. Materials and Methods

A TA1 titanium plate with high purity was selected as the material for this research, and its composition is presented in

Table 1, while its mechanical properties are listed in

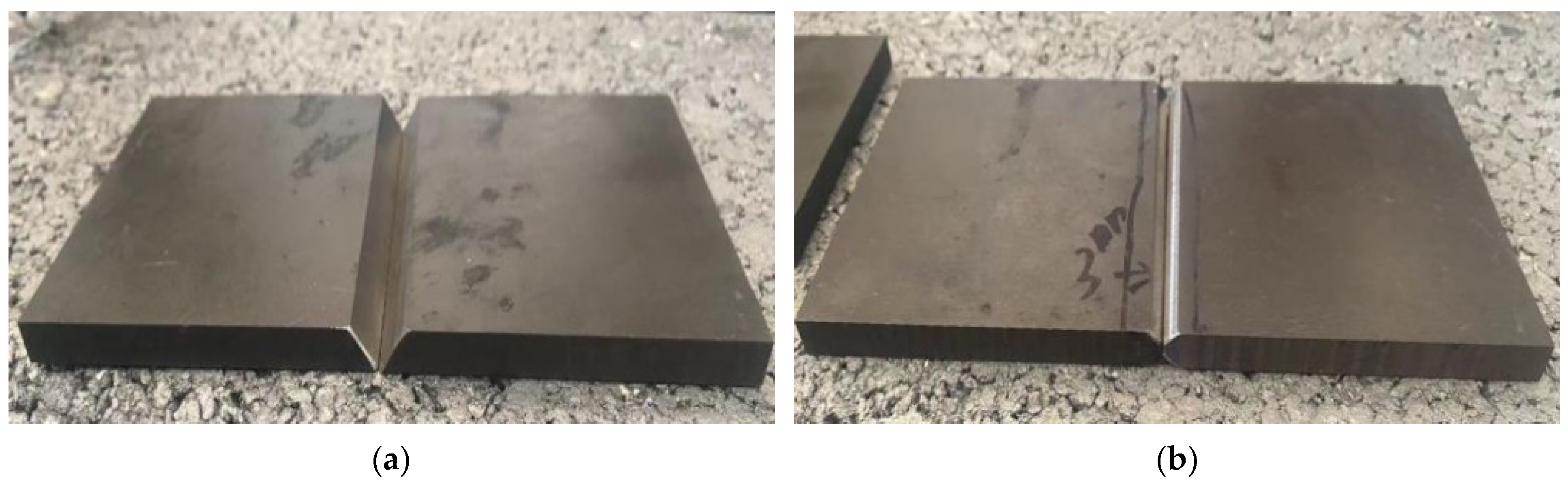

Table 2. Samples with dimensions of 80 mm × 30 mm × 8 mm were fabricated using wire-cut electrical discharge machining (WEDM). Welding grooves with a V shape and X shape were machined using a milling machine, and the morphologies of the two types of welding grooves are shown in

Figure 1, while their detailed dimensions are shown in

Table 3. The welding method employed in this research was manual tungsten inert gas (TIG) welding, performed by a qualified employee. The material of the filler wire was identical to the plate material of TA1, with a diameter of 2 mm. Argon gas, with purity of 99.99%, was used as the shielding gas.

As is well known, a V-shaped groove has the following advantages: it is easier to machine, and there is no need to turn it over during the welding process, enabling single-sided welding. However, this type of groove is more prone to deformation after welding, especially for thin plates; thus, it is mainly employed for medium- and thick-plate welding. In contrast, an X-shaped groove can reduce the volume of the weld metal by approximately 50% at the same thickness as compared to a V-shaped groove. Additionally, symmetrical welding with an X-shaped groove results in less residual deformation after welding. Given the advantages and characteristics of the two types of welding grooves, both V-shaped and X-shaped grooves were selected and explored in this study.

Three comprehensive experiments involving various welding and deformation processes were designed and conducted on the samples, which are described below.

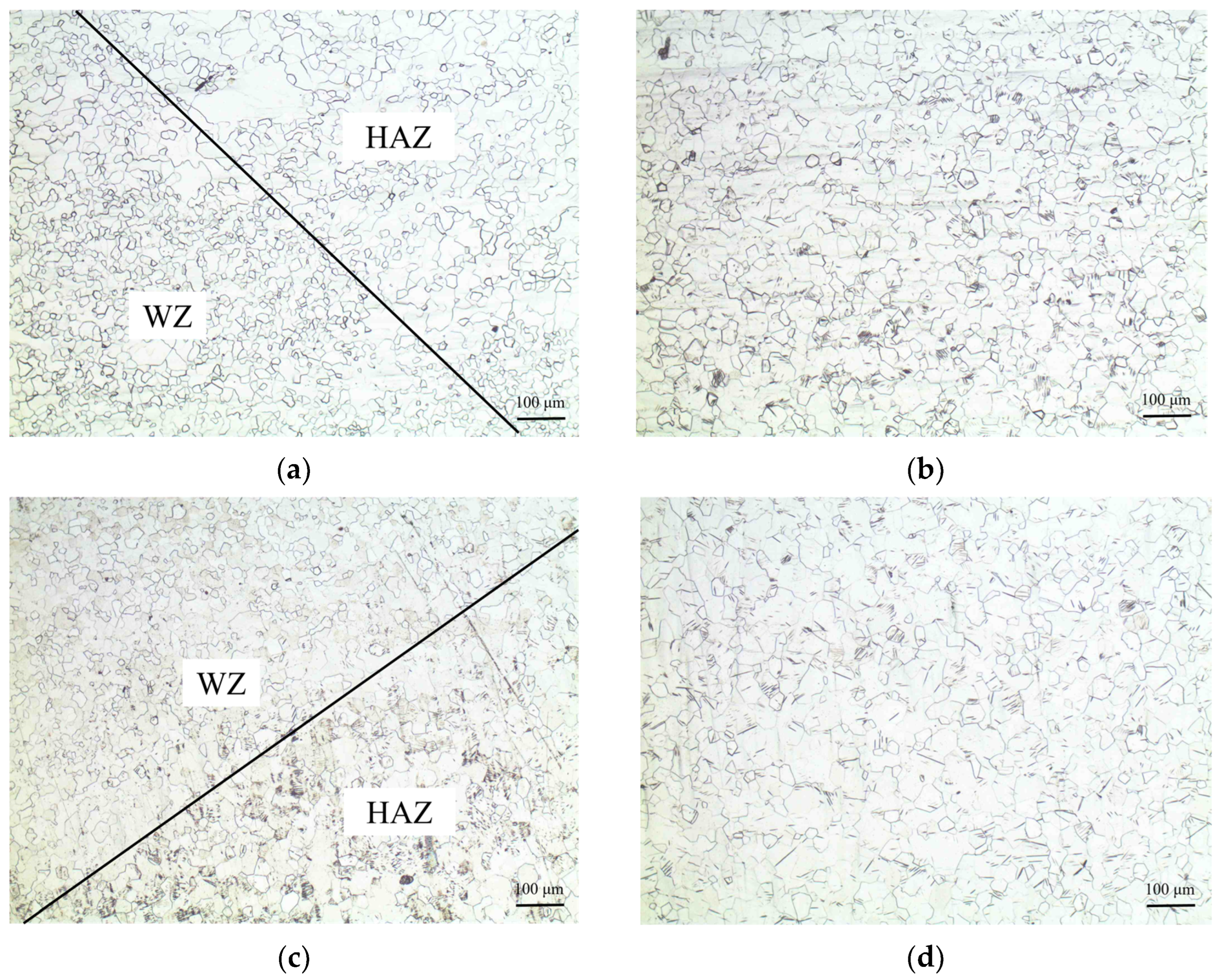

The first experiment: Both V-shaped and X-shaped grooves were used, and manual tungsten inert gas (TIG) welding was performed on titanium plates. The detailed welding parameters are shown in

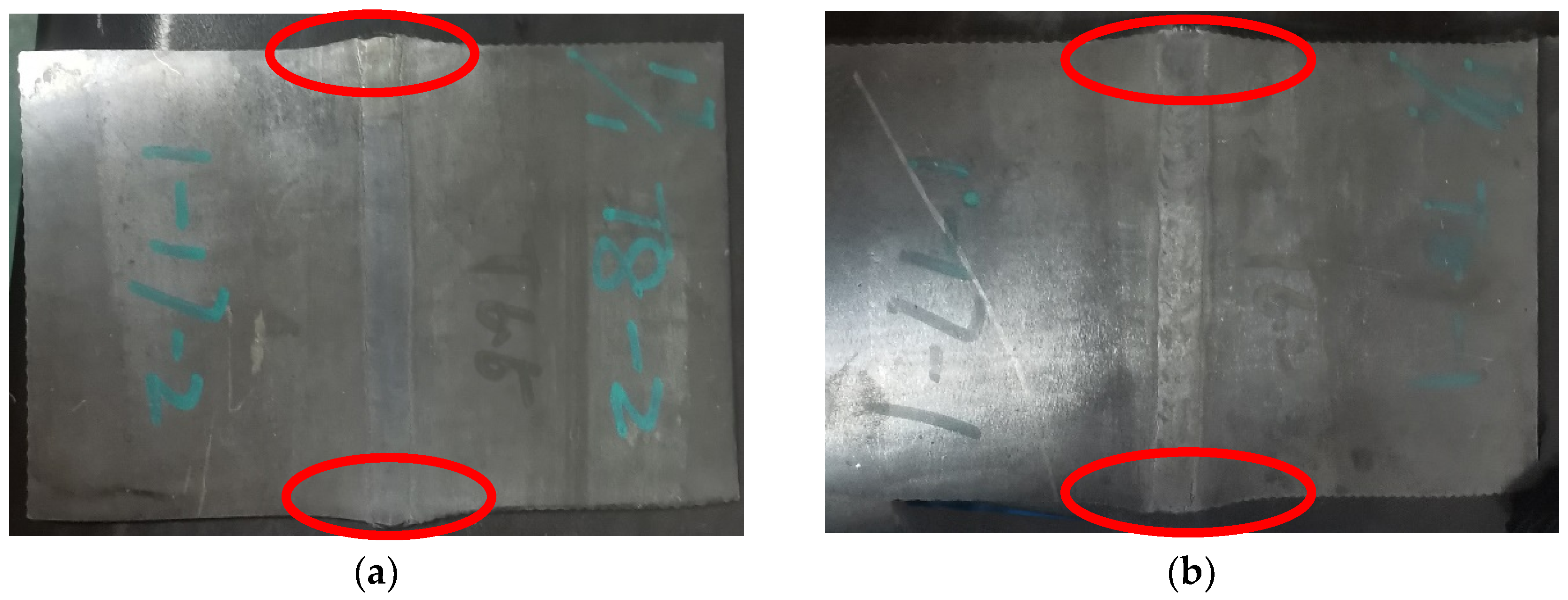

Table 4. Titanium plates with both types of grooves underwent the same number of welding passes, i.e., 12. Subsequently, the welded titanium plates were cold-pressed to 8 mm by a single operation using a 1600 T fast forging machine, with the thickness being consistent with that of the base material. In other words, the height of the weld bead was reduced by half, while the height of the base material remained unchanged.

The second experiment: Both V-shaped and X-shaped grooves were used again, and almost the same procedure as in Experiment 1 was adopted. However, the number of welding passes was decreased to 5, and the number of rolling passes was increased to 4. The weld seam of the titanium plates underwent 45% rolling deformation, and the base metal experienced 21% deformation.

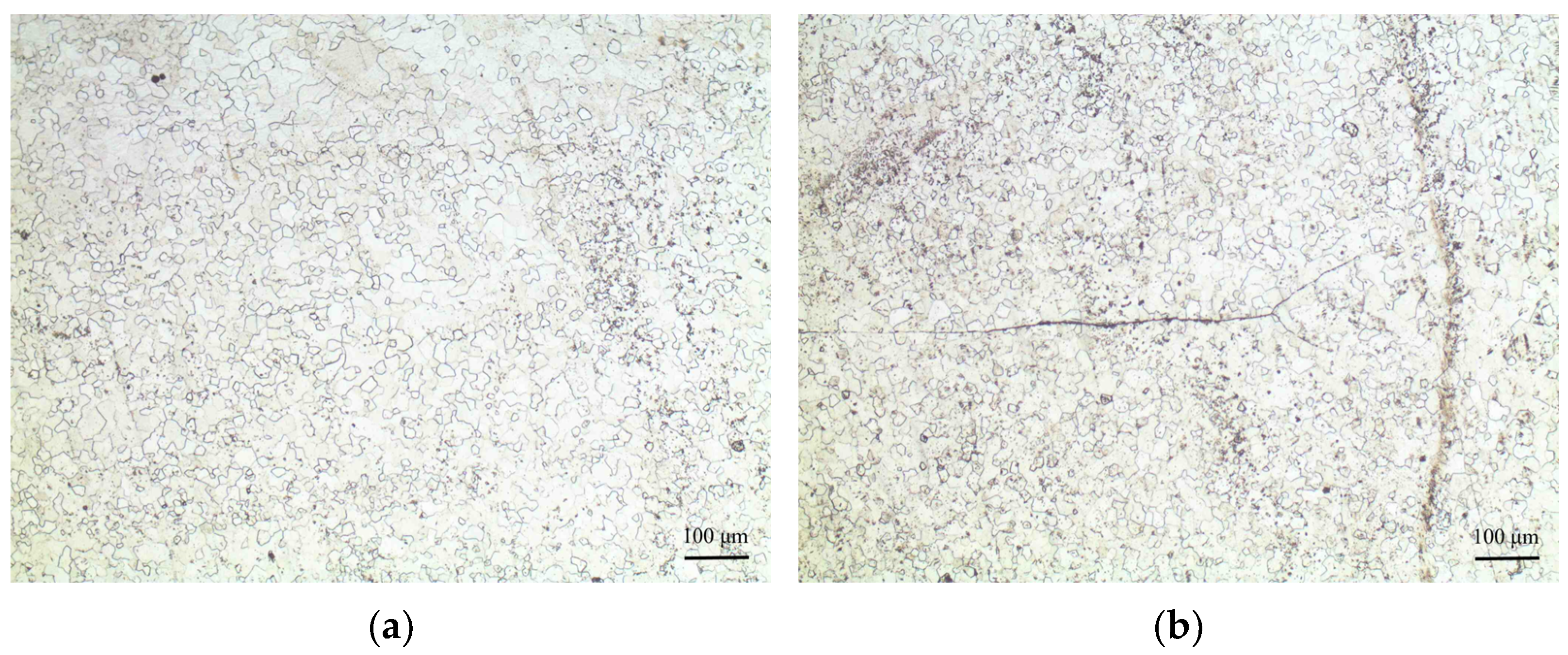

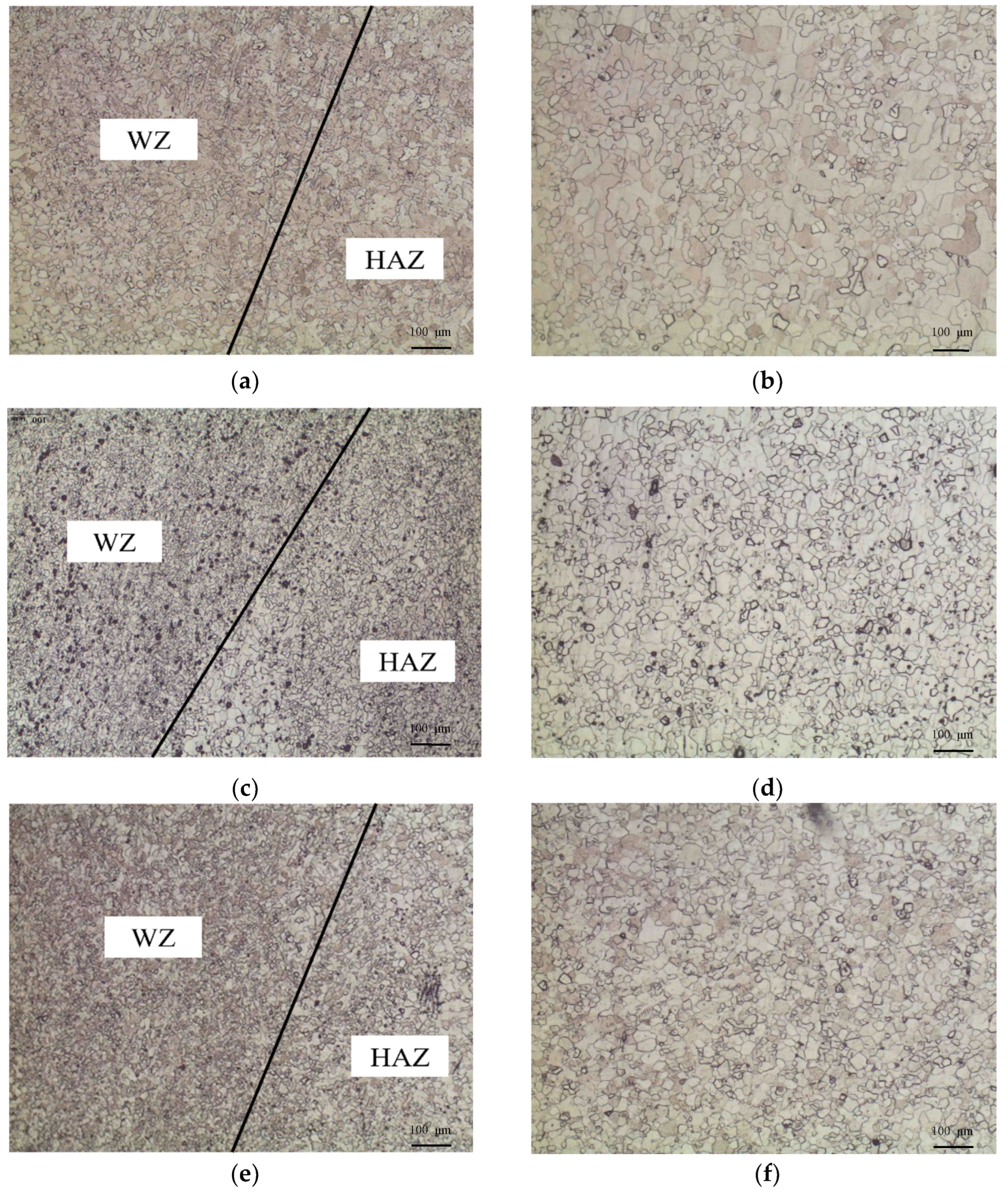

The third experiment: Only an X-shaped groove was used, and low-energy manual TIG arc welding with a lower welding current of 90 A was utilized. The number of welding passes was further decreased to 4, and the height of the weld bead remained consistent with that in the second experiment. Subsequently, the samples were processed through rolling passes of 6, 8, or 11 by a two-roll mill, and the total deformation of the weld seams was 45%, 55%, and 65%, while the deformation of the base metal was 21%, 35%, and 45%, respectively.

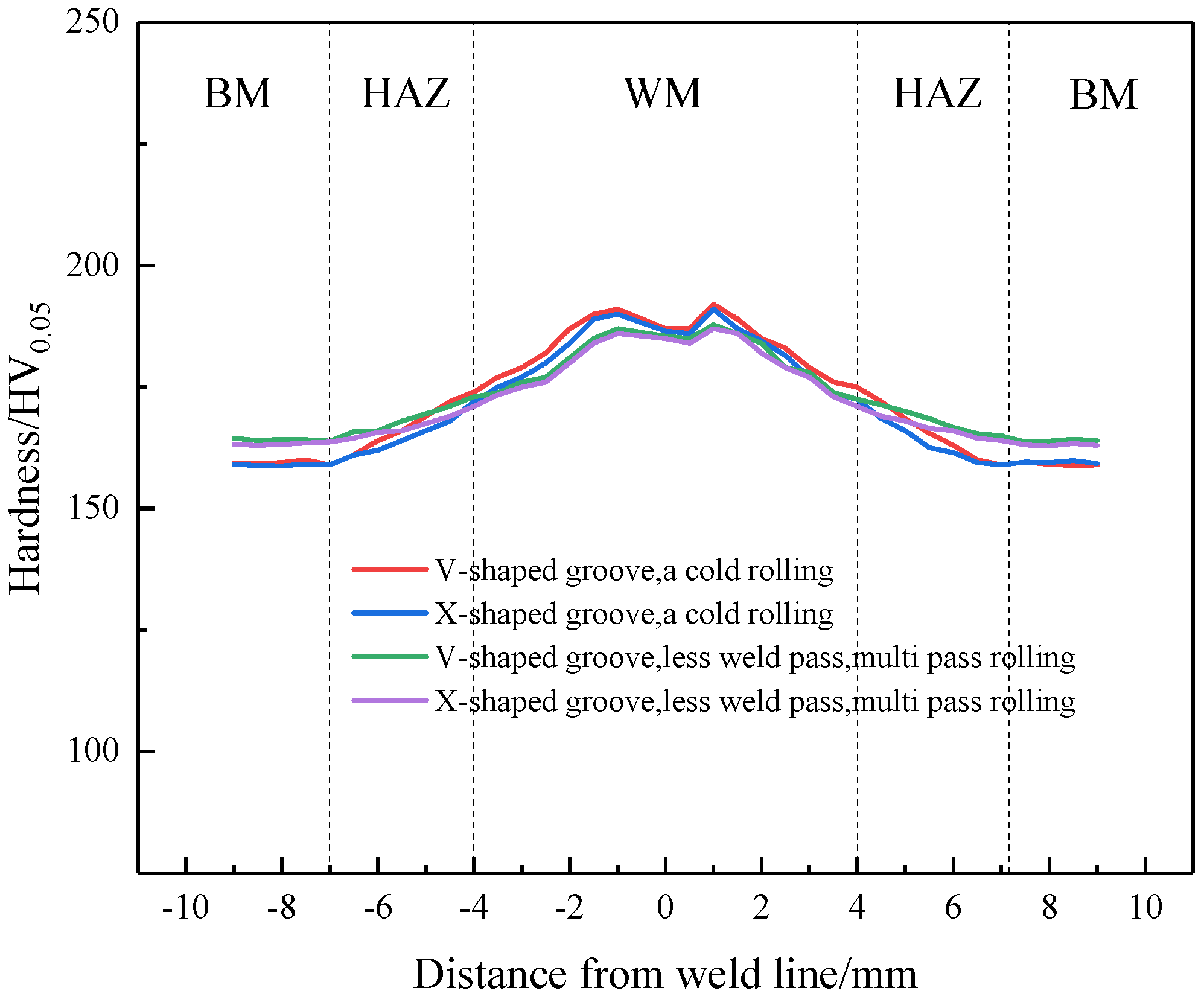

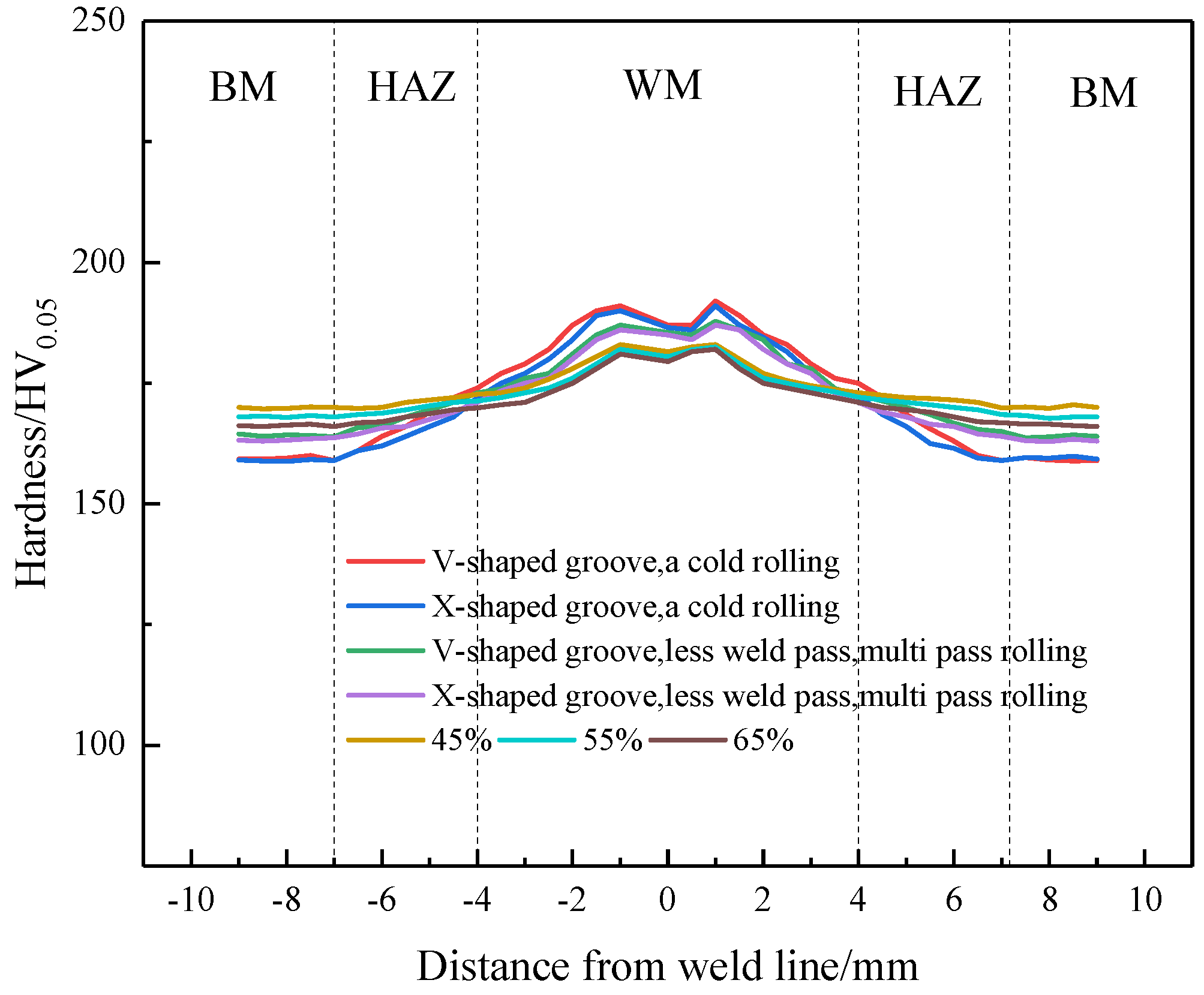

After the above three experiments involving various welding and deformation processes, all TA1 plates were annealed at 650 °C for a duration of 1 h in a BTF-1700C vacuum heat treatment furnace (Wuhan Fengshun Heat Treatment Technology Co., Ltd., Wuhan, China); then, wire cutting was employed to obtain samples from the junction between the weld area and the base metal of the TA1 plates. These samples were subsequently mounted on an XQ-2B metallographic sample mounting machine (Shanghai Shuyao Instrument Equipment Co., Ltd., Shanghai, China) at a temperature of 100 °C, with a holding time of 10 min. The mounted TA1 samples underwent sequential grinding using 80#, 400#, 800#, 1200#, and 2000# water sandpapers, followed by mechanical polishing on a YMP-2B metallographic sample grinding and polishing machine (Guangzhou Guru Tech Co., Ltd., Guangzhou, China). During the polishing process, a 50 nm alumina polishing solution was applied. Once the observed surfaces of the samples had achieved a scratch-free mirror finish, corrosion was performed using a solution composed of HF:HNO3:H2O in a ratio of 2:1:40. The microstructure of each area was observed using a DMI-3000M optical microscope (Shanghai Optical Instrument Factory, Shanghai, China), and the grain size was assessed via the intercept method. The Vickers hardness was measured using an HVS-30 Vickers hardness tester (Beijing Woway Technology Co., Ltd., Beijing, China).

4. Analysis

By systematically analyzing the results of the three experiments conducted under different conditions, a comparative evaluation of the grain size refinement effects across different regions of the titanium plate can be achieved, as presented in

Table 13.

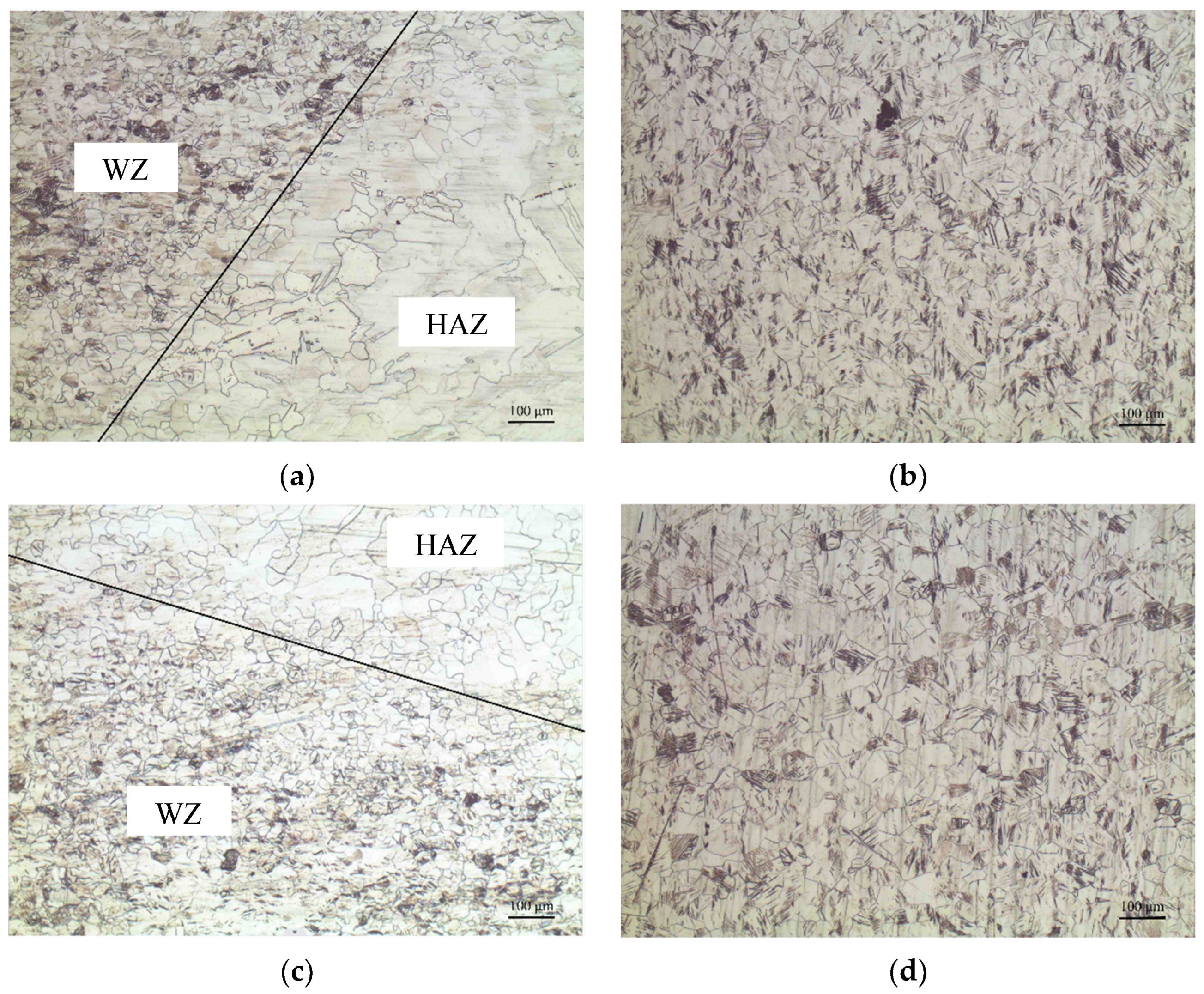

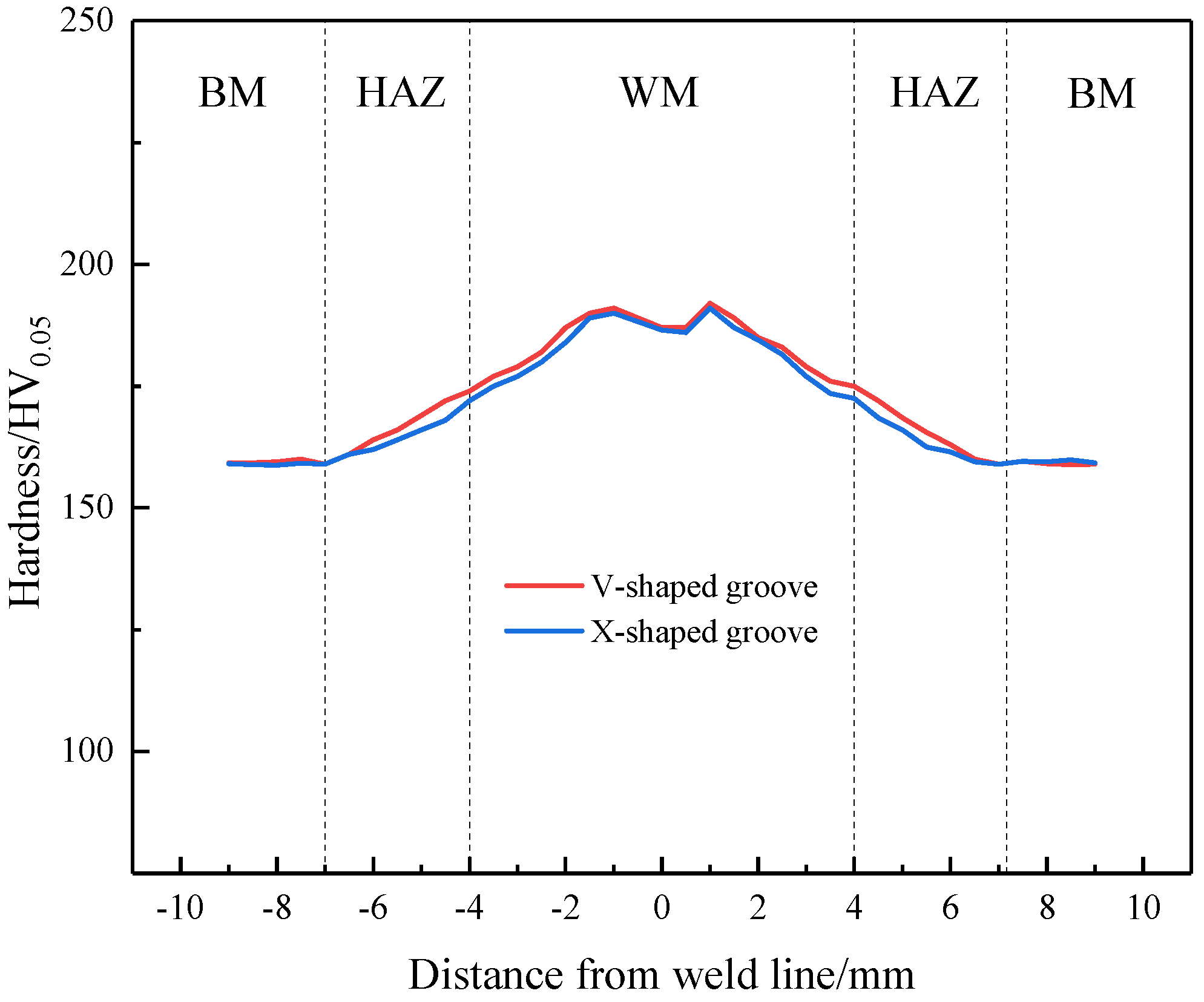

In comparison with the V-type groove, the X-type groove welding technique involves reduced metal deposition, thereby decreasing the required heat input for welding. Heat is transferred and dispersed between the two V-type grooves, leading to more uniform heat distribution. Consequently, the X-type groove is more effective in refining the microstructure of the heat-affected zone.

As for the selection of the number of welding passes, when the weld seam is subjected to excessive welding passes, corresponding to multiple heating and cooling cycles, it results in increased heat input. Each thermal cycle promotes grain growth within the heat-affected zone (HAZ), and repeated heating can lead to more complex microstructural changes, such as the formation of coarser grains. Consequently, reducing the number of welding passes to a suitable value can facilitate the attainment of finer grains.

Lowering the welding current typically reduces the energy input, thereby decreasing the generated heat and mitigating the risk of grain coarsening due to elevated temperatures. Therefore, when the welding current is reduced to a low energy level of 90 A, the microstructure in all regions of the weld seam exhibits finer grains.

Based on the results, it can also be concluded that increasing both the number of rolling passes and the degree of rolling deformation can effectively refine the microstructure in various regions of the welded plate. This refinement mechanism primarily results from the generation of high-density dislocations within α-Ti grains during rolling deformation, which form a sub-grain boundary network. The strain energy accumulated during cold rolling subsequently provides an enhanced driving force for recrystallization [

22].

5. Conclusions

A novel composite technology consisting of low-energy and fewer-pass welding combined with multi-pass rolling deformation and vacuum annealing treatment was developed for high-purity TA1 titanium plates used for cathode rolls, and its comprehensive effects on the microstructure and hardness of the weld zone and heat-affected zone (HAZ) was investigated in this study. The research results show that, after multi-pass welding followed by single-pass severe cold rolling, weld cracking occurs. By employing X-type grooves, reducing the number of welding passes, and subsequently applying multi-pass rolling deformation treatment, weld cracking is effectively prevented. After annealing heat treatment, the grain size in all regions is significantly refined compared to single-pass severe cold pressing, which facilitates the refinement of the microstructure in both the weld zone and HAZ, thus improving the grain uniformity and reducing the microhardness variations across the welded plate, indicating that the X-type groove welding method is more effective for grain refinement. Under low-energy welding conditions with a current of 90 A, the number of welding passes can be further reduced to four while maintaining a consistent weld height, thereby avoiding coarse grains in the HAZ caused by excessive heat from multiple passes. Additionally, after 45% multi-pass weld rolling and annealing heat treatment, the grains in the HAZ are significantly refined and indistinguishable from those of the base metal, with the overall microhardness variation minimized. Through the systematic exploration of this manufacturing technology, it is found that low-energy welding with four welding passes, followed by multiple passes of rolling with a deformation ratio of 45% and, finally, annealing at 650 °C for 1 h, is the optimal process to refine the grain size and improve the properties of welded TA1 titanium plates for cathode rollers. Therefore, this research provides a robust technical foundation for the advancement of the “welding” process of titanium cylinder sleeves for cathode roll surfaces.