The analyzed corpus comprises 18,363 publications—exclusively research articles and review papers—spanning 1361 journals, contributed by 61,038 authors from 32,821 institutions across 708 countries or regions. This extensive coverage underscores the global and interdisciplinary nature of coating-protection research between 2015 and 2025, reflecting substantial collaboration between academia and industry.

The subsequent sections systematically address: (1) annual publication trends to characterize output dynamics; (2) national and institutional collaboration networks to map geographic and organizational contributions; (3) journal co-occurrence analysis to identify key dissemination platforms; (4) cross-disciplinary domain mapping to reveal interdisciplinary linkages; (5) keyword contribution and clustering analyses to decode conceptual structures; (6) burst detection of emerging research hotspots to pinpoint transformative topics; and (7) co-citation analysis of the seminal literature to trace intellectual foundations. This structured approach integrates quantitative metrics and visual analytics to comprehensively characterize the field’s evolutionary landscape.

3.1. Analysis of Article Output Characteristics

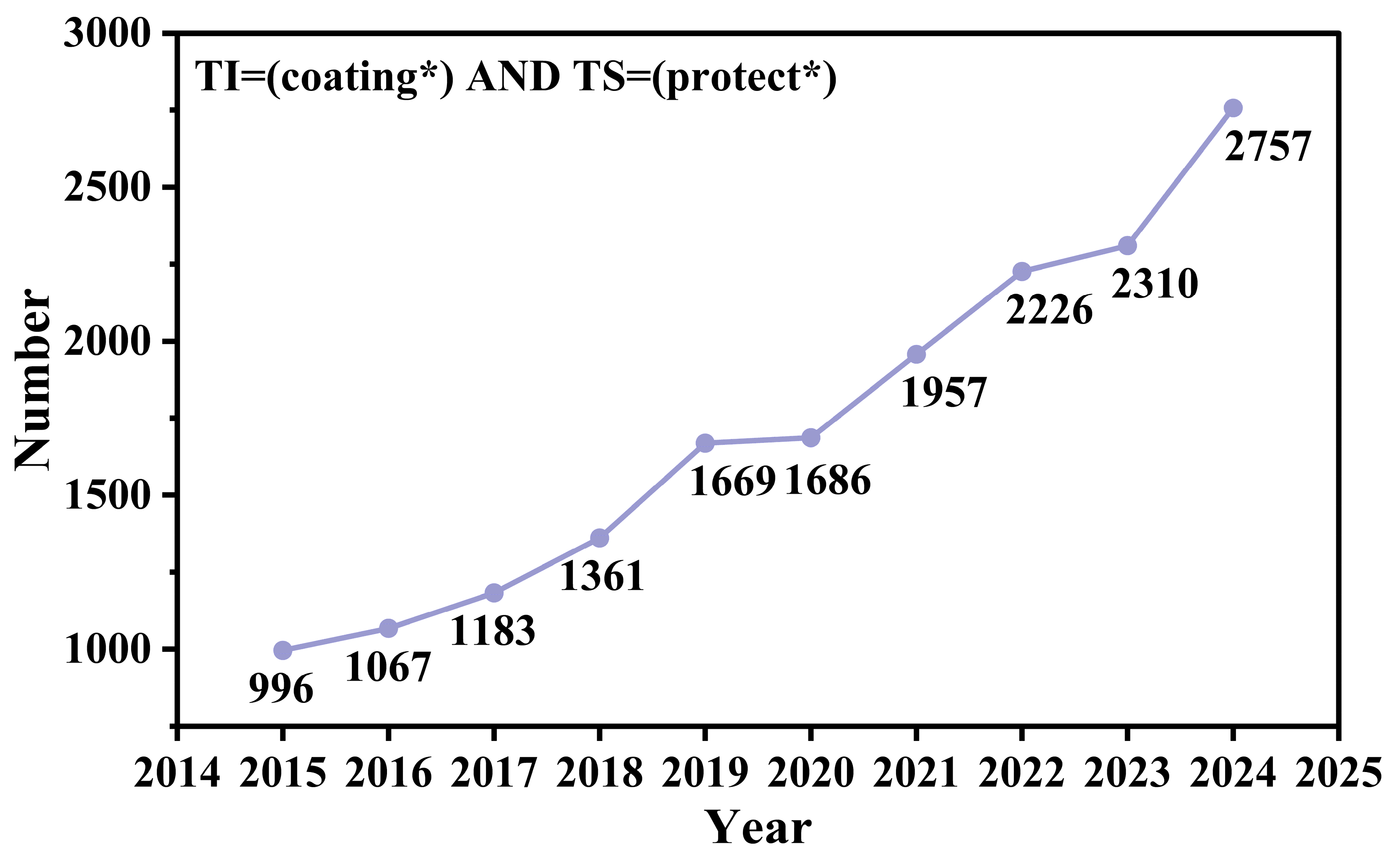

3.1.1. Trend Analysis of Issuance

Figure 1 illustrates the annual publication trends in the field of coating protection from 2015 to 2024, excluding the incomplete data for 2025. Over this decade, the number of publications exhibited a remarkable upward trajectory, growing from 996 in 2015 to a peak of 2757 in 2024, which underscores the increasing global research interest and momentum in this domain.

From 2015 to 2019, the annual publication volume experienced steady acceleration. The number of publications rose from 996 in 2015 to 1669 in 2019, reflecting a period of robust foundational development. This growth was likely fueled by escalating demands for advanced coating-protection technologies in industries such as aerospace, automotive, and manufacturing, prompting intensified research efforts. In 2020, the number of publications reached 1686, showing a minor increment compared to 2019. This slight slowdown might be attributed to transient disruptions in research activities. However, from 2021 to 2024, the field rebounded vigorously. Publications surged from 1957 in 2021 to 2757 in 2024, marking a significant phase of expansion. This later period likely witnessed increased translational research and industrial applications, as accumulated knowledge from earlier years paved the way for practical innovations.

Overall, the trend from 2015 to 2024 highlights two distinct phases: a rapid growth stage (2015–2019) centered on material science and coating formulation advancements, and a subsequent phase of stable, yet robust, expansion (2021–2024) characterized by applied research and real-world validation. This evolution aligns with the typical trajectory of emerging research fields, where initial theoretical explorations transition into broader practical implementations.

3.1.2. Country Analysis

This analysis of the collaborative network among countries/regions in the coating-protection field (as shown in

Figure 2) reveals distinct patterns. Node size denotes publication count, while centrality reflects a country’s role in connecting collaboration networks.

As presented in

Table 1, People’s R China leads with a publication count of 8502, underscoring its substantial research input and output. The USA (1299), India (1257), and Iran (944) follow, indicating their significant engagement. In terms of centrality, England (0.15) plays a pivotal bridging role, facilitating information and resource exchange. Spain (0.13), France (0.13), and Italy (0.11) also hold key positions, leveraging their strong foundations in related disciplines.

China collaborates widely with nations like the USA and India, promoting international knowledge exchange. The USA actively partners with various countries, capitalizing on its research strengths. However, challenges such as cultural–institutional differences and profit-sharing issues may hinder deeper collaboration. Establishing clearer communication and fair benefit-distribution systems is vital to enhance global cooperation, integrate resources, and advance coating-protection research collectively.

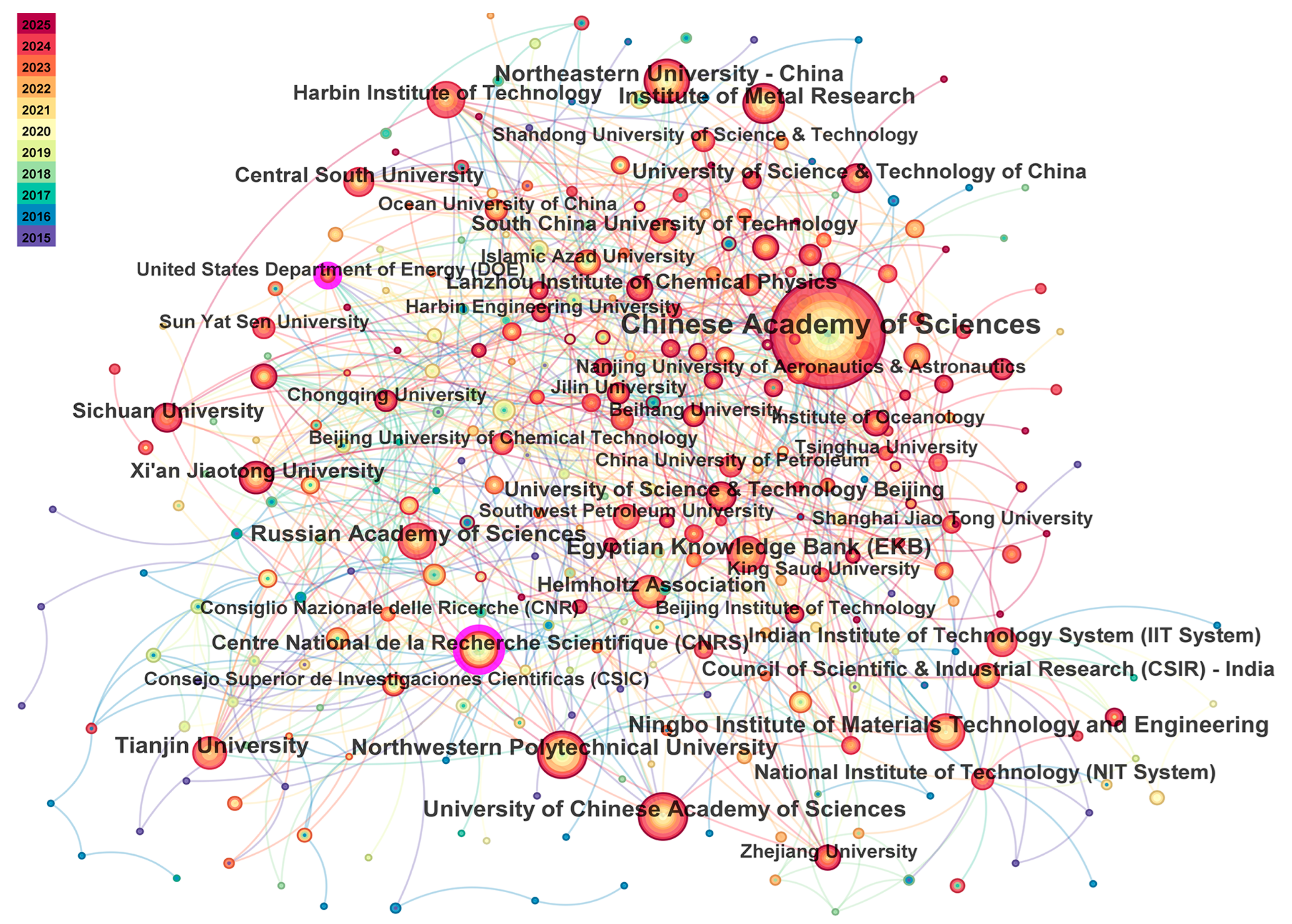

3.1.3. Institution Analysis

Table 2 and

Figure 3 delineate the institutional landscape of coatings and materials research, dominated by the Chinese Academy of Sciences (CAS) (1291 publications, centrality = 0.03) and Northwestern Polytechnical University (NWPU) (387 publications, centrality = 0.06). CAS leads globally, with its Ningbo Institute of Materials Technology and Engineering (282 publications) and Institute of Metal Research (291 publications) specializing in corrosion-resistant coatings and self-healing materials. NWPU distinguishes itself in ultra-high-temperature ceramics (UHTCs), as exemplified by their design of high-entropy environmental barrier coatings for C/SiC composites, aligning with aerospace demands for hypersonic vehicles [

42,

43].

Institutions with high centrality act as interdisciplinary bridges. The Centre National de la Recherche Scientifique (CNRS) (241 publications, centrality = 0.1) and the United States Department of Energy (DOE) (113 publications, centrality = 0.13) emerge as critical connectors (

Figure 3). CNRS coordinates European collaborations in icephobic coatings for aerospace, while the DOE leads in energy-related materials, such as boron nitride-based solid electrolyte interfaces for lithium-metal batteries. Their high centrality scores reflect cross-border partnerships (e.g., CNRS-France/DOE–USA collaborations in atomic layer deposition), showcasing the field’s reliance on international expertise [

44,

45,

46].

Chinese institutions (CAS, NWPU, University of Chinese Academy of Sciences) dominate applied materials innovation, with 68% of the top 10 institutions originating from China (

Table 2). For instance, CAS’s Shanghai Institute of Ceramics leads UHTC composite research, while NWPU pioneers micro/nano-reinforced C/C composites for ablation resistance [

47,

48]. Western institutions, such as the Helmholtz Association (235 publications) and the Russian Academy of Sciences (267 publications), focus on theoretical modeling (e.g., first-principles calculations for thermal-barrier coatings) and nuclear materials, respectively [

49,

50]. The Egyptian Knowledge Bank (EKB) (305 publications) highlights rising contributions from emerging regions, particularly in nanocomposite coatings for electrochemical corrosion protection [

49,

51].

The network’s temporal evolution (

Figure 3 timeline) reveals shifting priorities: pre-2015 research centered on barrier coatings (e.g., h-BN in epoxy), while post-2020 work emphasizes smart systems (self-healing polymers) and sustainability (e.g., bio-inspired anti-icing coatings). Institutions like the Ningbo Institute of Materials Technology (282 publications) exemplify this shift, integrating layered double hydroxides for active corrosion inhibition. Centrality scores correlate with translational impact: the DOE’s high centrality (0.13) stems from its role in scaling lab discoveries (e.g., TiO

2-cobaloxime photocathodes) toward commercial applications [

52,

53,

54].

Despite their dominance, discipline-specific collaborations remain underexplored. For example, the Harbin Institute of Technology (229 publications) excels in mechanical characterization, yet lacks strong ties with bio-inspired materials labs [

55,

56]. Future efforts should bridge nanomaterials (e.g., CAS’s graphene-oxide research) with machine learning (e.g., Helmholtz’s computational materials design) to accelerate discovery [

57,

58]. The rising role of China (6/10 top institutions) suggests opportunities for joint initiatives in standardizing testing protocols for extreme environment coatings, addressing global challenges in aerospace and energy [

59,

60].

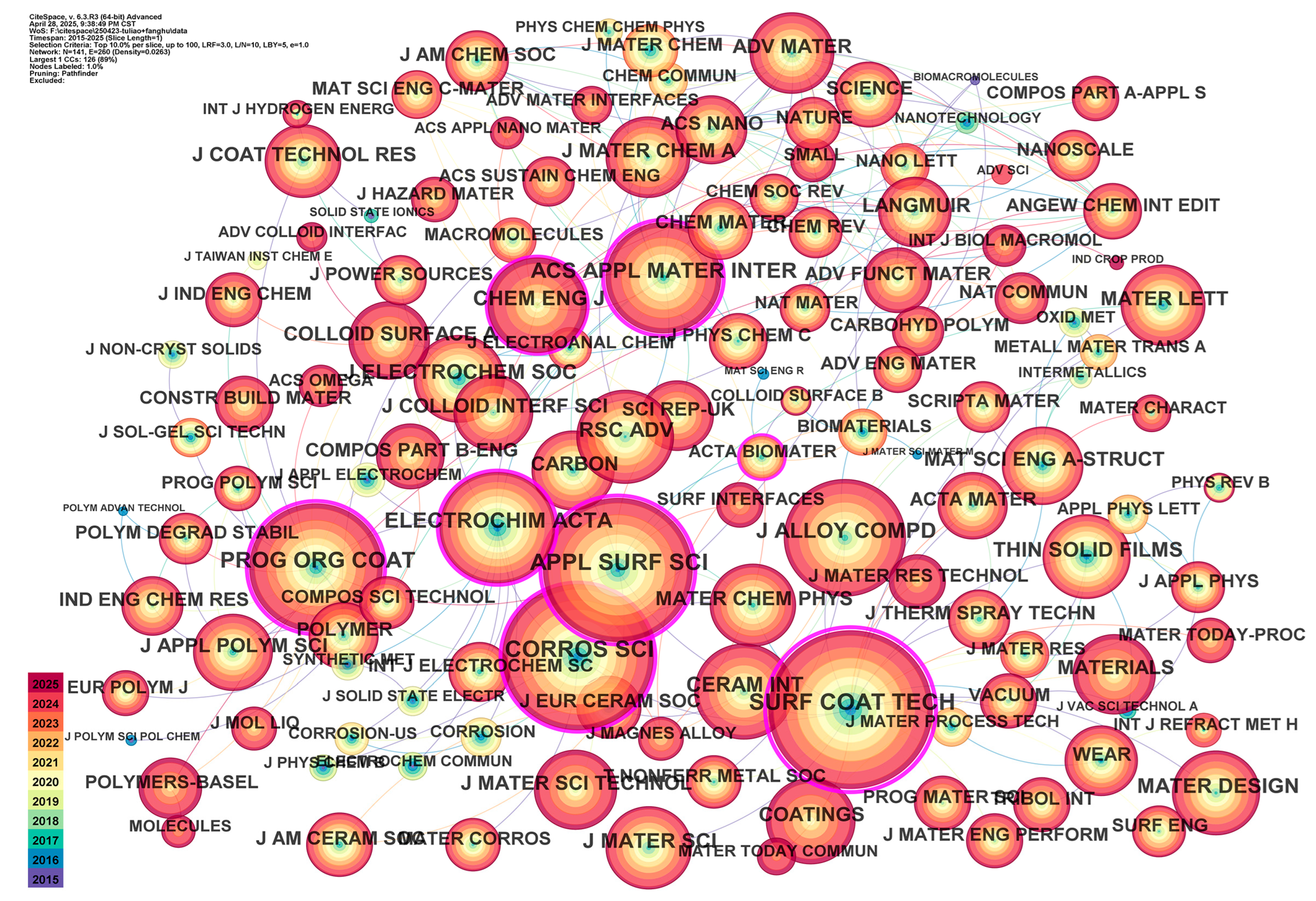

3.1.4. Analysis of Cited Journals

The landscape of cited journals in the field of coatings and materials science is dominated by a select group of high-impact publications that serve as pivotal knowledge hubs, as outlined in

Table 3 and visualized in

Figure 4. These journals exhibit distinct roles in shaping research directions, facilitating interdisciplinary dialogues, and disseminating groundbreaking findings.

Surface & Coatings Technology (cited 11,385 times, centrality = 0.69) stands out as the most influential journal, reflecting its dominance in surface engineering and protective coatings. Its publications, such as reviews on plasma electrolytic oxidation coatings for light metals and antibacterial titanium surface modifications, highlight its focus on industrial applications and translational research. The journal’s high centrality (0.69) underscores its role as a nexus connecting materials science, engineering, and corrosion science, evident in its coverage of both fundamental mechanisms (e.g., particle incorporation in coatings) and applied solutions (e.g., anti-icing coatings for aerospace).

Corrosion Science (9673 citations, centrality = 0.29) and

Applied Surface Science (9598 citations, centrality = 0.47) rank as key platforms for fundamental studies.

Corrosion Science excels in mechanistic research, such as self-healing mechanisms in organic coatings and graphene-oxide-based anticorrosive composites, while

Applied Surface Science emphasizes nanomaterial-enabled surface modifications, including amino-functionalized graphene oxide for enhanced barrier properties. Their high citation counts and moderate centrality indicate a broad disciplinary appeal, bridging chemistry, materials science, and electrochemistry [

48,

61,

62,

63].

Journals with high centrality act as interdisciplinary connectors.

Progress in Organic Coatings (7776 citations, centrality = 0.53) specializes in silicone-based protective materials (e.g., PDMS derivatives for anti-biofouling coatings), linking polymer science with environmental protection. ACS’s

Applied Materials & Interfaces (5705 citations, centrality = 0.44) integrates nanotechnology and engineering, showcasing works on photothermal deicing coatings and atomic-layer deposition for stable solid electrolytes, thus fostering connections between materials synthesis and energy applications. In contrast, journals like the

Journal of Alloys and Compounds (6598 citations, centrality = 0.06) and

Ceramics International (4581 citations, centrality = 0.02) exhibit a specialized focus on high-temperature materials (e.g., ultra-high-temperature ceramics) and ceramic composites, respectively. While their citation counts are substantial, lower centrality scores indicate narrower disciplinary scopes, primarily serving materials science and engineering communities [

48,

56].

All of the top-cited journals peaked in impact around 2015, reflecting a decade of rapid growth in nanocomposite coatings, self-healing materials, and surface engineering. Surface & Coatings Technology and Corrosion Science led this surge, with seminal reviews on self-healing mechanisms and graphene-based coatings driving subsequent research waves. Regionally, Elsevier journals dominate the list (7/15), highlighting European and North American editorial influence, while Chinese contributions (e.g., the Journal of Materials Science & Technology) are emerging, though with lower centrality, indicating opportunities for increased global collaboration.

Notable gaps include the underrepresentation of journals focusing on sustainable coatings (e.g., bio-based polymers) and computational modeling (e.g., machine learning for coating design). Journals like ACS’s

Sustainable Chemistry & Engineering (not in the top list) could bridge these areas, while high-centrality journals like

Surface & Coatings Technology are poised to integrate emerging trends, such as AI-aided coating design and multi-functional nanocomposites for extreme environments [

44,

48,

56].

In summary, cited journals form a hierarchical network where high-impact titles drive interdisciplinary progress, while specialized publications deepen niche areas. Their roles in disseminating both fundamental and applied research underscore the field’s reliance on robust academic platforms to translate scientific insights into technological innovation.

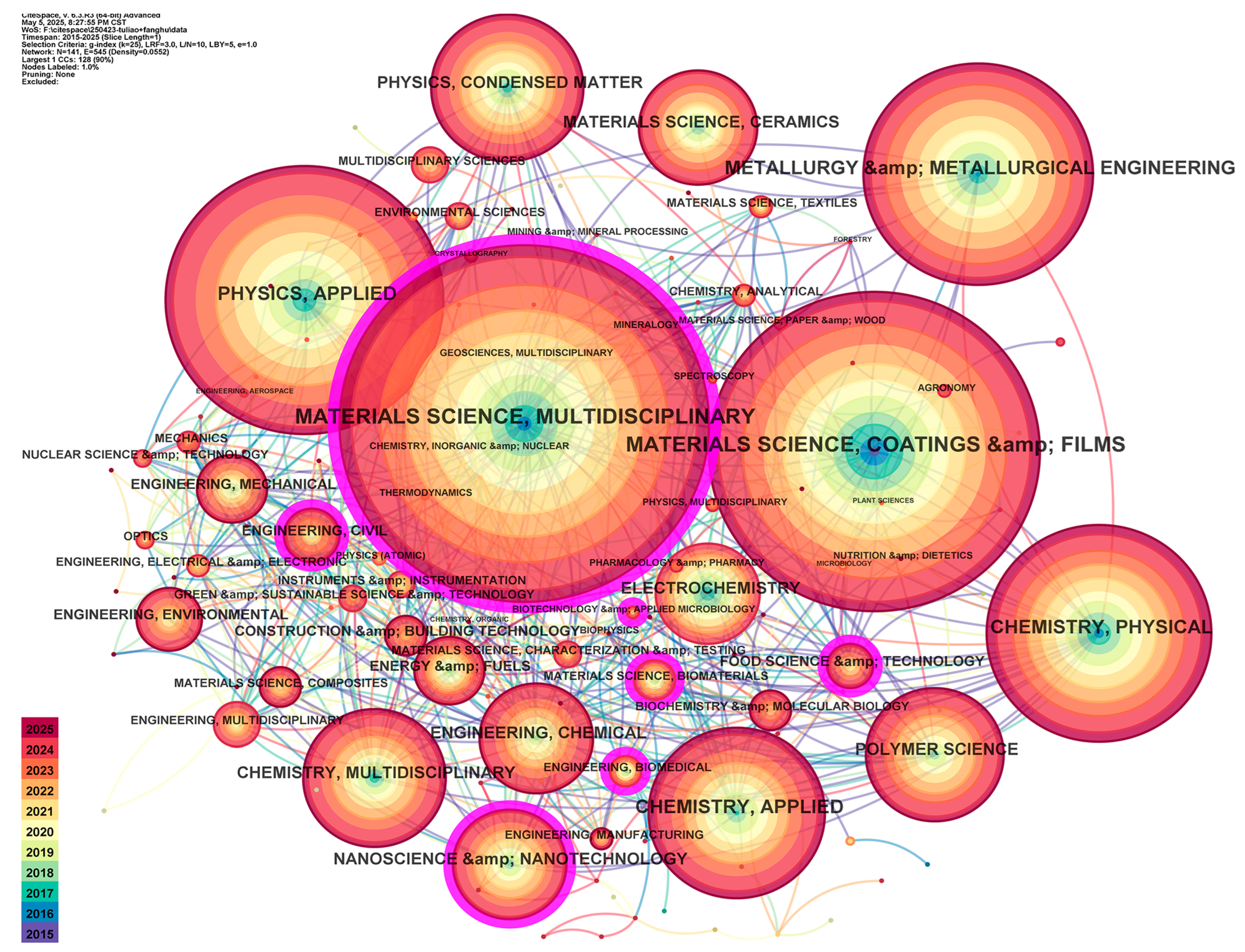

3.1.5. Subject Analysis

The subject category co-occurrence network, depicted in

Figure 5 and quantified in

Table 4, reveals a hierarchical structure of disciplinary interactions in coatings and materials research, dominated by Materials Science, Multidisciplinary (6671 counts, centrality = 0.39) as the pivotal hub connecting diverse scientific domains. This analysis underscores the field’s inherently interdisciplinary nature, with key subject categories forming interconnected clusters that drive innovation.

Materials Science, Multidisciplinary (centrality = 0.39) serves as the nucleus, encompassing foundational research on nanocomposite coatings, self-healing mechanisms, and surface engineering (e.g., amino-functionalized graphene oxide in epoxy coatings). Its high centrality reflects strong linkages with Physics, Applied (4108 counts, centrality = 0.04) and Chemistry, Physical (2563 counts, centrality = 0.09), evident in studies combining electrochemical impedance spectroscopy (EIS) with nanomaterial synthesis. These disciplines collectively advance understanding of coating durability, corrosion mechanisms, and functional material design. Materials Science, Coatings and Films (5122 counts) ranks second in publication volume but exhibits zero centrality, indicating a specialized focus rather than bridging roles. This category specializes in protective coatings (e.g., PDMS-based silicone films for anti-biofouling) and surface modification techniques (e.g., plasma electrolytic oxidation for light metals), catering to industrial and aerospace applications. Its disciplinary isolation highlights the need for stronger integration with adjacent fields like nanotechnology and engineering [

64,

65,

66,

67].

Subjects with moderate centrality act as critical connectors. Engineering, Civil (316 counts, centrality = 0.15) and Engineering, Biomedical (127 counts, centrality = 0.14) bridge materials science with practical applications: the former focuses on blast-resistant polyurea coatings for concrete structures, while the latter explores antibacterial titanium surfaces for orthopedic implants. Their roles demonstrate the translation of material innovations into civil infrastructure and medical devices, underscoring demand-driven research. Nanoscience and Nanotechnology (897 counts, centrality = 0.13) emerges as an enabler, facilitating nanocomposite development (e.g., superhydrophobic ZIF-8 coatings on Mg alloys) and stealth drug-delivery systems. Its integration with Polymer Science (1091 counts, centrality = 0.09) drives smart coatings responsive to environmental stimuli, such as pH- or temperature-triggered self-healing polymers [

68,

69,

70,

71].

European and Chinese institutions dominate Materials Science, Coatings and Films, reflecting strong industrial R&D ecosystems (e.g., CNRS’s work on plasma electrolytic oxidation). In contrast, Engineering, Biomedical is led by North American and European groups, focusing on biocompatible coatings for implantable devices. Temporally, all of the top categories peaked post-2015, coinciding with advances in nanomaterial synthesis (e.g., graphene oxide, hexagonal boron nitride) and computational modeling, which accelerated interdisciplinary collaborations [

72,

73,

74].

Notable gaps include understudied intersections like Sustainability Science and Environmental Engineering, crucial for developing eco-friendly coatings (e.g., bio-based polymers). Machine Learning and Artificial Intelligence represent emerging frontiers, yet are absent in the top categories, indicating opportunities for data-driven coating design. Strengthening ties between Materials Science, Biomaterials (240 counts, centrality = 0.11) and Applied Microbiology (64 counts, centrality = 0.11) could address biofilm-related challenges in medical implants, leveraging antibacterial nanocomposites. In summary, the subject landscape is characterized by a core-periphery structure, with materials science as the anchor and engineering/chemistry as key partners. Future progress will depend on fostering deeper interdisciplinary collaborations, particularly in sustainability and digital innovation, to address global challenges in infrastructure protection, energy storage, and biomedical engineering [

62,

75,

76].

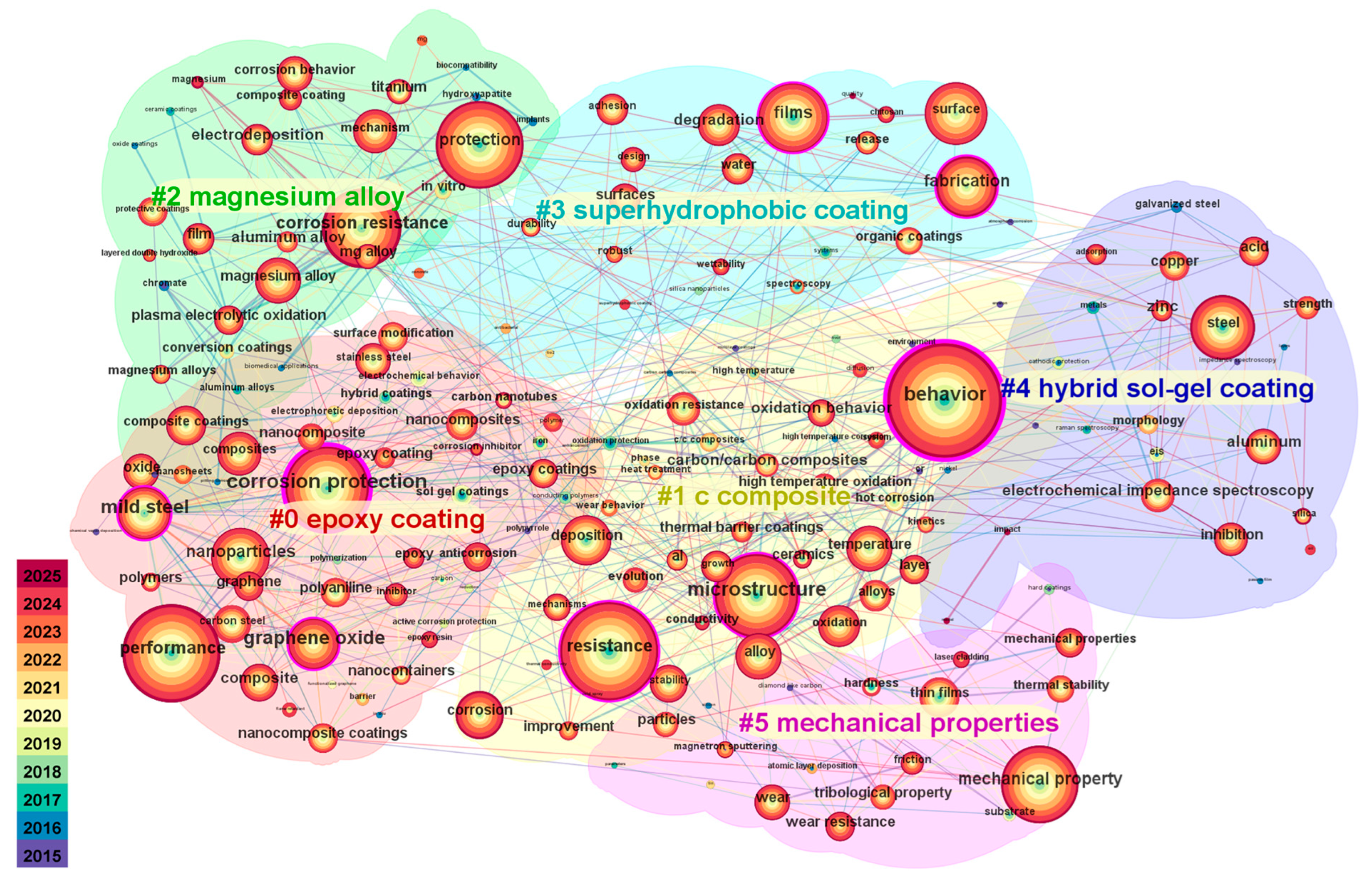

3.2. The Key Areas and Hot Issues of Research

3.2.1. Keywords Co-Occurrence Network

The keyword co-occurrence network, visualized in

Figure 6 and quantified in

Table 5, reveals a dense web of interconnected themes central to coatings research, dominated by behavior (3763 counts, centrality = 0.2), performance (2763 counts, centrality = 0.07), and resistance (2692 counts, centrality = 0.17). These keywords form the core of a hierarchical structure, linking fundamental material properties with applied engineering solutions.

- (1)

Corrosion Protection and Resistance

The keywords “corrosion protection” (2197 counts) and “corrosion resistance” (1946 counts) anchor the network, reflecting the field’s primary focus on mitigating metal degradation. Studies frequently link these to nanoparticles (1032 counts), such as graphene oxide and layered double hydroxides (LDH), which enhance barrier properties via mechanisms like improved dispersion in epoxy matrices. The high centrality of behavior (0.2) underscores its role as a bridge between material characterization (e.g., electrochemical impedance spectroscopy, EIS) and functional outcomes, such as hydrolytic-degradation resistance in waterborne coatings [

77];

- (2)

Material Design and Microstructure

“Microstructure” (2033 counts, centrality = 0.09) and “mechanical property” (1787 counts) cluster with “fabrication” (1138 counts), highlighting efforts to tailor coating architectures for durability. For example, sol-gel processes enable the precise control of silica-nanoparticle-decorated graphene-oxide hybrids, enhancing interfacial adhesion and reducing cathodic delamination. Such designs align with the rising interest in nanocomposite coatings (e.g., polyvinyl butyral/GO composites for aluminum alloys), which merge hydrophobicity and mechanical robustness [

78,

79,

80,

81];

- (3)

Interdisciplinary Linkages

Terms like “surface” (1290 counts) and “steel” (1219 counts) connect to “mild steel” (956 counts), indicating a focus on industrial substrates. Studies on polyaniline-functionalized graphene coatings for mild steel demonstrate how surface modification boosts corrosion resistance through redox catalytic effects, illustrating the translation of nanoscale design to practical engineering solutions [

82,

83,

84].

The co-occurrence of “performance” with “nanoparticles” and “film” (1582 counts) highlights synergy in developing multifunctional systems, such as superhydrophobic coatings combining polydopamine-modified GO with epoxy matrices for self-healing and anticorrosion dual functionality. These linkages reflect a shift toward integrated solutions addressing multiple challenges (e.g., mechanical wear and chemical degradation) simultaneously;

- (4)

Temporal Trends and Emerging Subfields

Post-2015, keywords like “self-healing” and “nanocomposite” gain prominence, aligning with the rise of smart materials. For instance, shape-memory polymers embedded with corrosion inhibitors exhibit adaptive repair under thermal stimuli, showcasing the fusion of material science with responsive engineering. The growing interest in biocompatibility (implied via biomedical coatings) and sustainability (e.g., eco-friendly waterborne formulations) signals emerging frontiers, though these appear as peripheral nodes, indicating room for expansion [

85,

86].

The network’s core emphasizes empirical characterization (e.g., EIS, SEM) but underrepresents computational modeling (e.g., molecular dynamics simulations for coating design) and machine-learning-driven optimization. Strengthening links between corrosion behavior and data-driven analytics could unlock predictive models for high-temperature or marine environments. Additionally, integrating biological inspiration (e.g., lotus-leaf-inspired superhydrophobic surfaces) with nanomaterials may drive innovations in antifouling and self-cleaning coatings [

87].

In summary, the keyword network underscores a field centered on material-performance interplay, with corrosion protection as the nucleus. Future research should leverage interdisciplinary linkages, particularly in sustainable design and computational tools, to address unmet challenges in extreme environments and biomedical applications.

3.2.2. Keyword Cluster Analysis

In co-citation analysis, clustering relies on the frequency of two references being co-cited by the same article. The underlying assumption is that frequently co-cited references are thematically related and belong to the same knowledge domain. In keyword analysis, clustering is based on keyword co-occurrence within documents. Frequently co-occurring keywords indicate shared research themes, enabling the grouping of related keywords into clusters representing distinct research areas. Both methods employ network analysis to identify densely connected subgraphs (clusters), which reflect cohesive research themes or intellectual structures. In co-citation analysis, clustering is based on the frequency of references being co-cited by the same article. The assumption is that frequent co-citation indicates thematic relatedness and membership in the same knowledge domain. In keyword analysis, clustering relies on keyword co-occurrence in documents, where frequent co-occurrence signals share research themes and in which the grouping of related keywords into thematic clusters is enabled. Size refers to the number of nodes (e.g., references or keywords) in a cluster, indicating the cluster’s scale or prominence within the dataset. Silhouette measures cluster quality, with values ranging from −1 to 1. A value close to 1 signifies high intra-cluster similarity and distinctiveness from other clusters. Values near 0 or negative indicate poor clustering validity. Interpretation of silhouette scores should be combined with modularity to ensure reliability.

The keyword clustering map (

Figure 7) reveals six distinct thematic clusters, each characterized by cohesive research foci and interdisciplinary linkages, as outlined in

Table 5 and supported by citation metrics. These clusters underscore the field’s emphasis on material design, functional performance, and environmental interaction, with corrosion protection, nanocomposites, and surface engineering as overarching themes.

Cluster #0: Epoxy Coating and Nanocomposite Systems

This cluster (size = 46, silhouette = 0.739) centers on epoxy coatings reinforced with nanomaterials, as evident from keywords like “corrosion protection” (2197 counts), “graphene oxide”, and “nanoparticles”. Studies here focus on enhancing barrier properties via functionalized fillers, such as amino-functionalized graphene oxide in solvent-based epoxy matrices, which improve ionic resistance and reduce cathodic delamination. The cluster highlights the critical role of dispersion quality and matrix compatibility, with research demonstrating that 0.1 wt.% graphene-oxide nanosheets significantly enhance corrosion resistance in mild steel substrates. Synergistic effects between nanohybrids (e.g., SiO2-GO) and epoxy matrices are a key focus, showcasing improved mechanical and electrochemical performance.

Cluster #1: Carbon Composite and Microstructural Design

Cluster #1 (size = 45, silhouette = 0.82) revolves around carbon composites and microstructure-property relationships, dominated by keywords like “behavior” (3763 counts), “resistance” (2692 counts), and “microstructure” (2033 counts). Research here spans thermal spray coatings for high-temperature applications, such as plasma-sprayed AlCoCrFeNi high-entropy alloys with superior wear resistance at 500 °C. The cluster also includes studies on covalent grafting of graphene oxide to polyurethane matrices, improving both mechanical robustness and corrosion protection through enhanced interfacial interactions. Microstructural analysis via techniques like neutron diffraction and nanoindentation is pivotal, linking phase evolution to functional performance in extreme environments [

78,

80].

Cluster #2: Magnesium Alloy and Surface Modification

Focused on magnesium alloys and protective coatings, this cluster (size = 29, silhouette = 0.798) features keywords such as “protection” (2284 counts), “corrosion resistance” (1946 counts), and “magnesium alloy”. The studies emphasize surface treatments like the electrophoretic deposition of graphene and layered double hydroxide (LDH) intercalated with 8-hydroxyquinoline, which enhance corrosion resistance through both barrier effects and inhibitor release. Biomimetic approaches, such as superhydrophobic coatings inspired by lotus leaves, are a key subtheme, demonstrating contact angles exceeding 160° and reduced electrolyte infiltration on magnesium substrates [

79,

81].

Cluster #3: Superhydrophobic Coating and Film Engineering

Cluster #3 (size = 23, silhouette = 0.795) centers on superhydrophobic coatings and film fabrication, with keywords like “films” (1582 counts), “surface” (1290 counts), and “fabrication”. The research here includes pulsed laser-induced triple-layer copper oxide structures for durable anti-icing and self-cleaning properties, as well as nanocomposite films of polyvinyl butyral/graphene oxide for aluminum alloys, achieving three orders of magnitude improvement in the impedance modulus. The cluster highlights the balance between superhydrophobicity and mechanical robustness, with applications in marine and aerospace environments.

Cluster #4: Hybrid Sol-Gel Coating and Electrochemical Characterization

This cluster (size = 22, silhouette = 0.756) focuses on hybrid sol-gel coatings and electrochemical analysis, featuring keywords like “electrochemical impedance spectroscopy” (504 counts), “inhibition”, and “aluminum”. The studies investigate sol-gel-derived silica nanoparticles decorated on graphene oxide for enhanced epoxy coatings, showcasing reduced hydrolytic degradation and improved ionic barrier properties. Electrochemical impedance spectroscopy (EIS) is a key tool here, used to characterize coating durability in saline environments and validate the efficacy of hybrid systems in mitigating localized corrosion [

59,

63].

Cluster #5: Mechanical Properties and Tribological Performance

Cluster #5 (size = 18, silhouette = 0.86) emphasizes mechanical properties and tribological behavior, with keywords like “mechanical property” (1787 counts), “wear resistance”, and “thermal stability”. The research includes multilayered TiAlCN/TiAlN coatings synthesized by cathodic arc evaporation, demonstrating improved hardness and reduced friction coefficients, and high-entropy nitride coatings with tailored Al/Ti ratios for enhanced thermal stability and wear resistance. The cluster underscores the importance of microstructural design in optimizing load-bearing and protective capabilities for industrial applications.

All clusters converge on nanocomposite design and stimuli-responsive mechanisms, with graphene oxide, LDH, and polymer matrices as recurring materials. Synergies between “corrosion protection” (Cluster #0) and “superhydrophobicity” (Cluster #3) are evident in self-healing coatings combining shape-memory polymers with corrosion inhibitors, enabling autonomous repair under thermal or light stimuli. Emerging trends include bioinspired designs (e.g., lotus-leaf mimics) and sustainable formulations, such as waterborne epoxy coatings with polydopamine-modified GO, addressing environmental concerns.

While experimental characterization (e.g., EIS, SEM) is robust, computational modeling (e.g., molecular dynamics for coating-substrate interactions) remains underrepresented. Additionally, standardized testing protocols for long-term durability in complex environments (e.g., marine, high-temperature) are needed. Future research could bridge these gaps by integrating machine learning for predictive coating design and exploring multi-scale synergies between nanoscale fillers and macroscale mechanical behavior [

62,

63].

In summary, the keyword clusters depict a field advancing through material innovation, interdisciplinary methodologies, and application-driven design, with corrosion protection and functional performance as enduring focal points.

3.2.3. Analysis of Keywords with the Strongest Citation Bursts

The analysis of the top 25 keywords with the strongest citation bursts (

Table 6,

Figure 7) reveals dynamic shifts in research focus over the 2015–2025 period, underscored by technological advancements, material innovation, and evolving application demands. These bursts highlight emerging themes and sustained interests, categorized into three distinct phases: early foundational research (2015–2018), methodological advancements (2018–2021), and next-generation material design (2021–2025).

- (1)

Early Foundational Research (2015–2018): Establishing Core Concepts

“Sol-gel coatings” (burst strength = 37.94, 2015–2020) dominated early research, focusing on silica-based hybrid materials for corrosion protection and functional surfaces. Studies emphasized sol-gel-derived PDMS derivatives, leveraging their inorganic–organic hybrid structure to enhance barrier properties and chemical resistance, particularly in marine and high-temperature environments [

88,

89].

“Metals” (30.31, 2015–2017) and “oxidation protection” (29.91, 2015–2018) reflected intensive investigations into metallic substrates (e.g., magnesium, aluminum alloys) and their protection against high-temperature oxidation. For example, the electrodeposition of Ni-W alloy laminar coatings on mild steel demonstrated enhanced corrosion resistance through microstructural optimization, while HfC nanowire-reinforced coatings improved ablation resistance in C/C composites [

90,

91].

“Hybrid coatings” (26, 2015–2018) and “conversion coatings” (24.09, 2015–2019) highlighted interdisciplinary efforts, such as graphene oxide/silane multilayers on aluminum alloys, combining barrier effects with self-healing mechanisms via pH-responsive nanovalves [

48,

92];

- (2)

Methodological Advancements (2018–2021): Analytical Tools and Fabrication Techniques

“Electrochemical behavior” (24.82, 2018–2020) and “EIS” (19.43, 2019–2020) emerged as pivotal analytical tools, enabling the precise characterization of coating durability. For instance, electrochemical impedance spectroscopy was used to evaluate the long-term performance of epoxy coatings embedded with self-doped polyaniline nanofibers, revealing improved ionic resistance over 120 days of immersion [

93,

94].

“Electrophoretic deposition” (16.96, 2020–2021) gained traction for its versatility in fabricating uniform, functional coatings, such as antibacterial chitosan-silver nanoparticle layers on porous titanium implants, though in vivo studies highlighted challenges in balancing antimicrobial efficacy and immune compatibility;

- (3)

Next-Generation Material Design (2021–2025): Emerging Frontiers

“Polymer” (29.62, 2022–2025) and “epoxy resin” (28.32, 2022–2025) dominated recent bursts, driven by sustainable and high-performance formulations. Bio-based epoxy resins derived from lignin and linseed oil showcased eco-friendly alternatives with comparable corrosion resistance to commercial systems, while shape-memory polymer composites enabled self-healing under thermal or solar stimuli, addressing mechanical damage in extreme environments [

95,

96].

“Nanosheets” (21.04, 2021–2023) and “protective coating” (23.29, 2022–2025) reflected a shift toward nanoscale engineering, such as graphene oxide nanohybrids for enhanced barrier properties and reduced cathodic delamination in epoxy matrices.

“Robust” (25.26, 2021–2023) underscored the demand for coatings with integrated functionalities, e.g., superhydrophobic–superoleophilic surfaces combining self-cleaning and anti-icing properties, critical for aerospace and marine applications;

- (4)

Cross-Phase Trends and Synergies

“Spectroscopy” (23.57, 2015–2018) and “Raman spectroscopy” (14.77, 2016–2017) remained essential for structural characterization, enabling insights into interfacial reactions in coatings like Al

2O

3 on LiNi

0.4Mn

0.4Co

0.2O

2 cathodes, where atomic-layer deposition mitigated electrolyte side reactions at high voltages [

48].

“Diffusion” (21.63, 2023–2025) and “system” (15.28, 2023–2025) indicated growing interest in multi-scale modeling, aiming to optimize ion transport and coating–substrate interactions, particularly for advanced energy-storage systems like solid-state lithium-metal batteries;

- (5)

Gaps and Future Directions

While early research focused on material synthesis and empirical characterization, recent bursts signal a transition toward sustainability (bio-based polymers, RoHS-compliant additives) and intelligent systems (self-healing, stimuli-responsive release). Gaps remain in standardizing testing protocols for long-term durability in complex environments (e.g., marine, nuclear) and integrating machine learning for predictive coating design. Future efforts could prioritize multi-functional nanocomposites, such as lignin-based epoxy blends with embedded sensors for real-time corrosion monitoring, bridging empirical experimentation with data-driven innovation.

In summary, citation bursts outline a field evolving from foundational material science to application-oriented, intelligent coatings, driven by advancements in nanotechnology, electrochemical analysis, and sustainable chemistry.

3.3. Reference Co-Citation Cluster Analysis

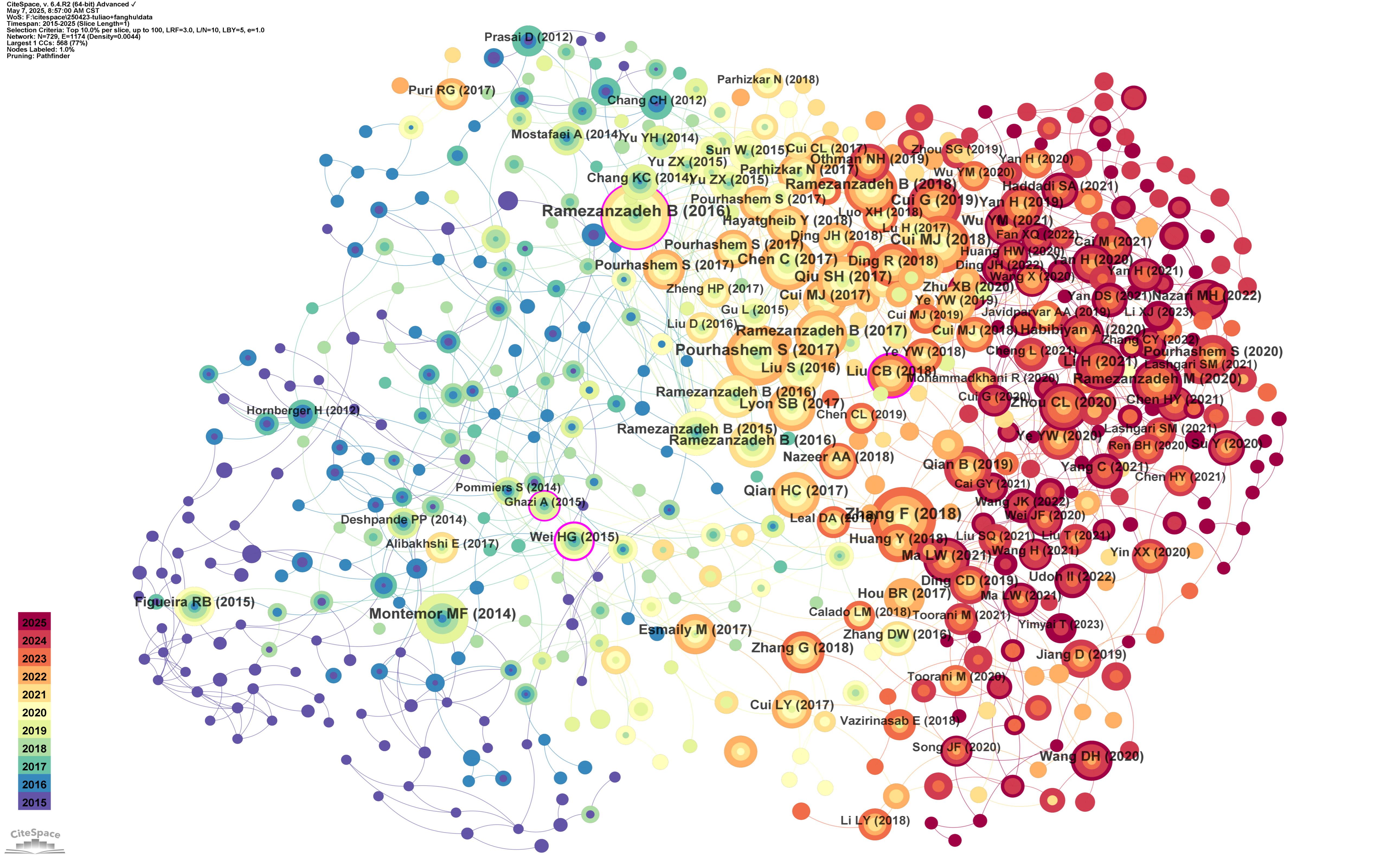

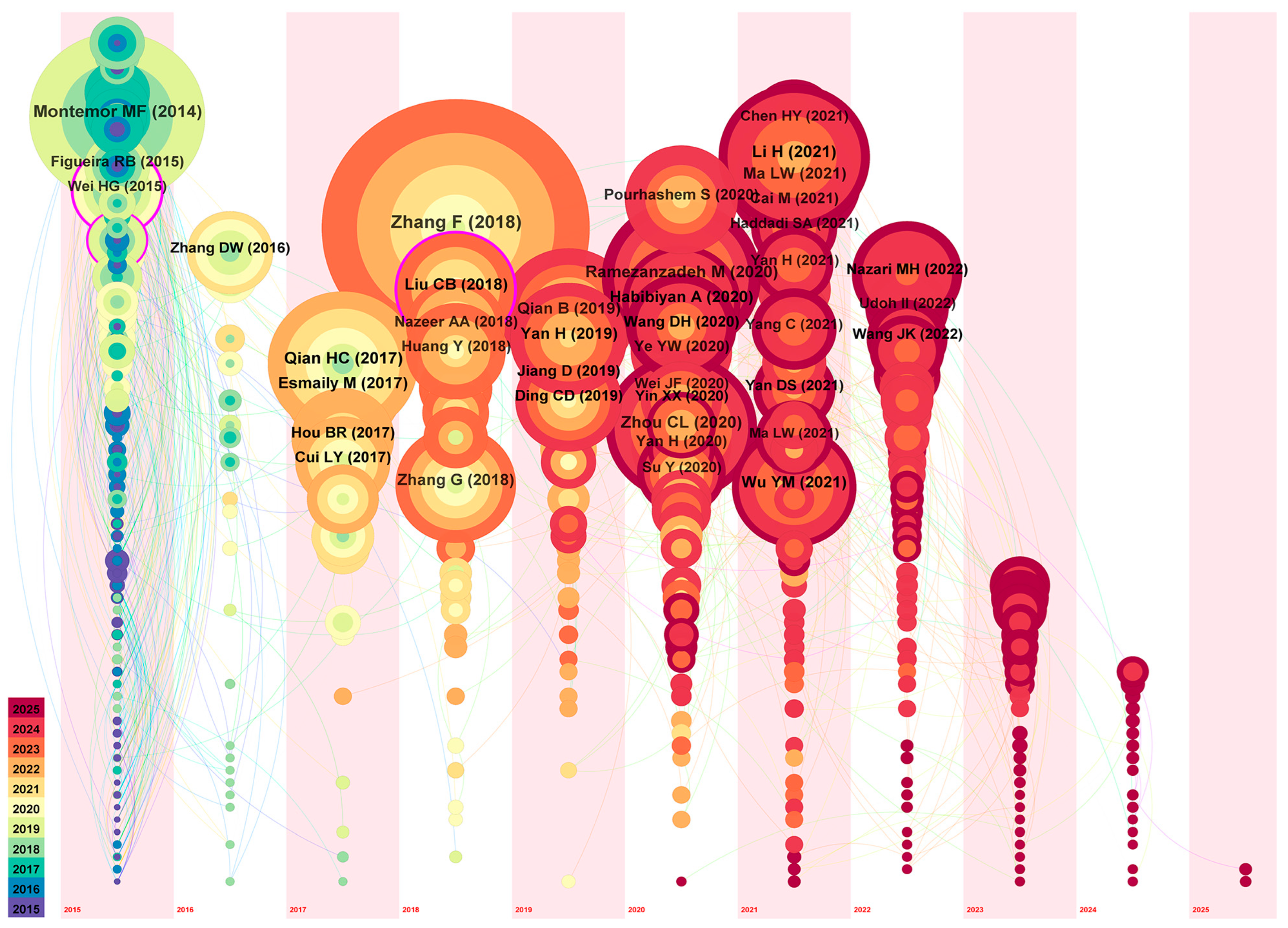

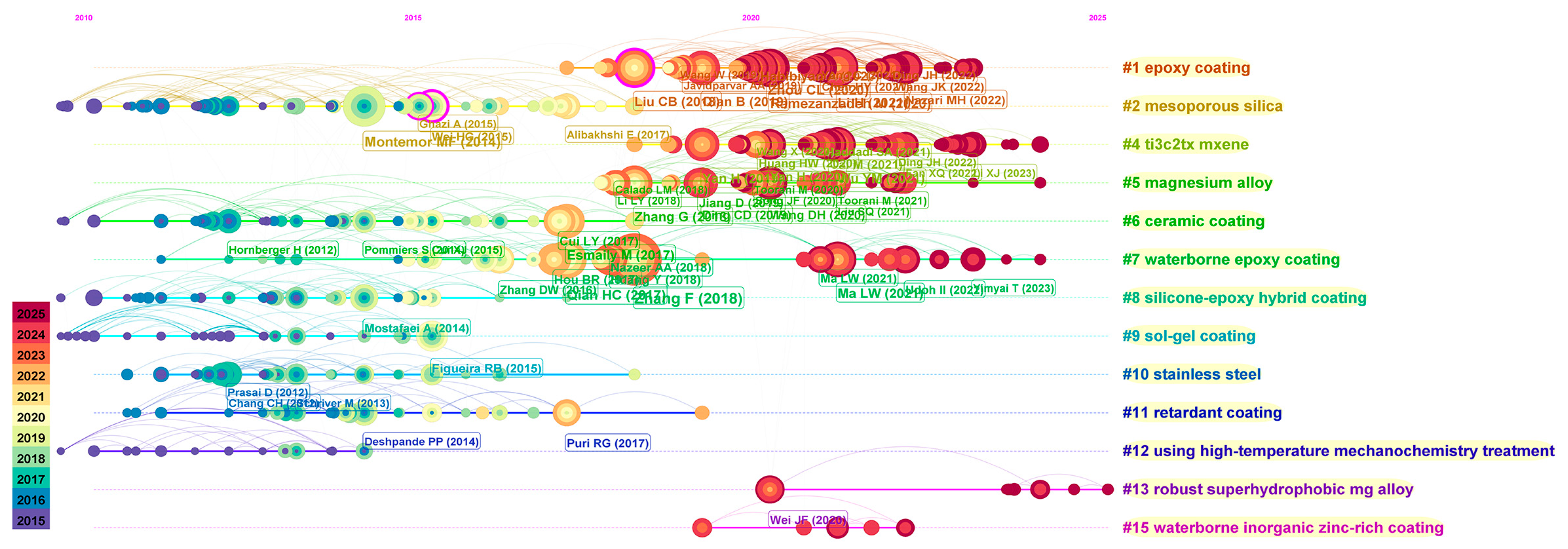

The reference co-citation cluster analysis reveals distinct thematic groupings of highly influential publications, highlighting foundational and emerging research trajectories in protective coatings and corrosion science.

Table 7 and the accompanying

Figure 8,

Figure 9 and

Figure 10 illustrate the structural and temporal distribution of these clusters, anchored by key studies that drive knowledge integration across the field.

- (1)

Core Clusters and Thematic Focus

Cluster #0: Graphene Oxide Dominance (Size = 100, Silhouette = 0.896)

This cluster, centered on graphene-oxide (GO)-based nanocomposites, is anchored by Ramezanzadeh B. (2016), whose study reports polydopamine-modified GO enhancing water-borne epoxy coatings’ corrosion resistance via improved dispersion and barrier properties. With a mean year of 2017, it highlights the pivotal role of 2D nanomaterials in modern coatings, integrating studies on GO functionalization, electrochemical characterization, and synergistic effects with polymers (e.g., Cui MJ, 2018; Qiu SH, 2017). The high silhouette value (0.896) signals strong internal homogeneity, with research focusing on defect engineering and eco-friendly formulations [

47,

81,

97].

Table 7.

The top 7 co-cited pieces of literature in the last 10 years.

Table 7.

The top 7 co-cited pieces of literature in the last 10 years.

| ID | Size | Centrality | Cited Publications |

|---|

| 1 | 228 | 0.14 | Ramezanzadeh B, 2016, Corros. Sci., V103, P283, DOI 10.1016/j.corsci.2015.11.033 [98] |

| 2 | 209 | 0.04 | Zhang F, 2018, Corros. Sci., V144, P74, DOI 10.1016/j.corsci.2018.08.005 [48] |

| 3 | 197 | 0.05 | Pourhashem S, 2017, Corros. Sci., V115, P78, DOI 10.1016/j.corsci.2016.11.008 [79] |

| 4 | 174 | 0.05 | Cui MJ, 2018, Chem Eng J., V335, P255, DOI 10.1016/j.cej.2017.10.172 [47] |

| 5 | 141 | 0.02 | Ramezanzadeh B, 2018, Corros. Sci., V137, P111, DOI 10.1016/j.corsci.2018.03.038 [98] |

| 6 | 35 | 0.15 | Brusciotti F, 2013, Corros. Sci., V67, P82, DOI 10.1016/j.corsci.2012.10.013 [99] |

| 7 | 68 | 0.1 | Wei HG, 2015, J Mater Chem A., V3, P469, DOI 10.1039/c4ta04791e [100] |

Cluster #1: Epoxy Coating Innovations (Size = 82, Silhouette = 0.845)

Dominated by recent reviews (e.g., Ghaderi, M. 2024), this cluster emphasizes epoxy-based smart coatings, including self-healing and superhydrophobic systems. Key studies like Qian HC (2017) detail dual-action coatings combining shape-memory polymers and corrosion inhibitors, showcasing advancements in stimulus-responsive materials. The mean year of 2020 reflects a shift toward multifunctional designs, addressing mechanical robustness and environmental durability [

15].

Cluster #2: Mesoporous Silica and Hybrid Systems (Size = 60, Silhouette = 0.902)

Focused on mesoporous silica and sol-gel hybrids, this cluster is rooted in Figueira RB’s study (2015), reviewing organic–inorganic coatings for metal protection. Studies here explore nanocontainers for inhibitor release (e.g., Wei HG, 2015) and hierarchical structures for enhanced barrier properties, dating back to 2013. The high centrality (0.15 for Brusciotti F, 2013) underscores its role in bridging material synthesis and corrosion mechanism analysis [

101,

102,

103];

- (2)

Emerging Trends and Cross-Disciplinary Synergies

Cluster #4: Ti3C2Tx MXene (Size = 50, Silhouette = 0.872)

Highlighting MXene-based coatings, this cluster (mean year = 2021) includes Ghaderi, M.’s study (2024), discussing 2D MXene’s role in active corrosion protection. Research here focuses on Ti

3C

2Tx nanosheets as physical barriers and inhibitor carriers, leveraging their high electrical conductivity and layered structure to enhance coating durability (e.g., Yan H, 2019). The cluster’s rising prominence reflects cross-disciplinary synergy between nanomaterial science and electrochemical engineering, addressing challenges in harsh environments like marine and high-temperature settings [

15,

104,

105].

Figure 8.

Reference co-citation network.

Figure 8.

Reference co-citation network.

Cluster #5: Magnesium Alloy Protection (Size = 41, Silhouette = 0.907)

Centered on magnesium alloys, this cluster (mean year = 2020) is driven by studies like Wu, J. (2025), which reports robust superhydrophobic coatings via hydrothermal processing and PDMS/TiO

2 composites. Research emphasizes bioinspired surface engineering (e.g., lotus-leaf mimics) and self-healing mechanisms to mitigate Mg’s inherent corrosion vulnerability. The cluster’s high silhouette value (0.907) indicates strong focus coherence, with applications spanning aerospace and biomedical implants [

2,

106,

107].

Figure 9.

Temporal distribution of core reference clusters in corrosion science.

Figure 9.

Temporal distribution of core reference clusters in corrosion science.

Figure 10.

Cluster diagram of the co-cited literature in the last 10 years.

Figure 10.

Cluster diagram of the co-cited literature in the last 10 years.

Cluster #13: Robust Superhydrophobic Mg Alloy (Size = 10, Silhouette = 0.949) (

Table 8)

Table 8.

Summary of the largest 14 clusters.

Table 8.

Summary of the largest 14 clusters.

| Cluster-ID | Cluster Name (LLR) | Size | Silhouette | Mean (Year) |

|---|

| 0 | graphene oxide (11198.02, 1.0 × 10−4) | 100 | 0.896 | 2017 |

| 1 | epoxy coating (1556.62, 1.0 × 10−4) | 82 | 0.845 | 2020 |

| 2 | mesoporous silica (1510.18, 1.0 × 10−4) | 60 | 0.902 | 2013 |

| 4 | ti3c2tx mxene (1582.1, 1.0 × 10−4) | 50 | 0.872 | 2021 |

| 5 | magnesium alloy (7467.95, 1.0 × 10−4) | 41 | 0.907 | 2020 |

| 6 | ceramic coating (1199.33, 1.0 × 10−4) | 39 | 0.964 | 2013 |

| 7 | graphene oxide (2161.52, 1.0 × 10−4) | 36 | 0.886 | 2018 |

| 8 | silicone-epoxy hybrid coating (1344.58, 1.0 × 10−4) | 35 | 0.941 | 2013 |

| 9 | sol-gel coating (655.77, 1.0 × 10−4) | 34 | 0.958 | 2012 |

| 10 | stainless steel (1098.33, 1.0 × 10−4) | 29 | 0.920 | 2013 |

| 11 | retardant coating (1571.03, 1.0 × 10−4) | 28 | 0.939 | 2014 |

| 12 | using high-temperature mechanochemistry treatment (311.01, 1.0 × 10−4) | 19 | 0.962 | 2012 |

| 13 | robust superhydrophobic mg alloy (299.73, 1.0 × 10−4) | 10 | 0.949 | 2023 |

| 14 | waterborne inorganic zinc-rich coating (381.23, 1.0 × 10−4) | 5 | 0.993 | 2021 |

A recent emergent cluster (mean year = 2023), this features cutting-edge work on superhydrophobic coatings integrating nanoscale roughness and chemical resistance (e.g., Cheng, J. 2025). Studies here address mechanical stability challenges via hybrid materials (e.g., ZnO-epoxy composites), demonstrating synergies between surface topography and corrosion inhibition. This aligns with industry demands for durable coatings in extreme environments, such as offshore wind and marine infrastructure [

42,

108];

- (3)

Temporal Evolution and Structural Insights

Early Foundations (Pre-2015): Clusters like #9 (sol-gel coatings) and #6 (ceramic coatings) anchor the field’s historical focus on organic–inorganic hybrids and thermal barrier materials, as seen in Figueira RB (2015) and Chen Y (2015). These laid groundwork for modern nanocomposite designs [

103,

109].

Recent Surge (2018–2025): Dominated by graphene oxide (#0, #7) and epoxy innovations (#1), recent clusters reflect a shift toward smart, stimuli-responsive systems. High-citation works like Ramezanzadeh B (2016) and Zhang F (2018) emphasize functionalization strategies to enhance dispersion and interface adhesion, critical for translating lab discoveries to industrial applications [

81,

110];

- (4)

Methodological and Theoretical Frontiers

High Centrality Nodes: Studies like Wei HG (2015) (centrality = 0.25) and Liu CB (2018) (centrality = 0.24) act as pivotal bridges, integrating advanced characterization techniques (e.g., in situ electrochemical impedance spectroscopy, SEM-TEM correlative microscopy) to decode nanocomposite degradation mechanisms. These methodologies enable precise quantification of barrier properties and inhibitor-release kinetics, essential for validating theoretical models of coating failure [

97,

111].

Computational Modeling Synergy: Emerging theoretical work leverages molecular dynamics (MD) and density functional theory (DFT) to simulate graphene–polymer interfacial interactions (e.g., Chen C, 2017), predicting optimal functionalization strategies to minimize defect-driven corrosion. Machine-learning (ML) algorithms also gain traction, optimizing coating formulations by correlating nanomaterial morphology with electrochemical performance, as hinted in Nazari MH (2022)’s review of data-driven design [

75,

86].

Mechanistic Elucidation: High-citation papers like Ramezanzadeh B (2016) and Cui MJ (2018) emphasize multi-scale analysis, combining surface science (XPS, AFM) with bulk property testing to unravel synergies between nanofiller dispersion and coating durability. This mechanistic clarity is critical for designing next-generation systems, such as pH-responsive nanocontainers for targeted inhibitor release (e.g., Zhou CL, 2020) [

81,

98,

112];

- (5)

Gaps and Future Directions

Standardization Challenges: Despite methodological advancements, standardized testing protocols for long-term durability in complex environments (e.g., cyclic thermal shock, multi-ion corrosion) remain lacking, limiting comparability across studies.

Sustainability Imperatives: The field increasingly demands eco-friendly formulations, as seen in Li J (2024)’s work on waterborne inorganic zinc-rich coatings, but lifecycle assessments and biocompatibility evaluations for biomedical applications (e.g., Mg alloy implants) are underdeveloped [

98,

112,

113].

Interdisciplinary Integration: Merging coating science with artificial intelligence (e.g., ML-driven defect detection) and sustainable chemistry (e.g., biomass-derived polymers) presents untapped opportunities, aligning with global trends in green engineering and smart infrastructure [

93].

In summary, reference co-citation clusters highlight a field advancing from empirical material synthesis to theoretically informed, multi-functional designs, with foundational studies in graphene oxide and epoxy systems serving as launchpads for emerging frontiers in MXene, superhydrophobicity, and sustainable formulations.