Abstract

Silicon-doped tetrahedral amorphous carbon (ta-C:Si) coatings are promising materials for achieving ultralow friction in water-lubricated environments, attributed to the formation of Si(OH)x-based tribofilms. However, the deposition process via filtered cathodic vacuum arc (FCVA) often introduces large particles into the film, increasing surface roughness and causing accelerated wear during the initial sliding phase, despite the high hardness of the coating. In this study, ball-on-disk tribological tests were performed to investigate the wear behavior of ta-C:Si coatings under water lubrication. Friction coefficients, wear volume, and surface roughness were analyzed over various sliding durations. The Archard wear equation and the plasticity index were used to analyze wear and contact behavior. The friction coefficient decreased from 0.14 to 0.04 within the initial 100 m section, and the surface roughness of ta-C:Si decreased sharply from 0.35 μm to 0.01 μm based on the Rpk parameter during 10 h. Following this period, the plasticity index decreased from an initial value of 1.1 to below 0.6, transitioning to a fully elastic contact stage, marking the onset of steady-state wear after 10 h. These results indicate that the reduction in surface roughness plays a crucial role in stabilizing wear behavior and provide insights into optimizing the long-term performance of ta-C:Si coatings in aqueous environments.

1. Introduction

As carbon emission regulations continue to tighten, research on improving internal combustion engines and lubricants has been actively conducted. Recently, eco-friendly lubricants have attracted increasing attention. Among them, water is the most environmentally friendly and cost-effective lubricant, and its potential use is gradually increasing across various industries [1,2]. Consequently, research on water-based or aqueous lubricants is actively underway. Water-based lubrication has potential applications in various fields such as automobiles, aerospace, and energy equipment because of its environmental friendliness and cost-effectiveness. However, the use of additives is limited due to water’s corrosiveness toward metals and low viscosity. To address these challenges, the development of coating materials with excellent wear and chemical resistance is required.

Silicon is a unique element that exhibits low friction properties in water environments, and oxide films and silica sol are formed in response to reactions with water. SiOx(OH)y-based lubricating films reduce friction energy by inducing low-energy van der Waals interactions on the surface [3,4]. Silicon-containing ceramics (i.e., SiO2, Si3N4, and SiC) have low fracture toughness, which is a drawback for wear resistance [5]. Alternatively, silicon-doped diamond-like carbon (DLC) can be proposed; it is lubricated by a similar mechanism and has relatively high hardness, making it easier to ensure durability. Among DLC coatings, tetrahedral amorphous carbon (ta-C) coatings with predominant sp3 bonding are widely used to improve the service life due to their high hardness and low friction characteristics [6]. In a water-lubricated environment, DLC coatings containing ta-C have different friction properties depending on their composition [7,8,9]. Hydrogenated amorphous carbon (a-C:H) films in water-lubricated conditions have a high coefficient of friction, which results from increased surface attraction due to the replacement of oxygen absorbed on the surface with hydrogen, leading to higher friction. Therefore, hydrogen-free Si-doped tetrahedral amorphous carbon (hereinafter called ta-C:Si) can be presented as a promising surface material that provides low-friction performance in a water-lubricated environment [10,11,12].

However, the rough surface caused by the manufacturing process of ta-C is a problem. A ta-C is manufactured by the arc discharge method, which has a high ionization rate and ejects solid particles with plasma due to the low thermal shock resistance of the solid graphite target [13,14]. The large particles ejected with the plasma flow onto the substrate and remain as surface defects (i.e., droplets, spikes, and pores), resulting in a rough surface [15,16,17]. These surface defects cause three-body abrasive wear during friction, resulting in deterioration of the wear characteristics [18]. This is because protruding defects such as droplets and spikes are worn away, forming wear debris with a hardness similar to that of ta-C, causing abrasive wear. We previously confirmed that the amount of wear of ta-C in an atmospheric environment changes non-linearly over time [19]. This behavior makes it difficult to predict the wear life of hard coatings, including ta-C, which can lead to serious failure of the entire friction system.

According to the Archard wear equation, the wear volume should theoretically increase linearly in proportion to the sliding distance [20]. However, previous reports show a different trend. Wear goes through a run-in period in which it increases rapidly or shows unstable fluctuations at the beginning, and then enters a steady state in which the wear volume increases linearly with the sliding time [21]. Among these, the run-in section can be described by Blau’s break-in model, and various types of run-in scenarios have been reported [22,23,24]. The causes of various increases in friction and wear can be inferred by the type of run-in period. Therefore, identifying the run-in section before entering the stable state can help predict and improve durability and ensure the reliability of mechanical parts.

Here, we aimed to identify the relationship between surface roughness and wear volume, and to determine the wear behavior over time in a water-lubricated environment for ta-C:Si coatings. For this purpose, the friction coefficient and wear volume of ta-C:Si were measured using a ball-on-disk type tribometer. Si3N4 balls were used as the counter material to induce the formation of Si(OH)x lubricating films. The experiment was conducted at sliding times of 5, 10, 15, and 30 h to define the steady-state wear interval. For each sliding interval, hardness and surface roughness of the wear surface were compared based on the Archard wear equation. The roughness parameters Rq, Ra, Rpk, and Rvk were used to assess the surface changes before and after wear.

2. Materials and Methods

2.1. Coating Preparation

The ta-C:Si coatings were fabricated on SUJ2 bearing steel disks (Rq = 14 nm). The substrate was ultrasonically cleaned in acetone to remove organic contaminants and dried to remove residual moisture. After that, the substrate was transferred to a vacuum chamber (base pressure: 2.67 × 10−3 Pa) for ta-C:Si deposition. To further remove contaminants, the substrate was sputtered with Ar+ ions accelerated by an anode layer ion source for 10 min. The Ar sputtering conditions were as follows: Ar pressure of 1.87 × 10−1 Pa, acceleration voltage of 1.7 kV, and current of 200 mA. After that, a 250 nm thick Ti layer was deposited by using an unbalanced magnetron sputtering (UBMS), which increases the adhesion between the substrate and ta-C:Si. Ti was deposited with DC power of 600 W under an Ar atmosphere at a pressure of 2.40 × 10−1 Pa. Finally, a 1 µm ta-C:Si layer was deposited using the filtered cathode vacuum arc (FCVA) method, and Si was simultaneously co-deposited via UBMS. A solid graphite target (ex-70, Ibiden Co. Ltd., Ogaki City, Japan) and a silicon target with a purity of 99.9% (3N) were used. A ta-C containing 11 at% Si was prepared by co-deposition, and this composition is based on previous studies [25]. During deposition, the argon flow rate was 28 sccm, the arc discharge current was 60 A, and the sputter discharge power was 100 W.

2.2. Characterization

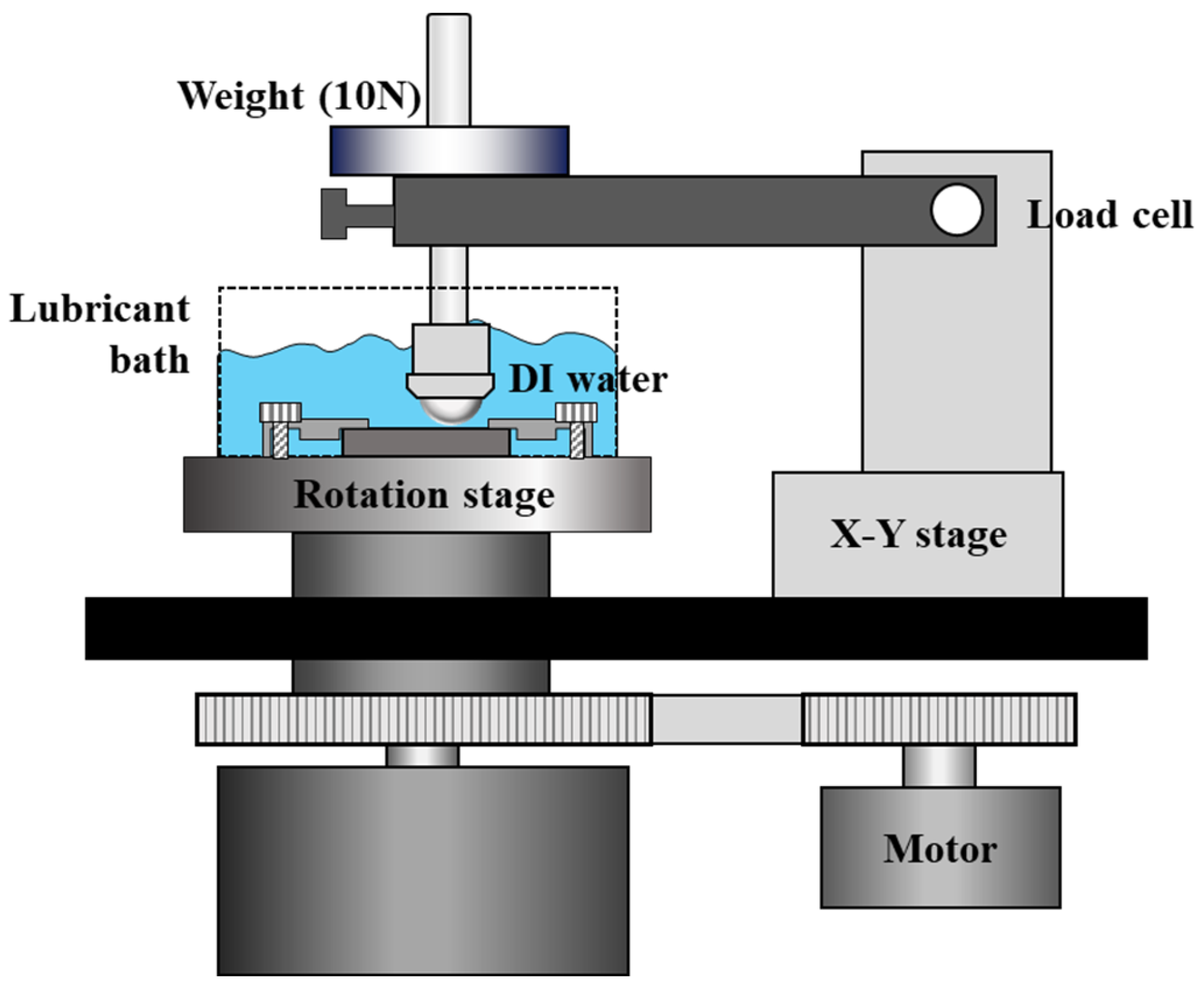

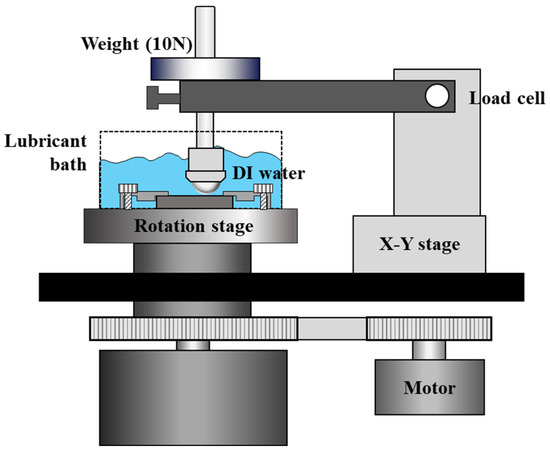

The friction coefficient was measured at room temperature using a ball-on-disk type tribometer on the deposited coating samples (Figure 1). Si3N4 balls were used as the counter material to induce the formation of a Si(OH)x lubricating film. The test was conducted under a rotation radius of 5 mm and a rotation speed of 200 RPM, corresponding to a normal load of 10 N and a sliding speed of 104.7 mm/s; 200 mL of deionized water was used as the lubricant. Sliding durations were set at 5, 10, 15, and 30 h to identify steady-state wear behavior. All tribo-tests were performed three times. The wear volume and roughness of the ta-C:Si and Si3N4 balls were obtained using the morphological information measured by a laser confocal microscope (Olympus OLS5100, Hachioji, Japan). The mechanical properties of the ta-C:Si coating were measured by nano-indentation (Anton Paar NHT3, Graz, Austria) for each sliding time. The maximum indentation load was 5 mN, and Poisson’s ratio was assumed to be 0.18 [26]. Measurements were taken at nine points per specimen; averages and standard deviations were calculated. The tribological tests were repeated twice, and the initial Hertz contact pressure was 1.3 GPa.

Figure 1.

Schematic diagram of water-lubricated ball-on-disk type tribometer.

3. Results and Discussion

3.1. Friction Characteristics

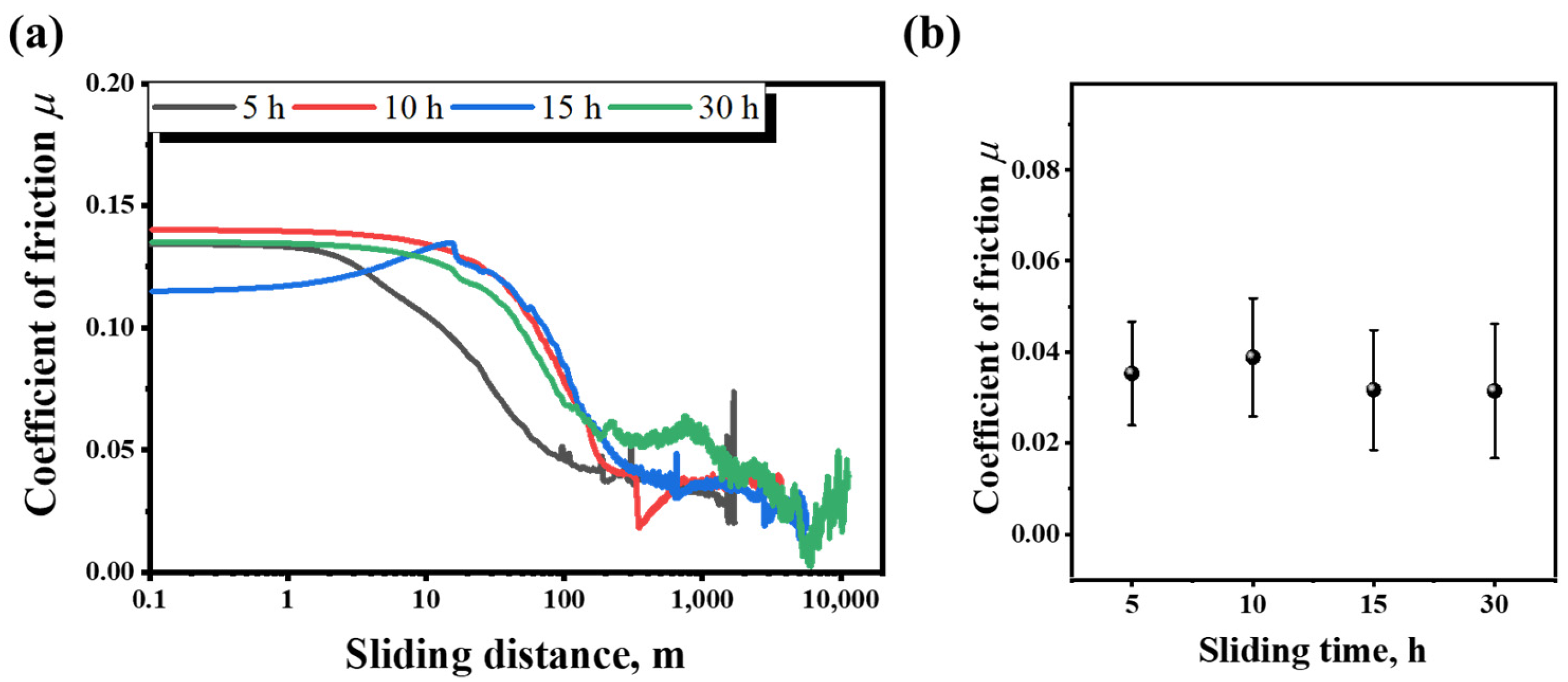

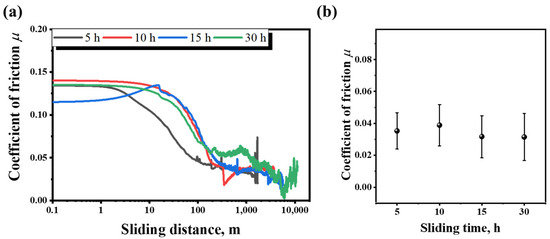

Figure 2a shows the friction curve of ta-C:Si as a function of sliding distance, with the sliding distance represented on a logarithmic scale. Each curve ends at the following sliding distance: 5 h—1700 m; 10 h—3800 m; 15 h—5700 m; 30 h—11,300 m. There are slight variations in the measurements for the first 100 m. This is because, even though all samples were prepared in the same way, slight differences in initial surface conditions, such as surface roughness and debris formation speed, may have caused differences in initial sliding behavior. The friction coefficient of ta-C:Si was within the range from 0.1 to 0.15 during the initial 10 m, and then rapidly decreased to below 0.05 as the sliding distance extended from 10 to 100 m. After 100 m, the friction coefficient stabilized, and this initial friction behavior was similar to the roughness reduction type in the run-in section defined by Blau [22]. In this type, the surface roughness is high at the beginning of sliding, which reduces the real contact area, thereby increasing local contact pressure, resulting in increased friction. However, as time passes, the surface roughness decreases, the contact area gradually widens and stabilizes, and the friction tends to decrease. Additionally, we confirmed the friction coefficient of ta-C with varying Si doping levels in previous studies. We also verified the formation of tribofilms through a component analysis of the tracks after wear. The results in Figure 2a show behavior similar to that of Si-doped ta-C, suggesting that tribofilms were formed in the friction-stabilized stage. Figure 2b represents the average friction coefficient of ta-C:Si as a function of sliding time over the entire sliding period, including both the run-in and steady-state stages, and it was approximately 0.03, independent of sliding time. This means that stable friction behavior was maintained after a drastic change in the run-in section.

Figure 2.

(a) Friction curves according to the sliding distance and (b) average friction coefficient according to the sliding time.

3.2. Wear Behavior

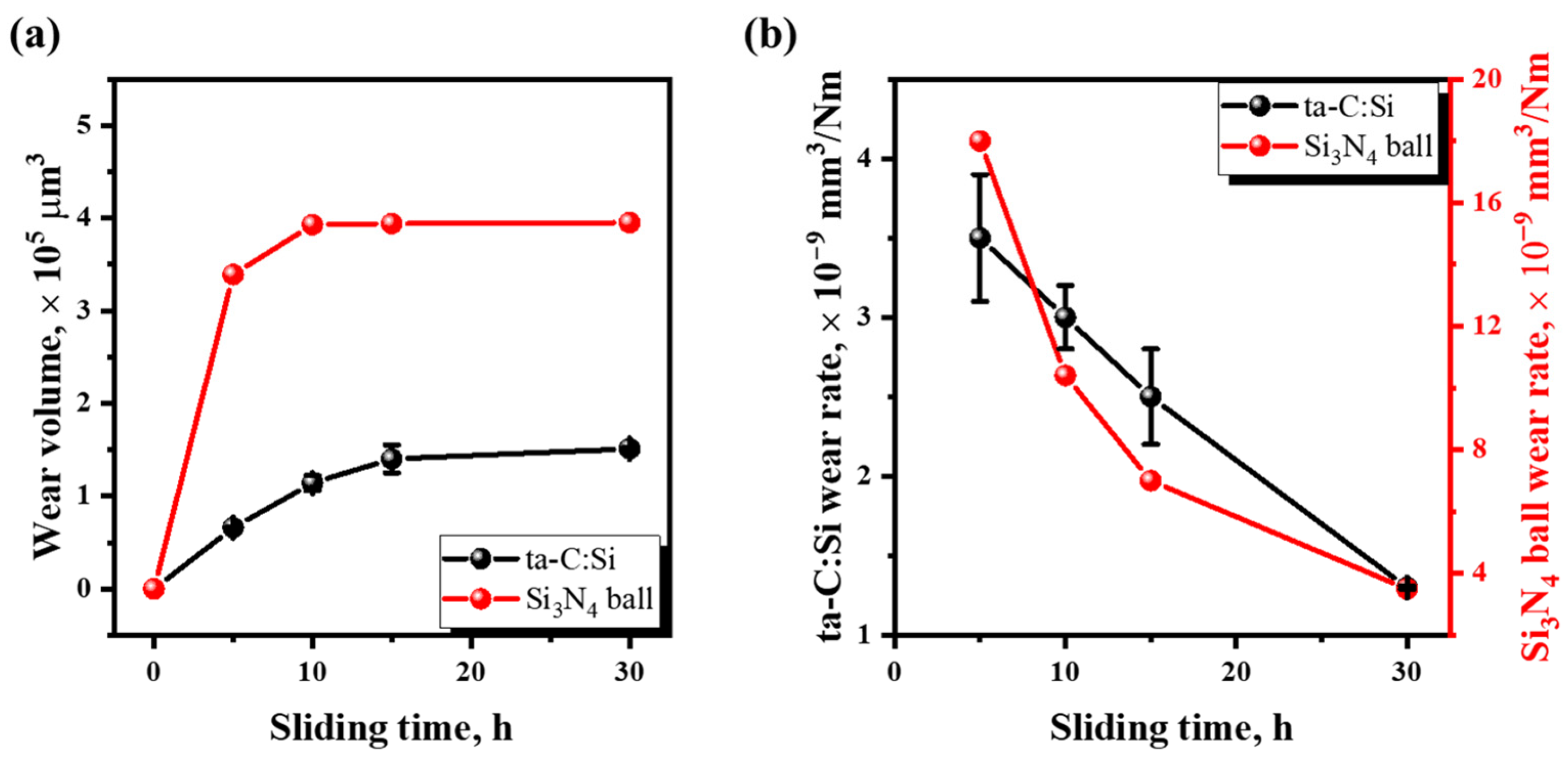

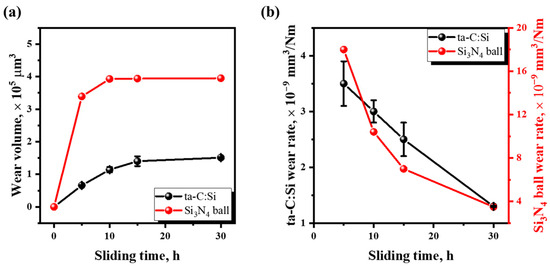

Figure 3a shows the change in wear volume of ta-C:Si and Si3N4 as a function of sliding distance. Both ta-C:Si and Si3N4 show non-linear wear behavior over time. The wear volume of the ta-C:Si disk and Si3N4 ball increases rapidly up to 10 h and then shows a slight increase thereafter. The point at which the wear rate stabilizes without a drastic change can be considered the starting point of the steady-state. As the sliding time increases, the wear rate of the disk and ball tends to decrease (Figure 3b). It is inappropriate to estimate the lifetime from this non-linear wear behavior. The phenomenon that the wear rate changes with sliding time can complicate the assessment of coating durability.

Figure 3.

(a) Wear volume and (b) specific wear rate of the ta-C:Si coating and Si3N4 ball as a function of sliding time.

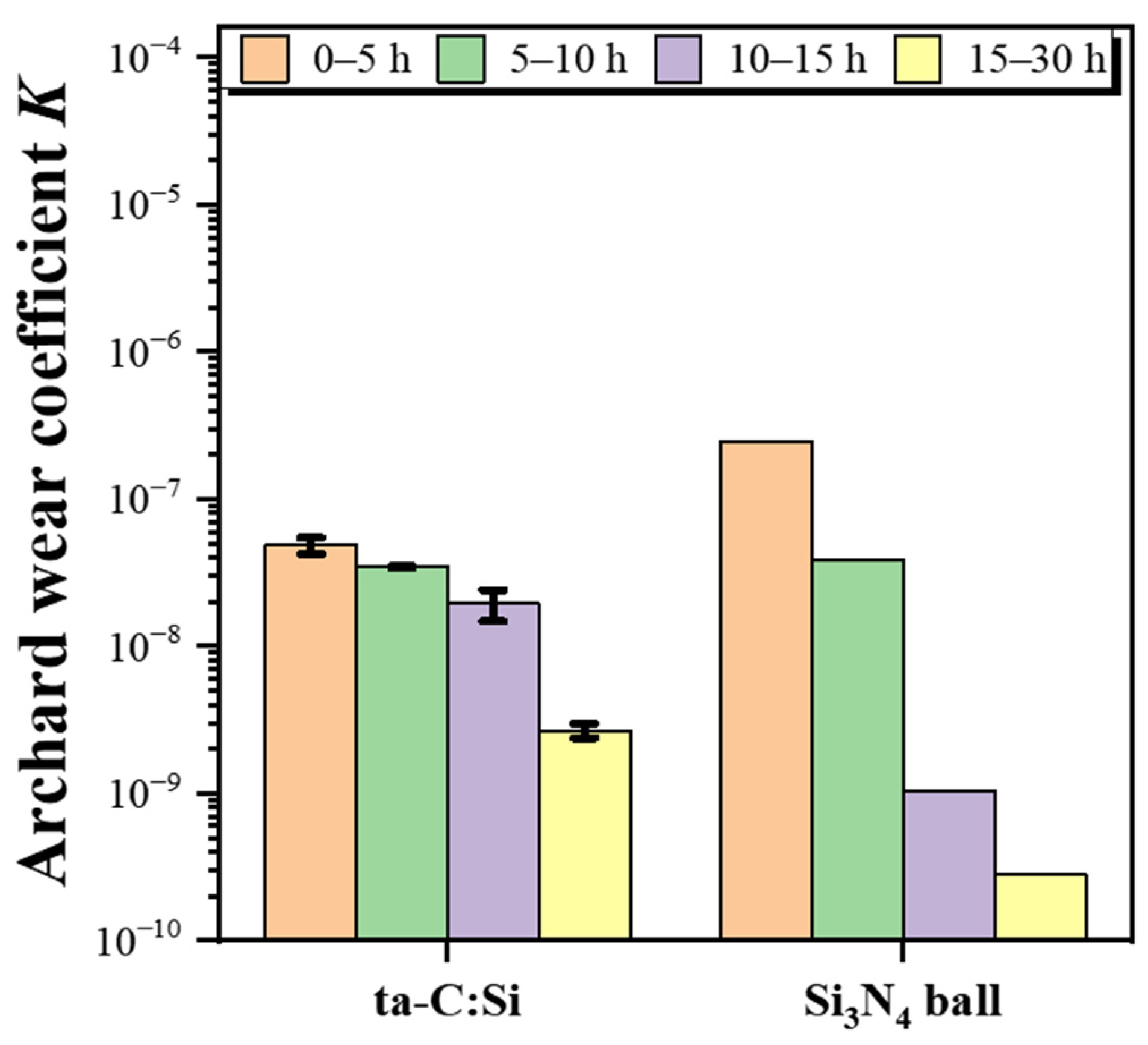

3.3. Discussion: Comparison with Archard Wear Equation

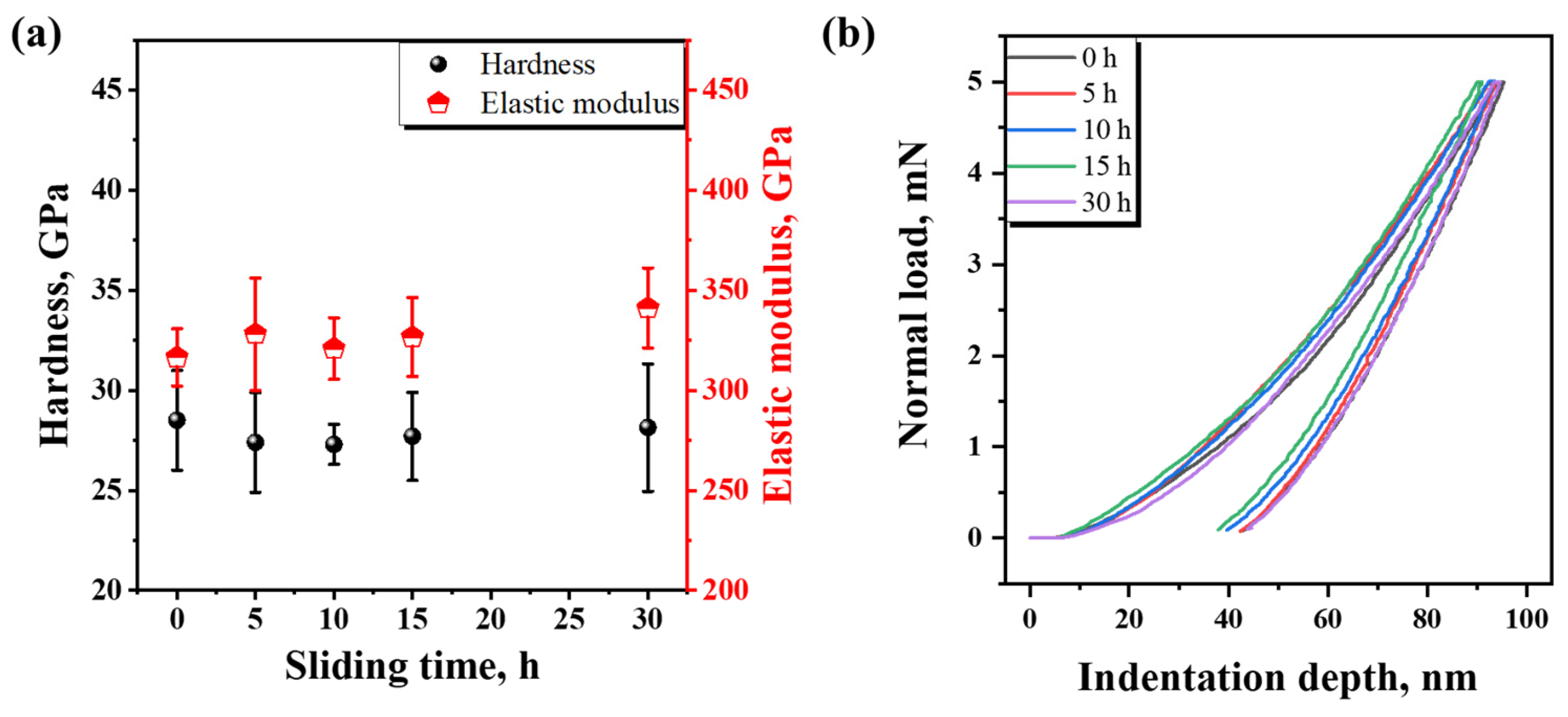

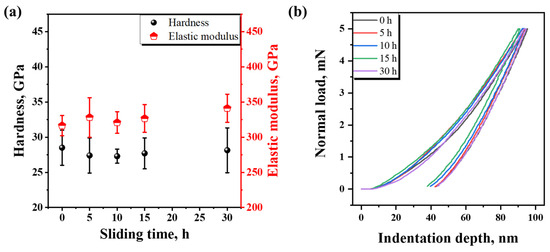

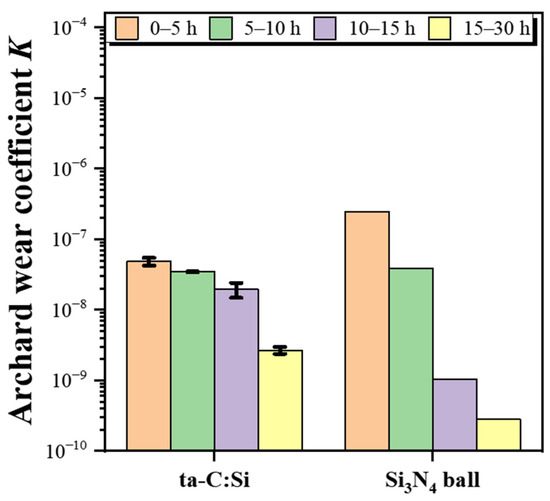

According to the Archard wear equation , the wear rate can be expressed as follows: . Here, is the wear volume, is the Archard wear coefficient, is the normal load, is the sliding distance, and is the hardness of the material. In light of the Archard wear equation, the decreasing wear rate can be attributed to changes in hardness and the wear coefficient. Therefore, hardness was investigated as a potential key factor in the decreasing wear rate. To investigate this, the change in hardness within the wear track according to the sliding distance was observed. As shown in Figure 4, the hardness over the sliding time ranges from 25 to 30 GPa, all within the range of standard deviation. This indicates that hardness did not influence the wear rate. Based on this, the calculated Archard wear coefficient is presented in Figure 5, which shows a decreasing trend over time. Theoretically, is a value obtained from experimental results and depends on several parameters [27,28]. These include the surface shape, the chemical affinity between the two surface materials, the surface hardening process, and the heat transfer between the two surfaces. However, in our experiments, we used materials produced under the same conditions; therefore, no difference in material properties is expected. It can be inferred that the wear coefficient is closely related to the surface morphology.

Figure 4.

(a) Changes in hardness and elastic modulus and (b) load-depth curve in nanoindentation with different sliding times.

Figure 5.

Variation of Archard wear coefficient according to the sliding time interval.

Several studies have noted that the Archard wear model, as a simple empirical formula, has limitations because it does not directly consider factors such as surface roughness, friction coefficient, or initial contact conditions. Ghatrehsamani et al. [29] experimentally investigated the relationship between the wear coefficient , friction coefficient, and surface roughness, and reported that the experimental results were in good agreement. Ghosh et al. [30] analyzed the influence of various surface roughness parameters on wear behavior using simulation-based methods and reported that these parameters directly affect the increase in wear rate. Furthermore, Janakiraman et al. [31] experimentally analyzed the effects of conditions such as contact load, speed, and lubricant viscosity on the wear coefficient and reported that the wear coefficient systematically changes depending on these conditions. These reports support the notion that the wear coefficient is a parameter that varies with surface morphology.

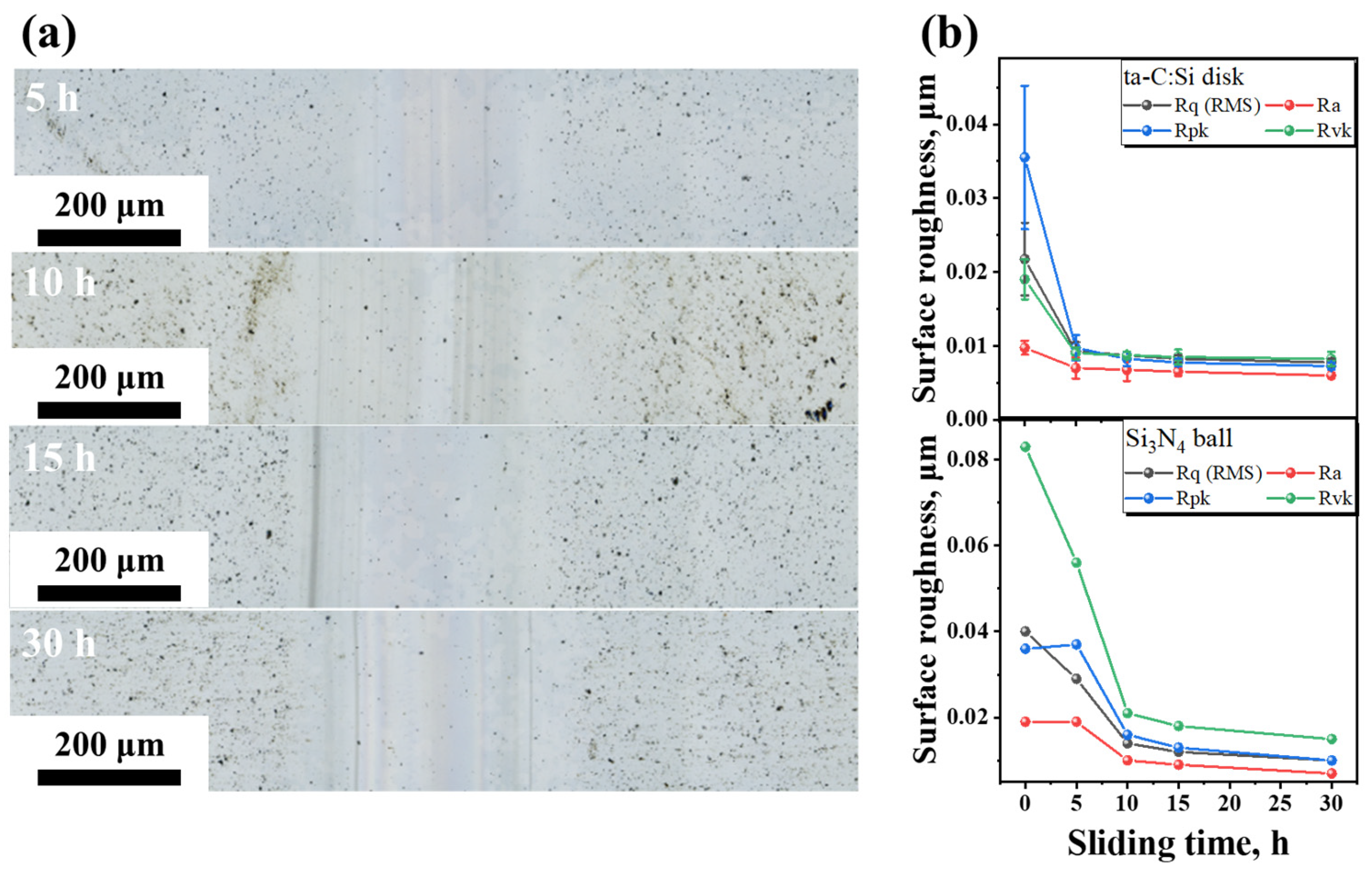

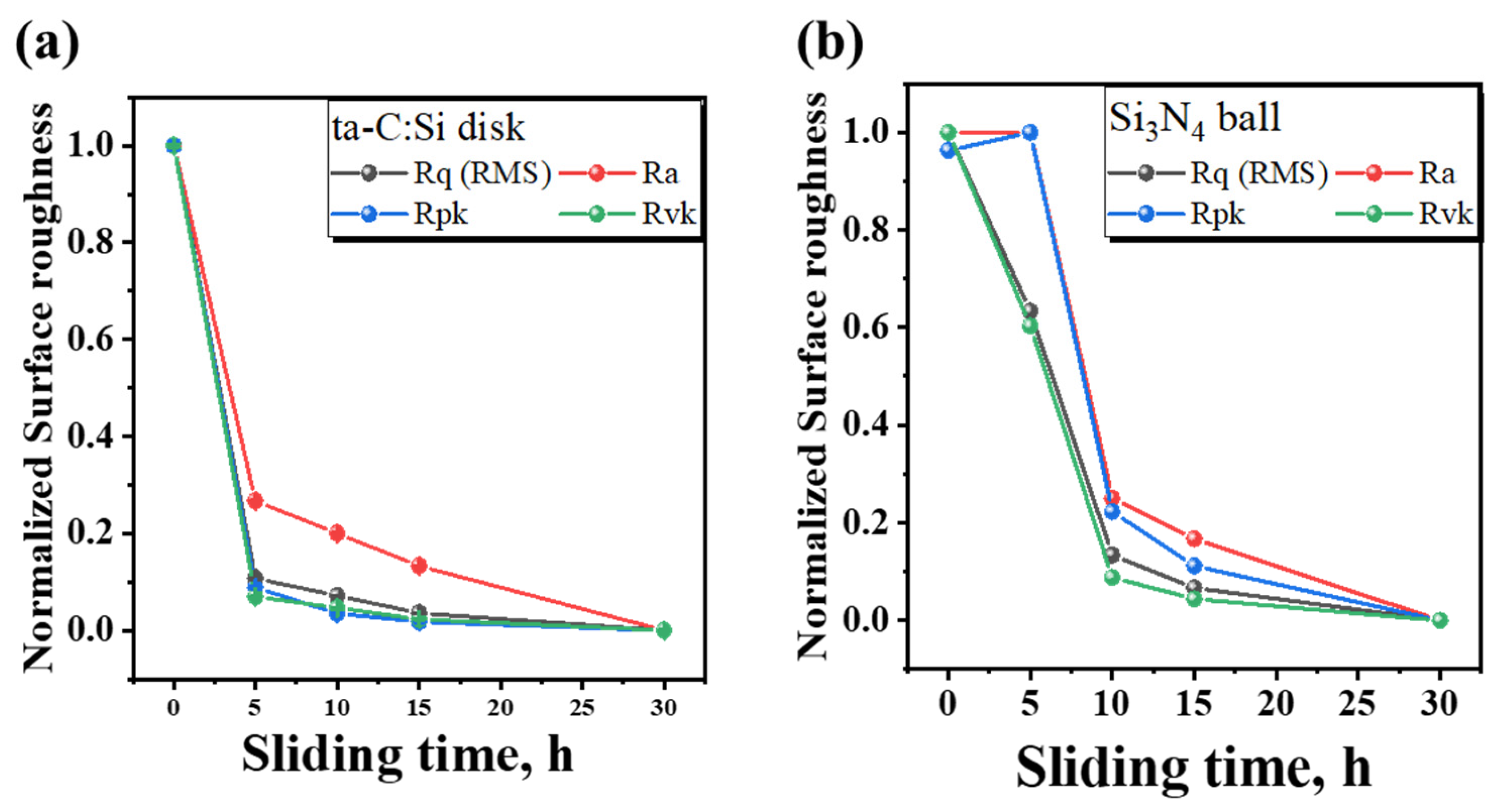

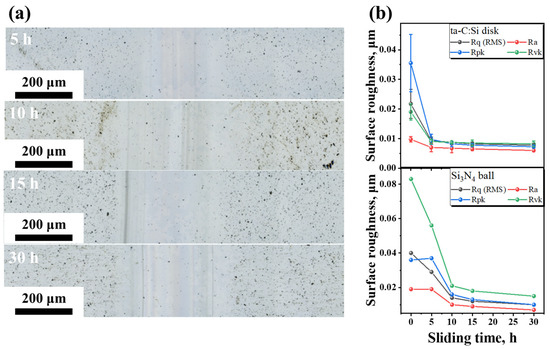

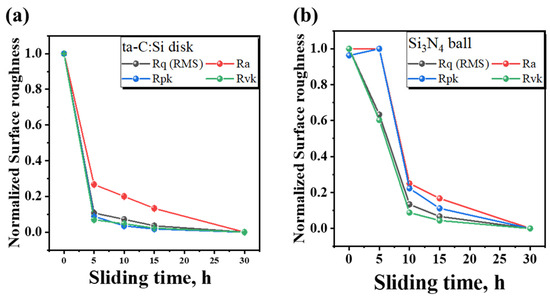

The wear coefficient tends to be proportional to the wear rate and is closely related to the surface morphology. In particular, the surface roughness is a major factor affecting wear behavior [32]. In addition, since the curve in Figure 2a is similar to the type of roughness reduction shown in Blau’s run-in model, the surface roughness within the wear track was measured as shown in Figure 6. It is difficult to confirm a clear difference when visually examining the inside of the wear track in Figure 6a. Further analysis is discussed through the roughness data in Figure 6b. As a result of measuring the roughness, both the ball and the disc showed a tendency to gradually decrease in roughness as the sliding time increased. For ta-C:Si, the roughness rapidly decreased from 0.35 μm to 0.01 μm based on Rpk for the first 5 h, and then decreased slightly over time. The roughness of the Si3N4 ball rapidly decreased from about 0.08 μm to 0.02 μm for up to 10 h based on Rvk, and then decreased slightly thereafter. This change in roughness behavior corresponds to the decrease in wear rate with sliding time. The roughness data were normalized for the relative comparison of roughness changes over time within each roughness parameter (Figure 7). These results support the conclusion that the transition from unstable to steady-state wear is partially dominated by the surface topography of the tribo-pair.

Figure 6.

(a) Wear track image and (b) change in roughness inside the wear track over the sliding time.

Figure 7.

Normalized surface roughness of (a) ta-C:Si and (b) Si3N4 ball over the sliding time.

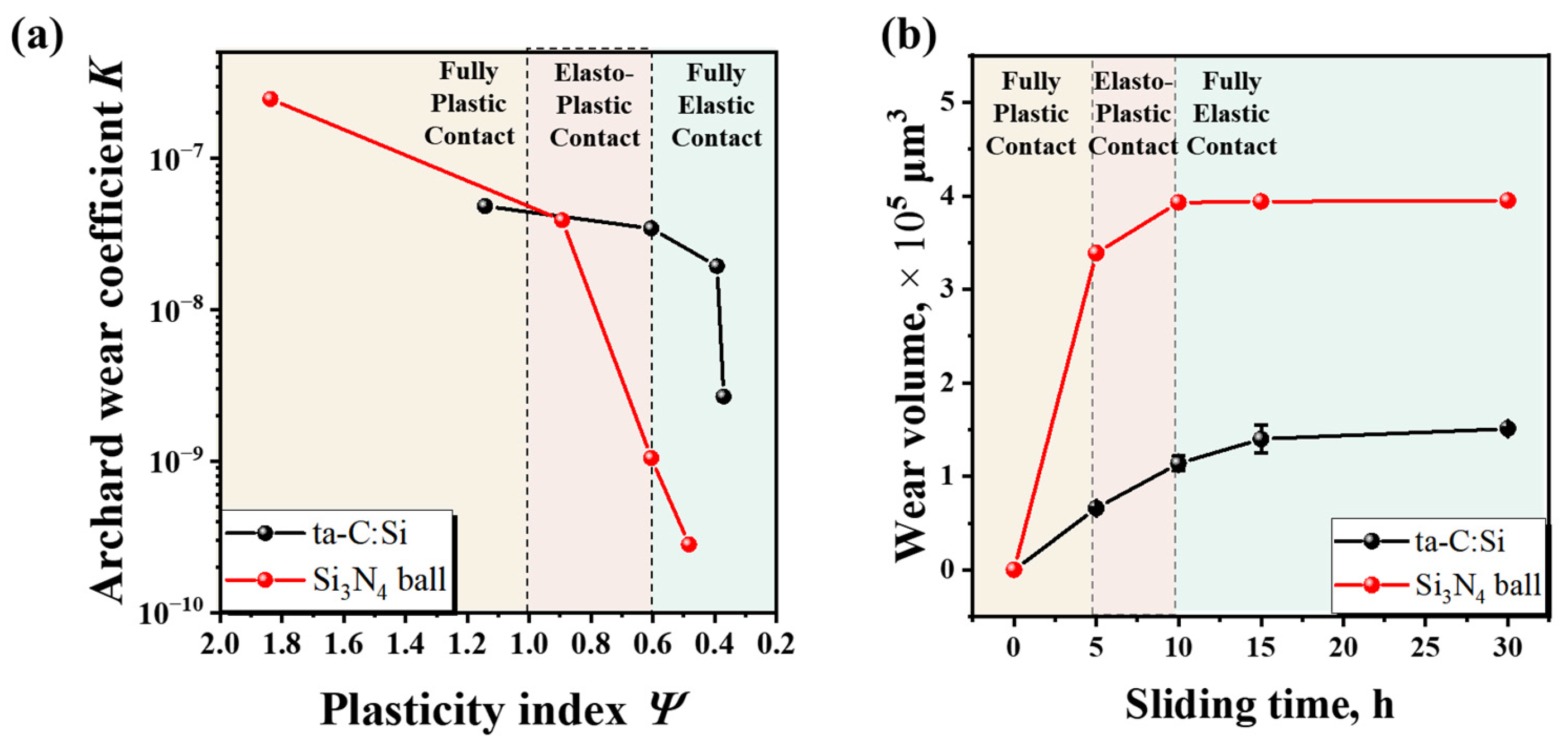

3.4. Discussion: Relationship with Plasticity Index

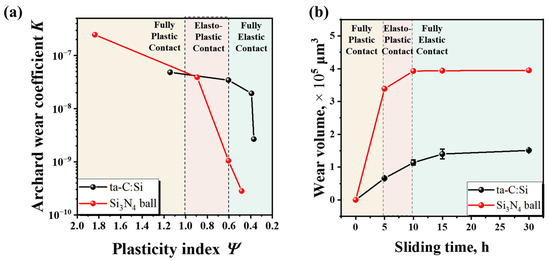

The plasticity index was adopted to define the steady-state section and the deformation behavior was analyzed according to the sliding time. The plasticity index evaluates the relative contribution of elastic and plastic deformation under contact conditions and was calculated using Equation (1) [33]:

where and are the composite elastic modulus and hardness, is the mean radius of curvature of the surface protrusions, and σ is the roughness (Rq). Generally, the contact behavior is interpreted according to the value of the plasticity index [34,35,36]. When the plasticity index is between 0 and 0.6, most of the deformation on the contact surface occurs elastically, which is called the fully elastic contact. When it is between 0.6 and 1, it shows elastoplastic behavior in which both elastic and plastic deformation occur simultaneously. When it is 1 or higher, it exhibits fully plastic behavior in which the deformation in the contact area is mainly plastic deformation.

Figure 8a shows the change in the wear coefficient according to the plasticity index calculated over the sliding time. Both the disk and the ball had a plasticity index of more than 1 when the sliding time was 5 h, and exhibited the highest wear coefficient. In the case of the ball, the plasticity index decreased to less than 1 after 10 h of sliding, entering the elastoplastic region, and the wear coefficient decreased. At 15 h, the plasticity index decreased to 0.6, while the wear coefficient decreased sharply, and at 30 h, the plasticity index and wear coefficient decreased further, indicating that the ball entered the fully elastic region. On the other hand, the wear coefficient of the disc did not change significantly until 15 h, but the plasticity index entered the fully elastic region after 10 h. After 30 h, the wear coefficient decreased rapidly in the fully elastic region. The wear deformation characteristics were analyzed by correlating the plasticity index calculated over the sliding time with the wear volume curve in Figure 3a, and the results are presented in Figure 8b. The plasticity index decreased to below 0.6 at 15 h, when the wear volume increased for both the ball and the disk rapidly decreased, and thus this indicates that the elastic behavior dominates. As a result of the analysis based on the plasticity index, the 0 to 10 h section can be interpreted as the run-in stage, and the section after 10 h corresponds to the steady-state stage. Therefore, the decrease in the wear coefficient is related to the condition of the two contacting surfaces, which means that the elastoplastic behavior of the contact affects the wear. Ultimately, the wear life of hard coatings including ta-C:Si should be evaluated through long-term tests, not short-term tests, and wear behavior transitions should be considered.

Figure 8.

(a) Relationship between the plasticity index and wear coefficient and (b) the wear volume over time considering section-wise elasto-plastic contact.

4. Conclusions

In this study, we analyzed the wear characteristics of ta-C:Si over time in a water-lubricated environment to obtain indicators for predicting and improving service life. We compared the plasticity index and wear coefficient to determine the contact state over time. Our main conclusions are as follows:

- -

- The surface roughness became smoother as the wear volume of the ta-C:Si coating decreased. This suggests a close relationship between the wear coefficient K of the Archard wear equation and surface roughness evolution.

- -

- From the perspective of the plasticity index in contact mechanics, the wear rate was the highest in the fully plastic contact state, and decreased by about 30% once the contact state became fully elastic (ψ ≤ 0.6).

- -

- From the relationship between the wear coefficient and the plasticity index, the steady-state wear rate can be defined starting from the point where the contact state becomes fully elastic.

- -

- This suggests that, in hard coatings including ta-C:Si, once the fully elastic contact is established, the wear proceeds in a more linear and predictable manner, which enables a more consistent analysis and evaluation of wear behavior.

Author Contributions

Conceptualization, Y.-J.J.; Methodology, J.-I.K.; Validation, J.-W.J.; Writing—review & editing, J.-I.K., J.-W.J., M.H.K., S.-H.K. and Y.-J.J.; Supervision, S.-H.K. and Y.-J.J.; Project administration, Y.-J.J. All authors have read and agreed to the published version of the manuscript.

Funding

This study was supported by the Fundamental Research Program (grant number: PKC2330) of the Korea Institute of Materials Science (KIMS).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data is contained within the article.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Rahman, M.H.; Warneke, H.; Webbert, H.; Rodriguez, J.; Austin, E.; Tokunaga, K.; Rajak, D.K.; Menezes, P.L. Water-Based Lubricants: Development, Properties, and Performances. Lubricants 2021, 9, 73. [Google Scholar] [CrossRef]

- Chen, M.; Kato, K.; Adachi, K. Friction and Wear of Self-Mated SiC and Si3N4 Sliding in Water. Wear 2001, 250, 246–255. [Google Scholar] [CrossRef]

- Wu, X.; Suzuki, M.; Ohana, T.; Tanaka, A. Characteristics and Tribological Properties in Water of Si-DLC Coatings. Diam. Relat. Mater. 2008, 17, 7–12. [Google Scholar] [CrossRef]

- Kim, J.I.; Jang, Y.J.; Kim, J.; Kim, J. Effects of Silicon Doping on Low-Friction and High-Hardness Diamond-like Carbon Coating via Filtered Cathodic Vacuum Arc Deposition. Sci. Rep. 2021, 11, 3529. [Google Scholar] [CrossRef] [PubMed]

- Huang, W.; Xu, Y.; Zheng, Y.; Wang, X. The Tribological Performance of Ti(C,N)-Based Cermet Sliding against Si3N4 in Water. Wear 2011, 4, 682–687. [Google Scholar] [CrossRef]

- McKenzie, D.R. Tetrahedral Bonding in Amorphous Carbon. Rep. Prog. Phys. 1996, 59, 1611–1664. [Google Scholar] [CrossRef]

- Sutton, D.C.; Limbert, G.; Stewart, D.; Wood, R.J.K. The Friction of Diamond-like Carbon Coatings in a Water Environment. Friction 2013, 1, 210–221. [Google Scholar] [CrossRef]

- Ronkainen, H.; Varjus, S.; Holmberg, K. Tribological Performance of Different DLC Coatings in Water-Lubricated Conditions. Wear 2001, 249, 267–271. [Google Scholar] [CrossRef]

- Wang, Q.; Zhou, F. Progress in Tribological Properties of Nano-Composite Hard Coatings under Water Lubrication. Lubricants 2017, 17, 5. [Google Scholar] [CrossRef]

- Kim, M.G.; Lee, K.R.; Eun, K.Y. Tribological Behavior of Silicon-Incorporated Diamond-like Carbon Films. Surf. Coat. Technol. 1999, 112, 204–209. [Google Scholar] [CrossRef]

- Camargo, S.S.; Gomes, J.R.; Carrapichano, J.M.; Silva, R.F.; Achete, C.A. Silicon-Incorporated Diamond-like Coatings for Si3N4 Mechanical Seals. Thin Solid Film. 2005, 482, 221–225. [Google Scholar] [CrossRef]

- Yang, S.H.; Kong, H.; Lee, K.R.; Park, S.; Kim, D.E. Effect of Environment on the Tribological Behavior of Si-Incorporated Diamond-like Carbon Films. Wear 2002, 252, 70–79. [Google Scholar] [CrossRef]

- Takikawa, H.; Tanoue, H. Review of Cathodic Arc Deposition for Preparing Droplet-Free Thin Films. In Proceedings of the IEEE Transactions on Plasma Science, Online, 13 August 2007; Volume 35, pp. 992–999. [Google Scholar]

- Fujii, Y.; Imai, T.; Miyamoto, Y.; Ueda, N.; Hosoo, M.; Harigai, T.; Suda, Y.; Takikawa, H.; Tanoue, H.; Kamiya, M.; et al. Dry Machining of Metal Using an Engraving Cutter Coated with a Droplet-Free Ta-C Film Prepared via a T-Shape Filtered Arc Deposition. Surf. Coat. Technol. 2016, 307, 1029–1033. [Google Scholar] [CrossRef]

- Lee, W.Y.; Jang, Y.J.; Tokoroyama, T.; Murashima, M.; Umehara, N. Effect of Defects on Wear Behavior in Ta-C Coating Prepared by Filtered Cathodic Vacuum Arc Deposition. Diam. Relat. Mater. 2020, 105, 107789. [Google Scholar] [CrossRef]

- Jang, Y.J.; Kim, J.I.; Lee, W.Y.; Kim, J. Friction Properties of Thick Tetrahedral Amorphous Carbon Coating with Different Surface Defects under Dry Contact Conditions. Appl. Surf. Sci. 2021, 550, 149332. [Google Scholar] [CrossRef]

- Deng, Y.; Chen, W.; Li, B.; Wang, C.; Kuang, T.; Li, Y. Physical Vapor Deposition Technology for Coated Cutting Tools: A Review. Ceram. Int. 2020, 46, 18373–18790. [Google Scholar] [CrossRef]

- Sun, L.; Li, Y.; Cao, C.; Bi, G.; Luo, X. Effect of Low-Temperature Plasma Carburization on Fretting Wear Behavior of AISI 316L Stainless Steel. Coatings 2024, 14, 158. [Google Scholar] [CrossRef]

- Kim, W.-S.; Kim, S.; Jang, Y.-J.; Kim, J. A Study on the Wear Behavior of Tetrahedral Amorphous Carbon Coatings Based on Bending Angles of the Filtered Cathodic Vacuum Arc with Different Arc Discharge Currents. Tribol. Lubr. 2022, 38, 101–108. [Google Scholar] [CrossRef]

- Archard, J.F.; Hirst, W. The Wear of Metals under Unlubricated Conditions. Proc. R. Soc. London. Ser. A. Math. Phys. Sci. 1956, 236, 397–410. [Google Scholar] [CrossRef]

- Alhadeff, L.; Marshall, M.; Slatter, T. The Influence of Tool Coating on the Length of the Normal Operating Region (Steady-State Wear) for Micro End Mills. Precis. Eng. 2019, 60, 306–319. [Google Scholar] [CrossRef]

- Blau, P.J. Interpretations of the Friction and Wear Break-in Behavior of Metals in Sliding Contact. Wear 1981, 71, 29–43. [Google Scholar] [CrossRef]

- Blau, P.J. On the Nature of Running-In. Tribol. Int. 2005, 38, 1007–1012. [Google Scholar] [CrossRef]

- Blau, P.J. How Common Is the Steady-State? The Implications of Wear Transitions for Materials Selection and Design. Wear 2015, 332–333, 1120–1128. [Google Scholar] [CrossRef]

- Jang, Y.J.; Kim, J.I.; Kim, W.S.; Kim, D.H.; Kim, J. Thermal Stability of Si/SiC/Ta-C Composite Coatings and Improvement of Tribological Properties through High-Temperature Annealing. Sci. Rep. 2022, 12, 3536. [Google Scholar] [CrossRef]

- Zawischa, M.; Makowski, S.; Krülle, T.; Weihnacht, V. Structural Changes of Doped Ta-C Coatings at Elevated Temperature. Carbon N.Y. 2023, 213, 118182. [Google Scholar] [CrossRef]

- Byon, S.-M. Experimental Study to Examine Wear Characteristics and Determine the Wear Coefficient of Ductile Cast Iron (DCI) Roll. J. Korean Soc. Tribol. Lubr. Eng. 2017, 33, 98–105. [Google Scholar] [CrossRef]

- Domínguez García, S.; Béjar Gómez, L.; Maya Yescas, R.; Lara Romero, J.; Castro Cedeño, B.; Espinosa Medina, M.A. Friction Coefficient Dynamics of Tribological Coatings from Engine Lubricants: Analysis and Interpretation. Coatings 2023, 10, 1753. [Google Scholar] [CrossRef]

- Ghatrehsamani, S.; Akbarzadeh, S. Predicting the wear coefficient and friction coefficient in dry point contact using continuum damage mechanics. Proc. Inst. Mech. Eng. Part J 2018, 233, 447–455. [Google Scholar] [CrossRef]

- Ghosh, A.; Sadeghi, F. A novel approach to model effects of surface roughness parameters on wear. Wear 2015, 338, 338–339. [Google Scholar] [CrossRef]

- Janakiraman, V.; Li, S.; Kahraman, A. An Investigation of the Impacts of Contact Parameters on Wear Coefficient. J. Tribol. 2014, 136, 031602-1. [Google Scholar] [CrossRef]

- Sedlaček, M.; Podgornik, B.; Vižintin, J. Influence of Surface Preparation on Roughness Parameters, Friction and Wear. Wear 2009, 266, 482–487. [Google Scholar] [CrossRef]

- Greenwood, J.A.; Williamson, J.B.P. Contact of Nominally Flat Surfaces. Proc. R. Soc. London. Ser. A. Math. Phys. Sci. 1966, 295, 300–319. [Google Scholar] [CrossRef]

- Kogut, L.; Etsion, I. A Static Friction Model for Elastic-Plastic Contacting Rough Surfaces. J. Tribol. 2004, 126, 34–40. [Google Scholar] [CrossRef]

- Beake, B.D. The Influence of the H/E Ratio on Wear Resistance of Coating Systems—Insights from Small-Scale Testing. Surf. Coat. Technol. 2022, 442, 128272. [Google Scholar] [CrossRef]

- Chowdhury, M.S.I.; Bose, B.; Rawal, S.; Fox-Rabinovich, G.S.; Veldhuis, S.C. Investigation of the Wear Behavior of Pvd Coated Carbide Tools during Ti6al4v Machining with Intensive Built up Edge Formation. Coatings 2021, 11, 266. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).