Effects of Surface Finishing Procedures, Coffee Immersion, and Simulated Tooth-Brushing on the Surface Roughness, Surface Gloss, and Color Stability of a Resin Matrix Ceramic

Abstract

1. Introduction

2. Materials and Methods

2.1. Specimen Preparation

2.2. Experimental Procedure

2.3. Measurement of Color Parameters

2.4. Measurement of Surface Gloss (Gloss Unit: GU)

2.5. Measurement of Surface Roughness

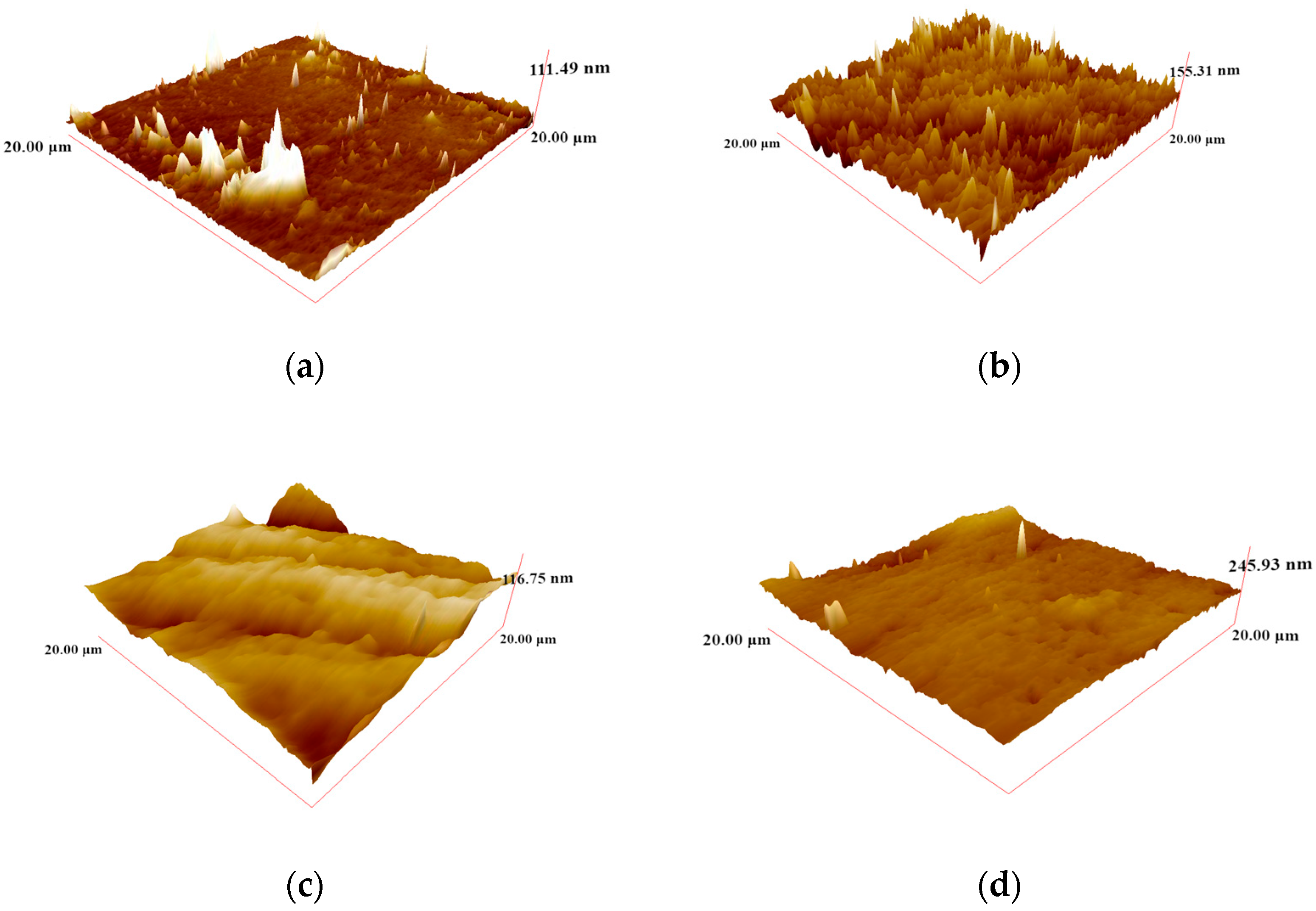

2.6. Surface Analysis Using Atomic Force Microscopy (AFM)

2.7. Statistical Analyses

3. Results

3.1. Average Surface Roughness (Ra)

3.2. AFM Images

3.3. Surface Gloss (Gloss Unit: GU)

3.4. Color Stability (DeltaE: ∆Eab)

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| AFM | Atomic force microscopy |

| CAD-CAM | Computer-aided design–computer-aided manufacturing |

| CIE | Internationale de l’Eclairage |

| GU | Gloss unit |

References

- Stamenković, D.D.; Tango, R.N.; Todorović, A.; Karasan, D.; Sailer, I.; Paravina, R.D. Staining and aging-dependent changes in color of CAD-CAM materials. J. Prosthet. Dent. 2021, 126, 672–678. [Google Scholar] [CrossRef] [PubMed]

- Joda, T.; Brägger, U. Digital vs. conventional implant prosthetic workflows: A cost/time analysis. Clin. Oral Implant. Res. 2015, 26, 1430–1435. [Google Scholar] [CrossRef]

- Joda, T.; Zarone, F.; Ferrari, M. The complete digital workflow in fixed prosthodontics: A systematic review. BMC Oral Health 2017, 17, 1–9. [Google Scholar] [CrossRef]

- Kilinc, H.; Turgut, S. Optical behaviors of esthetic CAD-CAM restorations after different surface finishing and polishing procedures and UV aging: An in vitro study. J. Prosthet. Dent. 2018, 120, 107–113. [Google Scholar] [CrossRef] [PubMed]

- Awada, A.; Nathanson, D. Mechanical properties of resin-ceramic CAD/CAM restorative materials. J. Prosthet. Dent. 2015, 114, 587–593. [Google Scholar] [CrossRef] [PubMed]

- Argyrou, R.; Thompson, G.A.; Cho, S.-H.; Berzins, D.W. Edge chipping resistance and flexural strength of polymer infiltrated ceramic network and resin nanoceramic restorative materials. J. Prosthet. Dent. 2016, 116, 397–403. [Google Scholar] [CrossRef] [PubMed]

- Goujat, A.; Abouelleil, H.; Colon, P.; Jeannin, C.; Pradelle, N.; Seux, D.; Grosgogeat, B. Mechanical properties and internal fit of 4 CAD-CAM block materials. J. Prosthet. Dent. 2018, 119, 384–389. [Google Scholar] [CrossRef]

- Laborie, M.; Naveau, A.; Menard, A. CAD-CAM resin-ceramic material wear: A systematic review. J. Prosthet. Dent. 2024, 131, 812–818. [Google Scholar] [CrossRef]

- Barutçugil, Ç.; Bilgili, D.; Barutcigil, K.; Dündar, A.; Büyükkaplan, U.Ş.; Yilmaz, B. Discoloration and translucency changes of CAD-CAM materials after exposure to beverages. J. Prosthet. Dent. 2019, 122, 325–331. [Google Scholar] [CrossRef]

- Paolone, G.; Mandurino, M.; De Palma, F.; Mazzitelli, C.; Scotti, N.; Breschi, L.; Gherlone, E.; Cantatore, G.; Vichi, A. Color stability of polymer-based composite CAD/CAM blocks: A systematic review. Polymers 2023, 15, 464. [Google Scholar] [CrossRef]

- Al Ahmari, N.M.; Alahmari, M.A.; Al Moaleem, M.M.; Alshahrani, R.S.A.; Alqahtani, F.F.; Mohammed, W.S.; Al-Makramani, B.M.A.; Mehta, V.; Meto, A.; Meto, A. Physical, optical, and mechanical properties of ceramic materials after coffee immersion and evaluation of cleaning impact with different oral hygiene tools. Int. J. Environ. Res. Public Health 2022, 19, 15047. [Google Scholar] [CrossRef]

- Commission Internationale de l’Eclairage (CIE) Colorimetry, 4th ed.; CIE Technical Report 015; CIE Central Bureau: Vienna, Austria, 2018.

- Tabatabaian, F. Color in zirconia-based restorations and related factors: A literature review. J. Prosthodont. 2018, 27, 201–211. [Google Scholar] [CrossRef]

- Vadher, R.; Parmar, G.; Kanodia, S.; Chaudhary, A.; Kaur, M.; Savadhariya, T. Basics of color in dentistry: A review. IOSR J. Dent. Med. Sci. 2014, 13, 78–85. [Google Scholar] [CrossRef]

- Sonza, Q.N.; Della Bona, A.; Pecho, O.E.; Borba, M. Effect of substrate and cement on the final color of zirconia-based all-ceramic crowns. J. Esthet. Restor. Dent. 2021, 33, 891–898. [Google Scholar] [CrossRef]

- Paravina, R.D.; Ghinea, R.; Herrera, L.J.; Bona, A.D.; Igiel, C.; Linninger, M.; Sakai, M.; Takahashi, H.; Tashkandi, E.; Perez, M.d.M. Color difference thresholds in dentistry. J. Esthet. Restor. Dent. 2015, 27, S1–S9. [Google Scholar] [CrossRef] [PubMed]

- Sayed, M.; Abdelhalim, E.; Rabeae, H. Effect of Beverage consumption on color stability of CAD/CAM ceramics. Egypt. Dent. J. 2023, 69, 1233–1240. [Google Scholar] [CrossRef]

- Yerliyurt, K.; Sarıkaya, I. Color stability of hybrid ceramics exposed to beverages in different combinations. BMC Oral Health 2022, 22, 180. [Google Scholar] [CrossRef]

- Abdelhafez, M.H.; Hassan, M.R. Effect of commonly consumed beverages on color stability of hybrid ceramics: An in vitro study. Egypt. Dent. J 2024, 70, 2451–2459. [Google Scholar] [CrossRef]

- Alghazali, N.; Hakami, A.A.; AlAjlan, G.A.; Alotaibi, R.M.; Alabdulwahab, F.N.; AlQuraishi, L.A.; Abdalkadeer, H.; Al Moaleem, M.M. Influence of the Arabic-coffee on the overall color of glazed or polished porcelain veneers–in vitro study. Open Dent. J. 2019, 13, 364–370. [Google Scholar] [CrossRef]

- Gupta, R.; Parkash, H.; Shah, N.; Jain, V. A spectrophotometric evaluation of color changes of various tooth colored veneering materials after exposure to commonly consumed beverages. J. Indian Prosthodont. Soc. 2005, 5, 72–78. [Google Scholar] [CrossRef]

- Carey, C.M. Tooth whitening: What we now know. J. Evid. Based Dent. Pract. 2014, 14, 70–76. [Google Scholar] [CrossRef] [PubMed]

- Suzuki, M.; Miyano, Y.; Sato, F.; Shinkai, K. Surface properties of resin composites and CAD/CAM blocks after simulated toothbrushing. Oper. Dent. 2023, 48, 575–587. [Google Scholar] [CrossRef]

- Karatas, O.; Gul, P.; Akgul, N.; Celik, N.; Gundogdu, M.; Duymus, Z.; Seven, N. Effect of staining and bleaching on the microhardness, surface roughness and color of different composite resins. Dent. Med. Probl. 2021, 58, 369–376. [Google Scholar] [CrossRef] [PubMed]

- Heimer, S.; Schmidlin, P.R.; Stawarczyk, B. Effect of different cleaning methods of polyetheretherketone on surface roughness and surface free energy properties. J. Appl. Biomater. Funct. Mater. 2016, 14, e248–e255. [Google Scholar] [CrossRef]

- Tekçe, N.; Fidan, S.; Tuncer, S.; Kara, D.; Demirci, M. The effect of glazing and aging on the surface properties of CAD/CAM resin blocks. J. Adv. Prosthodont. 2018, 10, 50–57. [Google Scholar] [CrossRef]

- Kozmacs, C.; Hollmann, B.; Arnold, W.H.; Naumova, E.; Piwowarczyk, A. Polishing of monolithic zirconia crowns—Results of different dental practitioner groups. Dent. J. 2017, 5, 30. [Google Scholar] [CrossRef]

- Porojan, L.; Vasiliu, R.-D.; Bîrdeanu, M.-I.; Porojan, S.-D. Surface characterization and optical properties of reinforced dental glass-ceramics related to artificial aging. Molecules 2020, 25, 3407. [Google Scholar] [CrossRef]

- Alhassan, M.; Maawadh, A.; Labban, N.; Alnafaiy, S.M.; Alotaibi, H.N.; BinMahfooz, A.M. Effect of different surface treatments on the surface roughness and gloss of resin-modified CAD/CAM ceramics. Appl. Sci. 2022, 12, 11972. [Google Scholar] [CrossRef]

- Tsenova-Ilieva, I.; Karova, E. Application of atomic force microscopy in dental investigations. Int. J. Sci. Res. 2020, 9, 1319–1326. [Google Scholar] [CrossRef]

- Tholt, B.; Miranda-Júnior, W.G.; Prioli, R.; Thompson, J.; Oda, M. Surface roughness in ceramics with different finishing techniques using atomic force microscope and profilometer. Oper. Dent. 2006, 31, 442–449. [Google Scholar] [CrossRef]

- Labban, N.; Al Amri, M.D.; Alnafaiy, S.M.; Alhijji, S.M.; Alenizy, M.A.; Iskandar, M.; Feitosa, S. Influence of toothbrush abrasion and surface treatments on roughness and gloss of polymer-infiltrated ceramics. Polymers 2021, 13, 3694. [Google Scholar] [CrossRef] [PubMed]

- Awad, D.; Stawarczyk, B.; Liebermann, A.; Ilie, N. Translucency of esthetic dental restorative CAD/CAM materials and composite resins with respect to thickness and surface roughness. J. Prosthet. Dent. 2015, 113, 534–540. [Google Scholar] [CrossRef] [PubMed]

- Topçu, S.; Tekçe, N.; Kopuz, D.; Özcelik, E.Y.; Kolaylı, F.; Tuncer, S.; Demirci, M. Effect of surface roughness and biofilm formation on the color properties of resin-infiltrated ceramic and lithium disilicate glass-ceramic CAD-CAM materials. J. Prosthet. Dent. 2024, 131, 935.e1–935.e8. [Google Scholar] [CrossRef]

- Kursoglu, P.; Motro, P.F.K.; Kazazoglu, E. Correlation of surface texture with the stainability of ceramics. J. Prosthet. Dent. 2014, 112, 306–313. [Google Scholar] [CrossRef]

- Dalkiz, M.; Sipahi, C.; Beydemir, B. Effects of six surface treatment methods on the surface roughness of a low-fusing and an ultra low-fusing feldspathic ceramic material. J. Prosthodont. 2009, 18, 217–222. [Google Scholar] [CrossRef]

- Jung, M. Finishing and polishing of a hybrid composite and a heat-pressed glass ceramic. Oper. Dent. 2002, 27, 175–183. [Google Scholar]

- Kara, D.; Tekçe, N.; Fidan, S.; Demirci, M.; Tuncer, S.; Balcı, S. The effects of various polishing procedures on surface topography of CAD/CAM resin restoratives. J. Prosthodont. 2021, 30, 481–489. [Google Scholar] [CrossRef]

- Lawson, N.C.; Burgess, J.O. Gloss and stain resistance of ceramic-polymer CAD/CAM restorative blocks. J. Esthet. Restor. Dent. 2016, 28, S40–S45. [Google Scholar] [CrossRef]

- Çakmak, G.; Subaşı, M.G.; Yilmaz, B. Effect of thermocycling on the surface properties of resin-matrix CAD-CAM ceramics after different surface treatments. J. Mech. Behav. Biomed. Mater. 2021, 117, 104401. [Google Scholar] [CrossRef]

- Tekce, N.; Pala, K.; Tuncer, S.; Demirci, M. The effect of surface sealant application and accelerated aging on posterior restorative surfaces: An SEM and AFM study. Dent. Mater. J. 2017, 36, 182–189. [Google Scholar] [CrossRef]

- Aldosari, L.I.; Alshadidi, A.A.; Porwal, A.; Al Ahmari, N.M.; Al Moaleem, M.M.; Suhluli, A.M.; Shariff, M.; Shami, A.O. Surface roughness and color measurements of glazed or polished hybrid, feldspathic, and Zirconia CAD/CAM restorative materials after hot and cold coffee immersion. BMC Oral Health 2021, 21, 422. [Google Scholar] [CrossRef] [PubMed]

- Gönülol, N.; Yılmaz, F. The effects of finishing and polishing techniques on surface roughness and color stability of nanocomposites. J. Dent. 2012, 40, e64–e70. [Google Scholar] [CrossRef]

- Anazi, A.A.; Sultan, S. The effect of brushing on coffee stainability of ceramic crowns constructed from repeatedly processed lithium disilicate ceramic ingots: An in vitro study. Appl. Sci. 2023, 13, 7398. [Google Scholar] [CrossRef]

- Prasad, M.; Rajula, P.B.; Pl, R.; Rao, S.; Gayathri, K.; Mounika, V.; Kodali, M.V.R.M.; Kalaivani, V.; Soloman, G.; Nisha, N. In vitro analysis of enamel abrasion using a novel manual nano-bristle toothbrush: An atomic force microscopy study. Cureus 2024, 16, e75243. [Google Scholar] [CrossRef] [PubMed]

- ISO T. 14569-1; Dental Materials-Guidance on Testing of Wear Resistance. Part 1: Wear by Tooth Brushing. International Organization for Standardization: Geneva, Switzerland, 2007.

- Rocha, R.; Fagundes, T.; Caneppele, T.; Bresciani, E. Perceptibility and acceptability of surface gloss variations in dentistry. Oper. Dent. 2020, 45, 134–142. [Google Scholar] [CrossRef] [PubMed]

- Öztürk, E.K.; Nemli, S.K.; Bal, B.T.; Güngör, M.B. Evaluation of the optical and surface properties of monolithic CAD-CAM ceramics after simulated tooth-brushing. J. Prosthet. Dent. 2024, 132, 1325.e1–1325.e8. [Google Scholar] [CrossRef]

- Gendia, S.M.; ElGuindy, J.F.; Taymour, M.A. Shade Changes of Cemented Cerasmart Laminate Veneers After Exposure to Commonly Consumed Beverages (An In Vitro Study). Al-Azhar J. Dent. Sci. 2017, 20, 195–200. [Google Scholar] [CrossRef]

- Al Amri, M.D.; Labban, N.; Alhijji, S.; Alamri, H.; Iskandar, M.; Platt, J.A. In vitro evaluation of translucency and color stability of CAD/CAM polymer-infiltrated ceramic materials after accelerated aging. J. Prosthodont. 2021, 30, 318–328. [Google Scholar] [CrossRef]

- Bozoğulları, H.N.; Temizci, T. Evaluation of the color stability, stainability, and surface roughness of permanent composite-based milled and 3D printed CAD/CAM restorative materials after thermocycling. Appl. Sci. 2023, 13, 11895. [Google Scholar] [CrossRef]

- Ozer, N.; Oguz, E. Influence of different finishing-polishing procedures and thermocycle aging on the surface roughness of nano-ceramic hybrid CAD/CAM material. Niger. J. Clin. Pract. 2023, 26, 604–611. [Google Scholar] [CrossRef]

- Siddanna, G.D.; Valcanaia, A.J.; Fierro, P.H.; Neiva, G.F.; Fasbinder, D.J. Surface evaluation of resilient CAD/CAM ceramics after contouring and polishing. J. Esthet. Restor. Dent. 2021, 33, 750–763. [Google Scholar] [CrossRef] [PubMed]

- Mota, E.G.; Smidt, L.N.; Fracasso, L.M.; Burnett Jr, L.H.; Spohr, A.M. The effect of milling and postmilling procedures on the surface roughness of CAD/CAM materials. J. Esthet. Restor. Dent. 2017, 29, 450–458. [Google Scholar] [CrossRef]

- de Oliveira, A.L.B.M.; Domingos, P.A.D.S.; Palma-Dibb, R.G.; Garcia, P.P.N.S. Chemical and morphological features of nanofilled composite resin: Influence of finishing and polishing procedures and fluoride solutions. Microsc. Res. Tech. 2012, 75, 212–219. [Google Scholar] [CrossRef] [PubMed]

- Incesu, E.; Yanikoglu, N. Evaluation of the effect of different polishing systems on the surface roughness of dental ceramics. J. Prosthet. Dent. 2020, 124, 100–109. [Google Scholar] [CrossRef]

- Yap, A.U.; Sau, C.W.; Lye, K.W. Effects of finishing/polishing time on surface characteristics of tooth-coloured restoratives. J. Oral Rehabil. 1998, 25, 456–461. [Google Scholar] [CrossRef] [PubMed]

- Marshall, S.J.; Bayne, S.C.; Baier, R.; Tomsia, A.P.; Marshall, G.W. A review of adhesion science. Dent. Mater. 2010, 26, e11–e16. [Google Scholar] [CrossRef]

- Akan, E.; Colgecen, O.; Meşe, I.T.; Bağiş, B. Effects of different finishing procedures on surface roughness of hybrid CAD/CAM materials. J. Dent. Indones. 2021, 28, 185–191. [Google Scholar] [CrossRef]

- Association, A.D. Product Review: Polishing Systems; American Dental Association: Chicago, IL, USA, 2010. [Google Scholar]

- de Andrade, G.S.; Augusto, M.G.; Simões, B.V.; Pagani, C.; Saavedra, G.S.F.A.; Bresciani, E. Impact of simulated toothbrushing on surface properties of chairside CAD-CAM materials: An in vitro study. J. Prosthet. Dent. 2021, 125, 469.e1–469.e6. [Google Scholar] [CrossRef]

- Bagheri, R.; Burrow, M.; Tyas, M. Influence of food-simulating solutions and surface finish on susceptibility to staining of aesthetic restorative materials. J. Dent. 2005, 33, 389–398. [Google Scholar] [CrossRef]

- Aydın, N.; Karaoğlanoğlu, S.; Oktay, E.A.; Kılıçarslan, M.A. Investigating the color changes on resin-based CAD/CAM blocks. J. Esthet. Restor. Dent. 2020, 32, 251–256. [Google Scholar] [CrossRef]

- Yannikakis, S.A.; Zissis, A.J.; Polyzois, G.L.; Caroni, C. Color stability of provisional resin restorative materials. J. Prosthet. Dent. 1998, 80, 533–539. [Google Scholar] [CrossRef] [PubMed]

- Arocha, M.A.; Basilio, J.; Llopis, J.; Di Bella, E.; Roig, M.; Ardu, S.; Mayoral, J.R. Colour stainability of indirect CAD–CAM processed composites vs. conventionally laboratory processed composites after immersion in staining solutions. J. Dent. 2014, 42, 831–838. [Google Scholar] [CrossRef] [PubMed]

- Papathanasiou, I.; Zinelis, S.; Papavasiliou, G.; Kamposiora, P. Effect of aging on color, gloss and surface roughness of CAD/CAM composite materials. J. Dent. 2023, 130, 104423. [Google Scholar] [CrossRef]

- Aydın, N.; Karaoglanoglu, S.; Oktay, E.A. Investigation the effects of whitening toothpastes on color change of resin-based CAD/CAM blocks. J. Esthet. Restor. Dent. 2021, 33, 884–890. [Google Scholar] [CrossRef]

- Arif, R.; Yilmaz, B.; Johnston, W.M. In vitro color stainability and relative translucency of CAD-CAM restorative materials used for laminate veneers and complete crowns. J. Prosthet. Dent. 2019, 122, 160–166. [Google Scholar] [CrossRef] [PubMed]

- Pouranfar, F.L.; Sheridan, R.; Salmon, C.; Vandewalle, K.S. Effect of toothbrushing on surface color of ceramic-polymer materials: An in vitro study. J. Contemp. Dent. Pract. 2020, 21, 1054–1058. [Google Scholar]

- Roselino, L.D.M.R.; Tirapelli, C.; Pires-de-Souza, F.D.C.P. Randomized clinical study of alterations in the color and surface roughness of dental enamel brushed with whitening toothpaste. J. Esthet. Restor. Dent. 2018, 30, 383–389. [Google Scholar] [CrossRef]

- O’Neill, C.; Kreplak, L.; Rueggeberg, F.A.; Labrie, D.; Shimokawa, C.A.K.; Price, R.B. Effect of tooth brushing on gloss retention and surface roughness of five bulk-fill resin composites. J. Esthet. Restor. Dent. 2018, 30, 59–69. [Google Scholar] [CrossRef]

- Wendler, M.; Stenger, A.; Ripper, J.; Priewich, E.; Belli, R.; Lohbauer, U. Mechanical degradation of contemporary CAD/CAM resin composite materials after water ageing. Dent. Mater. 2021, 37, 1156–1167. [Google Scholar] [CrossRef]

- Sharma, G.; Wu, W.; Dalal, E. The CIEDE2000 color-difference formula: Implementation notes, supplementary test data, and mathematical observations. Col. Res. Appl. 2005, 30, 21–30. [Google Scholar] [CrossRef]

| Surface Finishing Procedure | Application Sequence | Measurement Time | |||

|---|---|---|---|---|---|

| Baseline | First | Second | |||

| Glazed | First coffee immersion, then simulated tooth-brushing | Mean ± SD | 0.32 ± 0.08 | 0.27 ± 0.07 | 0.18 ± 0.04 |

| Median (Q1–Q3) | 0.32 (0.29–0.36) | 0.27 (0.25–0.34) | 0.16 (0.15–0.2) | ||

| Min–Max | 0.16–0.45 | 0.13–0.34 | 0.13–0.26 | ||

| First simulated tooth-brushing, then coffee immersion | Mean ± SD | 0.24 ± 0.03 | 0.18 ± 0.03 | 0.17 ± 0.03 | |

| Median (Q1–Q3) | 0.24 (0.21–0.27) | 0.17 (0.16–0.2) | 0.17 (0.15–0.19) | ||

| Min–Max | 0.18–0.27 | 0.14–0.24 | 0.13–0.22 | ||

| Mechanically polished | First coffee immersion, then simulated tooth-brushing | Mean ± SD | 0.27 ± 0.05 | 0.25 ± 0.06 | 0.15 ± 0.03 |

| Median (Q1–Q3) | 0.26 (0.24–0.29) | 0.24 (0.2–0.3) | 0.14 (0.13–0.16) | ||

| Min–Max | 0.17–0.37 | 0.14–0.34 | 0.11–0.22 | ||

| First simulated tooth-brushing, then coffee immersion | Mean ± SD | 0.25 ± 0.04 | 0.15 ± 0.03 | 0.15 ± 0.05 | |

| Median (Q1–Q3) | 0.24 (0.24–0.27) | 0.17 (0.13–0.17) | 0.13 (0.12–0.14) | ||

| Min–Max | 0.19–0.31 | 0.11–0.18 | 0.11–0.28 | ||

| Source | Adjusted Sum of Squares | Degree of Freedom | Adjusted Mean Squares | F-Value | p-Value |

|---|---|---|---|---|---|

| Surface finishing (SF) | 0.0158 | 1 | 0.0158 | 4.7827 | 0.0353 |

| Application sequence (AS) | 0.0674 | 1 | 0.0674 | 20.3873 | <0.001 |

| SF × AS | 0.0024 | 1 | 0.0024 | 0.7274 | 0.3994 |

| Measurement time (MT) | 0.2207 | 2 | 0.1103 | 65.6467 | <0.001 |

| SF × MT | 0.0003 | 2 | 0.0002 | 0.0904 | 0.9137 |

| AS × MT | 0.0380 | 2 | 0.0190 | 11.3124 | <0.001 |

| SF × AS × MT | 0.0084 | 2 | 0.0042 | 2.4849 | 0.0905 |

| Between-subjects | 0.1189 | 36 | 0.0033 | - | - |

| Error | 0.1210 | 72 | 0.0017 | - | - |

| Total | 0.5929 | 119 | - | - | - |

| Measurement Time | Application Sequence | ||

|---|---|---|---|

| First Coffee Immersion, Then Simulated Tooth-Brushing | First Simulated Tooth-Brushing, Then Coffee Immersion | ||

| Baseline | Mean ± SD | 0.29 ± 0.07 a,A | 0.24 ± 0.04 a,A |

| First | Mean ± SD | 0.26 ± 0.06 a,A | 0.17 ± 0.03 b,B |

| Second | Mean ± SD | 0.16 ± 0.04 b,A | 0.16 ± 0.04 b,A |

| Surface Finishing | Application Sequence | Measurement Time | |||

|---|---|---|---|---|---|

| Baseline | First | Second | |||

| Glazed | First coffee immersion then simulated tooth-brushing | Mean ± SD | 54 ± 10 | 64.3 ± 9.1 | 64.8 ± 10.0 |

| Median (Q1–Q3) | 53.1 (44.6–57.5) | 65.4 (56.3–72.1) | 67.7 (55.1–73.9) | ||

| Min–Max | 43.9–71.6 | 46.9–75.5 | 48.8–75.7 | ||

| First simulated tooth-brushing then coffee immersion | Mean ± SD | 57.7 ± 7.2 | 63.5 ± 9.7 | 66.4 ± 8.8 | |

| Median (Q1–Q3) | 57.5 (52.8–62.3) | 63.7 (57.4–70.6) | 67.3 (63.4–73.8) | ||

| Min–Max | 47.3–69.8 | 47.7–76.5 | 46.4–74.9 | ||

| Mechanically polished | First coffee immersion then simulated tooth-brushing | Mean ± SD | 56.1 ± 10.2 | 59.0 ± 8.1 | 73.6 ± 7.0 |

| Median (Q1–Q3) | 55.5 (47.8–62.3) | 61.6 (51.2–64.4) | 73.0 (70.1–80.4) | ||

| Min–Max | 41.6–71.9 | 46.9–70.8 | 58.8–81.9 | ||

| First simulated tooth-brushing then coffee immersion | Mean ± SD | 60.1 ± 5.8 | 74.7 ± 6.1 | 71.2 ± 5.9 | |

| Median (Q1–Q3) | 59.8 (56.8–64.1) | 75.9 (72.7–79.6) | 71.7 (65–76.6) | ||

| Min–Max | 51.4–68.4 | 63.2–81.7 | 60.9–77.8 | ||

| Source | Adjusted Sum of Squares | Degree of Freedom | Adjusted Mean Squares | F-Value | p-Value |

|---|---|---|---|---|---|

| Surface finishing (SF) | 1 | 483.2053 | 483.2053 | 3.5225 | 0.0687 |

| Application sequence (AS) | 1 | 391.6853 | 391.6853 | 2.8553 | 0.0997 |

| SF × AS | 1 | 136.1070 | 136.1070 | 0.9922 | 0.3259 |

| Measurement time (MT) | 2 | 3060.8565 | 1530.4283 | 42.923 | <0.001 |

| SF × MT | 2 | 120.8602 | 60.4301 | 1.6948 | 0.1909 |

| S × MT | 2 | 314.1002 | 157.0501 | 4.4046 | 0.0157 |

| SF × AS × MT | 2 | 581.2205 | 290.6102 | 8.1505 | <0.001 |

| Between-subjects | 36 | 4938.3873 | 137.1774 | - | - |

| Error | 72 | 2567.2027 | 35.6556 | - | - |

| Total | 119 | 12,593.625 | - | - | - |

| Surface Finishing Procedure | Application Sequence | Measurement Time | |||

|---|---|---|---|---|---|

| Baseline | First | Second | |||

| Glazed | First coffee immersion, then simulated tooth-brushing | Mean ± SD | 54 ± 10 a,A,1 | 64.3 ± 9.1 ab,A,1 | 64.8 ± 10 b,A,1 |

| First simulated tooth-brushing, then coffee immersion | Mean ± SD | 57.7 ± 7.2 a,A,1 | 63.5 ± 9.7 a,A,1 | 66.4 ± 8.8 a,A,1 | |

| Mechanically polished | First coffee immersion, then simulated tooth-brushing | Mean ± SD | 56.1 ± 10.2 a,A,1 | 59 ± 8.1 a,A,1 | 73.6 ± 7 b,A,1 |

| First simulated tooth-brushing, then coffee immersion | Mean ± SD | 60.1 ± 5.8 a,A,1 | 74.7 ± 6.1 b,B,1 | 71.2 ± 5.9 b,A,1 | |

| Surface Finishing Procedures | Application Sequence | Measurement Time | ||

|---|---|---|---|---|

| DeltaE1 (Baseline-First Measurement) | DeltaE2 (Baseline-Second Measurement) | |||

| Glazed | First coffee immersion, then simulated tooth-brushing | Mean ± SD | 4.75 ± 1.12 | 2.29 ± 0.67 |

| Median (Q1–Q3) | 5.14 (4.71–5.34) | 2.77 (2.49–3.16) | ||

| Min–Max | 1.91–5.64 | 2.02–4.41 | ||

| First simulated tooth-brushing, then coffee immersion | Mean ± SD | 1.89 ± 0.69 | 4.26 ± 0.93 | |

| Median (Q1–Q3) | 1.93 (1.36–2.18) | 4.38 (3.83–5.1) | ||

| Min–Max | 0.94–3.30 | 2.32–5.22 | ||

| Mechanically polished | First coffee immersion, then simulated tooth-brushing | Mean ± SD | 4.94 ± 0.80 | 2.49 ± 0.54 |

| Median (Q1–Q3) | 4.92 (4.23–5.78) | 2.4 (2.27–2.94) | ||

| Min–Max | 3.8–6.19 | 1.61–3.35 | ||

| First simulated tooth-brushing, then coffee immersion | Mean ± SD | 1.94 ± 0.47 | 4.66 ± 0.28 | |

| Median (Q1–Q3) | 1.87 (1.75–2.08) | 4.66 (4.43–4.85) | ||

| Min–Max | 1.1–2.75 | 4.29–5.16 | ||

| Source | Adjusted Sum of Squares | Degree of Freedom | Adjusted Mean Squares | F-Value | p-Value |

|---|---|---|---|---|---|

| Surface finishing (SF) | 0.0455 | 1 | 0.0455 | 0.0600 | 0.8079 |

| Application sequence (AS) | 6.9424 | 1 | 6.9424 | 9.1544 | 0.0046 |

| SF × AS | 0.6204 | 1 | 0.6204 | 0.8181 | 0.3718 |

| Measurement time (MT) | 0.8504 | 1 | 0.8504 | 2.7113 | 0.1083 |

| SF × MT | 0.0928 | 1 | 0.0928 | 0.2957 | 0.5899 |

| AS × MT | 109.5468 | 1 | 109.5468 | 349.2876 | <0.001 |

| SF × AS × MT | 1.2043 | 1 | 1.2043 | 3.8399 | 0.0578 |

| Between-subjects | 27.3010 | 36 | 0.7584 | - | - |

| Error | 11.2907 | 36 | 0.3136 | - | - |

| Total | 157.8943 | 79 | - | - | - |

| Measurement Time | Application Sequence | ||

|---|---|---|---|

| First Coffee Immersion Then Simulated Tooth-Brushing | First Simulated Tooth-Brushing Then Coffee Immersion | ||

| DeltaE1 (baseline–first measurement) | Mean ± SD | 4.85 ± 0.95 a,A | 1.92 ± 0.57 a,B |

| DeltaE2 (baseline–second measurement) | Mean ± SD | 2.71 ± 0.64 b,A | 4.46 ± 0.7 b,B |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kaynak Öztürk, E.; Binici Aygün, E.; Çiçek, E.S.; Sağlam, G.; Turhan Bal, B.; Karakoca Nemli, S.; Bankoğlu Güngör, M. Effects of Surface Finishing Procedures, Coffee Immersion, and Simulated Tooth-Brushing on the Surface Roughness, Surface Gloss, and Color Stability of a Resin Matrix Ceramic. Coatings 2025, 15, 627. https://doi.org/10.3390/coatings15060627

Kaynak Öztürk E, Binici Aygün E, Çiçek ES, Sağlam G, Turhan Bal B, Karakoca Nemli S, Bankoğlu Güngör M. Effects of Surface Finishing Procedures, Coffee Immersion, and Simulated Tooth-Brushing on the Surface Roughness, Surface Gloss, and Color Stability of a Resin Matrix Ceramic. Coatings. 2025; 15(6):627. https://doi.org/10.3390/coatings15060627

Chicago/Turabian StyleKaynak Öztürk, Esra, Ebru Binici Aygün, Elif Su Çiçek, Gaye Sağlam, Bilge Turhan Bal, Seçil Karakoca Nemli, and Merve Bankoğlu Güngör. 2025. "Effects of Surface Finishing Procedures, Coffee Immersion, and Simulated Tooth-Brushing on the Surface Roughness, Surface Gloss, and Color Stability of a Resin Matrix Ceramic" Coatings 15, no. 6: 627. https://doi.org/10.3390/coatings15060627

APA StyleKaynak Öztürk, E., Binici Aygün, E., Çiçek, E. S., Sağlam, G., Turhan Bal, B., Karakoca Nemli, S., & Bankoğlu Güngör, M. (2025). Effects of Surface Finishing Procedures, Coffee Immersion, and Simulated Tooth-Brushing on the Surface Roughness, Surface Gloss, and Color Stability of a Resin Matrix Ceramic. Coatings, 15(6), 627. https://doi.org/10.3390/coatings15060627