1. Introduction

Rammed earth architecture, as the crystallization of China’s traditional construction techniques that have lasted for thousands of years, carries important historical and cultural memories [

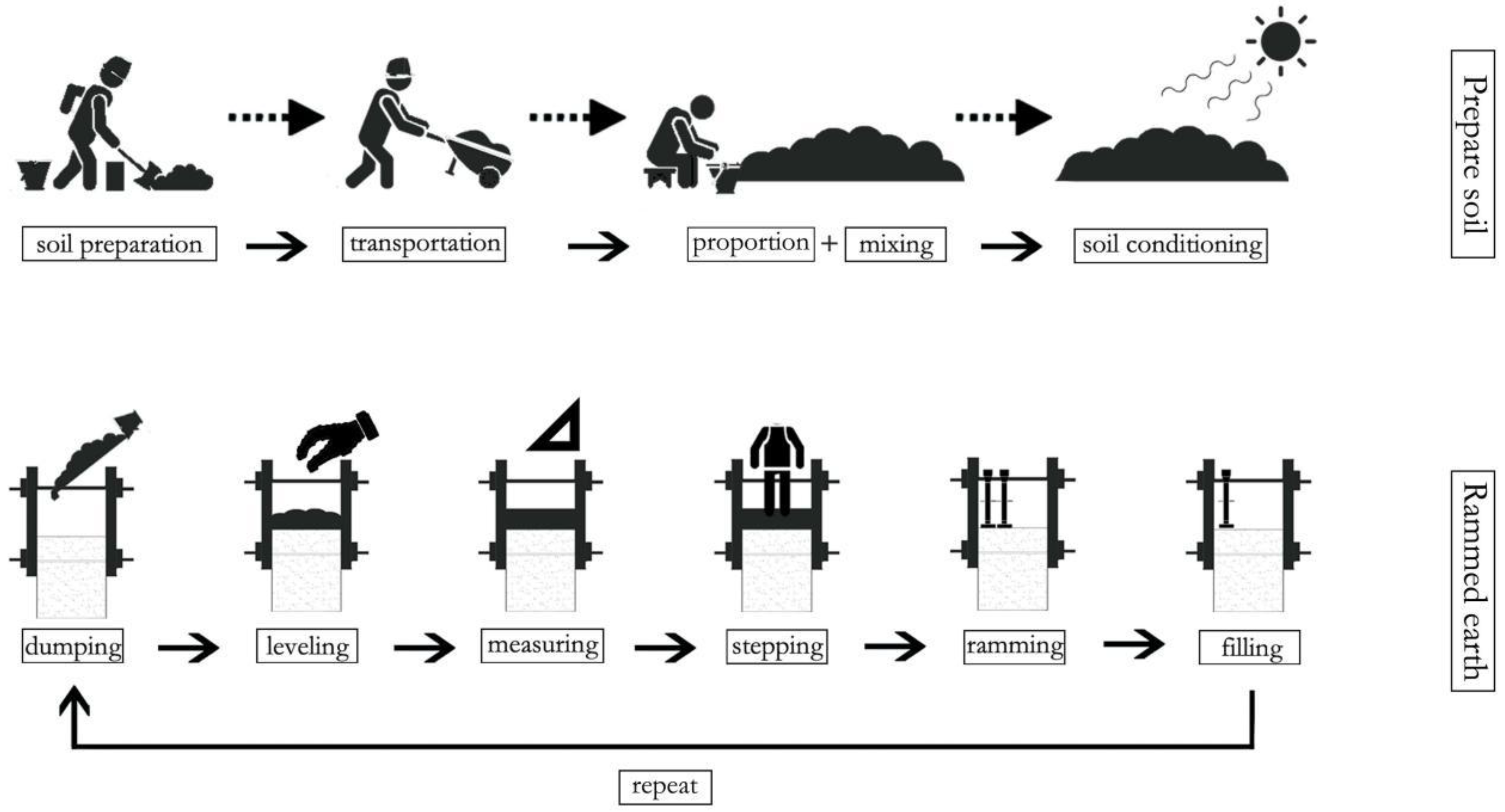

1]. The production techniques of rammed earth architecture are relatively complicated and are divided into two stages, namely soil preparation and ramming. The ramming stage is further divided into substages, such as soil dumping, ramming, layer-by-layer ramming, maintenance, mold removal, wall beautification, and wall solidification [

2] (

Figure 1). After going through these steps repeatedly, a solid and stable rammed earth wall can be completed. Songyang County is located in the hilly area of southwestern Zhejiang and was built in the fourth year of the Jian’an era of the Eastern Han Dynasty (199 AD), with a history of over 1800 years [

3]. Today, Songyang County is a demonstration county for the protection of Chinese traditional villages, and its number has long been among the top in the country. Up to now, a total of 78 villages have been listed in the Chinese Traditional Village List (data cover the first to the seventh batches), accounting for nearly one-fourth of the total in Zhejiang Province, and the county is known as the “county sample of classical China”. It is noteworthy that a large number of traditional rammed earth dwellings have been preserved in these villages. The wall thickness of these buildings is generally between 40–60 cm, forming a unique microclimate regulation system. At the same time, the biggest advantage of rammed earth is its small thermal conductivity coefficient and good thermal inertia, which creates the characteristic of warmth in winter and a cool interior in summer for rammed earth architecture, making it a valuable treasure in the history of human architectural development [

4]. However, influenced by the subtropical monsoon climate, the regional annual average precipitation exceeds 1800 mm. Meanwhile, with the rapid advancement of national industrialization under the background of a coal-dominated energy structure, the sharp increase in the number of coal-fired power plants, heavy industrial bases, and motor vehicle ownership has led to a continuous rise in emissions of acidic gases, such as sulfur dioxide and nitrogen oxides. This has resulted in frequent acid rain occurrences, causing pathological phenomena, such as cracking and flaky spalling on the surface of rammed earth. According to research, in the past decade, some rammed earth buildings in Songyang County have shown significant structural damage due to environmental erosion. Therefore, it is necessary to pay attention to the research on the anti-erosion properties of rammed earth dwellings.

Traditional villages carry the excellent traditional culture of China and are an important link in the protection of our national culture [

5]. Songyang County currently has 96 traditional Chinese villages, making it one of the counties in East China with the most traditional villages and the most abundant styles [

6], and it has high research and protection value. Chinese scholars have conducted extensive research on rural areas in the past, mainly focusing on economic issues related to economic crops in these areas [

7,

8,

9,

10]. With the promotion of the rural revitalization strategy, there have been considerable achievements in the research into these issues. However, the protection of the ancient residential heritage of traditional villages is also worthy of our attention. Among them, traditional rammed earth dwellings, as one of the most typical types of dwellings [

11], are widely used in traditional Chinese villages. In the process of historical evolution and inheritance, they have continuously adapted to the environment, forming a distinct and unique rammed earth culture [

12,

13]. However, with the passage of time, many young laborers have migrated out, leaving only elderly people living alone, which leads to the inability for ancient rammed earth dwellings to receive timely repairs and maintenance. In addition to natural environmental erosion, many ancient rammed earth dwellings have been damaged. In recent years, relevant scholars have carried out research in this regard, exploring the reasons for the erosion of rammed earth materials.

Some scholars have noticed that wind and rain erosion damage of rammed earth materials involves the physical wear and tear of the structure, which is the main form of damage to rammed earth walls. Under the condition of continuous loss of rammed earth materials, the cross-section of the wall becomes smaller and smaller, resulting in the continuous decline of the bearing capacity of the rammed earth structure [

14] and leading to in structural instability and other problems of the building. Some scholars have also analyzed the causes of the erosion of rammed earth materials from a biological point of view, such as the root spread of plants in rammed earth materials during the growth process, which will cause cracks in rammed earth [

15]. In addition, the erosion of rammed earth by plant litter will change the composition and structure of rammed earth, thus threatening the preservation of ancient dwellings [

16].

In the research into the erosion resistance of rammed earth, scholars at home and abroad start from different angles to improve the erosion resistance of rammed earth materials. These angles are mainly divided into physical modification and chemical modification: some scholars choose common admixtures, such as cement and lime, to improve the erosion resistance of rammed earth [

17]. In addition, some scholars have added plant fibers (coconut fiber, sisal fiber, sargassum seaweed fiber, etc.) to enhance the crack resistance and durability of rammed earth [

18,

19,

20,

21,

22].

In addition to this physical and chemical modification, it has also been found that the use of microorganisms to induce calcium carbonate precipitation has increased the water resistance of rammed earth, resulting in cracking repairs (autogenous healing) [

23,

24], and that algae can form complexes through its photosynthetic metabolites, thereby enhancing the erosion resistance of the surface layer of rammed earth [

25]. The authors believe that this method has the advantages of high ecological compatibility, endogenous self-healing function, and low environmental disturbance, but most of the current studies have not designed a scheme for the erosion resistance and crack resistance of the overall walls of rammed earth structures.

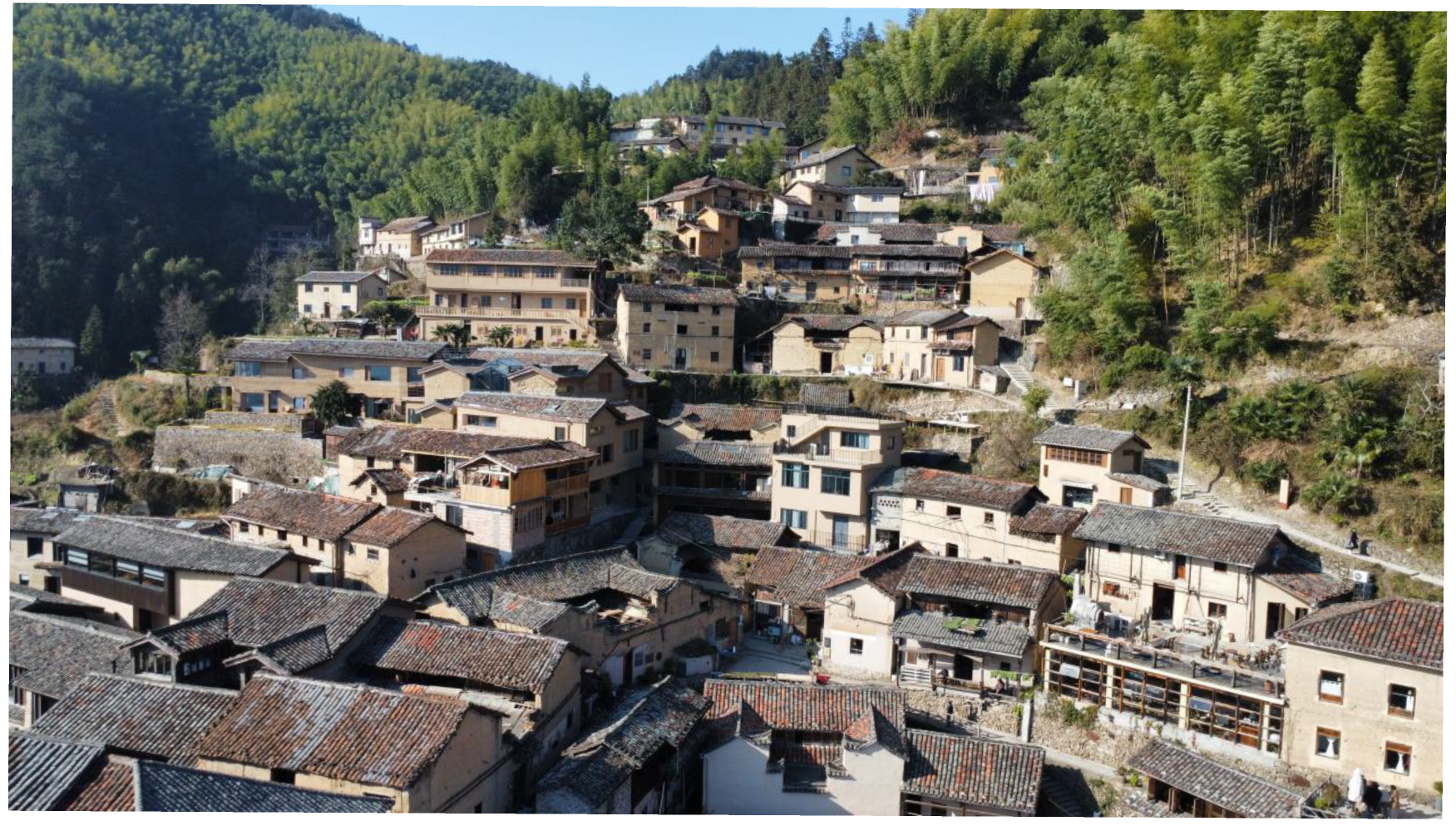

Therefore, this study took the traditional rammed-earth residential buildings in Chenjiapu Village, Songyang County, Zhejiang Province (which is a typical example of 78 villages in Songyang County that are included in the list of traditional Chinese villages and which is known as “villages on the cliff”), and systematically carried out research into the erosion and protection mechanisms of rammed earth buildings by combining field investigation, experimental analysis, and microscopic characterization research. First of all, through field investigation and drone aerial photography, researchers conducted a defects survey of representative ancient rammed earth residential buildings in Songyang County and recorded the cracks and eroded surface problems in detail. In terms of microscopic mechanism research, X-ray diffraction (XRD), field-emission scanning electron microscopy (FE-SEM), and microbial diversity detection were used to show that microbial communities and algae have a certain protective effect on the surface layer of rammed earth. Based on this comprehensive research, this analysis proposes a design for the protection of “eroded rammed earth walls and rammed earth with cracks”. Specifically, this design is a transparent film–biocellulose–acid inhibition layer composite biofilm scheme. This provides an innovative solution for the protection of traditional rammed earth buildings.

2. Materials and Research Process

2.1. Study Area: Songyang Ancient Village in Lishui

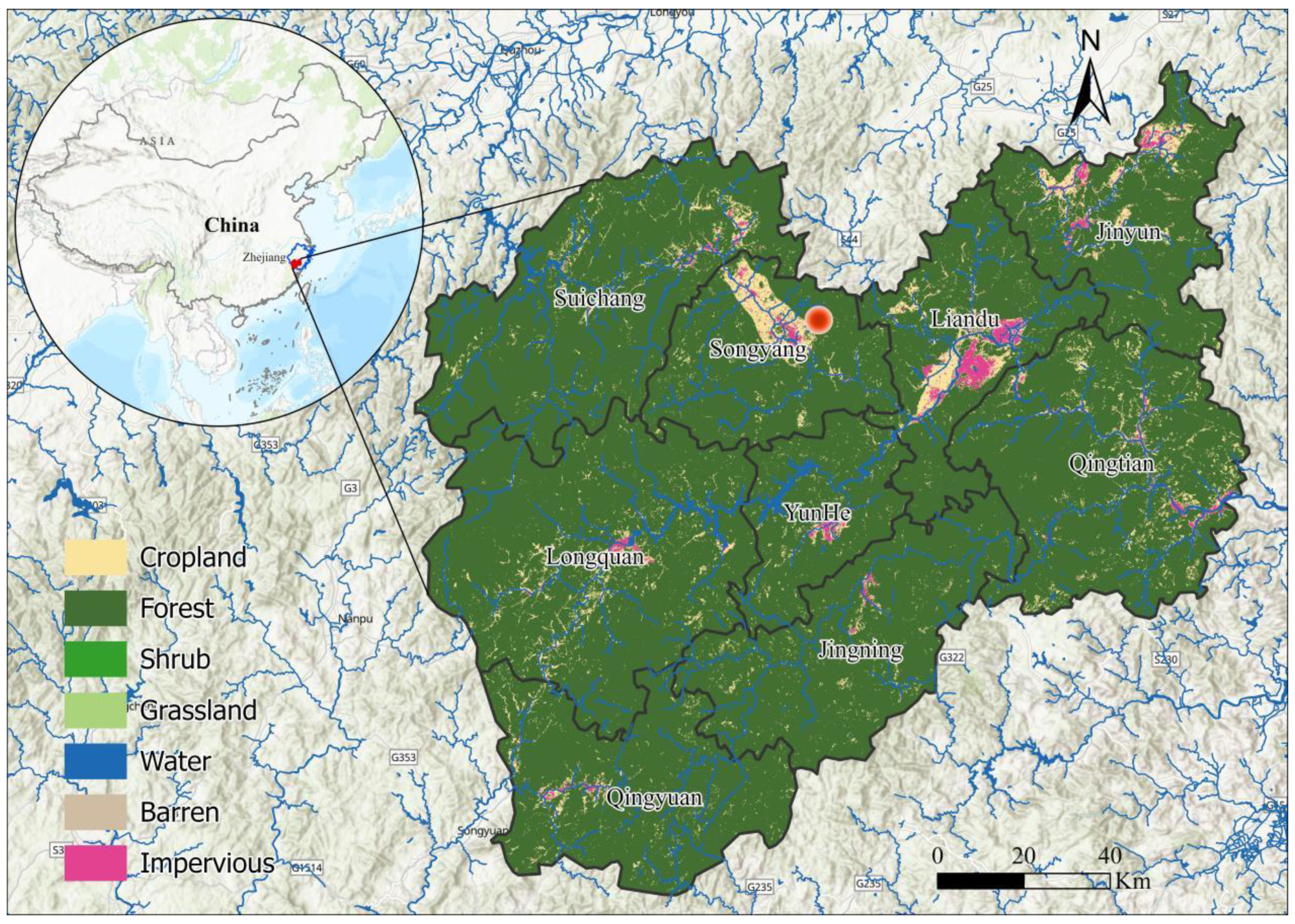

Songyang County is located in the southwest of Zhejiang Province (

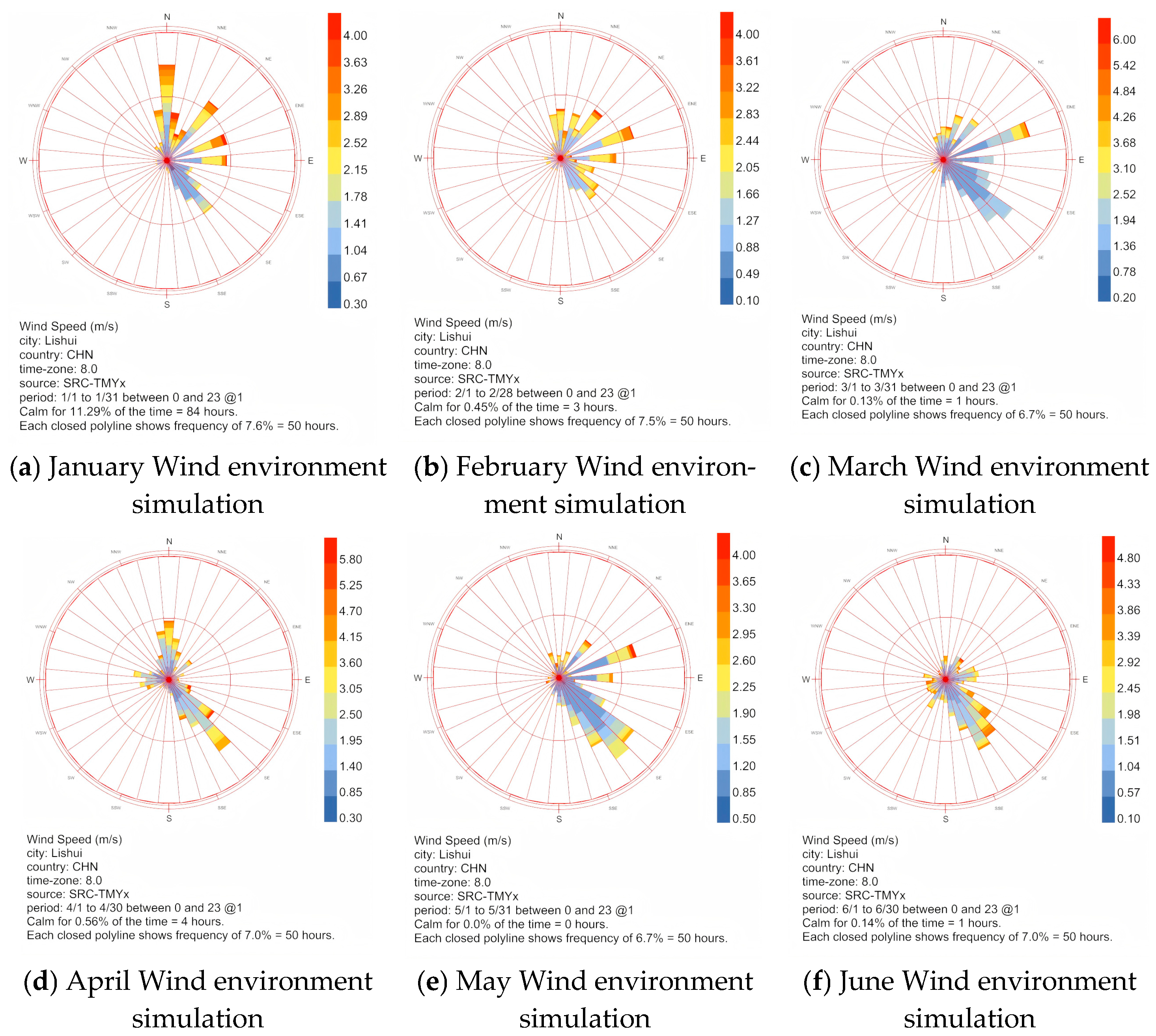

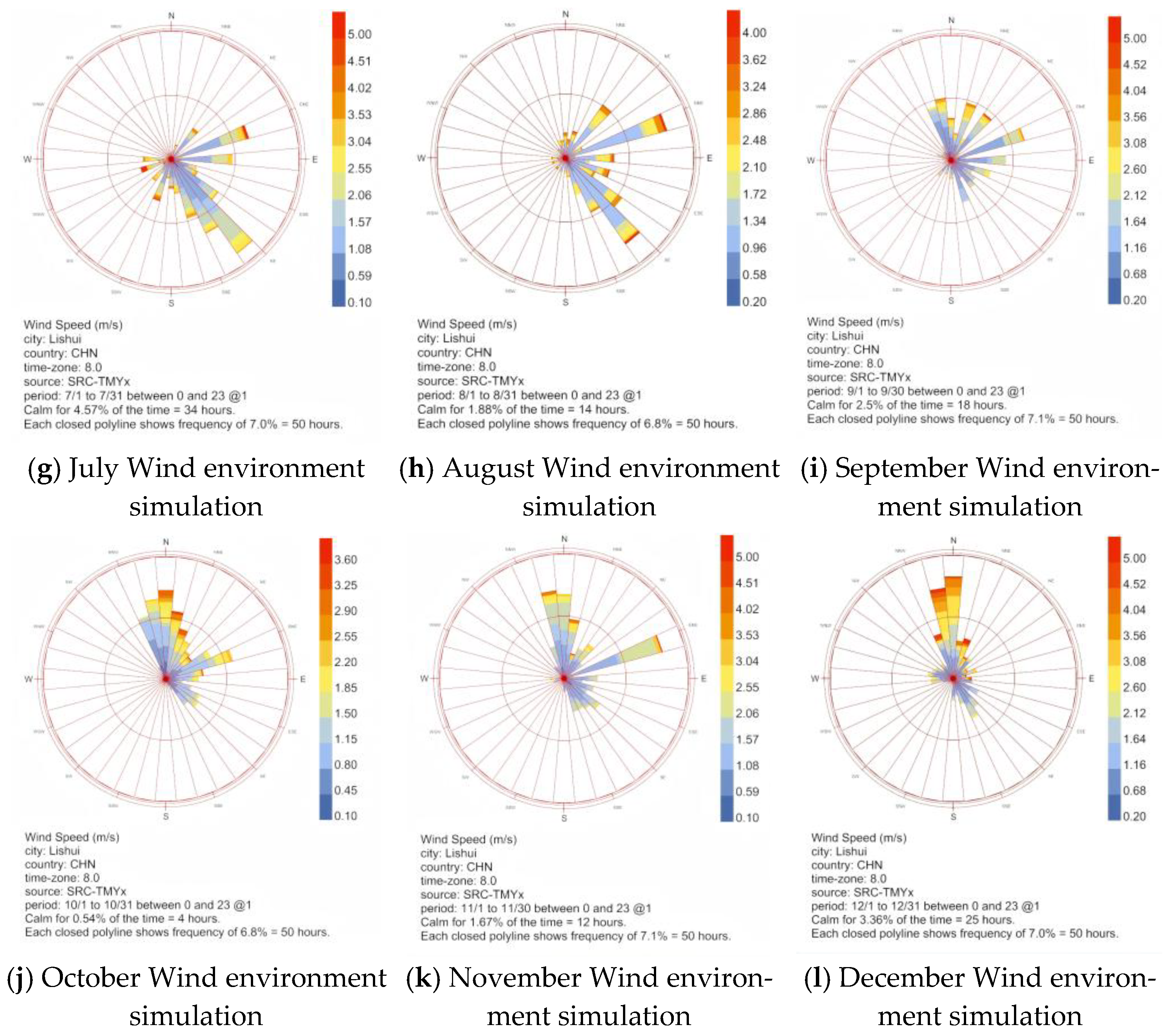

Figure 2), at the junction of Zhejiang, Fujian, and Jiangxi provinces, with geographical coordinates of 28°14′ to 28°36′ north latitude and 119°10′ to 119°42′ east longitude. The central basin is called “Songgu Plain” because of its openness and flatness, and is also called “Songgu Basin”. It preserves a complete local cultural context and has simple mountain characteristics in southwest Zhejiang [

26]. Lishui City, where this area is located, has a subtropical monsoon climate, with four pronounced seasons, abundant sunshine, and abundant rainfall. The wind speed in Lishui varies significantly throughout the year, and the wind speed is higher in summer (June–August), especially in July and August, when the wind speed frequently reaches 3–4 m/s. In winter (December to February), the wind speed is relatively low, generally ranging from 1 to 2 m/s. Its temperature changes obviously throughout the year, and the temperature is higher in summer (June–August), usually between 25–35 °C, especially in July and August, when the temperature frequently reaches above 35 °C. In winter (December–February of the following year), the temperature is low, usually between 0–10 °C. High temperatures in summer and cold and humid conditions in winter are the main temperature characteristics. At the same time, the direct radiation in Lishui varies significant throughout the year, and the radiation intensity is higher in summer (June–August), especially in July and August, when the solar radiation intensity frequently reaches 600–800 Wh/m

2. In winter (December–February of the following year), the solar radiation intensity is low, usually between 200 and 400 Wh/m

2—(

Figure 3).

Songyang County in Lishui City, with its unique geographical environment and climatic conditions, preserves a large number of ancient villages and rammed earth residential buildings with characteristics of the mountainous areas in southwestern Zhejiang. These buildings are not only important carriers of local folk culture but also valuable resources for studying the anti-erosion performance of rammed earth buildings. However, due to the significant changes in annual solar radiation and precipitation, the long-term preservation of rammed earth residential buildings is unfavorable, and erosion is prone to occurring. For example, high humidity and frequent precipitation in summer can cause the rammed earth walls to absorb water and expand, and the long-term wet expansion and dry shrinkage cycle will accelerate the cracking and peeling of the walls [

27]. At the same time, higher wind speeds in summer will also accelerate the evaporation of moisture on the surface of the walls, leading to dry and cracked wall surfaces. Over time, the stability of rammed earth residential buildings is greatly reduced [

28]. In recent years, with the enhanced awareness of traditional village protection, the ancient villages in Songyang County have gradually received attention from the academic community and the government. Therefore, this study selects Chenjiapu Village in Songyang County as the research area (

Figure 4).

In recent years, with the growing awareness of protecting traditional villages, the ancient villages in Songyang County have drawn increasing attention from academia and the government. Chenjiapu Village, Songyang County, has many rammed earth dwellings and ancestral hall relics. This study selected Chenjiapu Village in Songyang County as the study area (

Figure 4). This choice not only helps us deeply understand the anti-erosion mechanisms of traditional rammed earth buildings but also offers a scientific basis for the conservation and restoration of ancient villages.

2.2. Field Investigation and Sample Collection

Because the terrain of ancient villages in Songyang County is complex, and the buildings are mostly built according to the mountains (

Figure 5), the researchers chose to use a DJI Mini 4K, a consumer-grade drone with stability and flexible handling, to perform aerial photography tasks. The UAV is equipped with a high-definition camera and a three-axis mechanical pan/tilt system, which can keep the picture stable in complex environments. It is equipped with 1/2. A 3-inch CMOS sensor supports shooting 12-megapixel photos and 4K/30fps video. Enhanced Wi-Fi tech enables long-distance real-time HD image transmission. Regarding parameter configuration, the researchers synthesized the suggestions of several aerial photography experts and optimized the default settings of UAVs. The researchers set the ISO value of the camera to automatic mode to dynamically adapt to the complex environment of light and shadow interlacing in ancient villages (such as patio shadow and roof intense light). At the same time, according to the cloudy and sunny weather conditions on that day, the researchers fixed the aperture to f/2.8. Researchers set the shutter speed to 1/80 s to 1/2000 s for dynamic adjustment to avoid the overexposure of highlights. Finally, the researchers chose to shoot at 2 pm on 20 December 2024. During implementation, the UAV’s flying height was kept at 12–18 m. For the damaged rammed earth residential wall, the shooting distance was reduced to 2–4 m.

The traditional earthen wall construction in the Songyang area is usually rammed using the long-slab rafter construction method. Based on this method, the size of the rammed block of the formed earth wall is larger, generally about 1.8 m in height and 1.5 m in length (the specific size can be adjusted according to the actual situation). These large-size rammed blocks are combined with small, staggered masonry, so that there are certain gaps in the earthen wall structure. These gaps not only function as expansion joints but also have a certain structural rationality and can adapt to the natural deformation of the material. However, in the actual use process, due to factors, such as foundation settlement, camber of blocks, improper construction technology, or later maintenance loss, these gaps may gradually expand, which will adversely affect the earth wall structure. Specifically, gap enlargement may cause the following problems: loss of structural stability (the expansion of the gap may lead to uneven settlement of the overall structure of the earth wall, thereby weakening the stability of the structure); increased risk of rainwater infiltration (when a gap expands, rainwater may penetrate into the wall through the gap, causing the soil to soften and further exacerbate the damage to the wall); reduced strength (the widening of the gap may weaken the shear and compressive resistance of the soil wall, reducing its load-bearing capacity); appearance damage: the obvious enlargement of the gap will affect the appearance integrity of the earthen wall, reducing its historical and cultural value.

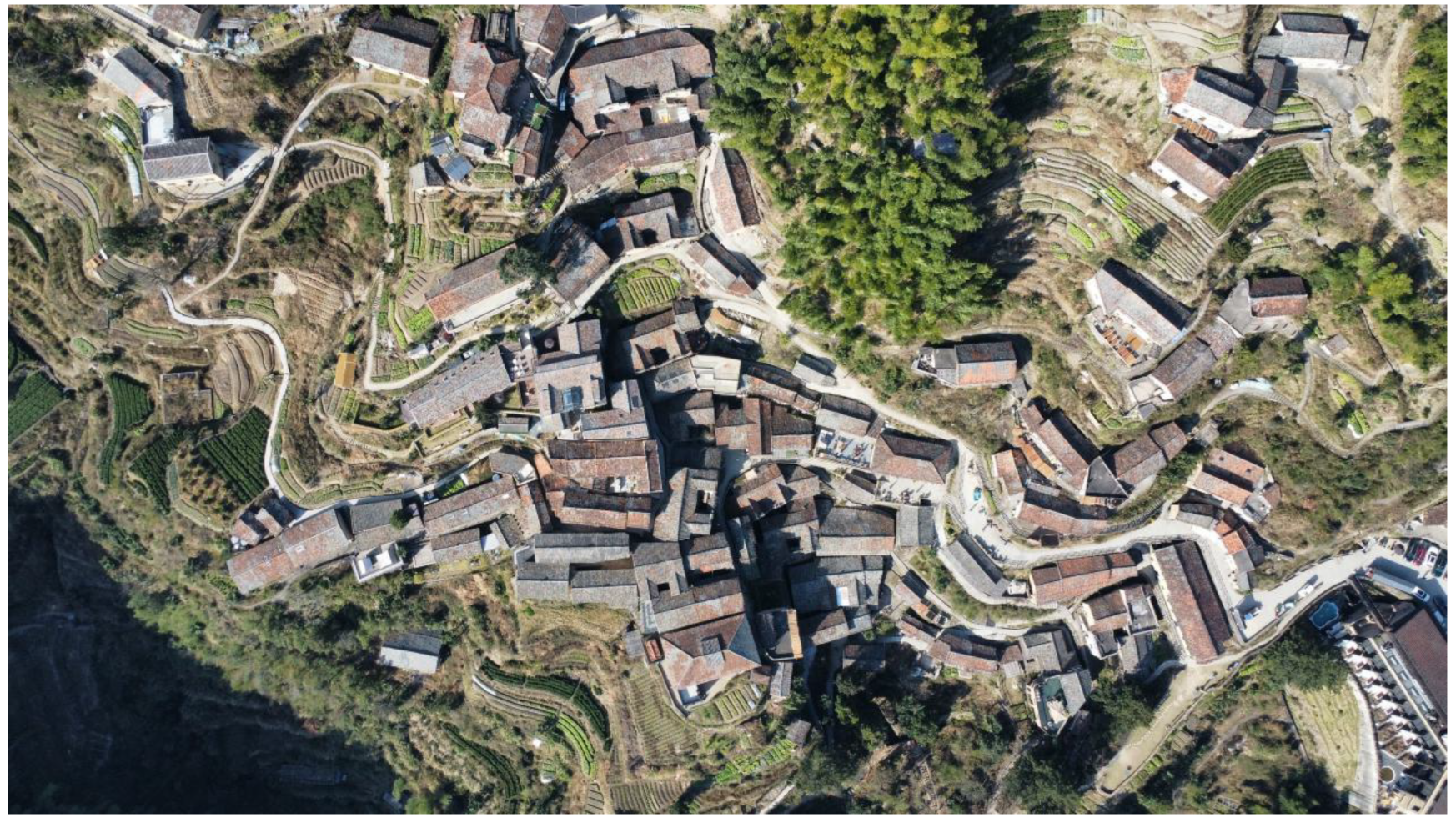

During the field trip, the researchers found that the residential house at No. 22 Chenjiapu West Road has some typical problems. These included the following: (1) erosion and recessing, mostly at the turning point of the rammed earth wall interface, with an average depth of 5–7 cm (

Figure 6(bA)); (2) cracks in the wall (

Figure 6(bB)); and (3) obvious traces of water erosion (

Figure 6(bC)). At the same time, researchers found that the west wall of the house was less eroded, and the rammed earth wall was grayish–green. The same is true of the other three parts of the wall with a gray–green surface, which makes us curious about their peculiarities.

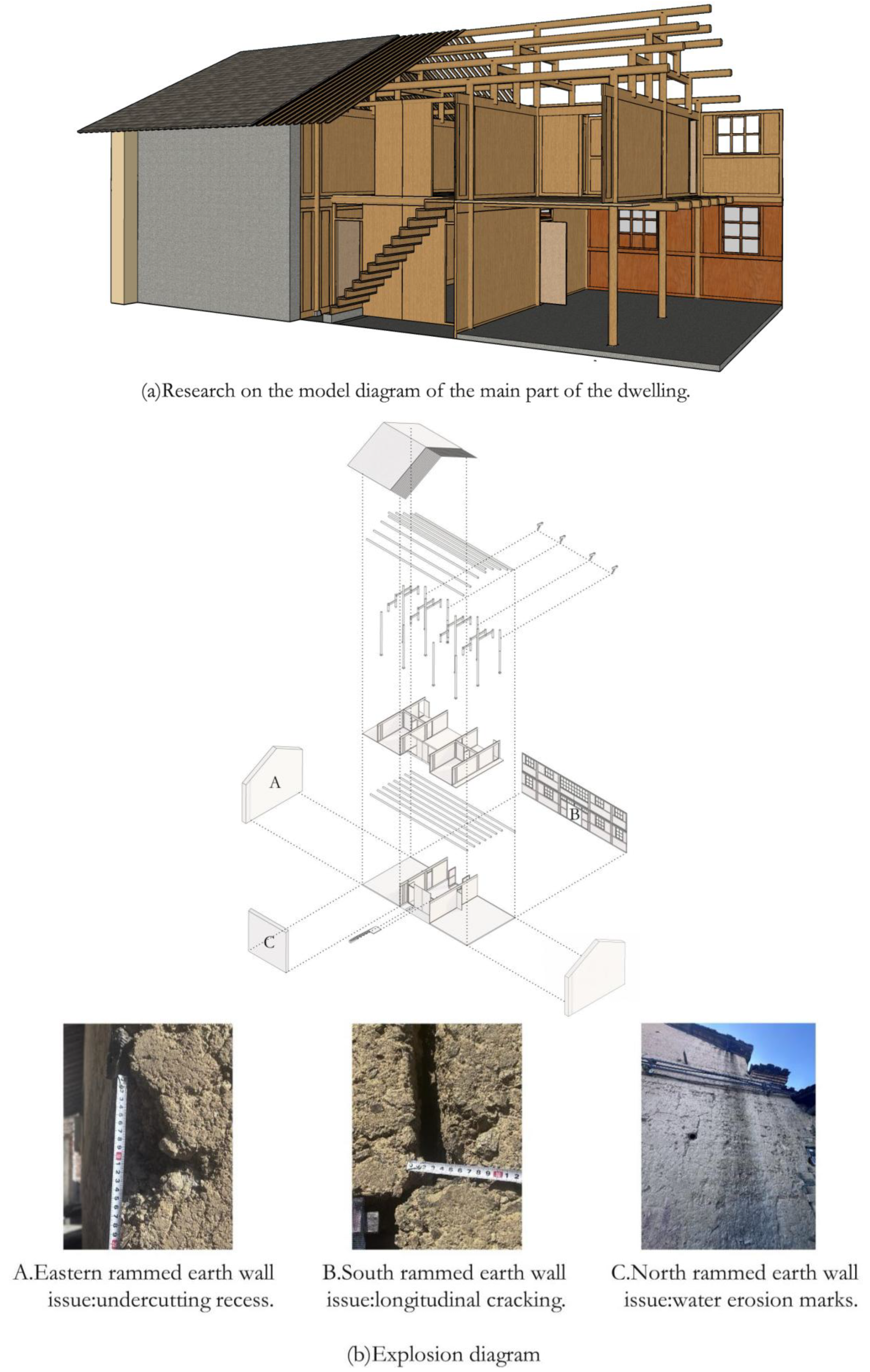

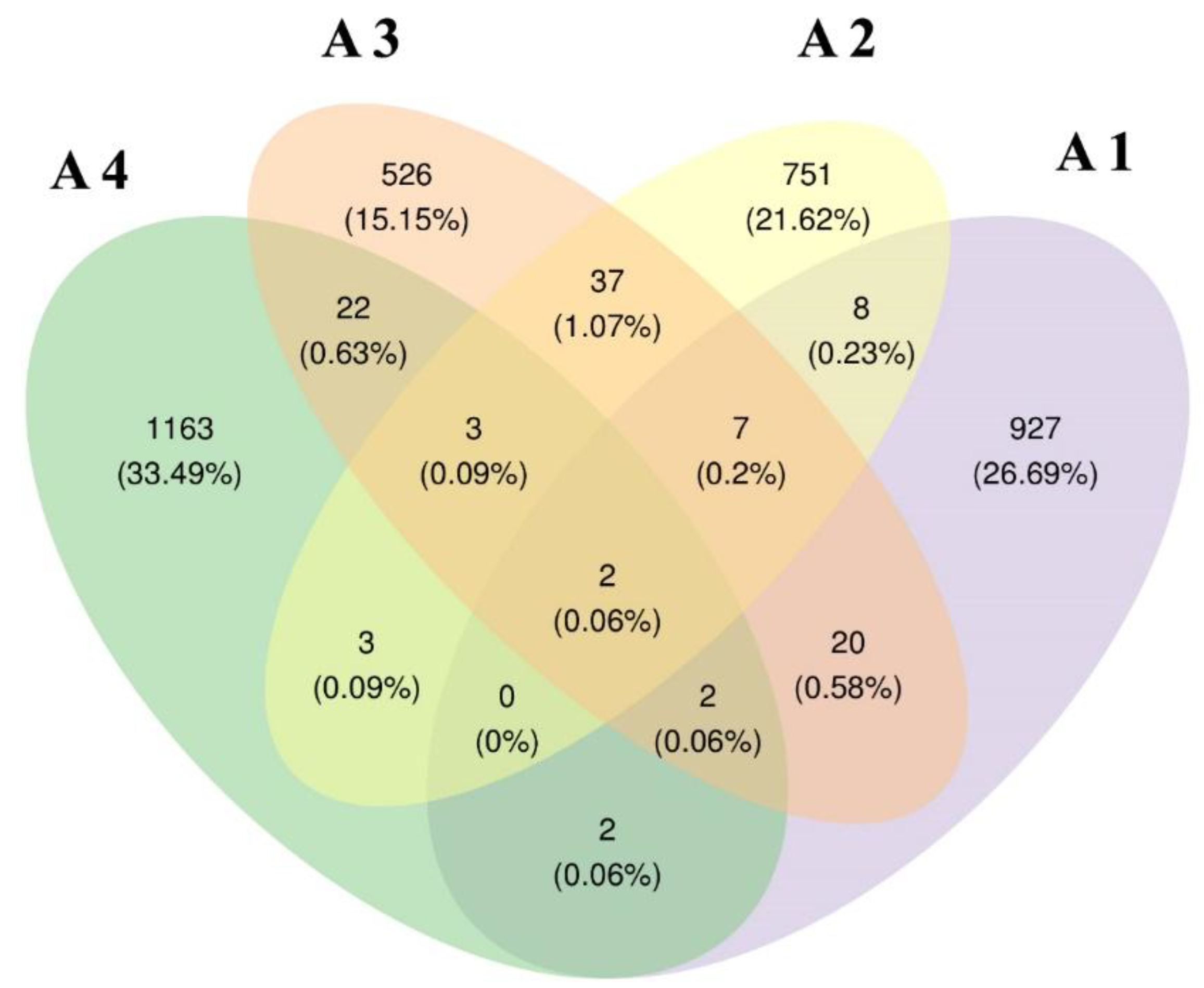

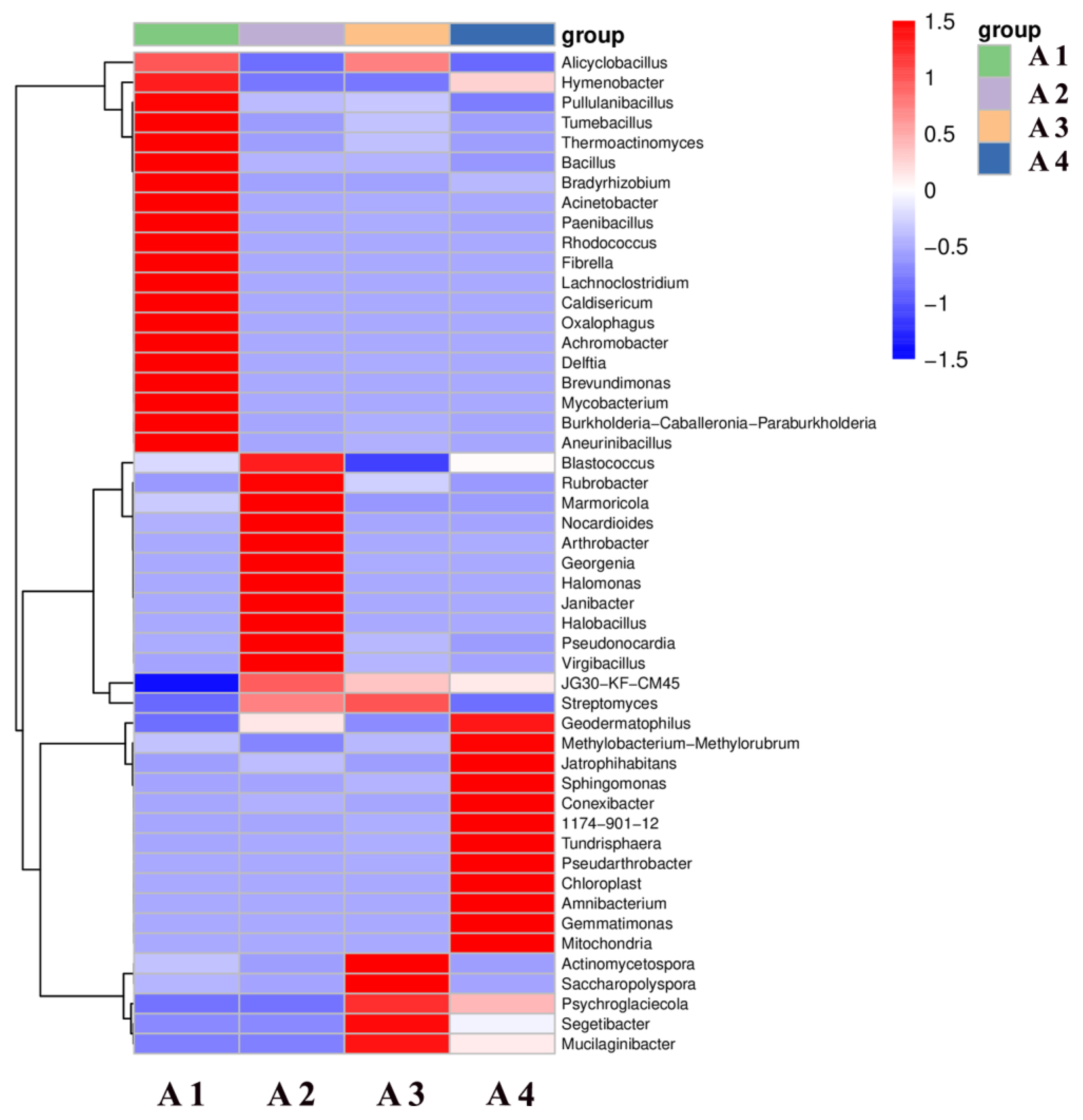

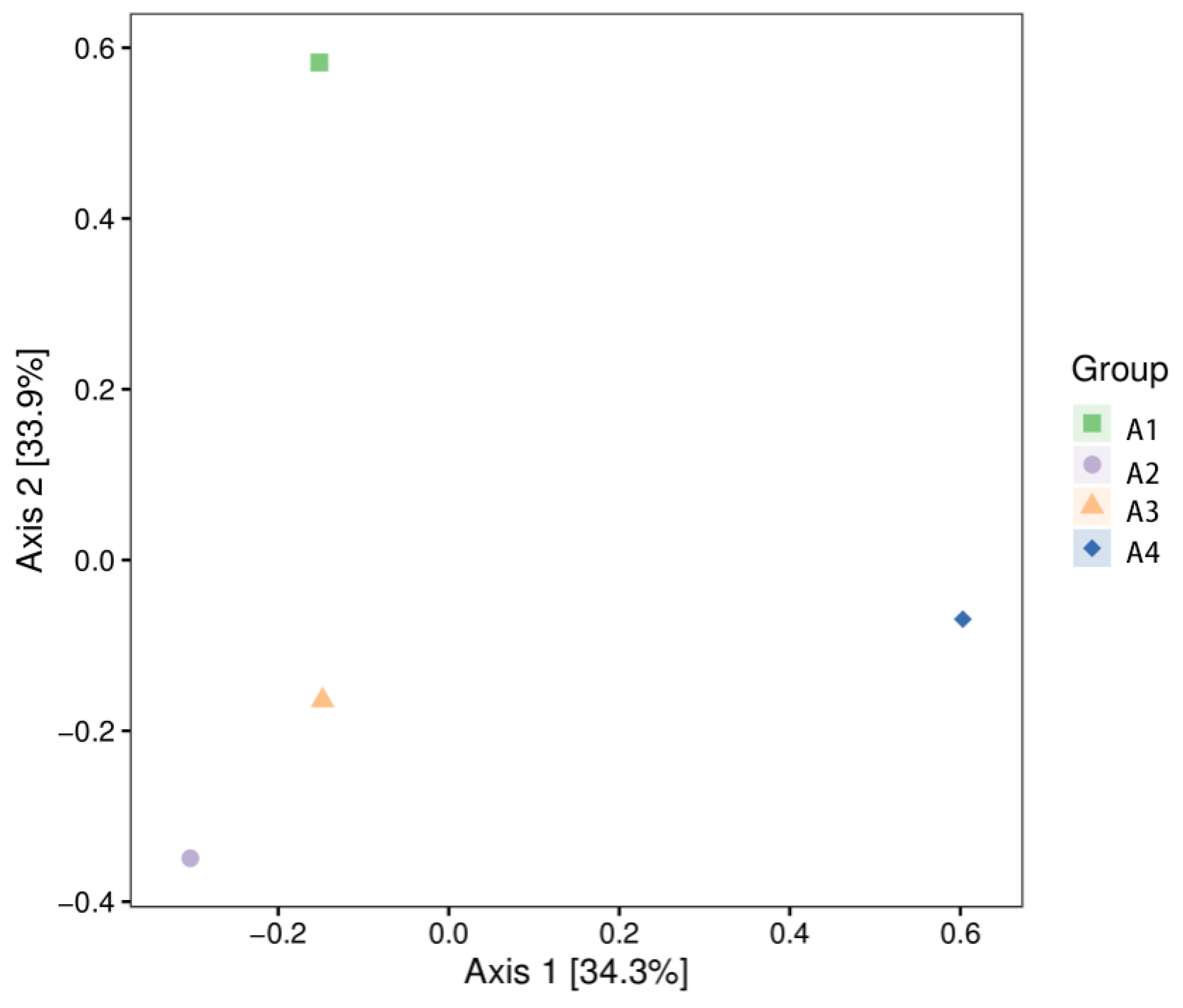

Based on the aforementioned research background, this study conducted systematic sampling of rammed earth walls exhibiting grayish–green surface crust characteristics on four facades (eastern, northern, southern, and western) of the target vernacular dwelling. Using archaeological scalpels, researchers performed stratified scraping along the normal line direction of wall surfaces to collect crust layer powders, with the sampling depth strictly controlled at 10 ± 0.5 mm and individual sample mass was precisely maintained at 10 ± 0.2 g (

Figure 7). The samples were coded by orientation as A1 (east), A2 (north), A3 (south), and A4 (west). A dual-sealing preservation protocol was implemented, as follows: primary containment involved sealing compacted earth powders in inert PVC tubes (φ25 × 100 mm), followed by secondary packaging in anti-static aluminum foil bags, effectively isolating environmental contaminants and suppressing moisture exchange. The time interval between sampling completion and laboratory characterization was rigorously limited to 48 h to ensure that test data accurately reflect material behavioral characteristics under in situ environmental conditions. Notably, the research team uniformly applied a specialized glutinous rice glue interface agent for rammed earth walls to the damaged areas incurred during the investigation. The surface was then dyed using a mixture of loess slurry and natural mineral pigments to ensure consistency with the surrounding rammed earth matrix. Finally, a toothed trowel was employed to replicate the original wall texture, with particular emphasis on restoring the horizontal textural characteristics between rammed layers, thereby preserving the visual continuity of the wall structure.

Before the sampling work was implemented, researchers had preliminary contact with the owner of the house, systematically explaining the research objectives and work procedures. After on-site communication and confirmation, it was found that the building is currently vacant, effectively avoiding potential interference risks from recent human activities to the rammed earth walls. After obtaining verbal authorization from the property owner in accordance with the law, our team conducted a systematic investigation and sampling work on the historical building in accordance with the technical specifications for cultural heritage protection.

2.3. Research Methods and Processes

To elucidate the synergistic interaction mechanisms between rammed earth substrates and algal microbial communities in erosion resistance and crack suppression within the gray–green wall coating system described in

Section 2.2, this investigation employed a multidisciplinary experimental approach combining microbial community diversity analysis, X-ray diffraction (XRD) phase characterization, and scanning electron microscopy (SEM) microstructural observation. All o these investigations were carried out using four sets of 10 ± 0.2 g samples.

During the sample preparation process, the rammed earth powder was not subjected to chemical fixation treatment. Since the sample is a complex of inorganic minerals and microorganisms, the integrity of the microstructure can be maintained by directly collecting the sample while avoiding physical damage. After collection, the sample was naturally dried at room temperature for 48 h to ensure complete dehydration and avoid the interference of moisture in a vacuum environment. Subsequently, the sample was sputter-coated with a gold–palladium alloy (Au-Pd, 60:40 ratio), and the coating thickness was 15 nm.

2.3.1. Detection of the Microbial Community Diversity Composition Spectrum

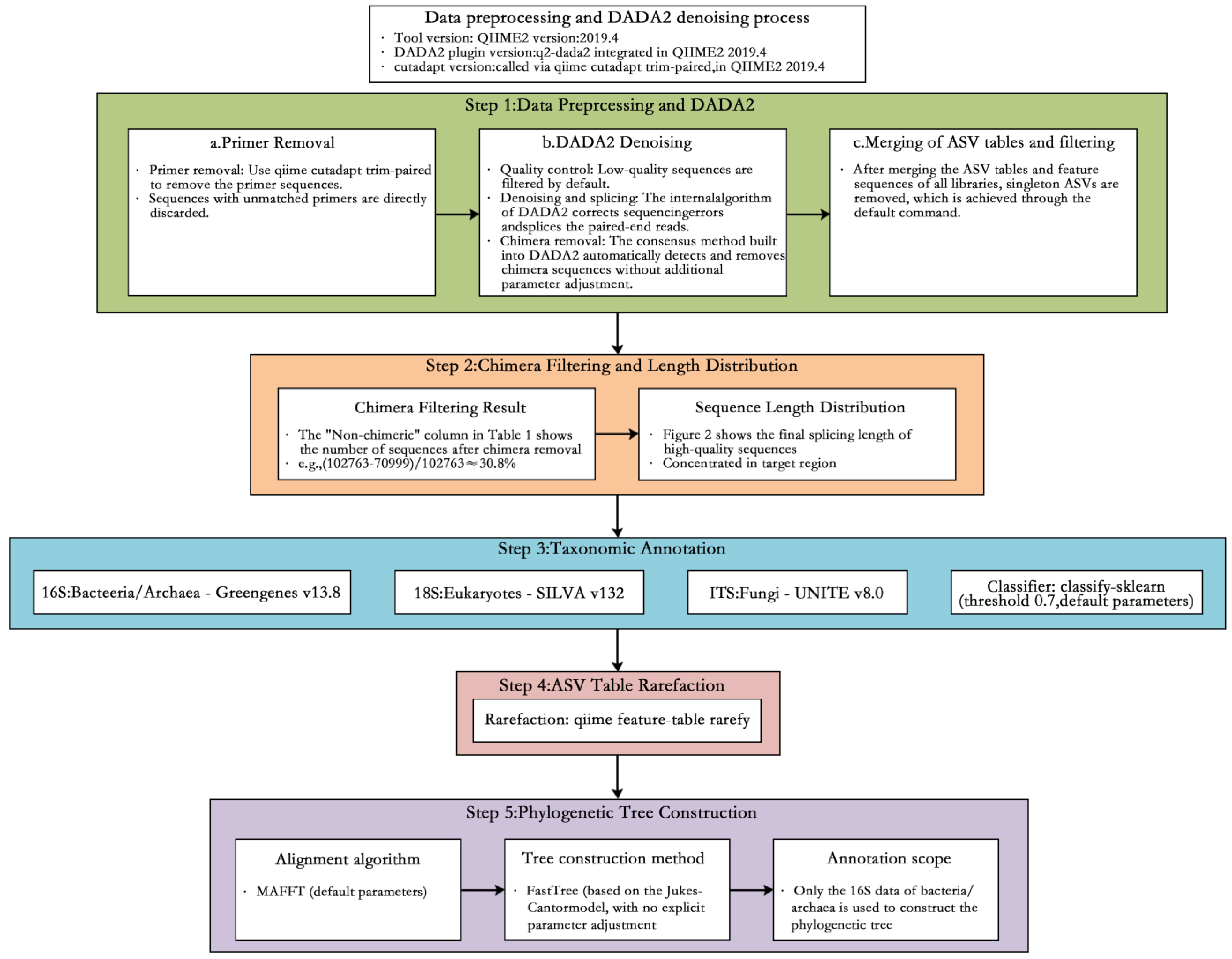

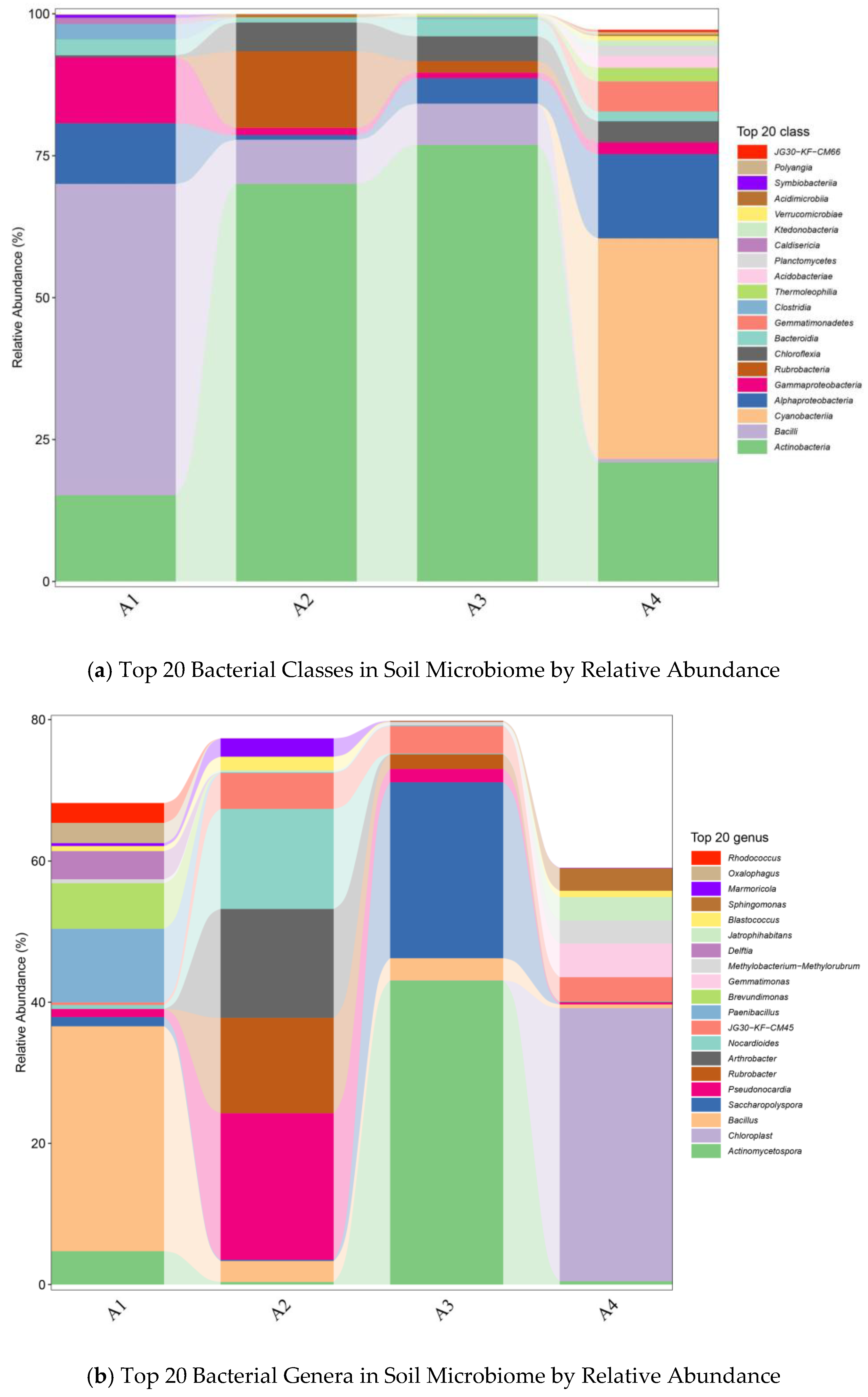

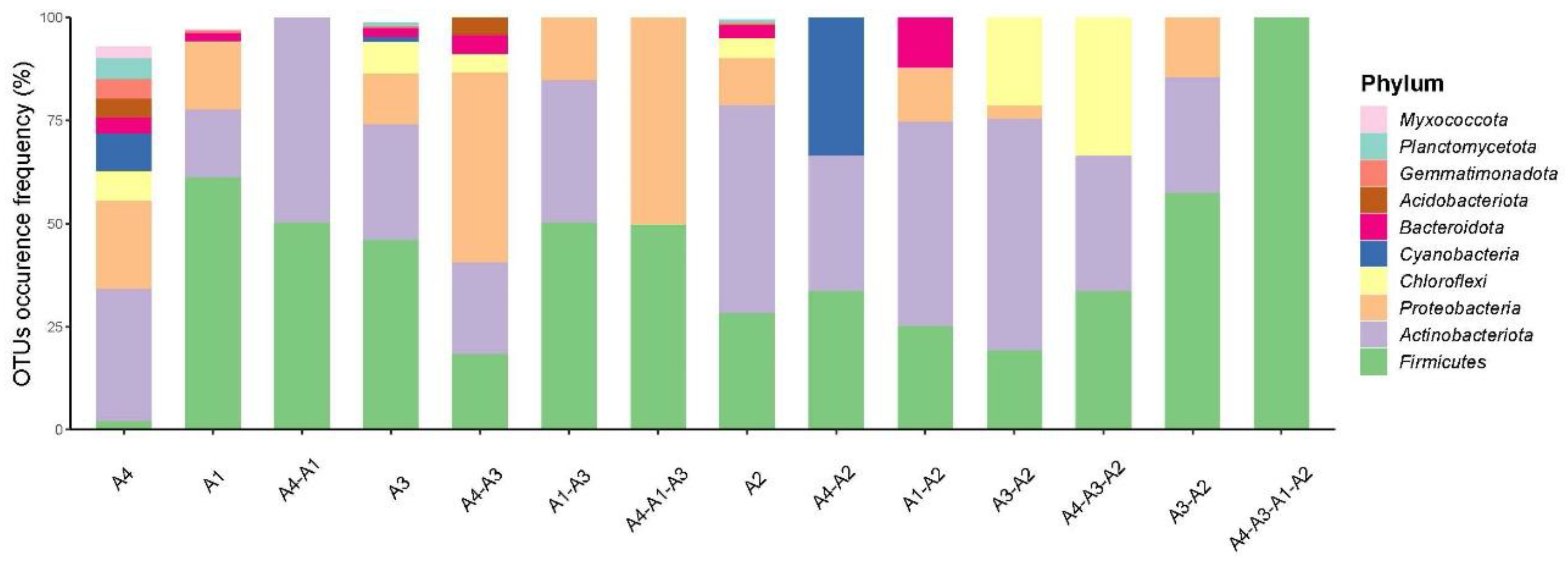

Microbial community diversity detection was used to analyze the microbial community composition on the surface of rammed earth walls. The testing process included total microbiome DNA extraction, PCR amplification of target fragments, magnetic bead purification and recovery of amplification products, fluorescence quantification of amplification products, sequencing library preparation (sequencing libraries were prepared using Illumina’s TruSeq Nano DNA LT Library Prep Kit), and high-throughput sequencing. Microbial community diversity detection determines the main microbial species and their relative abundance on rammed earth walls. This offers essential data for understanding microorganisms’ role in the erosion process. The complete flow of bioinformatics analysis is shown in

Figure 8.

In this study, the Illumina paired-end sequencing platform (MiSeq/NovaSeq) was employed to conduct amplification sequencing targeting the V3-V4 variable regions of the 16S rRNA gene. The primer design was based on the conserved regions of the 16S rRNA gene, and universal primer pairs, namely 338F (5′-ACTCCTACGGGAGGCAGCAG-3′) and 806R (5′-GGACTACHVGGGTWTCTAAT-3′), were used. Moreover, based on the conserved regions of the 16S rRNA gene, the V3-V4 hypervariable regions (~470 bp) could be specifically amplified. Meanwhile, in this study, an amplicon sequence variant (ASV) was used to describe the microbial community diversity.

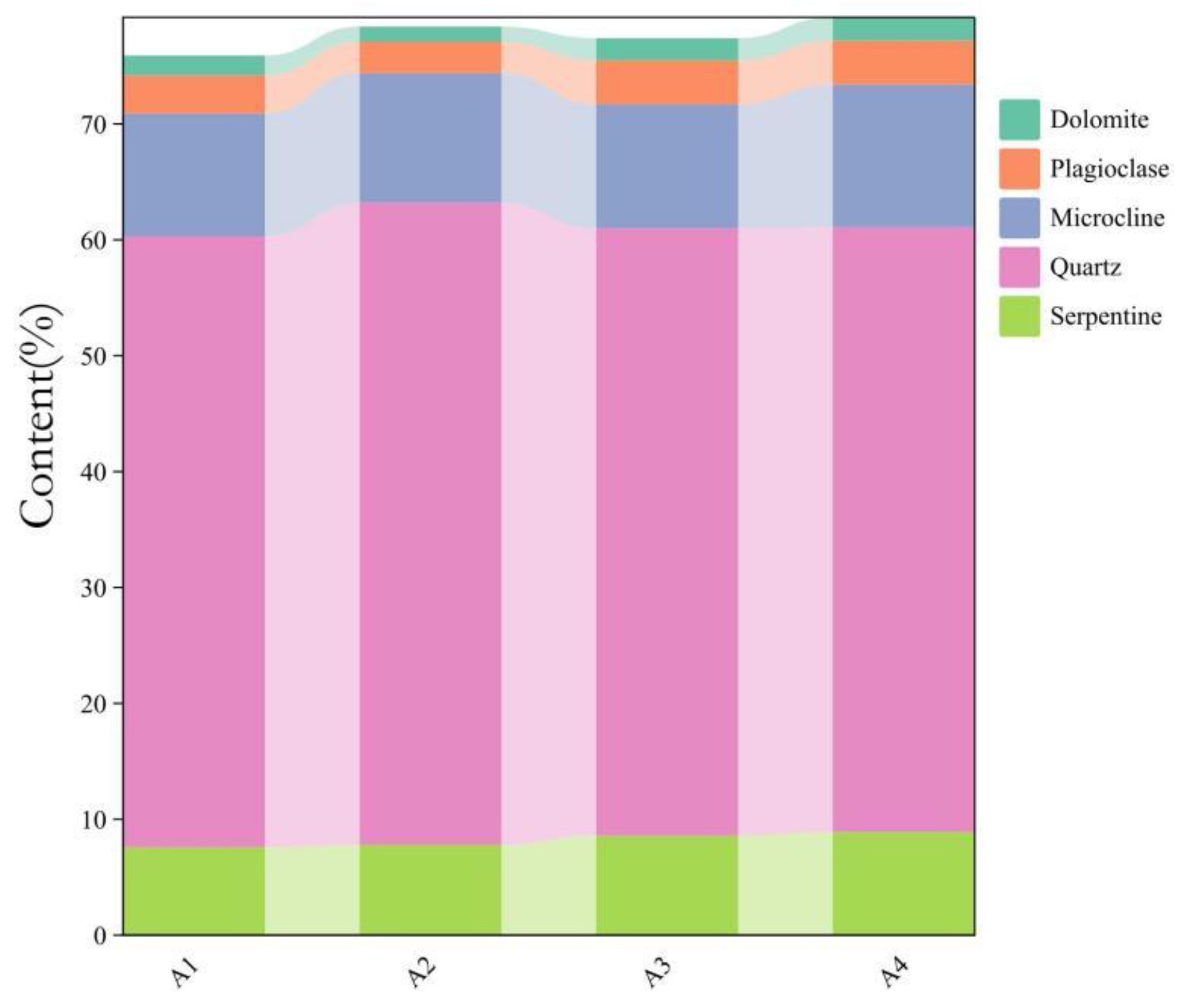

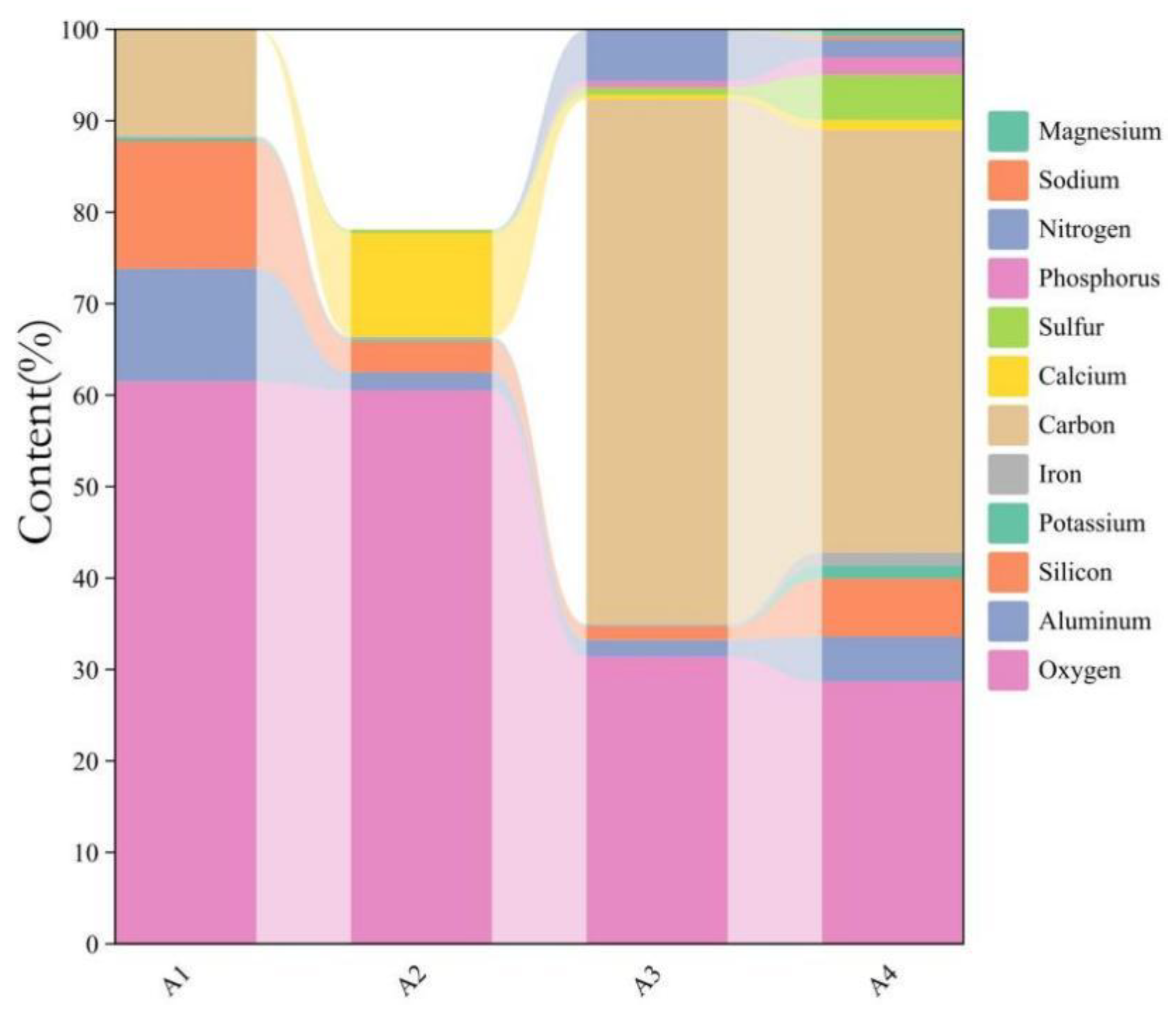

2.3.2. XRD Test

Samples for XRD testing were collected from rammed earth walls in the east, west, north, and south directions. The thickness of each sample was 10 mm and the weight was about 10 g. The detection instrument used was the SmartLab high-resolution the X-ray diffractometer produced by Rikaku Co., Ltd. of Akishima, Japan, with the reference standard being SY/T 5163-2018 “X-ray Diffraction Analysis Method for Clay Minerals and Common Non-clay Minerals in Sedimentary Rocks”. XRD testing identifies the main minerals in rammed earth (such as quartz, feldspar, calcite, montmorillonite, etc.) through X-ray diffraction patterns, clarifying their crystal structure and relative content. The type of mineral directly affects the soil’s pH value, porosity, ion exchange capacity, and other factors that determine the colonization environment of microorganisms and algae.

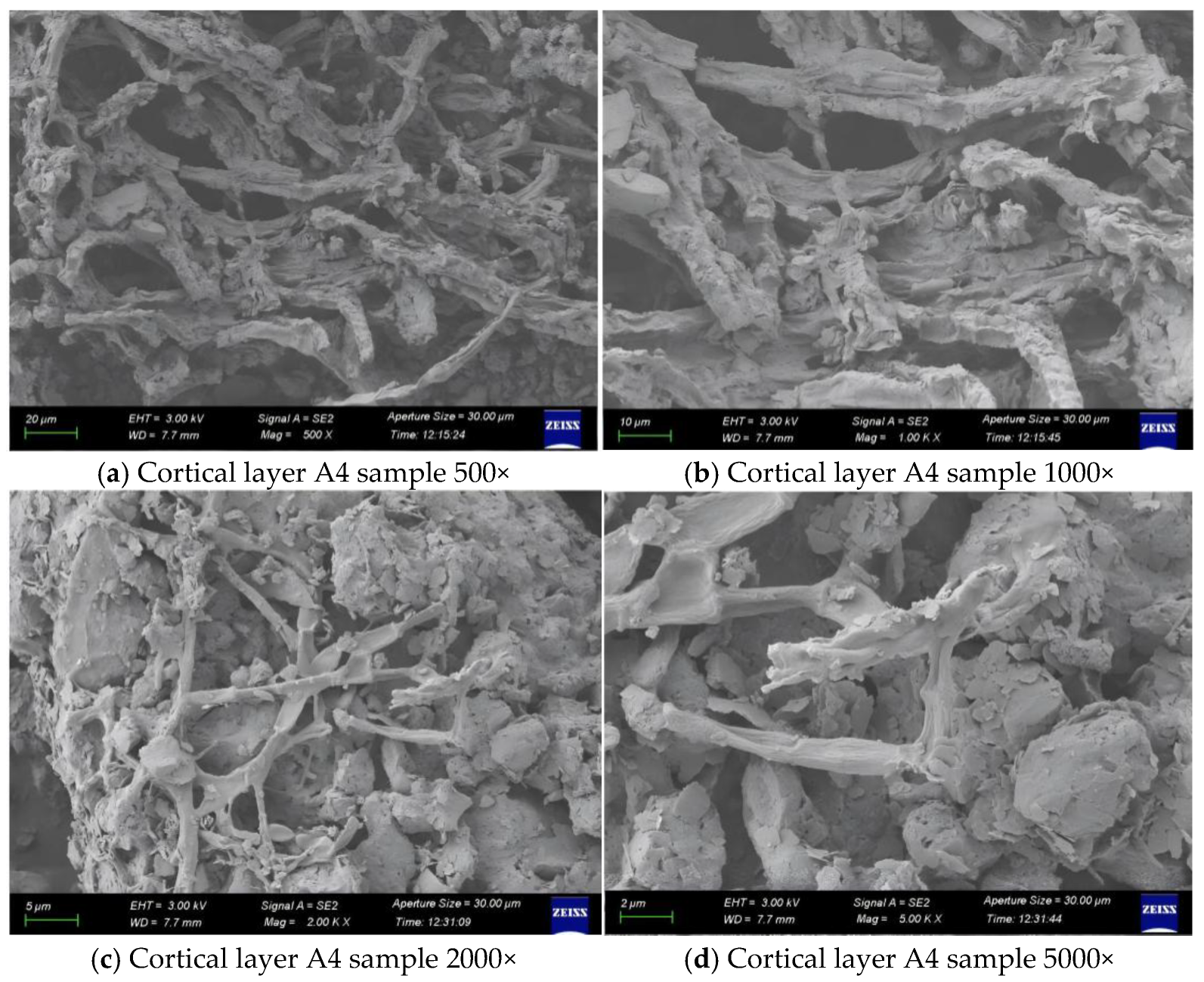

2.3.3. Scanning Electron Microscope (SEM) Testing

Scanning electron microscopy (SEM) testing was used to study the chemical elements and the microstructure of four different samples to determine the growth and morphology of algae on the surface of the rammed earth. The instrument used was a ZEISS Gemini SEM 360(Carl Zeiss AG, Jena, Germany) with a magnification range of 500 to 5000×. In this study, the test parameters were carefully set to balance the requirements of resolution and sample protection. A low accelerating voltage of 1.5 kV was selected to minimize damage to organic components, such as algal extracellular polysaccharides, caused by the electron beam. The working distance was set to 6.5 mm to optimize the collection efficiency of the secondary electron signals and imaging clarity. An in-lens secondary electron detector was chosen for signal detection.

4. Results and Discussion

The experimental results revealed that algal crusts exhibited a dual anti-erosion mechanism in soil protection. At the macro-protection level, the algae skin can significantly reduce the impact effect of raindrop kinetic energy on the soil surface and reduce the intensity of the splash erosion of rammed earth walls by forming a biological covering. Algal biofilms’ water-holding properties enable them to quickly absorb residual water on rammed earth walls after rain, reducing moisture that could otherwise cause structural damage.

Although algae may be damaged during sampling, preventing them from normal secretion, existing studies have shown that algal photosynthetic metabolites (including biopolymers, such as polysaccharides, lipids, and proteins) form stable complexes with soil particles through cementation [

30,

31]. More noteworthy, the algal filaments and symbiotic hyphae construct a three-dimensional network structure in the soil pores, combined with the viscoelastic matrix formed by exopolysaccharides, to construct a multi-scale stable system with hierarchical characteristics. This structure greatly enhances the topsoil’s mechanical strength and shear resistance, thereby improving the rammed earth wall’s surface stability.

However, during the study, the researchers found that although the west wall is more intact than the other walls, it still has erosion problems. Therefore, the researchers hypothesized that the protective mechanism of the algal biocrust layer on the rammed earth wall is two-sided. Based on previous scholars’ research on the protection mechanism of biocrusts on the rammed earth wall of the Great Wall of Shanhaiguan, the researchers can conclude that when in a dry and rainless environment, just like the hot temperature conditions in Songyang County in summer, the anti-erosion effect of algal biocrusts is more significant. This is because the stable structure formed by the exopolysaccharide it secures is more stable. However, due to the cold and humid winters in Songyang County and the frequent occurrence of acid rain in recent years, the algae on the crust layer accelerate the release of acidic substances in an acidic environment, which dissolve the cemented materials (such as calcium carbonate) inside the wall, resulting in a loose wall structure and small cracks, which may cause internal damage in the long term [

32]. Algal biofilms are not found all over the wall but are present in localized areas. For example, they may be present where rain washes repeatedly, such as the wall under the eaves (where the rainwater flows down the eaves) and the parts of the wall that are sunken or poorly drained (wet areas where water has accumulated for a long time). Therefore, in future conservation work, researchers should focus on the areas where algae find it easy to grow, inhibit the erosion of rammed earth walls by the acidic substances secreted by algae under certain conditions through chemical means, and optimize the compound materials of natural fiber and lime, to make algae biofilm play a better anti-erosion role.

Compared with the existing anti-erosion coatings for rammed earth buildings, the biocrust layer has the following significant advantages (

Table 2).

5. Design Strategy

5.1. Design Scheme

It is found that the MICP (microbially induced calcite precipitation) technology has been extended to the field of rammed earth building protection, and the idea of a microbial coating for tulou wall anti-erosion and microbial repair of tulou cracks is proposed, while its application effect is evaluated by experimental means. The results of the study demonstrate that MICP technology can be used as an effective method to alleviate the weathering and crack repair of the surface layer of rammed earth buildings [

23,

24].

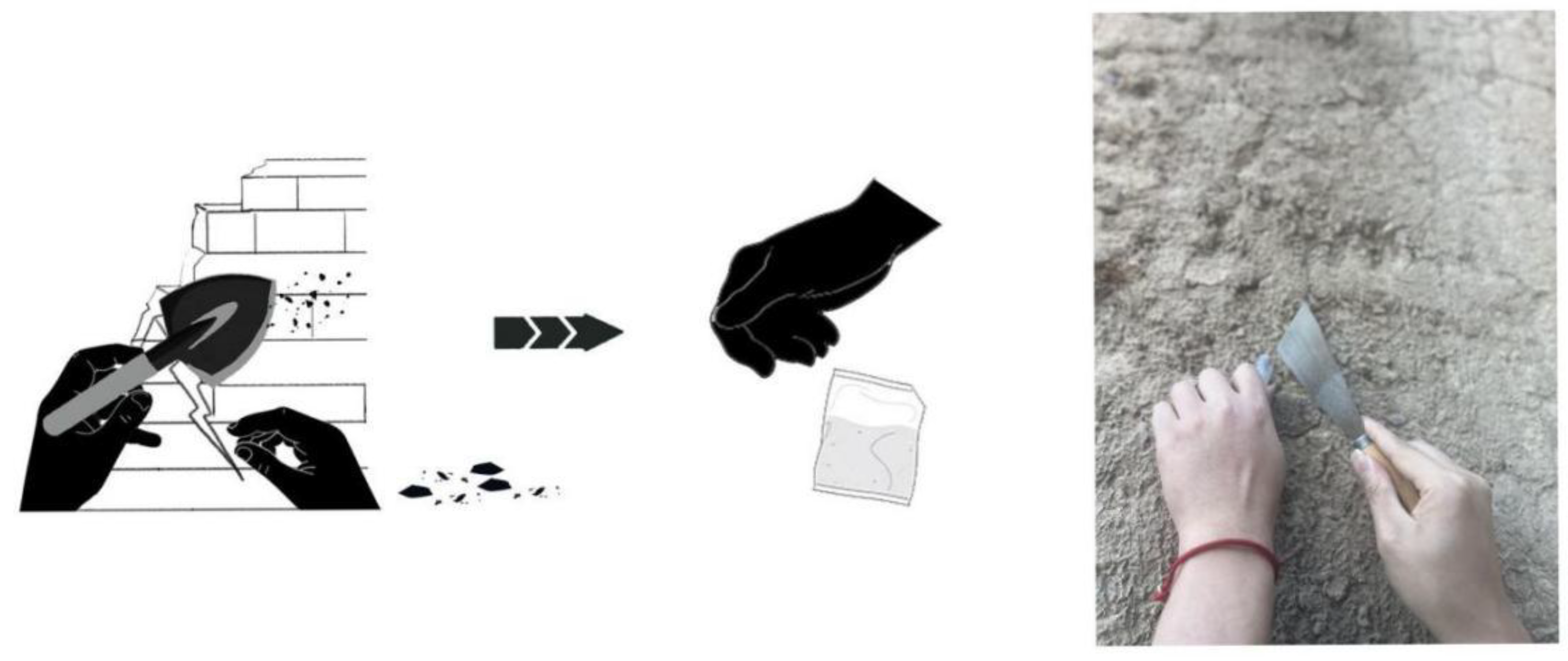

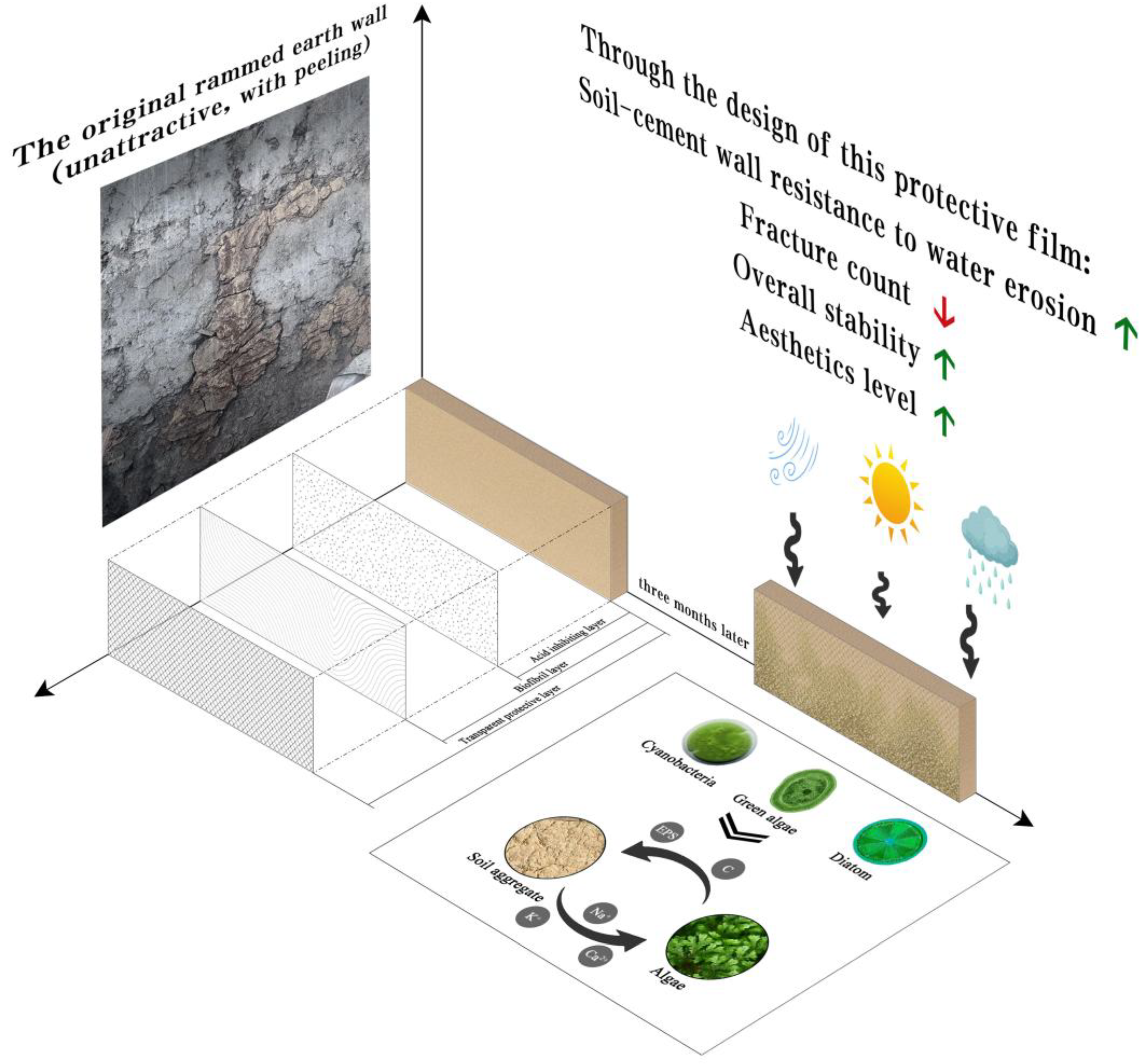

Based on the two main problems found in the rammed earth wall in this paper, namely (1) the existence of cracks and (2) wind and rain erosion, we determined the dual erosion resistance mechanism of algal biocrusts, as revealed by experimental analysis combined with MICP technology. Thus a composite biofilm design scheme of a “transparent film-biofiber-acid suppression layer” was proposed in this study (

Figure 17).

The transparent protective layer is made of a degradable polylactic acid (PLA) mesh (mesh size 2–5 mm), which takes into account the water permeability and raindrop kinetic energy dispersion function to avoid erosion. The biofiber layer is woven into a grid (mesh 5–10 mm) with hemp fiber and coconut shell fiber, which is pre-impregnated with a nitrogen and phosphorus nutrient solution and then paved on the surface of rammed earth, and the algae attachment base (with cyanobacteria as the core, accounting for 60%–70%, supplemented by green algae and diatoms, accounting for 30%–40%) is attached to the pore structure of its rough surface, forming a three-dimensional network complex cemented with extracellular polysaccharide (EPS) soil particles. At the same time, the researchers designed an acid suppression layer to solve the problem of the dissolution of rammed earth wall cementing materials caused by the release of acidic metabolites from algae, that is, calcium carbonate microparticles were embedded in the fiber grid to dynamically neutralize the acidic substances metabolized by algae and alleviate the contradiction of “external protection and internal damage”.

Glutinous rice syrup is used between the layers for bonding. First, glutinous rice flour and deionized water were mixed at a 1:4 mass ratio. Subsequently, the colloidal mixture was uniformly coated onto the contact interfaces between the PLA mesh, biological fiber layer, and acid-resistant layer using a spatula, with the coating thickness controlled to 0.5–0.8 mm to ensure no residual bubbles remained. Finally, the layers were laminated layer-by-layer in the order of “PLA mesh → biological fiber layer → acid-resistant layer”. The rationale behind the researchers’ choice of using glutinous rice syrup as an interlayer adhesive was multifold. Firstly, glutinous rice paste, being a natural organic material, does not pose toxic threats to the microbial community. Secondly, with its weak alkalinity, the glutinous rice paste can work in synergy with the calcium carbonate microparticles in the acid-resistant layer. This synergistic effect enables the neutralization of acidic substances resulting from environmental acid rain and algal metabolism, thereby mitigating chemical corrosion at the bonding interface.

5.2. Design Advantages

This design scheme leverages the experimentally revealed anti-erosion mechanism of algal biofilms to achieve coordinated optimization of ecological compatibility and dynamic protection through a composite structure of a “transparent film-biological fiber-acid inhibition layer”. The transparent polylactic acid (PLA) mesh, with its high light transmittance, supports algal photosynthesis while preventing water-induced erosion and washing. Cyanobacteria, as the core component, secrete large amounts of extracellular polysaccharides (EPS), forming a gelatinous protective layer that enhances surface stability. Green algae assist cyanobacteria by contributing to the formation of multi-layer biofilms, thereby increasing the redundancy of protection. Meanwhile, diatom shells increase surface roughness, promoting the attachment of other algal spores, and secrete silicate colloids that aid in filling micro-cracks in rammed earth [

25,

33]. This synergistic algal attachment base, with cyanobacteria as the primary component and green algae and diatoms as supporting elements, effectively improves the anti-erosion capability, compressive strength, and long-term durability of rammed earth walls.

Moreover, the biodegradable materials (PLA mesh and fiber layer) will naturally biodegrade over time after the algal biofilm stabilizes (after approximately 3 months), creating a self-sustaining protection system that requires no artificial maintenance. This system preserves the historical aesthetic of rammed earth walls through its natural materials and transparent structure, preventing the authenticity of cultural heritage from being compromised by traditional chemical coatings. Compared to conventional physical or chemical protection methods, this innovative design achieves a harmonious balance of efficient erosion resistance, ecological sustainability, and cultural compatibility through a multi-scale cooperative mechanism.

The sandwich-structured composite material developed by Masoud et al. (with an outer layer composed of polyhydroxyalkanoate (PHA) and an interlayer of polylactic acid (PLA) reinforced with sol–gel modified cellulose microfibers (CMF)) significantly enhanced the tensile modulus (approximately 30% increase) and hygrothermal stability of the PLA/CMF composites through chemical modification. Experimental results demonstrated that the modified CMF improved interfacial bonding with the PLA matrix, effectively inhibiting moisture penetration and microbial degradation [

34]. Accelerated aging tests under simulated hot–humid conditions (temperature: 25–35 °C, humidity: 70%–85%) revealed that the degradation rate of the PLA layer remained below 15% over 12 months, with mechanical property retention exceeding 80%, indicating its potential adaptability to the subtropical monsoon climate of Songyang County.

The design of this composite biofilm strictly adheres to the principles of minimal intervention and reversibility in the protection of cultural heritage. Its minimal intervention is manifested in non-invasive coverage, which only attaches to the surface layer of the rammed earth to avoid structural damage. Degradable polylactic acid (PLA) mesh, natural plant fibers (hemp, coconut shell), and algal components are used, while irreversible chemical additives, such as cement and resin are completely abandoned. The protective performance is dynamically regulated through the photosynthesis of algae and the acid inhibition layer, reducing the need for artificial intervention. Reversibility is achieved through controllable degradation: PLA and plant fibers gradually degrade into harmless carbon dioxide and water after the algal crust is stabilized (after about 3 months; the degradation rate is less than 15% within 12 months), and a multi-level removal strategy is preset to deal with potential residues—if artificial intervention is required, a soft brush is used to gently brush for physical stripping, or lactic acid bacteria fermentation broth (pH 5–6) is sprayed to accelerate the hydrolysis of PLA, avoiding damage to the rammed earth body. Compared with single physical or chemical protection schemes, this design achieves the unification of a high-efficiency anti-erosion, ecological cycle and cultural compatibility through a multi-scale collaborative mechanism.