Effect of TiC Addition on Microstructure and Performances of Double Pulse Electrodeposited Ni-TiC Coatings

Abstract

1. Introduction

2. Experiments

2.1. Materials

2.2. Preparation

2.3. Characterization

3. Results and Discussions

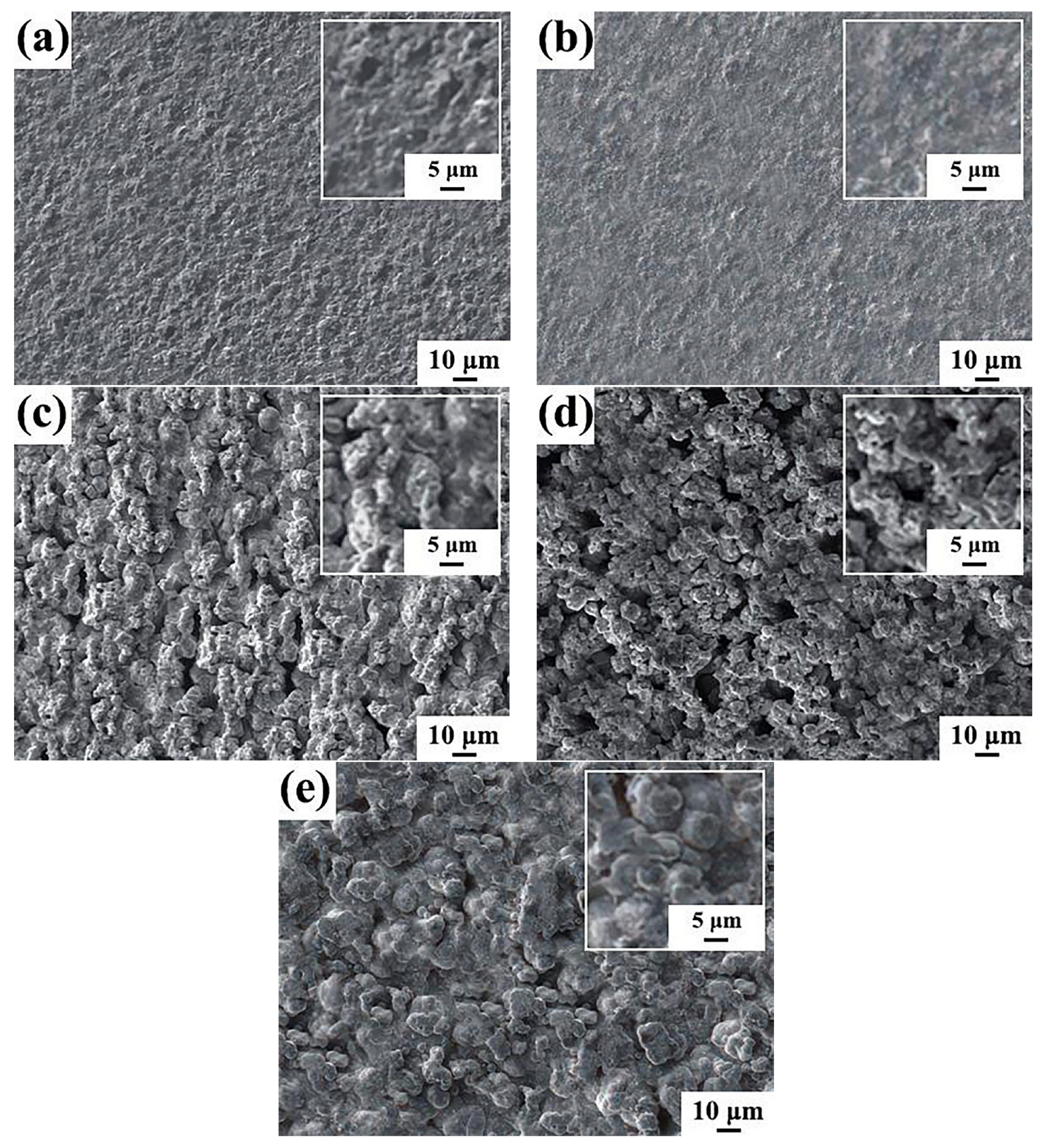

3.1. Surface Morphology

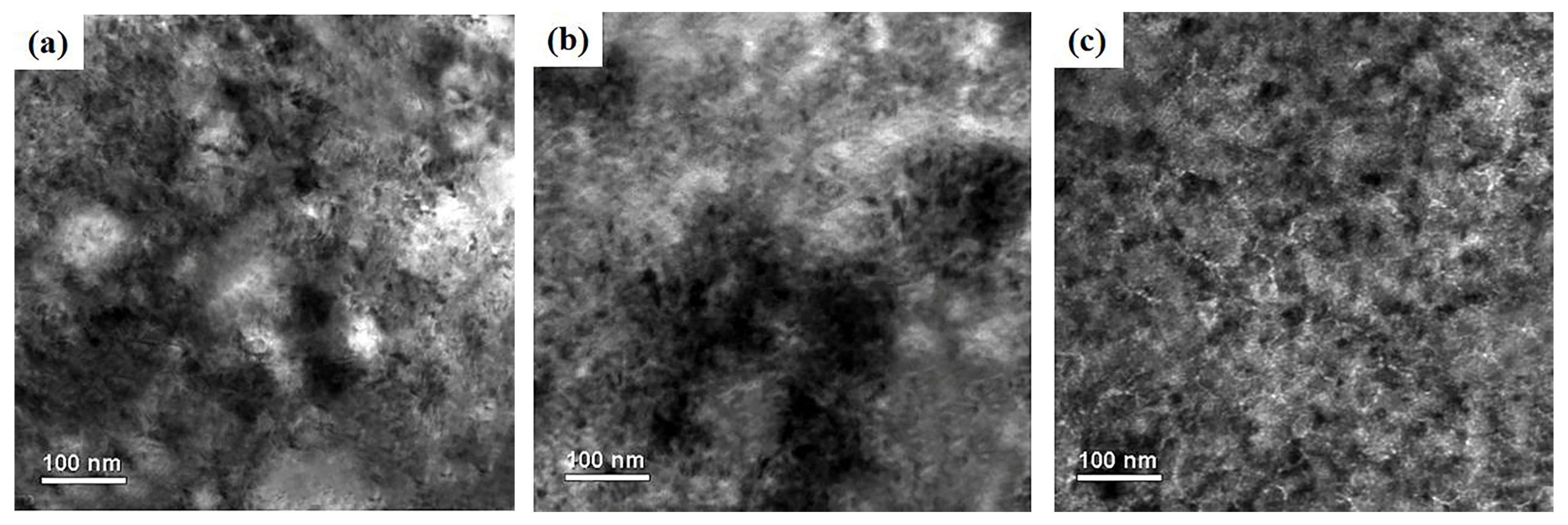

3.2. Microstructure

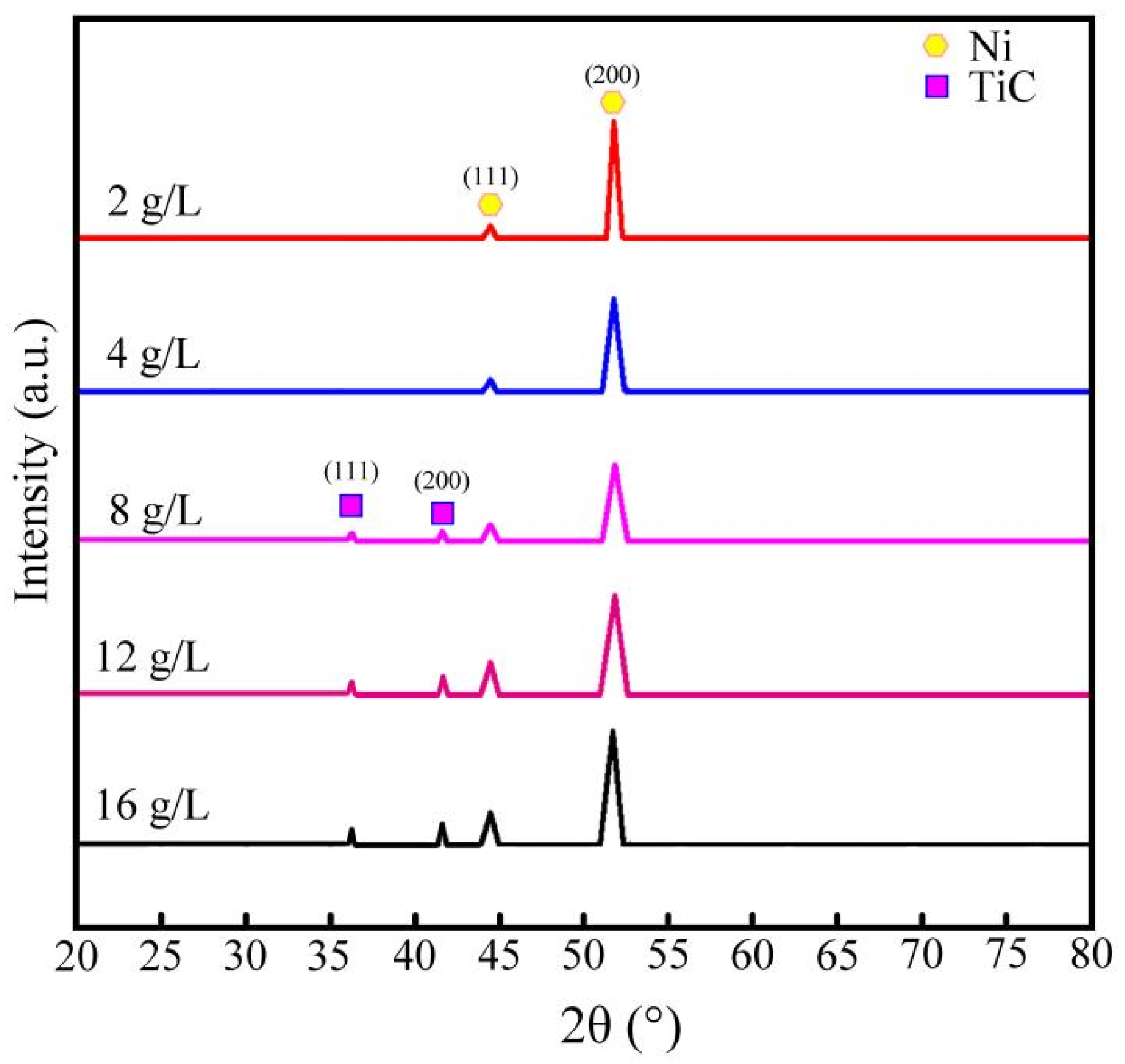

3.3. Phase Composition

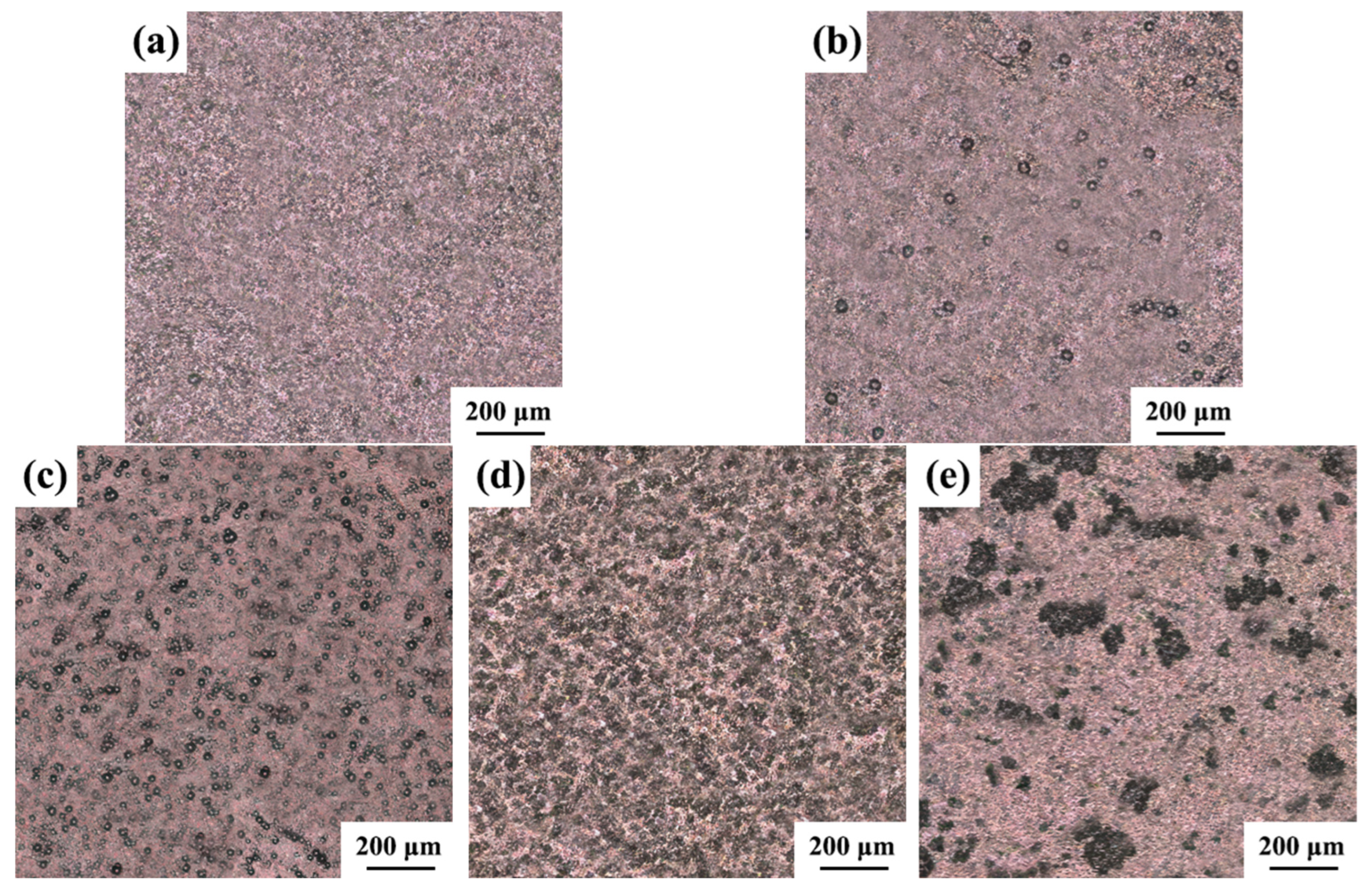

3.4. Surface Roughness

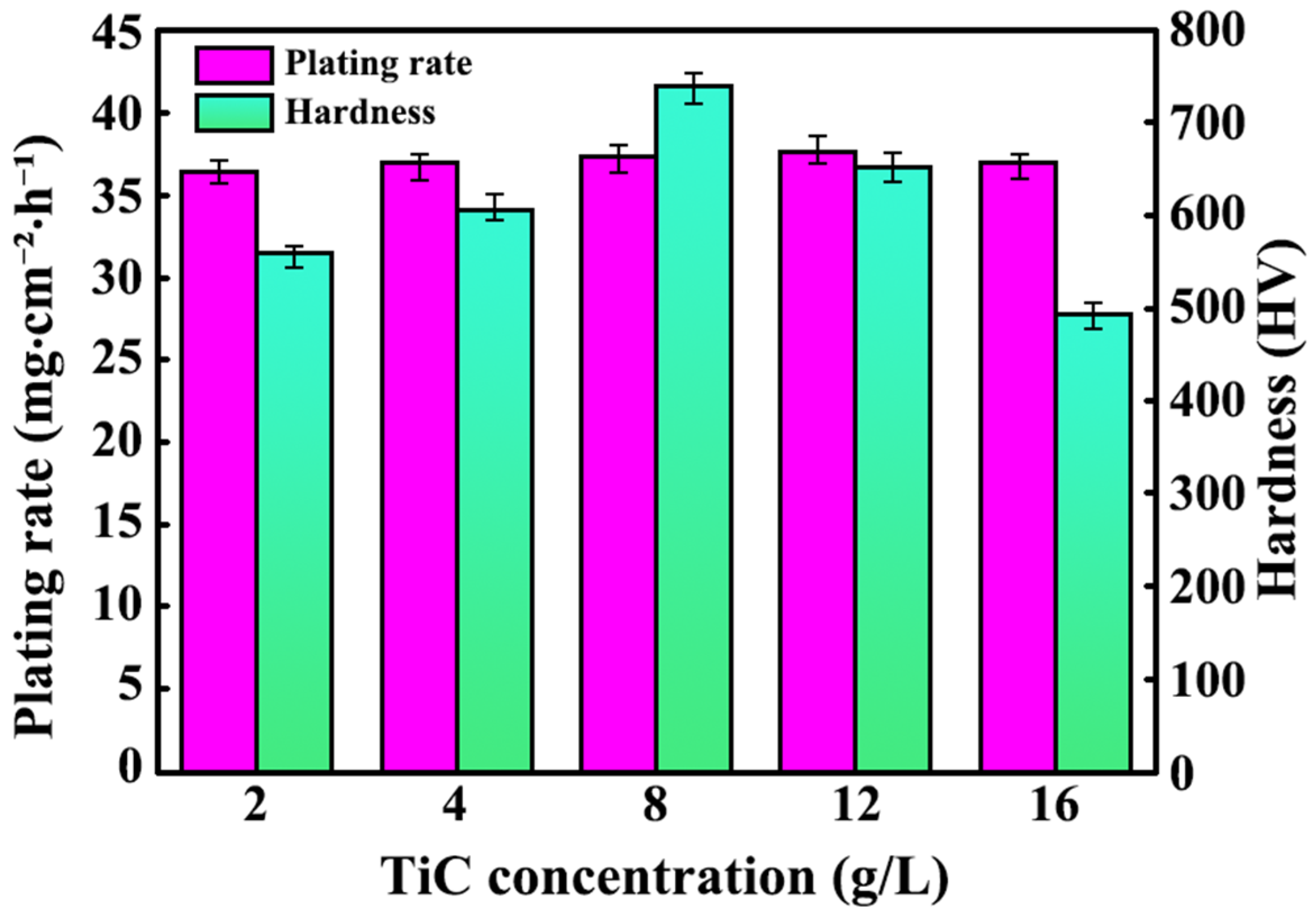

3.5. Plating Rate and Microhardness

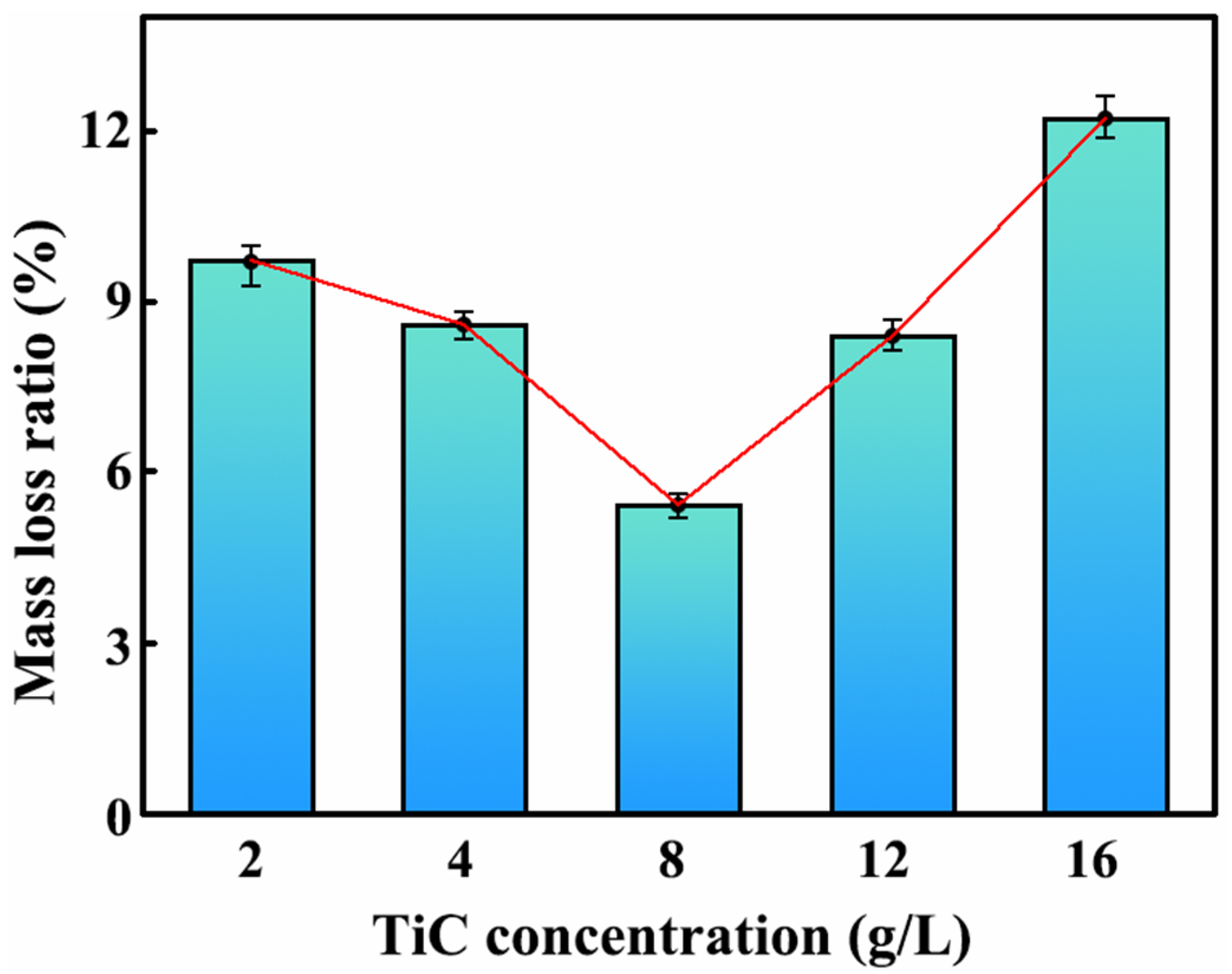

3.6. Wear Resistance

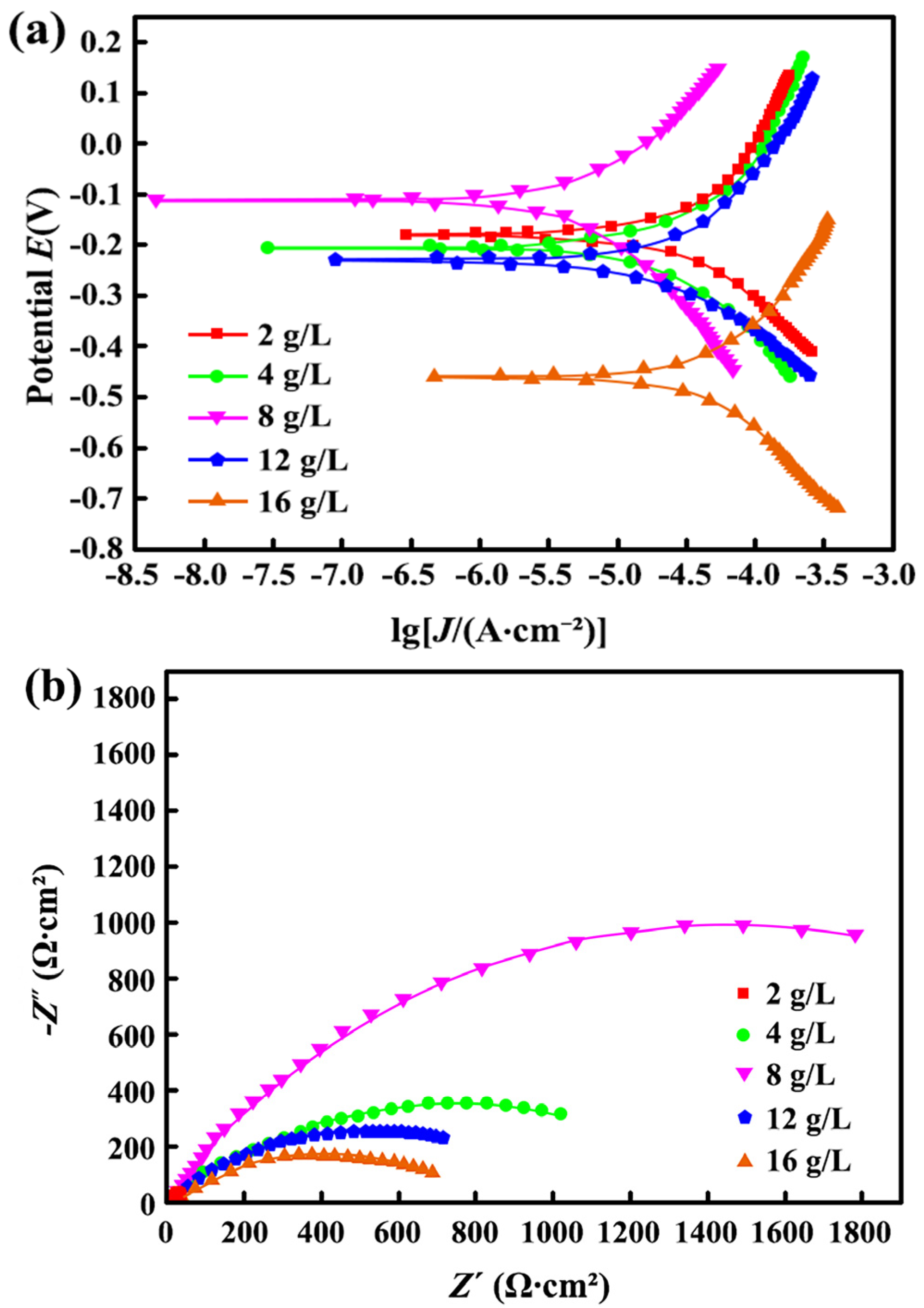

3.7. Corrosion Resistance

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, G.; Zhou, K.; Ren, B.K.; Yu, W.X. Influence of Cu/Ni coating on microstructure and mechanical properties in steel/aluminum single-sided resistance spot welding joint. J. Mater. Process. Technol. 2025, 335, 118675. [Google Scholar] [CrossRef]

- Pan, C.G.; Gong, M.C.; Feng, S.Q.; Chen, X.; Zhao, X.; He, P. Corrosion and thermal fatigue behaviors of induction-clad Ni-coated TiC particle-reinforced Ni60 coating in molten aluminum alloy. Surf. Coat. Technol. 2021, 419, 127278. [Google Scholar] [CrossRef]

- Zhang, C.; Wu, M.F.; Pu, J.; Rao, J.W.; Long, W.M.; Shen, Y.X. Effect of Ni Coating on Microstructure and Property of Al Alloy/Steel CMT Welding-Brazing Joints. Coatings 2023, 13, 418. [Google Scholar] [CrossRef]

- Li, D.Y.; Cui, X.F.; Wen, X.; Feng, L.T.; Hu, Y.T.; Jin, G.; Liu, E.B.; Zheng, W. Effect of CeO2 nanoparticles modified graphene oxide on electroless Ni-P coating for Mg-Li alloys. Appl. Surf. Sci. 2022, 593, 153381. [Google Scholar] [CrossRef]

- Kumar, S.; Kadian, A.K.; Sharma, M.; Mahato, A.C.; Mukhopadhyay, A. Development of Ni-B coating through the aid of artificial intelligence. Mater. Lett. 2025, 378, 137621. [Google Scholar] [CrossRef]

- Liu, Y.Z.; Li, Y.X.; Chen, H.; Zhu, Z.T. Preventing formation of intermetallic compounds in ultrasonic-assisted Sn soldering of Mg/Al alloys through pre-plating a Ni coating layer on the Mg substrat. J. Magnes. Alloys 2024, 12, 726–741. [Google Scholar] [CrossRef]

- Kayar, B.E.; Akin, I.; Goller, G. Densification, microstructure, and wear properties of TiB2-TiC-GNP and TiB2-TiC-BN composite. Ceram. Int. 2024, 50, 41490–41498. [Google Scholar] [CrossRef]

- Tang, L.; Liu, Y.H.; Liu, L.G.; Xu, P.H.; Xie, J.W. Probing the Atomic Erosion Wear Characteristics of TiC-Coated Fe in Oil and Gas Drilling Environments. Langmuir 2024, 40, 14173–14187. [Google Scholar] [CrossRef]

- Liu, D.Y.; Yang, X.F.; Zhao, A.T.; Cheng, X.M.; Zhang, Q.L. Preparation of nickel-based composite coatings by laser cladding technology: A review. Int. J. Adv. Manuf. Technol. 2024, 134, 3107–3137. [Google Scholar] [CrossRef]

- Yan, Z.B.; Lei, S.Y.; Li, W.Z.; Zeng, D.C.; Yan, R.X. Preparation and characterization of high-performance in-situ synthesized WC reinforced nickel-based coatings. J. Mater. Res. Technol. 2024, 31, 1450–1460. [Google Scholar] [CrossRef]

- Li, S.; Li, H.Q.; Zhai, Z.H.; Cao, X.J.; Liu, D.X.; Jiang, J.L. Corrosion resistance and tribological behavior of FeCoCrNi@GO/Ni high entropy alloy-based composite coatings prepared by electrodeposition. Surf. Coat. Technol. 2024, 477, 130379. [Google Scholar] [CrossRef]

- Ma, M.; Sun, W.C.; Zhang, Y.G.; Liu, X.J.; Xiao, Y. Effect of TiC particles concentration on microstructure and properties of Ni-TiC composite coatings. Mater. Res. 2019, 22, 0530. [Google Scholar] [CrossRef]

- Cai, L.P.; Luo, B.J.; Yang, J.; Jia, S.Q.; He, N.R.; Jia, J.H. Microstructure evolution and tribological properties over a wide temperature range of Ni-based composite coatings with Ti3AlC2 addition. Tribol. Int. 2025, 201, 110200. [Google Scholar] [CrossRef]

- Ogunbiyi, O.; Iwarere, S.A.; Sadiku, R.; Daramola, M.O. Microstructure, Mechanical, Tribological and Synergistic strengthening mechanisms of nickel/graphene nanoplatelets hybrid reinforced AZ91D magnesium-based matrix composites via spark plasma sintering. J. Mater. Res. Technol. Jmrt 2024, 29, 2628–2640. [Google Scholar] [CrossRef]

- Kaboli, A.; Esfandiari, N.; Darband, G.B.; Sharifi, R.; Aliofkhazraei, M.; Rouhaghdam, A.S. Electrodeposition of Fe-Co-Ni coating by cyclic voltammetry for efficient hydrogen production. J. Electroanal. Chem. 2024, 958, 118151. [Google Scholar] [CrossRef]

- Gao, M.Y.; Liu, L.L.; Huang, Z.X.; Jiang, C.; Wang, X.; Huang, F.; Li, X.X.; Zhang, X.H. Electrodeposition and properties of Ni-W-Ti2AlC composite coatings. Ceram. Int. 2024, 50, 18832–18842. [Google Scholar] [CrossRef]

- Li, X.; Zheng, Z.Z.; Xiao, X.J.; Chen, J.K.; Zhu, C.F. Corrosion Behavior of Ni-Mo Coatings Prepared by Different Electrodeposition Methods in Na2S Soluti. Russ. J. Phys. Chem. A 2023, 97, 2846–2854. [Google Scholar] [CrossRef]

- John, A.; Saeed, A.; Khan, Z.A. Influence of the Duty Cycle of Pulse Electrodeposition-Coated Ni-Al2O3 Nanocomposites on Surface Roughness Properties. Materials 2023, 16, 2192. [Google Scholar] [CrossRef]

- Wen, Y.X.; Zhao, Y.; Zhang, Z.Y.; Wu, Y.C.; Zhu, H.; Xu, K.; Liu, Y. Electrodeposition of Ni-Mo alloys and composite coatings: A review and future directions. J. Manuf. Process. 2024, 119, 929–951. [Google Scholar] [CrossRef]

- Xu, J.P.; Zhang, K.X.; Chen, J.; Wang, J.J.; Ma, Y.H. Microstructure and properties of TiB2/Cu composite coating with multi-layer structure prepared by electrodeposition. J. Adhes. Sci. Technol. 2024, 38, 4202–4219. [Google Scholar] [CrossRef]

- Yao, Y.L.; Cheng, J.H.; Ji, H.; Zhang, S.J.; Pang, H.Z.; Chen, Y.; Tian, Z.J. The preparation and properties of thick bronze coating using friction-assisted jet electrodeposition. Coatings 2024, 14, 150. [Google Scholar] [CrossRef]

- Zafarghandi, M.S.; Tavandashti, N.P. Electrodeposition of hierarchically structured superhydrophobic Ni-PTFE composite coating with remarkable corrosion resistance, chemical and mechanical stability. Sci. Iran. 2024, 31, 907–919. [Google Scholar] [CrossRef]

- Akbarpour, M.R.; Hosseini, S.F.; Kim, H.S. Microstructure; hardness, and tribological properties of Ni-Co/SiO2 nanocomposite coating produced through pulsed current electrodeposition. Ceram. Int. 2024, 50, 46113–46120. [Google Scholar] [CrossRef]

- Zhang, Q.Q.; He, L.J.; Hao, C.L.; Zhao, Z.R.; Lu, Y.; Wang, L.Q. Influence of Y2O3 content on the properties of Ni-Y2O3-MgO nanocomposite coatings prepared by pulse electrodeposition. Int. J. Electrochem. Sci. 2024, 19, 100769. [Google Scholar] [CrossRef]

- Liu, Y.L.; Jeng, M.C.; Hwang, J.R.; Chang, C.H. A study on wear resistance of HVOF-sprayed Ni-MoS2 self-lubricating composite coatings. J. Therm. Spray Technol. 2015, 24, 489–495. [Google Scholar] [CrossRef]

- Gana, A.; Temam, H.B.; Lwkmine, F.; Naoun, M.; Herzallah, O. Characterization of electrodeposited Ni-MoS2 composite coatings under the influence of current density. Dig. J. Nanomater. Biostruct. 2021, 16, 815–821. [Google Scholar] [CrossRef]

- Wang, C.J.; Li, Y.G.; Wu, Y.J. Influence of double-pulse electrodeposition parameters on the performance of Ag/AgCl electrochemical electrode for marine electric field. Sensors 2024, 24, 2103. [Google Scholar] [CrossRef] [PubMed]

- Fang, C.; Lei, W.N.; Xu, T.L.; Zhong, H.Y.; He, B.; Kong, L.L.; He, Y.L. Effect of reverse pulse current density on microstructure and properties of supercritical Ni-GQDs nanocomposite coatings. Electrochem. Commun. 2024, 160, 107680. [Google Scholar] [CrossRef]

- Demiroren, H. Electrochemical Synthesis of High Chromium Fe-Based TiC Composite Coating. Prot. Met. Phys. Chem. Surf. 2022, 58, 109–118. [Google Scholar] [CrossRef]

- Liu, Y.; Li, Z.Y.; Li, G.H.; Du, F.M.; Mu, Y. Microstructure and Wear Resistance of Ni-WC-TiC Alloy Coating Fabricated by Laser. Lubricants 2023, 11, 170. [Google Scholar] [CrossRef]

- Ma, C.Y.; He, H.X.; Xia, F.F.; Cao, M.Y. Effect of pulse electrodeposition mode on microstructures and properties of Ni-TiN composite coatings. Coatings 2024, 14, 1384. [Google Scholar] [CrossRef]

- Unal, E.; Yasar, A.; Karahan, H.I. Investigation of the Properties of Ni-B/TiC Nanocomposite Coatings Produced at Different Particle Concentrations by Electrodeposition. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2023, 54, 2340–2361. [Google Scholar] [CrossRef]

- Benkovsky, I.; Tsyntsaru, N.; Silkin, S.; Petrenko, V.; Pakstas, V.; Cesiulis, H.; Dikusar, A. Synthesis, Wear and Corrosion of Novel Electrospark and Electrospark-Electrochemical Hybrid Coatings Based on Carbon Steels. Lubricants 2023, 11, 205. [Google Scholar] [CrossRef]

- Ding, H.M.; Jin, W.C.; Qi, F.G.; Liu, Q.; Qiu, Q.W. Atomic insight on the electronic structure and interfacial bonding characterization of the Cu/TiC interface. Ceram. Int. 2024, 50, 46791–46801. [Google Scholar] [CrossRef]

- Xu, K.Y.; Lin, M.T.; Liu, Y.T.; Zhao, D.; Liu, M.; Wang, H.D.; Wang, Y.; Bai, Y. Enhanced thermal performance of CeYSZ coating on Ni-based high temperature alloy with a unique Y-doped Al2O3 barrier layer via cathodic plasma electrolytic deposition. Ceram. Int. 2024, 50, 56123–56130. [Google Scholar] [CrossRef]

- Kumar, A.; Das, A.K. Development of Al-Ni-TiC composite coating on commercially pure Al using tungsten inert gas welding route and its wear behavior. J. Mater. Eng. Perform. 2022, 31, 5324–5331. [Google Scholar] [CrossRef]

- Ma, C.Y.; He, H.X.; Zhang, H.B.; Xia, F.F.; Li, H.X. Impact of ultrasonic power density on the structure and performance of Ni-W-SiC composite nanocoatings. Surf. Coat. Technol. 2025, 496, 131641. [Google Scholar] [CrossRef]

- Li, H.X.; Ma, C.Y.; Xia, F.F.; Xiao, Z.M. Ultrasonic cavitation-enhanced synthesis electrodeposition of MgCo2O4@Ni (OH)2 nanoneedles for high-performance supercapacitor electrodes. J. Energy Storage 2025, 121, 116493. [Google Scholar] [CrossRef]

- Li, H.X.; Ma, C.Y.; Xia, F.F.; Xiao, Z.M. Ultrasonic disorder-induced deposition of TiO2 nanorod arrays and C60 coating on carbon cloth for high-performance supercapacitor electrodes. Ultrason. Sonochem. 2025, 117, 107347. [Google Scholar] [CrossRef]

- Ganji, M.; Yousefnia, H.; Seyedraoufi, Z.S.; Shajari, Y. The corrosion behavior of Ni-Fe and Ni-Fe-TiC nanoparticles deposited using pulse electrodeposition on low-carbon steel. J. Aust. Ceram. Soc. 2022, 58, 1283–1295. [Google Scholar] [CrossRef]

| Composition | Concentration (g/L) |

|---|---|

| NiSO4·6H2O | 240 |

| NiCl2·6H2O | 30 |

| H3BO3 | 35 |

| C12H25SO4Na | 0.1 |

| C7H5NO3S | 1.5 |

| TiC nanoparticles | 2–16 |

| Parameter | Value |

|---|---|

| Forward reverse duty cycles (Jm+) | 5 A/dm2 |

| Reverse average current densities (Jm−) | −1.4 A/dm2 |

| Forward reverse duty cycles (D+) | 50% |

| Reverse duty cycles (D−) | 10% |

| ) | 5 ms |

| 1 ms | |

| Bath temperature (T) | 50 °C |

| pH | 3.5 |

| Stirring rate v | 200 r/min |

| Plating time ttotal | 50 min |

| TiC Concentration (g/L) | Ra (μm) |

|---|---|

| 2 | 2.28 |

| 4 | 2.76 |

| 8 | 3.43 |

| 12 | 4.45 |

| 16 | 6.84 |

| TiC Concentration (g/L) | Ecorr (V) | Rp (Ω·cm2) | Jcorr (A·cm−2) |

|---|---|---|---|

| 2 | −0.18 | 1635.78 | 2.51 × 10−5 |

| 4 | −0.21 | 2088.93 | 2.02 × 10−5 |

| 8 | −0.11 | 7705.62 | 5.27 × 10−6 |

| 12 | −0.23 | 1677.44 | 2.36 × 10−5 |

| 16 | −0.45 | 1109.31 | 3.92 × 10−5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, H.; Wang, H.; Xia, F. Effect of TiC Addition on Microstructure and Performances of Double Pulse Electrodeposited Ni-TiC Coatings. Coatings 2025, 15, 598. https://doi.org/10.3390/coatings15050598

Liu H, Wang H, Xia F. Effect of TiC Addition on Microstructure and Performances of Double Pulse Electrodeposited Ni-TiC Coatings. Coatings. 2025; 15(5):598. https://doi.org/10.3390/coatings15050598

Chicago/Turabian StyleLiu, Haijun, Hui Wang, and Fafeng Xia. 2025. "Effect of TiC Addition on Microstructure and Performances of Double Pulse Electrodeposited Ni-TiC Coatings" Coatings 15, no. 5: 598. https://doi.org/10.3390/coatings15050598

APA StyleLiu, H., Wang, H., & Xia, F. (2025). Effect of TiC Addition on Microstructure and Performances of Double Pulse Electrodeposited Ni-TiC Coatings. Coatings, 15(5), 598. https://doi.org/10.3390/coatings15050598