The Properties of Self-Compacting Ultra-High Performance Concrete with Different Types of Mineral Admixtures

Abstract

:1. Introduction

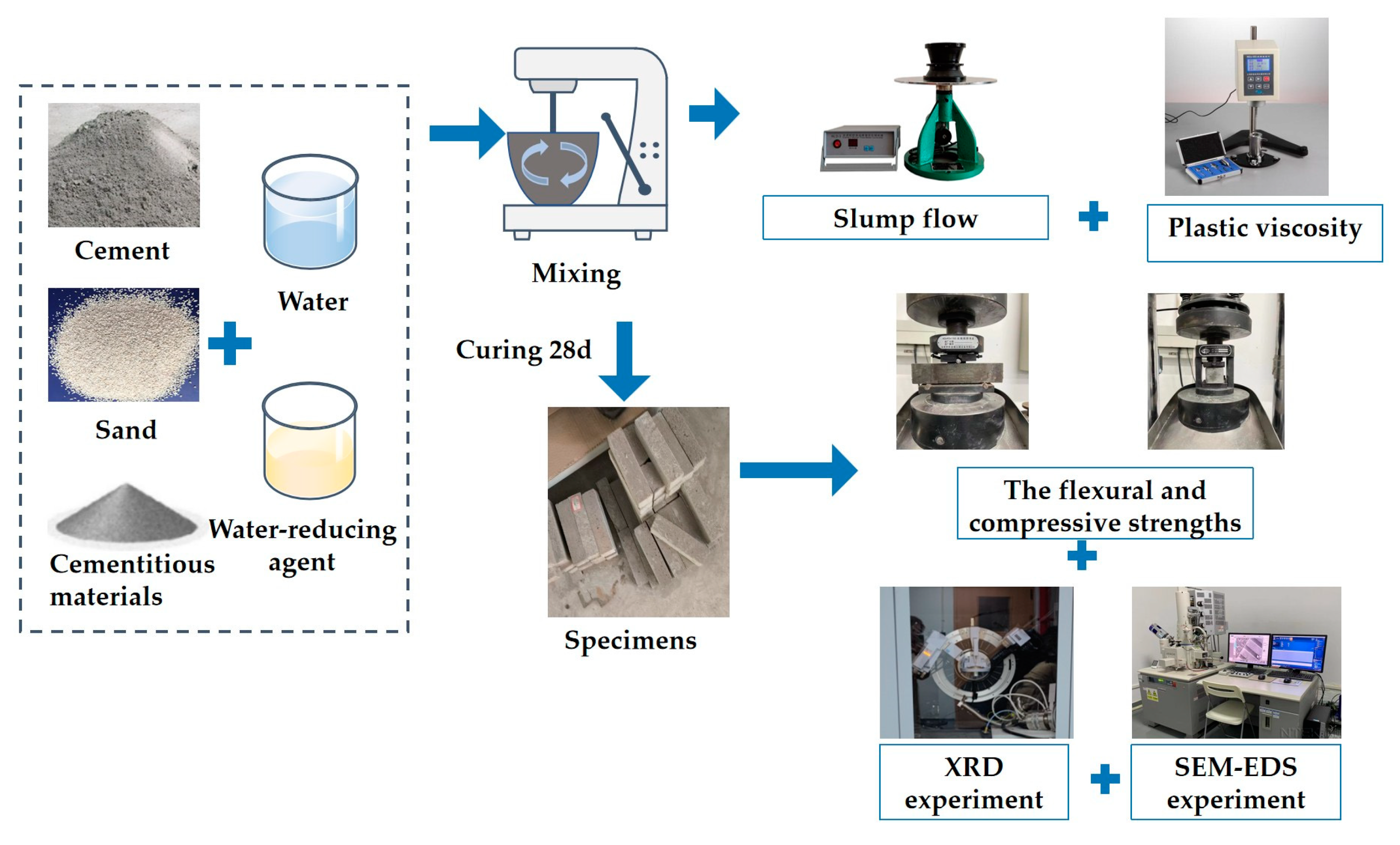

2. Materials and Methods

2.1. Raw Materials

2.2. Specimen Preparation

2.3. Measuring Methods

2.3.1. The Measurement of Rheological Parameters

2.3.2. Mechanical Strengths

2.3.3. Experiments of Microscopic Properties

3. Results and Discussions

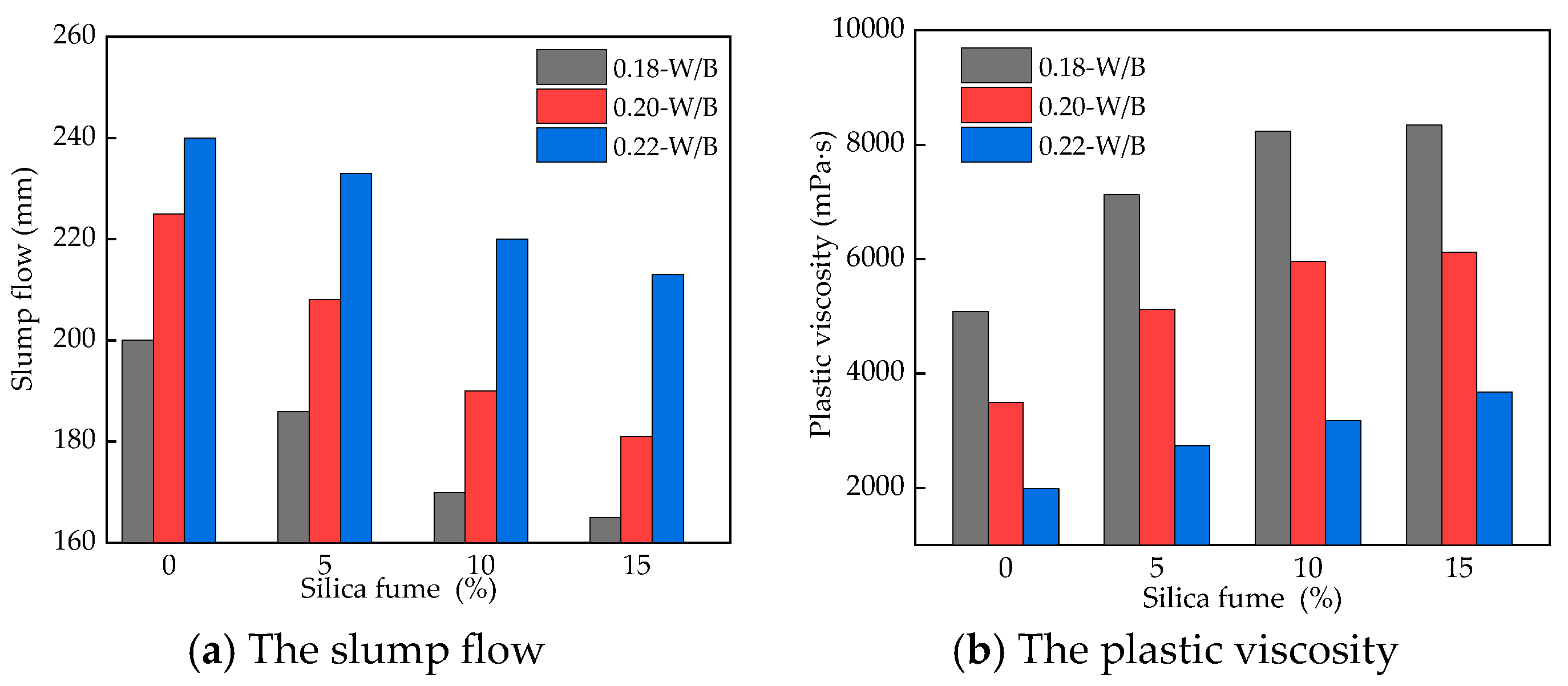

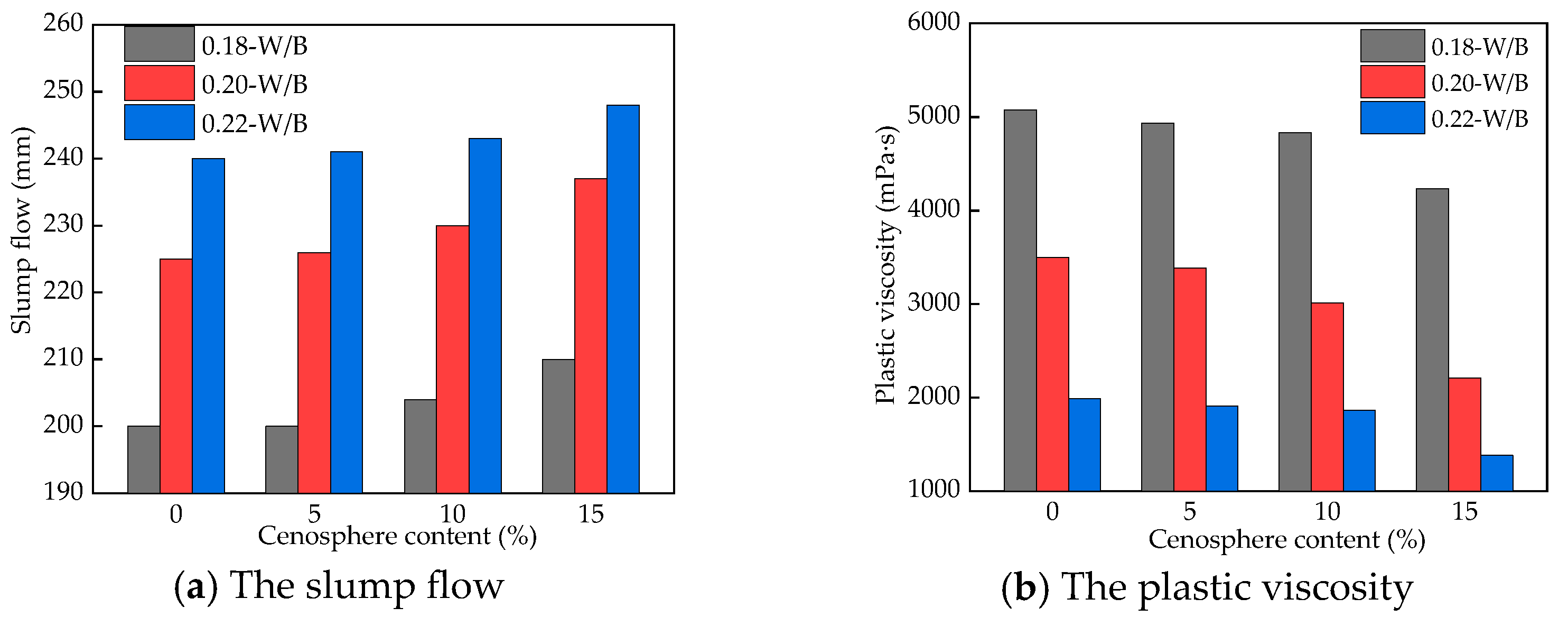

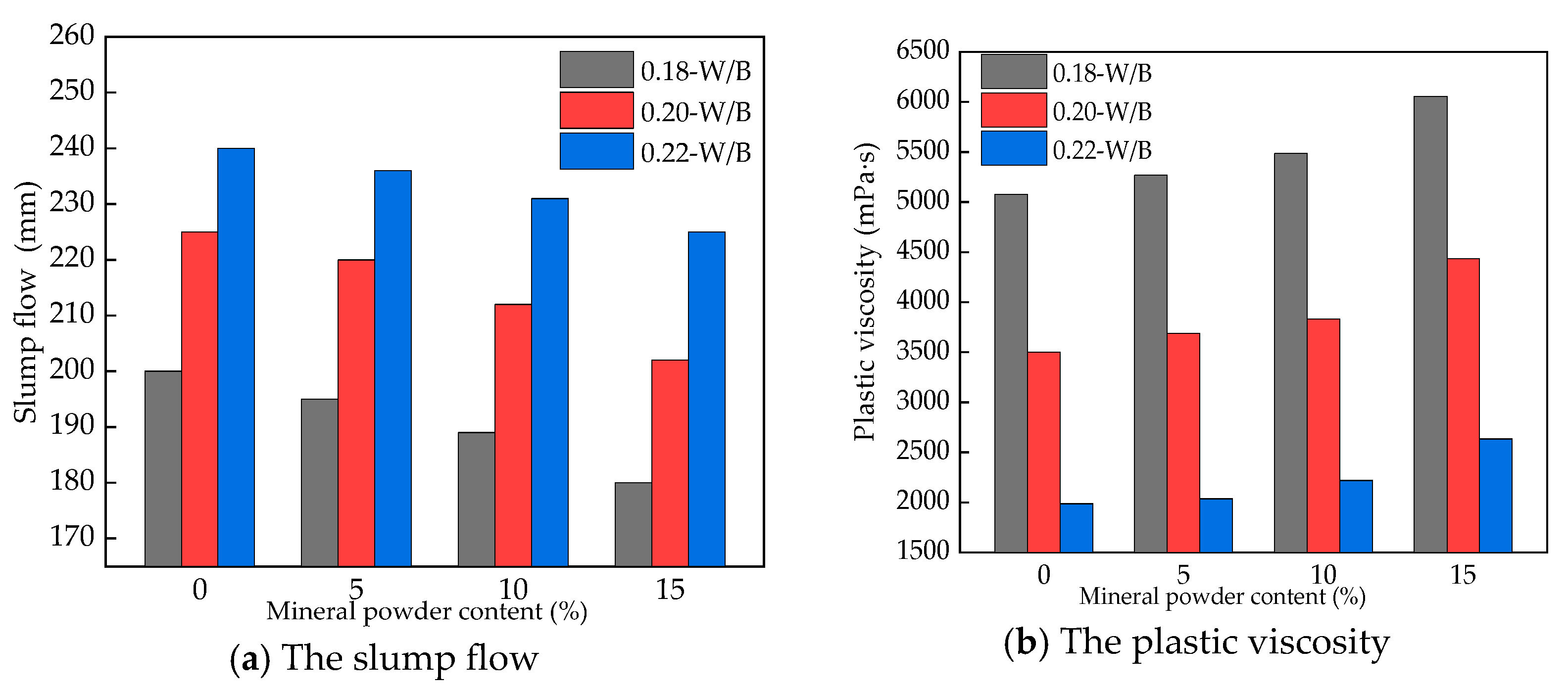

3.1. The Rheological Parameters

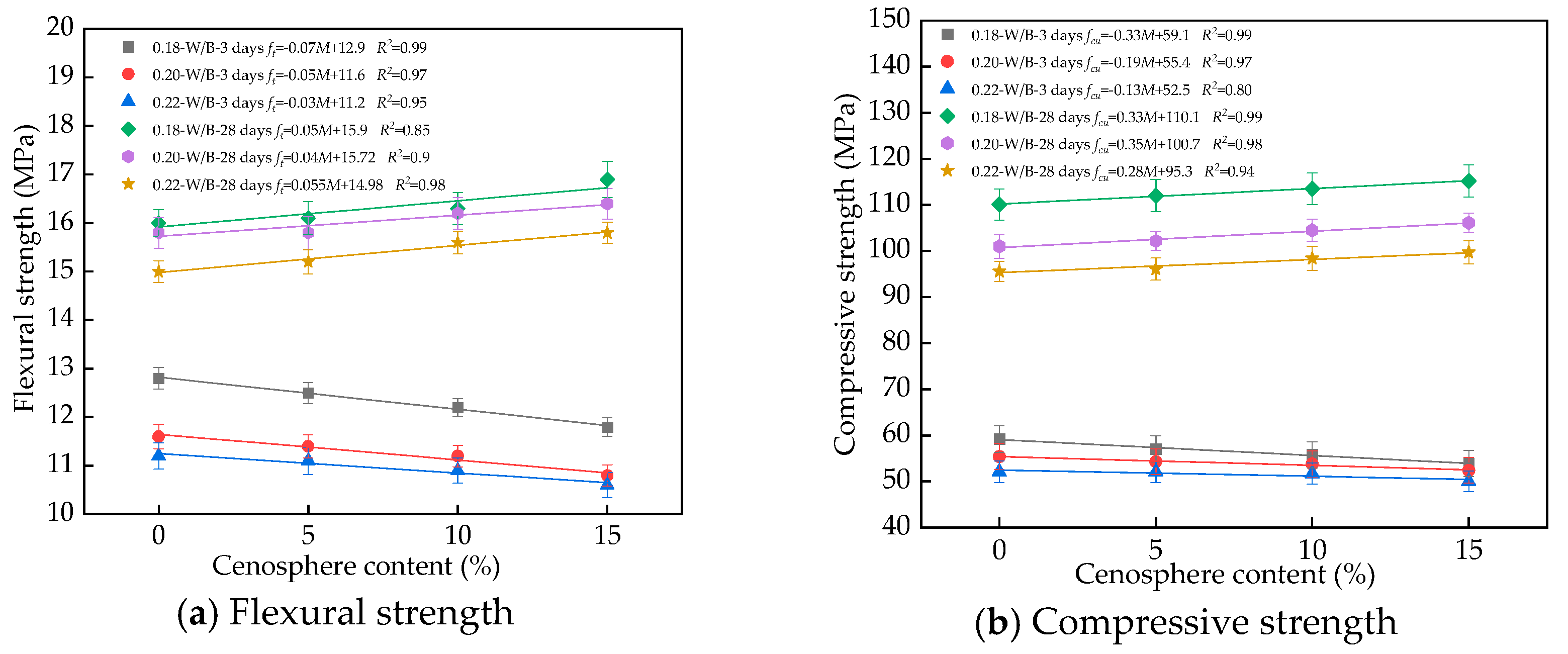

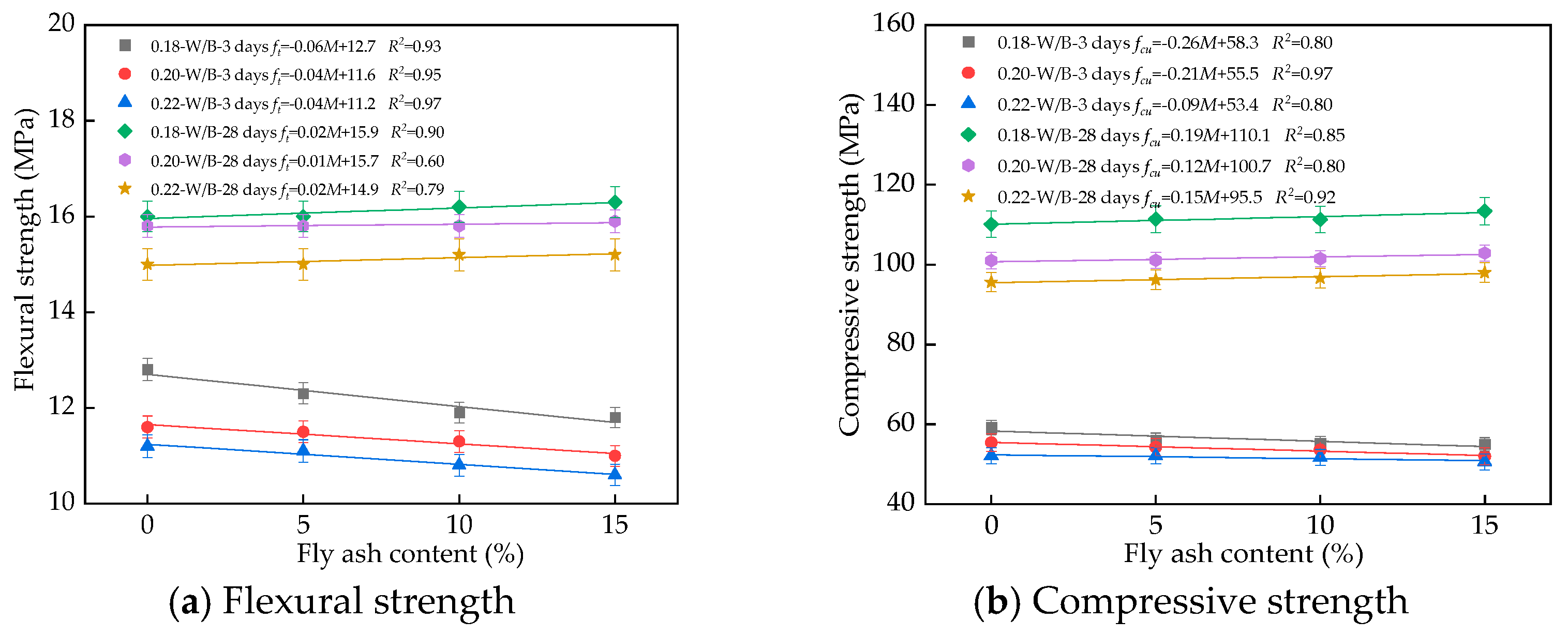

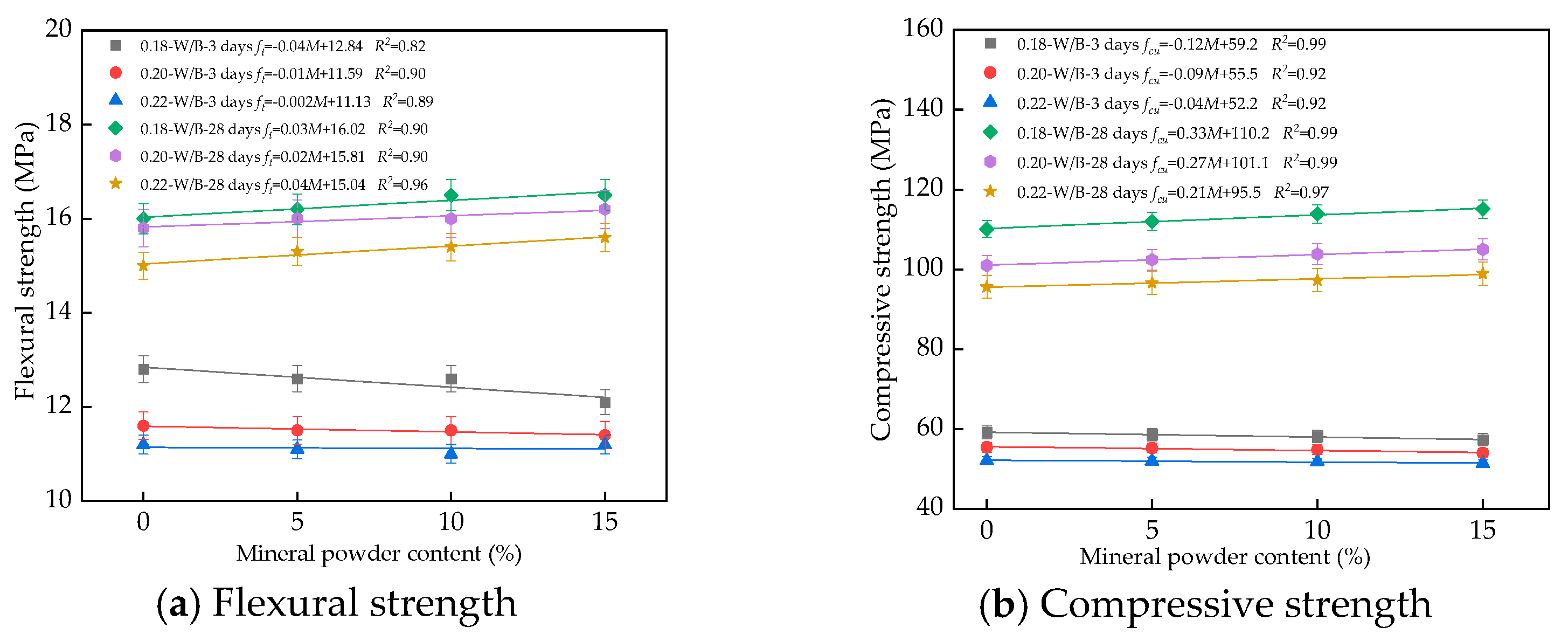

3.2. The Mechanical Strengths

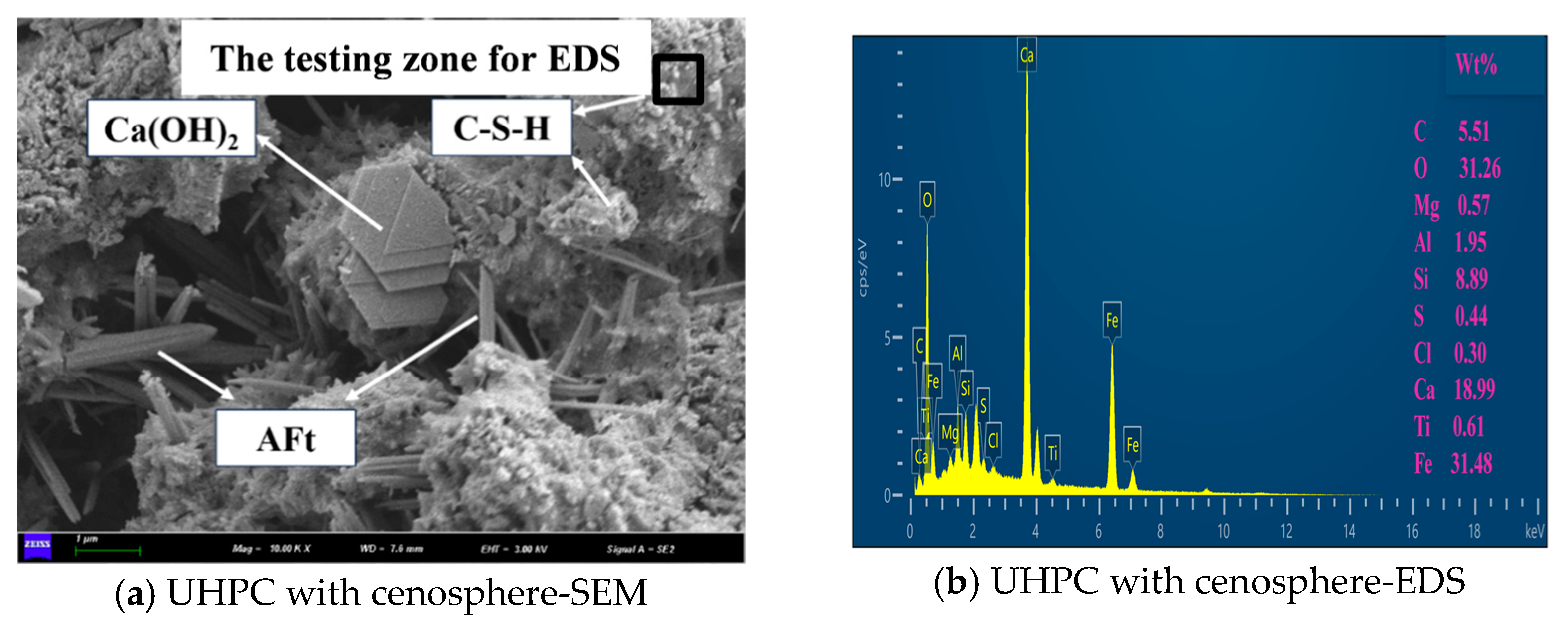

3.3. The Scanning Electron Microscope and X-Ray Diffraction Spectrum

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

| W/B | Silica Fume | Cenosphere | Fly Ash | Grade Slag Powder | Flexural Strength (MPa) | Compressive Strength (MPa) |

|---|---|---|---|---|---|---|

| 0.18 | 0% | 0 | 0 | 0 | 12.8 | 59.2 |

| 0.18 | 5% | 0 | 0 | 0 | 13.0 | 59.9 |

| 0.18 | 10% | 0 | 0 | 0 | 13.1 | 60.5 |

| 0.18 | 15% | 0 | 0 | 0 | 13.8 | 64.3 |

| 0.18 | 0 | 5% | 0 | 0 | 12.5 | 57.1 |

| 0.18 | 0 | 10% | 0 | 0 | 12.2 | 55.8 |

| 0.18 | 0 | 15% | 0 | 0 | 11.8 | 53.9 |

| 0.18 | 0 | 0 | 5% | 0 | 12.3 | 56.1 |

| 0.18 | 0 | 0 | 10% | 0 | 11.9 | 55.3 |

| 0.18 | 0 | 0 | 15% | 0 | 11.8 | 55.0 |

| 0.18 | 0 | 0 | 0 | 5% | 12.6 | 58.6 |

| 0.18 | 0 | 0 | 0 | 10% | 12.6 | 58.1 |

| 0.18 | 0 | 0 | 0 | 15% | 12.1 | 57.3 |

| 0.20 | 5% | 0 | 0 | 0 | 11.8 | 56.9 |

| 0.20 | 10% | 0 | 0 | 0 | 12.5 | 59.6 |

| 0.20 | 15% | 0 | 0 | 0 | 12.9 | 60.2 |

| 0.20 | 0 | 5% | 0 | 0 | 11.4 | 54.3 |

| 0.20 | 0 | 10% | 0 | 0 | 11.2 | 53.8 |

| 0.20 | 0 | 15% | 0 | 0 | 10.8 | 52.4 |

| 0.20 | 0 | 0 | 5% | 0 | 11.5 | 54.3 |

| 0.20 | 0 | 0 | 10% | 0 | 11.3 | 53.6 |

| 0.20 | 0 | 0 | 15% | 0 | 11.0 | 52.0 |

| 0.20 | 0 | 0 | 0 | 5% | 11.5 | 55.2 |

| 0.20 | 0 | 0 | 0 | 10% | 11.5 | 54.8 |

| 0.20 | 0 | 0 | 0 | 15% | 11.4 | 54.0 |

| 0.22 | 5% | 0 | 0 | 0 | 11.4 | 53.6 |

| 0.22 | 10% | 0 | 0 | 0 | 11.9 | 57.3 |

| 0.22 | 15% | 0 | 0 | 0 | 12.1 | 58.0 |

| 0.22 | 0 | 5% | 0 | 0 | 11.1 | 52.1 |

| 0.22 | 0 | 10% | 0 | 0 | 10.9 | 51.7 |

| 0.22 | 0 | 15% | 0 | 0 | 10.6 | 50.0 |

| 0.22 | 0 | 0 | 5% | 0 | 11.1 | 52.1 |

| 0.22 | 0 | 0 | 10% | 0 | 10.8 | 51.7 |

| 0.22 | 0 | 0 | 15% | 0 | 10.6 | 50.6 |

| 0.22 | 0 | 0 | 0 | 5% | 11.1 | 52.0 |

| 0.22 | 0 | 0 | 0 | 10% | 11.0 | 51.8 |

| 0.22 | 0 | 0 | 0 | 15% | 11.2 | 51.4 |

| W/B | Silica Fume | Cenosphere | Fly Ash | Grade Slag Powder | Flexural Strength (MPa) | Compressive Strength (MPa) |

|---|---|---|---|---|---|---|

| 0.18 | 0% | 0 | 0 | 0 | 16.0 | 110.1 |

| 0.18 | 5% | 0 | 0 | 0 | 16.2 | 111.4 |

| 0.18 | 10% | 0 | 0 | 0 | 16.9 | 118.6 |

| 0.18 | 15% | 0 | 0 | 0 | 17.1 | 119.5 |

| 0.18 | 0 | 5% | 0 | 0 | 16.1 | 112.0 |

| 0.18 | 0 | 10% | 0 | 0 | 16.3 | 113.5 |

| 0.18 | 0 | 15% | 0 | 0 | 16.9 | 115.2 |

| 0.18 | 0 | 0 | 5% | 0 | 16.0 | 111.4 |

| 0.18 | 0 | 0 | 10% | 0 | 16.2 | 111.3 |

| 0.18 | 0 | 0 | 15% | 0 | 16.3 | 113.4 |

| 0.18 | 0 | 0 | 0 | 5% | 16.2 | 112.0 |

| 0.18 | 0 | 0 | 0 | 10% | 16.5 | 113.9 |

| 0.18 | 0 | 0 | 0 | 15% | 16.5 | 115.1 |

| 0.20 | 5% | 0 | 0 | 0 | 16.3 | 108.6 |

| 0.20 | 10% | 0 | 0 | 0 | 16.5 | 109.1 |

| 0.20 | 15% | 0 | 0 | 0 | 16.6 | 110.8 |

| 0.20 | 0 | 5% | 0 | 0 | 15.8 | 102.2 |

| 0.20 | 0 | 10% | 0 | 0 | 16.2 | 104.5 |

| 0.20 | 0 | 15% | 0 | 0 | 16.4 | 106.1 |

| 0.20 | 0 | 0 | 5% | 0 | 15.8 | 101.1 |

| 0.20 | 0 | 0 | 10% | 0 | 15.8 | 101.5 |

| 0.20 | 0 | 0 | 15% | 0 | 15.9 | 102.9 |

| 0.20 | 0 | 0 | 0 | 5% | 16.0 | 102.4 |

| 0.20 | 0 | 0 | 0 | 10% | 16.0 | 103.8 |

| 0.20 | 0 | 0 | 0 | 15% | 16.2 | 105.0 |

| 0.22 | 5% | 0 | 0 | 0 | 15.6 | 100.7 |

| 0.22 | 10% | 0 | 0 | 0 | 15.9 | 102.0 |

| 0.22 | 15% | 0 | 0 | 0 | 15.9 | 103.8 |

| 0.22 | 0 | 5% | 0 | 0 | 15.2 | 96.1 |

| 0.22 | 0 | 10% | 0 | 0 | 15.6 | 98.4 |

| 0.22 | 0 | 15% | 0 | 0 | 15.8 | 99.7 |

| 0.22 | 0 | 0 | 5% | 0 | 15.0 | 96.2 |

| 0.22 | 0 | 0 | 10% | 0 | 15.2 | 96.6 |

| 0.22 | 0 | 0 | 15% | 0 | 15.2 | 98.0 |

| 0.22 | 0 | 0 | 0 | 5% | 15.3 | 96.6 |

| 0.22 | 0 | 0 | 0 | 10% | 15.4 | 97.3 |

| 0.22 | 0 | 0 | 0 | 15% | 15.6 | 98.9 |

References

- Zong, Z.; Zhang, Q.; Liu, Y.; Guo, Z.; Lin, S.; Jiang, T. Carbonation resistance of sustainable self-compacting concrete with recycled concrete aggregate and fly ash, slag, and silica fume. Eur. J. Environ. Civ. Eng. 2024, 28, 2177–2199. [Google Scholar] [CrossRef]

- Hao, Y.; Qin, L.; He, X.; Sun, H.; Wu, Z.; Hou, Y. Mechanical properties and constitutive model of fibre-reinforced high-performance class-F fly ash foam concrete. Eur. J. Environ. Civ. Eng. 2024, 28, 437–456. [Google Scholar] [CrossRef]

- Hua, C.; Tang, R.; Lu, X. Radon emission characteristics and pore structure evolution of self-compacting concrete with silica fume-molybdenum tailings under different curing environments. J. Build. Eng. 2024, 97, 110769. [Google Scholar] [CrossRef]

- Li, B.; Chen, Z.; Wang, S.; Xu, L. A Review on the Damage Behavior and Constitutive Model of Fiber Reinforced Concrete at Ambient Temperature. Constr. Build. Mater. 2024, 412, 134919. [Google Scholar] [CrossRef]

- Wang, Y.; Qiao, P.; Sun, J.; Chen, A. Influence of Fibers on Tensile Behavior of Ultra-High Performance Concrete: A Review. Constr. Build. Mater. 2024, 430, 136432. [Google Scholar] [CrossRef]

- Cao, Z.; Wang, K.; Peng, X.; Wang, H.; Huang, R. Influence of NaCl Solution External Erosion on Corrosion Resistance of RPC Reinforced with Straw Fiber. Coatings 2023, 13, 1308. [Google Scholar] [CrossRef]

- Grzymski, F.; Musiał, M.; Trapko, T. Mechanical Properties of Fibre Reinforced Concrete with Recycled Fibres. Constr. Build. Mater. 2019, 198, 323–331. [Google Scholar] [CrossRef]

- Zhagifarov, A.M.; Akhmetov, D.A.; Suleyev, D.K.; Zhumadilova, Z.O.; Begentayev, M.M.; Pukharenko, Y.V. Investigation of Hydrophysical Properties and Corrosion Resistance of Modified Self-Compacting Concretes. Materials 2024, 17, 2605. [Google Scholar] [CrossRef]

- Djebien, R.; Hebhoub, H.; Belachia, M.; Berdoudi, S.; Kherraf, L. Incorporation of Marble Waste as Sand in Formulation of Self-Compacting Concrete. Struct. Eng. Mech. 2018, 67, 87–91. [Google Scholar]

- Li, H.; Huang, F.; Tu, H.; Sun, D.; Wang, Z.; Yi, Z.; Yang, Z.; Xie, Y. Pumpability of Manufactured Sand Self-compacting Concrete. J. Wuhan Univ. Technol. Mater. Sci. Ed. 2023, 38, 1382–1390. [Google Scholar] [CrossRef]

- Adhikary, S.K.; Ashish, D.K.; Sharma, H.; Patel, J.; Rudzionis, Z.; Al-Ajamee, M.; Thomas, B.S.; Khatib, J.M. Lightweight Self-compacting Concrete: A review. Resour. Conserv. Recycl. Adv. 2022, 15, 200107. [Google Scholar] [CrossRef]

- Kumar, P.; Pasla, D.; Saravanan, T.J. Self-Compacting Lightweight Aggregate Concrete and Its Properties: A review. Constr. Build. Mater. 2023, 375, 130861. [Google Scholar] [CrossRef]

- Song, P.; Wang, X.; Wang, Y.; Taylor, P.; Li, C.; Sun, Q.; Ma, Y. Assessment of Rheological and Toughening Behavior of Basalt Fiber Sprayed Cementitious Composites (BFSCC). Constr. Build. Mater. 2024, 426, 136169. [Google Scholar] [CrossRef]

- ElNemr, A.; Shaltout, R. Rheological and Mechanical Characterization of Self-Compacting Concrete Using Recycled Aggregate. Materials 2025, 18, 1519. [Google Scholar] [CrossRef] [PubMed]

- Anish, V.; Logeshwari, J. A review on ultra high-performance fibre-reinforced concrete with nanomaterials and its applications. J. Eng. Appl. Sci. 2024, 71, 1–40. [Google Scholar] [CrossRef]

- Su, X.; Ren, Z.; Li, P. Review on physical and chemical activation strategies for ultra-high performance concrete (UHPC). J. Cem. Concr. Compos. 2024, 149, 105519. [Google Scholar] [CrossRef]

- Ullah, R.; Qiang, Y.; Ahmad, J.; Vatin, N.I.; El-Shorbagy, M.A. Ultra-High-Performance Concrete (UHPC): A State-of-the-Art Review. Materials 2022, 15, 4131. [Google Scholar] [CrossRef]

- He, J.; Chen, W.; Zhang, B.; Yu, J.; Liu, H. The Mechanical Properties and Damage Evolution of UHPC Reinforced with Glass Fibers and High-Performance Polypropylene Fibers. Materials 2021, 14, 2455. [Google Scholar] [CrossRef]

- Ge, J.; Du, S.; Chen, P.; Huang, W.; Yang, R.; Gao, X.; Ji, X. Preparation and Compressive Fracture Characteristics of Fiber Foam Concrete. J. Concr. 2024, 12, 213–218. [Google Scholar]

- Miyazaki, Y.; Nakayama, R.; Yasuo, N.; Watanabe, Y.; Shimizu, R.; Packwood, D.M.; Nishio, K.; Ando, Y.; Sekijima, M.; Hitosugi, T. Bayesian Statistics-Based Analysis of AC Impedance Spectra. AIP Adv. 2020, 10, 045231. [Google Scholar] [CrossRef]

- Zheng, S.; Liu, Q.; Han, F.; Liu, S.; Han, T.; Yan, H. Basic Mechanical Properties of Self-Compacting Concrete Prepared with Aeolian Sand and Recycled Coarse Aggregate. Buildings 2024, 14, 2949. [Google Scholar] [CrossRef]

- Lee, S.J.; You, I.; Kim, S.; Shin, H.O.; Yoo, D.Y. Self-Sensing Capacity of Ultra-High-Performance Fiber-Reinforced Concrete Containing Conductive Powders in Tension. Cem. Concr. Compos. 2022, 125, 104331. [Google Scholar] [CrossRef]

- Ashteyat, A.; Obaidat, A.T.; Qerba’a, R.; Abdel-Jaber, M. Influence of basalt fiber on the rheological and mechanical properties and durability behavior of self-compacting concrete (SCC). Fibers 2024, 12, 52. [Google Scholar] [CrossRef]

- Ahmad, J.; Zaid, O.; Aslam, F.; Shahzaib, M.; Ullah, R.; Alabduljabbar, H.; Khedher, K.M. A Study on the Mechanical Characteristics of Glass and Nylon Fiber Reinforced Peach Shell Lightweight Concrete. Materials 2021, 14, 4488. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Z.; Guo, B.; Yang, Z. Influence of fiber type on UHPC performance and its strengthening mechanism research progress. J. Jiangxi Build. Mater. 2024, 5, 13–15. [Google Scholar]

- Zhao, W.; Kong, J.; Sun, Q. Preparation and Properties of Ultra-High Performance Concrete Incorporation Multi-Mineral Admixtures. Mater. Res. Express 2024, 11, 085311. [Google Scholar] [CrossRef]

- Chen, Y.; Liu, P.; Sha, F.; Yin, J.; He, S.; Li, Q.; Yu, Z.; Chen, H. Study on the Mechanical and Rheological Properties of Ultra-High Performance Concrete. J. Mater. Res. Technol. 2022, 17, 111–124. [Google Scholar] [CrossRef]

- Ju, M.; Jeong, J.-G.; Palou, M.; Park, K. Mechanical Behavior of Fine Recycled Concrete Aggregate Concrete with the Mineral Admixtures. Materials 2020, 13, 2264. [Google Scholar] [CrossRef]

- ASTM C1856/C1856M-17; Standard Practice for Fabricating and Testing Specimens of Ultra-High Performance Concrete. ASTM International: West Conshohocken, PA, USA, 2017.

- Cheng, X.; Mu, R.; Liu, X. Research progress on preparation and mechanical properties of ultra-high performance concrete. Silic. Bull. 2024, 43, 4295–4312. [Google Scholar]

- GB/T 31387-2025; Ultra High Performance Concrete. Ministry of Housing and Urban Rural Development of the People’s Republic of China: Beijing, China, 2025.

- Pourjahanshahi, A.; Madani, H. Chloride diffusivity and mechanical performance of UHPC with hybrid fibers under heat treatment regime. Mater. Today Commun. 2021, 26, 102146. [Google Scholar] [CrossRef]

- Teng, L.; Meng, W.; Khayat, K.H. Rheology Control of Ultra-High-Performance Concrete Made with Different Fiber Contents. Cem. Concr. Res. 2020, 138, 106222. [Google Scholar] [CrossRef]

- Yoo, D.Y.; Kang, M.C.; Choi, H.J.; Shin, W.; Kim, S. Electromagnetic interference shielding of multi-cracked high-performance fiber-reinforced cement composites—Effects of matrix strength and carbon fiber. Constr. Build. Mater. 2020, 261, 119949. [Google Scholar] [CrossRef]

- Gong, K.; Liang, Z.; Peng, X.; Wang, H. Research into Preparation and Performance of Fast-Hardening RPC Mixed with Straw. Materials 2023, 16, 5310. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.; Xie, X.; Li, L. Experimental Study on Mechanical Properties and Durability of Grafted Nano-SiO2 Modified Rice Straw Fiber Reinforced Concrete. Constr. Build. Mater. 2022, 347, 128575. [Google Scholar] [CrossRef]

- Tai, Y.; Yang, L.; Gao, D.; Kang, K.; Cao, Z.; Zhao, P. Properties Evolution and Deterioration Mechanism of Steel Fiber Reinforced Concrete (SFRC) under the Coupling Effect of Carbonation and Chloride Attack. J. Build. Eng. 2024, 95, 110275. [Google Scholar] [CrossRef]

- Tu, Y.; Liu, D.; Yuan, L.; Zhang, Y. Corrosion Resistance of Concrete Strengthened with Fibre-Reinforced Polymer Sheets. Mag. Concr. Res. 2022, 74, 54–69. [Google Scholar] [CrossRef]

- Abdel-Jaber, M.; Beale, R.; Makhoul, N. Self-compacting concrete (SCC) strength prediction via optimized duple-deep-learning model and distance ranked fire-hawk optimizer (DRFO). Civ. Eng. Archit. 2023, 11, 2447–2460. [Google Scholar] [CrossRef]

- Guo, D.; Guo, M.; Zhou, Y.; Zhu, Z. Use of nano-silica to improve the performance of LC3-UHPC: Mechanical behavior and microstructural characteristics. Constr. Build. Mater. 2024, 411, 134280. [Google Scholar] [CrossRef]

- Shaban, W.M.; Heniegal, A.M.; Amin, M.; Zeyad, A.M.; Agwa, I.S.; Hassan, H.H. Effect of agricultural wastes as sugar beet ash, sugarcane leaf ash, and sugarcane bagasse ash on UHPC properties. J. Build. Eng. 2024, 98, 111359. [Google Scholar] [CrossRef]

- Khayat, K.H.; Meng, W.; Vallurupalli, K.; Teng, L. Rheological Properties of Ultra-High-Performance Concrete-An Overview. Cem. Concr. Res. 2019, 124, 105828. [Google Scholar] [CrossRef]

- Wei, X.; Liu, W. Study on temperature crack prevention and control measures for self-compacted large volume concrete with machine-made sand. J. China Cement 2024, 8, 88–90. [Google Scholar]

- Luo, Z.; Zhi, T.; Liu, X.; Yin, K.; Pan, H.; Feng, H.; Song, Y.; Su, Y. Effects of different nanomaterials on the early performance of ultra-high performance concrete (UHPC): C–S–H seeds and nano-silica. Cem. Concr. Compos. 2023, 142, 105211. [Google Scholar] [CrossRef]

- Yu, R.; Liu, K.; Yin, T.; Tang, L.; Ding, M.; Shui, Z. Comparative study on the effect of steel and polyoxymethylene fibers on the characteristics of Ultra-High Performance Concrete (UHPC). Cem. Concr. Compos. 2022, 127, 104418. [Google Scholar]

- Xie, J.; Liu, J.; Li, W.; Jin, L. Mechanical properties of magnesia fiber reinforced magnesium cement mortar composite materials. J. Compos. Mater. 2024, 41, 5492–5503. [Google Scholar]

- Li, Y.; Mu, J.; Wang, F.; Wang, X.; Ding, Q. Research on the Effect of Apparent Density on the Rheological Properties of Lightweight and Heavyweight Concrete. J. Build. Eng. 2024, 95, 110111. [Google Scholar] [CrossRef]

- Tariq, S.; Scott, A.; Mackechnie, J.; Shah, V. Glass powder replacement in self-compacting concrete and its effect on rheological and mechanical properties. J. Sustain. Cem.-Based Mater. 2022, 11, 240–256. [Google Scholar] [CrossRef]

- Rajasekar, A.; Arunachalam, K.; Kottaisamy, M. Assessment of strength and durability characteristics of copper slag incorporated ultra high strength concrete. J. Clean. Prod. 2019, 208, 402–414. [Google Scholar] [CrossRef]

- Wang, W.; Xiong, Z.; Yu, Y.; Chen, D.; Wu, C. Residual behaviour and damage assessment of UHPC-filled double-skin steel tubular columns after lateral impact. Thin-Walled Struct. 2024, 205, 112602. [Google Scholar] [CrossRef]

- Ting, T.Z.H.; Rahman, M.E.; Lau, H.H.; Ting, M.Z.Y. Recent development and perspective of lightweight aggregates based self-compacting concrete. Constr. Build. Mater. 2019, 201, 763–777. [Google Scholar] [CrossRef]

| Types | Chemical Composition (%) | |||||||

|---|---|---|---|---|---|---|---|---|

| SiO2 | Al2O3 | Fe2O3 | MgO | CaO | SO3 | K2O | Na2O | |

| Portland cement | 21.7 | 4.76 | 3.57 | 2.12 | 63.01 | 1.98 | 2.15 | 0.71 |

| Fly Ash | 55.76 | 32.86 | 3.65 | 0.34 | 2.44 | 0.72 | 0.98 | 3.25 |

| Grade Slag Powder | 27.74 | 14.84 | 0.89 | 3.24 | 48.45 | 2.49 | 0.46 | 1.89 |

| Silica fume | 95.6 | 0.41 | 0.42 | 0.40 | 0.12 | - | - | 3.05 |

| Cenosphere | 95.3 | 0.44 | 0.41 | 0.41 | 0.11 | - | - | 3.06 |

| Quartz sand | 98.5 | 0.6 | 0.5 | 0.1 | 0.1 | - | - | 0.2 |

| Types | Fineness (45 μm%) | Density (g/cm3) | Water Demand Ratio (%) | Specific Surface Area (m2/kg) | Heat Loss (%) | Mobility Ratio (%) | 28 d Activity Index (%) |

|---|---|---|---|---|---|---|---|

| Portland cement | 6.7 | 3.14 | 25.40 | 350 | - | - | - |

| Fly ash | 5.5 | 2.21 | 92 | 560 | 2.9 | - | - |

| Grade slag powder | 3.47 | 2.85 | - | 450 | - | 86 | - |

| Silica fume | - | 2.05 | 110 | 22,000 | 5.10 | - | 125 |

| Cenosphere | - | 2.23 | 113 | 215 | 4.03 | - | 73 |

| Quartz sand | 3.4 | 2.65 | - | 430 | 0.5 | - | - |

| Water | Cement | Silica Fume | Cenosphere | Fly Ash | Grade Slag Powder | Sand | Water Reducing Agent | Water-Binder Ratio |

|---|---|---|---|---|---|---|---|---|

| 162 | 900 | 0 | 0 | 0 | 0 | 1350 | 18 | 0.18 |

| 162 | 855 | 45 | 0 | 0 | 0 | 1350 | 18 | 0.18 |

| 162 | 810 | 90 | 0 | 0 | 0 | 1350 | 18 | 0.18 |

| 162 | 765 | 135 | 0 | 0 | 0 | 1350 | 18 | 0.18 |

| 162 | 855 | 0 | 45 | 0 | 0 | 1350 | 18 | 0.18 |

| 162 | 810 | 0 | 90 | 0 | 0 | 1350 | 18 | 0.18 |

| 162 | 765 | 0 | 135 | 0 | 0 | 1350 | 18 | 0.18 |

| 162 | 855 | 0 | 0 | 45 | 0 | 1350 | 18 | 0.18 |

| 162 | 810 | 0 | 0 | 90 | 0 | 1350 | 18 | 0.18 |

| 162 | 765 | 0 | 0 | 135 | 0 | 1350 | 18 | 0.18 |

| 162 | 855 | 0 | 0 | 0 | 45 | 1350 | 18 | 0.18 |

| 162 | 810 | 0 | 0 | 0 | 90 | 1350 | 18 | 0.18 |

| 162 | 765 | 0 | 0 | 0 | 135 | 1350 | 18 | 0.18 |

| 180 | 900 | 0 | 0 | 0 | 0 | 1350 | 18 | 0.20 |

| 180 | 855 | 45 | 0 | 0 | 0 | 1350 | 18 | 0.20 |

| 180 | 810 | 90 | 0 | 0 | 0 | 1350 | 18 | 0.20 |

| 180 | 765 | 135 | 0 | 0 | 0 | 1350 | 18 | 0.20 |

| 180 | 855 | 0 | 45 | 0 | 0 | 1350 | 18 | 0.20 |

| 180 | 810 | 0 | 90 | 0 | 0 | 1350 | 18 | 0.20 |

| 180 | 765 | 0 | 135 | 0 | 0 | 1350 | 18 | 0.20 |

| 180 | 855 | 0 | 0 | 45 | 0 | 1350 | 18 | 0.20 |

| 180 | 810 | 0 | 0 | 90 | 0 | 1350 | 18 | 0.20 |

| 180 | 765 | 0 | 0 | 135 | 0 | 1350 | 18 | 0.20 |

| 180 | 855 | 0 | 0 | 0 | 45 | 1350 | 18 | 0.20 |

| 180 | 810 | 0 | 0 | 0 | 90 | 1350 | 18 | 0.20 |

| 180 | 765 | 0 | 0 | 0 | 135 | 1350 | 18 | 0.20 |

| 198 | 900 | 0 | 0 | 0 | 0 | 1350 | 18 | 0.22 |

| 198 | 855 | 45 | 0 | 0 | 0 | 1350 | 18 | 0.22 |

| 198 | 810 | 90 | 0 | 0 | 0 | 1350 | 18 | 0.22 |

| 198 | 765 | 135 | 0 | 0 | 0 | 1350 | 18 | 0.22 |

| 198 | 855 | 0 | 45 | 0 | 0 | 1350 | 18 | 0.22 |

| 198 | 810 | 0 | 90 | 0 | 0 | 1350 | 18 | 0.22 |

| 198 | 765 | 0 | 135 | 0 | 0 | 1350 | 18 | 0.22 |

| 198 | 855 | 0 | 0 | 45 | 0 | 1350 | 18 | 0.22 |

| 198 | 810 | 0 | 0 | 90 | 0 | 1350 | 18 | 0.22 |

| 198 | 765 | 0 | 0 | 135 | 0 | 1350 | 18 | 0.22 |

| 198 | 855 | 0 | 0 | 0 | 45 | 1350 | 18 | 0.22 |

| 198 | 810 | 0 | 0 | 0 | 90 | 1350 | 18 | 0.22 |

| 198 | 765 | 0 | 0 | 0 | 135 | 1350 | 18 | 0.22 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, L.; Tian, X.; Pan, Y.; Wu, D.; Xu, S.; Wang, H.; Tian, X.; Xu, Y.; Guo, H.; Zou, M. The Properties of Self-Compacting Ultra-High Performance Concrete with Different Types of Mineral Admixtures. Coatings 2025, 15, 591. https://doi.org/10.3390/coatings15050591

Wang L, Tian X, Pan Y, Wu D, Xu S, Wang H, Tian X, Xu Y, Guo H, Zou M. The Properties of Self-Compacting Ultra-High Performance Concrete with Different Types of Mineral Admixtures. Coatings. 2025; 15(5):591. https://doi.org/10.3390/coatings15050591

Chicago/Turabian StyleWang, Lin, Xiying Tian, Yuefan Pan, Dingyuan Wu, Shengli Xu, Hangyang Wang, Xiaolu Tian, Yubo Xu, Hong Guo, and Min Zou. 2025. "The Properties of Self-Compacting Ultra-High Performance Concrete with Different Types of Mineral Admixtures" Coatings 15, no. 5: 591. https://doi.org/10.3390/coatings15050591

APA StyleWang, L., Tian, X., Pan, Y., Wu, D., Xu, S., Wang, H., Tian, X., Xu, Y., Guo, H., & Zou, M. (2025). The Properties of Self-Compacting Ultra-High Performance Concrete with Different Types of Mineral Admixtures. Coatings, 15(5), 591. https://doi.org/10.3390/coatings15050591