Research on the Basic Performance and Fiber Appearance Characteristics of Grass Paper from Stellera chamaejasme in Different Origins on the Qinghai–Tibet Plateau

Abstract

:1. Introduction

2. Materials and Research Methods

2.1. Overview of the Study Area

2.2. Experimental Materials and Treatment

2.3. Experimental Method

2.3.1. Measurement of Foundation Performance

2.3.2. Measurement of Fiber Morphology

3. Results and Analysis

3.1. Basic Properties of Grass Paper from Stellera chamaejasme in Different Origins

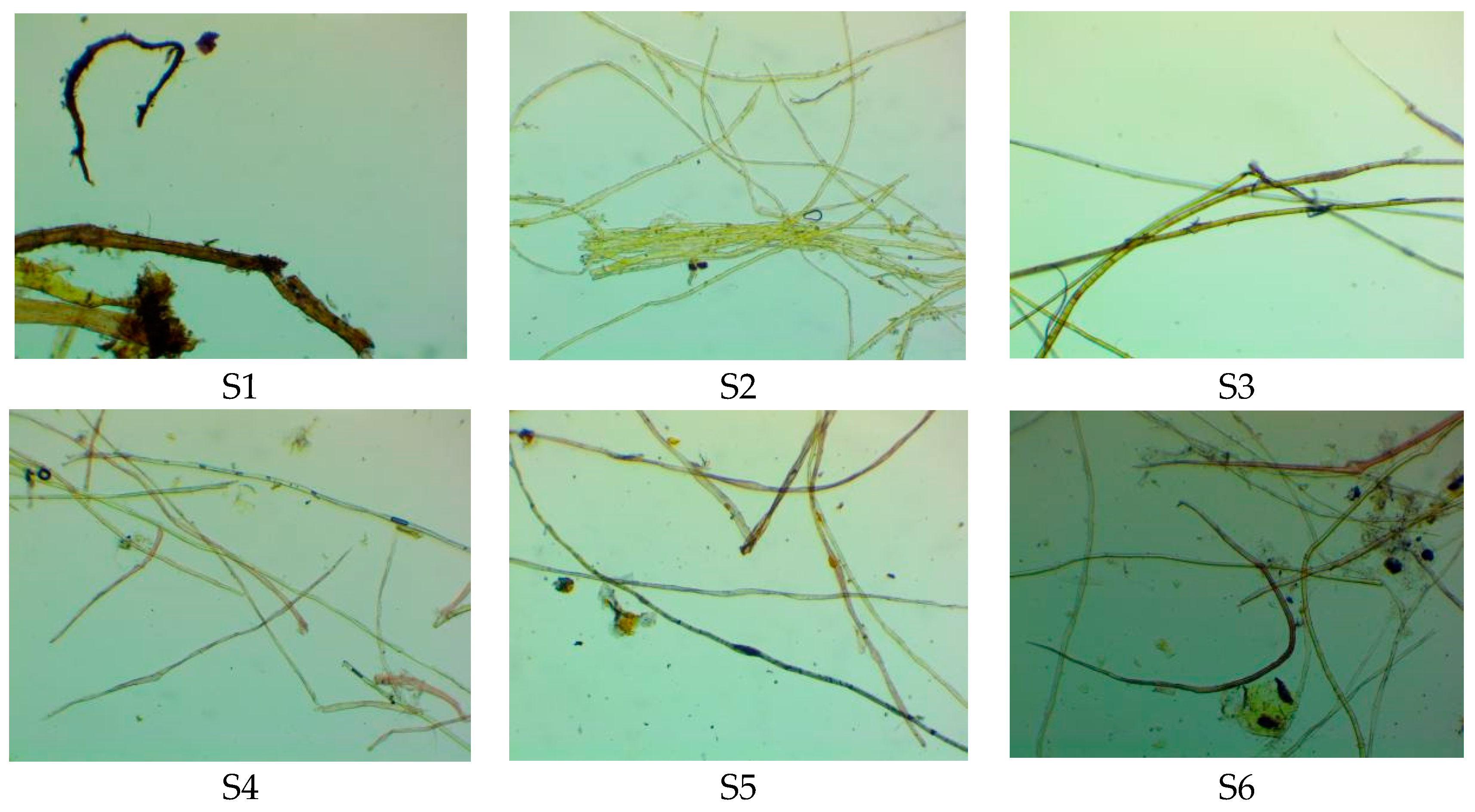

3.2. Fiber Morphology of Grass Paper from Stellera chamaejasme in Different Origins

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Li, H.C.; Sun, H.Z.; Xu, G.Y. Stellera Chamaejasme Paper and the Resource Utilization of Grassland Poisonous Plants. J. Tibet. Univ. (Nat. Sci. Ed.) 2009, 24, 1–4. [Google Scholar]

- Liu, X.; Zhang, Z.Y.; Jia, W. Old Book of Tang: Biography of Tubo; Zhonghua Book Company: Beijing, China, 1975; p. 5222. [Google Scholar]

- Tsangpa, G.D.; Dongka, L.T. (Eds.) The Red Annals; Chen, Q.Y.; Zhou, R.N., Translators; Tibet People’s Publishing House: Lhasa, China, 1988; pp. 16–18. [Google Scholar]

- Liu, R.Q. Princess Wencheng’s Contribution to Papermaking. Pap. Sci. Technol. 2016, 35, 85–87. [Google Scholar]

- Shi, Z.C. Important Poisonous Plants in Chinese Grasslands; China Agricultural Press: Beijing, China, 2001; pp. 141–146. [Google Scholar]

- Zhao, B.Y.; Wei, Y.H.; Wei, S.N.; Lu, H.; Mo, C.H.; Guo, Y.Z.; Shi, Z.C. Natural Grassland Poisonous Grass Disaster and Prevention and Control Strategies in China. In Proceedings of the 2015 China Grassland Forum; Grassland Supervision Center of the Ministry of Agriculture, Chinese Grassland Society: Beijing, China, 2015; pp. 217–232. [Google Scholar]

- Huang, Z.J.; Zhou, S.Q. Important Poisonous Plants in Grasslands—Stellera chamaejasme. Sichuan Grassl. 1993, 4, 24–27. [Google Scholar]

- Du, W.T.; Ji, H. Transforming harm into benefit, turning waste into treasure, and comprehensively utilizing wolf venom resources. Shanxi Agric. Sci. 2007, 11, 91–92. [Google Scholar]

- Liu, Y.; Long, R.J.; Yao, T. Research Progress of Stellera Chamaejasme in Grasslands. Grassl. Sci. 2004, 21, 55–61. [Google Scholar]

- Gao, D.; Zhang, S.P.; Zhang, G.; Song, R.J.; Sun, Y.F.; Zhao, W.; Zhao, B.Y. Research on Durability of Straight-Hole Tibetan Paper. China Papermak. 2019, 38, 36–40. [Google Scholar]

- Zhang, S.P.; Gao, D.; Zhang, G.; Song, R.J.; Sun, Y.F.; Yi, X.C.M.; Zhao, B.Y. Antibacterial Properties and Toxicological Safety Evaluation of Straight-Hole Tibetan paper. Pap. Sci. Technol. 2019, 38, 34–39. [Google Scholar]

- Zan, Q.G.; Li, H.C.; Ji, Q.S.; Zhang, X.P.; Liang, T.; Ren, Q.Z.M. Preliminary Study on the Anti-Aging Properties of Four Types of Tibetan Paper. China Papermak. 2020, 39, 87–90. [Google Scholar]

- Han, B.; Niang, J.J.; Rao, H.Y.; Lv, N.N.; Oda, H.; Sakamoto, S.; Yang, Y.M.; Sablier, M. Paper Fragments from the Tibetan Samye Monastery: Clues for an Unusual Sizing Recipe Implying Wheat Starch and Milk in Early Tibetan papermaking. J. Archaeol. Sci. Rep. 2021, 36, 102793. [Google Scholar] [CrossRef]

- Jia, M.H.; Huang, X.X.; Cai, M.L.; Zhang, M.F.; Hu, G. Study on the Photostability and Fluorescence Effect of Tibetan Handmade paper. Archaeol. Res. 2020, 12, 180–191. [Google Scholar]

- Wei, J.P. Preliminary Study on Tibetan Papermaking Techniques and the Properties of Tibetan Paper. Master’s Thesis, University of Science and Technology of China, Hefei, China, 2021. [Google Scholar]

- Yang, J.; Wei, Q.; Du, S.F. Comparison of Ultrastructures of Stellera Chamaejasme Bast Fibers and Five Tibetan Paper Fibers. J. China Papermak. 2021, 36, 87–92. [Google Scholar]

- Liu, J.H. Analysis of the Causes of Paper Quantitative Fluctuations. Hubei Papermak. 1994, 2, 45–48. [Google Scholar]

- Sun, H.Z. Paper and Printing (serial 5). Print. World 2010, 7, 47–50. [Google Scholar]

- He, J.X. Paper Properties and Printability. Print. World 2012, 5, 36–38. [Google Scholar]

- Yuan, S.J. Paper Structure, Performance and Influencing Factors. Hubei Papermak. 2004, 1, 8–10. [Google Scholar]

- Reverdy, C.; Belgacem, N.; Moghaddam, M.S.; Sundin, M.; Swerin, A.; Bras, J. One-Step Superhydrophobic Coating Using Hydrophobized Cellulose Nanofibrils. Colloids Surf. A Physicochem. Eng. Asp. 2017, 544, 152–158. [Google Scholar] [CrossRef]

- Yang, T.T. Influence of Fiber Characteristics on Paper Structure and Performance. Guangxi Light Ind. 2007, 10, 15–18. [Google Scholar]

- Wang, J.H. Fiber Characteristics and Microscopic Spectra of Chinese Papermaking Raw Materials; China Light Industry Press: Beijing, China, 1999; pp. 145–146. [Google Scholar]

- Hao, X.M.; Zhang, J.C.; Wu, J.N. Research on the New Process of Degumming Hanma Fiber. In Proceedings of the 7th Symposium on Functional Textiles and Nanotechnology Applications; China Academy of Textile Sciences, Textile Industry Productivity Promotion Center, Beijing Textile Engineering Society, Tianjin Key Laboratory of Modified and Functional Fibers, Tianjin University of Technology; Tianjin, China, 2007; pp. 299–304. [Google Scholar]

- Chen, B.; Tan, J.; Fu, X.H.; Lu, Y.J.; Zhu, Y.W.; Huang, J.; Di, Y.M.; Ding, Y.W. Pyrolysis Characteristics of Bamboo Paper Aging and Quantitative Evaluation of its Aging Degree. Mater. Guide 2022, 36, 213–217. [Google Scholar]

- You, C.E. Analysis of the Influence of Paper Characteristics on Printing Performance. Guangxi Light Ind. 2008, 3, 26–27. [Google Scholar]

- Chen, Y.C.; Liu, X.X. The Influence of Paper Properties on the Quality of Printed Products. China Packag. Ind. 2002, 9, 35–37. [Google Scholar]

- Qian, X.R.; Shen, J.; Xu, S.Y.; Yang, D.M. Modification Technology of Papermaking Fiber and Filler; Chemical Industry Press: Beijing, China, 2011; p. 8. [Google Scholar]

- Niskanen, K. Physical Properties of Paper; Liu, J.G.; Su, Y.Q.; Du, Y.F.; Li, H.C.; Yang, Y., Translators; China Light Industry Press: Beijing, China, 2017; p. 15. [Google Scholar]

- Gong, M.R. Introduction to Pulping and Papermaking; China Light Industry Press: Beijing, China, 2019; pp. 14–15. [Google Scholar]

| Sample No. | Paper Type | Plant Raw Materials | Paper Description | Paper Size (CM) | Origin/Manufacturer | Cooking Process |

|---|---|---|---|---|---|---|

| S1 | Xiangda Tibetan paper | Stellera chamaejasme L. | Dark yellow, smooth paper | 21 × 15 | Nangqian County, China | Steam and cook once in the earth alkali or industrial alkali |

| S2 | Qiangduo Tibetan paper | Stellera chamaejasme L. | Yellow, wrinkled, fiber bundle | 73 × 28 | Shangri-La, China | Steam and cook once in the stove ash or wood ash |

| S3 | Dege Tibetan paper | Stellera chamaejasme L. | White, uniform texture, fiber bundle | 71 × 55 | Dege County, China | Steam and cook once in the stove ash or industrial alkali |

| S4 | Potala Palace Tibetan paper | Stellera chamaejasme L. | Ivory white is gray, thinner, with black impurities | 74 × 55 | Lhasa, China | Steam and cook once in the earth alkali or industrial alkali |

| S5 | Jingdong Tibetan paper | Stellera chamaejasme L. | White gray, fiber bundles are clearly visible | 72 × 56 | Lang County, China | Steam and cook once in the wood ash or earth alkali or industrial alkali |

| S6 | Xuela Tibetan paper | Stellera chamaejasme L. | Gray, thinner | 76 × 49 | Nimu County, China | Steam and cook once in the earth alkali or industrial alkali |

| Sample No. | Grammage (g/m2) | Thickness (mm) | Density (g/cm3) | Bulk (c m3/g) |

|---|---|---|---|---|

| S1 | 80.87 | 0.111 | 0.729 | 1.373 |

| S2 | 142.97 | 0.269 | 0.531 | 1.882 |

| S3 | 60.00 | 0.194 | 0.309 | 3.233 |

| S4 | 56.49 | 0.190 | 0.297 | 3.363 |

| S5 | 72.41 | 0.344 | 0.210 | 4.751 |

| S6 | 60.00 | 0.179 | 0.335 | 2.983 |

| Sample No. | Brightness (%ISO) | |

|---|---|---|

| Surface A | Surface B | |

| S1 | 21.43 | 21.42 |

| S2 | 20.06 | 20.24 |

| S3 | 52.64 | 52.95 |

| S4 | 38.93 | 39.00 |

| S5 | 45.57 | 45.87 |

| S6 | 45.98 | 46.03 |

| Sample No. | 45° Brightness (%) | 60° Brightness (%) | 75° Brightness (%) | 85° Brightness (%) | ||||

|---|---|---|---|---|---|---|---|---|

| Surface A | Surface B | Surface A | Surface B | Surface A | Surface B | Surface A | Surface B | |

| S1 | 4.1 | 4.0 | 4.4 | 4.4 | 4.1 | 4.1 | 3.0 | 2.8 |

| S2 | 5.7 | 6.0 | 2.6 | 2.5 | 1.2 | 0.9 | 0.8 | 0.1 |

| S3 | 4.3 | 4.7 | 5.2 | 5.6 | 3.4 | 4.3 | 1.2 | 1.7 |

| S4 | 3.7 | 3.8 | 6.0 | 5.3 | 4.8 | 4.1 | 0.9 | 0.6 |

| S5 | 4.2 | 4.1 | 5.8 | 5.7 | 4.2 | 4.2 | 0.7 | 1.0 |

| S6 | 3.7 | 3.7 | 5.1 | 5.2 | 4.6 | 4.2 | 1.4 | 0.8 |

| Sample No. | Folding Resistance Average | Folding Resistance Index | ||

|---|---|---|---|---|

| Transverse | Longitudinal | Transverse | Longitudinal | |

| S1 | 116 | 132 | 1.43 | 1.63 |

| S2 | 148 | 249 | 1.04 | 1.74 |

| S3 | 18 | 44 | 0.30 | 0.73 |

| S4 | 70 | 82 | 1.24 | 1.45 |

| S5 | 30 | 68 | 0.41 | 0.94 |

| S6 | 25 | 37 | 0.42 | 0.62 |

| Sample No. | Tensile Strength (kN·m) | Tensile Index (N·m/g) | ||

|---|---|---|---|---|

| Transverse | Longitudinal | Transverse | Longitudinal | |

| S1 | 4.54 | 6.21 | 56.14 | 76.79 |

| S2 | 1.05 | 1.22 | 7.34 | 8.53 |

| S3 | 1.39 | 3.42 | 23.17 | 57.00 |

| S4 | 1.65 | 1.83 | 24.42 | 27.08 |

| S5 | 1.72 | 1.81 | 23.75 | 25.00 |

| S6 | 2.22 | 2.99 | 29.72 | 40.03 |

| Sample No. | Fiber Width (um) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | Average Value | |

| S1 | 34.44 | 29.71 | 16.45 | 24.34 | 28.94 | 14.34 | 22.41 | 15.83 | 34.28 | 16.45 | 23.72 |

| S2 | 8.23 | 9.85 | 7.47 | 6.76 | 9.85 | 9.42 | 9.02 | 10.69 | 6.12 | 9.47 | 8.69 |

| S3 | 10.30 | 9.56 | 10.30 | 16.51 | 10.30 | 11.51 | 12.25 | 11.67 | 15.45 | 16.94 | 12.48 |

| S4 | 9.56 | 13.92 | 9.42 | 10.34 | 14.63 | 10.9 | 11.63 | 7.47 | 13.59 | 14.57 | 11.60 |

| S5 | 10.69 | 8.55 | 11.67 | 11.67 | 6.9 | 6.76 | 6.96 | 5.15 | 7.71 | 7.47 | 8.35 |

| S6 | 13.42 | 14.38 | 13.69 | 12.58 | 13.52 | 12.87 | 11.51 | 12.47 | 11.67 | 12.10 | 12.82 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xiao, Z.; Li, Y.; Lv, X. Research on the Basic Performance and Fiber Appearance Characteristics of Grass Paper from Stellera chamaejasme in Different Origins on the Qinghai–Tibet Plateau. Coatings 2025, 15, 449. https://doi.org/10.3390/coatings15040449

Xiao Z, Li Y, Lv X. Research on the Basic Performance and Fiber Appearance Characteristics of Grass Paper from Stellera chamaejasme in Different Origins on the Qinghai–Tibet Plateau. Coatings. 2025; 15(4):449. https://doi.org/10.3390/coatings15040449

Chicago/Turabian StyleXiao, Zhipeng, Yanxiang Li, and Xiaohui Lv. 2025. "Research on the Basic Performance and Fiber Appearance Characteristics of Grass Paper from Stellera chamaejasme in Different Origins on the Qinghai–Tibet Plateau" Coatings 15, no. 4: 449. https://doi.org/10.3390/coatings15040449

APA StyleXiao, Z., Li, Y., & Lv, X. (2025). Research on the Basic Performance and Fiber Appearance Characteristics of Grass Paper from Stellera chamaejasme in Different Origins on the Qinghai–Tibet Plateau. Coatings, 15(4), 449. https://doi.org/10.3390/coatings15040449