A Large-Scale Preparation Approach for Daytime Radiative Cooling Using SiO2 Hollow Microsphere Composite Film

Abstract

1. Introduction

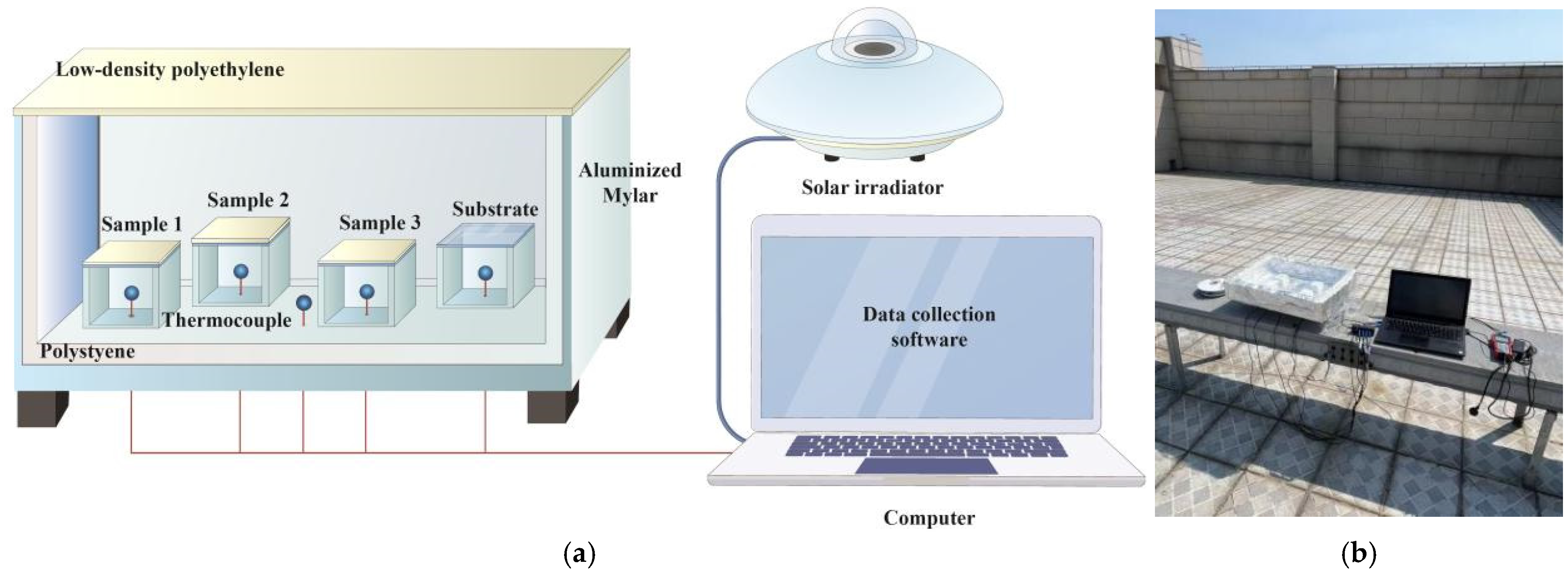

2. Materials and Methods

2.1. Theoretical Calculations

2.2. Fabrication

2.3. Characterization

3. Results and Discussion

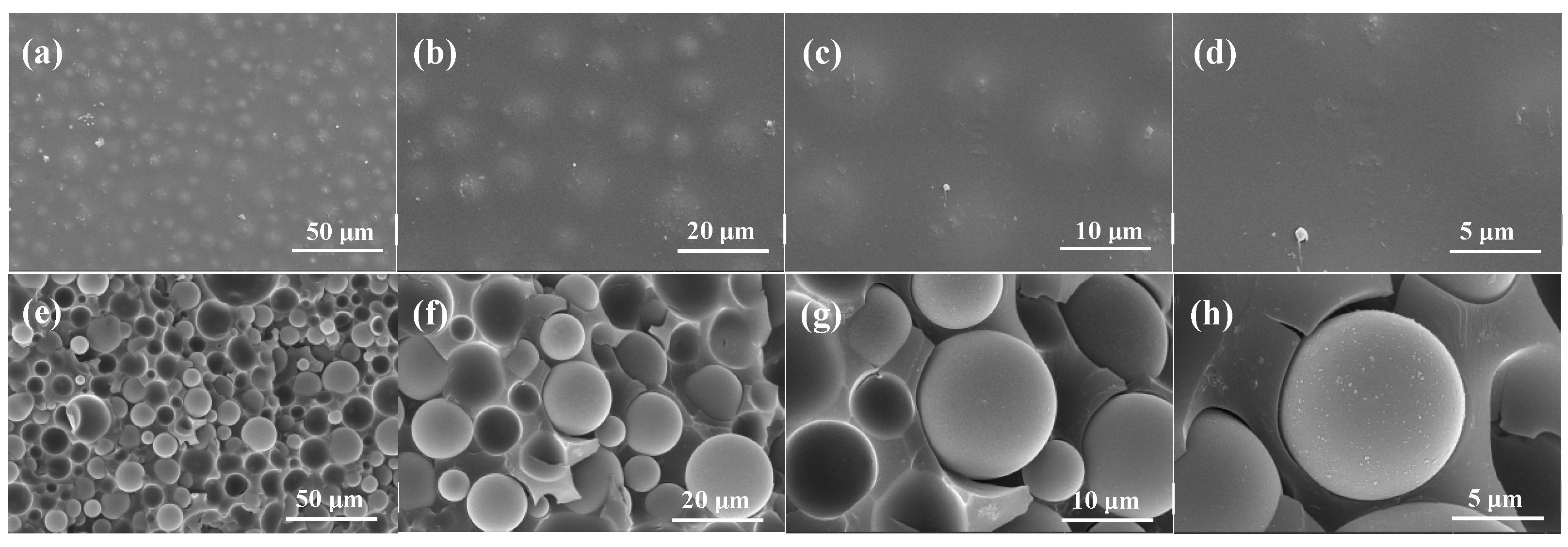

3.1. SEM Morphology Analysis

3.2. Optical Property Analysis

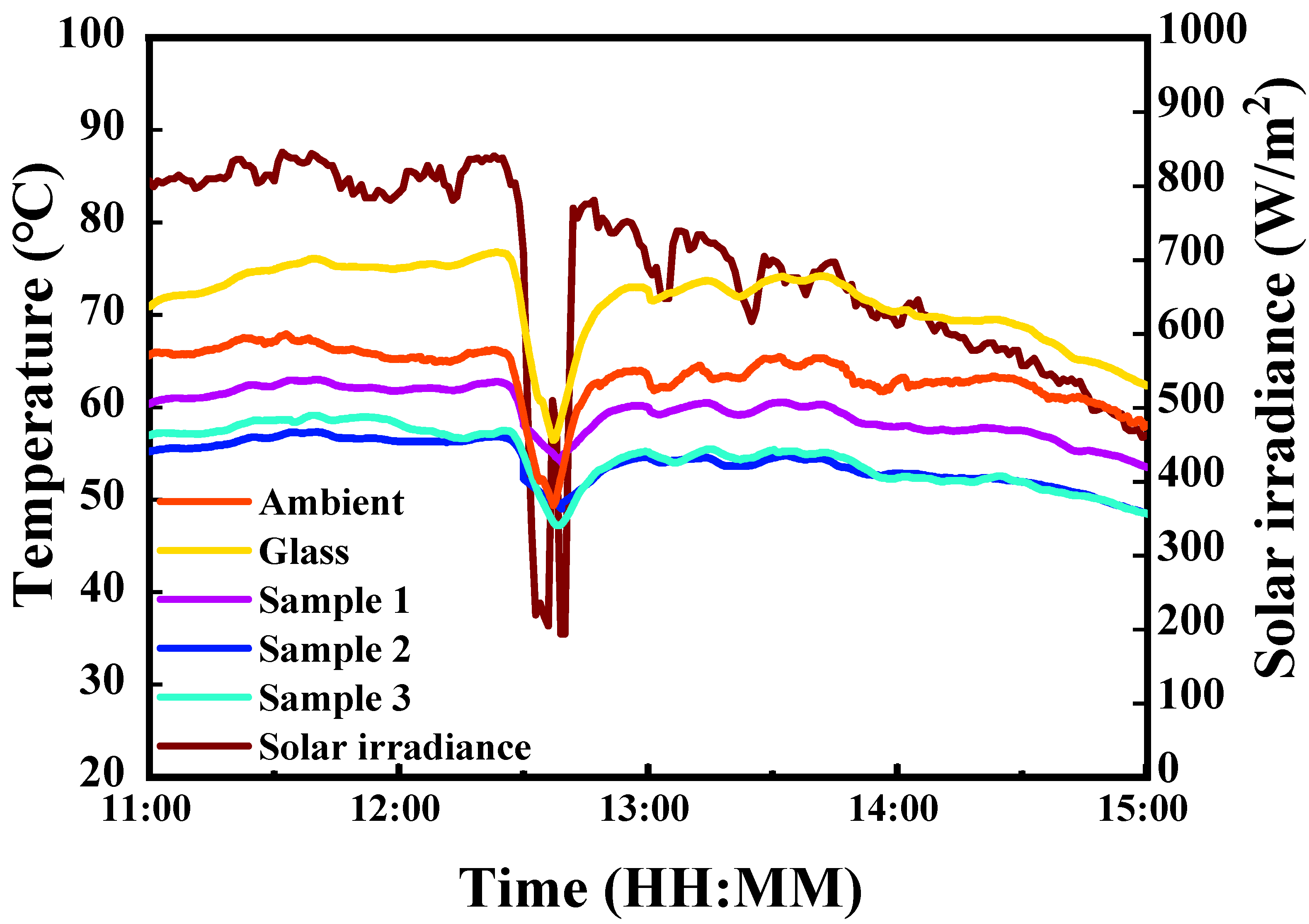

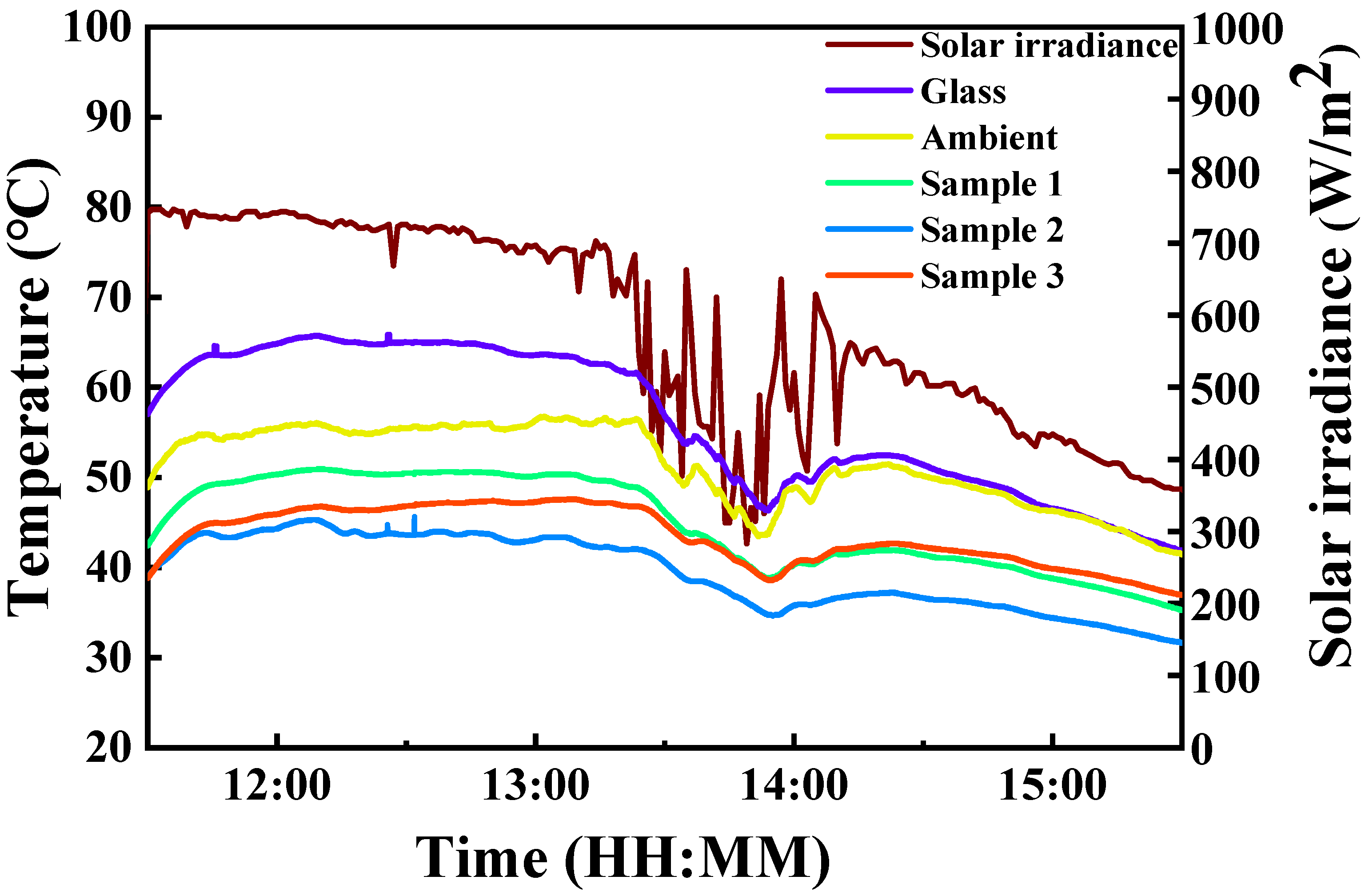

3.3. Cooling Performance Analysis

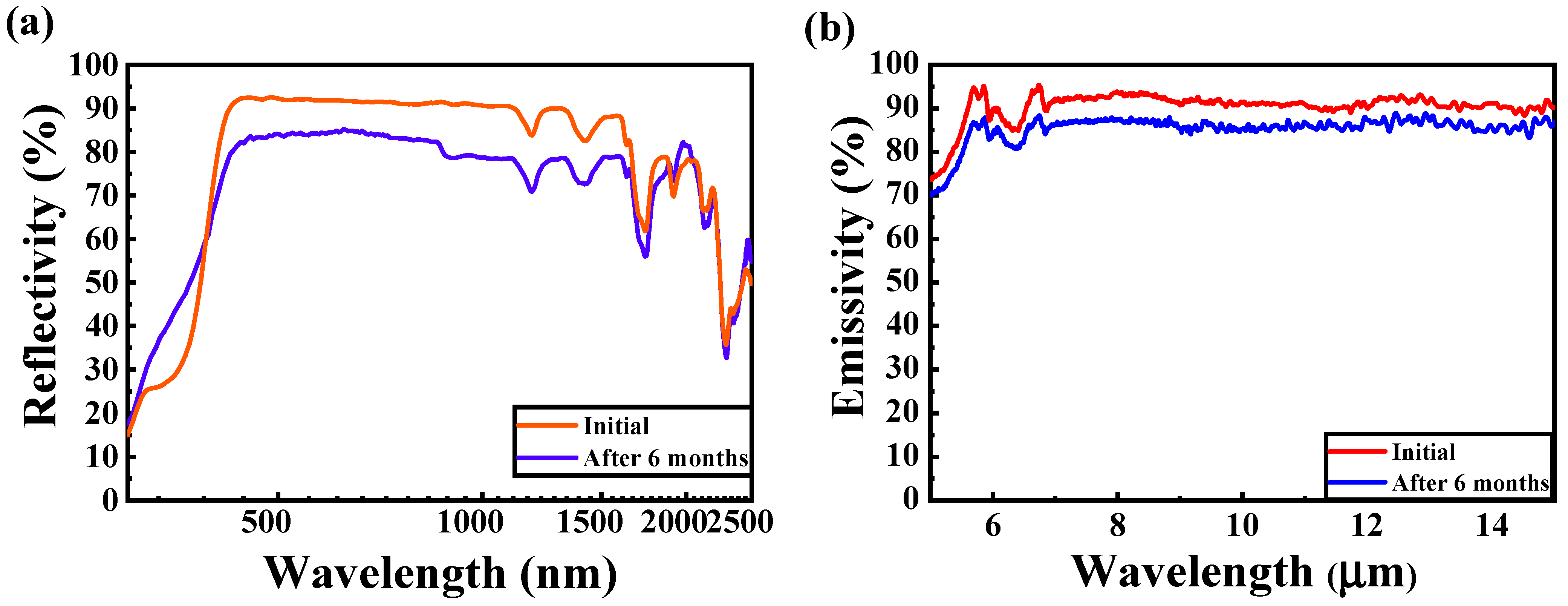

3.4. Stability Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| LWIR | long-wave infrared |

References

- Fan, S.; Li, W. Photonics and Thermodynamics Concepts in Radiative Cooling. Nat. Photon. 2022, 16, 182–190. [Google Scholar] [CrossRef]

- Gao, W.; Chen, Y. Emerging Materials and Strategies for Passive Daytime Radiative Cooling. Small 2023, 19, 2206145. [Google Scholar] [CrossRef] [PubMed]

- Zhou, L.; Rada, J.; Tian, Y.; Han, Y.; Lai, Z.; McCabe, M.F.; Gan, Q. Radiative Cooling for Energy Sustainability: Materials, Systems, and Applications. Phys. Rev. Mater. 2022, 6, 090201. [Google Scholar] [CrossRef]

- Zhao, B. Radiative Cooling: A Review of Fundamentals, Materials, Applications, and Prospects. Appl. Energy 2019, 236, 489–513. [Google Scholar] [CrossRef]

- Hossain, M.M.; Gu, M. Radiative Cooling: Principles, Progress, and Potentials. Adv. Sci. 2016, 3, 1500360. [Google Scholar] [CrossRef]

- Zhao, D.; Aili, A.; Zhai, Y.; Xu, S.; Tan, G.; Yin, X.; Yang, R. Radiative Sky Cooling: Fundamental Principles, Materials, and Applications. Appl. Phys. Rev. 2019, 6, 021306. [Google Scholar] [CrossRef]

- Yu, X.; Chan, J.; Chen, C. Review of Radiative Cooling Materials: Performance Evaluation and Design Approaches. Nano Energy 2021, 88, 106259. [Google Scholar] [CrossRef]

- An, Y.; Fu, Y.; Dai, J.-G.; Yin, X.; Lei, D. Switchable Radiative Cooling Technologies for Smart Thermal Management. Cell Rep. Phys. Sci. 2022, 3, 101098. [Google Scholar] [CrossRef]

- Wei, M.; Wu, W.; Li, D.; Xu, H.; Lu, Y.; Song, W. Universal Strategy for All-Weather and All-Terrain Radiative Cooling with Non-Reciprocal Mid-Infrared Windows. Sol. Energy 2020, 207, 471–478. [Google Scholar] [CrossRef]

- Fei, Y.; Xu, B.; Chen, X.; Pei, G. The Role of Emissivity of the Window Surface inside and Outside the Atmospheric Window in the Radiative Cooling Effect. Renew. Energy 2024, 226, 120444. [Google Scholar] [CrossRef]

- Raman, A.P.; Anoma, M.A.; Zhu, L.; Rephaeli, E.; Fan, S. Passive Radiative Cooling below Ambient Air Temperature under Direct Sunlight. Nature 2014, 515, 540–544. [Google Scholar] [CrossRef] [PubMed]

- Lu, Y.; Chen, Z.; Ai, L.; Zhang, X.; Zhang, J.; Li, J.; Wang, W.; Tan, R.; Dai, N.; Song, W. A Universal Route to Realize Radiative Cooling and Light Management in Photovoltaic Modules. Sol. RRL 2017, 1, 1700084. [Google Scholar] [CrossRef]

- Mandal, J.; Fu, Y.; Overvig, A.C.; Jia, M.; Sun, K.; Shi, N.N.; Zhou, H.; Xiao, X.; Yu, N.; Yang, Y. Hierarchically Porous Polymer Coatings for Highly Efficient Passive Daytime Radiative Cooling. Science 2018, 362, 315–319. [Google Scholar] [CrossRef]

- Rephaeli, E.; Raman, A.; Fan, S. Ultrabroadband Photonic Structures to Achieve High-Performance Daytime Radiative Cooling. Nano Lett. 2013, 13, 1457–1461. [Google Scholar] [CrossRef]

- Granqvist, C.; Hjortsberg, A. Radiative Cooling to Low-Temperatures—General-Considerations and Application to Selectively Emitting Sio Films. J. Appl. Phys. 1981, 52, 4205–4220. [Google Scholar] [CrossRef]

- Zhao, B.; Hu, M.; Ao, X.; Pei, G. Performance Evaluation of Daytime Radiative Cooling under Different Clear Sky Conditions. Appl. Therm. Eng. 2019, 155, 660–666. [Google Scholar] [CrossRef]

- Zhai, Y.; Ma, Y.; David, S.N.; Zhao, D.; Lou, R.; Tan, G.; Yang, R.; Yin, X. Scalable-Manufactured Randomized Glass-Polymer Hybrid Metamaterial for Daytime Radiative Cooling. Science 2017, 355, 1062–1066. [Google Scholar] [CrossRef]

- Wang, H.-D.; Xue, C.-H.; Ji, Z.-Y.; Huang, M.-C.; Jiang, Z.-H.; Liu, B.-Y.; Deng, F.-Q.; An, Q.-F.; Guo, X.-J. Superhydrophobic Porous Coating of Polymer Composite for Scalable and Durable Daytime Radiative Cooling. ACS Appl. Mater. Interfaces 2022, 14, 51307–51317. [Google Scholar] [CrossRef]

- Li, D.; Liu, X.; Li, W.; Lin, Z.; Zhu, B.; Li, Z.; Li, J.; Li, B.; Fan, S.; Xie, J.; et al. Scalable and Hierarchically Designed Polymer Film as a Selective Thermal Emitter for High-Performance All-Day Radiative Cooling. Nat. Nanotechnol. 2021, 16, 153–158. [Google Scholar] [CrossRef]

- Bokor, B.; Kajtár, L.; Eryener, D. Nocturnal Radiation: New Opportunity in Building Cooling. Energy Procedia 2017, 112, 118–125. [Google Scholar] [CrossRef]

- Park, C.; Park, C.; Park, S.; Lee, J.; Kim, Y.S.; Yoo, Y. Hybrid Emitters with Raspberry-like Hollow SiO2 Spheres for Passive Daytime Radiative Cooling. Chem. Eng. J. 2023, 459, 141652. [Google Scholar] [CrossRef]

- Leroy, A.; Bhatia, B.; Kelsall, C.C.; Castillejo-Cuberos, A.; Di Capua, M.H.; Zhao, L.; Zhang, L.; Guzman, A.M.; Wang, E.N. High-Performance Subambient Radiative Cooling Enabled by Optically Selective and Thermally Insulating Polyethylene Aerogel. Sci. Adv. 2019, 5, eaat9480. [Google Scholar] [CrossRef] [PubMed]

- Pokryshkin, N.S.; Mantsevich, V.N.; Timoshenko, V.Y. Anti-Stokes Photoluminescence in Halide Perovskite Nanocrystals: From Understanding the Mechanism towards Application in Fully Solid-State Optical Cooling. Nanomaterials 2023, 13, 1833. [Google Scholar] [CrossRef]

- Liao, S.; Lin, L.; Huang, J.; Jing, X.; Chen, S.; Li, Q. Microorganism-Templated Nanoarchitectonics of Hollow TiO2-SiO2 Microspheres with Enhanced Photocatalytic Activity for Degradation of Methyl Orange. Nanomaterials 2022, 12, 1606. [Google Scholar] [CrossRef] [PubMed]

- Mandal, J.; Yang, Y.; Yu, N.; Raman, A.P. Paints as a Scalable and Effective Radiative Cooling Technology for Buildings. Joule 2020, 4, 1350–1356. [Google Scholar] [CrossRef]

- Vall, S.; Castell, A. Radiative Cooling as Low-Grade Energy Source: A Literature Review. Renew. Sustain. Energy Rev. 2017, 77, 803–820. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhou, J.; Ren, Y.; Li, W.; Li, S.; Chai, N.; Zeng, Z.; Chen, X.; Yue, Y.; Zhou, L.; et al. Passive Deicing CFRP Surfaces Enabled by Super-Hydrophobic Multi-Scale Micro-Nano Structures Fabricated via Femtosecond Laser Direct Writing. Nanomaterials 2022, 12, 2782. [Google Scholar] [CrossRef]

- Gao, M.; Xia, Y.; Li, R.; Zhang, Z.; He, Y.; Zhang, C.; Chen, L.; Qi, L.; Si, Y.; Zhang, Q.; et al. The Design of Near-Perfect Spectrum-Selective Mirror Based on Photonic Structures for Passive Cooling of Silicon Solar Cells. Nanomaterials 2020, 10, 2483. [Google Scholar] [CrossRef]

- Fu, X.; Lu, P.; Bo, B.; Li, X.; Yin, R.; Duan, W. Different Deposition Technology Affecting Structure and Performance of Si Film. In Proceedings of the 2nd International Symposium on Advanced Optical Manufacturing and Testing Technologies: Advanced Optical Manufacturing Technologies, Xi’an, China, 9 June 2006; Volume 6149, pp. 677–682. [Google Scholar]

- Liu, B.J.; Duan, W.B.; Li, D.Q.; Yu, D.M.; Chen, G.; Wang, T.H.; Liu, D.Q. Effect of Annealing Temperature on Structure and Stress Properties of Ta2O5/SiO2 Multilayer Reflective Coating. Acta Phys. Sin. 2019, 68, 172–178. [Google Scholar]

- Bauer, F.; Flyunt, R.; Czihal, K.; Ernst, H.; Naumov, S.; Buchmeiser, M.R. UV Curing of Nanoparticle Reinforced Acrylates. Nucl. Instrum. Methods Phys. Res. Sect. B-Beam Interact. Mater. At. 2007, 265, 87–91. [Google Scholar] [CrossRef]

- Huang, Q.; Zhao, Y.; Wu, Y.; Zhou, M.; Tan, S.; Tang, S.; Ji, G. A Dual-Band Transceiver with Excellent Heat Insulation Property for Microwave Absorption and Low Infrared Emissivity Compatibility. Chem. Eng. J. 2022, 446, 137279. [Google Scholar] [CrossRef]

- Liu, J.; Xu, C.; Ao, X.; Lu, K.; Zhao, B.; Pei, G. A Dual-Layer Polymer-Based Film for All-Day Sub-Ambient Radiative Sky Cooling. Energy 2022, 254, 124350. [Google Scholar] [CrossRef]

- Zhang, Y.-S.; Liu, B.-J.; Sun, X.-J.; Duan, W.-B.; Yang, Y.-T.; Yu, D.-M.; Cai, Q.-Y.; Zhang, H.-T.; Peng, L.; Zhang, R.-J. Optimal Design and Preparation of High-Performance Multilayered Thin Film Daytime Radiative Coolers. Opt. Eng. 2024, 63, 091606. [Google Scholar] [CrossRef]

- Park, J.; Kim, D.; Kim, H.; Lee, J.; Chung, W. Thermal Radiative Copper Oxide Layer for Enhancing Heat Dissipation of Metal Surface. Nanomaterials 2021, 11, 2819. [Google Scholar] [CrossRef] [PubMed]

- Wen, J.; Chen, X.; Zhu, Z.; Zhu, Y.; Luo, H.; Wang, Y.; Liu, Y.; Wang, H.; Yuan, W.; Zhang, Y.; et al. Thin Film-Based Colorful Radiative Cooler Using Diffuse Reflection for Color Display. PhotoniX 2023, 4, 25. [Google Scholar] [CrossRef]

- Lin, K.-T.; Nian, X.; Li, K.; Han, J.; Zheng, N.; Lu, X.; Guo, C.; Lin, H.; Jia, B. Highly Efficient Flexible Structured Metasurface by Roll-to-Roll Printing for Diurnal Radiative Cooling. eLight 2023, 3, 22. [Google Scholar] [CrossRef]

- Liu, B.-Y.; Xue, C.-H.; Zhong, H.-M.; Guo, X.-J.; Wang, H.-D.; Li, H.-G.; Du, M.-M.; Huang, M.-C.; Wei, R.-X.; Song, L.-G.; et al. Multi-Bioinspired Self-Cleaning Energy-Free Cooling Coatings. J. Mater. Chem. A 2021, 9, 24276–24282. [Google Scholar] [CrossRef]

- Li, X.; Peoples, J.; Huang, Z.; Zhao, Z.; Qiu, J.; Ruan, X. Full Daytime Sub-Ambient Radiative Cooling in Commercial-like Paints with High Figure of Merit. Cell Rep. Phys. Sci. 2020, 1, 100221. [Google Scholar] [CrossRef]

- Luo, M.; Li, X.; Zhang, Z.; Ma, H.; Du, T.; Jiang, X.; Zhang, Z.; Yang, J. Tunable Infrared Detection, Radiative Cooling and Infrared-Laser Compatible Camouflage Based on a Multifunctional Nanostructure with Phase-Change Material. Nanomaterials 2022, 12, 2261. [Google Scholar] [CrossRef]

| Emissivity Test 8–14 μm | |

|---|---|

| Test Number | Emissivity |

| 1 | 0.912 |

| 2 | 0.915 |

| 3 | 0.911 |

| Instrument: Infrared radiation power detector | |

| Model specification: IR-2, China | |

| Number | Substrate Status | Thickness (mm) | Size (mm × mm) |

|---|---|---|---|

| 1 | Coated | 0.5 | 50 × 50 |

| 2 | Coated | 1.1 | 50 × 50 |

| 3 | Coated | 1.1 | 50 × 100 |

| 4 | Uncoated | / | / |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, C.; Sun, X.; Yang, Y.; Liu, B.; Zhang, H.; He, R.; Zhang, R.; Zheng, Y.; Wang, S.; Lee, Y.-P.; et al. A Large-Scale Preparation Approach for Daytime Radiative Cooling Using SiO2 Hollow Microsphere Composite Film. Coatings 2025, 15, 340. https://doi.org/10.3390/coatings15030340

Li C, Sun X, Yang Y, Liu B, Zhang H, He R, Zhang R, Zheng Y, Wang S, Lee Y-P, et al. A Large-Scale Preparation Approach for Daytime Radiative Cooling Using SiO2 Hollow Microsphere Composite Film. Coatings. 2025; 15(3):340. https://doi.org/10.3390/coatings15030340

Chicago/Turabian StyleLi, Changhai, Xiaojie Sun, Yuting Yang, Baojian Liu, Haotian Zhang, Rong He, Rongjun Zhang, Yuxiang Zheng, Songyou Wang, Young-Pak Lee, and et al. 2025. "A Large-Scale Preparation Approach for Daytime Radiative Cooling Using SiO2 Hollow Microsphere Composite Film" Coatings 15, no. 3: 340. https://doi.org/10.3390/coatings15030340

APA StyleLi, C., Sun, X., Yang, Y., Liu, B., Zhang, H., He, R., Zhang, R., Zheng, Y., Wang, S., Lee, Y.-P., & Chen, L. (2025). A Large-Scale Preparation Approach for Daytime Radiative Cooling Using SiO2 Hollow Microsphere Composite Film. Coatings, 15(3), 340. https://doi.org/10.3390/coatings15030340