Friction Behavior of Molybdenum Disulfide/Polytetrafluoroethylene-Coated Cemented Carbide Fabricated with a Spray Technique in Dry Friction Conditions

Abstract

1. Introduction

2. Materials and Methods

2.1. Coating Fabrication

2.2. Friction and Wear Tests

3. Results and Discussion

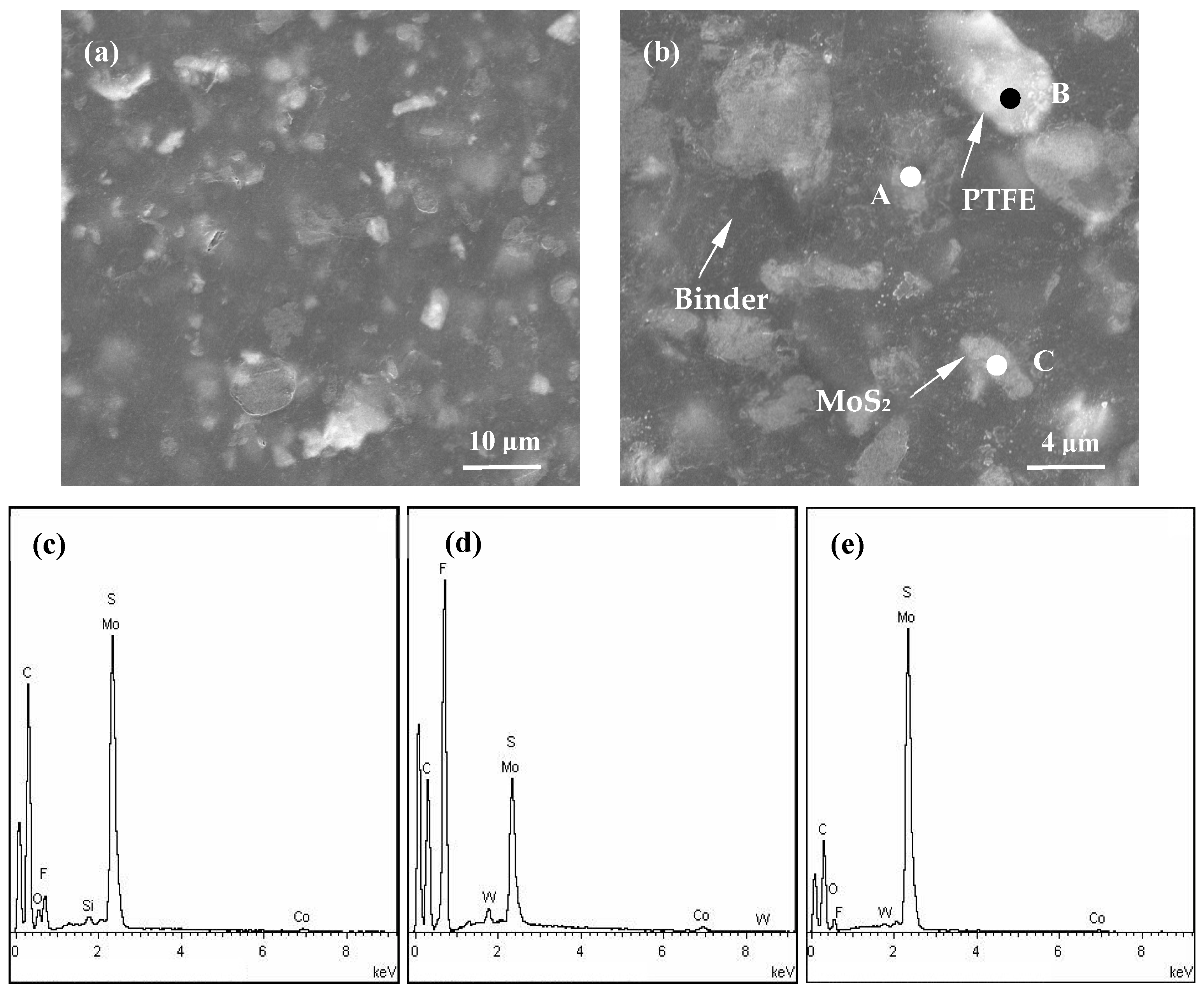

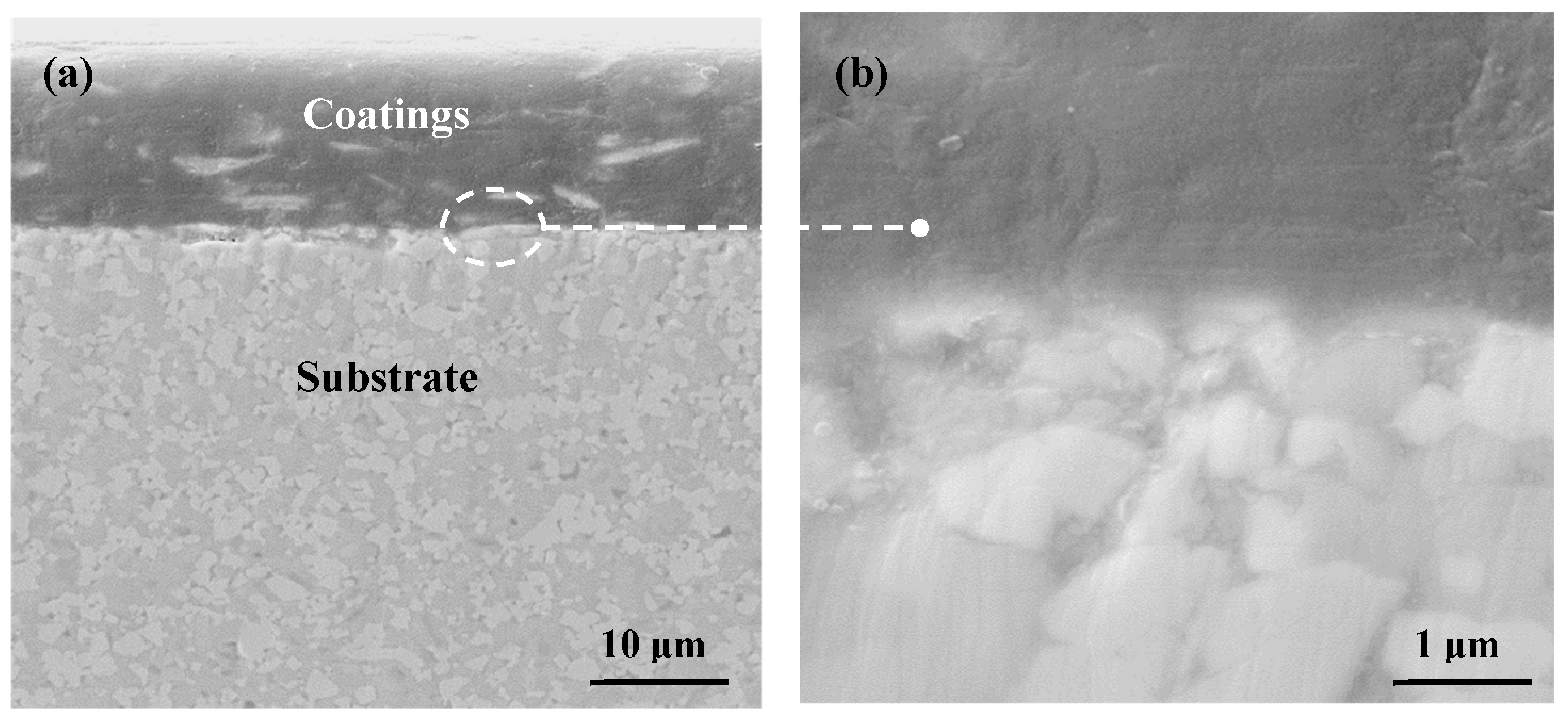

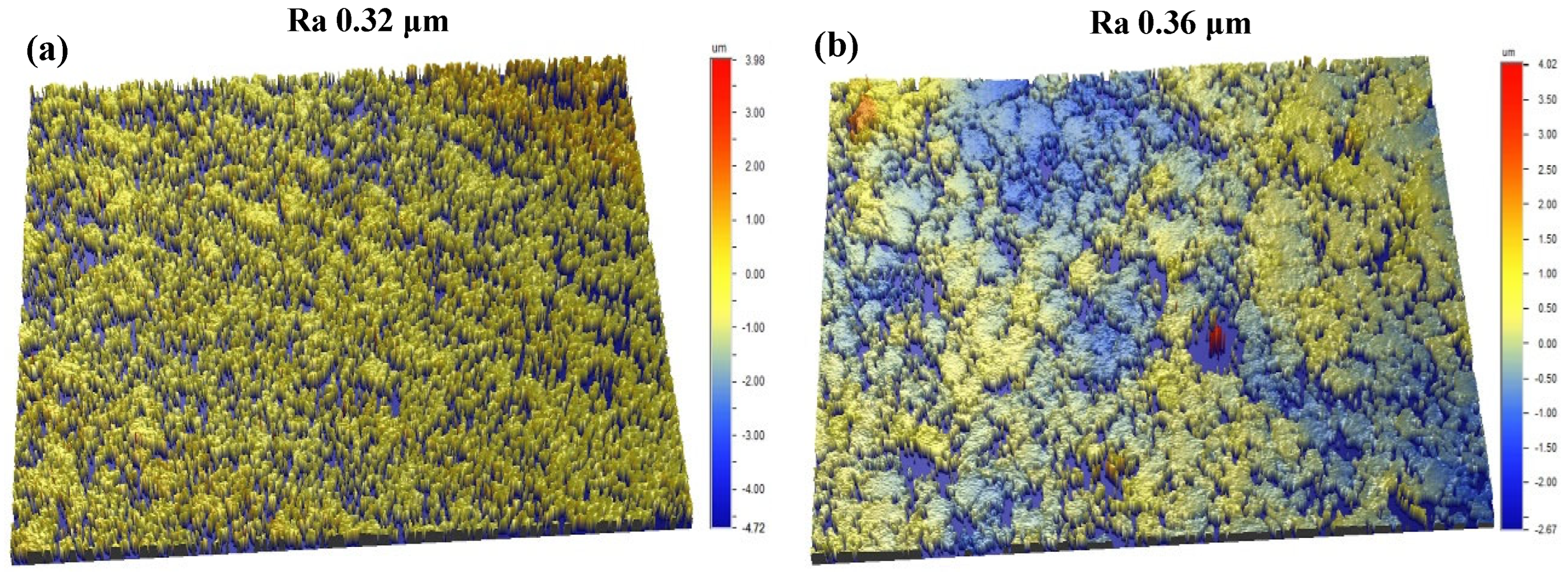

3.1. Coating Properties

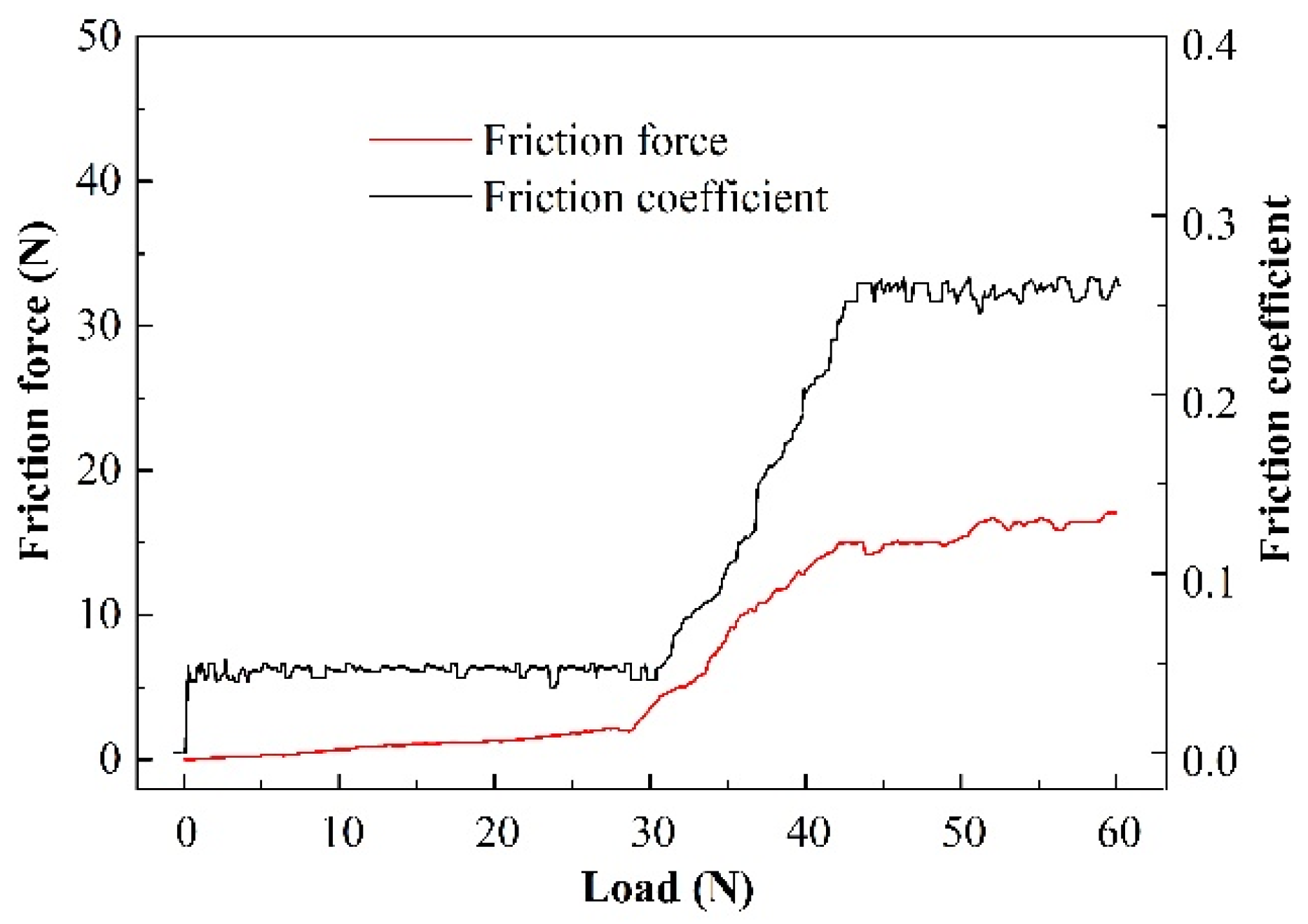

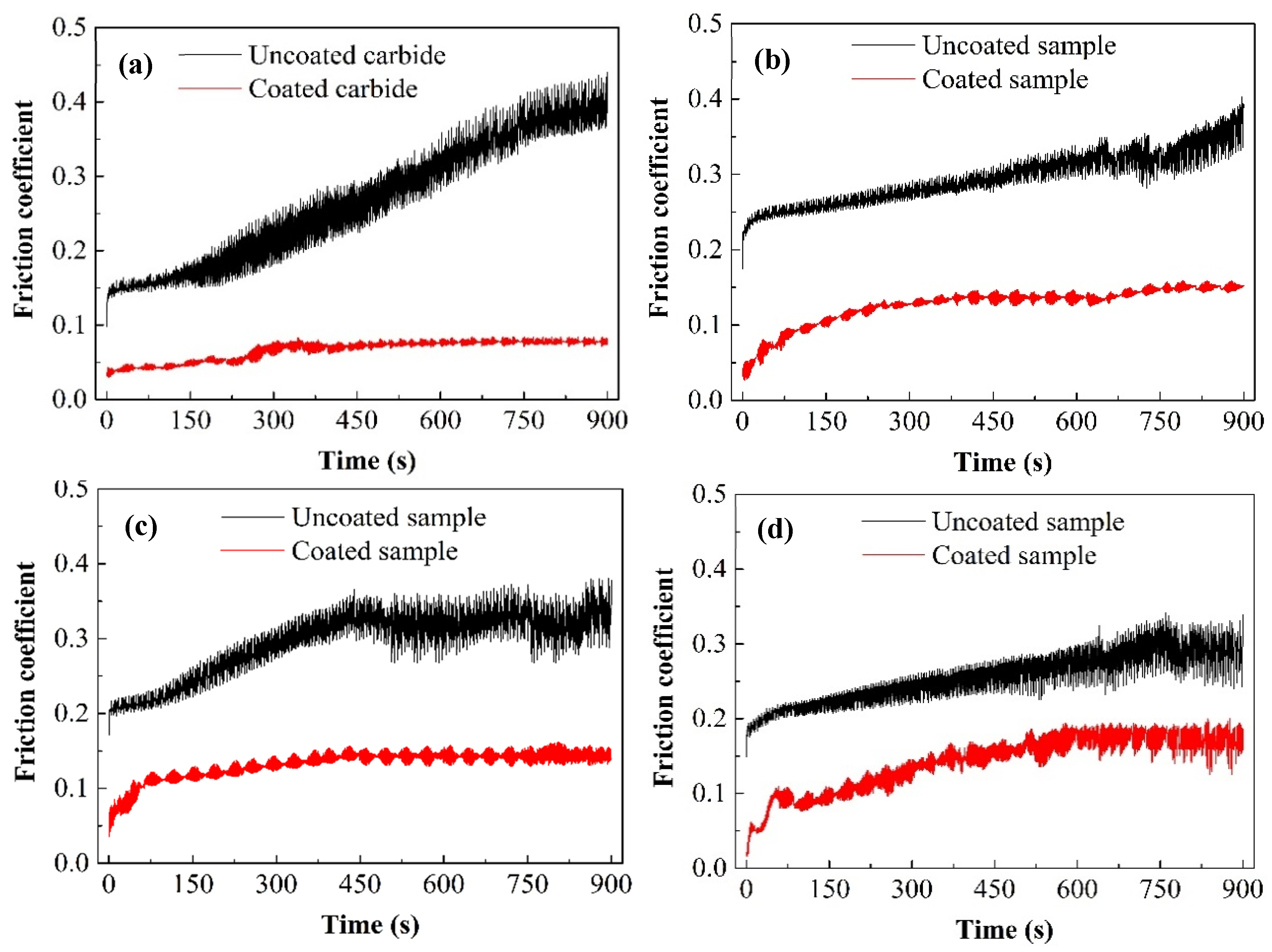

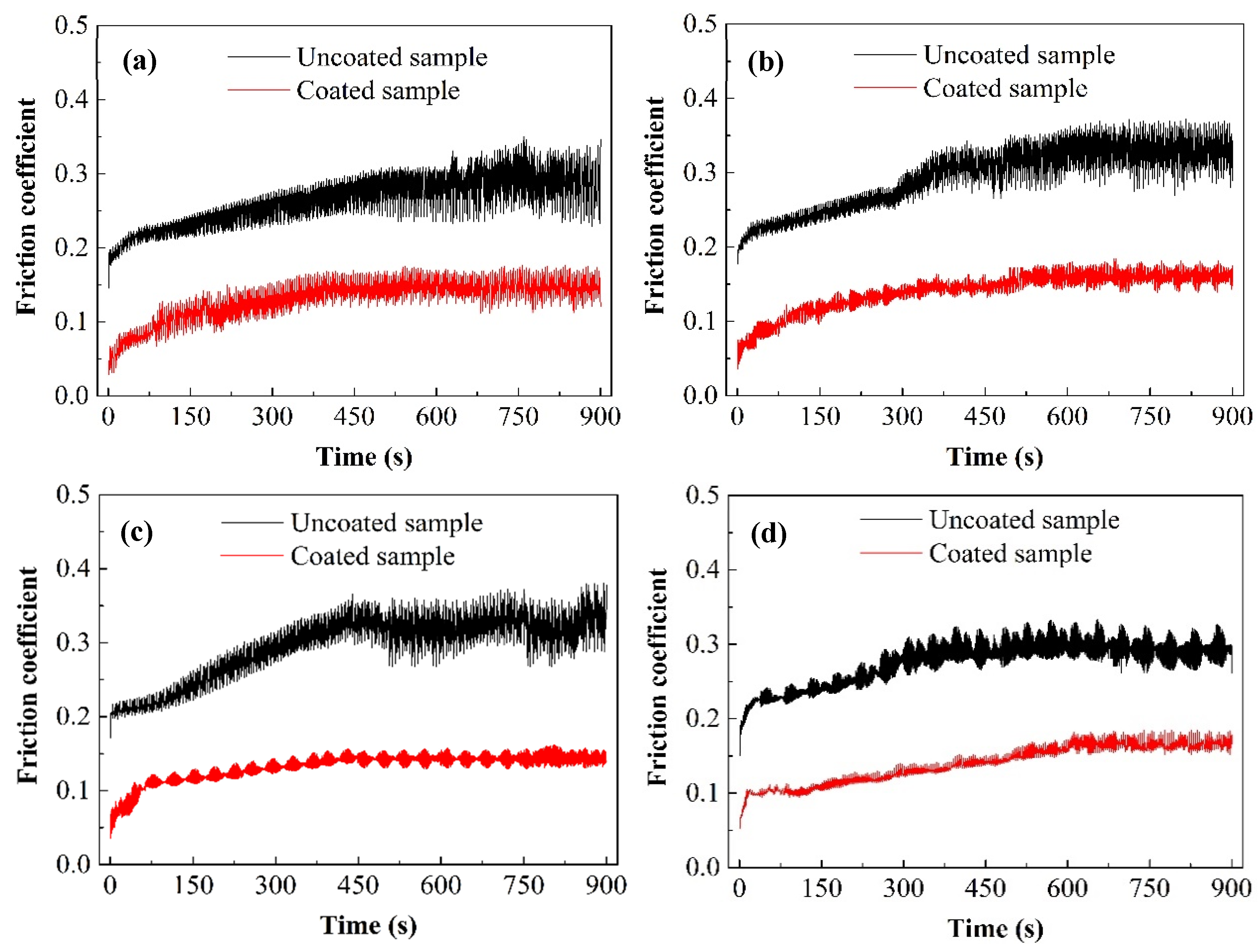

3.2. Friction Performance

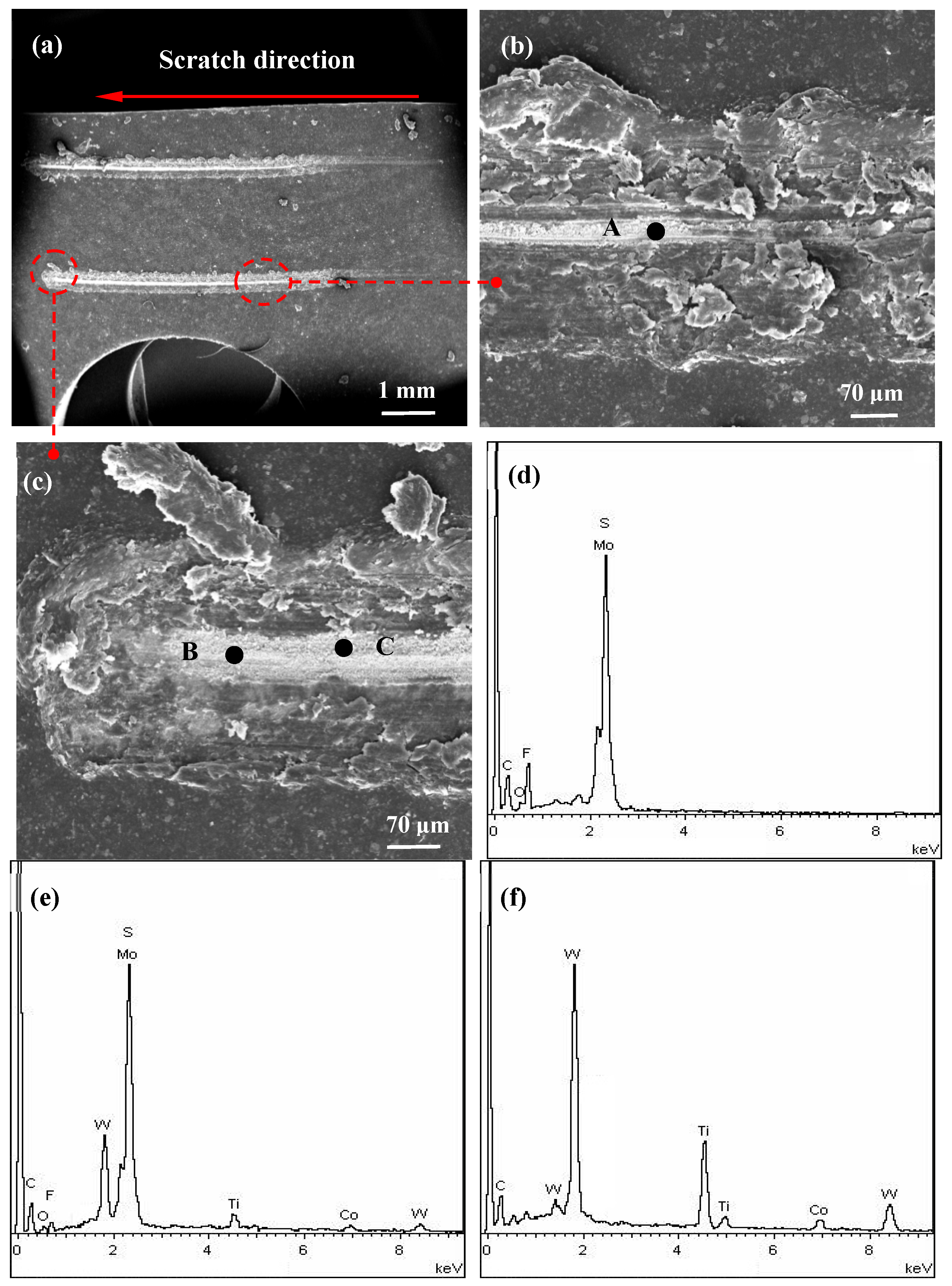

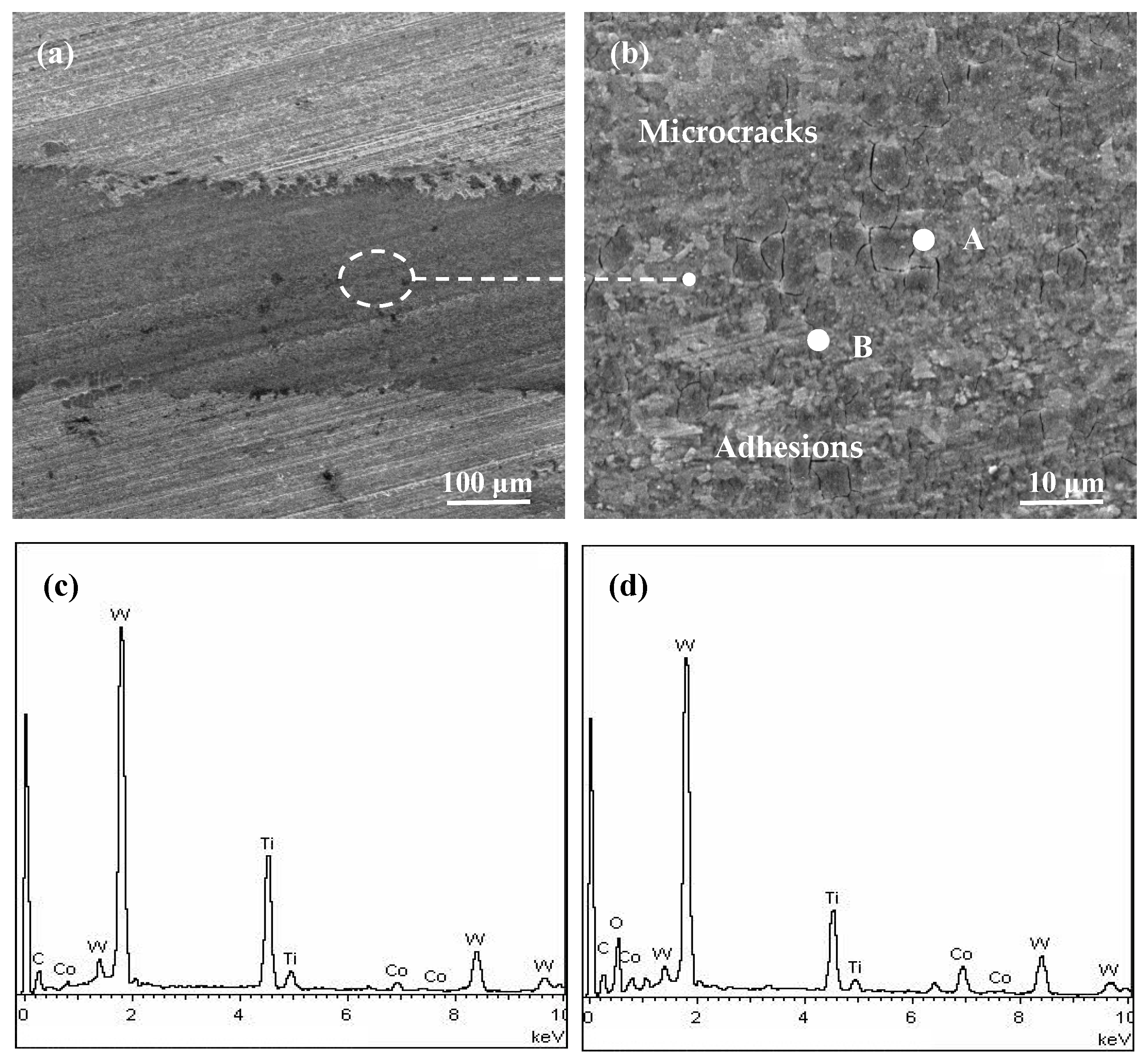

3.3. Wear Morphology Analysis of Sample

3.4. Discussion

4. Conclusions

- (1)

- MoS2/PTFE coatings were uniform and dense. The adhesion strength between MoS2/PTFE coatings and the substrate was up to 36 N. The hardness was about 0.42 GPa, the thickness was about 13 μm, and the surface roughness was about 0.36 μm.

- (2)

- MoS2/PTFE coatings significantly reduce the shear force between the sliding surfaces, which directly reduces the friction coefficient of carbide. The coatings help maintain a relatively steady and consistently low friction coefficient, irrespective of the varying test conditions.

- (3)

- MoS2/PTFE coatings can decrease surface adhesion and plowing and maintain a more uniform, continuous, and stable lubrication during the friction process due to the higher thickness. The results indicate the effect of MoS2/PTFE coatings in improving the friction property and the service life of cemented carbide, particularly in applications that involve dry sliding or abrasive contact.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Chen, Y.H.; Wang, J.; Chen, M. Enhancing the machining performance by cutting tool surface modifications: A focused review. Mach. Sci. Technol. 2019, 23, 477–509. [Google Scholar] [CrossRef]

- Sandoval, J.; Ali, A.; Kwon, P.; Stephenson, D.; Yang, G. Wear reduction mechanisms in modulated turning of compacted graphite iron with coated carbide tool. Tribol. Int. 2023, 178, 108062. [Google Scholar] [CrossRef]

- Koricherla, M.V.; Torgerson, T.B.; Alidokht, S.A.; Munagala, V.N.V.; Scharf, T.W. High temperature sliding wear behavior and mechanisms of cold-sprayed Ti and Ti-TiC composite coatings. Wear 2021, 476, 203746. [Google Scholar] [CrossRef]

- Boyle, H.; Norgren, S.; Crawforth, P.; Christofidou, K.; Boing, D.; Jackson, M. Insights in α-Al2O3 degradation in multilayer CVD coated carbide tools when turning IN718. Wear 2023, 523, 204786. [Google Scholar] [CrossRef]

- Bjerke, A.; Lenrick, F.; Hrechuk, A.; Slipchenko, K.; M’Saoubi, R.; Andersson, J.M.; Bushlya, V. On chemical interactions between an inclusion engineered stainless steel (316L) and (Ti,Al)N coated tools during turning. Wear 2023, 532–533, 205093. [Google Scholar] [CrossRef]

- Saikaew, C.; Paengchit, P.; Wisitsoraat, A. Machining performances of TiN+AlCrN coated WC and Al2O3+TiC inserts for turning of AISI 4140 steel under dry condition. J. Manuf. Process 2020, 50, 412–420. [Google Scholar] [CrossRef]

- Jackson, M.J.; Robinson, G.M.; Whitt, M.D.; Silva, R.B.; Silva, M.B.; Machado, A.R. Achieving clean production with nanostructured coated milling tools dry machining low carbon steel. J. Clean. Prod. 2023, 422, 138523. [Google Scholar] [CrossRef]

- Olsson, M.; Bushlya, V.; Lenrick, F.; Ståhl, J.E. Evaluation of tool wear mechanisms and tool performance in machining single-phase tungsten. Int. J. Refract. Met. Hard Mater. 2021, 94, 105379. [Google Scholar] [CrossRef]

- Roushan, A.; Rao, U.S.; Sahoo, P.; Patra, K.; Rawat, S.S. Wear behavior of AlTiN coated WC tools in micromilling of Ti6Al4V alloy using vegetable oil-based nanofluids. Tribol. Int. 2023, 188, 108825. [Google Scholar] [CrossRef]

- Kumar, C.S.; Urbikain, G.; Fernandes, F.; Rjoub, A.A.; Lacalle, L.N.L.D. Influence of V concentration in TiAlSiVN coating on self-lubrication, friction and tool wear during two-pass dry turning of austenitic steel 316L. Tribol. Int. 2024, 193, 109355. [Google Scholar] [CrossRef]

- Li, Y.T.; Xie, M.L.; Sun, Q.; Xu, X.J.; Fan, X.Q.; Zhang, G.A.; Li, H.; Zhu, M.H. The effect of atmosphere on the tribological behavior of magnetron sputtered MoS2 coatings. Surf. Coat. Technol. 2020, 378, 125081. [Google Scholar] [CrossRef]

- Sun, J.; Deng, J.X.; Li, X.M.; Meng, Y.; Zhang, Y.; Zhang, L.L.; Lu, Y. Preparation and tribological properties of MoS2-based multiple-layer structured films fabricated by electrohydrodynamic jet deposition. Surf. Coat. Technol. 2020, 384, 125334. [Google Scholar] [CrossRef]

- Mukhtar, S.H.; Wani, M.F.; Sehgal, R.; Sharma, M.D. Nano-mechanical and nano-tribological characterisation of self-lubricating MoS2 nano-structured coating for space applications. Tribol. Int. 2023, 178, 108017. [Google Scholar] [CrossRef]

- Lian, Y.S.; Long, Y.Y.; Zhao, G.L.; Mu, C.L.; Li, X.M.; Deng, J.X.; Xie, C.P. Performance of CrCN-WS2 hard/soft composite coated tools in dry cutting of titanium alloys. J. Manuf. Process 2020, 54, 201–209. [Google Scholar] [CrossRef]

- Abdelrazek, A.H.; Choudhury, I.A.; Nukman, Y.; Kazi, S.N. Metal cutting lubricants and cutting tools: A review on the performance improvement and sustainability assessment. Int. J. Adv. Manuf. Technol. 2020, 106, 4221–4245. [Google Scholar] [CrossRef]

- Saravanan, P.; Selyanchyn, R.; Watanabe, M.; Fujikawa, S.; Tanaka, H.; Lyth, S.M.; Sugimura, J. Ultra-low friction of polyethylenimine/molybdenum disulfide (PEI/MoS2)15 thin films in dry nitrogen atmosphere and the effect of heat treatment. Tribol. Int. 2018, 127, 255–263. [Google Scholar] [CrossRef]

- Xing, Y.Q.; Wu, Z.; Yang, J.J.; Wang, X.S.; Liu, L. LIPSS combined with ALD MoS2 nano-coatings for enhancing surface friction and hydrophobic performances. Surf. Coat. Technol. 2020, 385, 125396. [Google Scholar] [CrossRef]

- Pitenis, A.A.; Ewin, J.J.; Harris, K.L.; Sawyer, W.G.; Krick, B.A. In vacuo tribological behavior of polytetrafluoroethylene (PTFE) and alumina nanocomposites: The importance of water for ultralow wear. Tribol. Lett. 2014, 53, 189–197. [Google Scholar] [CrossRef]

- Wang, Y.; Zhao, Y.L.; Darutc, G.; Poirier, T.; Stella, J.; Wang, K.; Liao, H.L.; Planchece, M.P. A novel structured suspension plasma sprayed YSZ-PTFE composite coating with tribological performance improvement. Surf. Coat. Technol. 2019, 358, 108–113. [Google Scholar] [CrossRef]

- Zhang, Y.P.; Li, P.P.; Ji, L.; Wan, H.Q.; Chen, L.; Li, H.X.; Jin, Z.L. Tribological properties of MoS2 coating for ultra-long wear-life and low coefficient of friction combined with additive g-C3N4 in air. Friction 2021, 9, 789–801. [Google Scholar] [CrossRef]

- Peng, S.G.; Zhang, L.; Xie, G.X.; Guo, Y.; Si, L.N.; Luo, J.B. Friction and wear behavior of PTFE coatings modified with poly (methyl methacrylate). Compos. Part B Eng. 2019, 172, 316–322. [Google Scholar] [CrossRef]

- Mukhtar, S.H.; Gulzar, A.; Saleem, S. Advances in development of solid lubricating MoS2 coatings for space applications: A review of modeling and experimental approaches. Tribol. Int. 2024, 192, 109194. [Google Scholar] [CrossRef]

- Bashandeh, K.; Lan, P.X.; Meyer, J.L.; Polycarpou, A.A. Tribological performance of graphene and PTFE solid lubricants for polymer coatings at elevated temperatures. Tribol. Lett. 2019, 67, 99. [Google Scholar] [CrossRef]

- Lu, Y.; Deng, J.X.; Song, W.L.; Li, X.M.; Zhang, L.L.; Sun, J. Tribological performance of AlCrN-MoS2/PTFE hard-lubricant composite coatings. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2020, 234, 1355–1367. [Google Scholar] [CrossRef]

- Voevodin, A.A.; Zabinski, J.S. Nanocomposite and nanostructured tribological materials for space applications. Compos. Sci. Technol. 2005, 65, 741–748. [Google Scholar] [CrossRef]

- Chen, S.S.; Chen, S.Y.; Lan, J.L.; Qin, H.X.; Yang, S.; Wang, P.; You, Y. Core-shell structure polydopamine and polyethylenimine co-assisted MoS2-BaTiO3/polyarylene ether nitrile nanocomposites for high-temperature resistant organic dielectrics. J. Alloys Compd. 2024, 977, 173336. [Google Scholar] [CrossRef]

- Song, W.L.; An, L.; Lu, Y.; Zhang, X.; Wang, S.J. Friction behavior of TiN-MoS2/PTFE composite coatings in dry sliding against SiC. Ceram. Int. 2021, 47, 24003–24011. [Google Scholar] [CrossRef]

- Espallargas, N.; Vitoux, L.; Armada, S. The wear and lubrication performance of liquid-solid self-lubricated coatings. Surf. Coat. Technol. 2013, 235, 342–353. [Google Scholar] [CrossRef]

- Song, W.L.; Xia, Z.X.; Wang, S.J.; Zhang, Q.G. Effect of Zr target current on the mechanical and tribological performance of MoS2-Zr composite lubricating coatings. Coatings 2020, 10, 80. [Google Scholar] [CrossRef]

- Song, W.L.; Wang, S.J.; Lu, Y.; An, L.; Zhang, Q.G. Tribological performance of DLC-coated ceramics against cemented carbide under dry sliding conditions. Ceram. Int. 2021, 47, 16926–16934. [Google Scholar] [CrossRef]

- Wen, S.Z. Principle of Tribology; Tinghua University Press: Beijing, China, 2017. [Google Scholar]

| Composition (wt.%) | Density (g/cm3) | Size (mm) | Flexural Strength (MPa) | Young’s Modulus (GPa) | Hardness (GPa) |

|---|---|---|---|---|---|

| WC + 15%TiC + 6%Co | 11.65 | 16 × 16 × 5 | 1245 | 498 | 16.2 |

| Microhardness (GPa) | Coating Thickness (μm) | Adhesion Force (N) | Roughness (μm) |

|---|---|---|---|

| 0.42 ± 0.05 | 13 ± 0.2 | 36 ± 2 | 0.36 ± 0.03 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, L.; Song, W. Friction Behavior of Molybdenum Disulfide/Polytetrafluoroethylene-Coated Cemented Carbide Fabricated with a Spray Technique in Dry Friction Conditions. Coatings 2025, 15, 324. https://doi.org/10.3390/coatings15030324

Zhang L, Song W. Friction Behavior of Molybdenum Disulfide/Polytetrafluoroethylene-Coated Cemented Carbide Fabricated with a Spray Technique in Dry Friction Conditions. Coatings. 2025; 15(3):324. https://doi.org/10.3390/coatings15030324

Chicago/Turabian StyleZhang, Li, and Wenlong Song. 2025. "Friction Behavior of Molybdenum Disulfide/Polytetrafluoroethylene-Coated Cemented Carbide Fabricated with a Spray Technique in Dry Friction Conditions" Coatings 15, no. 3: 324. https://doi.org/10.3390/coatings15030324

APA StyleZhang, L., & Song, W. (2025). Friction Behavior of Molybdenum Disulfide/Polytetrafluoroethylene-Coated Cemented Carbide Fabricated with a Spray Technique in Dry Friction Conditions. Coatings, 15(3), 324. https://doi.org/10.3390/coatings15030324