The Effect of Warm Shot Peening on Microstructure Evolution and Residual Stress in Gradient Nanostructured Mg-8Gd-3Y-0.4Zr Alloys

Abstract

1. Introduction

2. Material Preparation and Measurement Methods

2.1. Materials Preparation and WSP Processing

2.2. Measurement and Analysis Method

3. Results

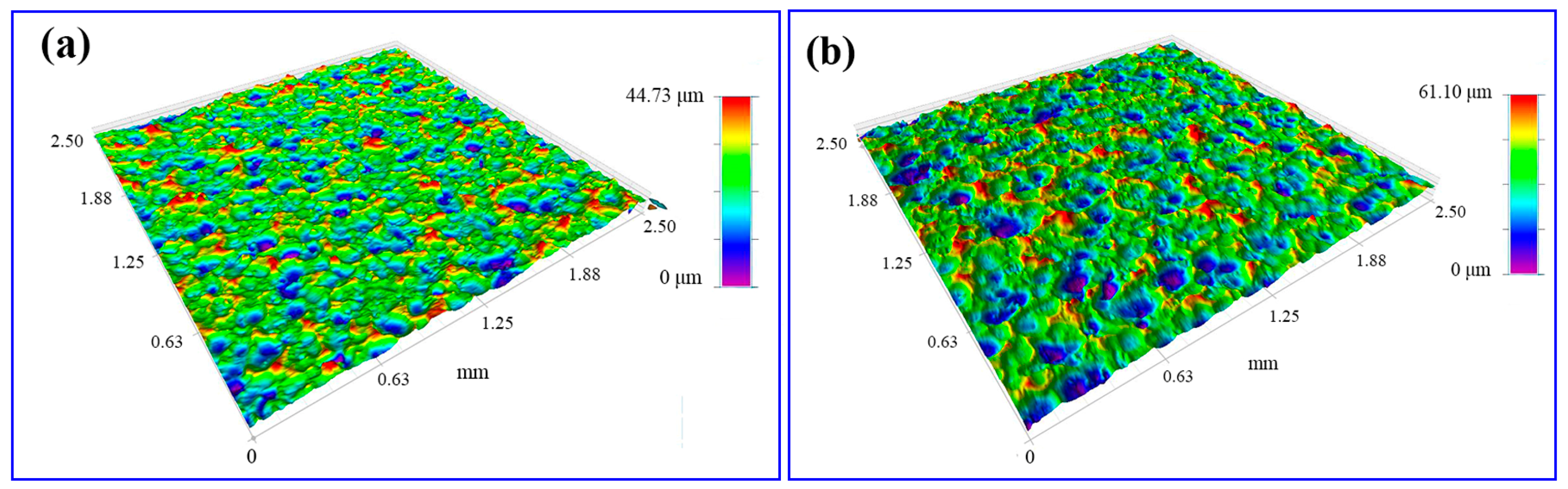

3.1. Surface Morphology and Roughness

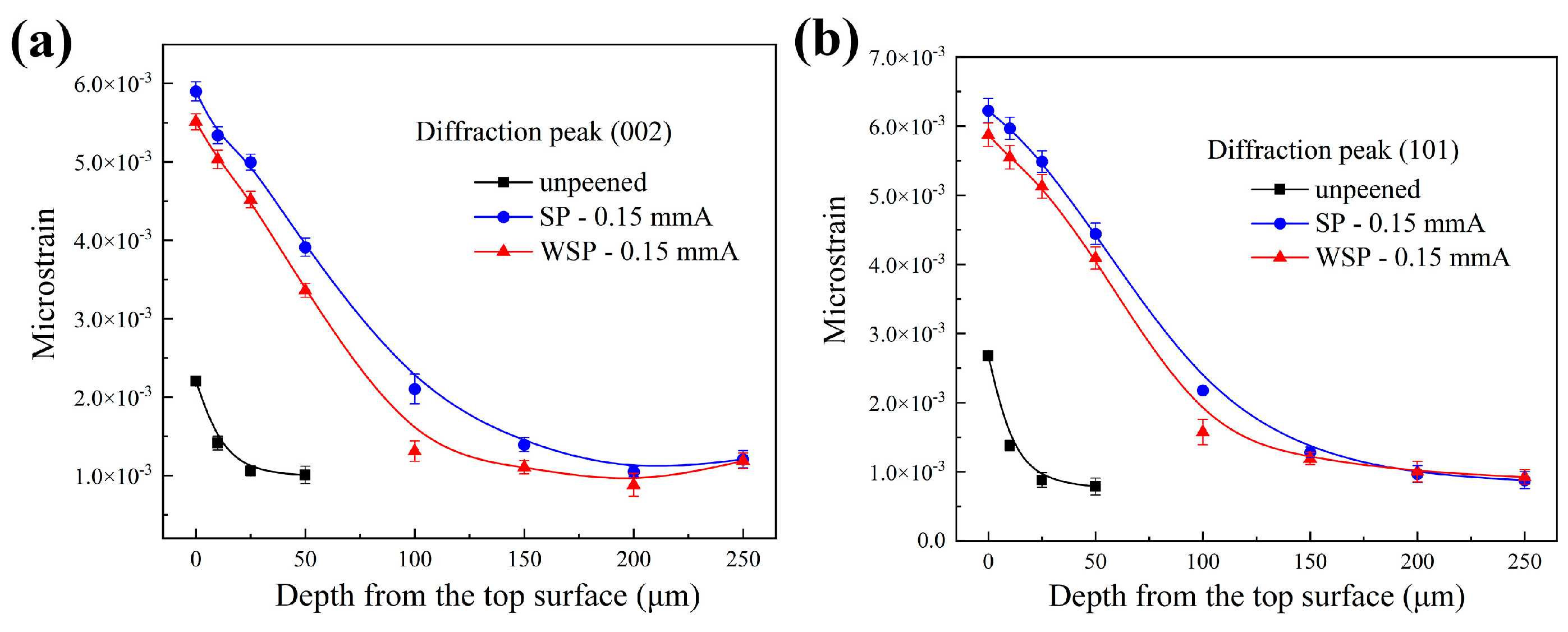

3.2. Microstructural Characterization Through XRD Line Profile Analysis Method

3.2.1. Quantification of Crystallite Size and Microstrain

3.2.2. Quantification of Dislocation Density

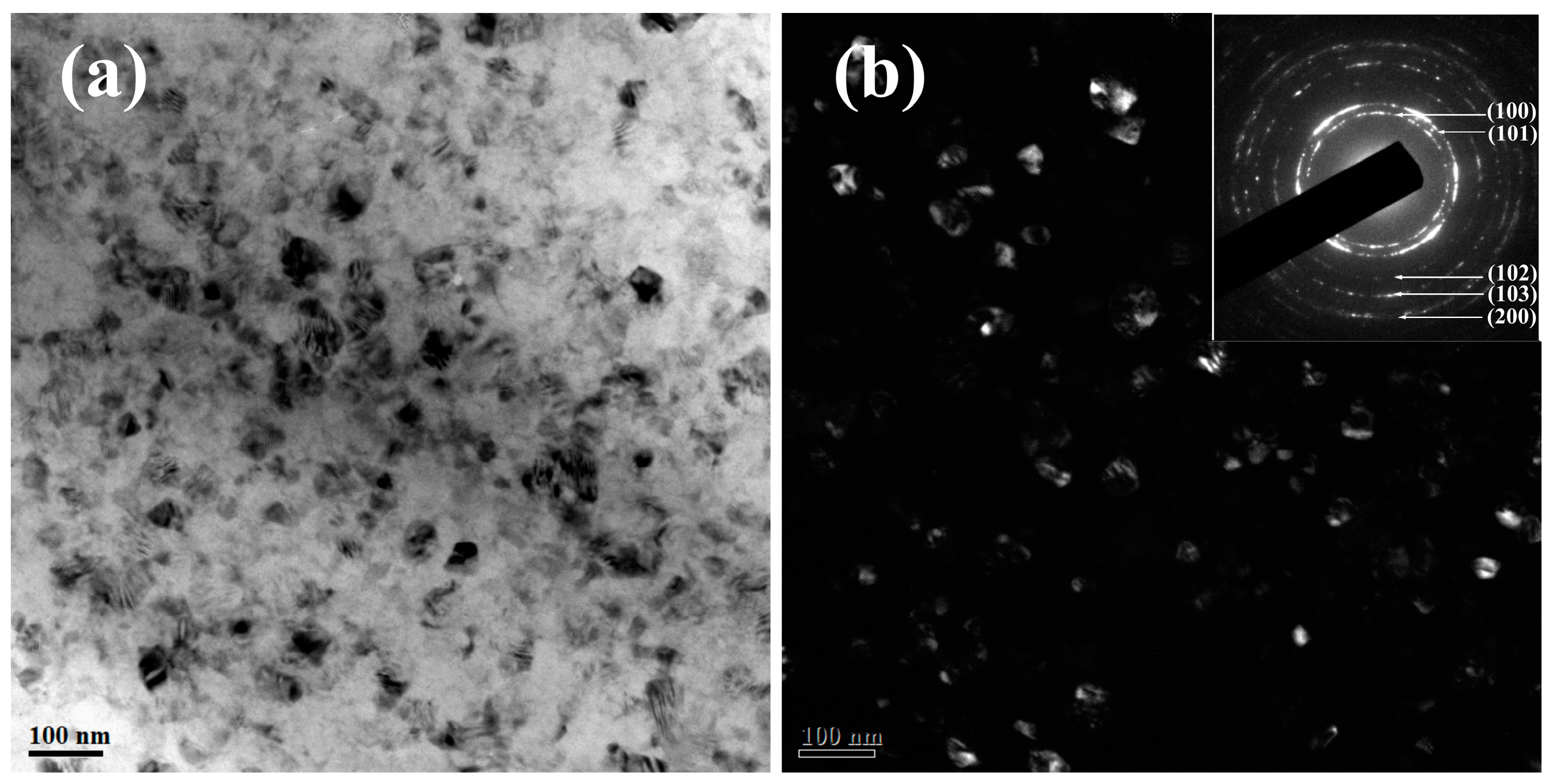

3.3. Microstructure Observations by TEM

3.3.1. Surface Microstructural Evolution of the GW83 Alloy Treated by CSP and WSP

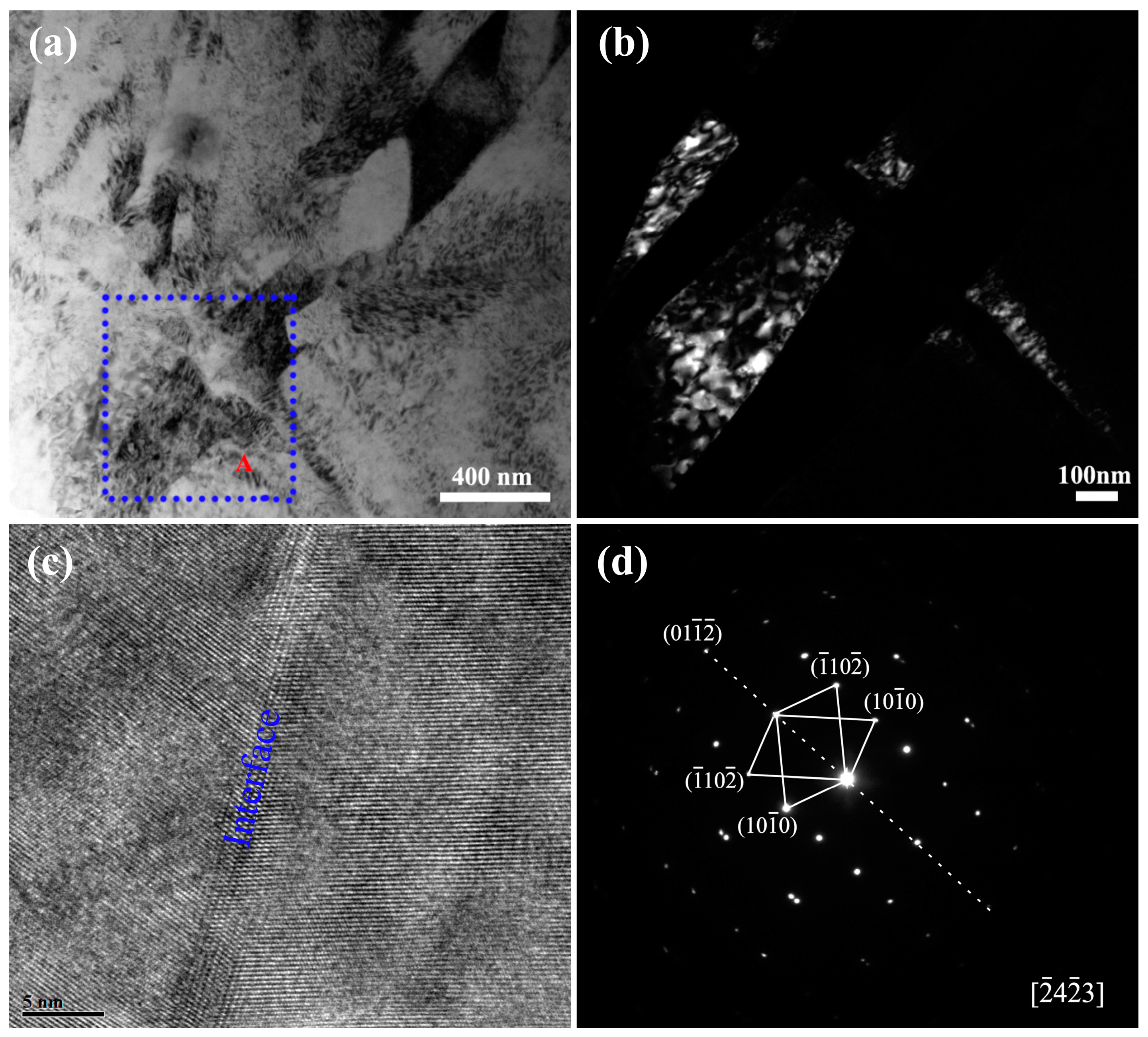

3.3.2. Microstructure Evolution of the GW83 Alloy upon WSP

3.4. Distribution of Residual Stress

3.5. Distribution of Microhardness

4. Discussion

4.1. Grain Refinement Process in GW83 Alloy During WSP

4.2. The Evolution of Microstructure and Mechanical Property of the GW83 Alloy After WSP

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yang, J.; Han, S.; Gu, Y.; Zhu, Z.; Zhang, H. Evolution, limitations, advantages, and future challenges of magnesium alloys as materials for aerospace applications. J. Alloys Compd. 2024, 1008, 176707. [Google Scholar] [CrossRef]

- Zhang, T.; Wang, W.; Liu, J.; Wang, L.; Tang, Y.; Wang, K. A review on magnesium alloys for biomedical applications. Front. Bioeng. Biotechnol. 2022, 10, 953344. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Lu, L.; Li, J.; Zhang, X.; Gao, H. Mechanical properties and deformation mechanisms of gradient nanostructured metals and alloys. Nat. Rev. Mater. 2020, 5, 706–723. [Google Scholar] [CrossRef]

- Pan, Q.; Lu, L.J. Synthesis and deformation mechanics of gradient nanostructured materials. Natl. Sci. Open 2022, 1, 20220010. [Google Scholar] [CrossRef]

- Li, J.; Soh, A. Modeling of the plastic deformation of nanostructured materials with grain size gradient. Int. J. Plast. 2012, 39, 88–102. [Google Scholar] [CrossRef]

- Unal, O.; Maleki, E.; Karademir, I.; Husem, F.; Efe, Y.; Das, T. Effects of conventional shot peening, severe shot peening, re-shot peening and precised grinding operations on fatigue performance of AISI 1050 railway axle steel. Int. J. Fatigue 2021, 155, 106613. [Google Scholar] [CrossRef]

- Bagherifard, S. Enhancing the Structural Performance of Lightweight Metals by Shot Peening. Adv. Eng. Mater. 2019, 21, 1801140. [Google Scholar] [CrossRef]

- Świetlicki, A.; Szala, M.; Walczak, M. Effects of Shot Peening and Cavitation Peening on Properties of Surface Layer of Metallic Materials-A Short Review. Materials 2022, 15, 2476. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, K.; Hu, Z.; Chen, T.; Susmel, L.; Wei, B. The synergetic effects of shot peening and laser-shot peening on the microstructural evolution and fatigue performance of a medium carbon steel. Int. J. Fatigue 2022, 166, 107246. [Google Scholar] [CrossRef]

- Zhang, P.; Lindemann, J.; Leyens, C. Shot peening on the high-strength wrought magnesium alloy AZ80—Effect of peening media. J. Mater. Process. Technol. 2010, 210, 445–450. [Google Scholar] [CrossRef]

- Liu, W.; Dong, J.; Zhang, P.; Zhai, C.; Ding, W. Effect of shot peening on surface characteristics and fatigue properties of T5-treated ZK60 alloy. Mater. Trans. 2009, 50, 791–798. [Google Scholar] [CrossRef]

- Liu, W.C.; Dong, J.; Zhang, P.; Korsunsky, A.M.; Song, X.; Ding, W.J. Improvement of fatigue properties by shot peening for Mg–10Gd–3Y alloys under different conditions. Mater. Sci. Eng. A 2011, 528, 5935–5944. [Google Scholar] [CrossRef]

- Liu, W.; Jiang, L.; Cao, L.; Mei, J.; Wu, G.; Zhang, S.; Xiao, L.; Wang, S.; Ding, W. Fatigue behavior and plane-strain fracture toughness of sand-cast Mg–10Gd–3Y–0.5 Zr magnesium alloy. Mater. Des. 2014, 59, 466–474. [Google Scholar] [CrossRef]

- Flynn, P.W.; Mote, J.; Dorn, J.E. On the thermally activated mechanism of prismatic slip in magnesium single crystals. Trans. Metall. Soc. AIME 1961, 221, 1148–1154. [Google Scholar]

- Barnett, M. A Taylor model based description of the proof stress of magnesium AZ31 during hot working. Metall. Mater. Trans. A 2003, 34, 1799–1806. [Google Scholar] [CrossRef]

- Chapuis, A.; Driver, J.H. Temperature dependency of slip and twinning in plane strain compressed magnesium single crystals. Acta Mater. 2011, 59, 1986–1994. [Google Scholar] [CrossRef]

- Huang, Y.; Liu, W.; Dong, J. Surface characteristics and fatigue performance of warm shot peened wrought magnesium alloy Mg–9Gd–2Y. Mater. Sci. Technol. 2014, 30, 1481–1487. [Google Scholar] [CrossRef]

- Wick, A.; Schulze, V.; Vöhringer, O. Effects of stress- and/or warm peening of AISI 4140 on fatigue life. Steel Res. Int. 2000, 71, 316–321. [Google Scholar] [CrossRef]

- Wick, A.; Schulze, V.; Vöhringer, O. Effects of warm peening on fatigue life and relaxation behavior of residual stresses in AISI 4140 steel. Mater. Sci. Eng. A 2000, 293, 191–197. [Google Scholar] [CrossRef]

- Menig, R.; Schulze, V.; Vöhringer, O. Optimized warm peening of the quenched and tempered steel AISI 4140. Mater. Sci. Eng. A 2002, 335, 198–206. [Google Scholar] [CrossRef]

- SLim, S.H.; Zhang, Z.; Seng, D.H.L.; Lin, M.; Teo, S.L.; Wei, F.; Cheong, A.K.H.; Wang, S.; Pan, J. In-situ warm shot peening on Ti-6Al-4V alloy: Effects of temperature on fatigue life, residual stress, microstructure and mechanical properties. J. Alloys Compd. 2021, 882, 160701. [Google Scholar]

- Huang, J.; Wang, Z.; Gan, J.; Yang, Y.; Wu, G.; Meng, Q. Investigation of fatigue performance improvement in SiC w/Al composites with different modified shot peening treatments by considering surface mechanical properties. J. Alloys Compd. 2017, 728, 169–178. [Google Scholar] [CrossRef]

- Liao, Y.; Ye, C.; Cheng, G.J. [INVITED] A review: Warm laser shock peening and related laser processing technique. Opt. Laser Technol. 2016, 78, 15–24. [Google Scholar] [CrossRef]

- Ye, C.; Liao, Y.; Cheng, G.J. Warm Laser Shock Peening Driven Nanostructures and Their Effects on Fatigue Performance in Aluminum Alloy 6160. Adv. Eng. Mater. 2010, 12, 291–297. [Google Scholar] [CrossRef]

- Peral, L.; Zafra, A.; Bagherifard, S.; Guagliano, M.; Fernández-Pariente, I. Effect of warm shot peening treatments on surface properties and corrosion behavior of AZ31 magnesium alloy. Surf. Coat. Technol. 2020, 401, 126285. [Google Scholar] [CrossRef]

- Liu, H.; Jiang, C.; Chen, M.; Wang, L.; Ji, V. Surface layer microstructures and wear properties modifications of Mg-8Gd-3Y alloy treated by shot peening. Mater. Charact. 2019, 158, 109952. [Google Scholar] [CrossRef]

- Liu, H.; Chen, M.; Wang, L.; Zhan, K.; Ji, V.; Jiang, C. Investigation on microstructure and properties of Al18B4O33 whisker reinforced Al Mg Si matrix composite after shot peening. Vacuum 2018, 160, 303–310. [Google Scholar] [CrossRef]

- Langford, J.I.; Wilson, A.J.C. Scherrer after sixty years: A survey and some new results in the determination of crystallite size. J. Appl. Crystallogr. 1978, 11, 102–113. [Google Scholar] [CrossRef]

- Vives, S.; Gaffet, E.; Meunier, C. X-ray diffraction line profile analysis of iron ball milled powders. Mater. Sci. Eng. A 2004, 366, 229–238. [Google Scholar] [CrossRef]

- Liu, H.; Zhu, W.; Jiang, C.; Guagliano, M.; Xing, S.; Wang, L.; Ji, V.; Zhan, K. Microstructure evolution and residual stress distribution of nanostructured Mg-8Gd-3Y alloy induced by severe shot peening. Surf. Coat. Technol. 2020, 404, 126465. [Google Scholar] [CrossRef]

- Williamson, G.; Smallman, R., III. Dislocation densities in some annealed and cold-worked metals from measurements on the X-ray debye-scherrer spectrum. Philos. Mag. 1956, 1, 34–46. [Google Scholar] [CrossRef]

- Kadiri, H.E.; Barrett, C.D.; Wang, J.; Tomé, C.N. Why are {101¯2} twins profuse in magnesium? Acta Mater. 2015, 85, 354–361. [Google Scholar] [CrossRef]

- Kobayashi, M.; Matsui, T.; Murakami, Y. Mechanism of creation of compressive residual stress by shot peening. Int. J. Fatigue 1998, 20, 351–357. [Google Scholar] [CrossRef]

- Weertman, J. Hall-Petch strengthening in nanocrystalline metals. Mater. Sci. Eng. A 1993, 166, 161–167. [Google Scholar] [CrossRef]

- Ren, X.; Huang, J.; Zhou, W.; Xu, S.; Liu, F. Surface nano-crystallization of AZ91D magnesium alloy induced by laser shock processing. Mater. Des. 2015, 86, 421–426. [Google Scholar] [CrossRef]

- Ashby, M.F. The deformation of plastically non-homogeneous materials. Philos. Mag. J. Theor. Exp. Appl. Phys. 1970, 21, 399–424. [Google Scholar] [CrossRef]

- Wang, Y.B.; Sui, M.L. Atomic-scale in situ observation of lattice dislocations passing through twin boundaries. Appl. Phys. Lett. 2009, 94, 737. [Google Scholar] [CrossRef]

- Wang, Y.B.; Wu, B.; Sui, M.L. Dynamical dislocation emission processes from twin boundaries. Appl. Phys. Lett. 2008, 93, 684. [Google Scholar] [CrossRef]

- Shi, X.Y.; Liu, Y.; Li, D.J.; Chen, B.; Zeng, X.Q.; Lu, J.; Ding, W.J. Microstructure evolution and mechanical properties of an Mg-Gd alloy subjected to surface mechanical attrition treatment. Mater. Sci. Eng. A 2015, 630, 146–154. [Google Scholar] [CrossRef]

- Barnett, M.R. A rationale for the strong dependence of mechanical twinning on grain size. Scr. Mater. 2008, 59, 696–698. [Google Scholar] [CrossRef]

- Fan, H.; Aubry, S.; Arsenlis, A.; El-Awady, J.A. Grain size effects on dislocation and twinning mediated plasticity in magnesium. Scr. Mater. 2016, 112, 50–53. [Google Scholar] [CrossRef]

- Huang, K.E.; Logé, R.E. A review of dynamic recrystallization phenomena in metallic materials. Mater. Des. 2016, 111, 548–574. [Google Scholar] [CrossRef]

- Sakai, T.; Belyakov, A.; Kaibyshev, R.; Miura, H.; Jonas, J.J. Dynamic and post-dynamic recrystallization under hot, cold and severe plastic deformation conditions. Prog. Mater. Sci. 2014, 60, 130–207. [Google Scholar] [CrossRef]

- Lou, X.; Li, M.; Boger, R.; Agnew, S.; Wagoner, R. Hardening evolution of AZ31B Mg sheet. Int. J. Plast. 2007, 23, 44–86. [Google Scholar] [CrossRef]

- Aitken, Z.H.; Fan, H.; El-Awady, J.A.; Greer, J.R. The effect of size, orientation and alloying on the deformation of AZ31 nanopillars. J. Mech. Phys. Solids 2015, 76, 208–223. [Google Scholar] [CrossRef]

- Cepeda-Jiménez, C.M.; Molina-Aldareguia, J.M.; Pérez-Prado, M.T. Origin of the twinning to slip transition with grain size refinement, with decreasing strain rate and with increasing temperature in magnesium. Acta Mater. 2015, 88, 232–244. [Google Scholar] [CrossRef]

- Zhang, Z.; Yuan, L.; Ma, J.; Zheng, M.; Shan, D.; Guo, B. Role of <a> and <c+ a> dislocations on the room-temperature grain boundary migration in a deformed Mg alloy. Int. J. Plast. 2024, 172, 103862. [Google Scholar]

- Tao, X.; Gao, Y.; Kang, J.; Wang, Y. Softening Effects Induced by Shot Peening for an Aluminum-Lithium Alloy. Met. Mater. Trans. A 2019, 51, 410–418. [Google Scholar] [CrossRef]

- Liu, H.; Gan, J.; Jiang, C.; Wu, W.; Guagliano, M. Work softening mechanism and microstructure evolution of nanostructured Mg-8Gd-3Y alloy during severe shot peening. Surf. Coat. Technol. 2022, 441, 128601. [Google Scholar] [CrossRef]

| Specimen | Yield Strength (MPa) | Tensile Strength (MPa) | Elongation (%) | Hardness (HV) |

|---|---|---|---|---|

| GW83 | 215 | 274 | 9 | 80 |

| Sample | Ra | Rz |

|---|---|---|

| Conventional SP | 2.88 | 15.41 |

| WSP | 4.59 | 23.38 |

| Domian Size (nm) | Microstrain | Dislocation Density (m−2) | ||||

|---|---|---|---|---|---|---|

| CSP | WSP | CSP | WSP | CSP | WSP | |

| 0 | 30 | 38 | 0.0059 | 0.00551 | 2.52 × 1015 | 2.10 × 1015 |

| 10 | 32 | 43 | 0.00534 | 0.00503 | 2.22 × 1015 | 1.75 × 1015 |

| 25 | 39 | 56 | 0.005 | 0.00452 | 1.85 × 1015 | 1.36 × 1015 |

| 50 | 53 | 78 | 0.00391 | 0.00336 | 1.258 × 1015 | 7.79 × 1014 |

| 100 | 166 | 200 | 0.0021 | 0.00131 | 2.24 × 1014 | 1.35 × 1014 |

| 150 | 227 | 236 | 0.00139 | 0.00111 | 8.87 × 1013 | 6.53 × 1013 |

| 200 | 237 | 236 | 0.00105 | 0.000879 | 5.98 × 1013 | 4.72 × 1013 |

| 250 | 237 | 233 | 0.00121 | 0.00119 | 5.43 × 1013 | 5.45 × 1013 |

| 0 | 10 | 25 | 50 | 100 | 150 | 200 | 250 | |

|---|---|---|---|---|---|---|---|---|

| CSP | −200.5 | −193 | −179 | −116 | −60.5 | −5.5 | 5 | 22.5 |

| WSP | −184.5 | −187 | −150 | −80 | −42 | −0.5 | 11 | 10.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, H.; Zhang, X.; Wei, X.; Gan, J.; Jiang, C. The Effect of Warm Shot Peening on Microstructure Evolution and Residual Stress in Gradient Nanostructured Mg-8Gd-3Y-0.4Zr Alloys. Coatings 2025, 15, 316. https://doi.org/10.3390/coatings15030316

Liu H, Zhang X, Wei X, Gan J, Jiang C. The Effect of Warm Shot Peening on Microstructure Evolution and Residual Stress in Gradient Nanostructured Mg-8Gd-3Y-0.4Zr Alloys. Coatings. 2025; 15(3):316. https://doi.org/10.3390/coatings15030316

Chicago/Turabian StyleLiu, Huabing, Xiang Zhang, Xiaoxiao Wei, Jin Gan, and Chuanhai Jiang. 2025. "The Effect of Warm Shot Peening on Microstructure Evolution and Residual Stress in Gradient Nanostructured Mg-8Gd-3Y-0.4Zr Alloys" Coatings 15, no. 3: 316. https://doi.org/10.3390/coatings15030316

APA StyleLiu, H., Zhang, X., Wei, X., Gan, J., & Jiang, C. (2025). The Effect of Warm Shot Peening on Microstructure Evolution and Residual Stress in Gradient Nanostructured Mg-8Gd-3Y-0.4Zr Alloys. Coatings, 15(3), 316. https://doi.org/10.3390/coatings15030316