Enhancing Strength and Ductility in the Nugget Zone of Friction Stir Welded X80 Pipeline Steel via Applying Cooling Medium

Abstract

1. Introduction

2. Experimental Procedure

3. Results and Discussion

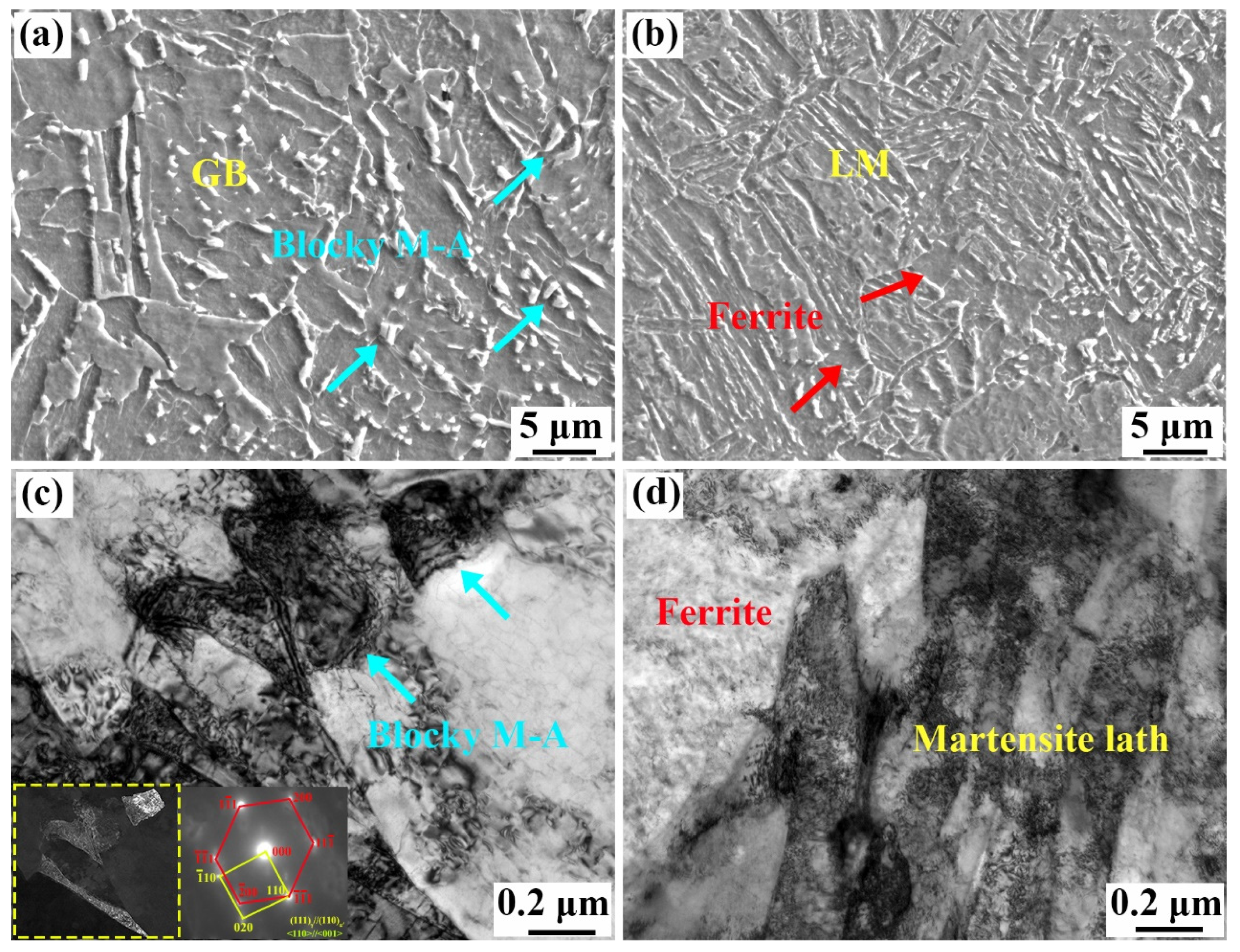

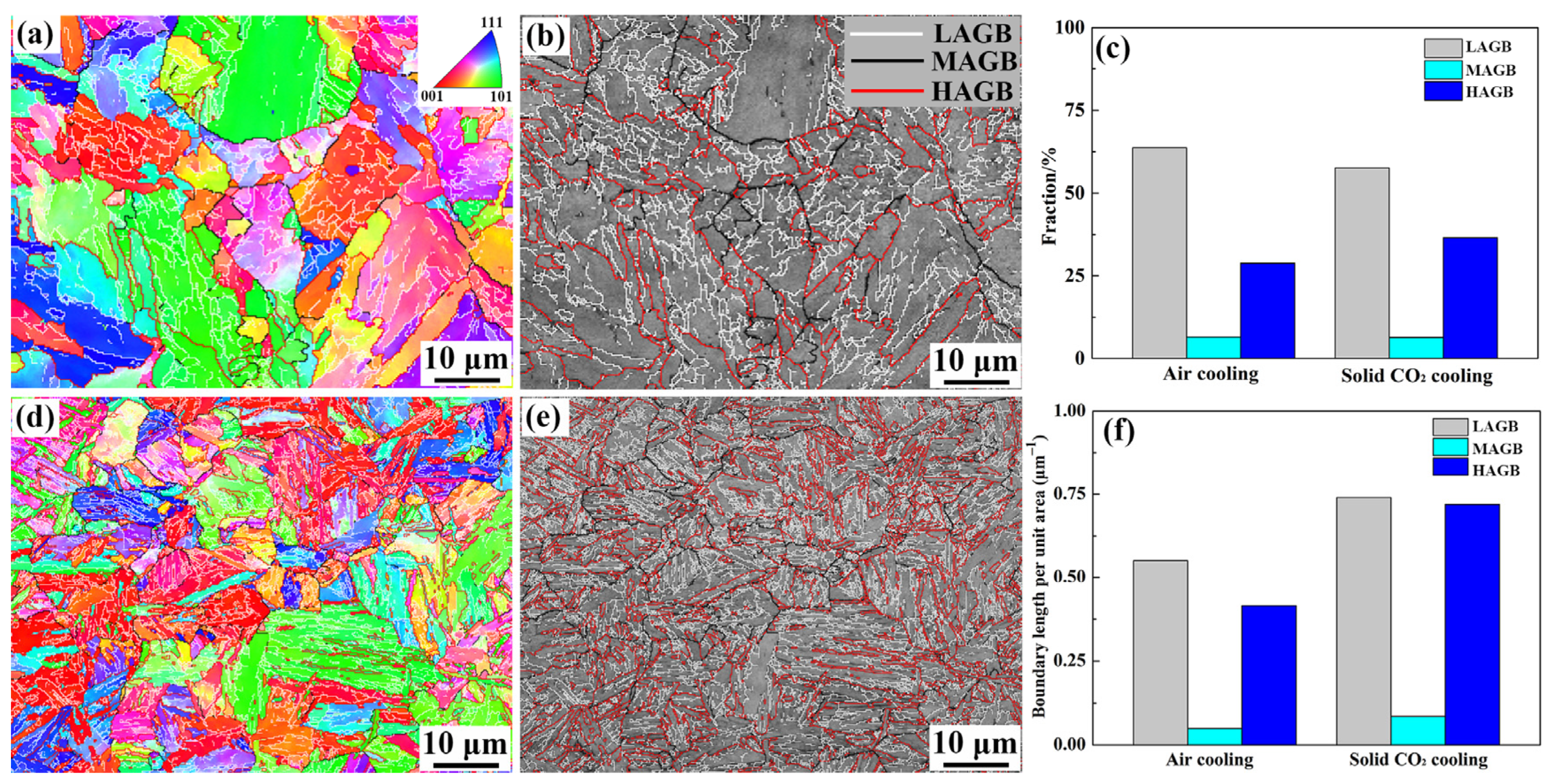

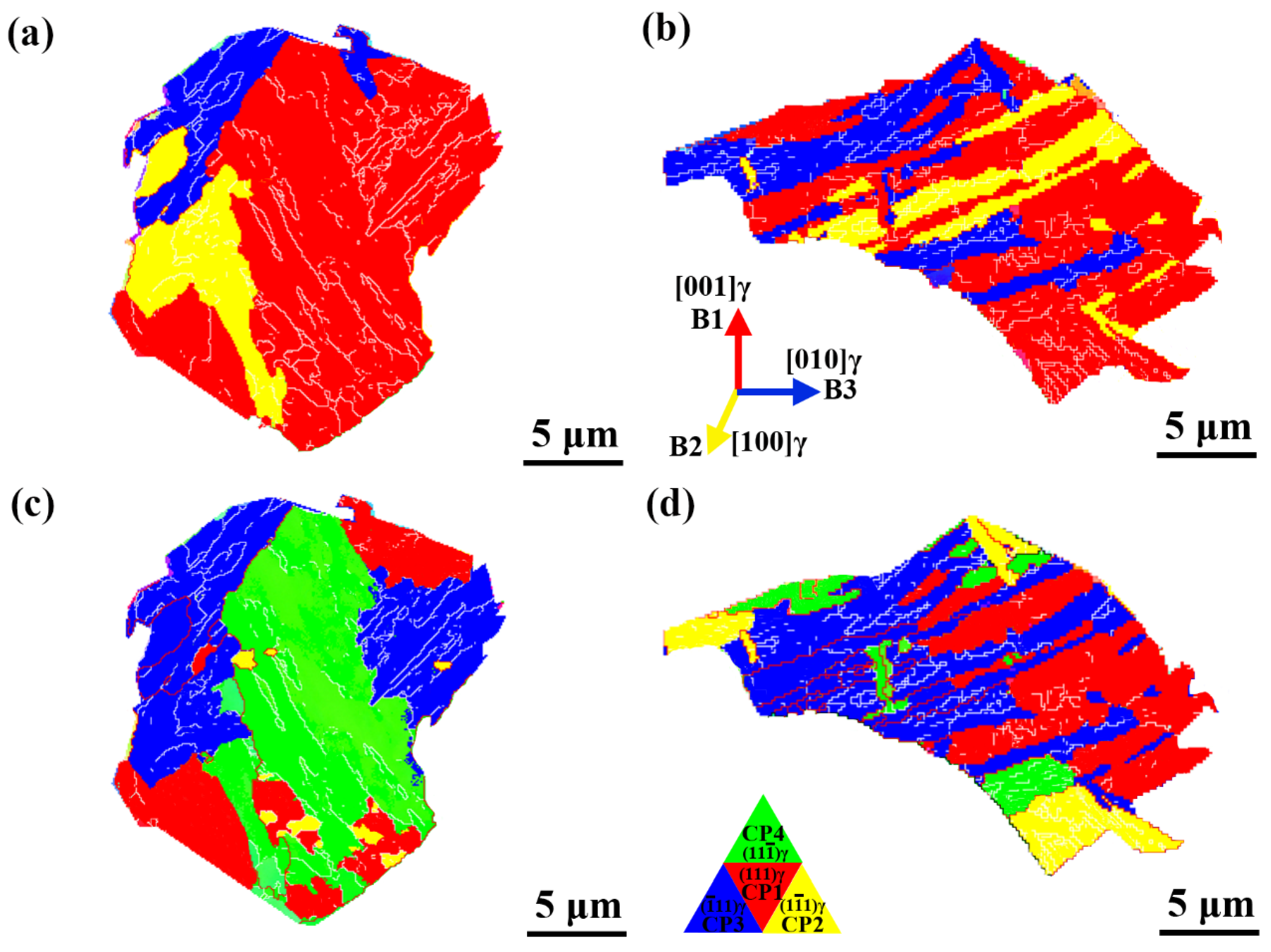

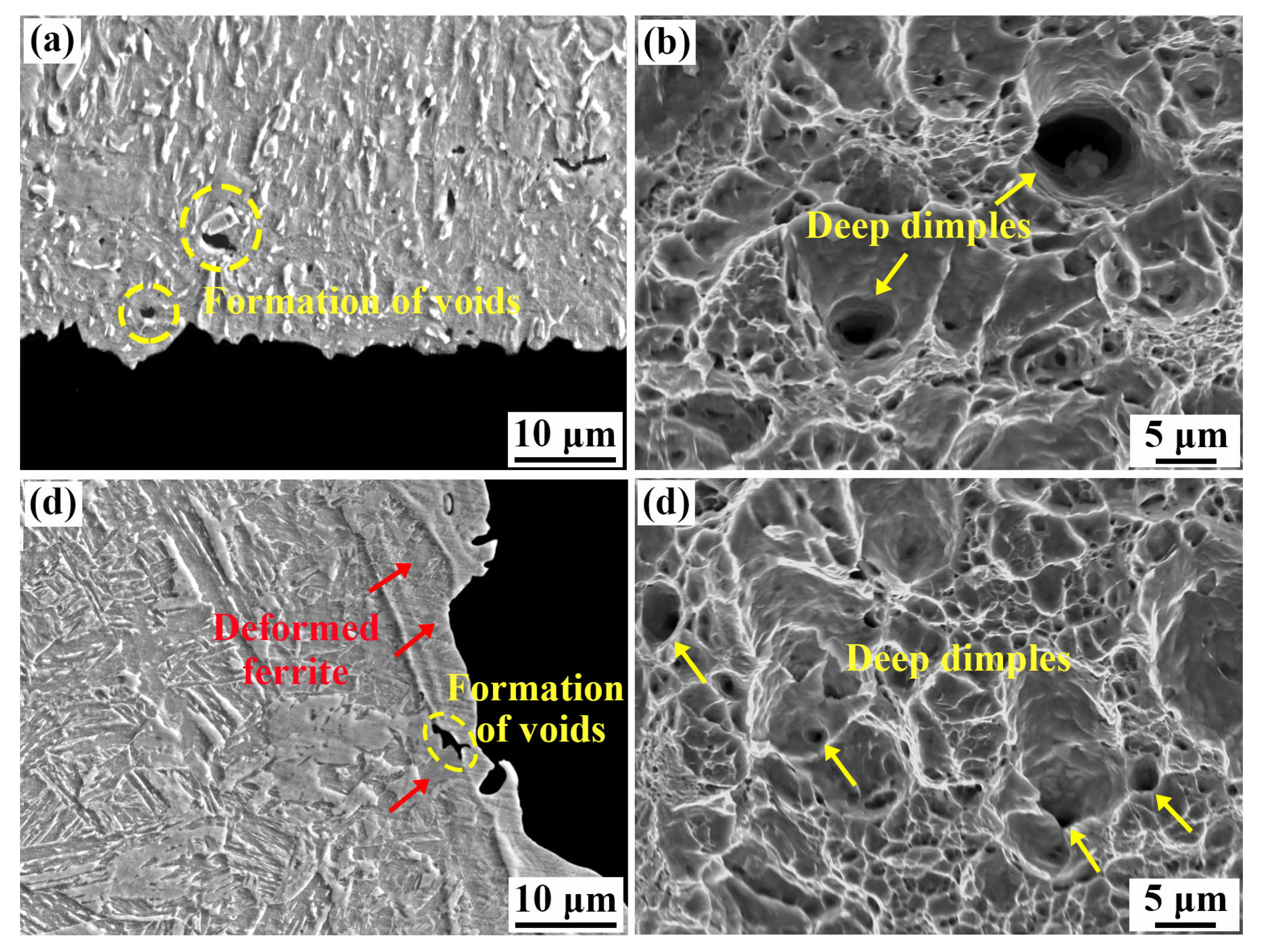

3.1. Microstructure Evolution

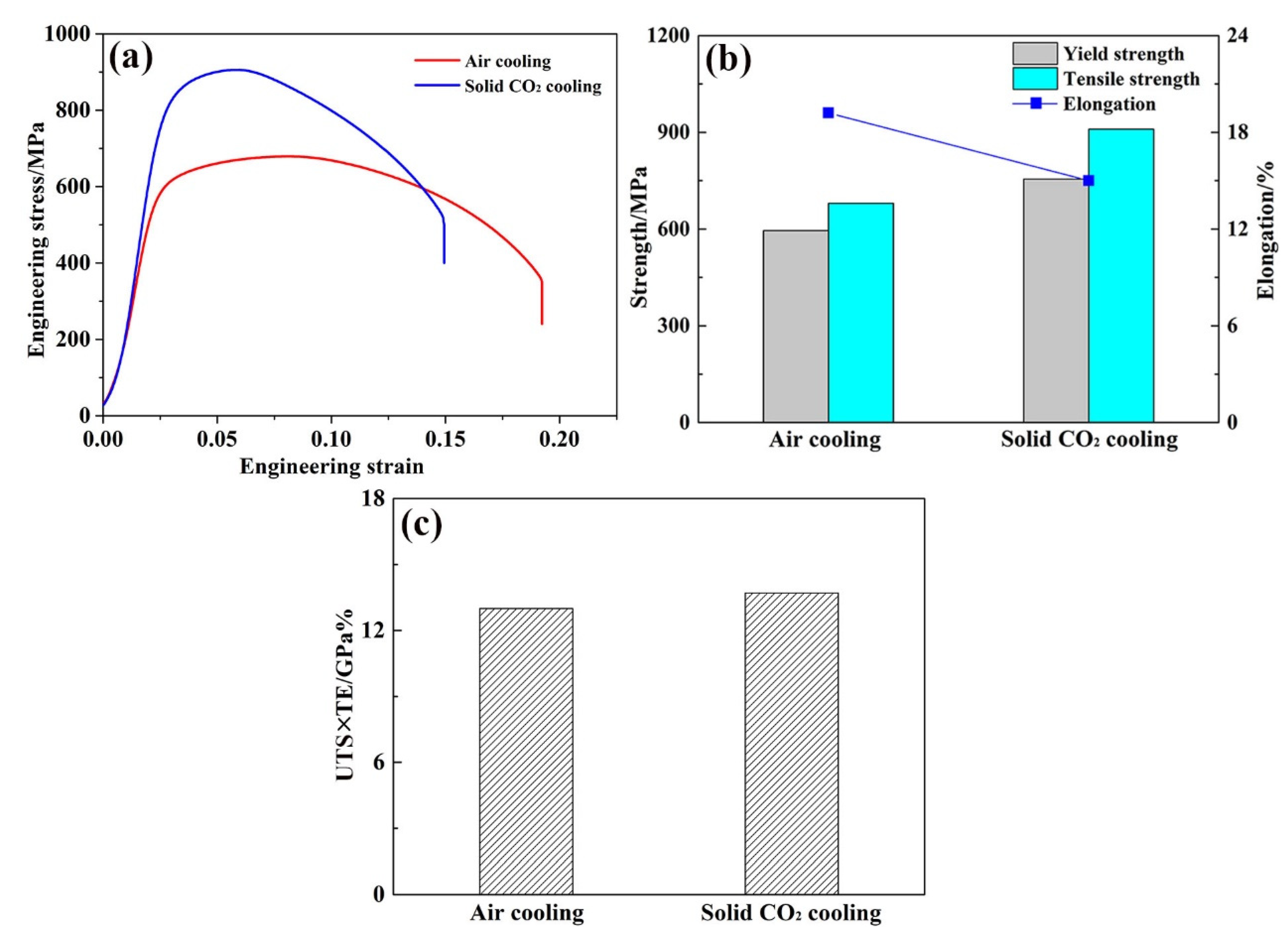

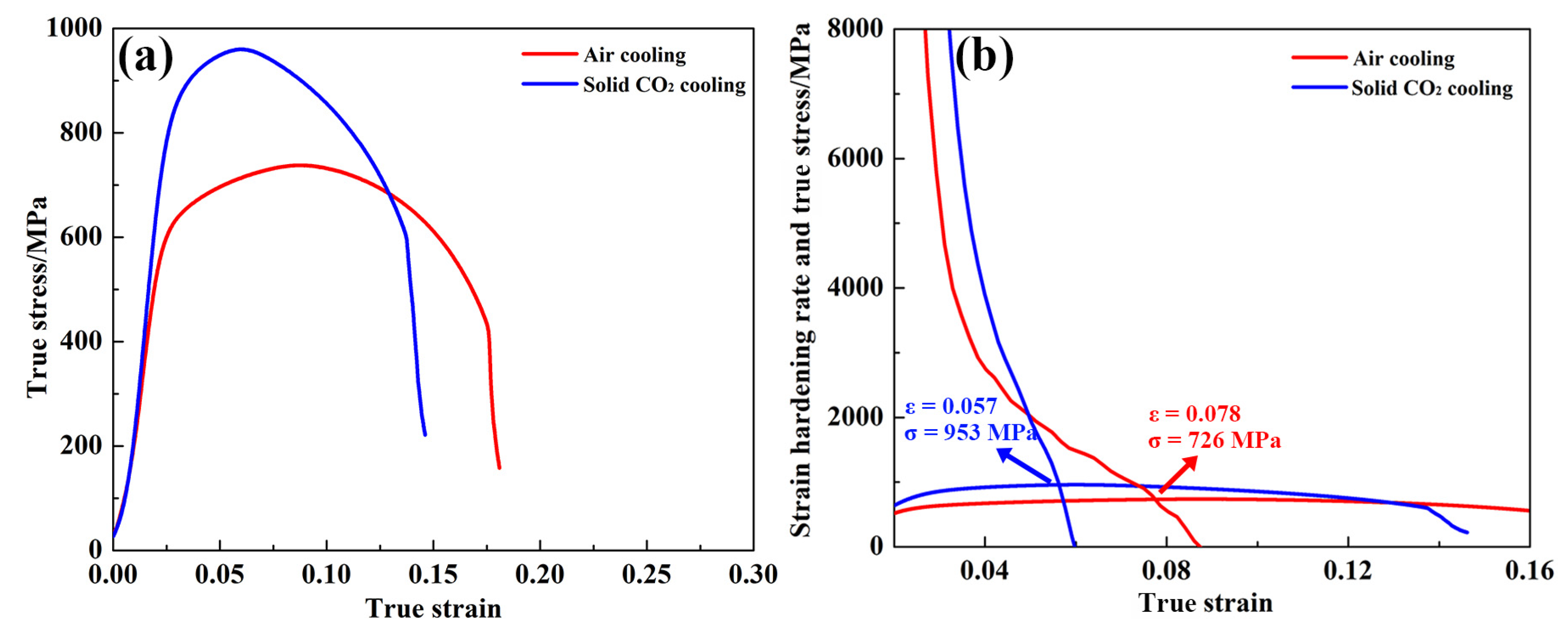

3.2. Mechanical Properties

4. Conclusions

- (1)

- Coarse GB was obtained in the NZ under air cooling, whereas a fine ferrite/martensite microstructure was identified in the NZ under solid CO2 cooling. The fraction of MAGBs and HAGBs obviously increased, while that of LAGBs decreased under solid CO2 cooling.

- (2)

- At air cooling, the variants were mainly distributed in the Bain1 group, causing the highest ratio of low-misorientation variant pairs, while a high ratio of high-misorientation variant pairs was obtained in the NZ under solid CO2 cooling.

- (3)

- At solid CO2 cooling, the excellent YS (755 MPa) of the NZ was obtained due to the dislocation strengthening and refinement grain strengthening. Furthermore, the NZ presented an ultra-high tensile strength (910 MPa) and utilizable elongation (15%) depending on consistently high work hardening rates caused by the generation of a fine ferrite/martensite microstructure.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Velázquez, J.C.; Hernández-Huerta, J.J.; Diaz-Cruz, M.; Hernández-Sánchez, E.; Cervantes-Tobón, A.; Capula-Colindres, S.I.; Cabrera-Sierra, R. Study on the influence of non-Metallic inclusions on the pitting corrosion of API 5L X60 steel. Coatings 2023, 13, 1040. [Google Scholar] [CrossRef]

- Yao, C.; Ming, H.L.; Chen, J.; Wang, J.Q.; Han, E.H. Effect of cold deformation on the hydrogen permeation behavior of X65 pipeline steel. Coatings 2023, 13, 280. [Google Scholar] [CrossRef]

- Cho, Y.H.; Lee, J.; Choo, W.Y.; Kang, J.; Han, H.N. Effect of separation on the fracture surface of pipeline steels with ferrite-bainite dual phases during drop weight tear test. Met. Mater. Int. 2022, 28, 1340–1348. [Google Scholar] [CrossRef]

- Duan, R.H.; Xie, G.M.; Luo, Z.A.; Xue, P.; Wang, C.; Misra, R.D.K.; Wang, G.D. Microstructure, crystallography, and toughness in nugget zone of friction stir welded high-strength pipeline steel. Mater. Sci. Eng. A 2020, 791, 139620. [Google Scholar] [CrossRef]

- Oi, X.N.; Huan, P.C.; Wang, X.N.; Shen, X.J.; Liu, Z.G.; Di, H.S. Effect of microstructure homogeneity on the impact fracture mechanism of X100 pipeline steel lase-MAG hybrid welds with an alternating magnetic field. Mater. Sci. Eng. A 2022, 851, 143656. [Google Scholar]

- Cheng, X.D.; Huang, R.K.; Xu, L.Y.; Ma, C.; Zhu, X.J. Parametric study on the trench designing for X80 buried steel pipeline crossing oblique-reverse fault. Soil Dyn. Earthq. Eng. 2021, 150, 106824. [Google Scholar] [CrossRef]

- Jia, Y.Z.; Wang, J.Q.; Han, E.H.; Ke, W. Stress corrosion cracking of X80 pipeline steel in Near-Neutral Ph environment under constant load tests with and without preload. J. Mater. Sci. Technol. 2011, 27, 1039–1046. [Google Scholar] [CrossRef]

- Midawi, A.R.H.; Santos, E.B.F.; Huda, N.; Sinha, A.K.; Lazor, R.; Gerlich, A.P. Microstructures and mechanical properties in two X80 weld metals produced using similar heat input. J. Mater. Process. Tech. 2015, 226, 272–279. [Google Scholar] [CrossRef]

- Jorge, L.J.; Candido, V.S.; Silva, A.C.R.; Garcia, F.C.; Pereira, A.C.; Luz, F.S.; Monteiro, S.N. Mechanical properties and microstructure of SMAW welded and thermically treated HSLA-80 steel. J. Mater. Res. Technol. 2018, 7, 598–605. [Google Scholar] [CrossRef]

- Midawi, A.R.H.; Simha, C.H.M.; Gerlich, A.P. Assessment of yield strength mismatch in X80 pipeline steel welds using instrumented indentation. Int. J. Press. Vessel. Pip. 2018, 168, 258–268. [Google Scholar] [CrossRef]

- Li, K.; Liu, X.M.; Zhao, Y. Research status and prospect of friction stir processing technology. Coatings 2019, 9, 129. [Google Scholar] [CrossRef]

- Ehiasarian, A.; Purandare, Y.; Sugumaran, A.; Hovsepian, P.; Hatto, P.; Backer, J.D. Improving the quality of friction stir welds in aluminium alloys. Coatings 2021, 11, 539. [Google Scholar] [CrossRef]

- Meng, X.C.; Huang, Y.X.; Cao, J.; Cao, J.J.; Santos, J.F. Recent progress on control strategies for inherent issues in friction. Prog. Mater. Sci. 2021, 115, 100706. [Google Scholar] [CrossRef]

- Magalhães, V.M.; Leitão, C.; Rodrigues, D.M. Friction stir welding industrialisation and research status. Sci. Technol. Weld. Join. 2018, 23, 400–409. [Google Scholar] [CrossRef]

- Aydin, H.; Nelson, T.W. Microstructure and mechanical properties of hard zone in friction stir welded X80 pipeline steel relative to different heat input. Mater. Sci. Eng. A 2013, 586, 313–322. [Google Scholar] [CrossRef]

- Santos, T.F.A.; Hermenegildo, T.F.C.; Afonso, C.R.M.; Marinho, R.R.; Paes, M.T.P.; Ramirez, A.J. Fracture toughness of ISO 3183 X80M (API 5L X80) steel friction stir welds. Eng. Fract. Mech. 2010, 77, 2937–2945. [Google Scholar] [CrossRef]

- Avila, J.A.; Rodriguez, J.; Mei, P.R.; Ramirez, A.J. Microstructure and fracture toughness of multipass friction stir welded joints of API-5L-X80 steel plates. Mater. Sci. Eng. A 2016, 673, 257–265. [Google Scholar] [CrossRef]

- Xie, G.M.; Duan, R.H.; Xue, P.; Ma, Z.Y.; Liu, H.L.; Luo, Z.A. Microstructure and mechanical properties of X80 pipeline steel joints by friction stir welding under various cooling conditions. Acta. Metall. Sin. (Engl. Lett.). 2020, 33, 88–102. [Google Scholar] [CrossRef]

- Xue, P.; Komizo, Y.C.; Ma, Z.Y. Microstructure and mechanical properties of friction stir welded X80 pipeline steel joint under additional cooling. In Proceedings of the 1st International Joint Symposium on Joining and Welding, Osaka, Japan, 6–8 November 2017. [Google Scholar]

- Yang, X.C.; Di, X.J.; Liu, X.G.; Wang, D.P.; Li, C.N. Effects of heat input on microstructure and fracture toughness of simulated coarse-grained heat affected zone for HSLA steels. Mater. Charact. 2019, 155, 109818. [Google Scholar] [CrossRef]

- Wang, X.L.; Wang, Z.Q.; Dong, L.L.; Shang, C.J.; Ma, X.P.; Subramanian, S.V. New insights into the mechanism of cooling rate on the impact toughness of coarse grained heat affected zone from the aspect of variant selection. Mater. Sci. Eng. A 2017, 704, 448–458. [Google Scholar] [CrossRef]

- Sun, M.Y.; Wang, X.L.; Wang, Z.Q.; Wang, X.M.; Li, X.C.; Yan, L.; Misra, R.D.K. The critical impact of intercritical deformation on variant pairing of bainite/martensite in dual-phase steels. Mater. Sci. Eng. A 2020, 771, 138668. [Google Scholar] [CrossRef]

- Takayama, T.; Miyamoto, G.; Furuhara, T. Effects of transformation temperature on variant pairing of bainitic ferrite in low carbon steel. Acta Mater. 2012, 33, 2387–2396. [Google Scholar] [CrossRef]

- Wang, X.L.; Wang, Z.Q.; Ma, X.P.; Subramanian, S.V.; Xie, Z.J.; Shang, C.J.; Li, X.C. Analysis of impact toughness scatter in simulated coarse-grained HAZ of E550 grade offshore engineering steel from the aspect of crystallographic structure. Mater. Charact. 2018, 140, 312–319. [Google Scholar] [CrossRef]

- Altuna, M.A.; Iza-Mendia, A.; Gutiérrez, I. Precipitation of Nb in ferrite after austenite conditioning. Part II: Strengthening contribution in high-strength low-alloy (HSLA) steels. Metall. Mater. Trans. A 2012, 43, 4571–4586. [Google Scholar] [CrossRef]

- Charleux, M.; Poole, W.J.; Militzer, M.; Deschamps, A. Precipitation behavior and its effect on strengthening of an HSLA-Nb/Ti steel. Metall. Mater. Trans. A 2001, 32, 1635–1647. [Google Scholar] [CrossRef]

- Gutiérrez, I.; Altuna, M.A. Work-hardening of ferrite and microstructure-based modeling of its mechanical behaviour under tension. Acta Mater. 2008, 56, 4682–4690. [Google Scholar] [CrossRef]

- Kostryzhev, A.G.; Shahrani, A.A.; Zhu, C.; Cairney, J.M.; Ringer, S.P.; Killmore, C.R.; Pereloma, E.V. Effect of niobium clustering and precipitation on strength of an NbTi-microalloyed ferritic steel. Mater. Sci. Eng. A 2014, 607, 226–235. [Google Scholar] [CrossRef]

- Xue, P.; Xiao, B.L.; Wang, W.G.; Zhang, Q.; Wang, D.; Wang, Q.Z.; Ma, Z.Y. Achieving ultrafine dual-phase structure with superior mechanical property in friction stir processed plain low carbon steel. Mater. Sci. Eng. A 2013, 575, 30–34. [Google Scholar] [CrossRef]

- Wang, Y.Q.; Duan, R.H.; Hu, J.; Luo, Z.A.; Ma, Z.Y.; Xie, G.M. Improvement in toughness and ductility of friction stir welded medium-Mn steel joint via post-welding annealing. J. Mater. Process. Tech. 2022, 306, 117621. [Google Scholar] [CrossRef]

- Ji, R.Y.; Zhang, H.C.; Chen, L.Y.; Cheng, L.W.; Luo, H.J.; Mao, J. Improving the strength and maintaining good ductility of as-forged Ti6Al4V alloy by regulating the microstructural defects. Mater. Sci. Eng. A 2024, 911, 146913. [Google Scholar] [CrossRef]

- Wang, H.S.; Zhang, Y.X.; Yuan, G.; Kang, J.; Wang, Y.; Misra, R.D.K.; Wang, G.D. Significance of cold rolling reduction on Lüders band formation and mechanical behavior in cold-rolled intercritically annealed medium-Mn steel. Mater. Sci. Eng. A 2018, 737, 176–181. [Google Scholar] [CrossRef]

- Duan, R.H.; Wang, Y.Q.; Luo, Z.A.; Wang, G.D.; Xie, G.M. Achievement of excellent strength and plasticity in the nugget zone of friction stir welded bainitic steel and its deformation behavior. J. Mater. Res. Technol. 2022, 20, 3381–3390. [Google Scholar] [CrossRef]

- Bouaziz, O.; Allain, S.; Scott, C. Effect of grain and twin boundaries on the hardening mechanisms of twinning-induced plasticity steels. Scr. Mater. 2008, 58, 484–487. [Google Scholar] [CrossRef]

- Duan, R.H.; Xie, G.M.; Xue, P.; Ma, Z.Y.; Luo, Z.A.; Wang, C.; Misra, R.D.K.; Wang, G.D. Microstructural refinement mechanism and its effect on toughness in the nugget zone of high-strength pipeline steel by friction stir welding. J. Mater. Sci. Technol. 2021, 93, 221–231. [Google Scholar] [CrossRef]

- Wang, J.; Li, W.; Zhu, X.D.; Zhang, L.Q. Effect of martensite morphology and volume fraction on the low-temperature impact toughness of dual-phase steels. Mater. Sci. Eng. A 2022, 832, 142424. [Google Scholar] [CrossRef]

| C | Si | Mn | Nb | P | V | Fe |

|---|---|---|---|---|---|---|

| 0.04 | 0.23 | 1.6 | 0.05 | 0.006 | 0.03 | Bal. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Duan, R.; Xie, G.; Qi, X.; Wang, Z.; Chen, S.; Dong, Y. Enhancing Strength and Ductility in the Nugget Zone of Friction Stir Welded X80 Pipeline Steel via Applying Cooling Medium. Coatings 2025, 15, 260. https://doi.org/10.3390/coatings15030260

Duan R, Xie G, Qi X, Wang Z, Chen S, Dong Y. Enhancing Strength and Ductility in the Nugget Zone of Friction Stir Welded X80 Pipeline Steel via Applying Cooling Medium. Coatings. 2025; 15(3):260. https://doi.org/10.3390/coatings15030260

Chicago/Turabian StyleDuan, Ruihai, Guangming Xie, Xiaonan Qi, Zhaojie Wang, Shujin Chen, and Ying Dong. 2025. "Enhancing Strength and Ductility in the Nugget Zone of Friction Stir Welded X80 Pipeline Steel via Applying Cooling Medium" Coatings 15, no. 3: 260. https://doi.org/10.3390/coatings15030260

APA StyleDuan, R., Xie, G., Qi, X., Wang, Z., Chen, S., & Dong, Y. (2025). Enhancing Strength and Ductility in the Nugget Zone of Friction Stir Welded X80 Pipeline Steel via Applying Cooling Medium. Coatings, 15(3), 260. https://doi.org/10.3390/coatings15030260