Preparation and Tribology of Textured Ti-6Al-4V with Thermal Oxide Coating

Abstract

1. Introduction

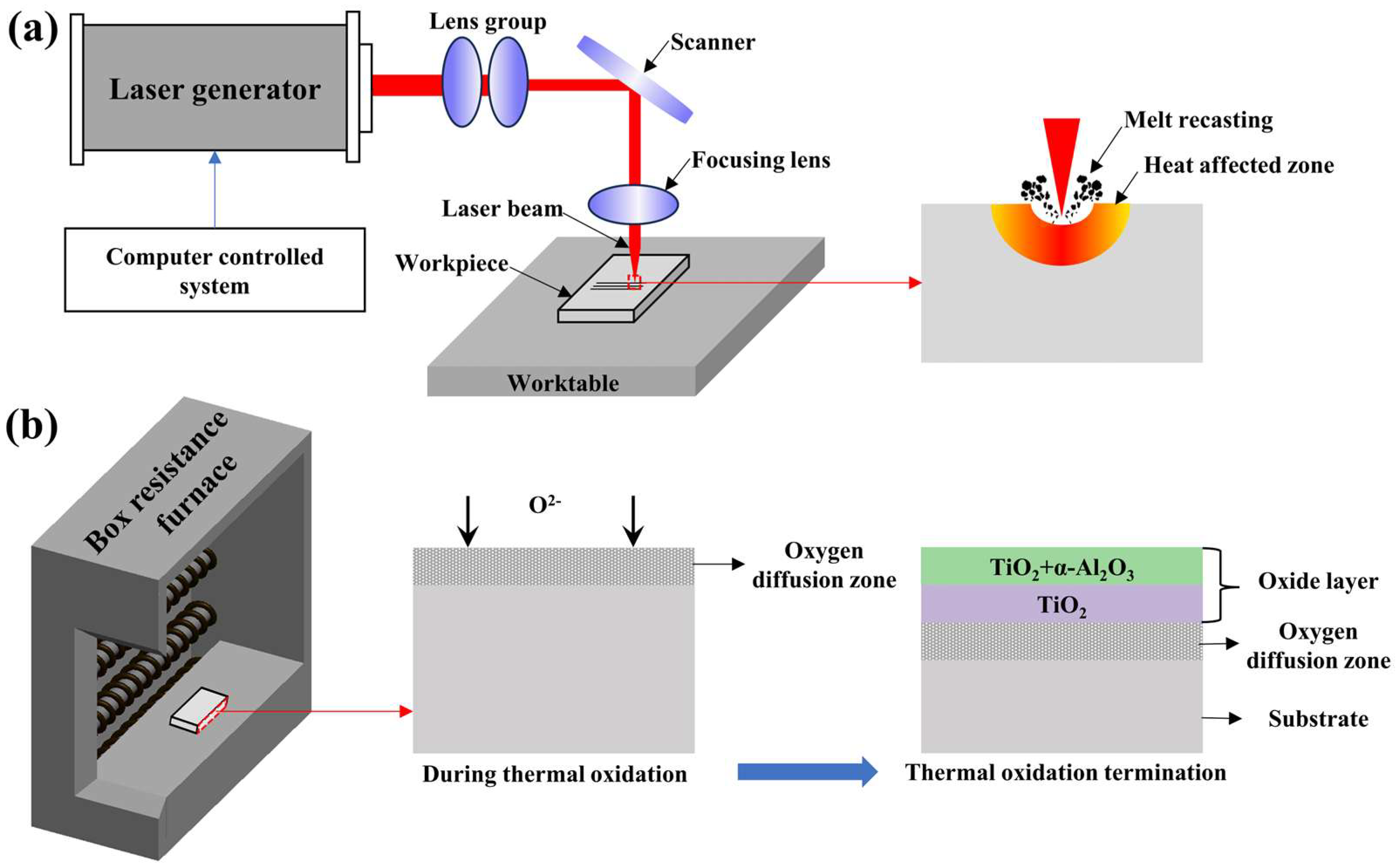

2. Materials and Methods

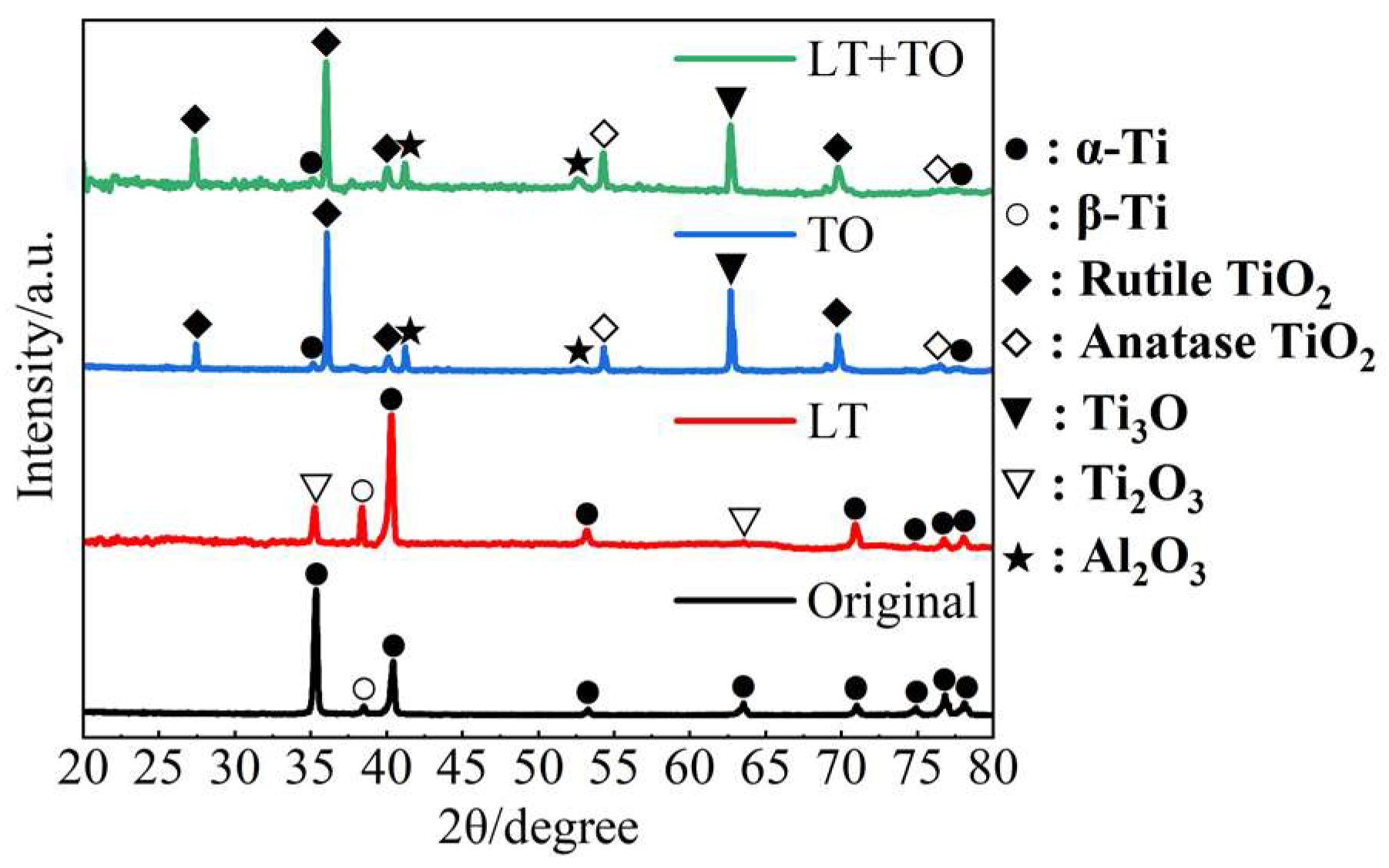

3. Results and Discussion

3.1. Surface Morphology

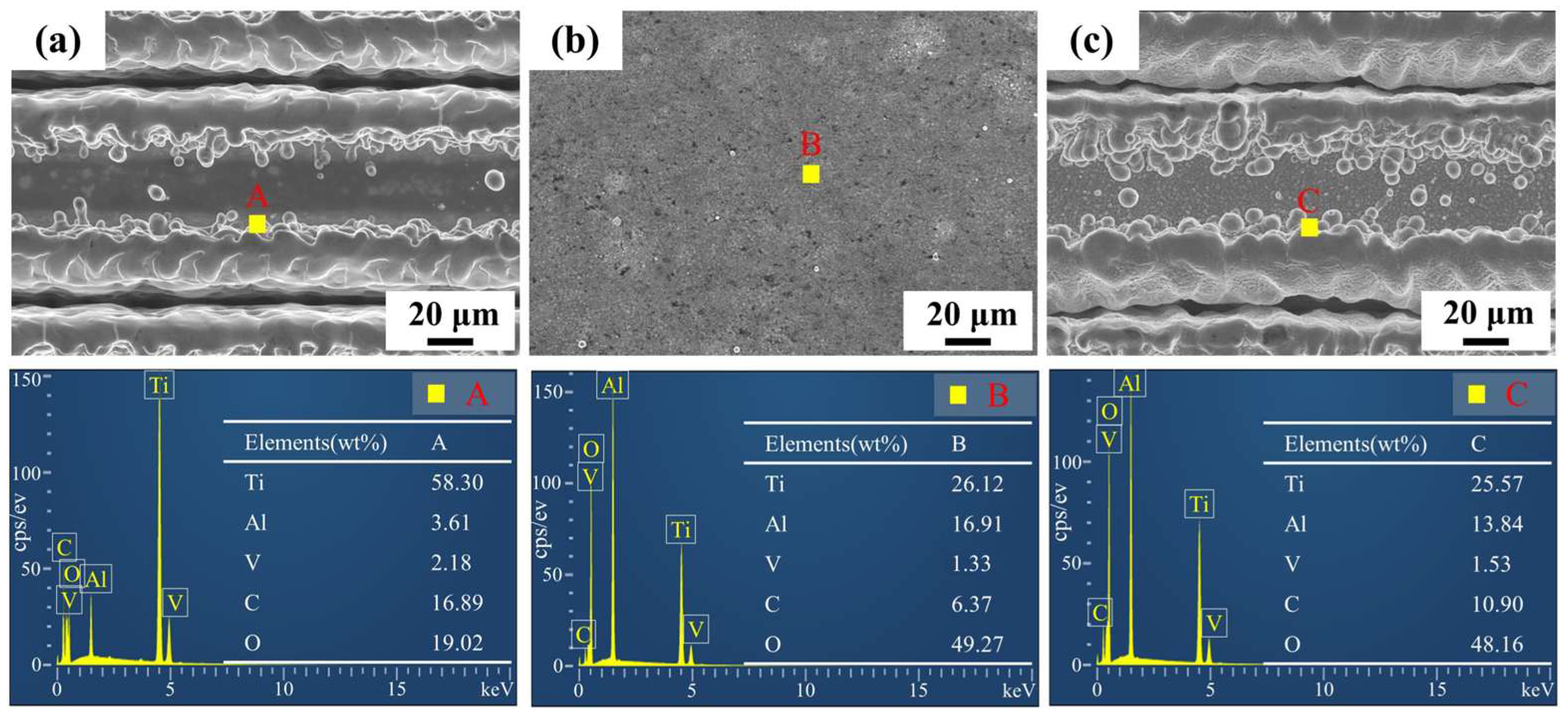

3.2. Surface Chemical Composition

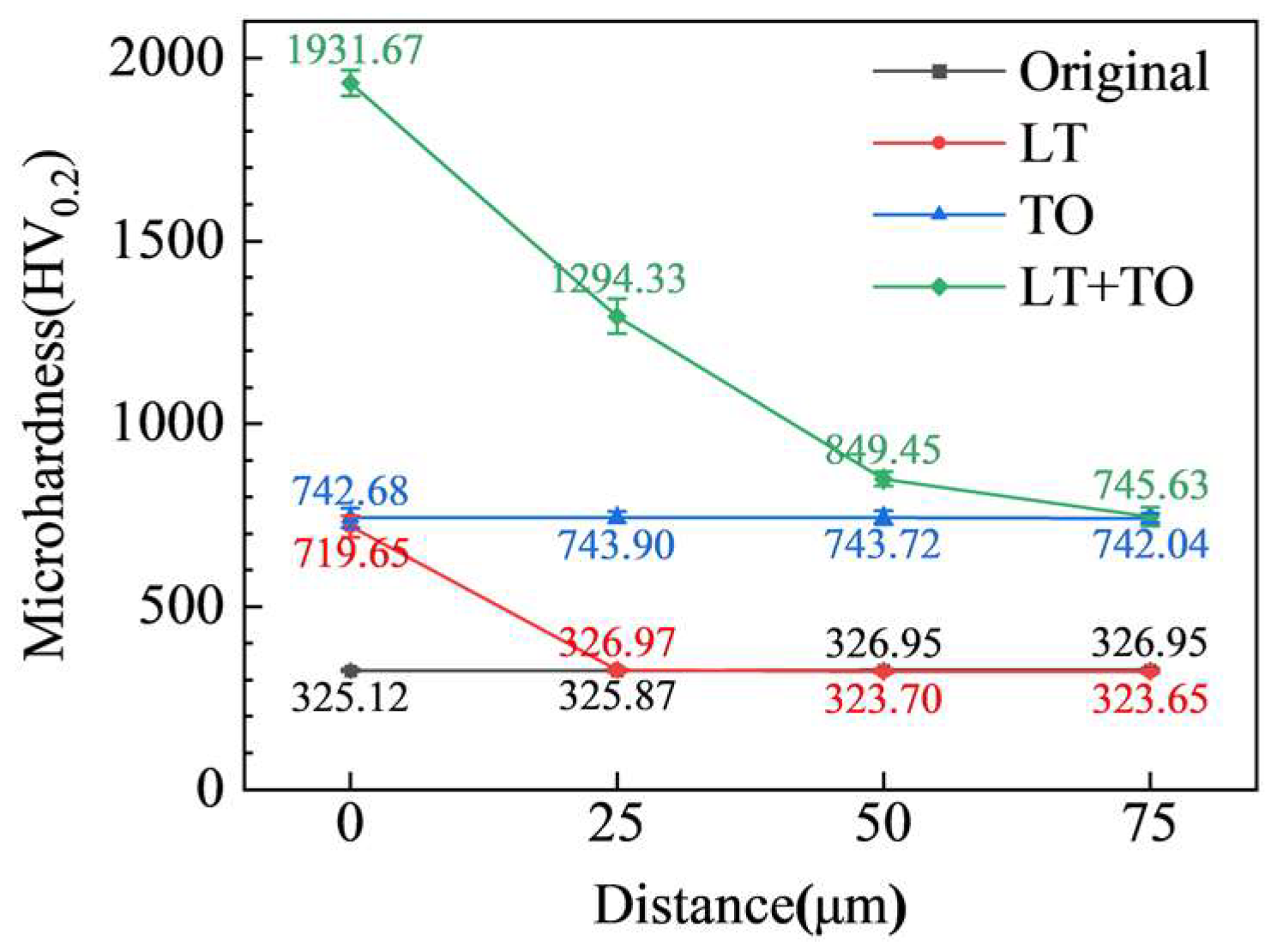

3.3. Surface Microhardness

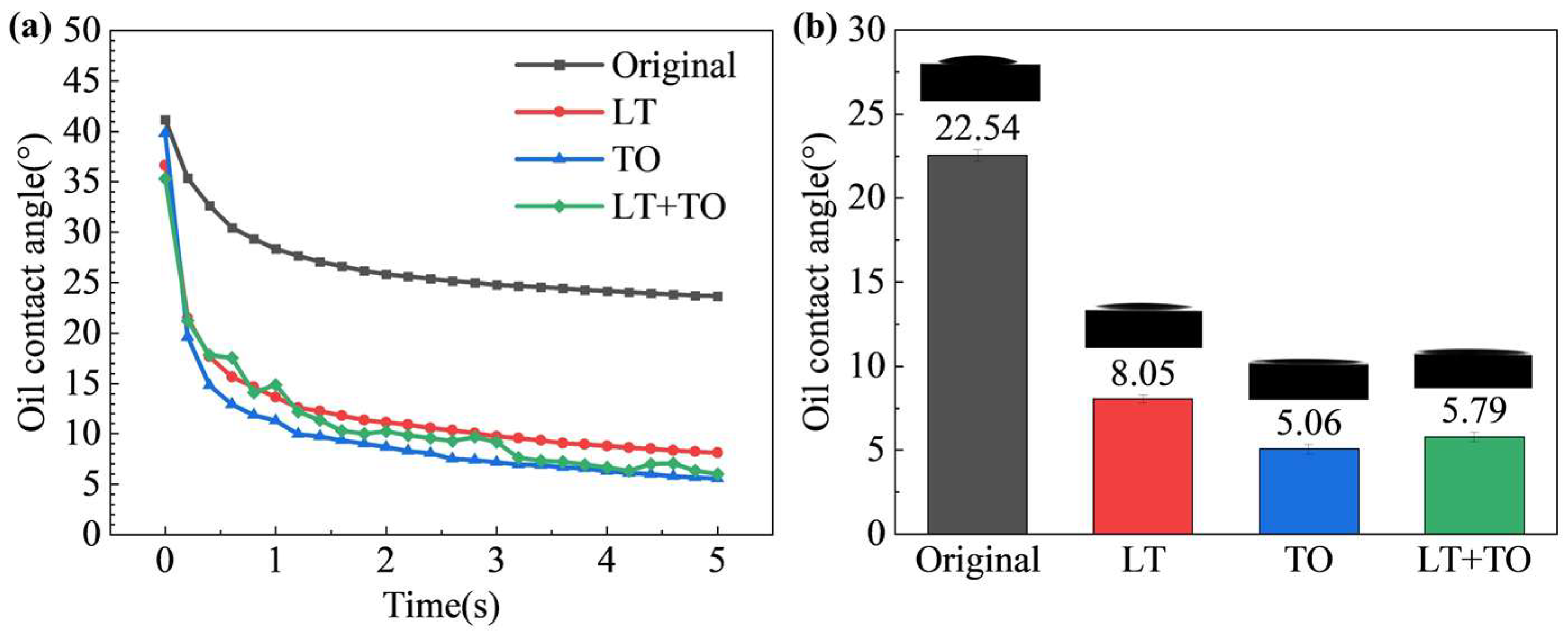

3.4. Surface Wettability

3.5. Friction and Wear

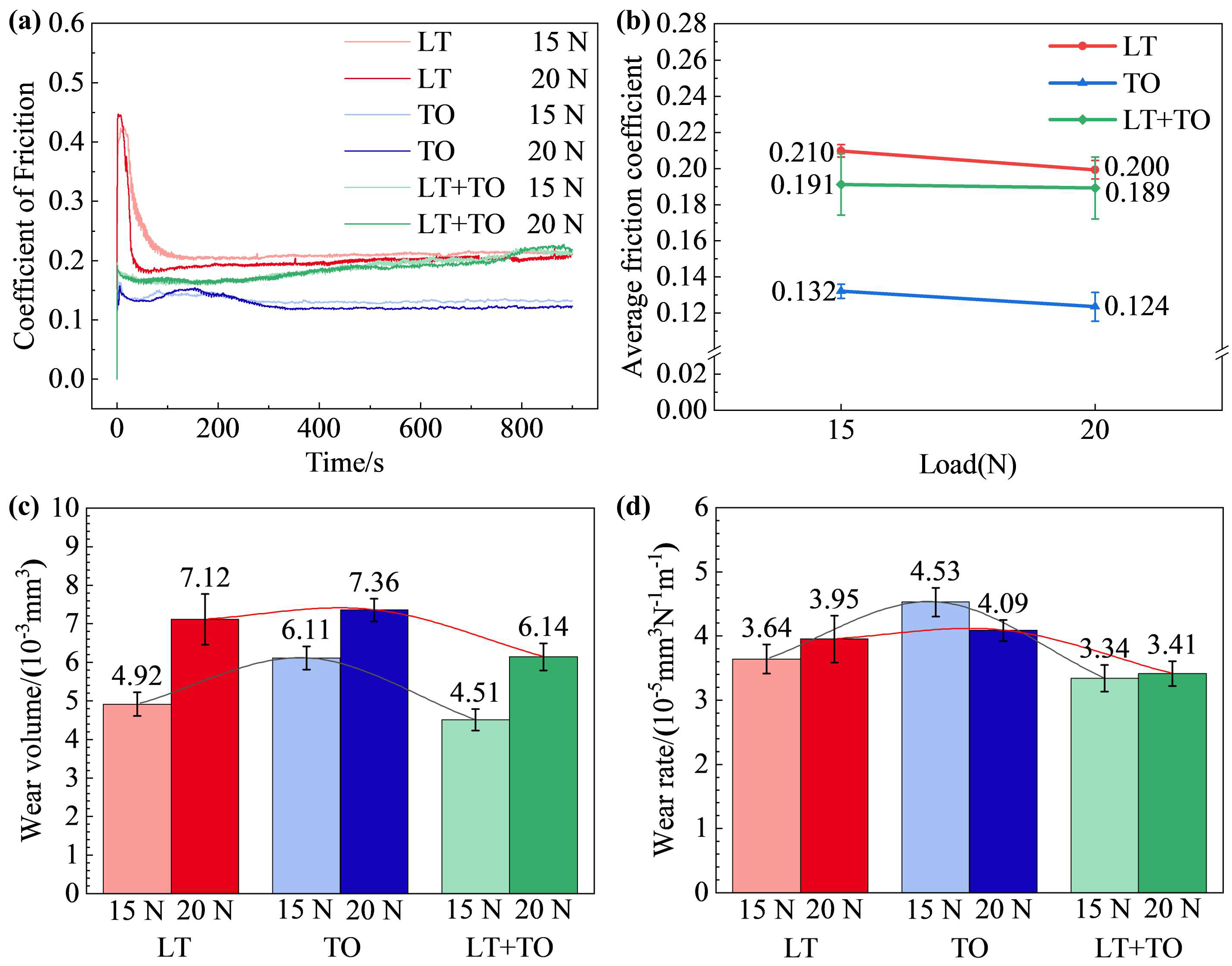

3.5.1. Tribological Properties

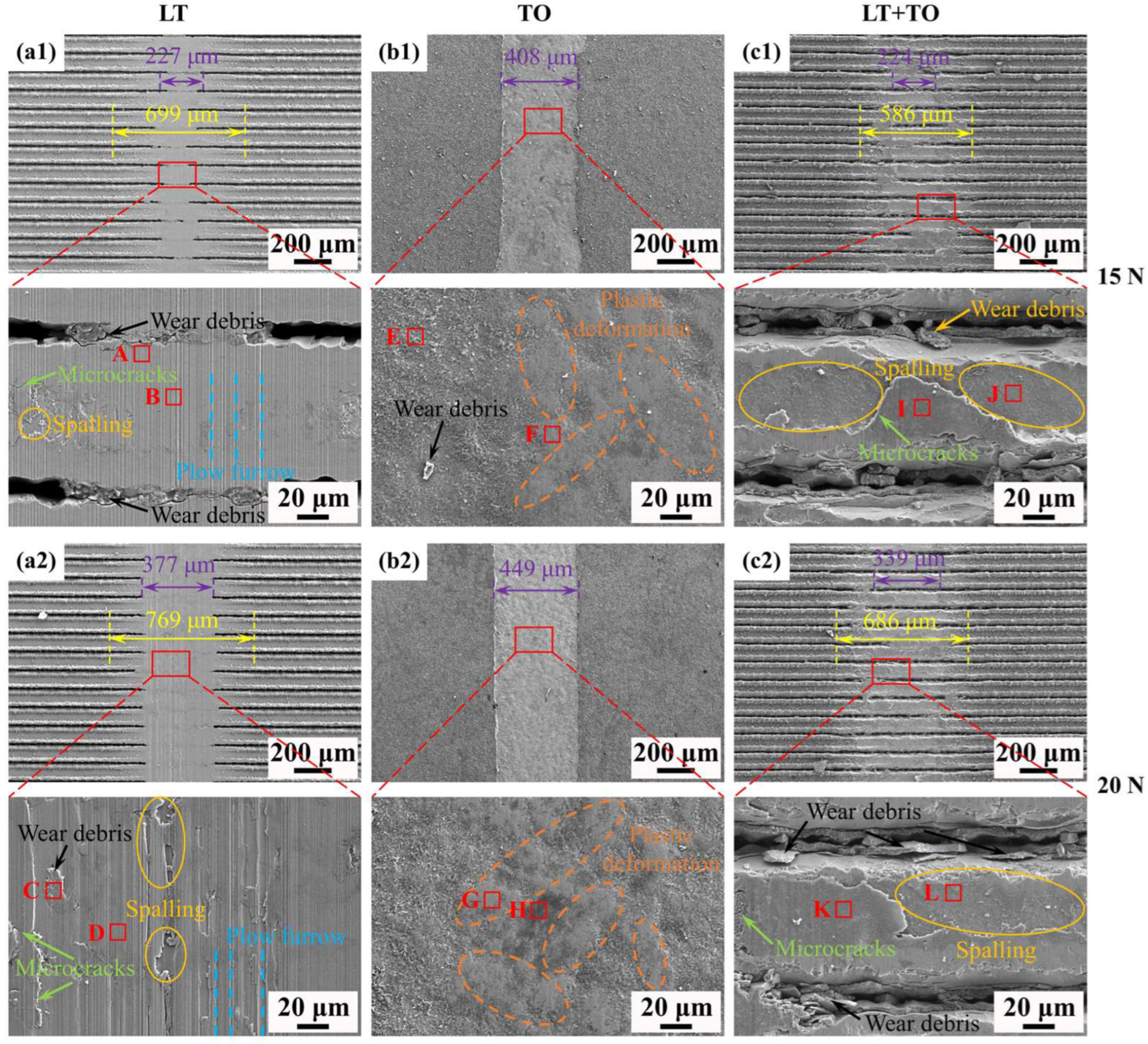

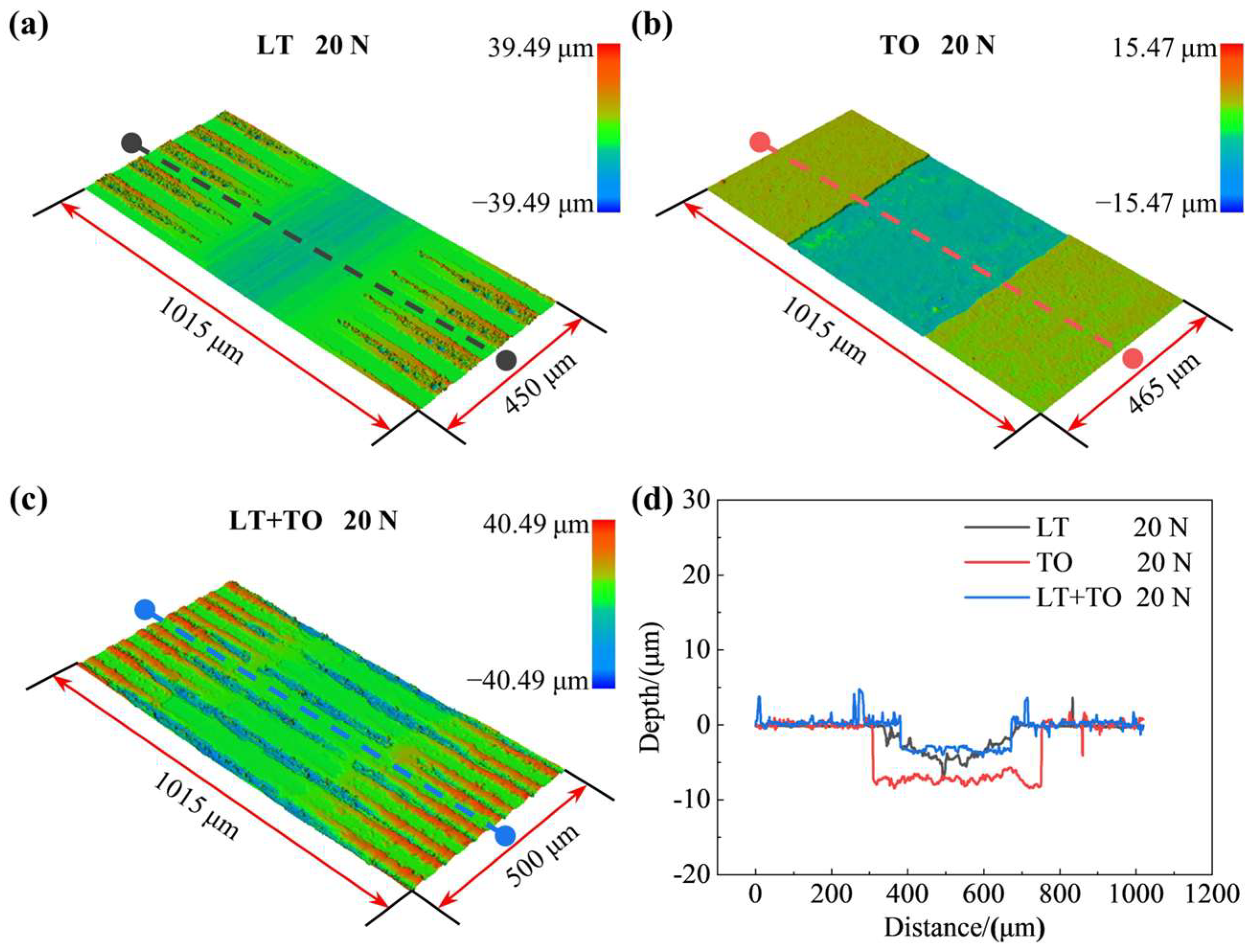

3.5.2. Wear Surface Morphology

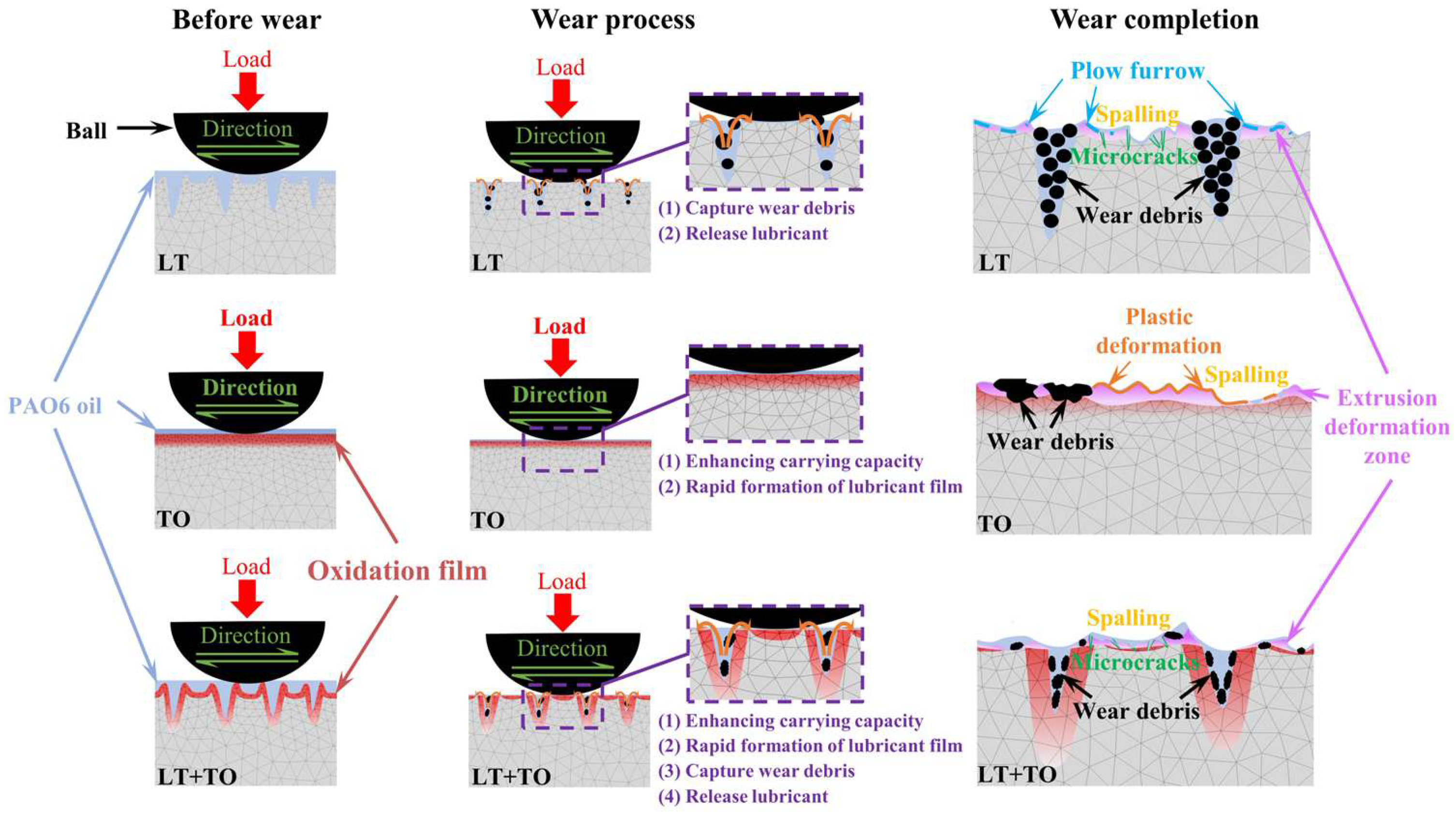

3.5.3. Wear Mechanisms

4. Conclusions

- (1)

- The LT + TO samples, affected by the combined influences of laser-induced heat affected zone and TO resulting in the formation of high-hardness rutile phase TiO2, exhibited significantly higher groove edge hardness (1932 HV0.2) compared to the LT samples (720 HV0.2). Relative to the original samples, all three surface treatment techniques effectively reduced the contact angle of PAO6 oil, enhancing wettability for the formation of lubricating oil films during sliding friction.

- (2)

- Compared to LT and TO samples, the LT + TO samples demonstrate reduced wear volume and wear rate. At a normal load of 15 N, the wear volume decreased by 8.33% and 26.19%, with corresponding decreases in wear rate by 8.24% and 26.27%. Under a normal load of 20 N, the wear volume decreased by 13.76% and 16.58%, and the wear rate decreased by 13.67% and 16.63%. The wear mechanisms observed were abrasive wear, adhesive wear, and fatigue wear for LT samples; adhesive wear and fatigue wear for TO samples; and adhesive wear and fatigue wear for LT + TO samples.

- (3)

- The surface of the LT + TO samples after processing combines the oil storage capability and debris capturing ability of the LT samples with the excellent load-bearing capacity of the TO samples. Furthermore, the composite treatment also effectively enhances the durability and reliability of the groove-type texture morphology, thereby significantly improving the tribological properties of Ti-6Al-4V alloy.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Gao, K.; Zhang, Y.; Yi, J.; Dong, F.; Chen, P. Overview of Surface Modification Techniques for Titanium Alloys in Modern Material Science: A Comprehensive Analysis. Coatings 2024, 14, 148. [Google Scholar] [CrossRef]

- Lei, X.; Lin, N.; Yuan, S.; Lei, C.; Nouri, M.; Liu, Z.; Yu, Y.; Zeng, Q.; Ma, G.; Li, D.; et al. Combining Laser Surface Texturing and Double Glow Plasma Surface Chromizing to Improve Tribological Performance of Ti6Al4V Alloy. Surf. Coat. Technol. 2024, 478, 130418. [Google Scholar] [CrossRef]

- Li, J.; Chen, S.; Liu, L.; Zhao, Y.; Huang, S.; Zhu, W.; Pan, H.; Ji, M.; Wu, X.; Chen, Y. Microstructural Evolution and Tribological Properties of TC6 Titanium Alloy Strengthened by Laser Peening Combined with Nitrogen Ion Implantation. Vacuum 2024, 222, 112964. [Google Scholar] [CrossRef]

- Li, G.; Ma, F.; Liu, P.; Qi, S.; Li, W.; Zhang, K.; Chen, X. Review of Micro-Arc Oxidation of Titanium Alloys: Mechanism, Properties and Applications. J. Alloys Compd. 2023, 948, 169773. [Google Scholar] [CrossRef]

- Ma, X. Application Mechanism and Anti-Corrosion Measures of Aluminum and Titanium Alloys in Marine Environment. Sci. Technol. Eng. Chem. Environ. Prot. 2023, 1, 3. [Google Scholar] [CrossRef]

- Shao, L.; Li, W.; Li, D.; Xie, G.; Zhang, C.; Zhang, C.; Huang, J. A Review on Combustion Behavior and Mechanism of Ti Alloys for Advanced Aero-Engine. J. Alloys Compd. 2023, 960, 170584. [Google Scholar] [CrossRef]

- Han, X.; Ma, J.; Tian, A.; Wang, Y.; Li, Y.; Dong, B.; Tong, X.; Ma, X. Surface Modification Techniques of Titanium and Titanium Alloys for Biomedical Orthopaedics Applications: A Review. Colloids Surf. B Biointerfaces 2023, 227, 113339. [Google Scholar] [CrossRef]

- Gupta, M.K.; Etri, H.E.; Korkmaz, M.E.; Ross, N.S.; Krolczyk, G.M.; Gawlik, J.; Yaşar, N.; Pimenov, D.Y. Tribological and Surface Morphological Characteristics of Titanium Alloys: A Review. Arch. Civ. Mech. Eng. 2022, 22, 72. [Google Scholar] [CrossRef]

- Li, Y.; Wang, X.; Yang, S.; Hou, L.; Wei, Y.; Zhang, Z.; Yang, X. Investigation on Wear Behavior of Cryogenically Treated Ti-6Al-4V Titanium Alloy under Dry and Wet Conditions. Materials 2019, 12, 2850. [Google Scholar] [CrossRef]

- Zhang, L.; Chen, L. A Review on Biomedical Titanium Alloys: Recent Progress and Prospect. Adv. Eng. Mater. 2019, 21, 1801215. [Google Scholar] [CrossRef]

- Cao, W.; Hu, T.; Fan, H.; Hu, L. Laser Surface Texturing and Tribological Behaviour under Solid Lubrication on Titanium and Titanium Alloy Surfaces. Int. J. Surf. Sci. Eng. 2021, 15, 50. [Google Scholar] [CrossRef]

- Wang, C.; Tian, P.; Cao, H.; Sun, B.; Yan, J.; Xue, Y.; Lin, H.; Ren, T.; Han, S.; Zhao, X. Enhanced Biotribological and Anticorrosion Properties and Bioactivity of Ti6Al4V Alloys with Laser Texturing. ACS Omega 2022, 7, 31081–31097. [Google Scholar] [CrossRef] [PubMed]

- Zeng, Q.; Sun, S.; Pang, Z.; Wei, X. Study on High-Temperature, Ultra-Low Wear Behaviors of Ti6Al4V Alloy with Thermal Oxidation Treatment. Coatings 2024, 14, 416. [Google Scholar] [CrossRef]

- Singh, K.; Raman, S.G.S. High Temperature Sliding Wear Behaviour of Ti6Al4V Thermal Oxidised for Different Oxidation Durations. Met. Mater. Int. 2023, 29, 357–368. [Google Scholar] [CrossRef]

- Kaminski, M.; Budzynski, P.; Wiertel, M.; Drozdziel, A. Use of Nitrogen Ion Implantation for Modification of the Tribological Properties of Titanium Alloy Ti6Al4V. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Bangkok, Thailand, 24–26 February 2018; IOP Publishing: Bristol, UK, 2018; Volume 421, p. 032013. [Google Scholar]

- Demirbaş, Ç.; Ayday, A. Effect of Ag Concentration on Structure and Wear Behaviour of Coatings Formed by Micro-Arc Oxidation on Ti6Al4 V Alloy. Surf. Eng. 2021, 37, 24–31. [Google Scholar] [CrossRef]

- Ozan, S.; Bilgin, A.; Kasman, Ş. Laser Textured Ti-6Al-7Nb Alloy for Biomedical Applications: An Investigation of Texturing Parameters on Surface Properties. Proc. Inst. Mech. Eng. 2023, 237, 1139–1153. [Google Scholar] [CrossRef]

- Shivakoti, I.; Kibria, G.; Das, S.; Sharma, A.; Pradhan, B.B.; Chatterjee, S. Laser Surface Texturing on Ti-6Al-4V. Mater. Manuf. Process. 2021, 36, 858–867. [Google Scholar] [CrossRef]

- Li, L.; Li, Z.; Xing, Z.; Guo, W.; Huang, Y.; Wang, H. Effect of Femtosecond Laser Bionic Texture on Anti-Wear Properties of Medical Ti-6Al-4 V. Tribol. Int. 2023, 190, 109062. [Google Scholar] [CrossRef]

- Wu, G.; Yin, Y.; Zhang, S.; Wang, Y.; Xiang, Y.; Li, L.; Yao, J. Effect of Laser Texturing on the Antiwear Properties of Micro-Arc Oxidation Coating Formed on Ti-6Al-4V. Surf. Coat. Technol. 2023, 453, 129114. [Google Scholar] [CrossRef]

- Xue, Y.; Shi, X.; Zhou, H.; Yang, Z.; Zhang, J.; Wu, C.; Xue, B. Effects of Textured Surface Combined with Sn-Ag-Cu Coating on Tribological Properties and Friction-Induced Noise of Ti-6Al-4V Alloy. Tribol. Trans. 2021, 64, 562–577. [Google Scholar] [CrossRef]

- Zhang, Q.; Li, Y.; Liang, F.; Zhang, H.; Wang, B.; Li, X.; Lin, Z.; Lin, Y.; Chen, X. Tailoring Tribological Characteristics in Titanium Alloys by Laser Surface Texturing and 2D Ti3C2T MXene Nanocoating. Adv. Funct. Mater. 2024, 34, 2401231. [Google Scholar] [CrossRef]

- Guleryuz, H.; Cimenoglu, H. Surface Modification of a Ti–6Al–4V Alloy by Thermal Oxidation. Surf. Coat. Technol. 2005, 192, 164–170. [Google Scholar] [CrossRef]

- Cao, L.; Wan, Y.; Yang, S.; Pu, J. The Tribocorrosion and Corrosion Properties of Thermally Oxidized Ti6Al4V Alloy in 0.9 Wt.% NaCl Physiological Saline. Coatings 2018, 8, 285. [Google Scholar] [CrossRef]

- Pitchi, C.S.; Priyadarshini, A.; Narala, S.K.R. Synthesis of TiO2 Coatings by Thermal Oxidation with a Suitable Cooling Process for Improved Wettability. Surf. Eng. 2021, 37, 1586–1595. [Google Scholar] [CrossRef]

- Lin, N.; Xie, R.; Zou, J.; Qin, J.; Wang, Y.; Yuan, S.; Li, D.; Zhao, L.; Zhang, L.; Wang, Z. Surface Damage Mitigation of Titanium and Its Alloys via Thermal Oxidation: A Brief Review. Rev. Adv. Mater. Sci. 2019, 58, 132–146. [Google Scholar] [CrossRef]

- Sun, Q.; Hu, T.; Fan, H.; Zhang, Y.; Hu, L. Thermal Oxidation Behavior and Tribological Properties of Textured TC4 Surface: Influence of Thermal Oxidation Temperature and Time. Tribol. Int. 2016, 94, 479–489. [Google Scholar] [CrossRef]

- Xu, Z.; Lv, X.; Wang, X.; Feng, J.; Liu, X.; Peng, J.; Wu, H. Electrochemically Assisted Laser Surface Microtexture Preparation and Tribological Properties Research. J. Manuf. Process. 2024, 122, 54–64. [Google Scholar] [CrossRef]

- Kaczmarek, D.; Domaradzki, J.; Wojcieszak, D.; Prociow, E.; Mazur, M.; Placido, F.; Lapp, S. Hardness of Nanocrystalline TiO2 Thin Films. J. Nano Res. 2012, 18, 195–200. [Google Scholar] [CrossRef]

- Cui, J.; Wang, C.; Yang, G. Experimental Research on Microsecond-Laser-Induced Superhydrophobic Surface and Its Ice Suppression Properties. JOM 2022, 74, 4551–4563. [Google Scholar] [CrossRef]

- Liu, Z.; Niu, T.; Lei, Y.; Luo, Y. Metal Surface Wettability Modification by Nanosecond Laser Surface Texturing: A Review. Biosurf. Biotribol. 2022, 8, 95–120. [Google Scholar] [CrossRef]

- Zhai, W.; Bai, L.; Zhou, R.; Fan, X.; Kang, G.; Liu, Y.; Zhou, K. Recent Progress on Wear-Resistant Materials: Designs, Properties, and Applications. Adv. Sci. 2021, 8, 2003739. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Yang, X.; Ma, J.; Li, K.; Chen, M.; Gu, Y. Research Progress of Surface Texturing to Improve the Tribological Properties: A Review. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2024, 238, 347–371. [Google Scholar] [CrossRef]

- Wang, S.; Liu, Y.; Zhang, C.; Liao, Z.; Liu, W. The Improvement of Wettability, Biotribological Behavior and Corrosion Resistance of Titanium Alloy Pretreated by Thermal Oxidation. Tribol. Int. 2014, 79, 174–182. [Google Scholar] [CrossRef]

| Element | Al | V | Fe | C | N | H | O | Ti |

|---|---|---|---|---|---|---|---|---|

| % | 6.05 | 3.90 | 0.15 | 0.02 | 0.006 | 0.004 | 0.12 | Bal |

| Lubrication Condition | Normal Constant Load (Fn) | Constant Traverse Speed (v) | Sliding Distance (d) | Friction Test Time (t) | Test Temperature (T) |

|---|---|---|---|---|---|

| PAO6 oil lubrication | 15 N, 20 N | 10 mm/s | 2.5 mm | 900 s | 20~25 °C |

| Elment (wt%) | Corresponding Area Points in Figure 8 | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A | B | C | D | E | F | G | H | I | J | K | L | |

| Ti | 84.49 | 84.04 | 83.84 | 85.89 | 57.98 | 64.26 | 69.83 | 53.74 | 58.97 | 61.50 | 57.67 | 65.07 |

| Al | 4.55 | 5.00 | 4.63 | 4.79 | 2.52 | 3.33 | 3.69 | 2.11 | 3.37 | 3.21 | 3.24 | 3.29 |

| V | 3.69 | 3.87 | 5.04 | 2.61 | 2.23 | 0.65 | 0.88 | 5.30 | 1.73 | 1.24 | 3.90 | 0.67 |

| O | 7.22 | 6.87 | 6.43 | 6.57 | 37.23 | 31.69 | 25.49 | 38.50 | 35.82 | 34.04 | 35.09 | 30.89 |

| Si | 0.06 | 0.23 | 0.06 | 0.14 | 0.03 | 0.07 | 0.11 | 0.36 | 0.12 | 0.01 | 0.09 | 0.07 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, X.; Xu, Z.; Lu, H.; Tan, Y.; Xu, X.; Wu, H. Preparation and Tribology of Textured Ti-6Al-4V with Thermal Oxide Coating. Coatings 2025, 15, 258. https://doi.org/10.3390/coatings15030258

Wang X, Xu Z, Lu H, Tan Y, Xu X, Wu H. Preparation and Tribology of Textured Ti-6Al-4V with Thermal Oxide Coating. Coatings. 2025; 15(3):258. https://doi.org/10.3390/coatings15030258

Chicago/Turabian StyleWang, Xiaoyi, Zhibiao Xu, Haowen Lu, Yue Tan, Xing Xu, and Hao Wu. 2025. "Preparation and Tribology of Textured Ti-6Al-4V with Thermal Oxide Coating" Coatings 15, no. 3: 258. https://doi.org/10.3390/coatings15030258

APA StyleWang, X., Xu, Z., Lu, H., Tan, Y., Xu, X., & Wu, H. (2025). Preparation and Tribology of Textured Ti-6Al-4V with Thermal Oxide Coating. Coatings, 15(3), 258. https://doi.org/10.3390/coatings15030258