Effect of Cathodic Voltage on Phase Composition, Microstructure, and Elevated-Temperature Oxidation Resistance of Micro-Arc Oxidation Ceramic Coatings on Ti65 Alloy

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials and Coating Preparation Process

2.2. Coating Characterization

2.3. Thermal Shock Tests of the Coatings

2.4. High Temperature Oxidation Tests of the Coating Samples

3. Results and Discussion

3.1. Coating Microstructure Characteristics

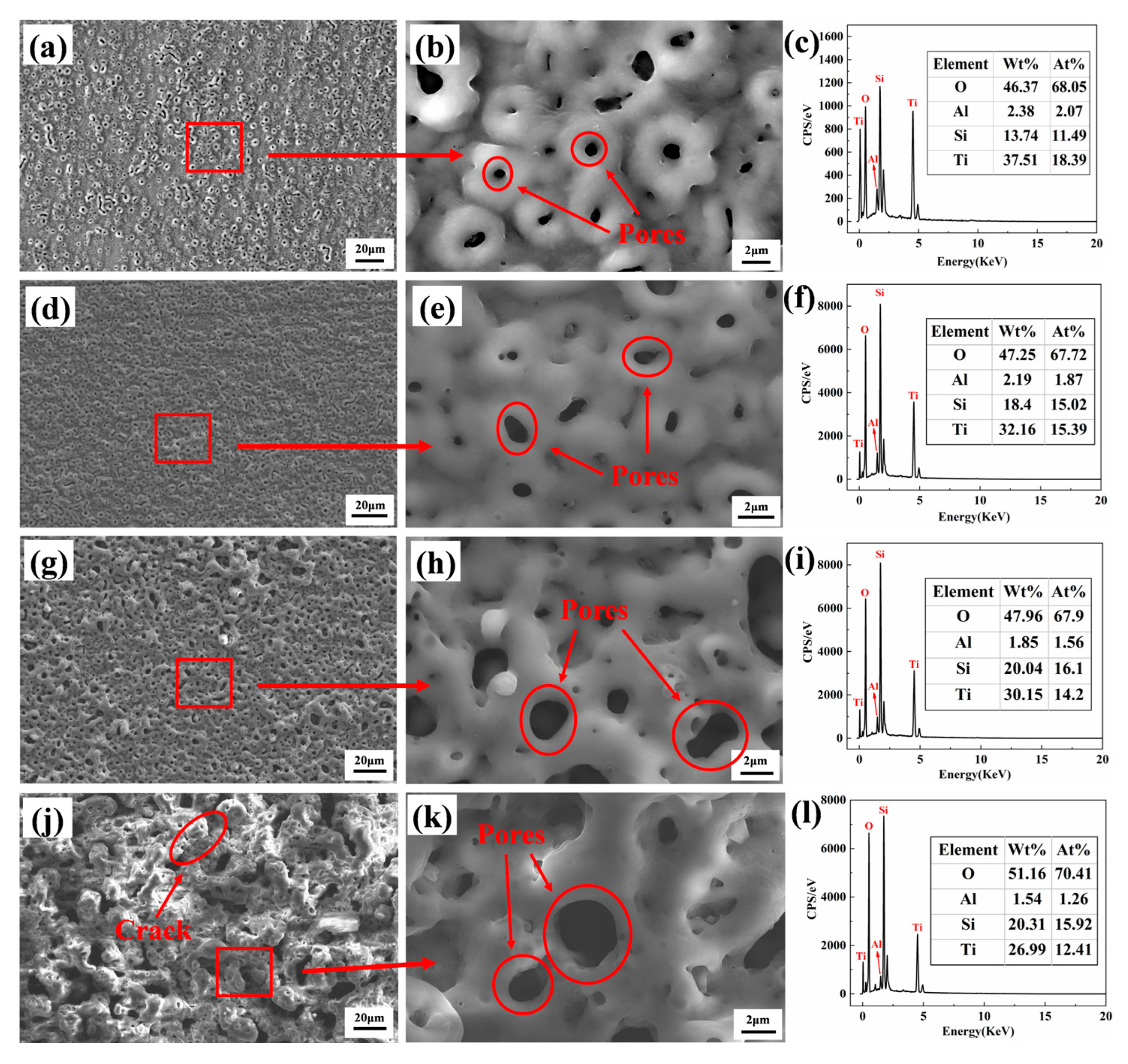

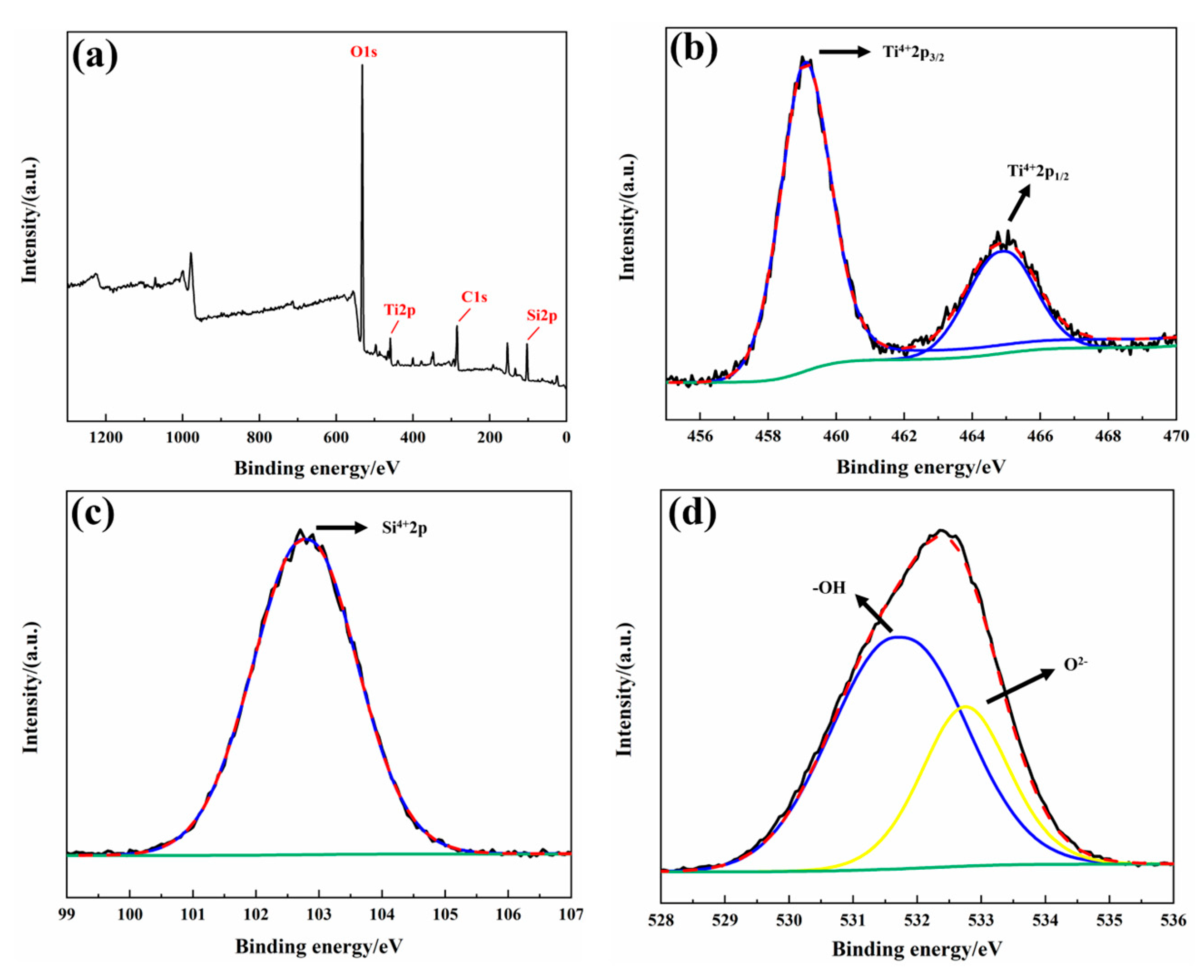

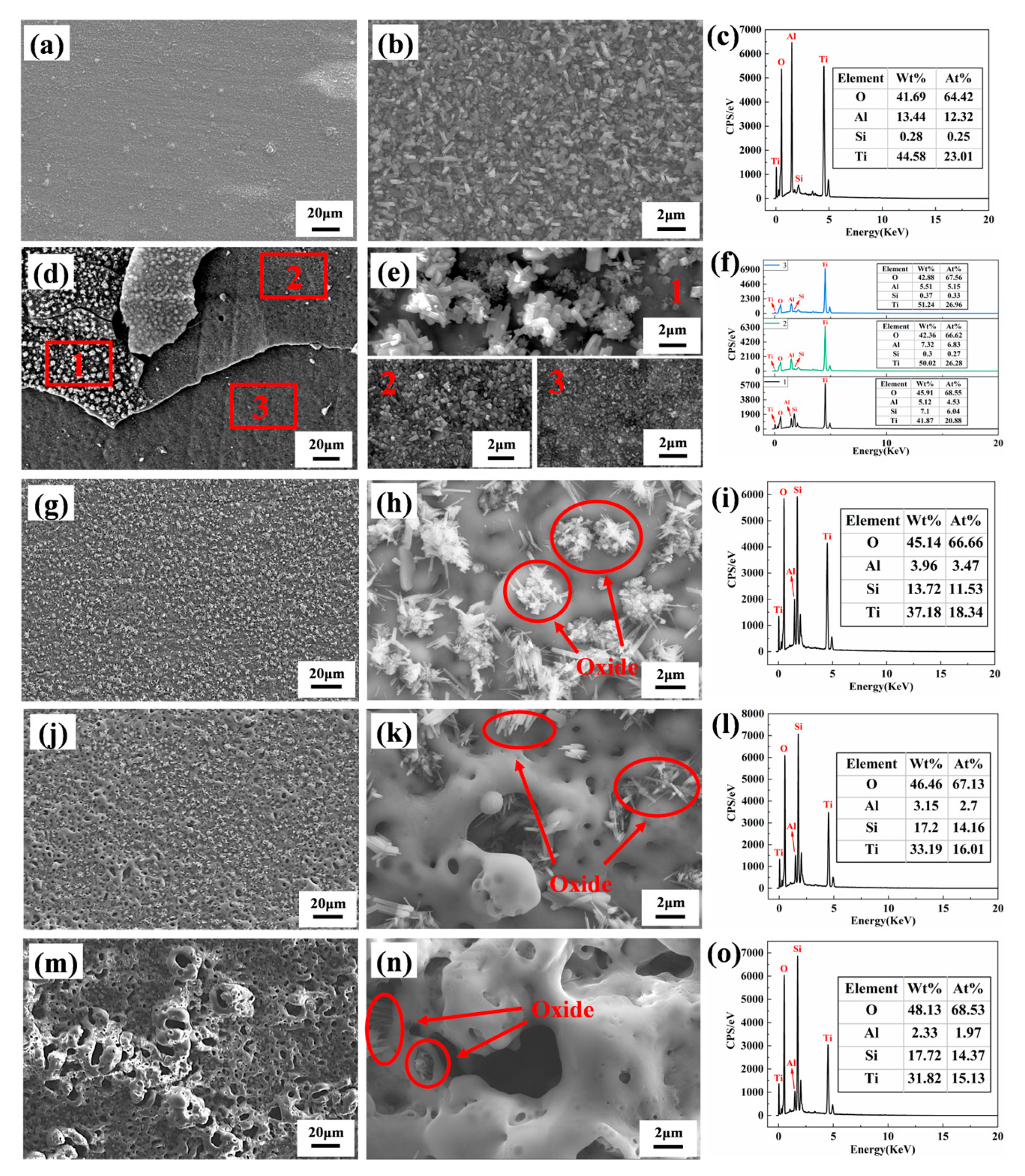

3.1.1. Surface Morphologies and EDS Analyses of the MAO Coatings

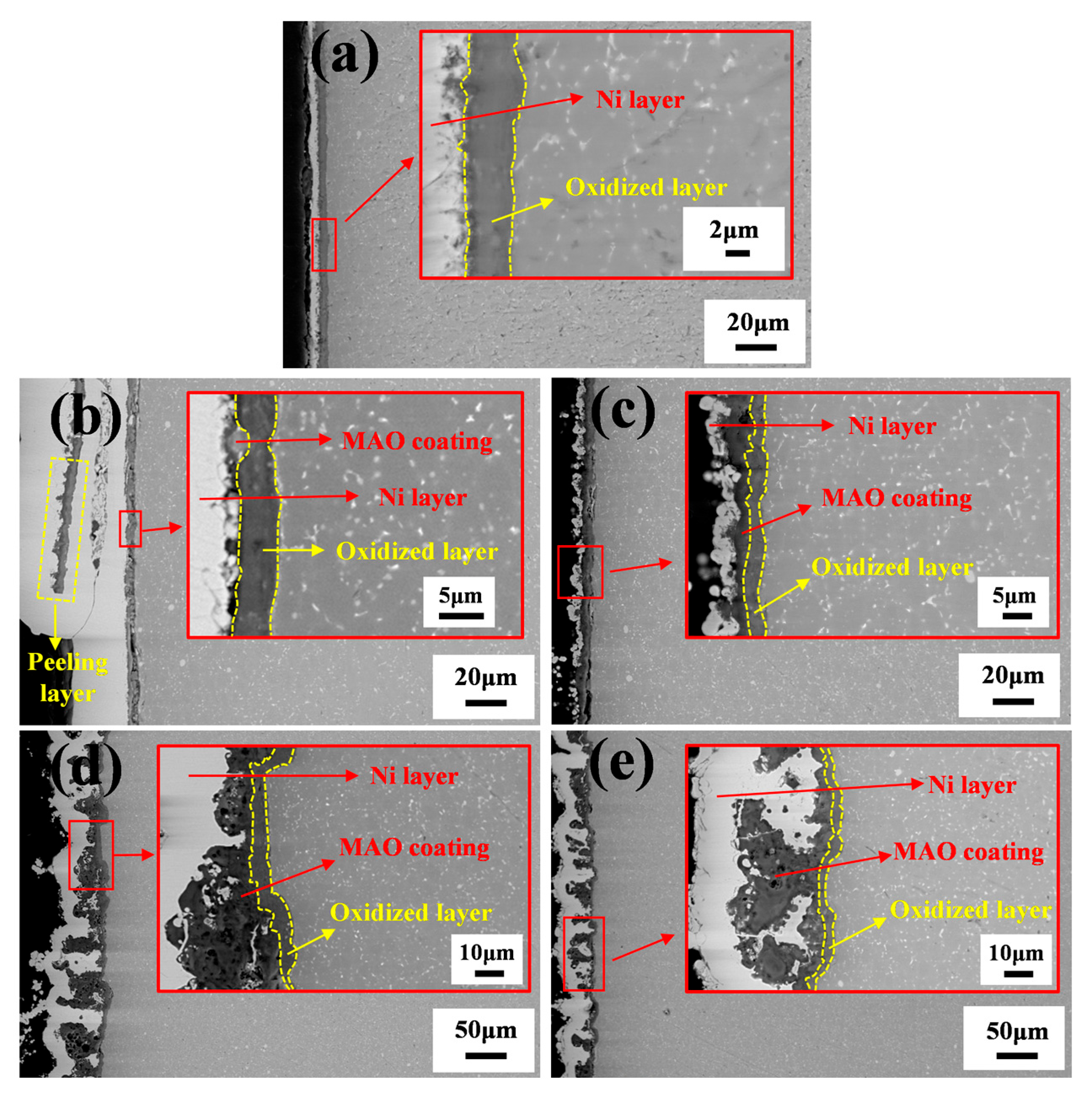

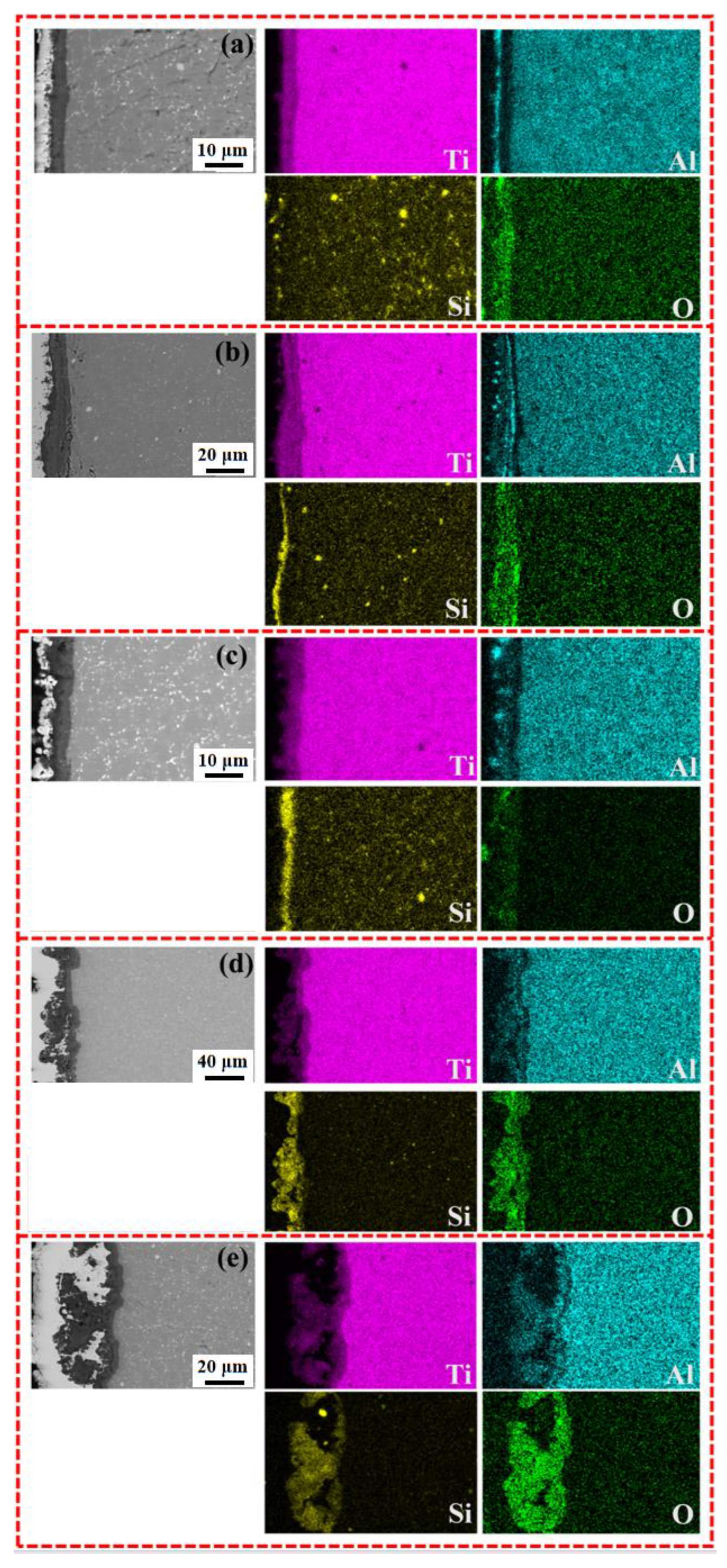

3.1.2. Cross-Sectional Morphologies and EDS Analyses of the MAO Coatings

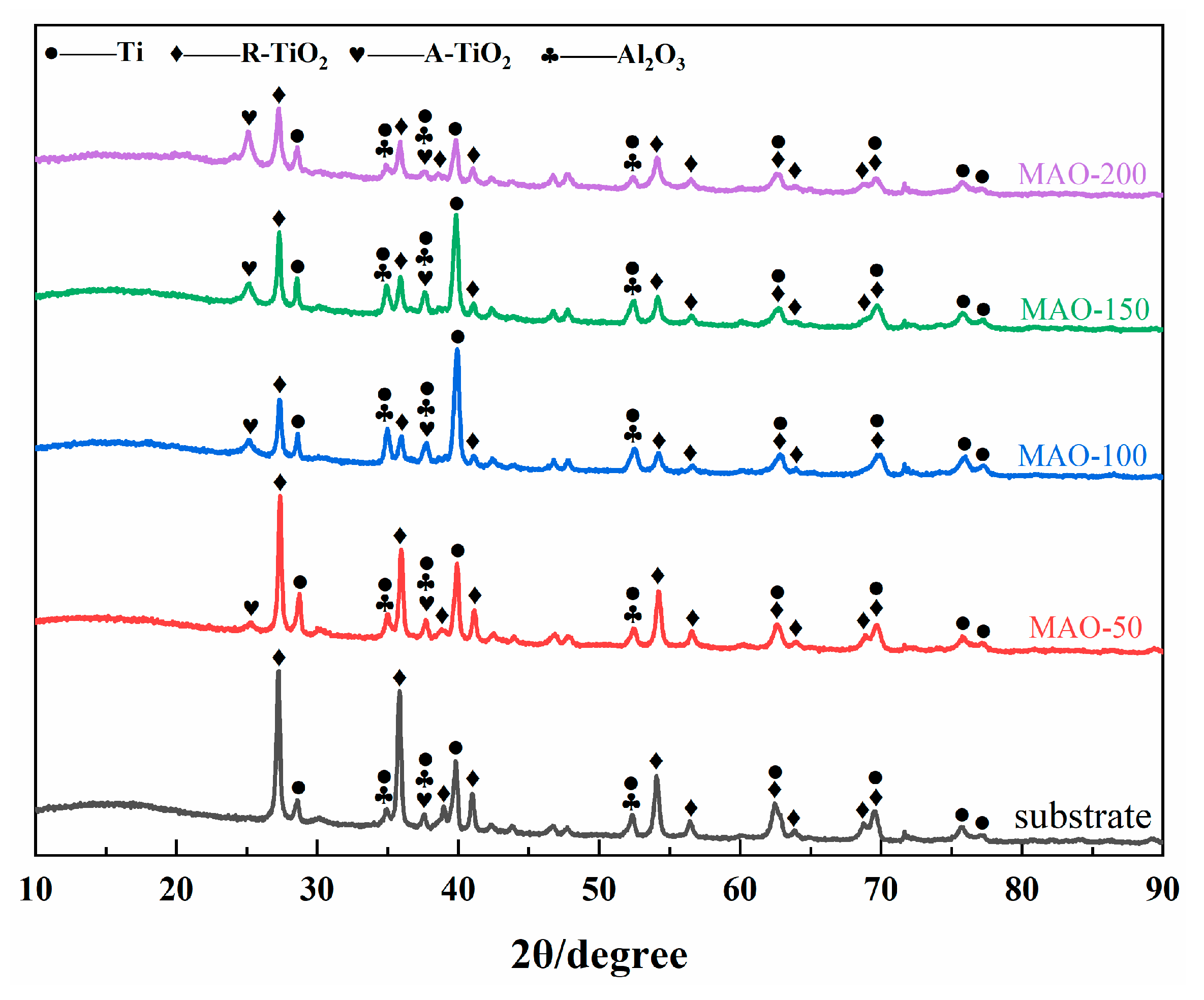

3.1.3. Phase Composition of the MAO Coatings

3.2. Coating Properties

3.2.1. Thermal Shock Property of the MAO Coatings

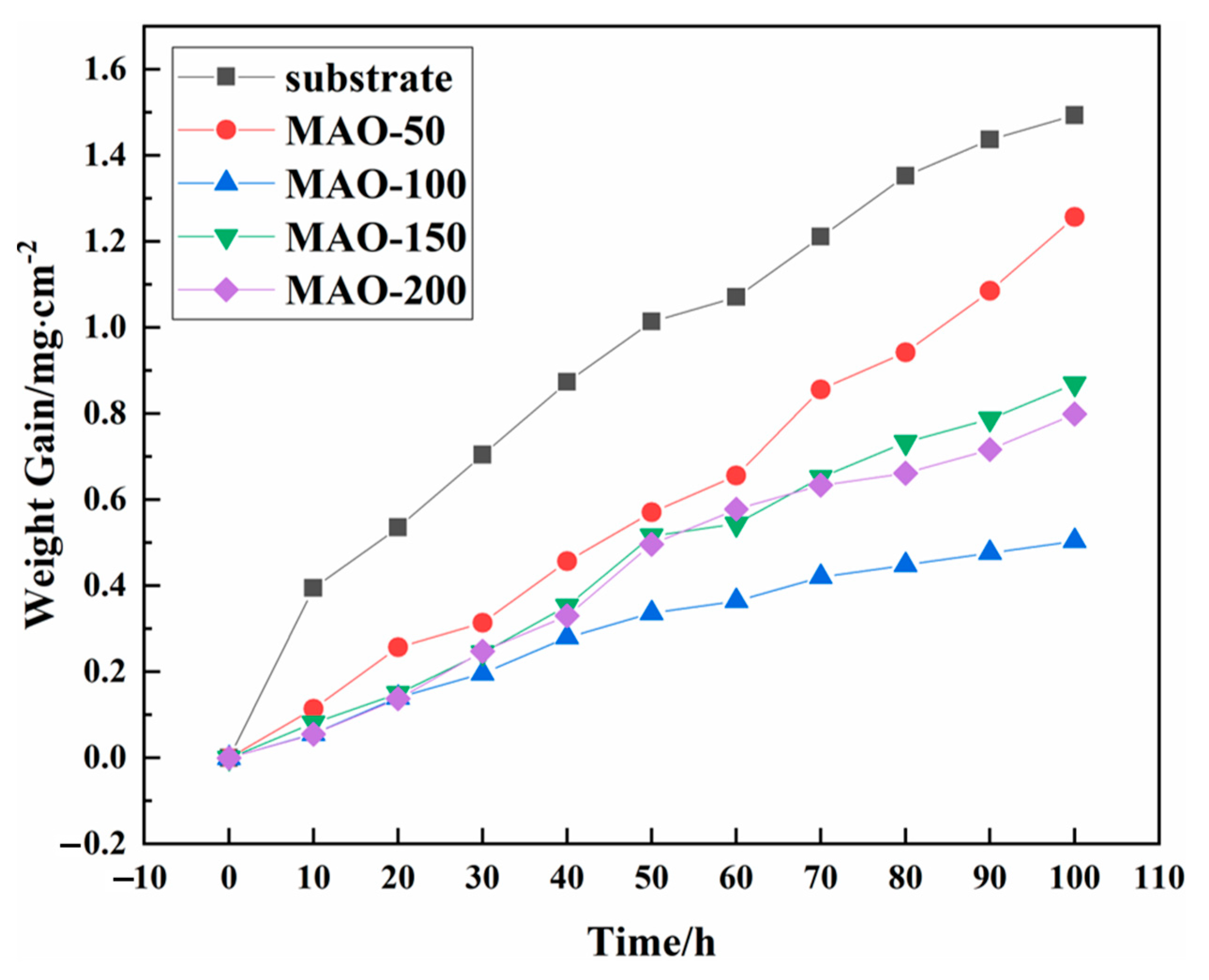

3.2.2. High-Temperature Oxidation Resistance of the MAO Coatings

4. Conclusions

- (1)

- Novel high-temperature oxidation-resistant ceramic coatings were fabricated on Ti65 alloy using MAO technology. The ceramic coatings primarily consisted of abundant amorphous SiO2, rutile TiO2 (R-TiO2), minor anatase TiO2 (A-TiO2), and trace Al2O3. All coatings fabricated at varied cathodic voltages demonstrated superior thermal shock resistance.

- (2)

- The influence of the cathodic voltage on microstructure and high-temperature oxidation performance at 750 °C of the MAO coatings was studied. The average surface pore size and surface porosity of the coatings show a trend of first decreasing and then increasing with the increase in cathodic voltage. The MAO-100 coating (with cathodic voltage of 100 V), with the smallest pore size and surface porosity, exhibited minimal oxidation weight gain after elevated-temperature exposure, only one-third that of the bare Ti65 substrate.

- (3)

- During the high-temperature oxidation process, new oxide layers were primarily formed at the interface between the MAO coating and the substrate, while simultaneously growing outward and progressively filling the micropores within the MAO coating. For the MAO-100 coating, the tendency for oxidation weight gain decreased significantly once the micropores within the coating were fully filled.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Antunes, R.A.; Salvador, C.A.F.; Oliveira, M.C.L. Materials selection of optimized titanium alloys for aircraft applications. Mater. Res. 2018, 21, e20170979. [Google Scholar] [CrossRef]

- Zhang, W.; Fan, J.; Huang, H.; Xue, X.; Wang, Y.; Zhang, B.; Jiang, P.; Wang, C.; Kou, H.; Li, J. Creep anisotropy characteristics and microstructural crystallography of marine engineering titanium alloy Ti6321 plate at room temperature. Mater. Sci. Eng. A 2022, 854, 143728. [Google Scholar] [CrossRef]

- Wang, L.; Zhao, X.; Wang, X.; Shang, S.; Xiu, Z.; Xi, Y.; Jia, H.; Xu, S.; Liu, H.; Wen, L.; et al. Current Status Review of Corrosion Resistance Applications of Titanium Alloys in the Petroleum Industry. Coatings 2024, 14, 941. [Google Scholar] [CrossRef]

- Zhang, L.C.; Chen, L.Y. A review on biomedical titanium alloys: Recent progress and prospect. Adv. Eng. Mater. 2019, 21, 1801215. [Google Scholar] [CrossRef]

- Zhu, S.; Zhu, C.; Luo, D.; Zhang, X.; Zhou, K. Development of a low-density and high-strength titanium alloy. Metals 2023, 13, 251. [Google Scholar] [CrossRef]

- Kang, L.M.; Yang, C. A review on high-strength titanium alloys: Microstructure, strengthening, and properties. Adv. Eng. Mater. 2019, 21, 1801359. [Google Scholar] [CrossRef]

- Zhao, Y.; Wang, H.; Meng, F.; Wang, L.; Xu, Q.; Zhou, T.; Wu, J. Formation of hydrogen resistant oxides of titanium alloy in water corrosion environment. J. Mater. Res. Technol. 2024, 33, 7293–7302. [Google Scholar] [CrossRef]

- Baltatu, M.S.; Tugui, C.A.; Perju, M.C.; Benchea, M.; Spataru, M.C.; Sandu, A.V.; Vizureanu, P. Biocompatible titanium alloys used in medical applications. Rev. Chim. 2019, 70, 1302–1306. [Google Scholar] [CrossRef]

- Qu, S.J.; Tang, S.Q.; Feng, A.H.; Feng, C.; Shen, J.; Chen, D.L. Microstructural evolution and high-temperature oxidation mechanisms of a titanium aluminide based alloy. Acta Mater. 2018, 148, 300–310. [Google Scholar] [CrossRef]

- Gloria, A.; Montanari, R.; Richetta, M.; Varone, A. Alloys for aeronautic applications: State of the art and perspectives. Metals 2019, 9, 662. [Google Scholar] [CrossRef]

- Williams, J.C.; Boyer, R.R. Opportunities and issues in the application of titanium alloys for aerospace components. Metals 2020, 10, 705. [Google Scholar] [CrossRef]

- Dong, E.; Yu, W.; Cai, Q.; Cheng, L.; Shi, J. High-temperature oxidation kinetics and behavior of Ti-6Al-4V alloy. Oxid. Met. 2017, 88, 719–732. [Google Scholar] [CrossRef]

- Dai, J.; Zhu, J.; Chen, C.; Weng, F. High temperature oxidation behavior and research status of modifications on improving high temperature oxidation resistance of titanium alloys and titanium aluminides: A review. J. Alloys Compd. 2016, 685, 784–798. [Google Scholar] [CrossRef]

- Satko, D.P.; Shaffer, J.B.; Tiley, J.S.; Semiatin, S.L.; Pilchak, A.L.; Kalidindi, S.R.; Kosaka, Y.; Glavicic, M.G.; Salem, A.A. Effect of microstructure on oxygen rich layer evolution and its impact on fatigue life during high-temperature application of α/β titanium. Acta Mater. 2016, 107, 377–389. [Google Scholar] [CrossRef]

- Li, S.; Deng, T.; Zhang, Y.; Liang, Y.; Li, R.; Dong, T. Review on the creep resistance of high-temperature titanium alloy. Trans. Indian Inst. Met. 2021, 74, 215–222. [Google Scholar] [CrossRef]

- Mordyuk, B.N.; Voloshko, S.M.; Zakiev, V.I.; Burmak, A.P.; Mohylko, V.V. Enhanced resistance of Ti6Al4V alloy to high-temperature oxidation and corrosion by forming alumina composite coating. J. Mater. Eng. Perform. 2021, 30, 1780–1795. [Google Scholar] [CrossRef]

- Dai, J.; Zhu, J.; Zhuang, L.; Li, S. Effect of surface aluminizing on long-term high-temperature thermal stability of TC4 titanium alloy. Surf. Rev. Lett. 2016, 23, 1550102. [Google Scholar] [CrossRef]

- Haanappel, V.A.C.; Clemens, H.; Stroosnijder, M.F. The high temperature oxidation behaviour of high and low alloyed TiAl-based intermetallics. Intermetallics 2002, 10, 293–305. [Google Scholar] [CrossRef]

- Zhao, R.T.; Sun, S.C.; Zhang, Y.Y. Recent advances in silicon containing high temperature titanium alloy. J. Mater. Res. Technol. 2021, 14, 3029–3042. [Google Scholar] [CrossRef]

- Xu, Y.; Fu, Y.; Li, J.; Xiao, W.; Zhao, X.; Ma, C. Effects of tungsten addition on the microstructural stability and properties of Ti-6.5 Al-2Sn-4Hf-2Nb-based high temperature titanium alloys. J. Mater. Sci. Technol. 2021, 93, 147–156. [Google Scholar] [CrossRef]

- Lee, D.B. Effect of Cr, Nb, Mn, V, W and Si on high temperature oxidation of TiAl alloys. Met. Mater. Int. 2005, 11, 141–147. [Google Scholar] [CrossRef]

- Pflumm, R.; Donchev, A.; Mayer, S.; Clemens, H.; Schütze, M. High-temperature oxidation behavior of multi-phase Mo-containing γ-TiAl-based alloys. Intermetallics 2014, 53, 45–55. [Google Scholar] [CrossRef]

- Tegner, B.; Zhu, L.; Siemers, C.; Saksl, K.; Ackland, G. High temperature oxidation resistance in titanium–niobium alloys. J. Alloys Compd. 2015, 643, 100–105. [Google Scholar] [CrossRef]

- Gong, X.; Chen, R.R.; Fang, H.Z.; Ding, H.S.; Guo, J.J.; Su, Y.Q.; Fu, H.Z. Synergistic effect of B and Y on the isothermal oxidation behavior of TiAl-Nb-Cr-V alloy. Corros. Sci. 2018, 131, 376–385. [Google Scholar] [CrossRef]

- Gogia, A.K. High-temperature titanium alloys. Def. Sci. J. 2005, 55, 149. [Google Scholar] [CrossRef]

- Hosseini, S.H.; Mirdamadi, S.; Rastegari, S. Investigating efficiency of α-Al2O3 diffusion barrier layer in oxidation of EB-PVD NiCrAlY coatings. Surf. Eng. 2015, 31, 146–155. [Google Scholar] [CrossRef]

- Alhafian, M.-R.; Chemin, J.-B.; Valle, N.; El Adib, B.; Penoy, M.; Bourgeois, L.; Ghanbaja, J.; Barrirero, J.; Soldera, F.; Mücklich, F.; et al. Study of the oxidation mechanism at high temperature of nanofiber textured AlTiCrN coatings produced by physical vapor deposition using high-resolution characterization techniques. Corros. Sci. 2022, 201, 110226. [Google Scholar] [CrossRef]

- Bobzin, K.; Brögelmann, T.; Kalscheuer, C.; Liang, T. High temperature oxidation protection of γ-titanium aluminide using (Cr, Al) ON coatings deposited by high-speed physical vapor deposition. Surf. Coat. Technol. 2017, 332, 2–11. [Google Scholar] [CrossRef]

- Chen, D.; Colas, J.; Mercier, F.; Boichot, R.; Charpentier, L.; Escape, C.; Balat-Pichelin, M.; Pons, M. High temperature properties of AlN coatings deposited by chemical vapor deposition for solar central receivers. Surf. Coat. Technol. 2019, 377, 124872. [Google Scholar] [CrossRef]

- Zhu, L.; Zhang, Y.; Hu, T.; Leicht, P.; Liu, Y. Oxidation resistance and thermal stability of Ti (C, N) and Ti (C, N, O) coatings deposited by chemical vapor deposition. Int. J. Refract. Met. Hard Mater. 2016, 54, 295–303. [Google Scholar] [CrossRef]

- Zhuang, Q.; Zhang, P.; Li, M.; Yan, H.; Yu, Z.; Lu, Q. Microstructure, Wear Resistance and Oxidation Behavior of Ni-Ti-Si Coatings Fabricated on Ti6Al4V by Laser Cladding. Materials 2017, 10, 1248. [Google Scholar] [CrossRef]

- Sayyedan, F.S.; Enayati, M.H. On structure and oxidation behaviour of non-stoichiometric amorphous aluminium phosphate coating. Surf. Eng. 2019, 35, 670–676. [Google Scholar] [CrossRef]

- Saremi, M.; Valefi, Z.; Abaeian, N. Hot corrosion, high temperature oxidation and thermal shock behavior of nanoagglomerated YSZ-Alumina composite coatings produced by plasma spray method. Surf. Coat. Technol. 2013, 221, 133–141. [Google Scholar] [CrossRef]

- Ghosh, D.; Das, S.; Roy, H.; Mitra, S.K. Oxidation behaviour of nanostructured YSZ plasma sprayed coated Inconel alloy. Surf. Eng. 2018, 34, 22–29. [Google Scholar] [CrossRef]

- Reddy, G.M.S.; Prasad, C.D.; Shetty, G.; Ramesh, M.R.; Rao, T.N.; Patil, P. High-temperature oxidation behavior of plasma-sprayed NiCrAlY/TiO2 and NiCrAlY/Cr2O3/YSZ coatings on titanium alloy. Weld. World 2022, 66, 1069–1079. [Google Scholar] [CrossRef]

- Tsai, D.C.; Deng, M.J.; Chang, Z.C.; Kuo, B.H.; Chen, E.C.; Chang, S.Y.; Shieu, F.S. Oxidation resistance and characterization of (AlCrMoTaTi)-Six-N coating deposited via magnetron sputtering. J. Alloys Compd. 2015, 647, 179–188. [Google Scholar] [CrossRef]

- Liang, J.; Chen, S.; Zou, C.; Tian, C.; Wang, Z.; Liao, S. Influence of oxygen contents on the microstructure, high temperature oxidation and corrosion resistance properties of Cr-Si-O-N coatings. Coatings 2018, 8, 19. [Google Scholar] [CrossRef]

- Wang, X.; Zhang, H.; Liu, B.; Man, T.; Cui, X.; Liu, T.; Zhao, T.; Luhovskyi, Y.; Lu, S.; Nong, Z. Design, preparation, and tribological properties of novel wide temperature range self-lubricating coatings on TC4 alloy. Surf. Coatings Technol. 2025, 517, 132852. [Google Scholar] [CrossRef]

- Yao, W.; Wu, L.; Wang, J.; Jiang, B.; Zhang, D.; Serdechnova, M.; Shulha, T.; Blawert, C.; Zheludkevich, M.L.; Pan, F. Micro-arc oxidation of magnesium alloys: A review. J. Mater. Sci. Technol. 2022, 118, 158–180. [Google Scholar] [CrossRef]

- Zhang, Z.; Fan, J.; Tang, B.; Kou, H.; Wang, J.; Wang, X.; Wang, S.; Wang, Q.; Chen, Z.; Li, J. Microstructural evolution and FCC twinning behavior during hot deformation of high temperature titanium alloy Ti65. J. Mater. Sci. Technol. 2020, 49, 56–69. [Google Scholar] [CrossRef]

- Li, F.; He, W.; Hu, X. Effect of Cr on microstructure and high temperature oxidation resistance of Ti-Al-Si composite coatings prepared by two-step hot-dipping + pre-oxidation method on Ti65 alloy. Appl. Surf. Sci. 2024, 678, 161070. [Google Scholar] [CrossRef]

- Han, R.; Li, J.; Kong, L.; Liu, J.; Shan, X.; Cui, X.; Xiong, T. A novel phosphate-ceramic coating for high temperature oxidation resistance of Ti65 alloys. Ceram. Int. 2019, 45, 23895–23901. [Google Scholar] [CrossRef]

- Ma, K.; Li, Y.; Li, J. Long-term oxidation resistance of a Ti65 alloy with Cr2AlC coating by magnetron sputtering. Corros. Commun. 2025, 18, 66–75. [Google Scholar] [CrossRef]

- Li, G.; Ma, F.; Liu, P.; Qi, S.; Li, W.; Zhang, K.; Chen, X. Review of micro-arc oxidation of titanium alloys: Mechanism, properties and applications. J. Alloys Compd. 2023, 948, 169773. [Google Scholar] [CrossRef]

- Zhou, Y.H.; Chen, P.H.; Huang, D.N.; Wu, Z.Z.; Yang, T.; Kai, J.J.; Yan, M. Micro-arc oxidation for improving high-temperature oxidation resistance of additively manufacturing Ti2AlNb. Surf. Coat. Technol. 2022, 445, 128719. [Google Scholar] [CrossRef]

- Zhou, K.; Xie, F.; Wu, X.; Wang, S. Fabrication of high temperature oxidation resistance nanocomposite coatings on PEO treated TC21 alloy. Materials 2019, 13, 11. [Google Scholar] [CrossRef]

- Chi, J.; Zhang, H.; Song, S.; Zhang, W.; He, X.; Nong, Z.; Cui, X.; Liu, T.; Man, T. The impact of pre- and post-treatment processes on corrosion resistance of micro-arc oxidation coatings on Mg alloys: A systematic review. Materials 2025, 18, 723. [Google Scholar] [CrossRef]

- Hussein, R.; Nie, X.; Northwood, D. A spectroscopic and microstructural study of oxide coatings produced on a Ti-6Al-4V alloy by plasma electrolytic oxidation. Mater. Chem. Phys. 2019, 134, 484–492. [Google Scholar] [CrossRef]

- Li, Q.; Liang, J.; Liu, B.; Peng, Z.; Wang, Q. Effects of cathodic voltages on structure and wear resistance of plasma electrolytic oxidation coatings formed on aluminium alloy. Appl. Surf. Sci. 2014, 297, 176–181. [Google Scholar] [CrossRef]

- Liu, F.; Xu, J.; Yu, D.; Wang, F.; Zhao, L. Effects of cathodic voltages on the structure and properties of ceramic coatings formed on NiTi alloy by micro-arc oxidation. Mater. Chem. Phys. 2010, 121, 172–177. [Google Scholar] [CrossRef]

- Pérez-Larios, A.; Torres-Ramos, I.; Zanella, R.; Rico, J.L. Ti-Co mixed oxide as photocatalysts in the generation of hydrogen from water. Int. J. Chem. React. Eng. 2022, 20, 129–140. [Google Scholar] [CrossRef]

- Wang, Q.; Qiu, L.; Tan, X.; Liu, Z.; Gao, S.; Wang, R. Amorphous TiO2 granular nanodisks on porous Ti foam for highly effective solar cells and photocatalysts. J. Taiwan Inst. Chem. Eng. 2019, 102, 85–91. [Google Scholar] [CrossRef]

- Biaggi-Labiosa, A.; Solá, F.; Resto, O.; Fonseca, L.F.; González-Berríos, A.; De Jesús, J.; Morell, G. Nanocrystalline silicon as the light emitting material of a field emission displaydevice. Nanotechnology 2008, 19, 225202. [Google Scholar] [CrossRef]

- Wang, X.; Liu, Y.; Han, H.; Zhao, Y.; Ma, W.; Sun, H. Polyaniline coated Fe3O4 hollow nanospheres as anode materials for lithium ion batteries. Sustain. Energy Fuels 2017, 1, 915–922. [Google Scholar] [CrossRef]

- Ke, W.; Qin, X.; Palomino, R.M.; Simonovis, J.P.; Senanayake, S.D.; Rodriguez, J.A.; Zaera, F. Redox properties of TiO2 thin films grown on mesoporous silica by atomic layer deposition. J. Phys. Chem. Lett. 2023, 14, 4696–4703. [Google Scholar] [CrossRef]

- Nguyen, N.M.; Nguyen, Y.H.; Phan, H.N.; Phan, M.N.; Duc, D.D.; Nga, P.T.; Van Nguyen, M.; Nguyen, T.M.; Duong, V.Q.; Nguyen, K.C. Investigation of origin optical properties of TiO2/graphene nanohybrids. Mater. Lett. 2020, 276, 128042. [Google Scholar] [CrossRef]

- Xu, J.L.; Xiao, Q.F.; Mei, D.D.; Zhong, Z.C.; Tong, Y.X.; Zheng, Y.F.; Li, L. Preparation and characterization of amorphous SiO2 coatings deposited by mirco-arc oxidation on sintered NdFeB permanent magnets. J. Magn. Magn. Mater. 2017, 426, 361–368. [Google Scholar] [CrossRef]

- Wang, Y.; Hu, Z.; Wu, G.; Zhang, X.; Yin, Y.; Li, L.; Yao, J. Effect of laser power on the microstructure and wear resistance of TiO2-SiO2 ceramic coating by laser-assisted micro-arc oxidation on Ti6Al4V alloy. Surf. Coat. Technol. 2025, 497, 131764. [Google Scholar] [CrossRef]

- Kumar, S.; Narayanan, T.S.; Raman, S.G.S.; Seshadri, S. Thermal oxidation of Ti6Al4V alloy: Microstructural and electrochemical characterization. Mater. Chem. Phys. 2010, 119, 337–346. [Google Scholar] [CrossRef]

| Samples | Positive Voltage (V) | Cathodic Voltage (V) | Frequency (Hz) | Duty Cycle (%) |

|---|---|---|---|---|

| MAO-50 | 300 | 50 | 200 | 10 |

| MAO-100 | 300 | 100 | 200 | 10 |

| MAO-150 | 300 | 150 | 200 | 10 |

| MAO-200 | 300 | 200 | 200 | 10 |

| Samples | Average Pore Size/(μm) | Surface Porosity/(%) |

|---|---|---|

| MAO-50 | 0.92 | 3.04 |

| MAO-100 | 0.77 | 3.30 |

| MAO-150 | 1.77 | 14.01 |

| MAO-200 | 2.14 | 15.54 |

| Samples | n | Kn (mgn/(cm2n·h)) |

|---|---|---|

| Substrate | 1.62 | 0.020 |

| MAO-50 | 0.92 | 0.013 |

| MAO-100 | 1.66 | 0.003 |

| MAO-150 | 1.02 | 0.009 |

| MAO-200 | 1.08 | 0.008 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, H.; Ma, Y.; Liu, B.; Wang, X.; Zhang, H. Effect of Cathodic Voltage on Phase Composition, Microstructure, and Elevated-Temperature Oxidation Resistance of Micro-Arc Oxidation Ceramic Coatings on Ti65 Alloy. Coatings 2025, 15, 1500. https://doi.org/10.3390/coatings15121500

Li H, Ma Y, Liu B, Wang X, Zhang H. Effect of Cathodic Voltage on Phase Composition, Microstructure, and Elevated-Temperature Oxidation Resistance of Micro-Arc Oxidation Ceramic Coatings on Ti65 Alloy. Coatings. 2025; 15(12):1500. https://doi.org/10.3390/coatings15121500

Chicago/Turabian StyleLi, Haitao, Yu Ma, Baicheng Liu, Xugang Wang, and Hongliang Zhang. 2025. "Effect of Cathodic Voltage on Phase Composition, Microstructure, and Elevated-Temperature Oxidation Resistance of Micro-Arc Oxidation Ceramic Coatings on Ti65 Alloy" Coatings 15, no. 12: 1500. https://doi.org/10.3390/coatings15121500

APA StyleLi, H., Ma, Y., Liu, B., Wang, X., & Zhang, H. (2025). Effect of Cathodic Voltage on Phase Composition, Microstructure, and Elevated-Temperature Oxidation Resistance of Micro-Arc Oxidation Ceramic Coatings on Ti65 Alloy. Coatings, 15(12), 1500. https://doi.org/10.3390/coatings15121500