Seismic Performance of Concrete Square Column Confined by Five-Spiral Composite Stirrups

Abstract

1. Introduction

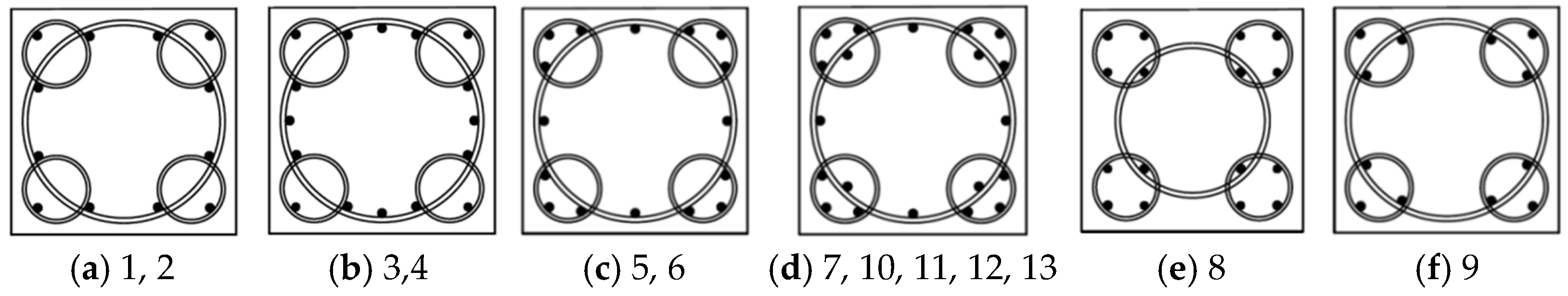

2. Existing Experimental Studies

3. Numerical Simulation and Validation

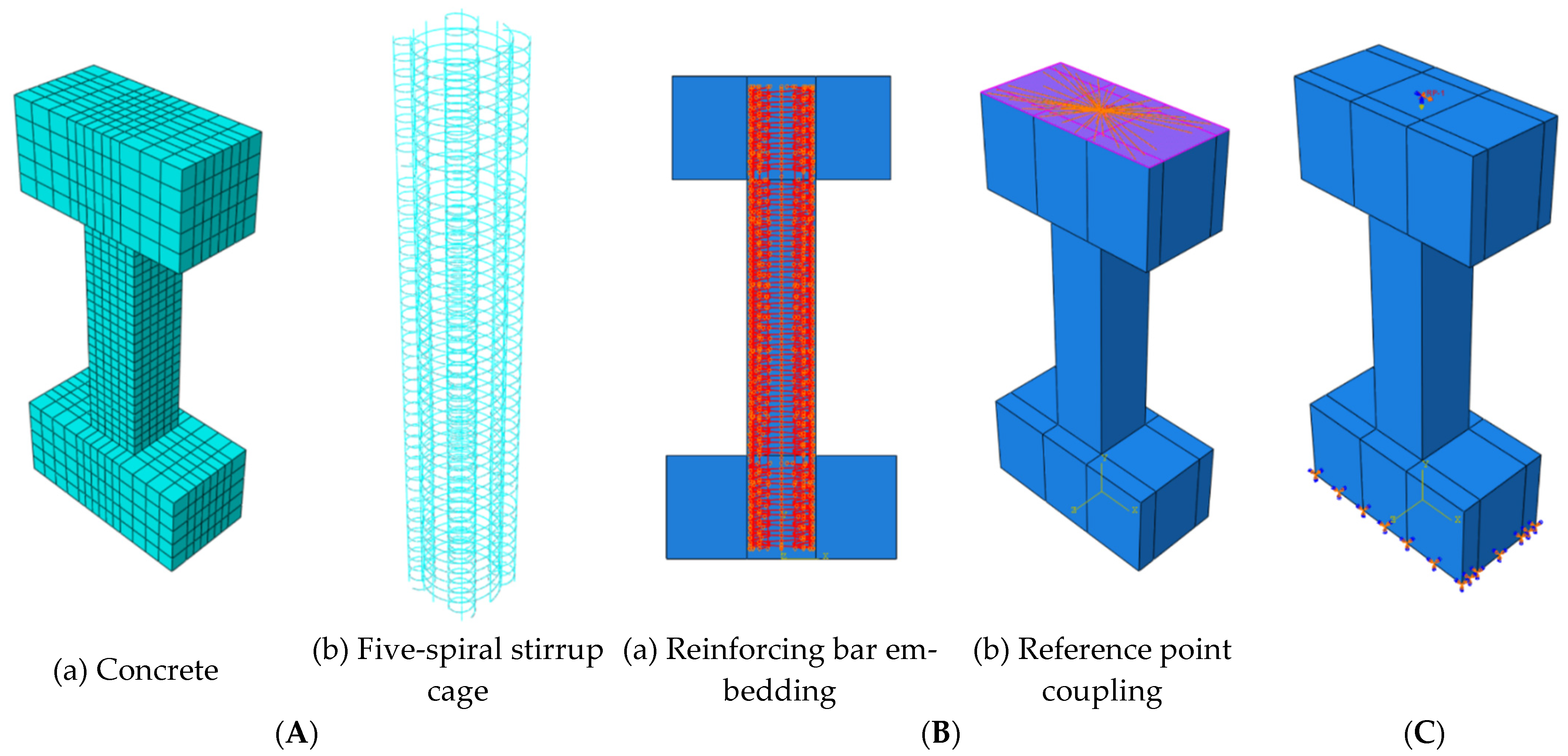

3.1. Numerical Model

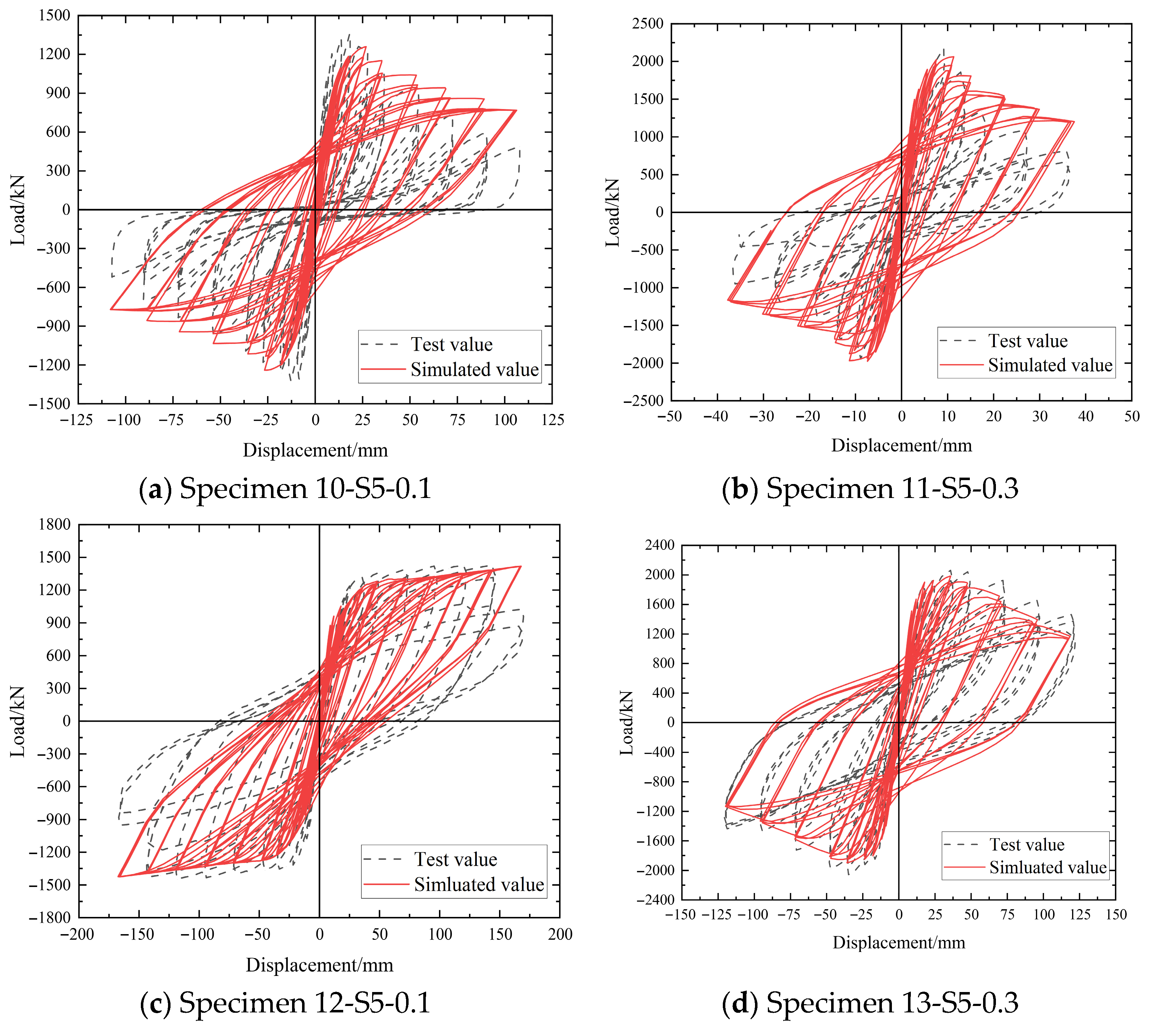

3.2. Simulation Results Verification

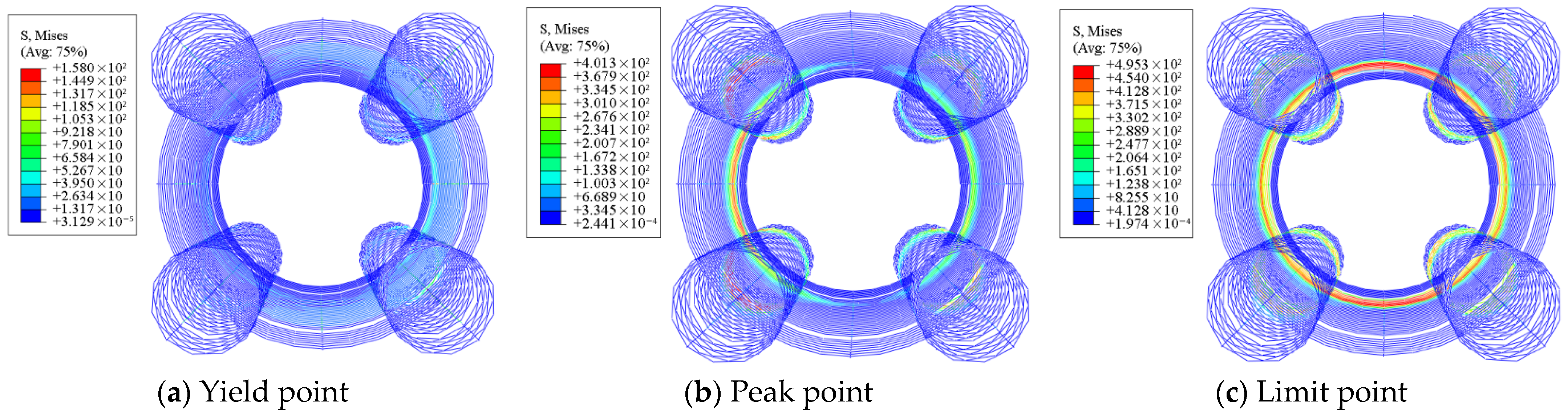

3.3. Stress Analysis of Five-Spiral Stirrups

4. Seismic Performance and Parametric Analysis

4.1. Parameter Design

4.2. Parametric Analysis

4.2.1. Axial Compression Ratio

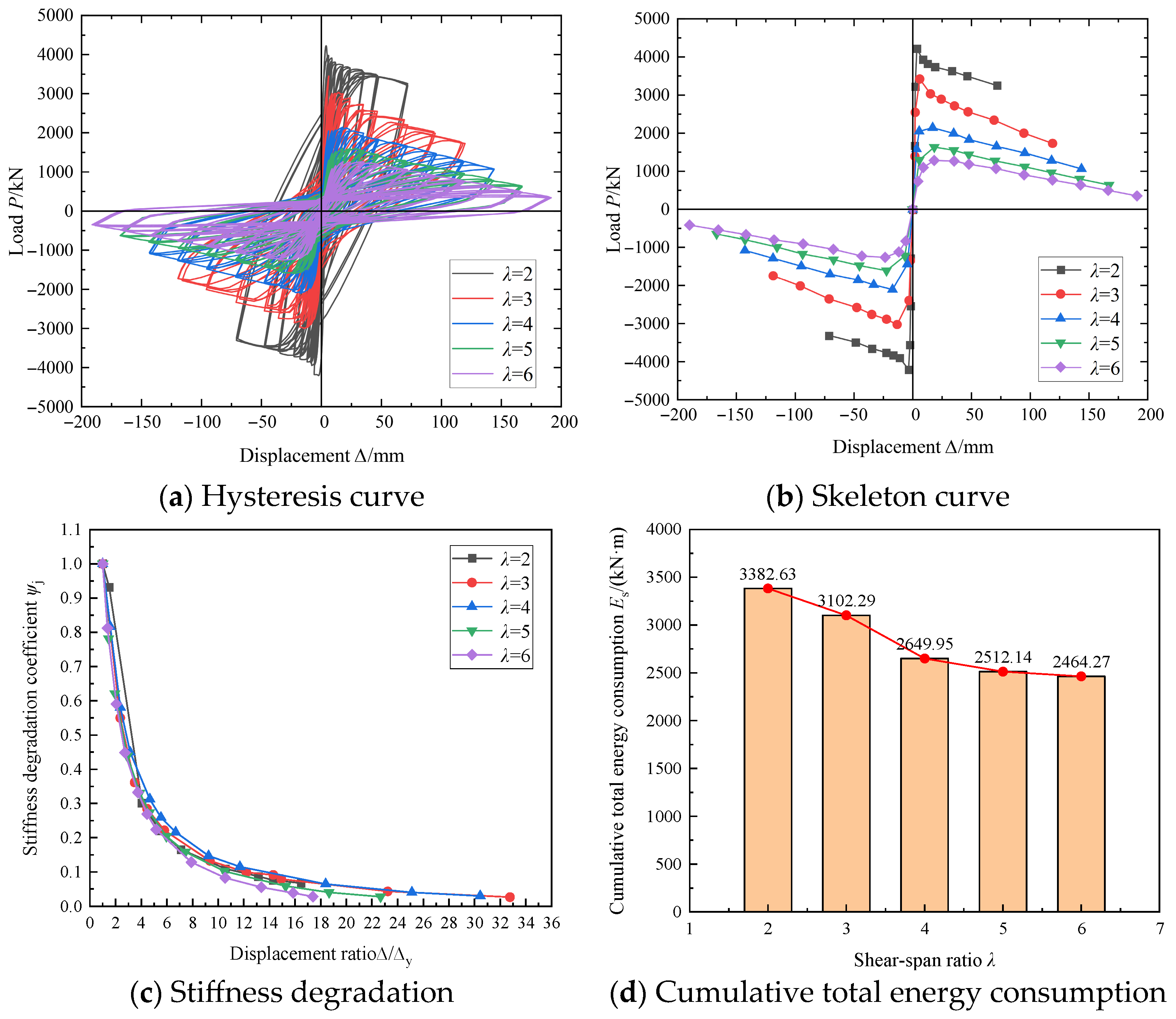

4.2.2. Shear-Span Ratio

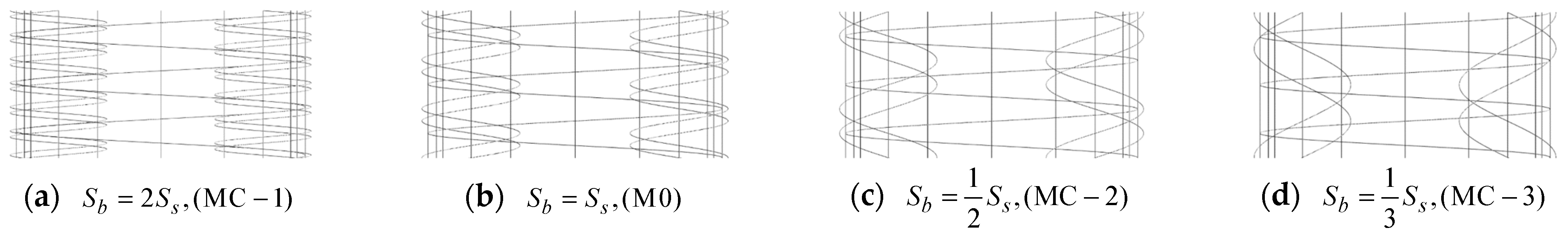

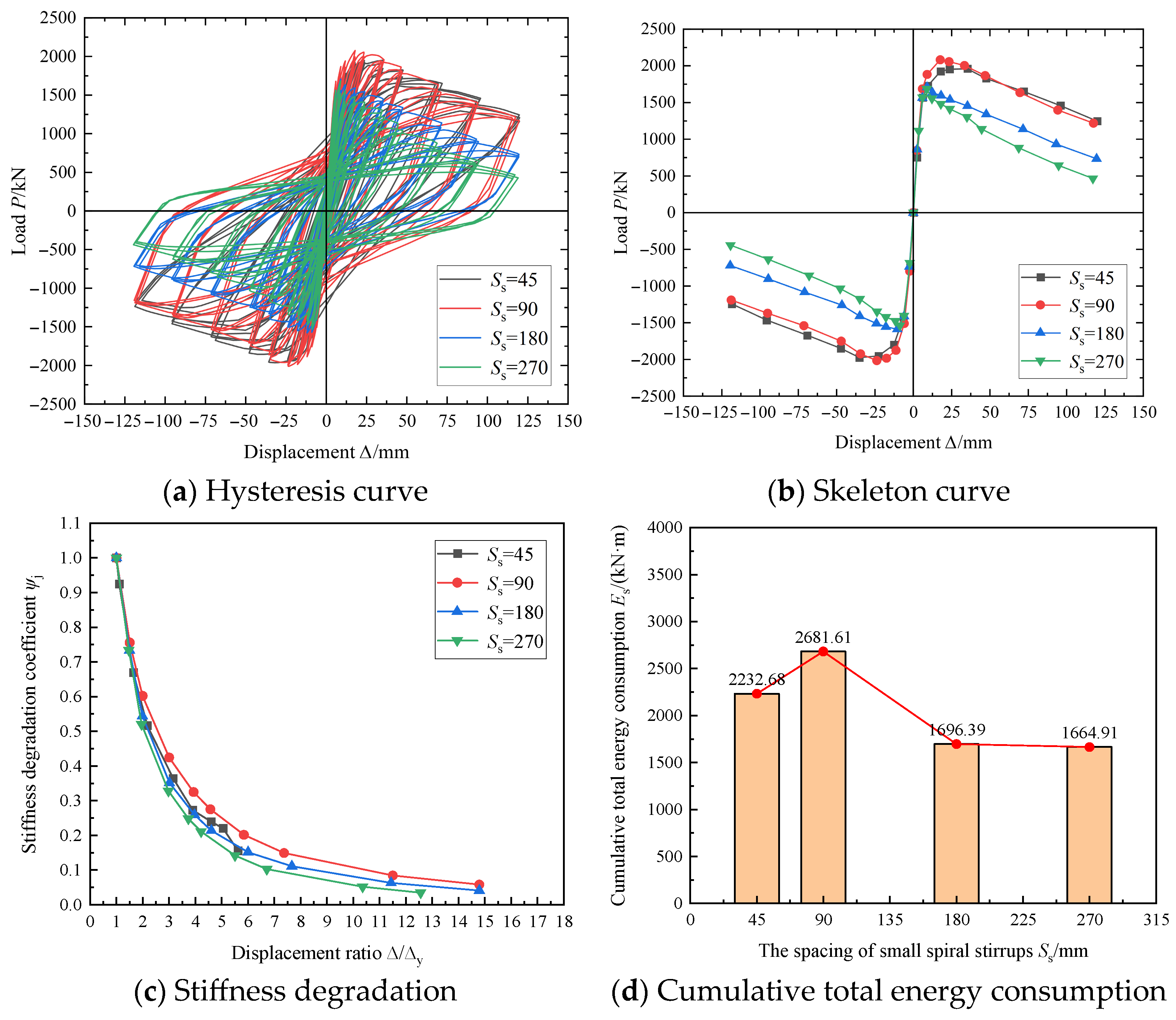

4.2.3. Spacing of Small Helical Stirrups

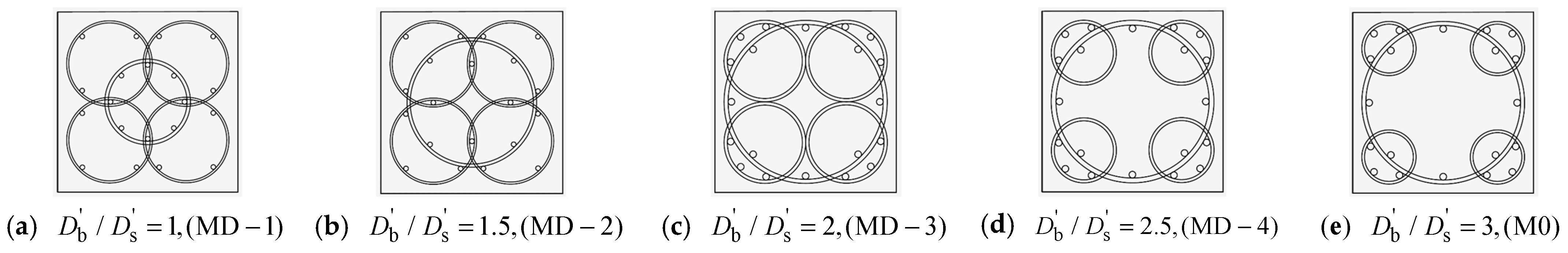

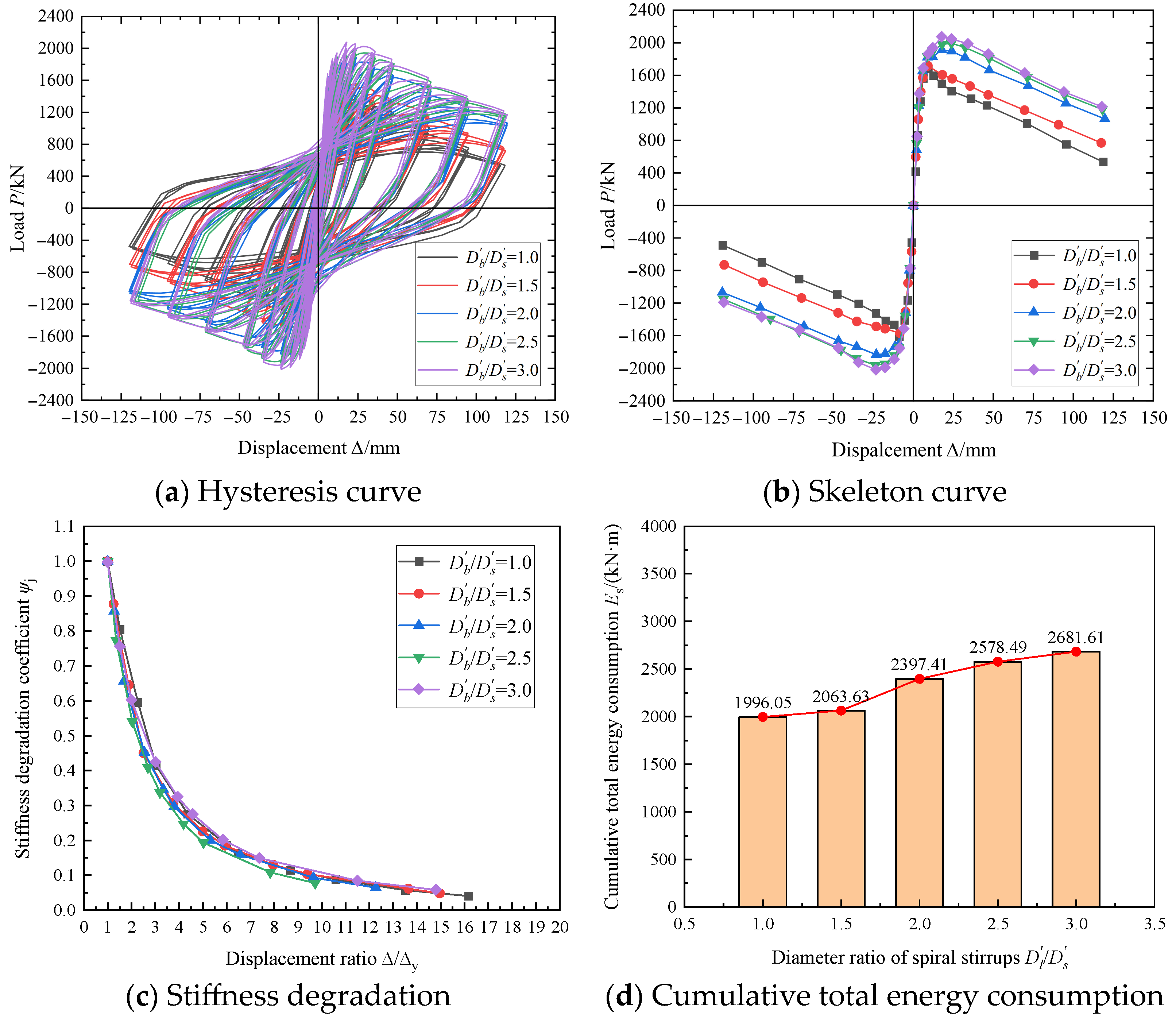

4.2.4. Spiral Diameter Ratio of Large and Small Spiral Stirrups

5. Shear Capacity Calculation

5.1. Shear Resistance Mechanism

5.2. Shear Strength of Concrete

5.2.1. Low-Constraint Zone

5.2.2. Medium-Constraint Zone

5.2.3. High-Constraint Zone

5.3. Shear Capacity of Stirrup Section

5.4. Axial Force Influence

5.5. Shear Capacity Calculation for Square Concrete Columns Constrained by Five-Spiral Stirrups

6. Conclusions

- (1)

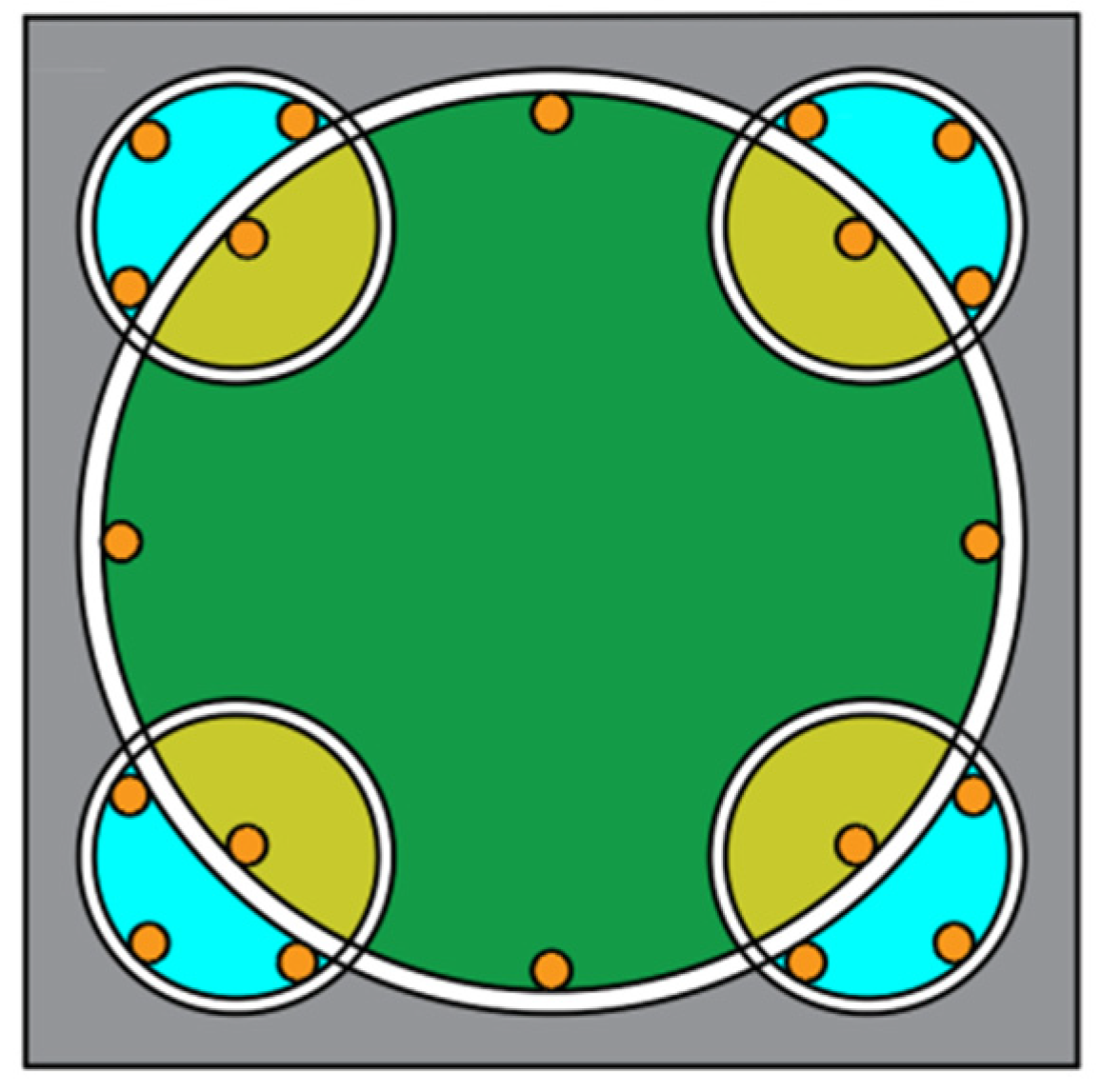

- The confinement effect of the five-spiral composite stirrups manifests predominantly in the post-peak loading phase. The central large spiral stirrup sustains tensile stresses throughout the entire loading process until ultimate failure. In contrast, the four corner small spirals contribute more significantly during initial loading stages by providing effective confinement to the corner concrete regions. As loading progresses to the middle and late stages, the small spirals located in the intersection zones with the large spiral experience rapid stress development, generating the highest lateral confinement pressure in these interaction regions.

- (2)

- Although increased axial compression ratios moderately enhance the load-bearing capacity of five-spiral composite stirrup columns, they substantially compromise member ductility. Higher shear-span ratios lead to significant deterioration in both load-bearing capacity and energy dissipation performance.

- (3)

- Specimen M0 (Figure 11) represents the optimal geometric configuration for a column constrained by five-spiral stirrups. When the spacing of small spiral stirrups is equal to that of large spiral stirrups, the specimen exhibits optimal strength and ductility, achieving the best overall performance. When the diameter of the central large spiral reaches the maximum allowable value for the cross-section, and the small spiral stirrups are one-third the diameter of the large spiral, the five-spiral stirrup column demonstrates the most favorable comprehensive performance. This configuration ensures the maximum possible area of core-constrained concrete.

- (4)

- For five-spiral stirrup-constrained concrete square columns, the interlocking design between the four corner small spiral stirrups and the central large spiral divides the cross-section into three zones with varying constraint levels: low, medium, and high. The concrete contribution to the column’s shear capacity is the sum of these three zones. Simultaneously, by separately considering the contributions of the central large stirrups and the four corner small stirrups, combined with a discrete calculation shear strength model, a simplified calculation formula for the shear capacity of five-spiral composite stirrups is proposed.

- (5)

- The shear capacity of the five-spiral stirrup reinforced concrete square columns comprises both the concrete portion and the stirrup portion, while also accounting for the influence of axial loads. Based on this, this study proposes a shear capacity calculation formula applicable to five-spiral composite stirrup-constrained concrete square columns. When compared with experimental results, the minimum error is 0.30%, with most errors falling within 10%.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Samuel, Y. Researches and Developments of Alternative Confinements for Rectangular Concrete Columns (II). China Civ. Eng. J. 2004, 37, 1–12. [Google Scholar]

- Yin, S. Helical Rebar Structure. U.S. Patent US6860077B2, 1 March 2005. [Google Scholar]

- Yin, S.Y.L.; Wang, J.C.; Wang, P.H. Development of multi-spiral confinements in rectangular columns for construction automation. J. Chin. Inst. Eng. 2012, 35, 309–320. [Google Scholar] [CrossRef]

- Ou, Y.C.; Li, J.Y.; Roh, H. Shear strength of reinforced concrete columns with five-spiral reinforcement. Eng. Struct. 2021, 233, 111929. [Google Scholar] [CrossRef]

- Ou, Y.C.; Lau, J.V.J.; Li, J.Y.; Havlásek, P.; Bittnar, Z. Cyclic behavior of reinforced concrete columns with five-spiral reinforcement. J. Build. Eng. 2022, 61, 105245. [Google Scholar] [CrossRef]

- Zheng, W.; Hao, M.; Chang, W. Seismic behavior of full-scale RC columns jacketed by modified multi-spiral stirrups. Arch. Civ. Mech. Eng. 2022, 22, 158. [Google Scholar] [CrossRef]

- Xiong, Z.; Zheng, J.; Chen, Z.; Huang, Y.; Wang, Z.; Chen, J.; Lin, L.; Li, L.; Qiao, S.; Liu, F. Seismic behavior and design method of seawater sea-sand concrete reinforced with GFRP and five interlocking spirals. Eng. Struct. 2023, 291, 116410. [Google Scholar] [CrossRef]

- Wang, P.H.; Chang, K.C.; Yin, S.Y.L.; Wang, J.C.; Ou, Y.C. Simplified finite-element analysis method for axial compression behavior of rectangular concrete columns with interlocking multispiral reinforcements. J. Struct. Eng. 2020, 146, 04019176. [Google Scholar] [CrossRef]

- Wu, J. The Seismic Behavior of Multi-Spiral Stirrup Toughening Reforced Lightweight Concrete. Doctoral Dissertation, Wuhan University of Technology, Wuhan, China, 2010. [Google Scholar]

- Weng, Z.Q.; Yin, Y.L.; Wang, R.Z.; Liang, C.; Lin, G. Seismic Cyclic Loading Test of Full-Scale Reinforced Concrete Columns Confined with 5-Spirals. J. Struct. Eng. 2011, 26, 57–91. [Google Scholar]

- Lu, D.H.; Wu, Z.L.; Cao, J.Y.; Gong, C. Experimental Study on Seismic Resistance of Fabricated Five-screw-stirrup Column. Build. Constr. 2019, 41, 2237–2241. [Google Scholar]

- Ngo, S.H.; Ou, Y.C. Expected maximum moment of multi-spiral columns. Eng. Struct. 2021, 249, 113386. [Google Scholar] [CrossRef]

- Liu, Y. Study on Axial Compression Capacity and Seismic Performance of Innovative Five-Spiral Stirrup for Steel Rectangular Columns. Master’s Thesis, Southwest Jiaotong University, Chengdu, China, 2021. [Google Scholar]

- Lubliner, J.; Oliver, J.; Oller, S.; Onate, E. A plastic-damage model for concrete. Int. J. Solids Struct. 1989, 25, 299–326. [Google Scholar] [CrossRef]

- Lee, J.; Fenves, G.L. Plastic-damage model for cyclic loading of concrete structures. J. Eng. Mech. 1998, 124, 892–900. [Google Scholar] [CrossRef]

- GB50010-2015; Code for Design of Concrete Structures. China Architecture & Building Press: Beijing, China, 2015.

- Mander, J.B.; Priestley, M.J.; Park, R. Theoretical stress-strain model for confined concrete. J. Struct. Eng. 1988, 114, 1804–1826. [Google Scholar] [CrossRef]

- Fang, Z.H.; Zhen, Y.; Li, X.P. Steel hysteretic model of reinforced concrete structures. Eng. J. Wuhan Univ. 2018, 51, 613–619. [Google Scholar]

- Chen, Z.; Chen, J.; Jiang, X.; Mo, L. Experimental research and finite element analysis on seismic behavior of square reinforced concrete columns with four interlocking spirals. Structures 2022, 39, 1–16. [Google Scholar] [CrossRef]

- Kunnath, S.K.; Jenne, C. Seismic damage assessment of inelastic RC structures. In Proceedings of the 5th US National Conference on Earthquake Engineering (EERI), Chicago, IL, USA, 10–14 July 1994; Volume 1, pp. 55–64. [Google Scholar]

- T/CECS 512-2018; Technical Specification for Application of Multi-Spiral Columns. Planning Press: Beijing, China, 2018.

- Yu, Z.W.; Ding, F.X. Unified calculation method of compressive mechanical properties of concrete. J. Build. Struct. 2003, 24, 41–46. [Google Scholar]

- Ding, F.X.; Yu, Z.W. Unified Calculation Method of Mechanical Properties of Concrete in Tension. J. Civ. Eng. Manag. 2004, 5, 29–34. [Google Scholar]

- Ou, Y.C.; Kurniawan, D.P. Effect of axial compression on shear behavior of high-strength reinforced concrete columns. ACI Struct. J. 2015, 112, 209–220. [Google Scholar] [CrossRef]

| Specimen ID | Geometric Dimensions Length × Width × Height | Concrete Core Compressive Strength | Longitudinal Reinforcement Ratio | Volume Stirrup Ratio | Stirrup Strength |

|---|---|---|---|---|---|

| 1-S5-0.3 | 300 × 300 × 1160 | 40.3 | 2.68 | 2.33 | 465 |

| 2-S5-0.5 | 300 × 300 × 1160 | 40.3 | 2.68 | 2.33 | 465 |

| 3-S5-0.3 | 300 × 300 × 1160 | 40.3 | 3.18 | 2.33 | 454 |

| 4-S5-0.5 | 300 × 300 × 1160 | 40.3 | 3.18 | 2.33 | 454 |

| 5-S5-0.1 | 600 × 600 × 3250 | 30.5 | 2.25 | 1.77 | 493 |

| 6-S5-0.1 | 600 × 600 × 3250 | 30.5 | 2.25 | 1.46 | 493 |

| 7-S5-0.1 | 600 × 600 × 3250 | 30.5 | 2.39 | 1.46 | 451 |

| 8-S5-0.1 | 600 × 600 × 1200 | 28.9 | 2.18 | 2.20 | 481 |

| 9-S5-0.1 | 450 × 450 × 2000 | 23.4 | 2.25 | 2.34 | 429 |

| 10-S5-0.1 | 600 × 600 × 1800 | 36.3 | 3.84 | 0.75 | 476 |

| 11-S5-0.3 | 600 × 600 × 1800 | 51.2 | 3.84 | 0.75 | 466 |

| 12-S5-0.1 | 600 × 600 × 2400 | 46.7 | 2.15 | 1.98 | 481 |

| 13-S5-0.3 | 600 × 600 × 2400 | 50.1 | 2.15 | 1.98 | 481 |

| Specimen Number | Axial Pressure Ratio/ | Shear-Span Ratio/ | Diameter /mm, Spacing /mm | Spiral Diameter Ratio | Volume Fitting Ratio /% | |

|---|---|---|---|---|---|---|

| Big Spiral | Small Spiral | |||||

| M0 | 0.3 | 4.57 | Φ16@90 | Φ10@90 | 3 | 1.98 |

| MA-1 | 0.2 | 4.57 | Φ16@90 | Φ10@90 | 3 | 1.98 |

| MA-2 | 0.4 | 4.57 | Φ16@90 | Φ10@90 | 3 | 1.98 |

| MA-3 | 0.5 | 4.57 | Φ16@90 | Φ10@90 | 3 | 1.98 |

| MA-4 | 0.6 | 4.57 | Φ16@90 | Φ10@90 | 3 | 1.98 |

| MB-1 | 0.3 | 2 | Φ16@90 | Φ10@90 | 3 | 1.98 |

| MB-2 | 0.3 | 3 | Φ16@90 | Φ10@90 | 3 | 1.98 |

| MB-3 | 0.3 | 4 | Φ16@90 | Φ10@90 | 3 | 1.98 |

| MB-4 | 0.3 | 5 | Φ16@90 | Φ10@90 | 3 | 1.98 |

| MB-5 | 0.3 | 6 | Φ16@90 | Φ10@90 | 3 | 1.98 |

| MC-1 | 0.3 | 4.57 | Φ16@90 | Φ10@45 | 3 | 2.65 |

| MC-2 | 0.3 | 4.57 | Φ16@90 | Φ10@180 | 3 | 1.64 |

| MC-3 | 0.3 | 4.57 | Φ16@90 | Φ10@270 | 3 | 1.53 |

| MD-1 | 0.3 | 4.57 | Φ16@90 | Φ10@90 | 1 | 1.76 |

| MD-2 | 0.3 | 4.57 | Φ16@90 | Φ10@90 | 1.5 | 2.10 |

| MD-3 | 0.3 | 4.57 | Φ16@90 | Φ10@90 | 2 | 2.32 |

| MD-4 | 0.3 | 4.57 | Φ16@90 | Φ10@90 | 2.5 | 2.11 |

| Specimen Number | Experimental Value | Theoretical Calculated Value | Error |

|---|---|---|---|

| 1-S5-0.3 | 191.10 | 191.68 | 0.30% |

| 2-S5-0.3 | 197.50 | 191.71 | 2.93% |

| 3-S5-0.5 | 192.50 | 206.92 | 7.49% |

| 4-S5-0.1 | 493.80 | 557.38 | 12.88% |

| 5-S5-0.1 | 490.10 | 472.31 | 3.63% |

| 6-S5-0.1 | 476.30 | 472.34 | 0.83% |

| 7-S5-0.1 | 530.10 | 481.62 | 9.15% |

| 8-S5-0.1 | 263.40 | 268.95 | 2.11% |

| 9-S5-0.3 | 336.10 | 288.68 | 14.11% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, S.; Yu, T.; Gao, X.; Zhang, Z.; Su, T.; Hao, Z. Seismic Performance of Concrete Square Column Confined by Five-Spiral Composite Stirrups. Coatings 2025, 15, 1499. https://doi.org/10.3390/coatings15121499

Sun S, Yu T, Gao X, Zhang Z, Su T, Hao Z. Seismic Performance of Concrete Square Column Confined by Five-Spiral Composite Stirrups. Coatings. 2025; 15(12):1499. https://doi.org/10.3390/coatings15121499

Chicago/Turabian StyleSun, Shanshan, Tao Yu, Xiangyu Gao, Zhaoqiang Zhang, Tian Su, and Zhixing Hao. 2025. "Seismic Performance of Concrete Square Column Confined by Five-Spiral Composite Stirrups" Coatings 15, no. 12: 1499. https://doi.org/10.3390/coatings15121499

APA StyleSun, S., Yu, T., Gao, X., Zhang, Z., Su, T., & Hao, Z. (2025). Seismic Performance of Concrete Square Column Confined by Five-Spiral Composite Stirrups. Coatings, 15(12), 1499. https://doi.org/10.3390/coatings15121499