Microstructure Evolution and Toughening Mechanisms in the Nugget Zone of Friction-Stir-Welded X80 Pipeline Steel

Abstract

1. Introduction

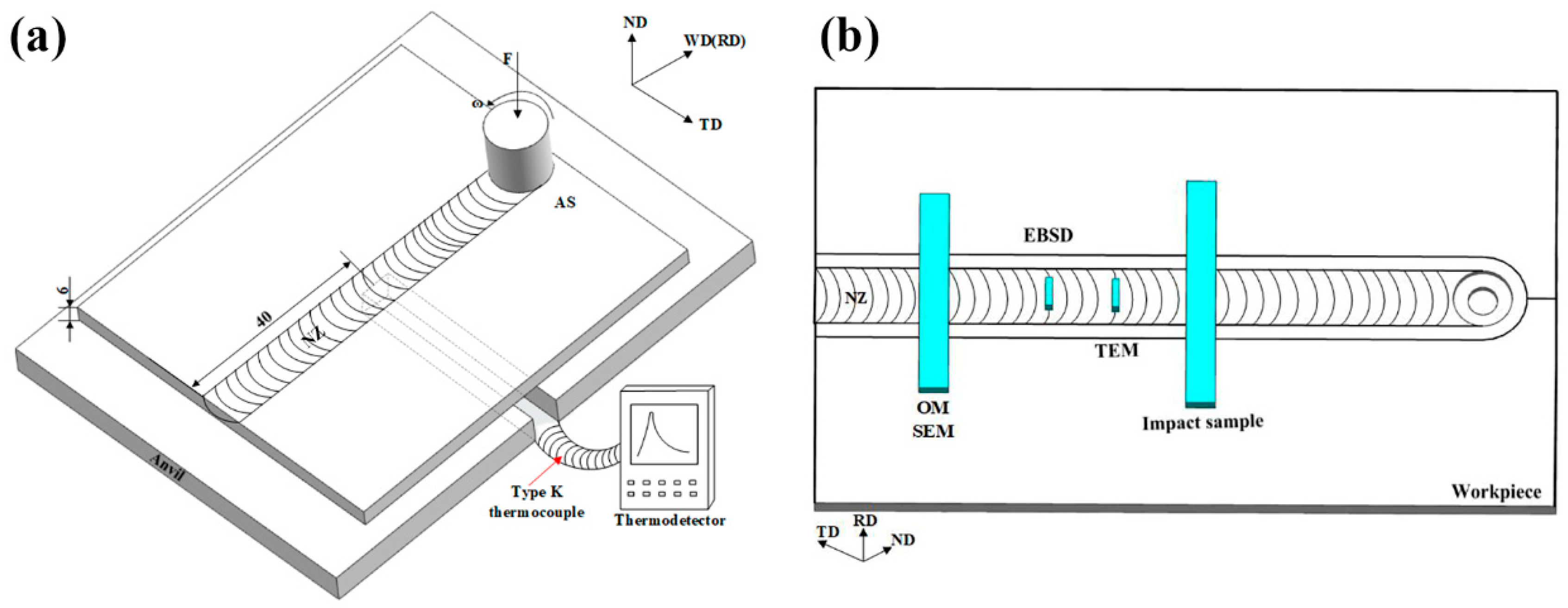

2. Experimental Procedure

3. Results and Discussion

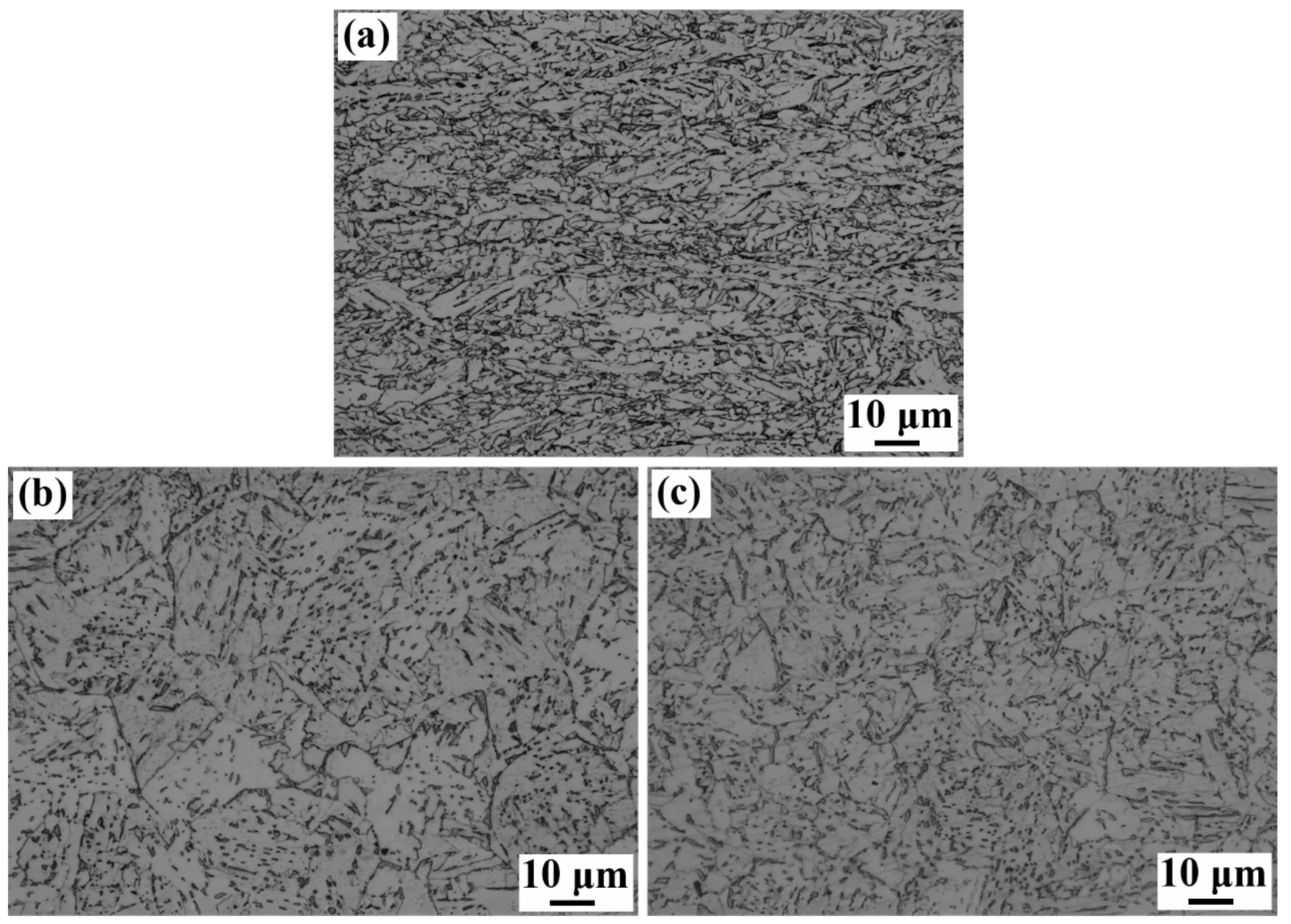

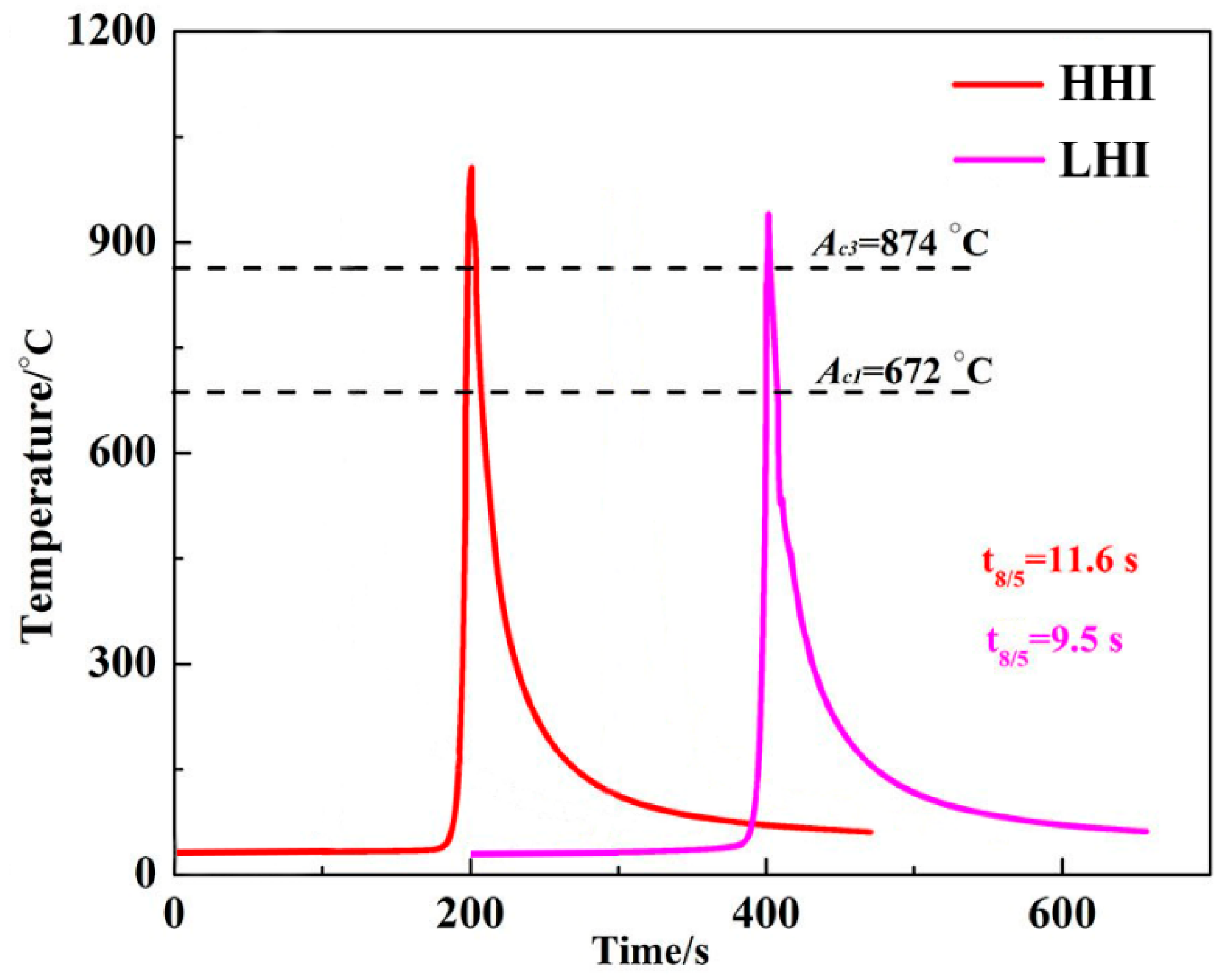

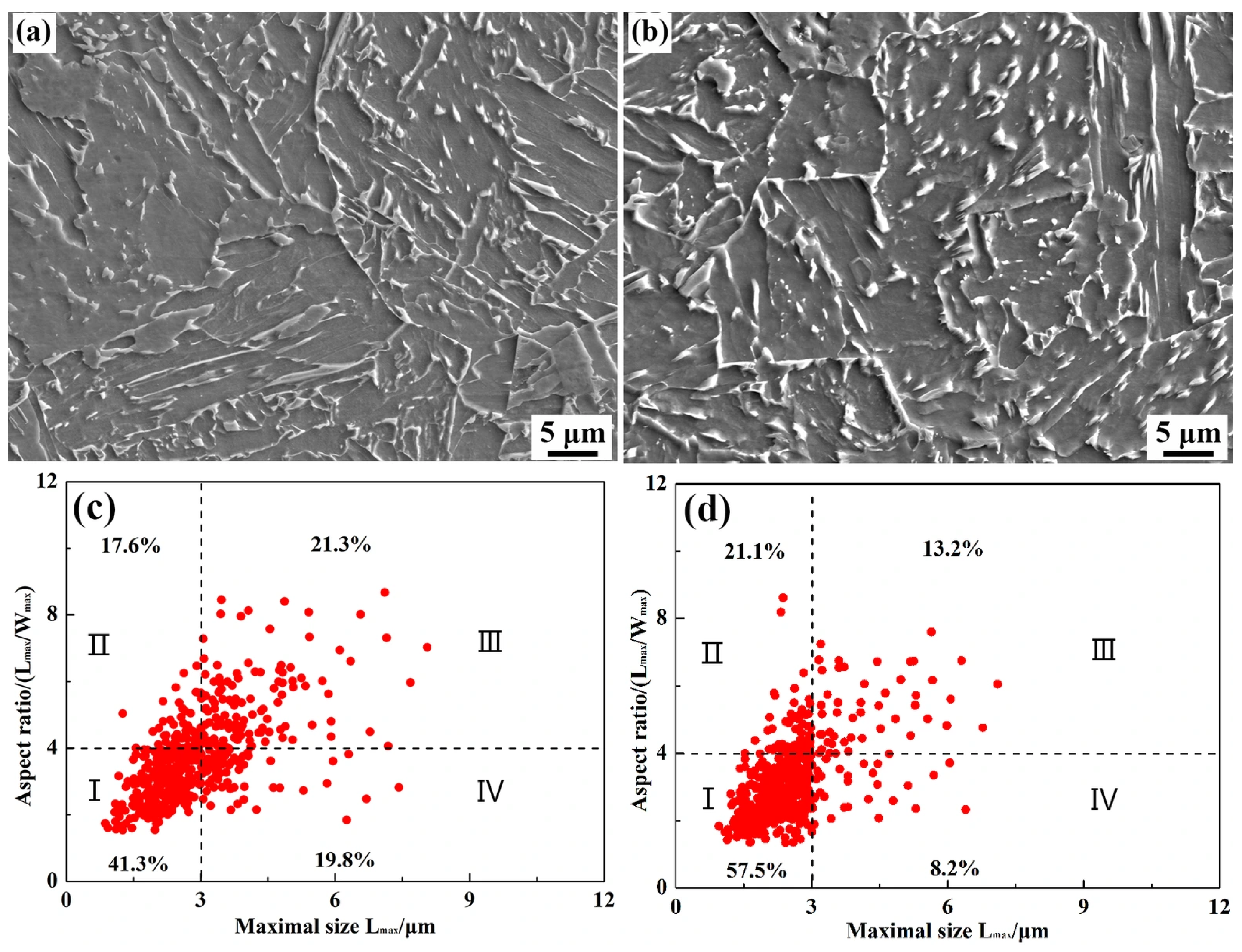

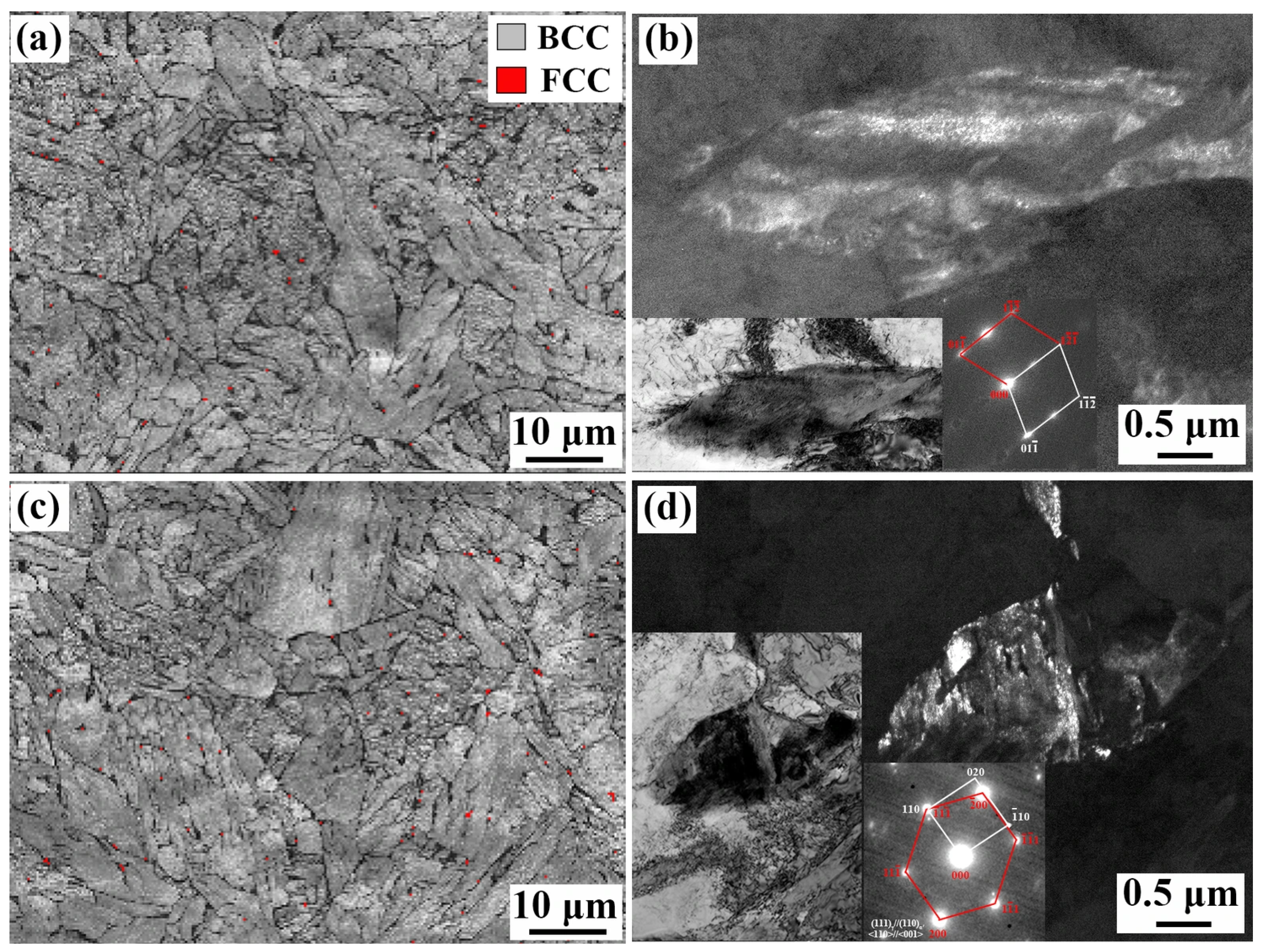

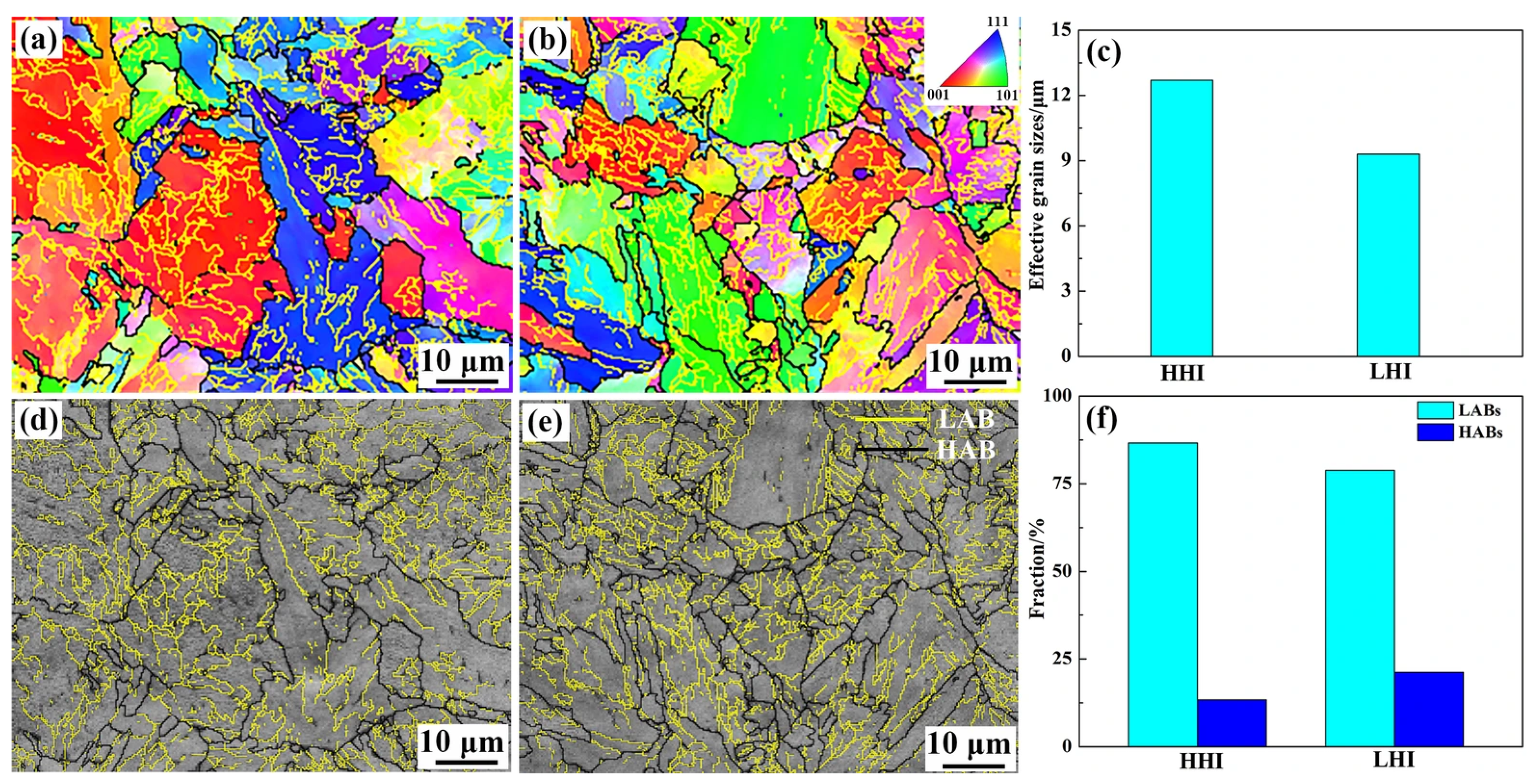

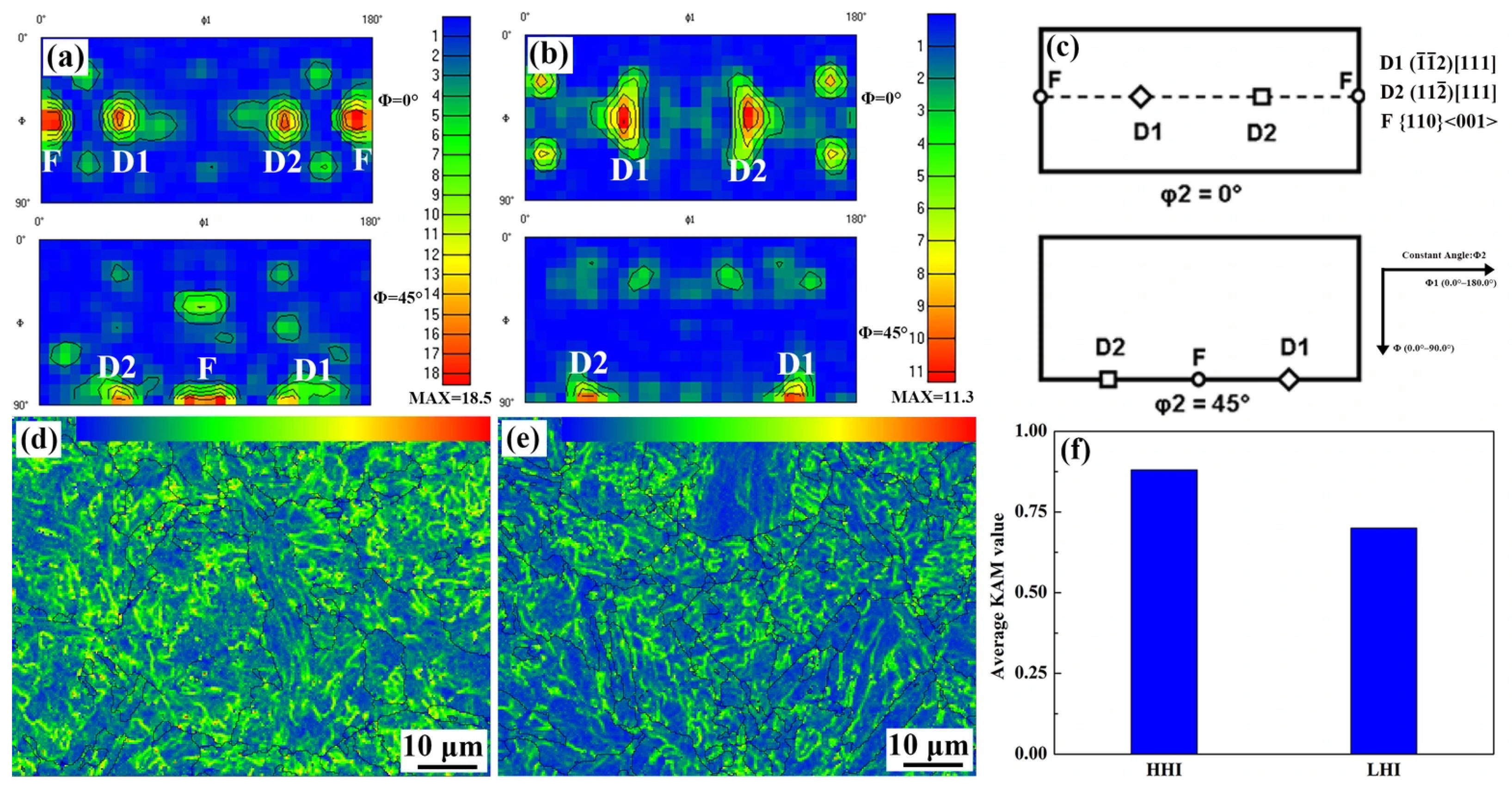

3.1. Microstructural Evolution in the NZs

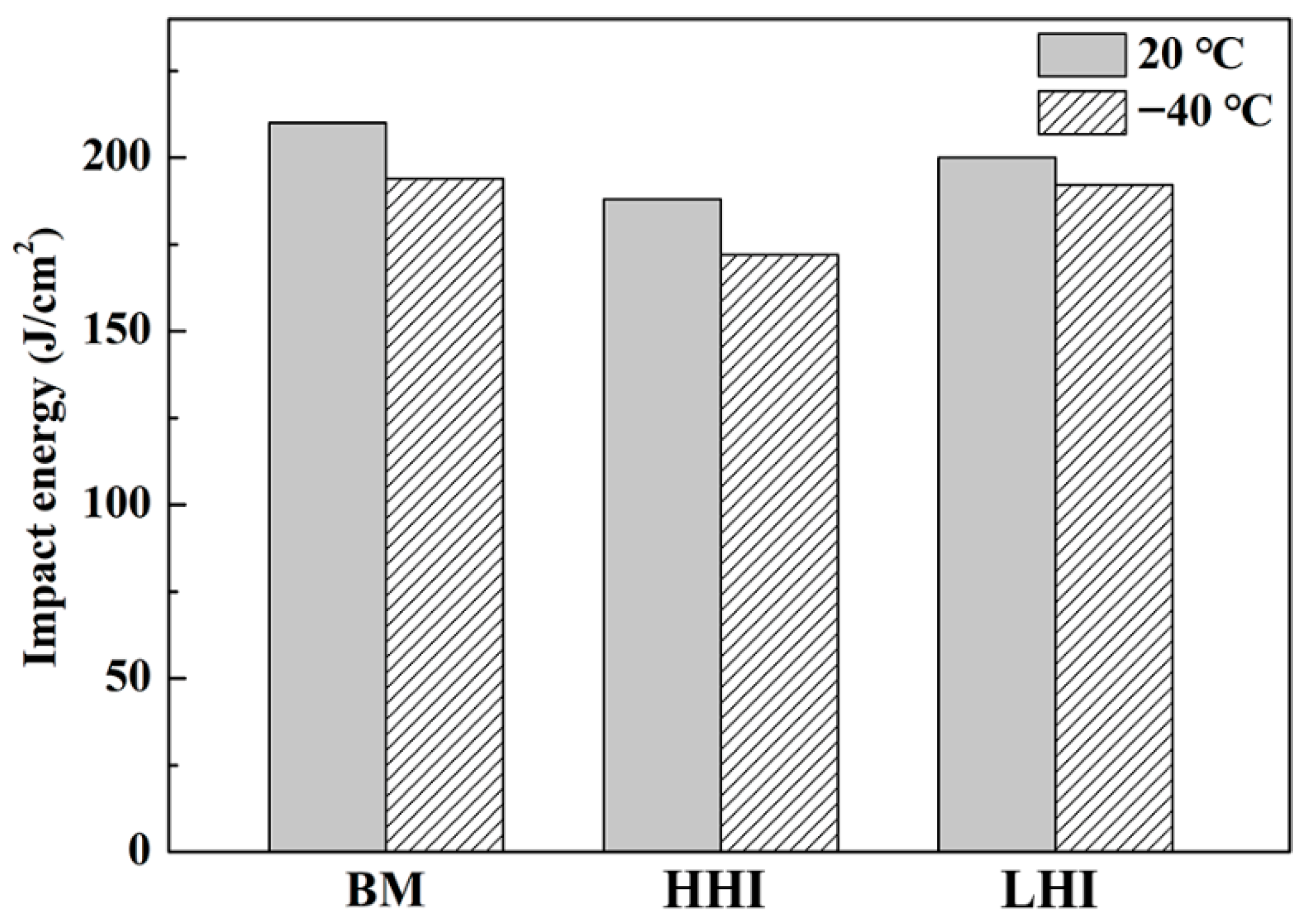

3.2. Toughness Variation in the NZs

4. Conclusions

- (1)

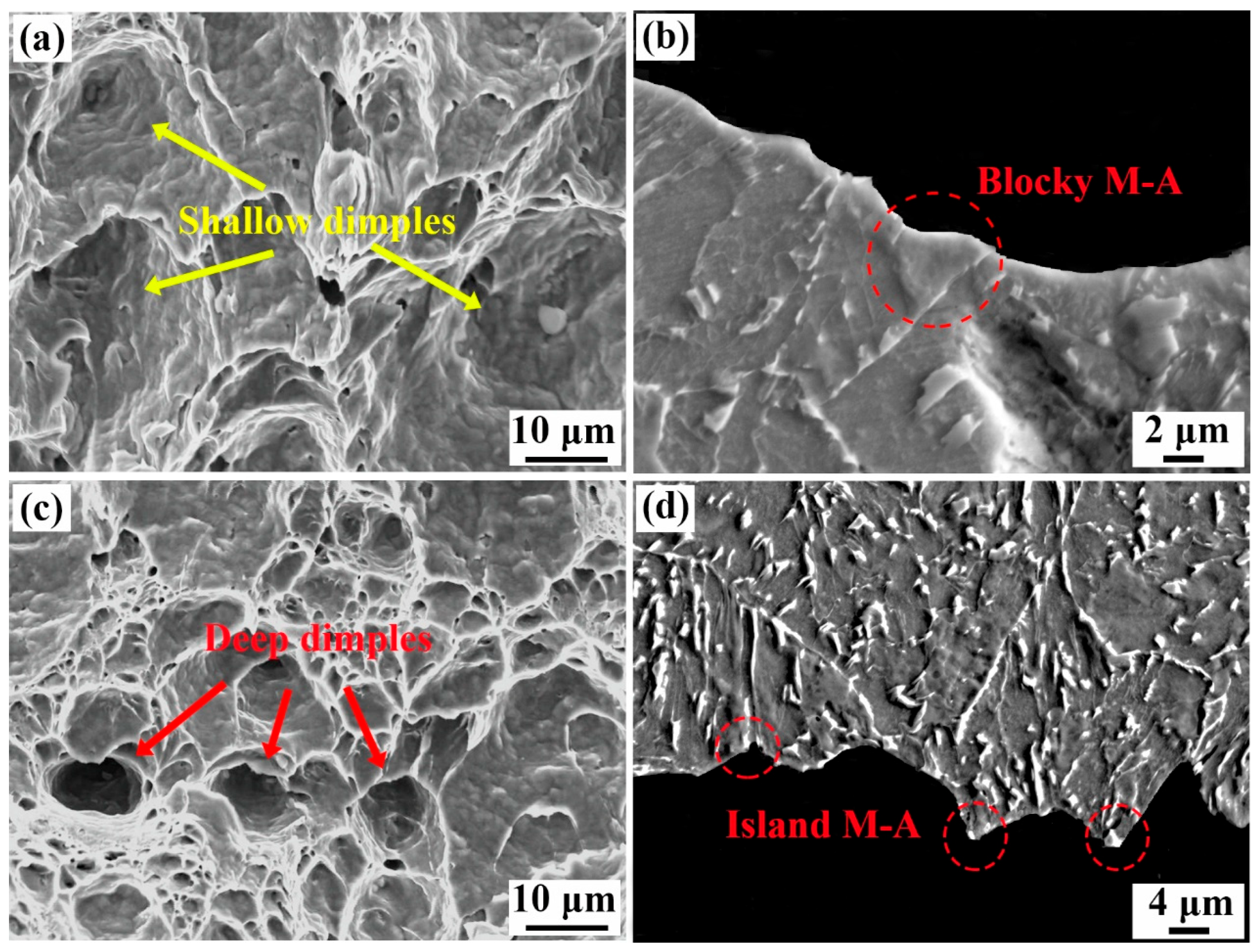

- Coarse granular bainite (GB) appeared in the NZ at high heat input (HHI), while fine GB and lath bainite (LB) were observed in the NZ at low HI (HHI). Meanwhile, there was a marked reduction in effective grain size within the NZ at LHI, and a significant increase in the ratio of refined M-A constituent was observed.

- (2)

- Different types of shear textures such as D1, D2, and F were generated in the NZ under various HIs. Furthermore, the decreased HI leads to weak texture component accompanied by a decrease in the kernel average misorientation (KAM) value.

- (3)

- An excellent toughness value of 200 J, representing 95.3% of the basal metal (BM), was achieved in the NZ at LHI. This is attributed to the fact that a high proportion of effective grain boundaries and fine M-A constituents can effectively arrest and deflect the crack propagation, enhancing the toughness.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, C.; Di, X.J.; Dai, L.S.; Liu, J.; Han, J.W.; Yang, X.C.; Yang, Z.Q.; Cui, S.H.; Zhang, C.; Ma, Z.B.; et al. Synchronously improving strength and toughness for pipeline steel weld via cerium adding. Int. J. Press. Vessel. Pip. 2025, 215, 105466. [Google Scholar] [CrossRef]

- Wei, H.T.; Duan, B.Q.; Shi, X.S.; Gao, R.Z.; Hua, Z.L.; Qiu, S.Y.; Zhao, Y.M. Influence of hydrogen in natural gas mixed hydrogen environment on mechanical properties of X80 pipeline steel. Int. J. Hydrogen Energy 2024, 54, 908–921. [Google Scholar] [CrossRef]

- Qi, X.N.; Huan, P.C.; Wang, X.N.; Shen, X.J.; Liu, Z.G.; Di, H.S. Effect of microstructure homogeneity on the impact fracture mechanism of X100 pipeline steel laser–MAG hybrid welds with an alternating magnetic field. Mater. Sci. Eng. A 2022, 851, 143656. [Google Scholar] [CrossRef]

- Zhu, Z.X.; Kuzmikova, L.; Li, H.J.; Barbaro, F. Effect of inter-critically reheating temperature on microstructure and properties of simulated inter-critically reheated coarse grained heat affected zone in X70 steel. Mater. Sci. Eng. A 2014, 605, 8–13. [Google Scholar] [CrossRef]

- Shin, S.Y.; Gong, G.; Kim, S.; Lee, S. Analysis of fracture toughness in the transition temperature region of API X70 pipeline steels rolled in two-phase region. Metall. Mater. Trans. A 2007, 38, 1012–1021. [Google Scholar] [CrossRef]

- Midawi, A.R.H.; Santos, E.B.F.; Huda, N.; Sinha, A.K.; Lazor, R.; Gerlich, A.P. Microstructures and mechanical properties in two X80 weld metals produced using similar heat input. J. Mater. Process. Technol. 2025, 226, 272–279. [Google Scholar] [CrossRef]

- Midawi, A.R.H.; Simha, C.H.M.; Gerlich, A.P. Assessment of yield strength mismatch in X80 pipeline steel welds using instrumented indentation. Int. J. Press. Vessel. Pip. 2018, 168, 258–268. [Google Scholar] [CrossRef]

- Ci, Y.; Zhang, Z.Z. Fracture toughness of the materials in welded joint of X80 pipeline steel. J. Iron. Steel. Res. Int. 2017, 24, 966–972. [Google Scholar] [CrossRef]

- Li, X.D.; Fan, Y.R.; Ma, X.P.; Subramanian, S.V.; Shang, C.J. Influence of Martensite-Austenite constituents formed at different intercritical temperatures on toughness. Mater. Des. 2015, 67, 457–463. [Google Scholar] [CrossRef]

- Qi, X.N.; Di, H.S.; Wang, X.N.; Liu, Z.G.; Misra, R.D.K.; Huan, P.C.; Gao, Y. Effect of secondary peak temperature on microstructure and toughness in ICCGHAZ of laser-arc hybrid welded X100 pipeline steel joints. J. Mater. Res. Technol. 2020, 9, 7838–7849. [Google Scholar] [CrossRef]

- Haugen, V.G.; Rogne, B.R.S.; Akselsen, O.M.; Thaulow, C.; Østby, E. Local mechanical properties of intercritically reheated coarse grained heat affected zone in low alloy steel. Mater. Des. 2014, 59, 135–140. [Google Scholar] [CrossRef]

- Li, X.D.; Shang, C.J.; Ma, X.P.; Subramanian, S.V. Study on the toughness of X100 pipeline steel heat affected zone. In Proceedings of the Conference on Energy Materials, Xian, China, 4–6 November 2014. [Google Scholar]

- Aydin, H.; Nelson, T.W. Microstructure and mechanical properties of hard zone in friction stir welded X80 pipeline steel relative to different heat input. Mater. Sci. Eng. A 2013, 586, 313–322. [Google Scholar] [CrossRef]

- Duan, R.H.; Liu, J.H.; Wang, Y.Q.; Chen, S.J.; Yang, Z.D.; Dong, Y.; Xie, G.M. Improved microstructure and mechanical properties of high strength pipeline steel joints via modulating rotation rate of friction stir welding. J. Mater. Sci. 2025, 60, 2658–2672. [Google Scholar] [CrossRef]

- Barnes, S.J.; Bhatti, A.R.; Steuwer, A.; Johnson, R.; Altenkirch, J.; Withers, P.J. Friction stir welding in HSLA-65 Steel: Part I. Influence of weld speed and tool material on microstructural development. Metall. Mater. Trans. A 2012, 43, 2342–2355. [Google Scholar] [CrossRef]

- Xie, G.M.; Cui, H.B.; Luo, Z.A.; Misra, R.D.K.; Wang, G.D. Asymmetric distribution of microstructure and impact toughness in stir zone during friction stir processed a high strength pipeline steel. Mater. Sci. Eng. A 2017, 704, 401–411. [Google Scholar] [CrossRef]

- Xie, G.M.; Duan, R.H.; Xue, P.; Ma, Z.Y.; Liu, H.L.; Luo, Z.A. Microstructure and mechanical properties of X80 pipeline steel joints by friction stir welding under various cooling conditions. Acta. Metall. Sin. 2020, 33, 88–102. [Google Scholar] [CrossRef]

- Duan, R.H.; Xie, G.M.; Luo, Z.A.; Xue, P.; Wang, C.; Misra, R.D.K.; Wang, G.D. Microstructure, crystallography, and toughness in nugget zone of friction stir welded high-strength pipeline steel. Mater. Sci. Eng. A 2020, 791, 139620. [Google Scholar] [CrossRef]

- Xie, G.M.; Cui, H.B.; Luo, Z.A.; Yu, W.; Ma, J.; Wang, G.D. Effect of Rotation Rate on Microstructure and Mechanical Properties of Friction Stir Spot Welded DP780 Steel. J. Mater. Sci. Technol. 2016, 32, 326–332. [Google Scholar] [CrossRef]

- Lambert, A.; Lambert, A.; Drillet, J.; Gourgues, A.F.; Sturel, T.; Pineau, A. Microstructure of martensite-austenite constituents in heat affected zones of high strength low alloy steel welds in relation to toughness properties. Sci. Technol. Weld. Join. 2000, 5, 168–173. [Google Scholar] [CrossRef]

- Duan, R.H.; Xie, G.M.; Xue, P.; Ma, Z.Y.; Luo, Z.A.; Wang, C. Microstructural refinement mechanism and its effect on toughness in the nugget zone of high-strength pipeline steel by friction stir welding. J. Mater. Sci. Technol. 2021, 93, 221–231. [Google Scholar] [CrossRef]

- Lan, H.F.; Du, L.X.; Misra, R.D.K. Effect of microstructural constituents on strength-toughness combination in a low carbon bainitic steel. Mater. Sci. Eng. A 2014, 611, 194–200. [Google Scholar] [CrossRef]

- Hu, J.; Du, L.X.; Wang, J.J. Effect of cooling procedure on microstructures and mechanical properties of hot rolled Nb-Ti bainitic high strength steel. Mater. Sci. Eng. A 2012, 554, 79–85. [Google Scholar] [CrossRef]

- Xue, P.; Komizo, Y.; Ueji, R.; Fujii, H. Enhanced mechanical properties in friction stir welded low alloy steel joints via structure refining. Mater. Sci. Eng. A 2014, 606, 322–329. [Google Scholar] [CrossRef]

- Hutchinson, B.; Ryde, L.; Lindh, E.; Tagashira, K. Texture in hot rolled austenite and resulting transformation products. Mater. Sci. Eng. A 1998, 257, 9–17. [Google Scholar] [CrossRef]

- Abbasi, M.; Nelson, T.W.; Sorensen, C.D. Transformation and deformation texture study in friction stir processed API X80 pipeline stee. Metall. Mater. Trans. A 2012, 43, 4940–4946. [Google Scholar] [CrossRef]

- Yasavol, N.; Abdollah-zadeh, A.; Vieira, M.T.; Jafarian, H.R. Microstructure evolution and texture development in a friction stir-processed AISI D2 tool steel. Appl. Surf. Sci. 2014, 293, 151–159. [Google Scholar] [CrossRef]

- Xie, G.M.; Duan, R.H.; Wang, Y.Q.; Luo, Z.A.; Wang, G.D. Microstructure and toughness of thick-gauge pipeline steel joint via double-sided friction stir welding combined with preheating. Int. J. Min. Met. Mater. 2023, 30, 724–733. [Google Scholar] [CrossRef]

- You, Y.; Shang, C.J.; Nie, W.J.; Subramanian, S. Investigation on the microstructure and toughness of coarse grained heat affected zone in X-100 multi-phase pipeline steel with high Nb content. Mater. Sci. Eng. A 2012, 558, 692–701. [Google Scholar] [CrossRef]

- Yang, X.C.; Di, X.J.; Liu, X.G.; Wang, D.P.; Li, C.N. Effects of heat input on microstructure and fracture toughness of simulated coarse-grained heat affected zone for HSLA steels. Mater. Charact. 2019, 155, 109818. [Google Scholar] [CrossRef]

- Cui, H.B.; Xie, G.M.; Luo, Z.A.; Ma, J.; Wang, G.D.; Misra, R.D.K. The microstructural evolution and impact toughness of nugget zone in friction stir welded X100 pipeline steel. J. Alloy Compd. 2016, 681, 426–433. [Google Scholar] [CrossRef]

| Chemical composition | Fe | C | Si | Mn | P | S | Nb | V |

| Balance | 0.038 | 0.2329 | 1.611 | 0.0098 | 0.017 | 0.0535 | 0.0029 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Han, M.; Yang, M.; Rao, Y.; Luo, X.; Duan, R.; Guo, S.; Dong, Y.; Chen, S. Microstructure Evolution and Toughening Mechanisms in the Nugget Zone of Friction-Stir-Welded X80 Pipeline Steel. Coatings 2025, 15, 1384. https://doi.org/10.3390/coatings15121384

Han M, Yang M, Rao Y, Luo X, Duan R, Guo S, Dong Y, Chen S. Microstructure Evolution and Toughening Mechanisms in the Nugget Zone of Friction-Stir-Welded X80 Pipeline Steel. Coatings. 2025; 15(12):1384. https://doi.org/10.3390/coatings15121384

Chicago/Turabian StyleHan, Miaoye, Min Yang, Yinhui Rao, Xiong Luo, Ruihai Duan, Sheng Guo, Ying Dong, and Shujin Chen. 2025. "Microstructure Evolution and Toughening Mechanisms in the Nugget Zone of Friction-Stir-Welded X80 Pipeline Steel" Coatings 15, no. 12: 1384. https://doi.org/10.3390/coatings15121384

APA StyleHan, M., Yang, M., Rao, Y., Luo, X., Duan, R., Guo, S., Dong, Y., & Chen, S. (2025). Microstructure Evolution and Toughening Mechanisms in the Nugget Zone of Friction-Stir-Welded X80 Pipeline Steel. Coatings, 15(12), 1384. https://doi.org/10.3390/coatings15121384