Performance Reinforcement of Basalt Fiber–Reinforced Polymer by Guiding Hierarchical Aramid/Zirconia Hybrid Fiber

Abstract

1. Introduction

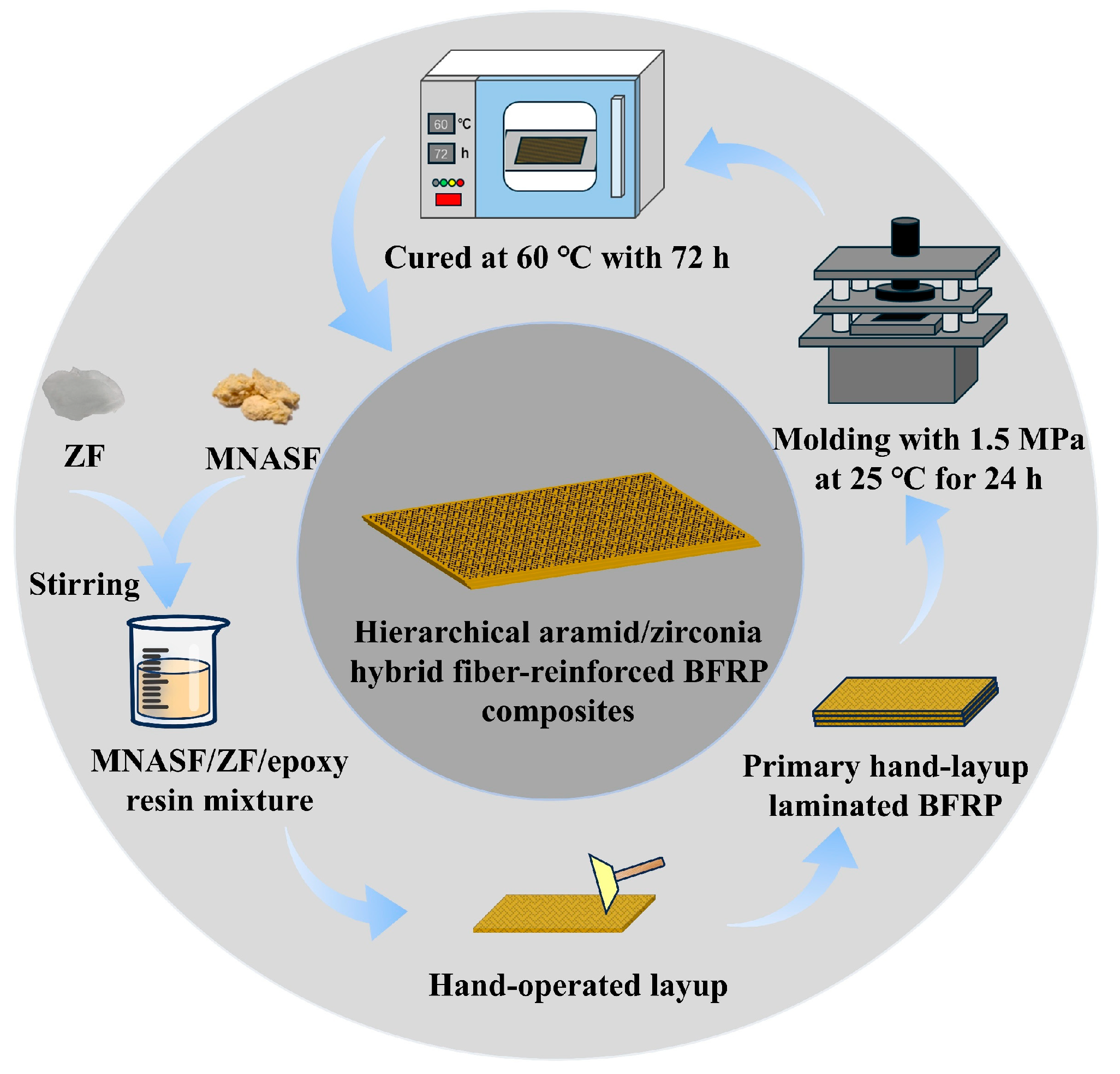

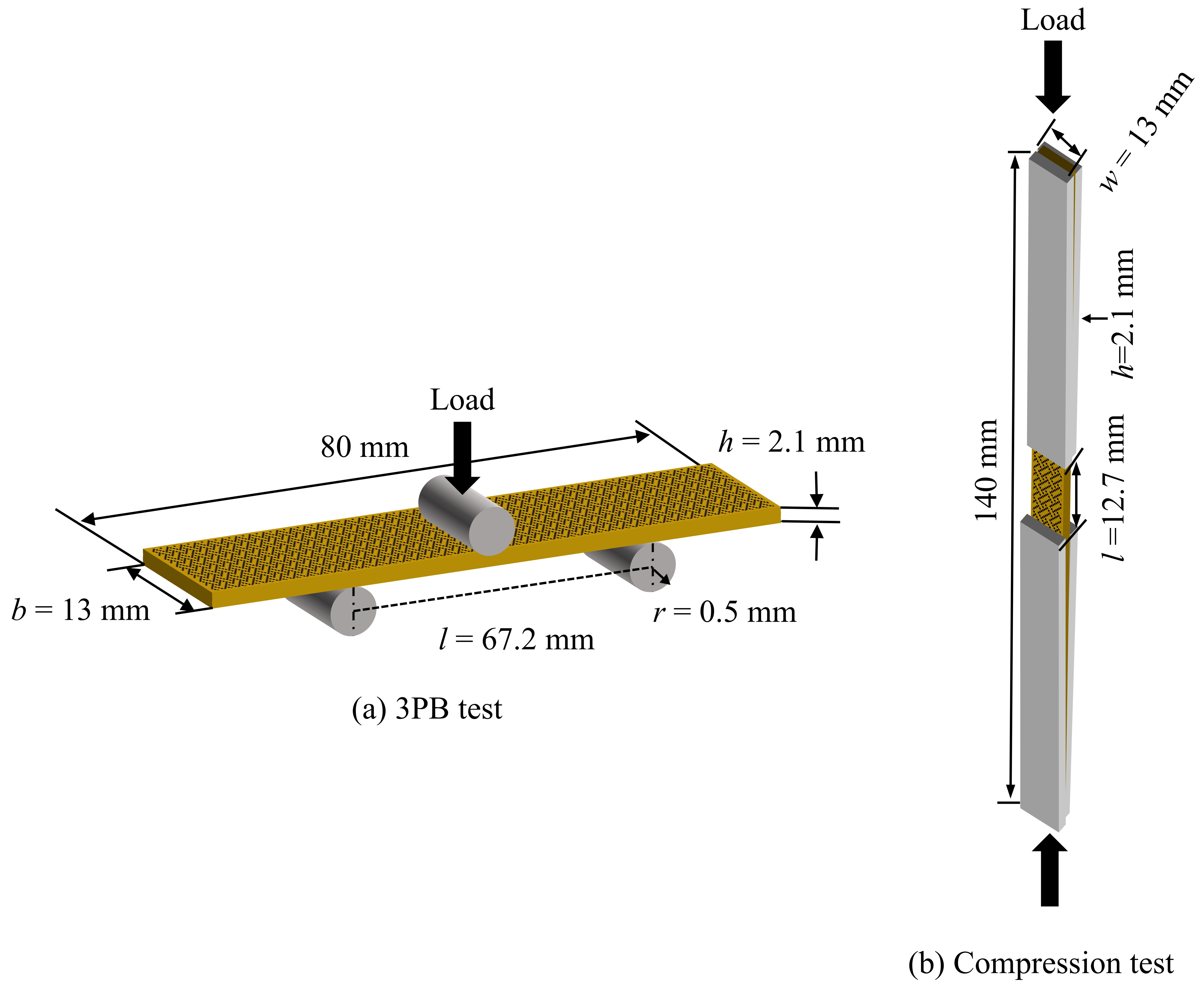

2. Composite Design, Manufacture, and Characterization

2.1. Design Concept of Hierarchical Aramid/Zirconia Hybrid Fiber-Reinforced BFRP Composites

2.2. Major Raw Materials and Preparation

2.3. Tests and Characterizations of Composites

3. Results and Discussion

3.1. Interlayer Fiber Distribution Structure

3.2. Flexural Properties Analysis

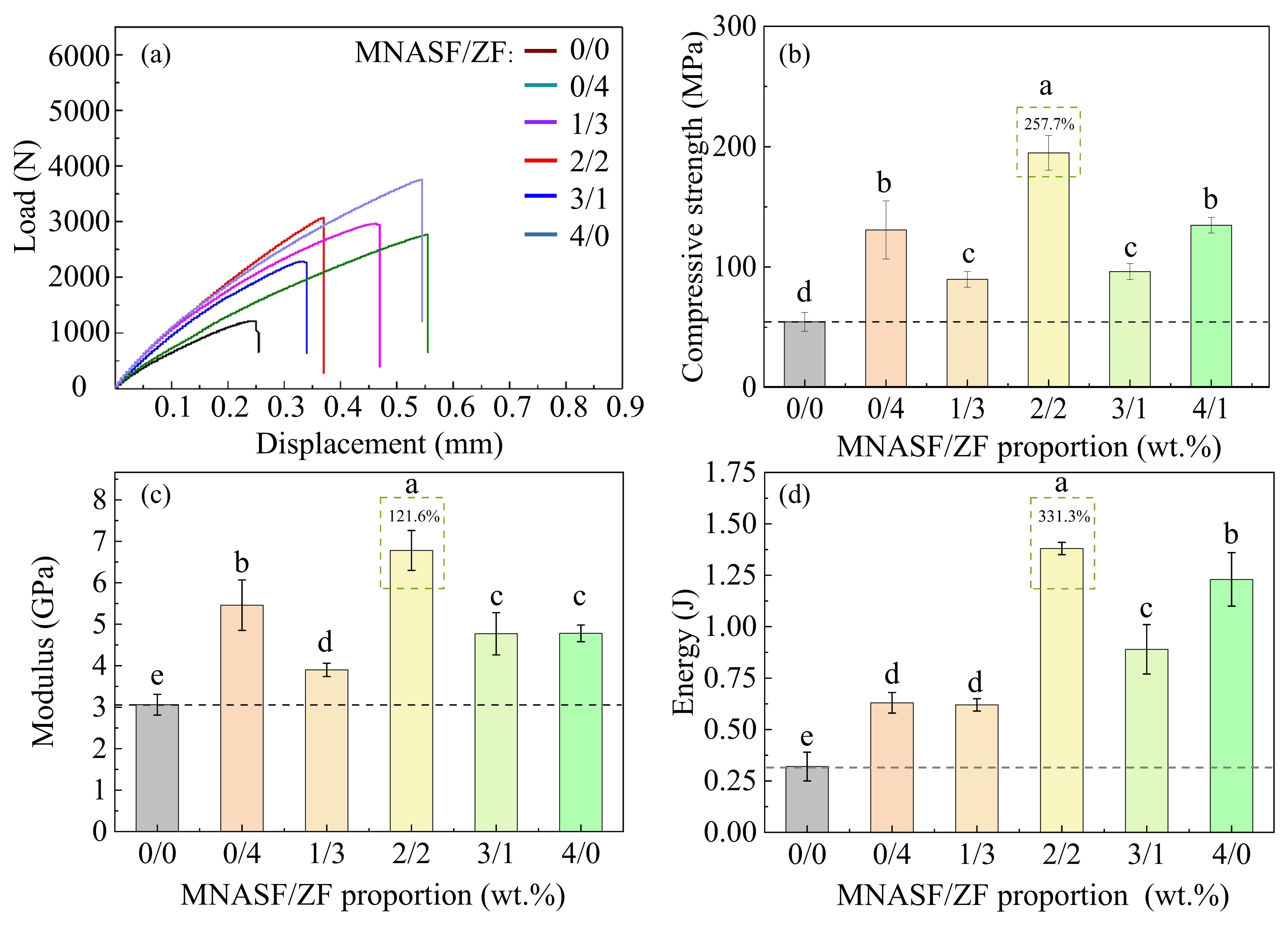

3.3. Compressive Properties Analysis

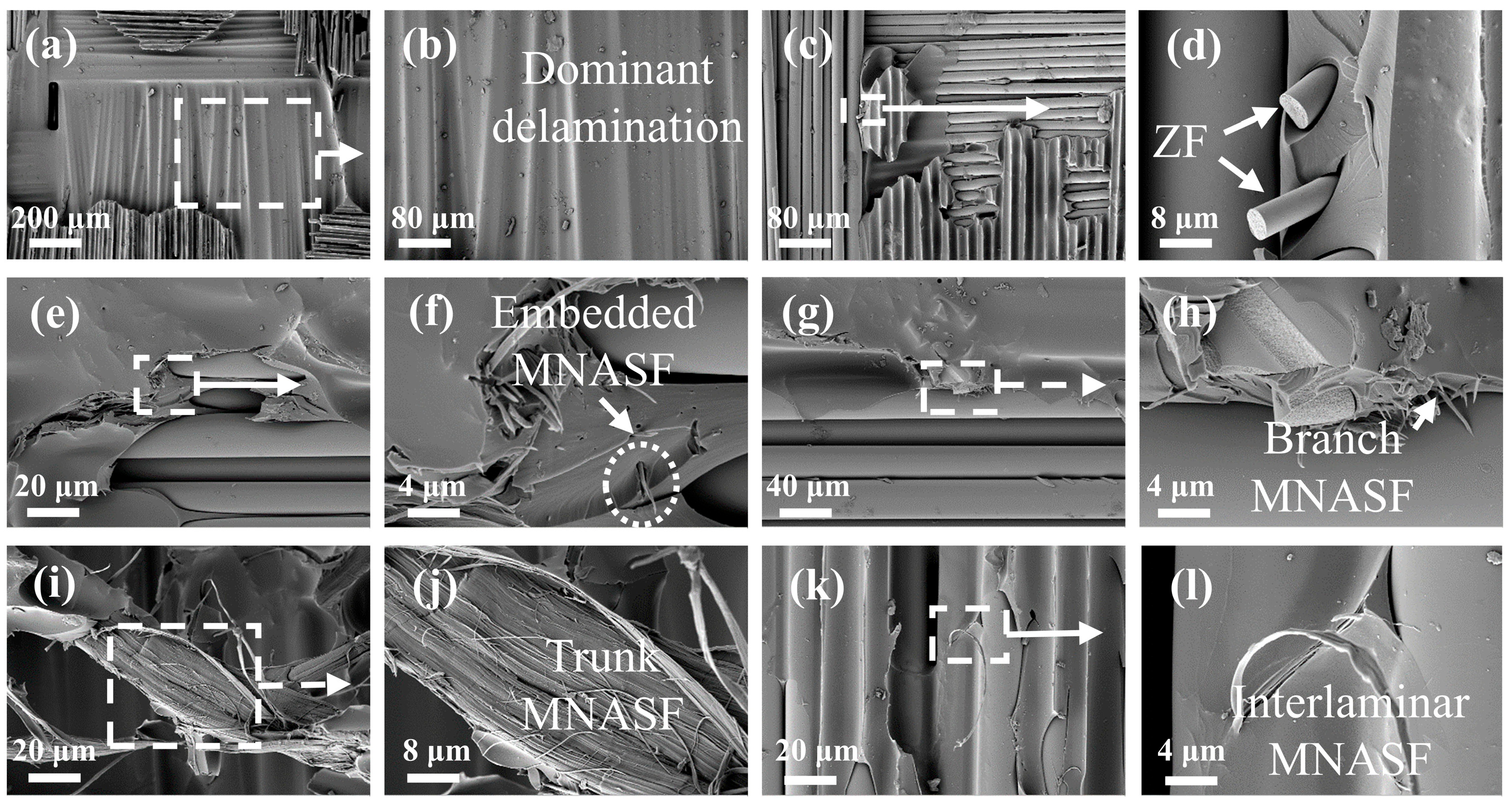

3.4. Failure Model Analysis

3.5. Damaged Interlayer Microstructure of BFRP Composites with Various Masses of MNASF and ZF

3.6. Contribution of MNASF and ZF on Improving BFRP Composites

4. Conclusions

- (1)

- The introduction of MNASF and ZF effectively optimized the interlayer microstructure of the BFRP composites. The incorporation of the two fibers reduced the volume fraction of the resin-rich regions and mitigated resin brittleness, while the fibers were simultaneously embedded within the basalt fiber layers, which confirmed the fiber-bridging structure.

- (2)

- BFRP composites with 2 wt.% MNASF and 2 wt.% ZF content demonstrated the best properties. Compared to unreinforced BFRP composites, the reinforced BFRP composites exhibited a 119.2% increase in flexural strength and a 62.6% increase in modulus. Additionally, the compressive strength and modulus increased by 257.7% and 121.6%.

- (3)

- MNASF and ZF formed fiber-bridging structures between the fiber layers, and the combination of the two fibers created a multi-scale fiber network structure, which transformed microcrack propagation from horizontal expansion to vertical expansion. This caused the dominant failure mode of the BFRP composites to transition from delamination failure to shear failure.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zheng, H.; Zhang, W.J.; Li, B.W.; Zhu, J.J.; Wang, C.H.; Song, G.J.; Wu, G.S.; Yang, X.P.; Huang, Y.D.; Ma, L.C. Recent advances of interphases in carbon fiber-reinforced polymer composites: A review. Compos. Pt. B Eng. 2022, 233, 19. [Google Scholar] [CrossRef]

- Ni, X.C.; Furtado, C.; Kalfon-Cohen, E.; Zhou, Y.; Valdes, G.A.; Hank, T.J.; Camanho, P.P.; Wardle, B.L. Static and fatigue interlaminar shear reinforcement in aligned carbon nanotube-reinforced hierarchical advanced composites. Compos. Pt. A Appl. Sci. Manuf. 2019, 120, 106–115. [Google Scholar] [CrossRef]

- Zhang, J.; Lin, G.; Vaidya, U.; Wang, H. Past, present and future prospective of global carbon fibre composite developments and applications. Compos. Pt. B Eng. 2023, 250, 19. [Google Scholar] [CrossRef]

- Lefeuvre, A.; Garnier, S.; Jacquemin, L.; Pillain, B.; Sonnemann, G. Anticipating in-use stocks of carbon fiber reinforced polymers and related waste flows generated by the commercial aeronautical sector until 2050. Resour. Conserv. Recycl. 2017, 125, 264–272. [Google Scholar] [CrossRef]

- Dhand, V.; Mittal, G.; Rhee, K.Y.; Park, S.J.; Hui, D. A short review on basalt fiber reinforced polymer composites. Compos. Pt. B Eng. 2015, 73, 166–180. [Google Scholar] [CrossRef]

- Jagadeesh, P.; Rangappa, S.M.; Siengchin, S. Basalt fibers: An environmentally acceptable and sustainable green material for polymer composites. Constr. Build. Mater. 2024, 436, 27. [Google Scholar] [CrossRef]

- Lu, G.J.; Wang, W.H.; Shen, S.J. Mechanical Properties of Wood Flour Reinforced High Density Polyethylene Composites with Basalt Fibers. Mater. Sci.-Medzg. 2014, 20, 464–467. [Google Scholar] [CrossRef]

- Kim, S.H.; Lee, J.H.; Kim, J.W.; Lee, S.Y.; Park, S.J. Interfacial Behaviors of Basalt Fiber-Reinforced Polymeric Composites: A Short Review. Adv. Fiber Mater. 2022, 4, 1414–1433. [Google Scholar] [CrossRef]

- Banibayat, P.; Patnaik, A. Variability of mechanical properties of basalt fiber reinforced polymer bars manufactured by wet-layup method. Mater. Des. 2014, 56, 898–906. [Google Scholar] [CrossRef]

- Li, X.; Li, G.M.; Su, X.H. NanoSiO2, strengthens and toughens epoxy resin/basalt fiber composites by acting as a nano-mediator. J. Polym. Eng. 2019, 39, 10–15. [Google Scholar] [CrossRef]

- Alaimo, G.; Valenza, A.; Enea, D.; Fiore, V. The durability of basalt fibres reinforced polymer (BFRP) panels for cladding. Mater. Struct. 2016, 49, 2053–2064. [Google Scholar] [CrossRef]

- Yang, G.M.; Cheng, F.; Zuo, S.H.; Zhang, J.H.; Xu, Y.; Hu, Y.S.; Hu, X.Z.; Wei, Y.; Gou, G.J. Constructing quasi-vertical fiber bridging behaviors of aramid pulp at interlayer of laminated basalt fiber reinforced polymer composites to improve flexural performances. Chin. J. Aeronaut. 2023, 36, 477–488. [Google Scholar] [CrossRef]

- Hu, Y.S.; Han, G.; Cheng, F.; Hu, X.Z. Thickness effect on flexural strengths of laminar carbon fibre composites. Thin-Walled Struct. 2023, 186, 8. [Google Scholar] [CrossRef]

- Yoshimura, A.; Nakao, T.; Yashiro, S.; Takeda, N. Improvement on out-of-plane impact resistance of CFRP laminates due to through-the-thickness stitching. Compos. Pt. A Appl. Sci. Manuf. 2008, 39, 1370–1379. [Google Scholar] [CrossRef]

- Hui, C.; Wang, P.; Legrand, X. Improvement of tufting mechanism during the advanced 3-dimensional tufted composites manufacturing: To the optimisation of tufting threads degradation. Compos. Struct. 2019, 220, 423–430. [Google Scholar] [CrossRef]

- Huang, T.; Wang, Y.L.; Wang, G. Review of the Mechanical Properties of a 3D Woven Composite and Its Applications. Polym.-Plast. Technol. Eng. 2018, 57, 740–756. [Google Scholar] [CrossRef]

- Knopp, A.; Scharr, G. Effect of z-pin surface treatment on delamination and debonding properties of z-pinned composite laminates. J. Mater. Sci. 2014, 49, 1674–1683. [Google Scholar] [CrossRef]

- Sohn, M.-S.; Hu, X.-Z. Comparative study of dynamic and static delamination behaviour of carbon fibre/epoxy composite laminates. Composites 1995, 26, 849–858. [Google Scholar] [CrossRef]

- Zheng, H.; Li, Y.; Tu, H.Y. Research on interlayer properties of short fiber intercalated carbon fiber/epoxy composites. Acta Mater. Compos. Sin. 2022, 39, 3674–3683. [Google Scholar]

- Sathishkumar, T.P.; Naveen, J.; Satheeshkumar, S. Hybrid fiber reinforced polymer composites—A review. J. Reinf. Plast. Compos. 2014, 33, 454–471. [Google Scholar] [CrossRef]

- Wong, D.W.Y.; Zhang, H.; Bilotti, E.; Peijs, T. Interlaminar toughening of woven fabric carbon/epoxy composite laminates using hybrid aramid/phenoxy interleaves. Compos. Pt. A Appl. Sci. Manuf. 2017, 101, 151–159. [Google Scholar] [CrossRef]

- Gupta, M.K.; Srivastava, R.K. Mechanical Properties of Hybrid Fibers-Reinforced Polymer Composite: A Review. Polym.-Plast. Technol. Eng. 2016, 55, 626–642. [Google Scholar] [CrossRef]

- Dikshit, V.; Bhudolia, S.K.; Joshi, S.C. Multiscale Polymer Composites: A Review of the Interlaminar Fracture Toughness Improvement. Fibers 2017, 5, 38. [Google Scholar] [CrossRef]

- Saghafi, H.; Palazzetti, R.; Heidary, H.; Brugo, T.M.; Zucchelli, A.; Minak, G. Toughening Behavior of Carbon/Epoxy Laminates Interleaved by PSF/PVDF Composite Nanofibers. Appl. Sci.-Basel 2020, 10, 5618. [Google Scholar] [CrossRef]

- Li, P.; Liu, D.W.; Zhu, B.; Li, B.; Jia, X.L.; Wang, L.L.; Li, G.; Yang, X.P. Synchronous effects of multiscale reinforced and toughened CFRP composites by MWNTs-EP/PSF hybrid nanofibers with preferred orientation. Compos. Pt. A Appl. Sci. Manuf. 2015, 68, 72–80. [Google Scholar] [CrossRef]

- Feng, P.F.; Ma, L.C.; Wu, G.S.; Li, X.R.; Zhao, M.; Shi, L.L.; Wang, M.Y.; Wang, X.J.; Song, G.J. Establishment of multistage gradient modulus intermediate layer between fiber and matrix via designing double “rigid-flexible” structure to improve interfacial and mechanical properties of carbon fiber/resin composites. Compos. Sci. Technol. 2020, 200, 8. [Google Scholar] [CrossRef]

- Johnson, R.K.; Zink-Sharp, A.; Renneckar, S.H.; Glasser, W.G. Mechanical properties of wetlaid lyocell and hybrid fiber-reinforced composites with polypropylene. Compos. Part A Appl. Sci. Manuf. 2008, 39, 470–477. [Google Scholar] [CrossRef]

- Zhang, J.; Lin, T.; Wang, X.G. Electrospun nanofibre toughened carbon/epoxy composites: Effects of polyetherketone cardo (PEK-C) nanofibre diameter and interlayer thickness. Compos. Sci. Technol. 2010, 70, 1660–1666. [Google Scholar] [CrossRef]

- Bovicelli, F.; Saghafi, H.; Brugo, T.M.; Belcari, J.; Zucchelli, A.; Minak, G. On consideration the mode I fracture response of CFRP composite interleaved by composite nanofibers. In Proceedings of the 20th European Conference on Fracture (ECF), Norwegian Univ Sci Technol, Trondheim, Norway, 30 June–4 July 2014; pp. 1316–1321. [Google Scholar]

- Zhang, Z.S.; Fu, K.K.; Li, Y. Improved interlaminar fracture toughness of carbon fiber/epoxy composites with a multiscale cellulose fiber interlayer. Compos. Commun. 2021, 27, 6. [Google Scholar] [CrossRef]

- Lan, B.W.; Liu, Y.; Mo, S.; He, M.H.; Zhai, L.; Fan, L. Interlaminar Fracture Behavior of Carbon Fiber/Polyimide Composites Toughened by Interleaving Thermoplastic Polyimide Fiber Veils. Materials 2021, 14, 2695. [Google Scholar] [CrossRef]

- Yuan, B.Y.; Tan, B.; Hu, Y.S.; Shaw, J.; Hu, X.Z. Improving impact resistance and residual compressive strength of carbon fibre composites using un-bonded non-woven short aramid fibre veil. Compos. Pt. A Appl. Sci. Manuf. 2019, 121, 439–448. [Google Scholar] [CrossRef]

- Nasser, J.; Lin, J.J.; Steinke, K.; Sodano, H.A. Enhanced interfacial strength of aramid fiber reinforced composites through adsorbed aramid nanofiber coatings. Compos. Sci. Technol. 2019, 174, 125–133. [Google Scholar] [CrossRef]

- Yang, G.M.; Lyu, Y.N.; Cheng, F.; He, J.X.; Zuo, S.H.; Huang, W.Y.; Hu, Y.S.; Hu, X.Z.; Chen, X. A low-cost and high-strength basalt/carbon fiber reinforced polymer improved by imitating tree-root micro/nano aramid short fiber. Chin. J. Aeronaut. 2024, 37, 526–538. [Google Scholar] [CrossRef]

- Azizi, H.; Eslami-Farsani, R. Study of mechanical properties of basalt fibers/epoxy composites containing silane-modified nanozirconia. J. Ind. Text. 2021, 51, 649–663. [Google Scholar] [CrossRef]

- Xu, Z.; Wang, F.; Yin, X.; Cheng, L.D.; Yu, J.Y.; Liu, Y.T.; Ding, B. Recent advances in ZrO2 nanofibers: From structural design to emerging applications. Sci. China-Mater. 2023, 66, 421–440. [Google Scholar] [CrossRef]

- Jia, Y.J.; Ajayi, T.D.; Ramakrishnan, K.R.; Negi, A.; Liu, J.; Ekkad, S.; Xu, C.Y. A skin layer made of cured polysilazane and yttria stabilized zirconia for enhanced thermal protection of carbon fiber reinforced polymers (CFRPs). Surf. Coat. Technol. 2020, 404, 8. [Google Scholar] [CrossRef]

- Zhang, X.X.; Wang, F.; Dou, L.Y.; Cheng, X.T.; Si, Y.; Yu, J.Y.; Ding, B. Ultrastrong, Superelastic, and Lamellar Multiarch Structured ZrO2-Al2O3 Nanofibrous Aerogels with High-Temperature Resistance over 1300 °C. ACS Nano 2020, 14, 15616–15625. [Google Scholar] [CrossRef] [PubMed]

- He, J.X.; Lyn, Y.; Cheng, F.; Yuan, X.; Yang, G.M.; Liang, X.L.; Shi, S.Y.; Jiang, H.Y.; Hu, X.Z.; Chen, X. Flexural and flexural-after-impact strength of basalt fiber reinforced polymer improved by ultra-thin zirconia fiber/epoxy films. Compos. Pt. B Eng. 2025, 303, 14. [Google Scholar] [CrossRef]

- ASTM D7264; Standard Test Method for Flexural Properties of Polymer Matrix Composite Materials. ASTM International: West Conshohocken, PA, USA, 2007.

- ASTM D6641; Standard Test Method for Compressive Properties of Polymer Matrix Composite Materials Using a Combined Loading Compression (CLC) Test Fixture. ASTM International: West Conshohocken, PA, USA, 2012.

- Liu, H.; Sun, Y.; Yu, Y.; Zhang, M.; Li, L.; Ma, L. Effect of Nano-SiO2 Modification on Mechanical and Insulation Properties of Basalt Fiber Reinforced Composites. Polymers 2022, 14, 3353. [Google Scholar] [CrossRef] [PubMed]

- Chen, C.; Li, P.; Xiang, D.; Liu, L.; Sun, H.; Wu, Y.; Mu, M.; Wang, B.; Zhao, C.; Li, H. Study on Mechanical Properties and Acid Corrosion Resistance of Basalt Fiber/Epoxy Resin Composites Modified by Silicon Nanowires. J. Mater. Eng. Perform. 2025, 34, 22784–22794. [Google Scholar] [CrossRef]

- Jiang, L.; Yang, Y.H.; Sheng, J.; Li, Y.Z.; Huang, Z.Q.; Li, J.Q.; Geng, T. Effects of different nano-SiO2/silane coupling agent “rigid-flexible” hybrid interfaces on the mechanical performance of basalt fiber/epoxy composites. Polym. Compos. 2025, 46, 6956–6969. [Google Scholar] [CrossRef]

| Major Raw Material | Physical Form | Main Feature | Supplier |

|---|---|---|---|

| Basalt fiber fabrics | 0°/90° woven fiber | Density 2.63–2.65 g/cm3, tensile strength 3000–4800 MPa, and modulus 91–110 GPa | Haining Anjie composites Ltd., Haining, China |

| MNASF | Micro/nano aramid short fiber | Diameter 200 nm to 10 µm, tensile strength 3.5 GPa, and modulus 130 GPa | Hubei Jiateng Fangzhi Ltd., Xianning, China |

| ZF | Polycrystalline refractory fiber | Density 5.6–5.9 g/cm3, melting point up to 2715 °C, tensile strength 3 GPa, modulus 100–250 GPa | Laboratory preparation |

| Epoxy resin | Transparent liquid | 105 epoxy resin, toxic (boiling point higher than 204 °C) | West System, Ltd., Bay City, MI, USA |

| Hardener | Yellow | 206 slow hardener, toxic (boiling point higher than 204 °C) | |

| Acetone | Colorless liquid | AR, toxic, boiling point 56 °C | Chengdu Kelong Chemical Ltd., Chengdu, China |

| Number of Specimen Groups | Mass of MNASF and ZF in Mixture (wt.%) | Areal Mass of MNASF in Each Interlayer (g/m2) | Areal Mass of ZF in Each Interlayer (g/m2) | Thickness (mm) |

|---|---|---|---|---|

| Plain BFRP | 0/0 | 0 | 0 | 1.78 |

| 1-MNASF/ZF | 0/4 | 0 | 4.88 | 2.21 |

| 2-MNASF/ZF | 1/3 | 1.22 | 3.66 | 2.16 |

| 3-MNASF/ZF | 2/2 | 2.44 | 2.44 | 2.21 |

| 4-MNASF/ZF | 3/1 | 3.66 | 1.22 | 2.14 |

| 5-MNASF/ZF | 4/0 | 4.88 | 0 | 1.98 |

| MNASF Mass Proportion (wt.%) | 0 | 0 | 1 | 2 | 3 | 4 | |

|---|---|---|---|---|---|---|---|

| ZF Mass Proportion (wt.%) | 0 | 4 | 3 | 2 | 1 | 0 | |

| Flexural strength (MPa) | Average | 131.62 | 198.28 | 150.62 | 288.49 | 156.26 | 208.74 |

| Standard deviation | 4.79 | 24.5 | 19.76 | 17.49 | 9.53 | 8.81 | |

| Coefficients of variation (%) | 3.64% | 12.36% | 13.12% | 6.06% | 6.10% | 4.22% | |

| Elasticity modulus (GPa) | Average | 14.15 | 23.57 | 13.88 | 22.95 | 13.17 | 16.19 |

| Standard deviation | 0.47 | 0.70 | 0.99 | 0.73 | 0.52 | 0.49 | |

| Coefficients of variation (%) | 3.32 | 2.97 | 7.13 | 3.18 | 3.95 | 3.03 | |

| Energy absorption (J) | Average | 0.15 | 0.18 | 0.17 | 0.34 | 0.10 | 0.19 |

| Standard deviation | 0.02 | 0.02 | 0.03 | 0.03 | 0.01 | 0.01 | |

| Coefficients of variation (%) | 13.33 | 11.11 | 17.65 | 8.82 | 10.00 | 5.26 | |

| Per unit volume energy absorption (kJ/m−3) | Average | 79.64 | 75.72 | 69.77 | 140.67 | 42.08 | 90.32 |

| Standard deviation | 10.67 | 8.39 | 13.01 | 12.58 | 4.38 | 5.37 | |

| Coefficients of variation (%) | 13.40 | 11.08 | 18.65 | 8.94 | 10.41 | 5.95 | |

| MNASF Mass Proportion (wt.%) | 0 | 0 | 1 | 2 | 3 | 4 | |

|---|---|---|---|---|---|---|---|

| ZF Mass Proportion (wt.%) | 0 | 4 | 3 | 2 | 1 | 0 | |

| Compressive strength (MPa) | Average | 54.49 | 130.84 | 89.75 | 194.89 | 96.23 | 134.74 |

| Standard deviation | 7.85 | 24.17 | 6.51 | 14.40 | 6.67 | 6.50 | |

| Coefficients of variation (%) | 14.41 | 18.47 | 7.25 | 7.39 | 6.93 | 4.82 | |

| Elasticity modulus (GPa) | Average | 3.06 | 5.46 | 3.90 | 6.78 | 4.77 | 4.78 |

| Standard deviation | 0.25 | 0.61 | 0.16 | 0.48 | 0.51 | 0.20 | |

| Coefficients of variation (%) | 8.17 | 11.17 | 4.10 | 7.08 | 10.69 | 4.18 | |

| Energy absorption (J) | Average | 0.32 | 0.63 | 0.62 | 1.38 | 0.89 | 1.23 |

| Standard deviation | 0.07 | 0.05 | 0.03 | 0.03 | 0.12 | 0.13 | |

| Coefficients of variation (%) | 21.88 | 7.93 | 4.38 | 4.84 | 13.48 | 10.57 | |

| Per unit volume energy absorption (kJ/m−3) | Average | 107.99 | 165.05 | 162.82 | 327.04 | 216.71 | 312.35 |

| Standard deviation | 12.67 | 15.63 | 18.29 | 25.67 | 20.95 | 18.64 | |

| Coefficients of variation (%) | 11.73 | 9.47 | 11.23 | 7.84 | 9.67 | 5.97 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, Z.; Yang, B.; He, J.; Yuan, X.; Cheng, F.; Zhang, P.; Shi, S.; Lomakin, E.; Bondarchuk, D.; Tojiyev, R.; et al. Performance Reinforcement of Basalt Fiber–Reinforced Polymer by Guiding Hierarchical Aramid/Zirconia Hybrid Fiber. Coatings 2025, 15, 1356. https://doi.org/10.3390/coatings15111356

Zhou Z, Yang B, He J, Yuan X, Cheng F, Zhang P, Shi S, Lomakin E, Bondarchuk D, Tojiyev R, et al. Performance Reinforcement of Basalt Fiber–Reinforced Polymer by Guiding Hierarchical Aramid/Zirconia Hybrid Fiber. Coatings. 2025; 15(11):1356. https://doi.org/10.3390/coatings15111356

Chicago/Turabian StyleZhou, Ziteng, Buerke Yang, Jiaxin He, Xiang Yuan, Fei Cheng, Peng Zhang, Shuying Shi, Evgeny Lomakin, Daria Bondarchuk, Rasuljon Tojiyev, and et al. 2025. "Performance Reinforcement of Basalt Fiber–Reinforced Polymer by Guiding Hierarchical Aramid/Zirconia Hybrid Fiber" Coatings 15, no. 11: 1356. https://doi.org/10.3390/coatings15111356

APA StyleZhou, Z., Yang, B., He, J., Yuan, X., Cheng, F., Zhang, P., Shi, S., Lomakin, E., Bondarchuk, D., Tojiyev, R., Liu, H., & Hu, X. (2025). Performance Reinforcement of Basalt Fiber–Reinforced Polymer by Guiding Hierarchical Aramid/Zirconia Hybrid Fiber. Coatings, 15(11), 1356. https://doi.org/10.3390/coatings15111356