Environmentally Friendly Silk Fibroin/Polyethyleneimine High-Performance Triboelectric Nanogenerator for Energy Harvesting and Self-Powered Sensing

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Silk Fibroin Solution

2.3. Preparation of SF Films and SF/PEI Composite Films

2.3.1. Preparation of SF Film

2.3.2. Preparation of SF/PEI Composite Films

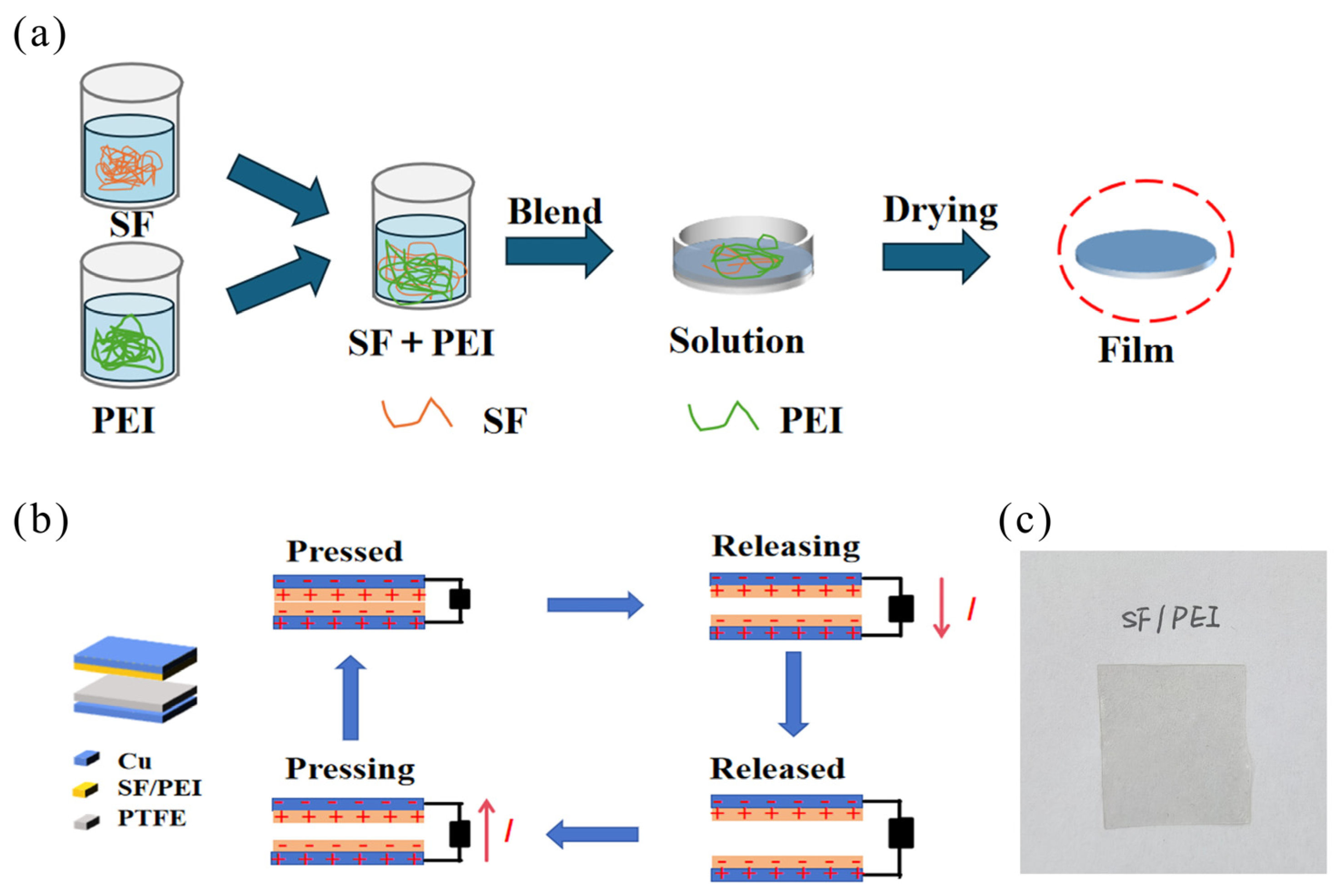

2.4. Assembly of TENG Devices

2.5. Characterization and Measurement

3. Results and Discussion

3.1. Design and Working Mechanism of SF/PEI-TENG

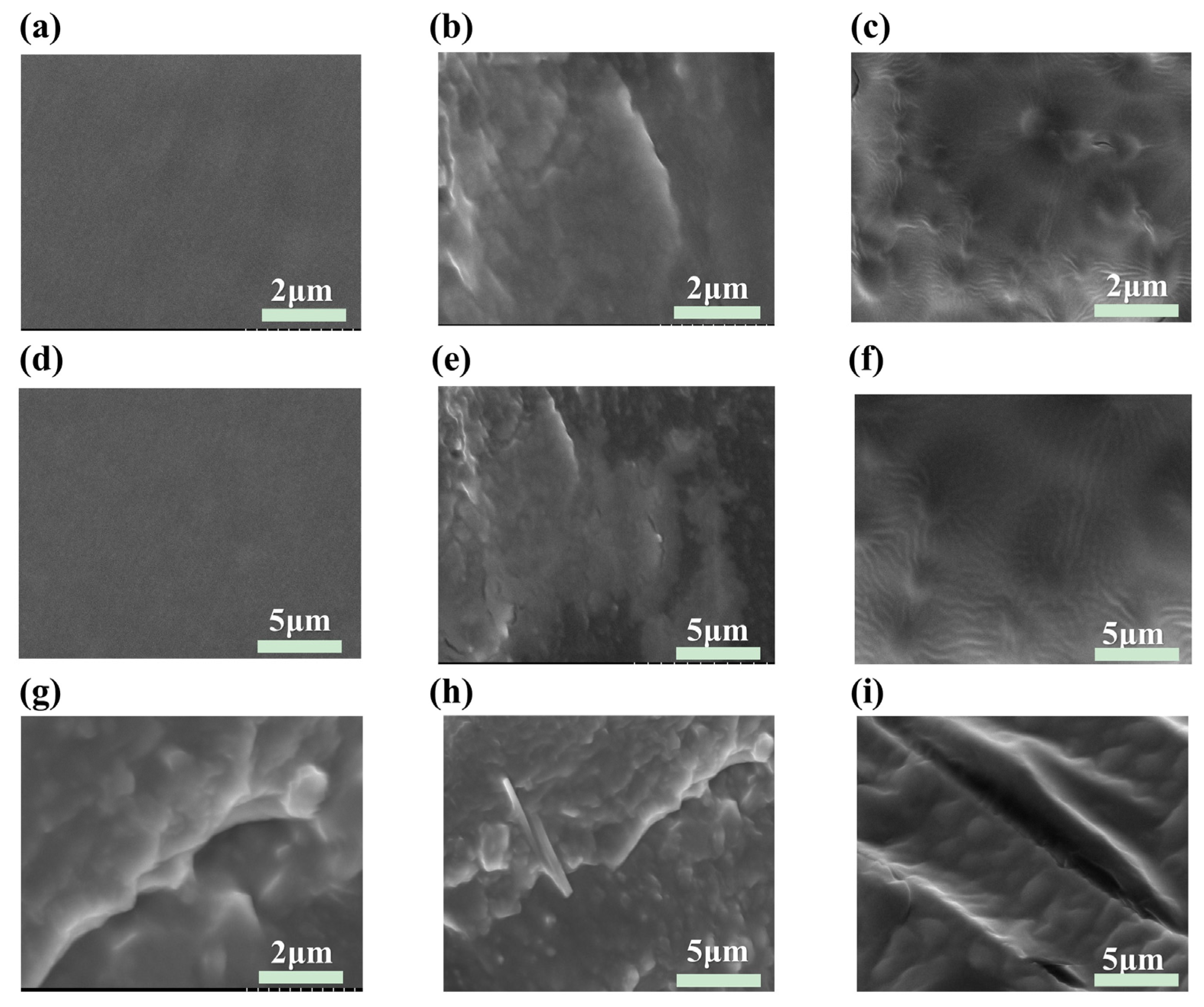

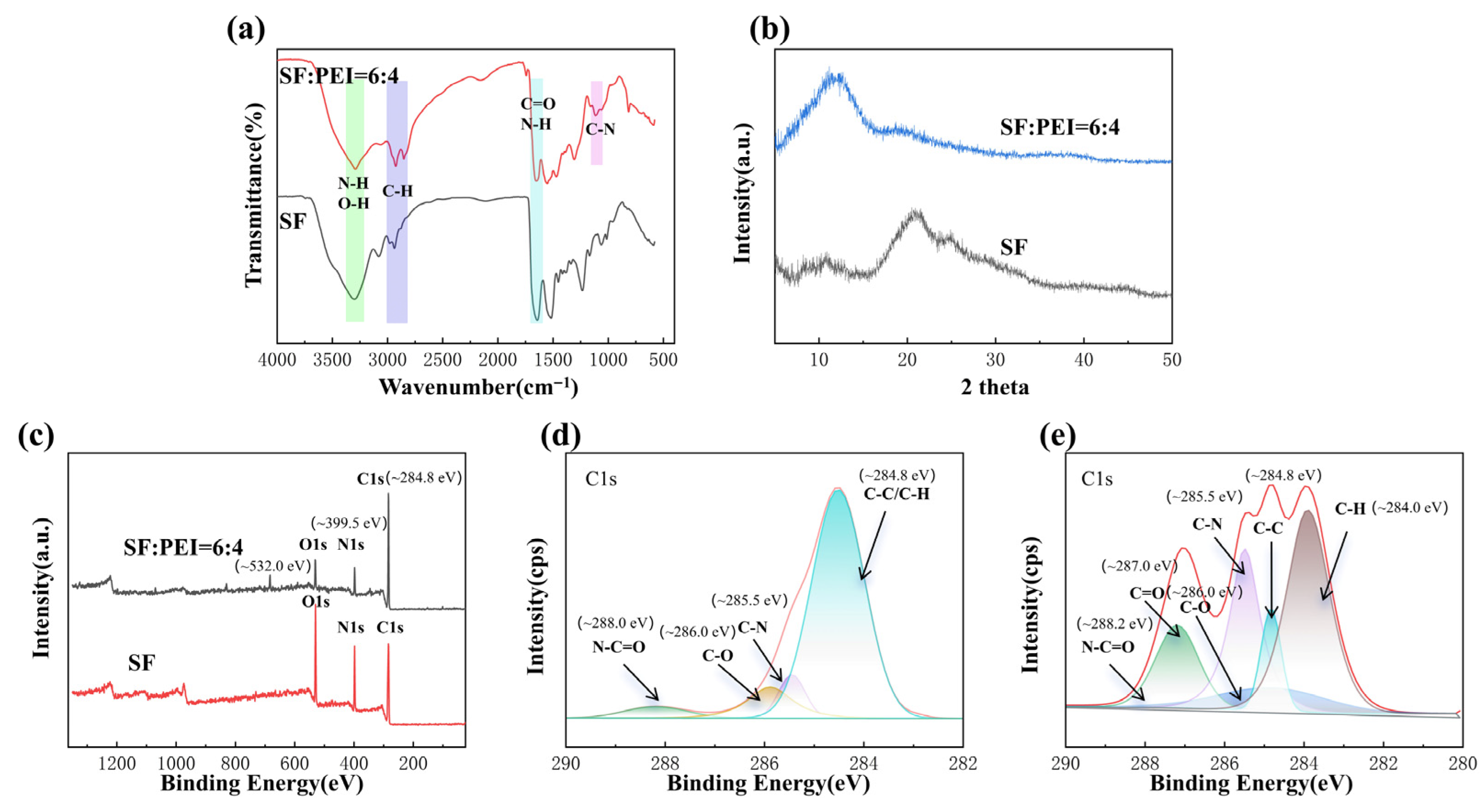

3.2. Microscopic Morphology and Structural Characterization of SF/PEI Films

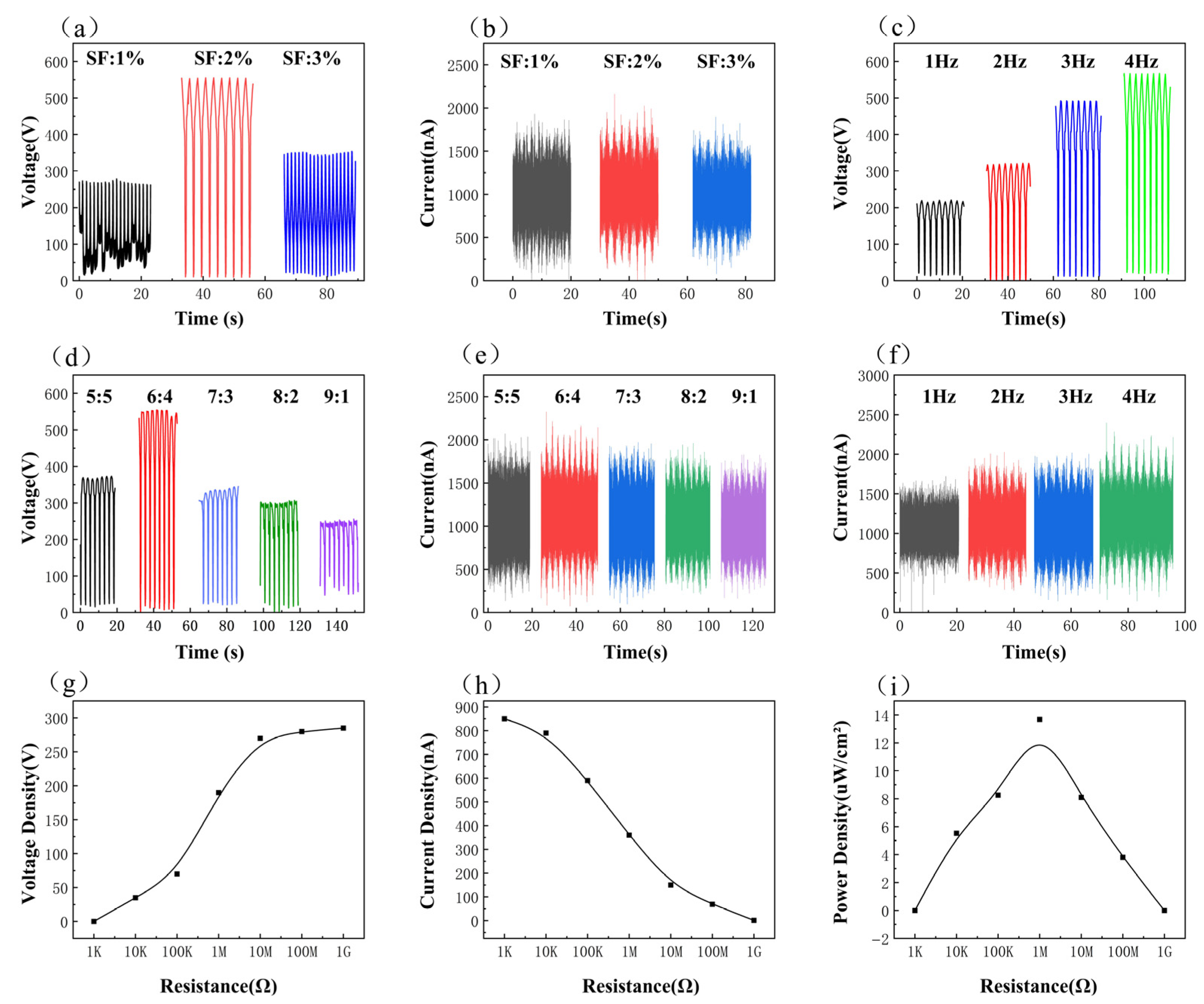

3.3. Output Performance Analysis of SF/PEI-TENG

3.4. Performance Verification as a Self-Powered Power Source

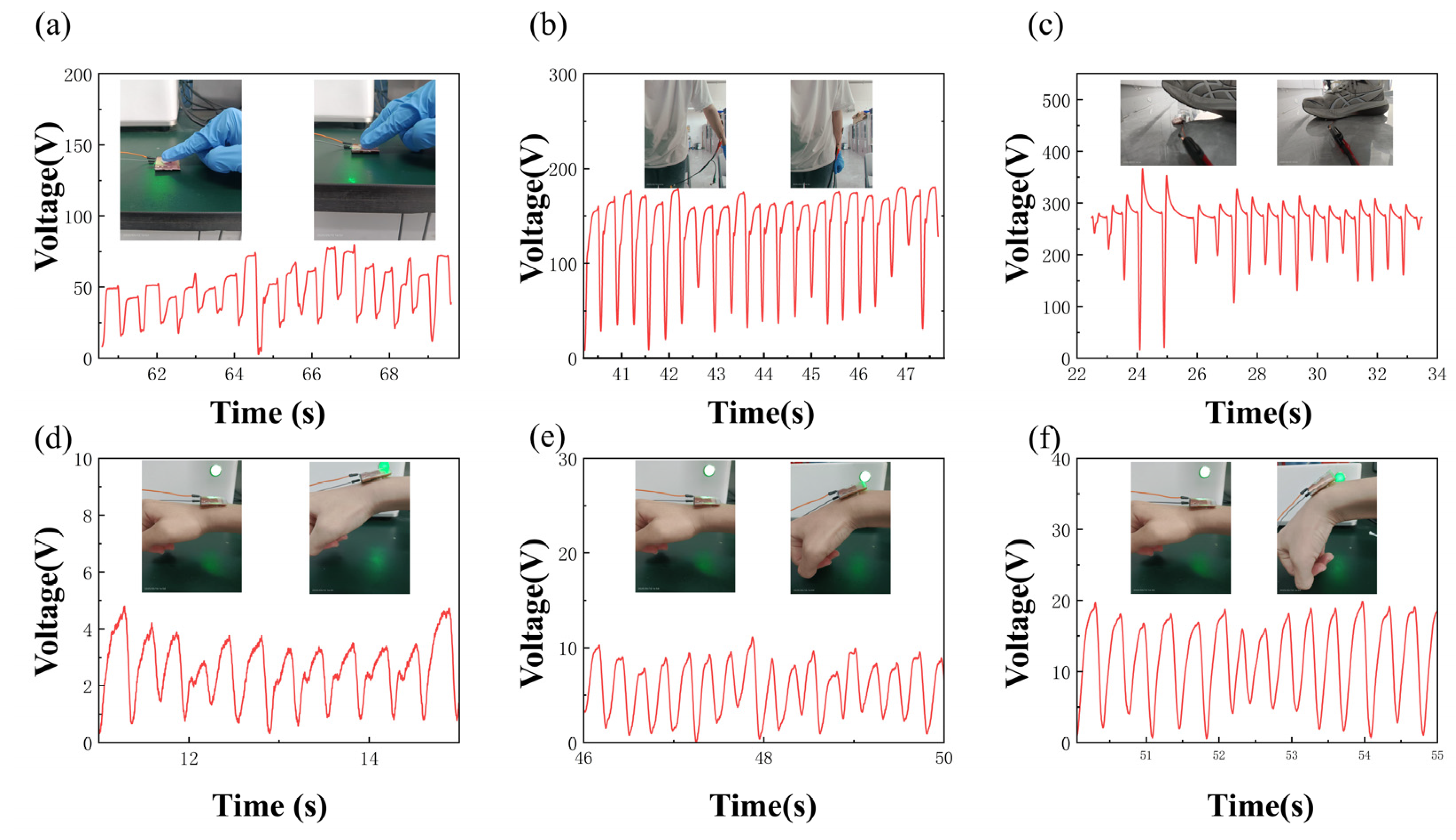

3.5. Human Mechanical Energy Harvesting Applications as Self-Powered Sensors

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Niculescu, R.; Clenci, A.; Shirneshan, A.; Năstase, M. A review of the synthetic transport fuels as a solution for carbon neutrality. Next Energy 2025, 8, 100355. [Google Scholar] [CrossRef]

- Chaudhary, S.; Bano, K.S.; Mohanty, T.; Kumari, A.; Mehdi, M.M. Exploring microalgae-based biodiesel as an alternative fuel: Development, production techniques and environmental impacts. Biomass Bioenergy 2025, 202, 108249. [Google Scholar] [CrossRef]

- Feng, Y.; Mohsin, M. Promoting climate-compatible Approaches: Managing carbon neutrality and evaluating China’s energy impact on global economic development. Energy Strategy Rev. 2025, 59, 101716. [Google Scholar] [CrossRef]

- Slimi, K.; Chrouda, A.; Hakan, F. Traffic effects on global warming: A review. Renew. Sustain. Energy Rev. 2026, 226, 116248. [Google Scholar] [CrossRef]

- Sohaib, M.; Majeed, A.; Liu, J.; Oláh, J. The role of renewable energy in mitigating carbon emissions: Insights from China’s energy consumption patterns. Energy Strategy Rev. 2025, 61, 101860. [Google Scholar] [CrossRef]

- Ding, Y.; Deng, L.; Liu, X.; Wang, L.; Meng, Y.; Ouyang, M.; Chen, F.; Huang, Z.-X.; Kuang, T. Bio-based materials for sustainable energy harvesting: Applications in TENGs, PENGs, and solar-powered seawater desalination systems. Chem. Eng. J. 2025, 516, 164101. [Google Scholar] [CrossRef]

- Wang, C.; Liang, L.; Wei, L.; Shao, D.; Zhang, C.; Lu, J.; Yang, W. Green-in-green biohybrids as transient biotriboelectric nanogenerators. iScience 2022, 25, 105494. [Google Scholar] [CrossRef]

- Chen, P.; Zhu, X.; Tian, G.; Feng, X. Recent advances of TENGs for marine applications: Opportunities and challenges coexist. Nano Energy 2025, 142, 111212. [Google Scholar] [CrossRef]

- Gao, D.; Wang, H.; Tang, J.; Ye, C.; Wang, L. Charge-Excited Enhanced Piezoelectric-Triboelectric Hybrid Nanogenerator for High-Efficiency Energy Harvesting and Applications. Sustain. Mater. Technol. 2025, 45, e01539. [Google Scholar] [CrossRef]

- Wang, J.; Li, P.; Kang, X.; Li, Z.; Dai, S. Soft-soft contact TENG using nonlinear coupling galloping phenomenon for harvesting wind energy. Nano Energy 2025, 133, 110471. [Google Scholar] [CrossRef]

- Xiong, T.; Xu, Z.; He, Q.; Li, S.; Tang, G.; Meng, Y.; Zhang, X.; Liu, C.; Shi, C.; Wang, Z.L. Direction-adaptive triboelectric-electromagnetic hybrid nanogenerator for harvesting omnidirectional breeze wind energy. Nano Energy 2025, 143, 111323. [Google Scholar] [CrossRef]

- Cao, L.N.Y.; Su, E.; Xu, Z.; Wang, Z.L. Fully enclosed microbeads structured TENG arrays for omnidirectional wind energy harvesting with a portable galloping oscillator. Mater. Today 2023, 71, 9–21. [Google Scholar] [CrossRef]

- Xi, Z.; Du, H.; Wang, Y.; Yu, H.; Dai, S.; Fan, M.; Liu, J.; Su, Q.; Wang, H.; Hu, G.; et al. A ternary-dielectric rolling TENG array for robust ocean energy harvesting and distributed environmental monitoring. Nano Energy 2025, 143, 111318. [Google Scholar] [CrossRef]

- Zhao, B.; Wang, Y.; Huang, S.; Tian, T.; Liao, X.; Wang, W.; Li, Z. High-durability pendulum-structured TENG-EMG hybrid with stacked liquid-solid triboelectric layers for efficient low-frequency ocean wave energy capture. Chem. Eng. J. 2025, 523, 168505. [Google Scholar] [CrossRef]

- Pan, Y.; Li, M.; Lu, Y.; Lu, M.; Guo, B.; Liu, X.; Zhang, K.; Wang, Y.; Feng, L.; Qin, A. Hydrophobic sisal cellulose paper-based TENG for collecting rain energy and raindrop-based sensor. Chem. Eng. J. 2024, 490, 151590. [Google Scholar] [CrossRef]

- Hu, Y.; Sun, R.; Li, S.; Liu, C.; Zhao, J.; Mo, J.; Luo, D.; Pan, Y. Optimizing raindrop energy harvesting: Exploring water droplet spreading effects on IDE-based TENG for sustainable power generation. Nano Energy 2024, 123, 109358. [Google Scholar] [CrossRef]

- Im, B.; Lee, S.K.; Kang, G.; Moon, J.; Byun, D.; Cho, D.-H. Electrohydrodynamic jet printed silver-grid electrode for transparent raindrop energy-based triboelectric nanogenerator. Nano Energy 2022, 95, 107049. [Google Scholar] [CrossRef]

- Yu, S.; Li, P.; Ding, H.; Shi, F.; Li, X. Superhydrophobic PET-Cu-Ni@MWCNT with electropositive layer to enhance the electrical properties of TENG for human wearable sensors. Chem. Eng. J. 2025, 512, 162385. [Google Scholar] [CrossRef]

- Xing, F.; Tang, G.; Wang, H.; Wang, M.; Wu, M.; Xu, M. Exploring the synergy of EMG and TENG in motion based hybrid energy harvesting. Nano Energy 2025, 134, 110584. [Google Scholar] [CrossRef]

- He, P.; Li, X.; Wang, M.; Lv, D.; Wang, J.; Zou, L.; Cheng, R.; Yin, R.; Chi, X.; Li, J.; et al. High humidity-resisted all-wood-based triboelectric nanogenerator for energy harvesting and human motion monitoring. Chem. Eng. J. 2025, 521, 167158. [Google Scholar] [CrossRef]

- Gao, Y.; Zong, R.; Feng, J.; Li, Y.; Chen, Z.; Qi, L. Flexible self-powered and self-sensing shoes based on aeroelastic structure for application in human motion monitoring. J. Power Sources 2025, 638, 236626. [Google Scholar] [CrossRef]

- Manchi, P.; Paranjape, V.M.; Kurakula, A.; Kavarthapu, V.S.; Kim, C.-W.; Yu, J.S. Graphene oxide-incorporated PVA/sodium alginate composite hydrogel-based flexible and sensitive single-electrode TENGs for efficient energy harvesting and smart security applications. Nano Energy 2025, 142, 111184. [Google Scholar] [CrossRef]

- Sheikh, K.A.; Khan, M.M. Experimental analysis and voltage optimization of water-solid triboelectric nanogenerators for sustainable energy harvesting using a hybrid PSO–random forest model. J. Electrost. 2025, 138, 104197. [Google Scholar] [CrossRef]

- Fan, F.; Tian, Z.; Wang, L.Z. Flexible triboelectric generator. Nano Energy 2012, 1, 328–334. [Google Scholar] [CrossRef]

- Delgado-Alvarado, E.; Martínez-Castillo, J.; Morales-González, E.A.; González-Calderón, J.A.; Armendáriz-Alonso, E.F.; Rodríguez-Liñán, G.M.; López-Esparza, R.; Hernández-Hernández, J.; Elvira-Hernández, E.A.; Herrera-May, A.L. Eco-friendly, compact, and cost-efficient triboelectric nanogenerator for renewable energy harvesting and smart motion sensing. Heliyon 2024, 10, e28482. [Google Scholar] [CrossRef]

- Liu, R.; Feng, H.; Sun, Z.; Cai, Y.; Qiu, Y.; Zhou, R.; Zhang, Y.; Xiao, Y.; Yang, W.; Weng, M.; et al. Enhancing output performance of triboelectric nanogenerator based on high-dielectric Ti3CNTx/PVA nanofiber membrane for human–computer interaction applications. Chem. Eng. J. 2025, 519, 165703. [Google Scholar] [CrossRef]

- He, S.; Jellicoe, M.; Chakraborthy, A.; Alahi, E.E.; Nag, A.; Powell, W. Carbon allotropes/fabrics-based triboelectric nanogenerators: Current progress and future perspectives. Mater. Sci. Eng. R 2025, 166, 101049. [Google Scholar] [CrossRef]

- Gu, Y.; Niu, Q.; Cao, Q.; Zhou, X.; Zhao, W.; Hu, Z.; Fan, S.; Yao, X.; Zhang, Y. Biodegradable silk fibroin-based triboelectric nanogenerator with enhanced output regulated by interfacial and ionic polarization. Int. J. Biol. Macromol. 2025, 304, 140832. [Google Scholar] [CrossRef]

- Ong, D.T.K.; Koay, J.S.C.; Sim, M.T.; Aw, K.C.; Nakajima, T.; Chen, B.; Tan, S.T.; Gan, W.C. High performance composition-tailored PVDF triboelectric nanogenerator enabled by low temperature-induced phase transition. Nano Energy 2023, 113, 108555. [Google Scholar] [CrossRef]

- Ozen, A.; Ozel, F.; Kınas, Z.; Karabiber, A.; Polat, S. Spring assisted triboelectric nanogenerator based on sepiolite doped polyacrylonitrile nanofibers. Sustain. Energy Technol. Assess. 2021, 47, 101492. [Google Scholar] [CrossRef]

- Xu, K.; Peng, T.; Zhang, B.; Wu, Y.; Huang, Z.; Guan, Q. Zinc oxide bridges the nanofillers to enhance the wear resistance and stability of triboelectric nanogenerators. Chem. Eng. J. 2024, 493, 152532. [Google Scholar] [CrossRef]

- Dangelico, R.M.; Pontrandolfo, P. From green product definitions and classifications to the Green Option Matrix. J. Clean. Prod. 2010, 18, 1608–1628. [Google Scholar] [CrossRef]

- Feng, Q.; Xie, Z.; Wen, Y.; Cheng, Z.; Zhang, M.; Wang, Y.; Liu, D.; Cao, Y.; Mao, Y.; Zhao, C. An eco-friendly, sodium alginate degradable conformal triboelectric nanogenerator for self-powered sensing and real-time injury monitoring. Sustain. Mater. Technol. 2025, 43, e01262. [Google Scholar] [CrossRef]

- Jin, Z.; Wang, L.; Zheng, K.; Gao, Q.; Feng, W.; Hu, S.; Yue, M.; Shan, X. Microelectronic printed chitosan/chondroitin sulfate/ZnO flexible and environmentally friendly triboelectric nanogenerator. J. Colloid Interface Sci. 2024, 669, 275–282. [Google Scholar] [CrossRef]

- Saqib, M.; Rehman, M.M.; Khan, M.; Iqbal, S.; Ali, A.U.; Siddiqui, G.U.; Kim, W.Y. Adaptable self-powered humidity sensor based on a highly permeable, hierarchically fibrous, and chaotically textured sustainable biowaste. Sustain. Mater. Technol. 2025, 44, e01374. [Google Scholar] [CrossRef]

- Yang, K.; Ma, T.; Qin, Z.; Liu, Y.; Chen, Y.; Yu, H.; Fang, M.; Zhang, X.; Zhao, W.; Mao, Z.; et al. Silk fibroin coating on biometals: Processing, anti-corrosion and biofunctionality. Int. J. Biol. Macromol. 2025, 332, 146643. [Google Scholar] [CrossRef]

- Zhou, K.; Yuan, T.; Wang, S.; Hu, F.; Luo, L.; Chen, L.; Yang, L. Beyond Natural Silk: Bioengineered Silk Fibroin for Bone regeneration. Mater. Today Bio. 2025, 33, 102014. [Google Scholar] [CrossRef]

- Hardy, J.G.; Scheibel, T.R. Composite materials based on silk proteins. Prog. Polym. Sci. 2010, 35, 1093–1115. [Google Scholar] [CrossRef]

- Numata, K.; Kaplan, D.L. Silk proteins: Designs from nature with multipurpose utility and infinite future possibilities. Adv. Mater. 2025, 37, 2411256. [Google Scholar] [CrossRef] [PubMed]

- Niu, Q.; Wei, H.; Hsiao, B.S.; Zhang, Y. Biodegradable silk fibroin-based bio-piezoelectric/triboelectric nanogenerators as self-powered electronic devices. Nano Energy 2022, 96, 107101. [Google Scholar] [CrossRef]

- Shang, B.; Wang, C.Y.; Wang, X.X.; Yu, S.-S.; Wu, Z.-F.; Qiao, S.-L.; Chen, K.-Z. Silk protein-based triboelectric nanogenerators for energy harvesting and self-powered sensing. Sens. Actuators A Phys. 2025, 387, 116449. [Google Scholar] [CrossRef]

- Rana, I.; Aslam, M.; Ranjan, K.R.; Singh, P.; Kumari, K. A review on the use of composites of a natural protein, silk fibroin with Mxene/carbonaceous materials in biomedical science. Int. J. Biol. Macromol. 2024, 278, 135101. [Google Scholar] [CrossRef] [PubMed]

- Xiong, Q.; Yang, Z.; Zhang, X. Flexible triboelectric nanogenerator based on silk fibroin-modified carbon nanotube arrays. Chem. Eng. J. 2024, 482, 148986. [Google Scholar] [CrossRef]

- He, J.; Xue, Y.; Sun, W.; Shen, L.; Zhao, Y.; Yan, J.; Wu, Y.; Zhang, B.; Qu, M. High-performance flexible triboelectric nanogenerator based on environmentally friendly, low-cost sodium carboxymethylcellulose for energy harvesting and self-powered sensing. ACS Appl. Electron. Mater. 2022, 5, 291–301. [Google Scholar] [CrossRef]

- Fattahi, N.; Gorgannezhad, L.; Masoule, S.F.; Babanejad, N.; Ramazani, A.; Raoufi, M.; Sharifikolouei, E.; Foroumadi, A.; Khoobi, M. PEI-based functional materials: Fabrication techniques, properties, and biomedical applications. Adv. Colloid Interface Sci. 2024, 325, 103119. [Google Scholar] [CrossRef]

- Ayalew, Z.M.; Guo, X.; Zhang, X. Synthesis and application of polyethyleneimine (PEI)-based composite/nanocomposite material for heavy metals removal from wastewater: A critical review. J. Hazard. Mater. Adv. 2022, 8, 100158. [Google Scholar] [CrossRef]

- Baburaj, A.; Kumar, S.K.N.; Aliyana, A.K.; Banakar, M.; Bairagi, S.; Stylios, G. Factors affecting the performance of flexible triboelectric nanogenerators (F-TENGs) and their sensing capabilities: A comprehensive review. Nano Energy 2023, 118, 108983. [Google Scholar] [CrossRef]

- Khan, S.A.; Saqib, Q.M.; Bae, J.; Cho, S.W. Advances in tribonegative layer for 2D material-based triboelectric nanogenerators: Material modifications and architectural designs. Chem. Eng. J. 2025, 516, 163854. [Google Scholar] [CrossRef]

- Tao, Y.; Jiang, W.; Yang, Q.; Cao, X.; Wang, N. Lotus leaf-inspired triboelectric sensor for detecting seismic transverse wave. Nano Energy 2025, 135, 110621. [Google Scholar] [CrossRef]

- Zhou, S.; Jia, C.; Shu, G.; Guan, Z.; Wu, H.; Li, J.; Ou-Yang, W. Recent advances in TENGs collecting acoustic energy: From low-frequency sound to ultrasound. Nano Energy 2024, 129, 109951. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, Z.; Xu, X.; Shen, Y.; Wang, M.; Zhai, Y.; Zheng, H.; Cao, J. Environmentally Friendly Silk Fibroin/Polyethyleneimine High-Performance Triboelectric Nanogenerator for Energy Harvesting and Self-Powered Sensing. Coatings 2025, 15, 1323. https://doi.org/10.3390/coatings15111323

Guo Z, Xu X, Shen Y, Wang M, Zhai Y, Zheng H, Cao J. Environmentally Friendly Silk Fibroin/Polyethyleneimine High-Performance Triboelectric Nanogenerator for Energy Harvesting and Self-Powered Sensing. Coatings. 2025; 15(11):1323. https://doi.org/10.3390/coatings15111323

Chicago/Turabian StyleGuo, Ziyi, Xinrong Xu, Yue Shen, Menglong Wang, Youzhuo Zhai, Haiyan Zheng, and Jiqiang Cao. 2025. "Environmentally Friendly Silk Fibroin/Polyethyleneimine High-Performance Triboelectric Nanogenerator for Energy Harvesting and Self-Powered Sensing" Coatings 15, no. 11: 1323. https://doi.org/10.3390/coatings15111323

APA StyleGuo, Z., Xu, X., Shen, Y., Wang, M., Zhai, Y., Zheng, H., & Cao, J. (2025). Environmentally Friendly Silk Fibroin/Polyethyleneimine High-Performance Triboelectric Nanogenerator for Energy Harvesting and Self-Powered Sensing. Coatings, 15(11), 1323. https://doi.org/10.3390/coatings15111323