Cobalt-Based Ceramic Wear-Resistant Cutting Pick Laser Cladding Process and Its Law Analysis

Abstract

1. Introduction

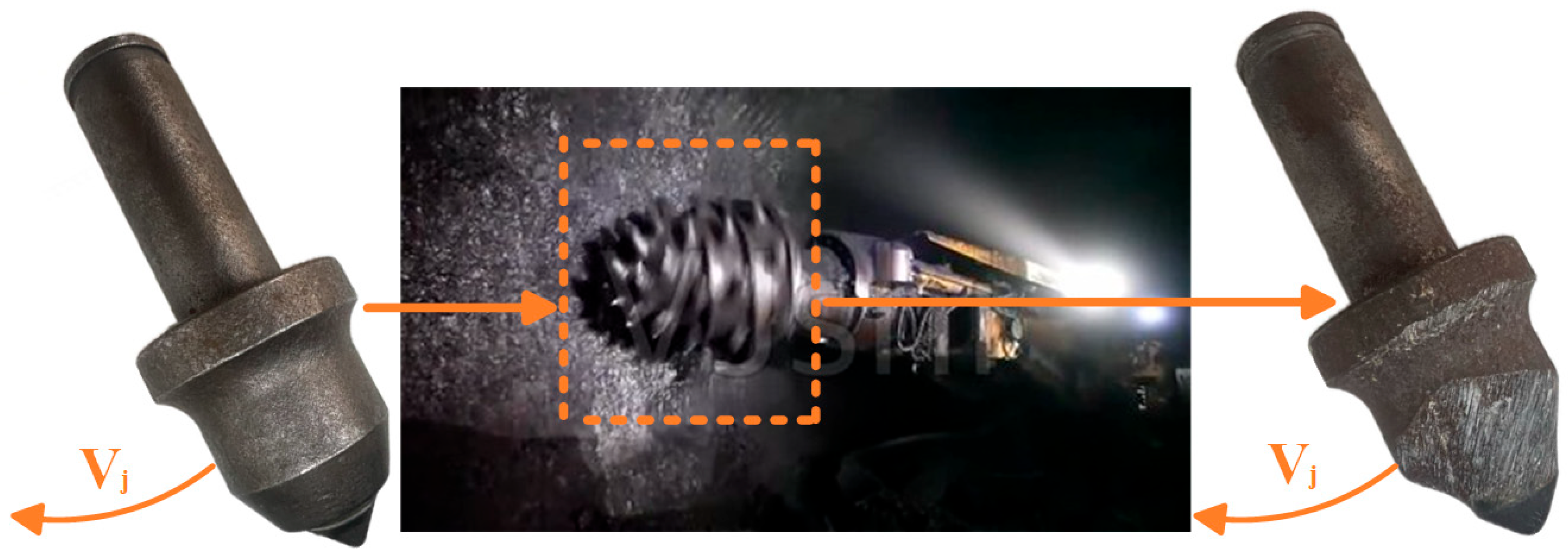

2. The Failure Mechanism of Cutting Pick and Testing Methods

2.1. The Failure Mechanism of the Cutting Pick

2.2. Experimental Materials

2.3. Experimental Plan

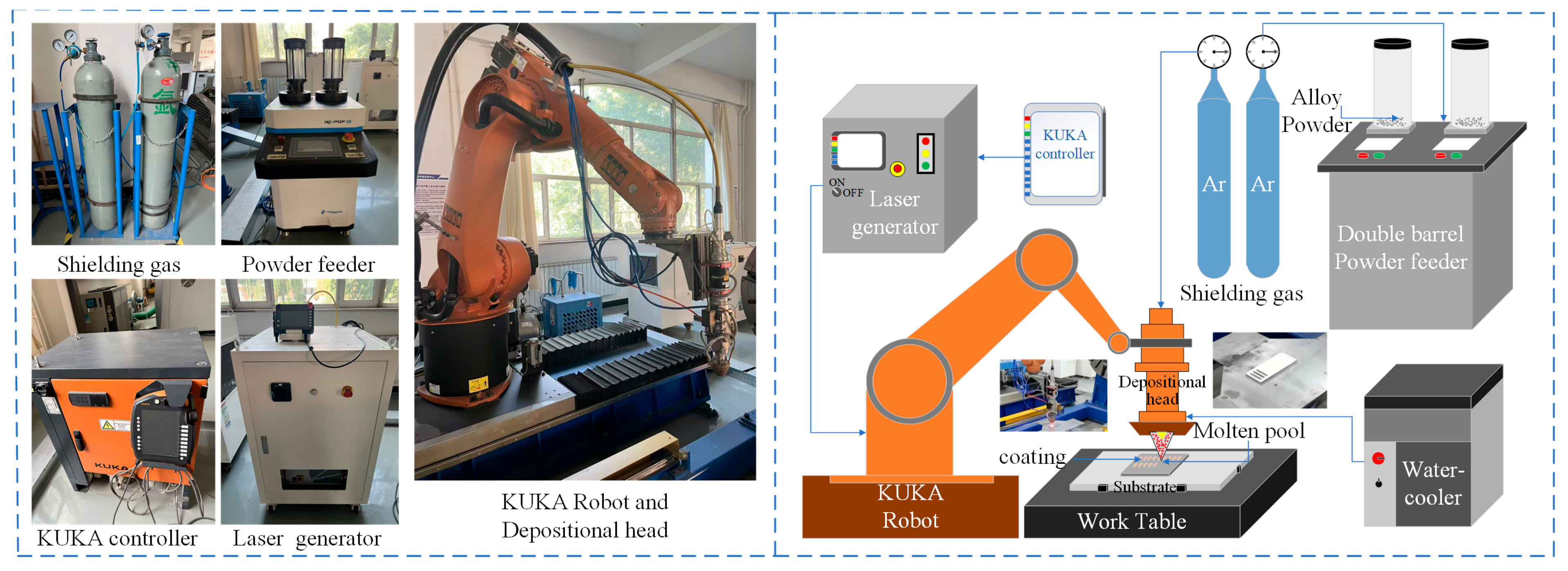

2.4. Experimental Preparation and Performance Testing

3. Results and Discussion

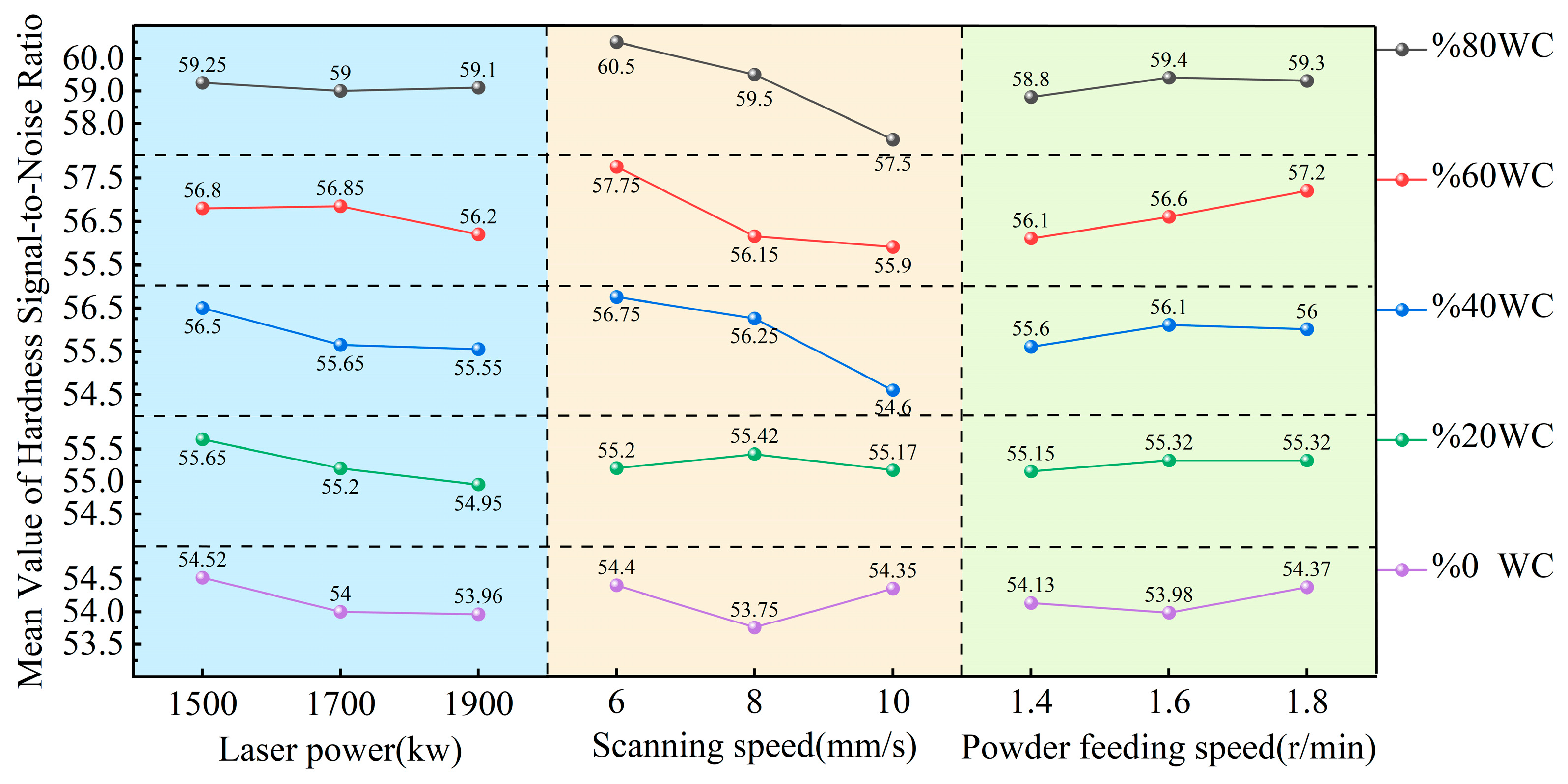

3.1. Microhardness Signal-to-Noise Ratio Analysis

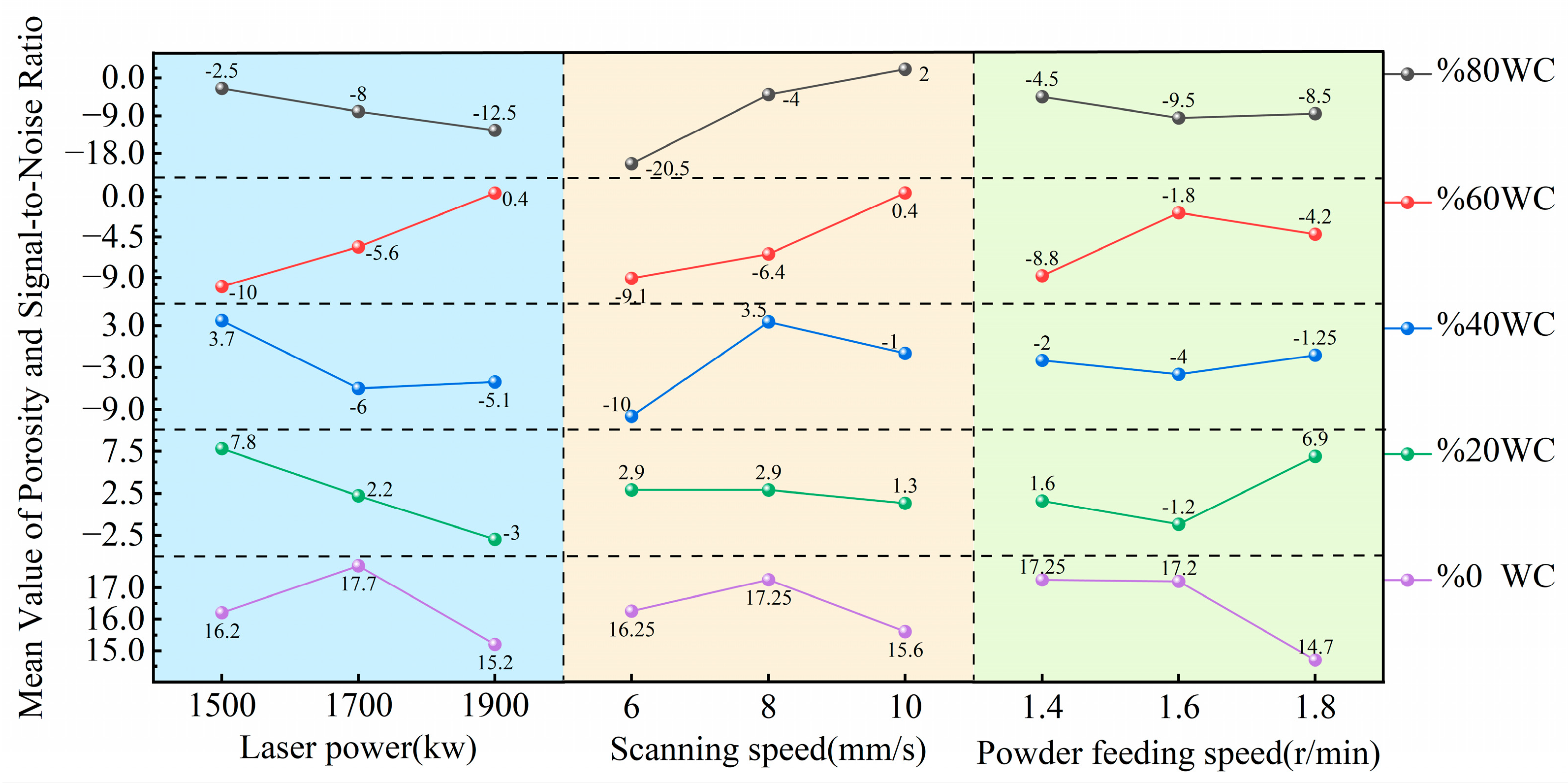

3.2. Dilution Rate Signal-to-Noise Ratio Analysis

3.3. Porosity Signal-to-Noise Ratio Analysis

3.4. Multi-Objective Optimization Based on Grey Relational Theory

3.5. Comparison and Analysis of Optimal Parameters Under Different Ratios

3.6. Verification Experiment

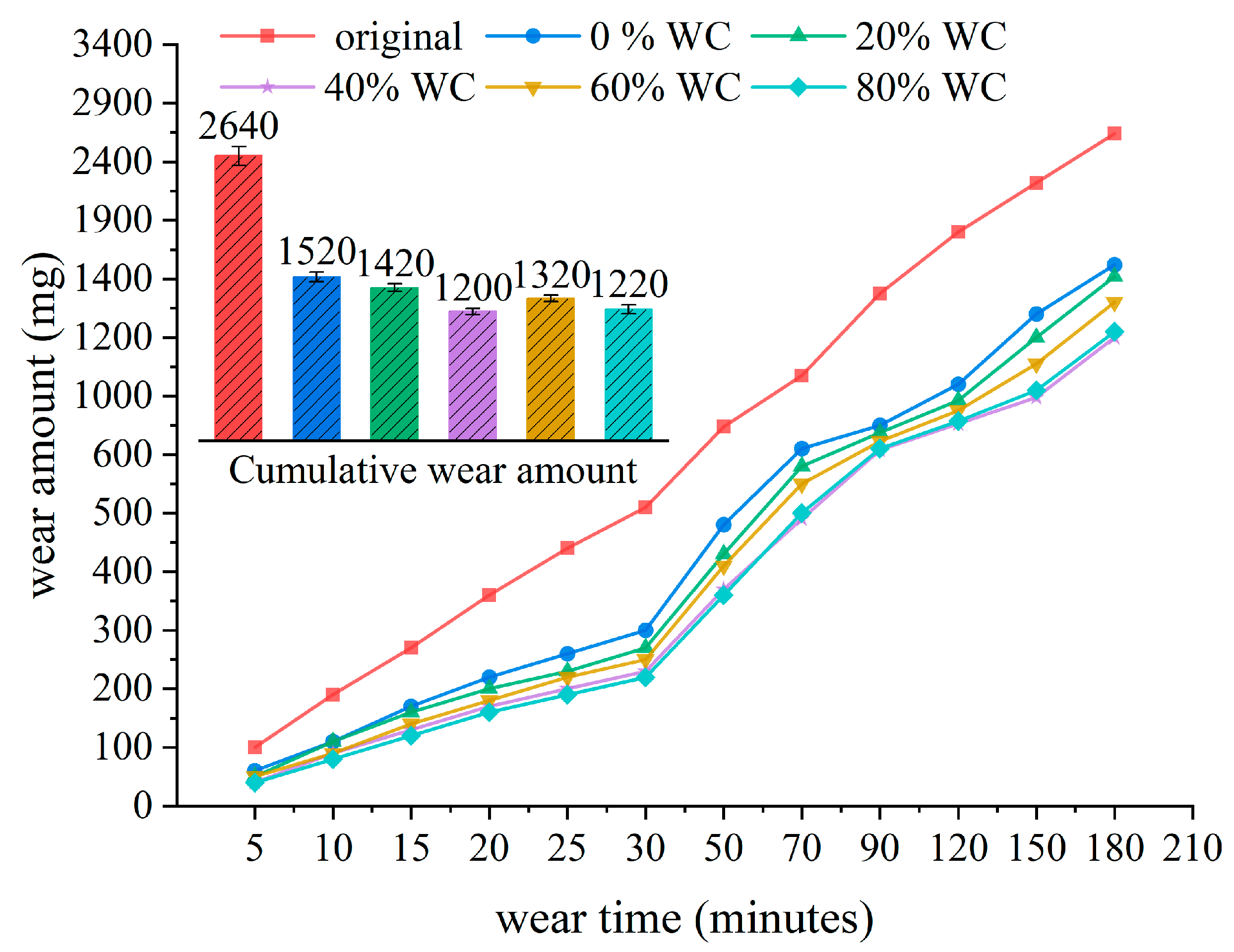

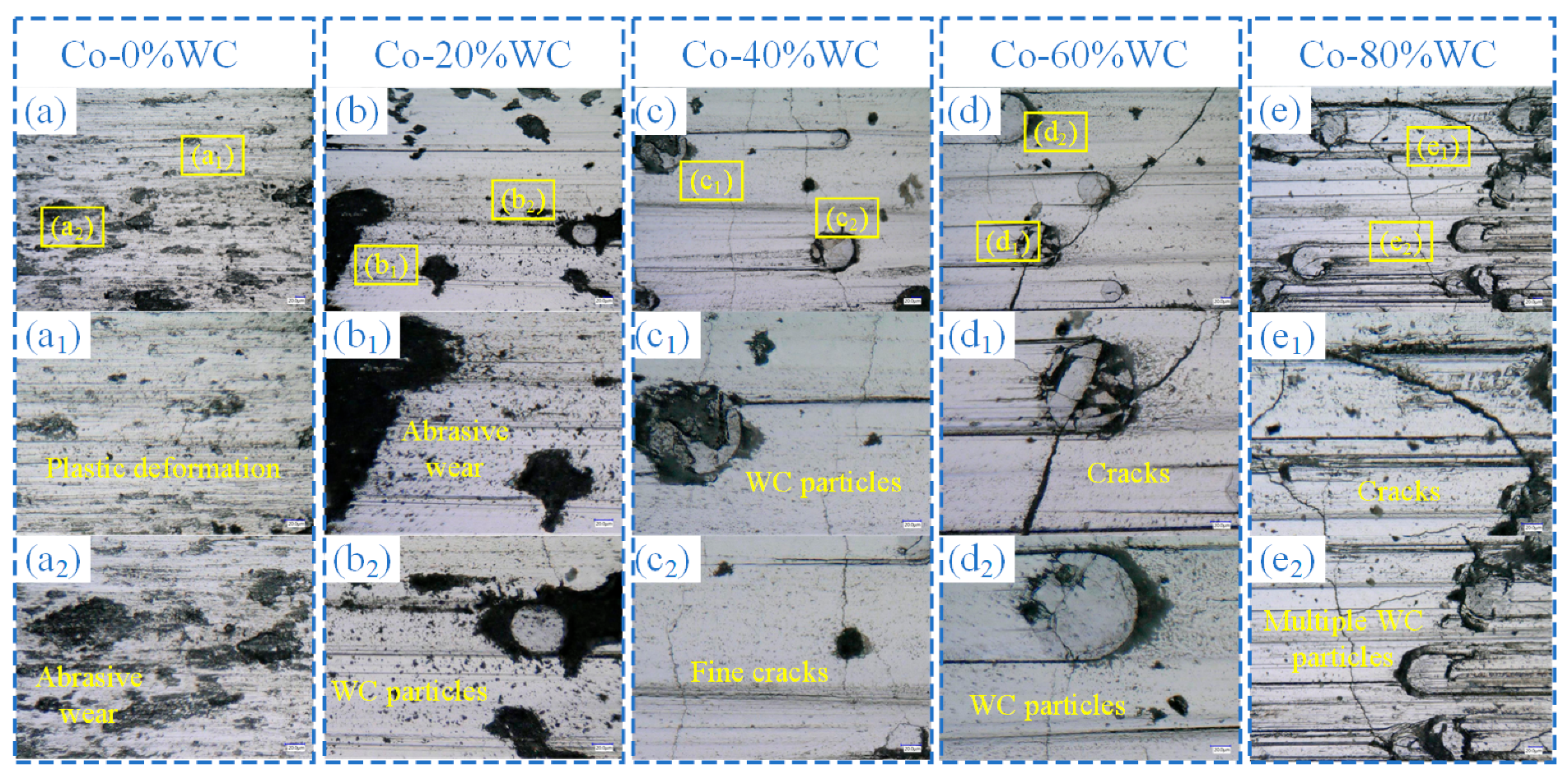

3.7. Friction and Wear Testing

4. Conclusions

- (1)

- The impact of process parameters on coating performance is related to the ratio: in terms of microhardness, when the WC content is low, the scanning speed is the main influencing factor; as the WC ratio increases, its influence decreases, while the influence of laser power and powder feeding speed increases. In terms of dilution rate, laser power is always the core factor; under high WC content, powder feeding speed has a greater influence than scanning speed. For porosity, at low WC ratios, powder feeding speed is the dominant factor; at high WC ratios, laser power becomes the most significant influencing factor.

- (2)

- Comparative display shows that as the WC ratio increases, the optimal parameter line energy increases, manifested by an increase in laser power and a decrease in scanning speed, with little change in powder feeding speed.

- (3)

- The optimal process parameters are cobalt-based alloy paired with 40% WC, laser power of 1900 W, scanning speed of 6 mm/s, and powder feeding rate of 1.8 r/min. Under these parameters, the coating has high microhardness and low dilution rate and porosity, and improves the wear resistance of the cutting pick by 45% compared to the standard cutting pick.

- (4)

- Future work will include SEM, EDS, and XRD analyses to examine WC particle distribution, interfacial bonding, and phase formation in the cladding layer. These investigations will help clarify the mechanisms behind improved wear resistance and guide further optimization of laser cladding parameters.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lin, B.; Shi, F. Coal price economic growth and electricity consumption in China under the background of energy transition. Energy Policy 2024, 195, 114400. [Google Scholar] [CrossRef]

- Che, L.; Sun, W.; Huang, Y.; Chao, Y. Laser cladding technology in the repair of shearer picks. Comput. Model. New Technol. 2014, 18, 563–565. [Google Scholar]

- Singh, S.; Goyal, D.K.; Kumar, P.; Bansal, A. Influence of laser cladding parameters on slurry erosion performance of NiCrSiBC+ 50WC claddings. Int. J. Refract. Hard Met. 2022, 105, 105825. [Google Scholar] [CrossRef]

- Liu, H.; Qin, X.; Huang, S.; Hu, Z.; Ni, M. Geometry modeling of single track cladding deposited by high power diode laser with rectangular beam spot. Opt. Lasers Eng. 2018, 100, 38–46. [Google Scholar] [CrossRef]

- Aghili, S.E.; Shamanian, M. Technology, Investigation of powder fed laser cladding of NiCr-chromium carbides single-tracks on titanium aluminide substrate. Opt. Laser Technol. 2019, 119, 105652. [Google Scholar] [CrossRef]

- Alphonsa, J.; Raja, V.; Mukherjee, S. Development of highly hard and corrosion resistant A286 stainless steel through plasma nitrocarburizing process. Surf. Coat. Technol. 2015, 280, 268–276. [Google Scholar] [CrossRef]

- Shi, X.; Wen, D.; Wang, S.; Wang, G.; Zhang, M.; Li, J.; Xue, C. Investigation on friction and wear performance of laser cladding Ni-based alloy coating on brake disc. Optik 2021, 242, 167227. [Google Scholar] [CrossRef]

- Yuan, L.; Gu, D.; Lin, K.; Dai, D.; Yang, J.; Huang, G.; Xiong, K. Laser-Directed Energy Deposition Additive Manufac turing of Nickel-Titanium Coatings: Deposition Morphology, Microstructures, and Mechanical Properties. Adv. Eng. Mater. 2022, 25, 2200965. [Google Scholar] [CrossRef]

- Wang, Z.; Zhang, S. Research progress of laser cladding coating on titanium alloy surface. Coatings 2024, 14, 1495. [Google Scholar] [CrossRef]

- Wang, G.; Huang, L.; Liu, Z.; Qin, Z.; He, W.; Liu, F.; Chen, C.; Nie, Y. Process optimization and mechanical properties of oxide dispersion strengthened nickel-based superalloy by selec tive laser melting. Mater. Des. 2020, 188, 108418. [Google Scholar] [CrossRef]

- Lin, Y.; Yao, J.; Lei, Y.; Fu, H.; Wang, L. Microstructure and properties of TiB2–TiB reinforced titanium matrix composite coating by laser cladding. Opt. Lasers Eng. 2016, 86, 216–227. [Google Scholar] [CrossRef]

- Yang, P.; Lu, N.; Liang, J.; Guo, Y.; Zhang, G.; Song, X.; Zhou, Y.; Sun, X.; Li, J. Hot crack formation mechanism and inhibition of a novel cobalt-based alloy coating during laser cladding. Materials 2024, 17, 3914. [Google Scholar] [CrossRef]

- Eshaghian, O.; Seyed, H.H.; Hamidreza, S.J. Effects of Ni-based composite coatings on failure mechanism and wear resistance of cutting picks on coal shearer machine. Eng. Fail. Anal. 2023, 151, 107342. [Google Scholar] [CrossRef]

- Yue, H.; Lv, N.; Guo, C.; Zhao, L.; Li, Q.; Zhang, J.; Zhang, Y. Microstructure and mechanical properties of TiC/FeCrSiB coating by laser additive remanufacturing on shearer spiral blade. Surf. Coat. Technol. 2022, 431, 128043. [Google Scholar] [CrossRef]

- Akintunde, I.B.; Lindsay, E.E.; Eyitayo, O.O.; Raghupatruni, V.S.P.; Annelize, B.; Sisa, L.P.; Samuel, S.; Tshephang, M. Optimised consolidation and characterisation of TiC-SiC-reinforced AISI-4340 composite coatings for conical pick remanufacture. Int. J. Adv. Manuf. Technol. 2025, 1, 21. [Google Scholar] [CrossRef]

- Luo, D.; Liu, C.; Wang, C.; Wang, Y.; Wang, X.; Zhao, J.; Jiang, S. Optimization of multilayer laser cladding process parameters based on NSGA-II-MOPSO algorithm. Opt. Laser Technol. 2024, 176, 111025. [Google Scholar] [CrossRef]

- Hu, D.; Liu, Y.; Chen, H.; Wang, M. Microstructure and wear resistance of Ni-based tungsten carbide coating by laser cladding on tunnel boring machine cutter ring. Surf. Coat. Technol. 2020, 404, 126432. [Google Scholar] [CrossRef]

- Guo, C.; Chen, J.; Zhou, J.; Zhao, J. Effects of WC–Ni content on microstructure and wear resistance of laser cladding Ni-based alloys coating. Surf. Coat. Technol. 2012, 206, 2064–2071. [Google Scholar] [CrossRef]

- Tosun, G. Ni–WC coating on AISI 1010 steel using TIG: Microstructure and microhardness. Arab. Sci. Eng. 2014, 39, 2097–2106. [Google Scholar] [CrossRef]

- Bartkowski, D.; Mynarczak, A.; Piasecki, A.; Dudziak, B.; Goscianski, M.; Bartkowska, A. Microstructure, microhardness and corrosion resistance of Stellite-6 coatings reinforced with WC particles using laser cladding. Opt. Laser Technol. 2015, 68, 191–201. [Google Scholar] [CrossRef]

- Eghlimi, A.; Shamanian, M.; Raeissi, K. Dilution and ferrite number prediction in pulsed current cladding of super-duplex stainless steel using RSM. J. Mater. Eng. Perform. 2013, 22, 3657–3664. [Google Scholar] [CrossRef]

- Madadi, F.; Ashrafizadeh, F.; Shamanian, M. Optimization of pulsed TIG cladding process of stellite alloy on carbon steel using RSM. Alloys Compd. 2012, 510, 71–77. [Google Scholar] [CrossRef]

- Moi, S.C.; Bandyopadhyay, A.; Pal, P.K. Parametric optimization of TIG welding process on mechanical properties of 316L stainless steel using RSM. Adv. Mater. Mech. Ind. Eng. 2018, 21, 315–336. [Google Scholar]

- Wang, K.; Liu, W.; Hong, Y.; Sohan, H.; Tong, Y.; Hu, Y.; Zhang, M.; Zhang, J.; Zhang, D.; Fu, H.; et al. An overview of technological parameter optimization in the case of laser cladding. Coatings 2023, 13, 496. [Google Scholar] [CrossRef]

- Erfanmanesh, M.; Shoja-Razavi, R.; Barekat, M.; Hashemi, S.Y.; Borhani, M.R.; Naderi-Samani, H.; Lanlou, M.; Nourollahi, A. High-temperature wear behavior of HVOF sprayed, laser glazed, and laser cladded Stellite 6 coatings on stainless steel substrate. J. Adhes. Sci. Technol. 2023, 37, 2440–2460. [Google Scholar] [CrossRef]

- Wang, H.; Zhang, X.; Cheng, M.; Ren, L.; Li, J. Research on the influence of laser power on the microstructure and performance of Fe-based coating. J. Therm. Spray Technol. 2025, 34, 316–336. [Google Scholar] [CrossRef]

- Wei, A.; Tang, Y.; Tong, T. Effect of WC on microstructure and wear resistance of Fe-based coating fabricated by laser cladding. Coatings 2022, 12, 1209. [Google Scholar] [CrossRef]

- Wang, S.; Shi, W.; Cheng, C. Effect of process parameters on microstructure and properties of laser cladding Ni60+30% WC coating on Q235 steel. Materials 2023, 16, 7070. [Google Scholar] [CrossRef]

- Škamat, J.; Černašėjus, O.; Zhetessova, G. Effect of laser processing parameters on microstructure, hardness and tribology of NiCrCoFeCBSi/WC coatings. Materials 2021, 14, 6034. [Google Scholar] [CrossRef]

- Sefene, E.M.; Tsegaw, A.A. Temperature-based optimization of friction stir welding of AA 6061 using GRA synchronous with Taguchi method. Int. J. Adv. Manuf. Technol. 2022, 119, 1479–1490. [Google Scholar] [CrossRef]

| C | Si | Mn | Cr | Mo | P | S | W | Ni | Co | Fe | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 42CrMo | 0.42 | 0.25 | 0.65 | 1.00 | 0.20 | 0.01 | 0.01 | - | - | - | Bal. |

| Stellite6 | 1.15 | 4.00 | 0.50 | 29.00 | 1.00 | - | - | 4.00 | 3.00 | Bal. | 3.00 |

| Number | Laser Power (W) | Powder Feeding Speed (r/min) | Scanning Speed (mm/s) |

|---|---|---|---|

| 1 | 1500 | 1.4 | 6 |

| 2 | 1700 | 1.6 | 6 |

| 3 | 1900 | 1.8 | 6 |

| 4 | 1700 | 1.4 | 8 |

| 5 | 1900 | 1.6 | 8 |

| 6 | 1500 | 1.8 | 8 |

| 7 | 1900 | 1.4 | 10 |

| 8 | 1500 | 1.6 | 10 |

| 9 | 1700 | 1.8 | 10 |

| No. | MH (HV) | DR | PO (%) | CS | No. | MH (HV) | DR | PO (%) | CS |

|---|---|---|---|---|---|---|---|---|---|

| A1 | 547.94 | 0.13 | 0.17 |  | B1 | 579.85 | 0.15 | 2.75 |  |

| A2 | 519.97 | 0.15 | 0.12 |  | B2 | 597.06 | 0.15 | 0.79 |  |

| A3 | 505.57 | 0.13 | 0.18 |  | B3 | 550.41 | 0.30 | 0.17 |  |

| A4 | 458.34 | 0.19 | 0.09 |  | B4 | 570.77 | 0.13 | 0.17 |  |

| A5 | 468.55 | 0.20 | 0.17 |  | B5 | 559.49 | 0.18 | 12.68 |  |

| A6 | 534.58 | 0.12 | 0.17 |  | B6 | 644.74 | 0.11 | 0.17 |  |

| A7 | 524.35 | 0.15 | 0.17 |  | B7 | 566.17 | 0.30 | 0.87 |  |

| A8 | 513.03 | 0.13 | 0.13 |  | B8 | 594.86 | 0.19 | 0.15 |  |

| A9 | 528.52 | 0.23 | 0.21 |  | B9 | 559.66 | 0.17 | 3.22 |  |

| C1 | 693.13 | 0.28 | 0.52 |  | D1 | 760.36 | 0.27 | 7.99 |  |

| C2 | 701.53 | 0.31 | 4.02 |  | D2 | 765.46 | 0.35 | 2.58 |  |

| C3 | 678.49 | 0.42 | 0.78 |  | D3 | 799.34 | 0.41 | 1.41 |  |

| C4 | 615.78 | 0.31 | 3.63 |  | D4 | 630.24 | 0.36 | 2.58 |  |

| C5 | 623.16 | 0.38 | 3.41 |  | D5 | 623.43 | 0.42 | 0.79 |  |

| C6 | 713.65 | 0.20 | 0.21 |  | D6 | 673.63 | 0.24 | 4.52 |  |

| C7 | 512.54 | 0.33 | 1.00 |  | D7 | 537.74 | 0.43 | 1.00 |  |

| C8 | 593.46 | 0.23 | 2.58 |  | D8 | 651.65 | 0.30 | 0.89 |  |

| C9 | 513.78 | 0.35 | 0.51 |  | D9 | 696.78 | 0.26 | 1.00 |  |

| E1 | 1044.60 | 0.39 | 27.15 |  | E6 | 985.82 | 0.29 | 1.00 |  |

| E2 | 1087.71 | 0.38 | 13.95 |  | E7 | 722.26 | 0.41 | 0.99 |  |

| E3 | 1077.34 | 0.26 | 3.16 |  | E8 | 743.88 | 0.26 | 0.76 |  |

| E4 | 867.86 | 0.29 | 1.55 |  | E9 | 747.94 | 0.36 | 1.26 |  |

| E5 | 992.04 | 0.38 | 2.61 |  |  |

| No. | MH (HV) | DR | PO (%) | No. | MH (HV) | DR | PO (%) | No. | MH (HV) | DR | PO (%) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| A1 | 54.77 | 17.72 | 15.39 | B1 | 55.27 | 16.48 | −8.79 | C1 | 56.82 | 11.06 | 5.68 |

| A2 | 54.32 | 16.48 | 18.42 | B2 | 55.52 | 16.48 | 2.05 | C2 | 56.92 | 10.17 | −12.08 |

| A3 | 54.08 | 17.72 | 14.89 | B3 | 54.81 | 10.46 | 15.39 | C3 | 56.63 | 7.54 | −23.32 |

| A4 | 53.22 | 14.42 | 20.92 | B4 | 55.13 | 17.72 | 15.39 | C4 | 55.79 | 10.17 | −11.20 |

| A5 | 53.42 | 13.98 | 15.39 | B5 | 54.96 | 14.89 | −22.06 | C5 | 55.89 | 8.40 | 7.74 |

| A6 | 54.56 | 18.42 | 15.39 | B6 | 56.19 | 19.17 | 15.39 | C6 | 57.07 | 13.98 | 13.56 |

| A7 | 54.39 | 16.48 | 15.39 | B7 | 55.06 | 10.46 | −2.21 | C7 | 54.19 | 9.63 | 0.00 |

| A8 | 54.20 | 17.72 | 17.72 | B8 | 55.49 | 14.42 | 16.48 | C8 | 55.47 | 12.77 | −8.23 |

| A9 | 54.46 | 12.77 | 13.56 | B9 | 54.96 | 15.39 | −10.16 | C9 | 54.22 | 9.12 | 5.85 |

| D1 | 57.62 | 11.37 | −18.05 | E1 | 60.65 | 11.70 | −9.99 | ||||

| D2 | 57.68 | 9.12 | −8.23 | E2 | 60.73 | 8.40 | −22.89 | ||||

| D3 | 58.05 | 7.74 | 0.00 | E3 | 60.38 | 8.18 | −28.68 | ||||

| D4 | 55.99 | 8.87 | −8.23 | E4 | 58.77 | 10.75 | −3.81 | ||||

| D5 | 55.90 | 7.54 | 2.05 | E5 | 59.93 | 8.40 | −8.33 | ||||

| D6 | 56.57 | 12.40 | −13.10 | E6 | 59.88 | 10.75 | 0.00 | ||||

| D7 | 54.61 | 7.33 | 0.00 | E7 | 57.17 | 7.74 | 0.09 | ||||

| D8 | 56.28 | 10.46 | 1.01 | E8 | 57.43 | 11.70 | 2.38 | ||||

| D9 | 56.86 | 11.70 | 0.00 | E9 | 54.77 | 8.87 | 2.38 |

| No. | MH (HV) | DR | PO (%) | No. | MH (HV) | DR | PO (%) | No. | MH (HV) | DR | PO (%) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| A1 | 0.21 | 0.12 | 0.11 | B1 | 0.27 | 0.23 | 0.6 | C1 | 0.48 | 0.69 | 0.31 |

| A2 | 0.15 | 0.23 | 0.05 | B2 | 0.31 | 0.23 | 0.38 | C2 | 0.49 | 0.76 | 0.67 |

| A3 | 0.11 | 0.12 | 0.12 | B3 | 0.21 | 0.74 | 0.11 | C3 | 0.45 | 0.98 | 0.89 |

| A4 | 0 | 0.4 | 0 | B4 | 0.25 | 0.12 | 0.11 | C4 | 0.34 | 0.76 | 0.65 |

| A5 | 0.03 | 0.44 | 0.11 | B5 | 0.23 | 0.36 | 0.87 | C5 | 0.36 | 0.91 | 0.27 |

| A6 | 0.18 | 0.06 | 0.11 | B6 | 0.39 | 0 | 0.11 | C6 | 0.51 | 0.44 | 0.15 |

| A7 | 0.16 | 0.23 | 0.11 | B7 | 0.24 | 0.74 | 0.47 | C7 | 0.13 | 0.81 | 0.42 |

| A8 | 0.13 | 0.12 | 0.06 | B8 | 0.3 | 0.4 | 0.09 | C8 | 0.3 | 0.54 | 0.59 |

| A9 | 0.16 | 0.54 | 0.15 | B9 | 0.23 | 0.32 | 0.63 | C9 | 0.13 | 0.85 | 0.3 |

| D1 | 0.59 | 0.66 | 0.79 | E1 | 0.99 | 0.63 | 0.62 | ||||

| D2 | 0.59 | 0.85 | 0.59 | E2 | 1 | 0.91 | 0.88 | ||||

| D3 | 0.64 | 0.97 | 0.42 | E3 | 0.95 | 0.93 | 1 | ||||

| D4 | 0.37 | 0.87 | 0.59 | E4 | 0.74 | 0.71 | 0.5 | ||||

| D5 | 0.36 | 0.98 | 0.38 | E5 | 0.89 | 0.91 | 0.59 | ||||

| D6 | 0.45 | 0.57 | 0.69 | E6 | 0.89 | 0.71 | 0.42 | ||||

| D7 | 0.18 | 1 | 0.42 | E7 | 0.53 | 0.97 | 0.42 | ||||

| D8 | 0.41 | 0.74 | 0.4 | E8 | 0.56 | 0.63 | 0.37 | ||||

| D9 | 0.48 | 0.63 | 0.42 | E9 | 0.21 | 0.87 | 0.37 |

| No. | MH (HV) | Error Range | DR | Error Range | PO (%) | Error Range | CS |

|---|---|---|---|---|---|---|---|

| A9 | 526.14 | 0.4% | 0.22 | 8.4% | 0.19 | 9.5% |  |

| B7 | 580.89 | 2.5% | 0.29 | 3.3% | 0.91 | 2.2% |  |

| C3 | 694.31 | 2.4% | 0.42 | 0% | 0.85 | 9.0% |  |

| D3 | 792.60 | 0.9% | 0.40 | 2.4% | 1.28 | 9.2% |  |

| E3 | 1058.23 | 1.8% | 0.27 | 3.8% | 2.94 | 7.0% |  |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, Y.; Guo, C.; Xue, S.; Yue, H.; Dai, J. Cobalt-Based Ceramic Wear-Resistant Cutting Pick Laser Cladding Process and Its Law Analysis. Coatings 2025, 15, 1289. https://doi.org/10.3390/coatings15111289

Zhu Y, Guo C, Xue S, Yue H, Dai J. Cobalt-Based Ceramic Wear-Resistant Cutting Pick Laser Cladding Process and Its Law Analysis. Coatings. 2025; 15(11):1289. https://doi.org/10.3390/coatings15111289

Chicago/Turabian StyleZhu, Yiming, Chenguang Guo, Shengli Xue, Haitao Yue, and Junlin Dai. 2025. "Cobalt-Based Ceramic Wear-Resistant Cutting Pick Laser Cladding Process and Its Law Analysis" Coatings 15, no. 11: 1289. https://doi.org/10.3390/coatings15111289

APA StyleZhu, Y., Guo, C., Xue, S., Yue, H., & Dai, J. (2025). Cobalt-Based Ceramic Wear-Resistant Cutting Pick Laser Cladding Process and Its Law Analysis. Coatings, 15(11), 1289. https://doi.org/10.3390/coatings15111289