Aqueous Polyhydroxyalkanoate Solution-Based Knife Coatings: An Alternative Approach to the Production of Coated Cotton Fabrics

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials and Reagents

2.2. Preparation of PHBHHx-Based Coating Formulations

2.3. Application of PHBHHx-Based Coatings on Cotton Fabrics

2.4. Characterization

2.4.1. Surface Analysis

2.4.2. Thickness and Grammage

2.4.3. Fourier Transform Infrared Spectroscopy (FTIR)

2.4.4. Wettability

2.4.5. Permeabilities

2.4.6. Abrasion of Fabrics

2.4.7. Resistance to Washing

3. Results and Discussion

3.1. Development of Aqueous PHBHHx Knife Coatings

3.1.1. Preparation and Application of Stable Aqueous PHBHHx Suspensions Using Knife Coating

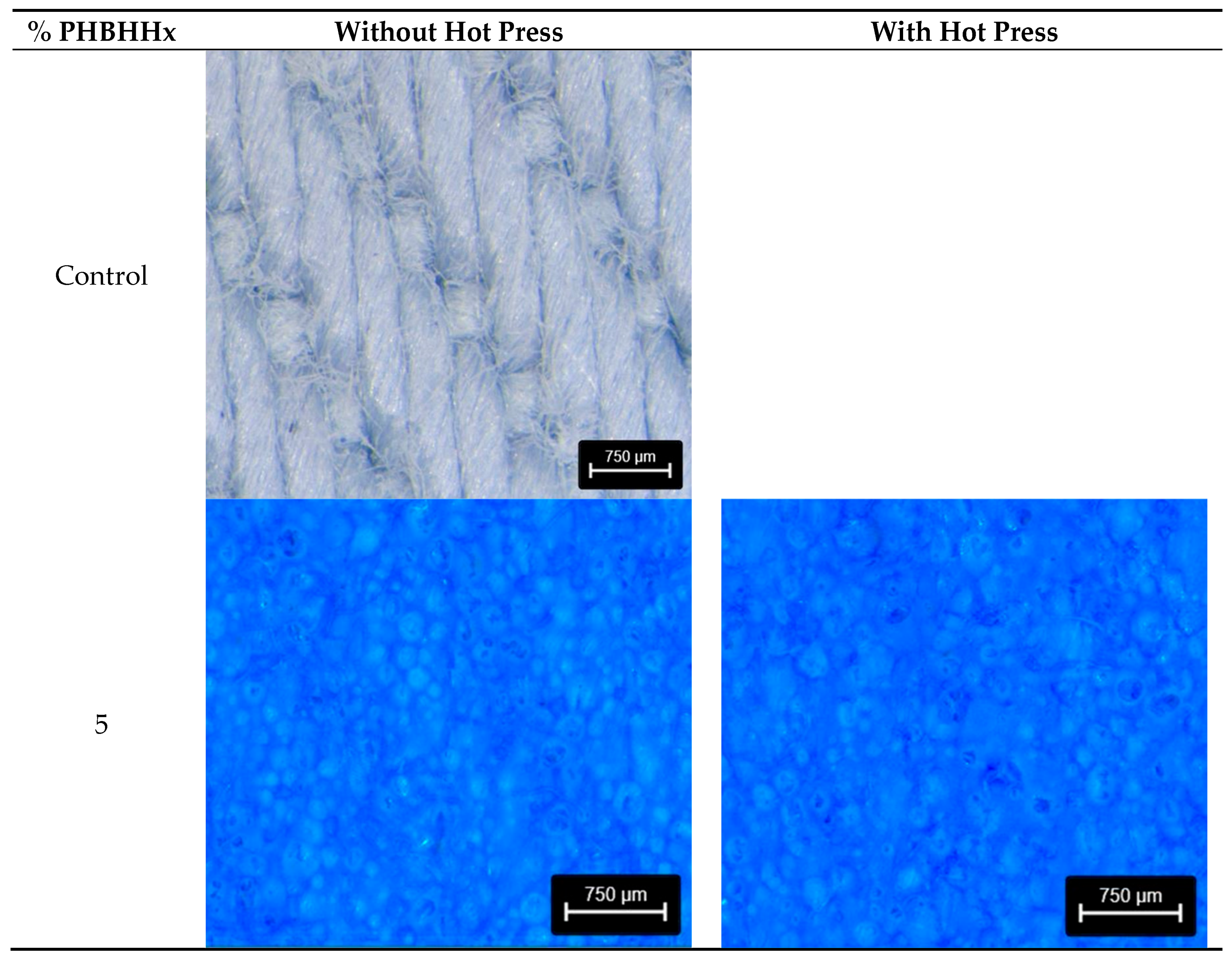

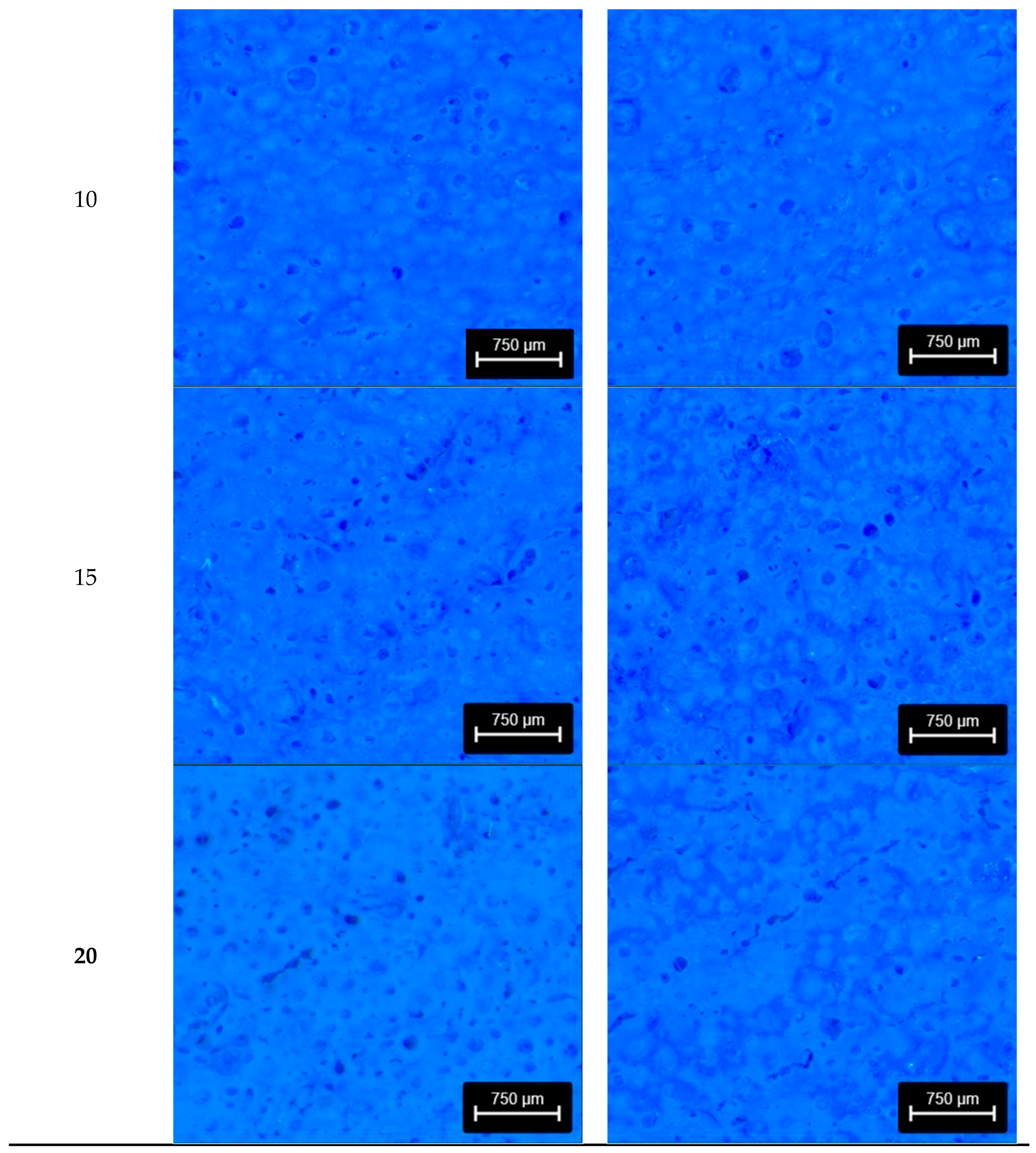

3.1.2. Determining Suitable PHBHHx Concentration for Knife Coating Applications on Textiles

3.1.3. Effect of a Synthetic Rheology Modifier and Additive Absence on the Performance of 10% PHBHHx Knife-Coated Fabrics

3.2. Characterizations of Aqueous 10% PHBHHx Knife Coatings

3.2.1. Surface and Thickness Analysis

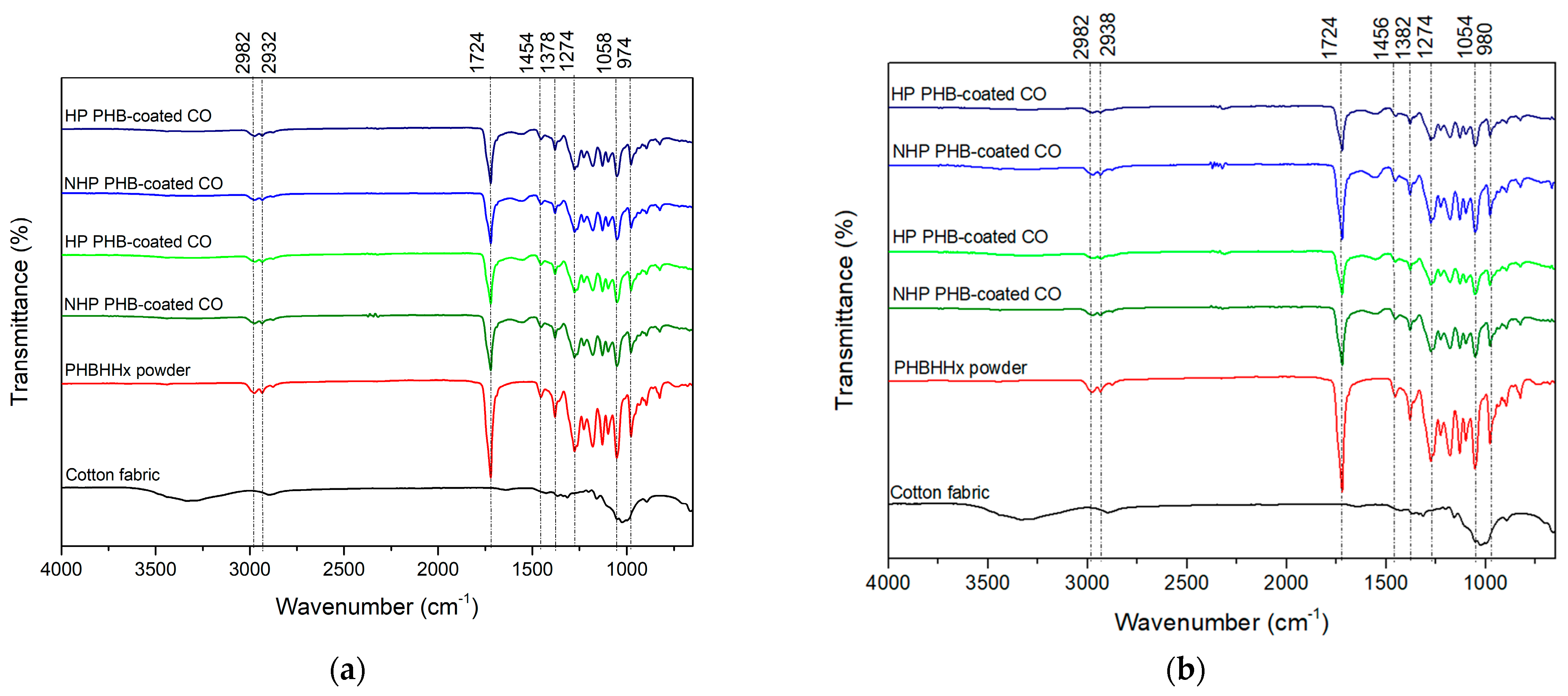

3.2.2. FTIR Analysis

3.2.3. Wettability Analysis

3.2.4. Permeability Analysis

3.2.5. Abrasion Resistance

3.3. Washing Resistance

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Islam, N.F.; Gogoi, B.; Saikia, R.; Yousaf, B.; Narayan, M.; Sarma, H. Encouraging Circular Economy and Sustainable Environmental Practices by Addressing Waste Management and Biomass Energy Production. Reg. Sustain. 2024, 5, 100174. [Google Scholar] [CrossRef]

- Jadhav, N.C.; Jadhav, A.C. Waste and 3R’s in Footwear and Leather Sectors. In Leather and Footwear Sustainability; Springer: Singapore, 2020; pp. 261–293. [Google Scholar]

- European Environment Agency (EEA). Consumption of Clothing, Footwear and Household Textiles per Person; European Environment Agency: Copenhagen, Denmark, 2025. [Google Scholar]

- Firtikiadis, L.; Manavis, A.; Kyratsis, P.; Efkolidis, N. Product Design Trends within the Footwear Industry: A Review. Designs 2024, 8, 49. [Google Scholar] [CrossRef]

- Navarro, D.; Wu, J.; Lin, W.; Fullana-i-Palmer, P.; Puig, R. Life Cycle Assessment and Leather Production. J. Leather Sci. Eng. 2020, 2, 26. [Google Scholar] [CrossRef]

- Silva, A.; Vilaça, H.; Antunes, J.; Rocha, A.; Silva, C. Textile Bio-Based and Bioactive Coatings Using Vegetal Waste and by-Products. Base Diseño Innovación 2022, 7, 57–70. [Google Scholar] [CrossRef]

- Wang, Y.; Zheng, M.; Liu, X.; Yue, O.; Wang, X.; Jiang, H. Advanced Collagen Nanofibers-Based Functional Bio-Composites for High-Value Utilization of Leather: A Review. J. Sci. Adv. Mater. Devices 2021, 6, 153–166. [Google Scholar] [CrossRef]

- Meyer, M.; Dietrich, S.; Schulz, H.; Mondschein, A. Comparison of the Technical Performance of Leather, Artificial Leather, and Trendy Alternatives. Coatings 2021, 11, 226. [Google Scholar] [CrossRef]

- Oruko, R.O.; Selvarajan, R.; Ogola, H.J.O.; Edokpayi, J.N.; Odiyo, J.O. Contemporary and Future Direction of Chromium Tanning and Management in Sub Saharan Africa Tanneries. Process Saf. Environ. Prot. 2020, 133, 369–386. [Google Scholar] [CrossRef]

- Sharma, P.; Singh, S.P.; Parakh, S.K.; Tong, Y.W. Health Hazards of Hexavalent Chromium (Cr (VI)) and Its Microbial Reduction. Bioengineered 2022, 13, 4923–4938. [Google Scholar] [CrossRef] [PubMed]

- Wang, H. Advantages of Animal Leather over Alternatives and Its Medical Applications. Eur. Polym. J. 2024, 214, 113153. [Google Scholar] [CrossRef]

- Ojo, A.B.; Agbeye, O.D.; Ogwa, T.O.; Adedoyin, D.; Rotimi, D.E.; Ojo, O.A. Implications of Plastic-Derived Endocrine Disruptors on Human Health. Toxicol. Mech. Methods 2025, 35, 894–918. [Google Scholar] [CrossRef]

- Campisi, L.; La Motta, C.; Napierska, D. Polyvinyl Chloride (PVC), Its Additives, Microplastic and Human Health: Unresolved and Emerging Issues. Sci. Total Environ. 2025, 960, 178276. [Google Scholar] [CrossRef]

- Duangsuwan, S.; Junkong, P.; Phinyocheep, P.; Thanawan, S.; Amornsakchai, T. Development of Green Leather Alternative from Natural Rubber and Pineapple Leaf Fiber. Sustainability 2023, 15, 15400. [Google Scholar] [CrossRef]

- Amobonye, A.; Lalung, J.; Awasthi, M.K.; Pillai, S. Fungal Mycelium as Leather Alternative: A Sustainable Biogenic Material for the Fashion Industry. Sustain. Mater. Technol. 2023, 38, e00724. [Google Scholar] [CrossRef]

- Asabuwa Ngwabebhoh, F.; Saha, N.; Nguyen, H.T.; Brodnjak, U.V.; Saha, T.; Lengalova, A.; Saha, P. Preparation and Characterization of Nonwoven Fibrous Biocomposites for Footwear Components. Polymers 2020, 12, 3016. [Google Scholar] [CrossRef]

- Fernandes, P.R.B.; Contin, B.; Siqueira, M.U.; Ruschel-Soares, R.; Baruque-Ramos, J. Biocomposites from Cotton Denim Waste for Footwear Components. Mater. Circ. Econ. 2021, 3, 29. [Google Scholar] [CrossRef]

- Dhanda, V.; Arsalan, S.; Kaushal, S. Revolutionizing Material: The Rise of Bio Leather as Eco-Friendly and Sustainable Approach. Int. J. Res. Agron. 2024, 7, 121–128. [Google Scholar] [CrossRef]

- Hadri, S.H.; Tareen, N.; Hassan, A.; Naseer, M.; Ali, K.; Javed, H. Alternatives to Conventional Plastics: Polyhydroxyalkanoates (PHA) from Microbial Sources and Recent Approaches—A Review. Process Saf. Environ. Prot. 2025, 195, 106809. [Google Scholar] [CrossRef]

- Teixeira, M.A.; Leite, I.; Gonçalves, R.; Vilaça, H.; Guise, C.; Silva, C. Comprehensive Evaluation of Wet-Spun Polyhydroxyalkanoate Fibres: Morphology, Crystallinity, and Thermal Properties. Fibers 2025, 13, 111. [Google Scholar] [CrossRef]

- Chang, H.M.; Wang, Z.H.; Luo, H.N.; Xu, M.; Ren, X.Y.; Zheng, G.X.; Wu, B.J.; Zhang, X.H.; Lu, X.Y.; Chen, F.; et al. Poly(3-Hydroxybutyrate-Co-3-Hydroxyhexanoate)-Based Scaffolds for Tissue Engineering. Braz. J. Med. Biol. Res. 2014, 47, 533–539. [Google Scholar] [CrossRef] [PubMed]

- Amabile, C.; Abate, T.; Muñoz, R.; Chianese, S.; Musmarra, D. Production of Poly(3-Hydroxybutyrate) and Poly(3-Hydroxybutyrate-Co-3-Hydroxyvalerate) from Methane and Volatile Fatty Acids: Properties, Metabolic Routes and Current Trend. Sci. Total Environ. 2024, 927, 172138. [Google Scholar] [CrossRef] [PubMed]

- Park, H.; He, H.; Yan, X.; Liu, X.; Scrutton, N.S.; Chen, G.-Q. PHA Is Not Just a Bioplastic! Biotechnol. Adv. 2024, 71, 108320. [Google Scholar] [CrossRef] [PubMed]

- Tull, S.W. Aqueous Suspensions of Polyhydroxyalkanoate and Their Application as Functional Barrier Coatings. Ph.D. Thesis, University of Georgia, Athens, GA, USA, 2021. [Google Scholar]

- Nsengiyumva, E.M.; Alexandridis, P. Xanthan Gum in Aqueous Solutions: Fundamentals and Applications. Int. J. Biol. Macromol. 2022, 216, 583–604. [Google Scholar] [CrossRef]

- Jung, S.K. Textile Fabric Sheet Having Stain and Liquid Resistance and the Preparation Method Thereof. US9103067B2, 5 August 2011. [Google Scholar]

- Zhang, L.; Li, X.; Zhang, S.; Gao, Q.; Lu, Q.; Peng, R.; Xu, P.; Shang, H.; Yuan, Y.; Zou, H. Micro-FTIR Combined with Curve Fitting Method to Study Cellulose Crystallinity of Developing Cotton Fibers. Anal. Bioanal. Chem. 2021, 413, 1313–1320. [Google Scholar] [CrossRef]

- Kong, D.; Liu, J.; Zhang, Z.; Wang, S.; Lu, Z. Preparation of Synergistic Silicon, Phosphorus and Nitrogen Flame Retardant Based on Cyclosiloxane and Its Application to Cotton Fabric. Cellulose 2021, 28, 8115–8128. [Google Scholar] [CrossRef]

- Trakunjae, C.; Boondaeng, A.; Apiwatanapiwat, W.; Kosugi, A.; Arai, T.; Sudesh, K.; Vaithanomsat, P. Enhanced Polyhydroxybutyrate (PHB) Production by Newly Isolated Rare Actinomycetes Rhodococcus Sp. Strain BSRT1-1 Using Response Surface Methodology. Sci. Rep. 2021, 11, 1896. [Google Scholar] [CrossRef]

- Julinová, M.; Šašinková, D.; Minařík, A.; Kaszonyiová, M.; Kalendová, A.; Kadlečková, M.; Fayyazbakhsh, A.; Koutný, M. Comprehensive Biodegradation Analysis of Chemically Modified Poly(3-Hydroxybutyrate) Materials with Different Crystal Structures. Biomacromolecules 2023, 24, 4939–4957. [Google Scholar] [CrossRef]

- Ramezani, M.; Amoozegar, M.A.; Ventosa, A. Screening and Comparative Assay of Poly-Hydroxyalkanoates Produced by Bacteria Isolated from the Gavkhooni Wetland in Iran and Evaluation of Poly-β-Hydroxybutyrate Production by Halotolerant Bacterium Oceanimonas Sp. GK1. Ann. Microbiol. 2015, 65, 517–526. [Google Scholar] [CrossRef]

- Parvate, S.; Dixit, P.; Chattopadhyay, S. Superhydrophobic Surfaces: Insights from Theory and Experiment. J. Phys. Chem. B 2020, 124, 1323–1360. [Google Scholar] [CrossRef]

- Jothi Prakash, C.G.; Prasanth, R. Approaches to Design a Surface with Tunable Wettability: A Review on Surface Properties. J. Mater. Sci. 2021, 56, 108–135. [Google Scholar] [CrossRef]

- Brogly, M.; Bistac, S.; Fahs, A. Surface Migration of Fatty Acid to Improve Sliding Properties of Hypromellose-Based Coatings. Surfaces 2024, 7, 666–679. [Google Scholar] [CrossRef]

- Kaziur, P.; Mikołajczyk, Z. Structural and Physiological Properties of Footwear Textiles. Fibres Text. East. Eur. 2023, 31, 75–85. [Google Scholar] [CrossRef]

| % PHBHHx | Treatment | Thickness (mm) | Contact Angle (°) ± S.D. |

|---|---|---|---|

| 5 | Without hot pressing | 0.70 ± 0.01 | 76.6 ± 38.9 |

| Hot Pressing (180 °C) | 0.66 ± 0.02 | 84.9 ± 13.5 | |

| 10 | Without hot pressing | 0.79 ± 0.00 | 81.7 ± 9.0 |

| Hot Pressing (180 °C) | 0.65 ± 0.00 | 63.3 ± 7.9 | |

| 15 | Without hot pressing | 0.88 ± 0.01 | 81.7 ± 10.1 |

| Hot Pressing (180 °C) | 0.73 ± 0.01 | 69.5 ± 14.8 | |

| 20 | Without hot pressing | 0.91 ± 0.00 | 81.6 ± 10.3 |

| Hot Pressing (180 °C) | 0.74 ± 0.01 | 69.1 ± 10.7 |

| Sample | Additives/Thermal Treatment | Contact Angle (°) ± S.D. |

|---|---|---|

| 10% PHBHHx-coated cotton fabric | With/Without | 93.6 ± 14.3 |

| With/With | 76.0 ± 3.7 | |

| Without/Without | 121.1 ± 10.7 | |

| Without/With | 110.5 ± 13.5 |

| Sample | Additives/Thermal Treatment | Air Permeability L/(m2/s) ± S.D. | WVP (g/m2/24 h) ± S.D. | I (%) |

|---|---|---|---|---|

| Control cotton | 94.0 ± 2.3 | 669.8 ± 12.1 | 95.3 | |

| 10% PHBHHx-coated cotton fabric | With/Without | 20.3 ± 4.7 | 398.1 ± 27.8 | 62.0 |

| With/With | 68.0 ± 3.1 | 651.0 ± 5.4 | 92.6 | |

| Without/Without | 25.4 ± 1.9 | 510.7 ± 2.9 | 81.0 | |

| Without/With | 19.5 ± 4.4 | 245.6 ± 66.2 | 39.0 |

| Sample | Additives/Thermal Treatment | Degree of Specimen Degradation |

|---|---|---|

| 10% PHBHHx-coated cotton fabric | With/Without | 0 |

| With/With | 0 | |

| Without/Without | 1 | |

| Without/With | 0 |

| Sample | Additives/Thermal Treatment | Contact Angle (°) ± S.D. | Thicknesses (mm) | |||

|---|---|---|---|---|---|---|

| Without Washings | 1 Wash Cycle | 5 Wash Cycles | 1 Wash Cycle | 5 Wash Cycles | ||

| 10% PHBHHx-coated cotton fabric | With/Without | 93.6 ± 14.3 | 93.6 ± 7.7 | Absorbed instantly | 1.04 ± 0.03 | 1.31 ± 0.06 |

| With/With | 76.0 ± 3.7 | 88.0 ± 9.6 | 119.1 ± 6.8 | 0.90 ± 0.03 | 0.96 ± 0.02 | |

| Without/Without | 121.1 ± 10.7 | 106.4 ± 4.5 | 88.9 ± 8.1 | 1.11 ± 002 | 1.18 ± 0.06 | |

| Without/With | 110.5 ± 13.5 | 122.4 ± 22.7 | 99.5 ± 6.0 | 1.01 ± 0.05 | 0.95 ± 0.03 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Teixeira, M.A.; Castro, J.; Lima, B.; Guise, C.; Vilaça, H.; Silva, C.J. Aqueous Polyhydroxyalkanoate Solution-Based Knife Coatings: An Alternative Approach to the Production of Coated Cotton Fabrics. Coatings 2025, 15, 1278. https://doi.org/10.3390/coatings15111278

Teixeira MA, Castro J, Lima B, Guise C, Vilaça H, Silva CJ. Aqueous Polyhydroxyalkanoate Solution-Based Knife Coatings: An Alternative Approach to the Production of Coated Cotton Fabrics. Coatings. 2025; 15(11):1278. https://doi.org/10.3390/coatings15111278

Chicago/Turabian StyleTeixeira, Marta A., Joana Castro, Beatriz Lima, Catarina Guise, Helena Vilaça, and Carla Joana Silva. 2025. "Aqueous Polyhydroxyalkanoate Solution-Based Knife Coatings: An Alternative Approach to the Production of Coated Cotton Fabrics" Coatings 15, no. 11: 1278. https://doi.org/10.3390/coatings15111278

APA StyleTeixeira, M. A., Castro, J., Lima, B., Guise, C., Vilaça, H., & Silva, C. J. (2025). Aqueous Polyhydroxyalkanoate Solution-Based Knife Coatings: An Alternative Approach to the Production of Coated Cotton Fabrics. Coatings, 15(11), 1278. https://doi.org/10.3390/coatings15111278