Superwettable Carbon Fiber Membranes Functionalized with Cu-TiO2: High-Performance Oil–Water Separation and Sustainable Reusability

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Pretreatment of CF Raw Materials

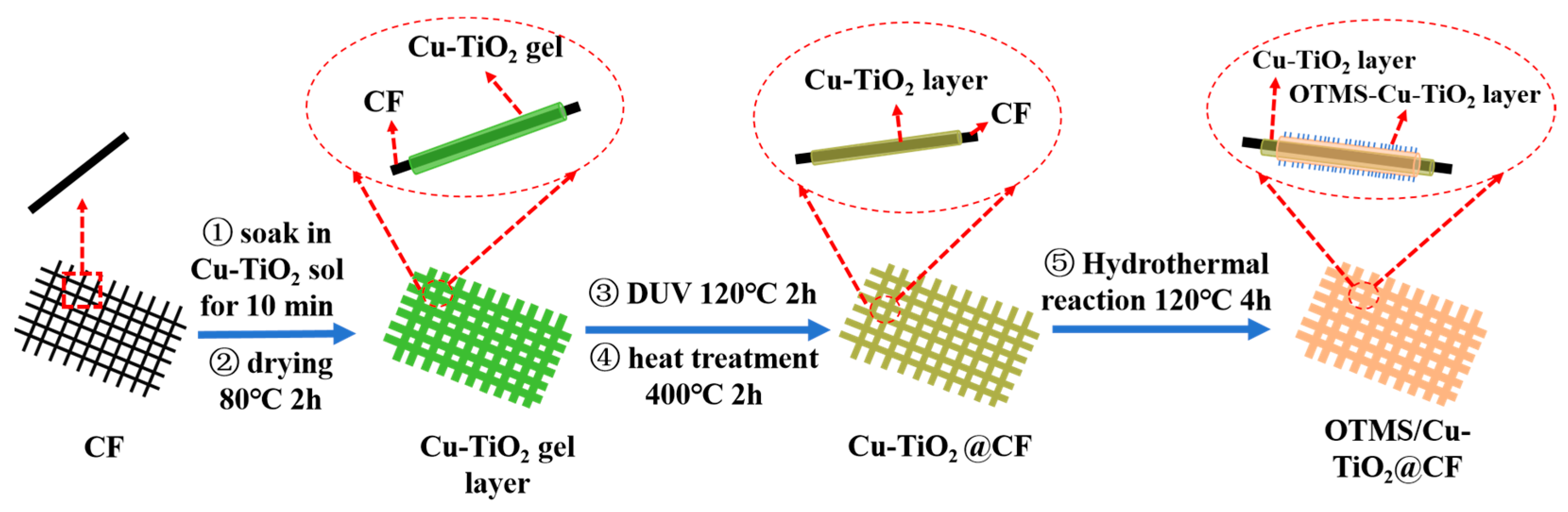

2.3. Preparation of Cu-TiO2@CF Membranes

2.4. Preparation of OTMS/Cu-TiO2@CF Membranes

2.5. Material Characterization

2.6. Performance Testing

2.6.1. Adsorption Performance Testing

2.6.2. Wear Resistance Testing

2.6.3. Oil–Water Separation Performance

2.7. Restoration of Oil–Water Separation Membranes

3. Results and Discussion

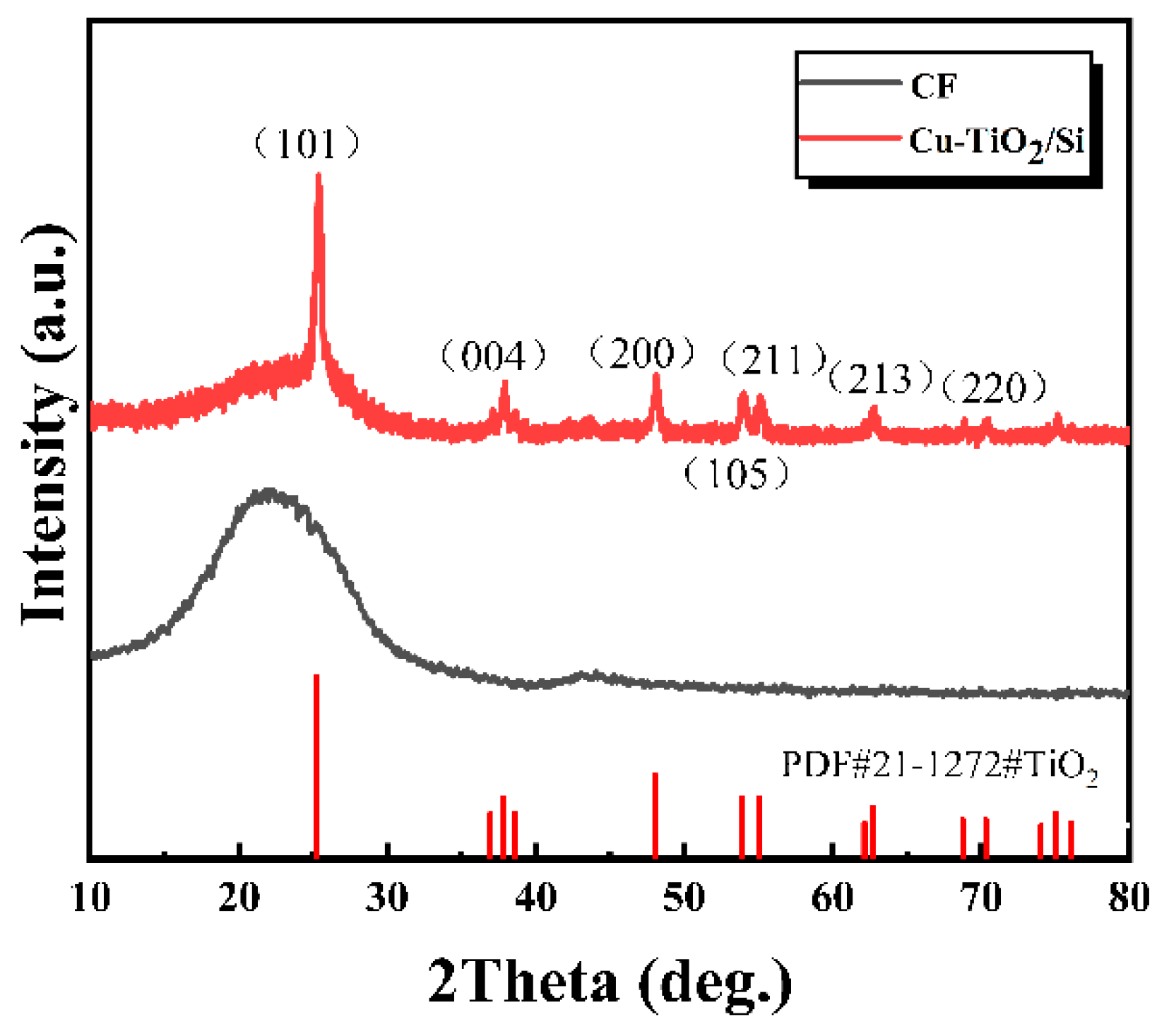

3.1. Phase Structure Analysis of Cu-TiO2 Coatings

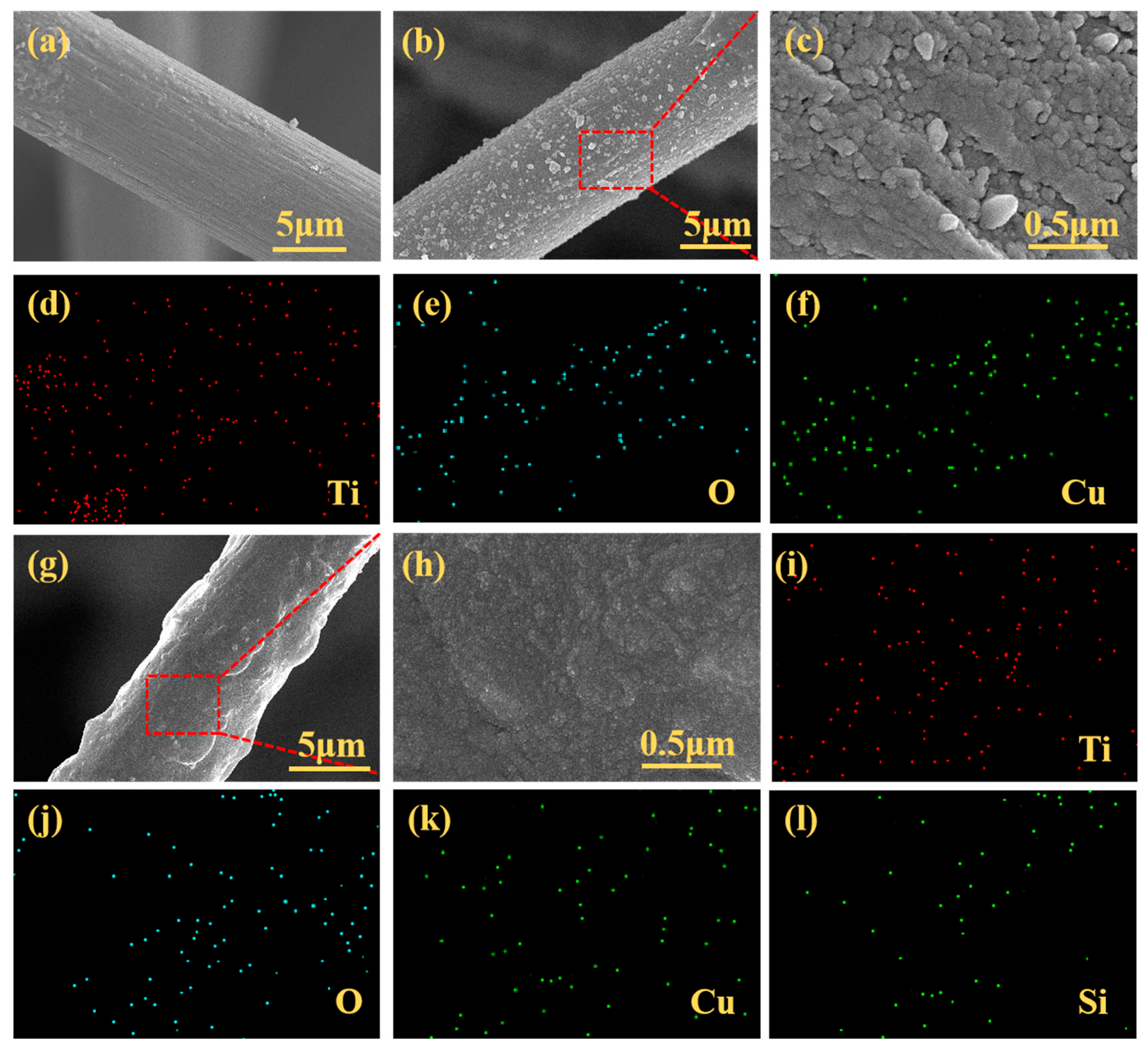

3.2. Analysis of Material Surface Morphology

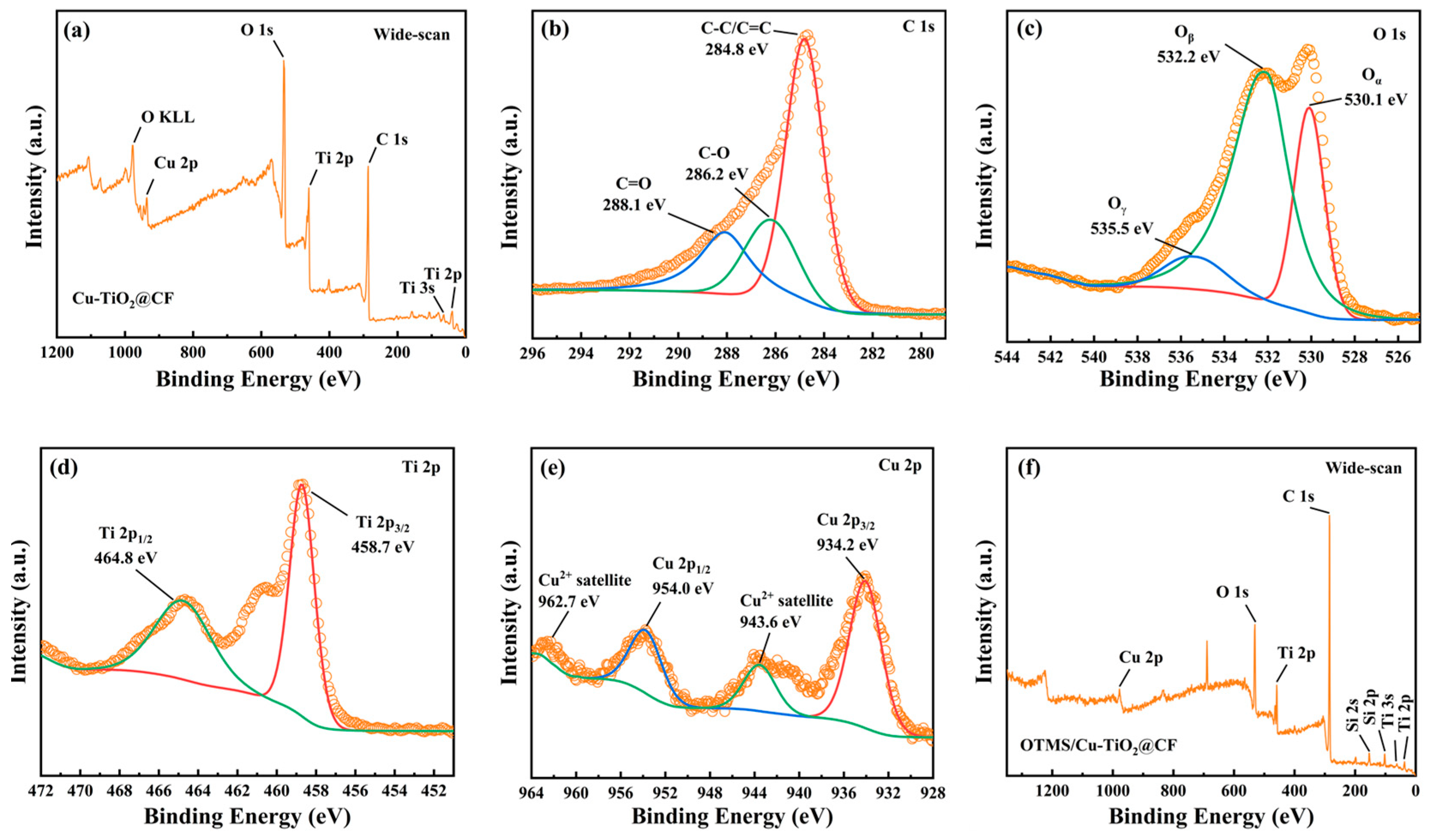

3.3. XPS Analysis

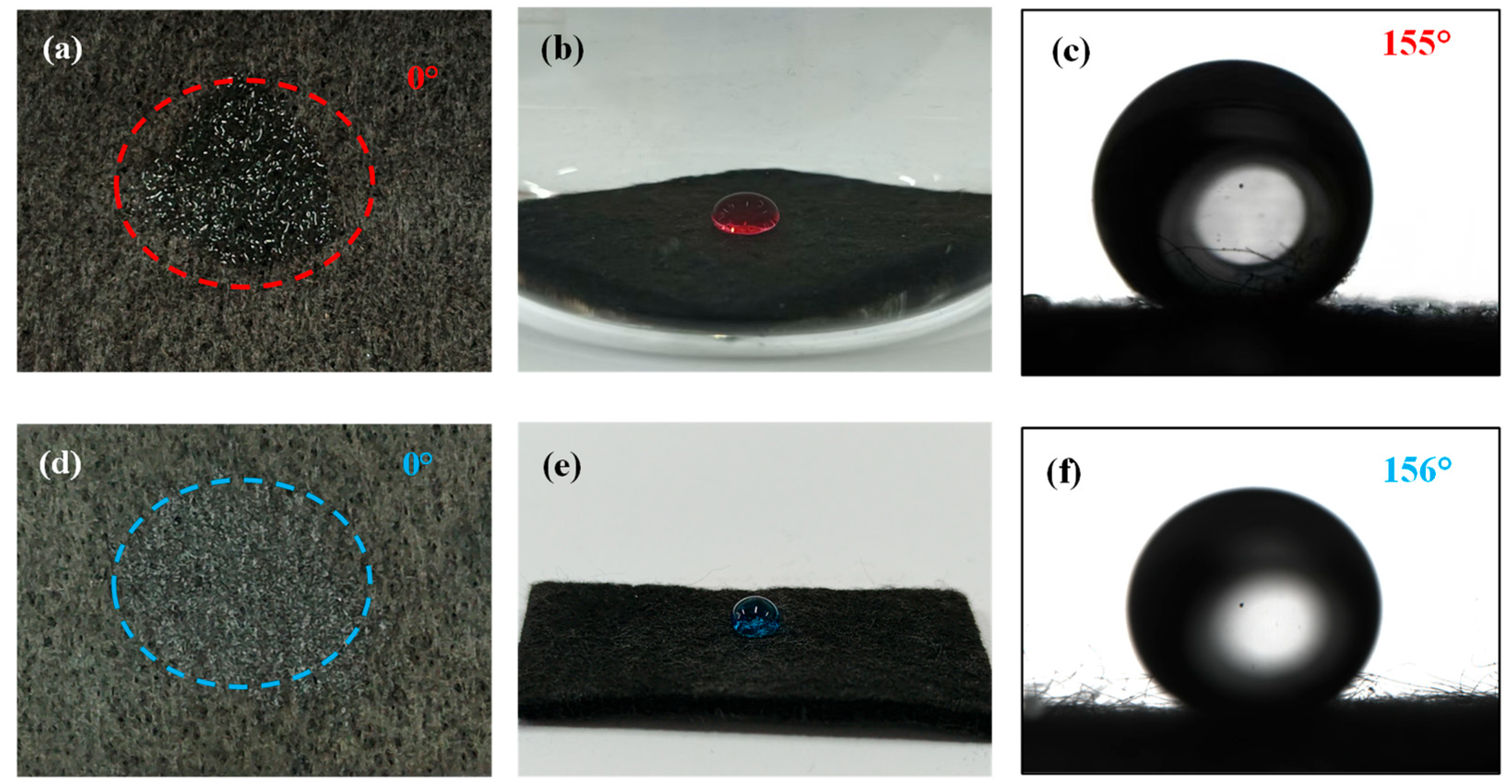

3.4. Wettability Characterization and Mechanism Analysis

3.5. Adsorption Performance

3.6. Mechanical Wear Resistance

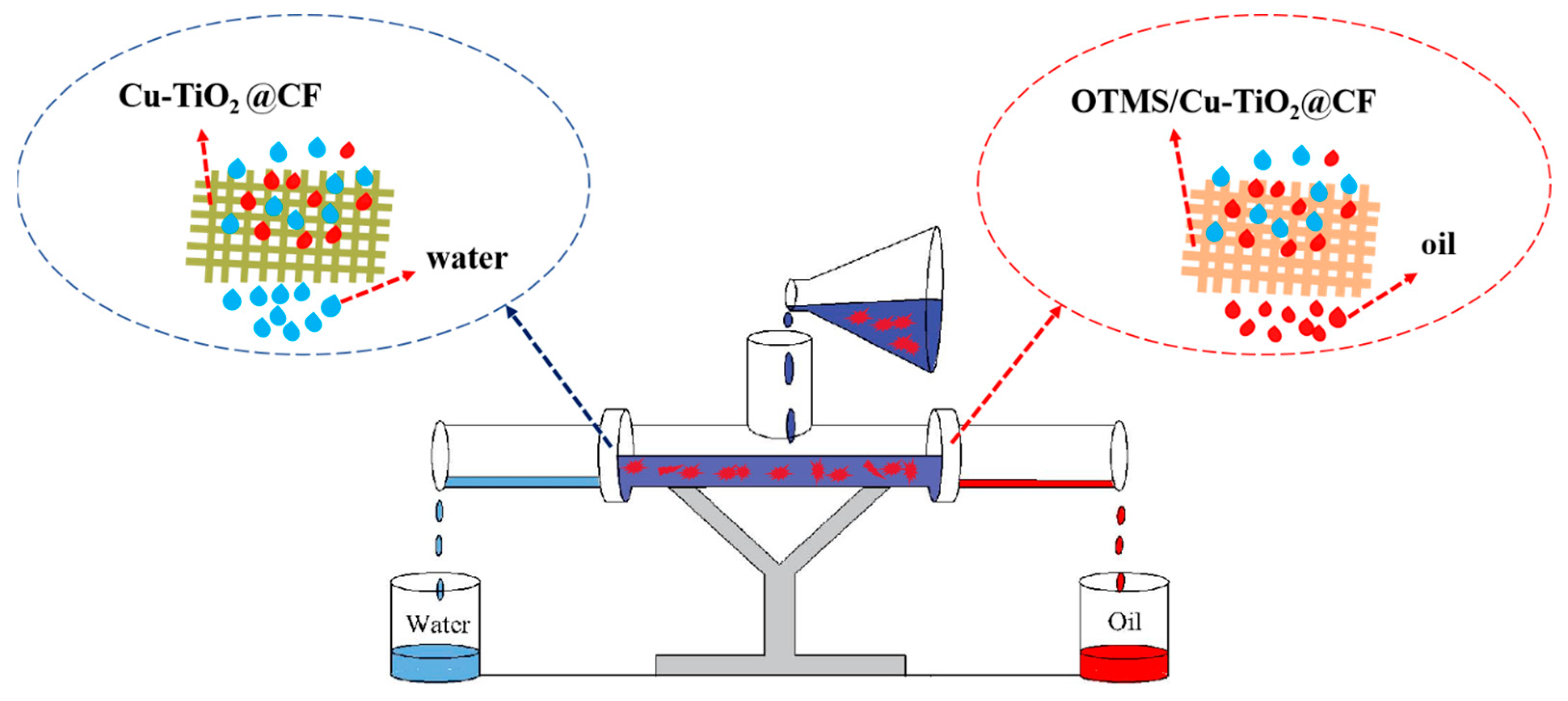

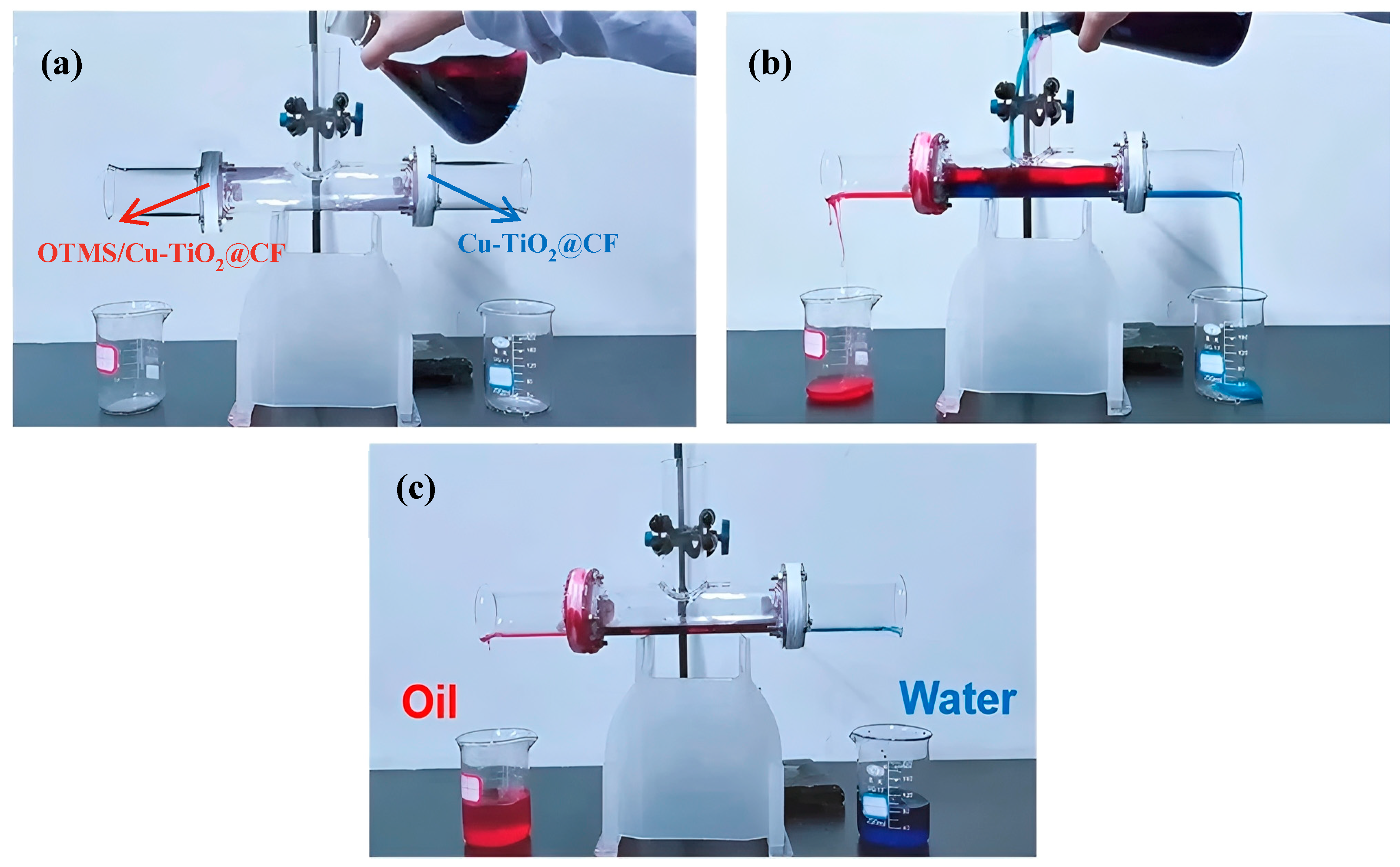

3.7. Oil–Water Separation Performance

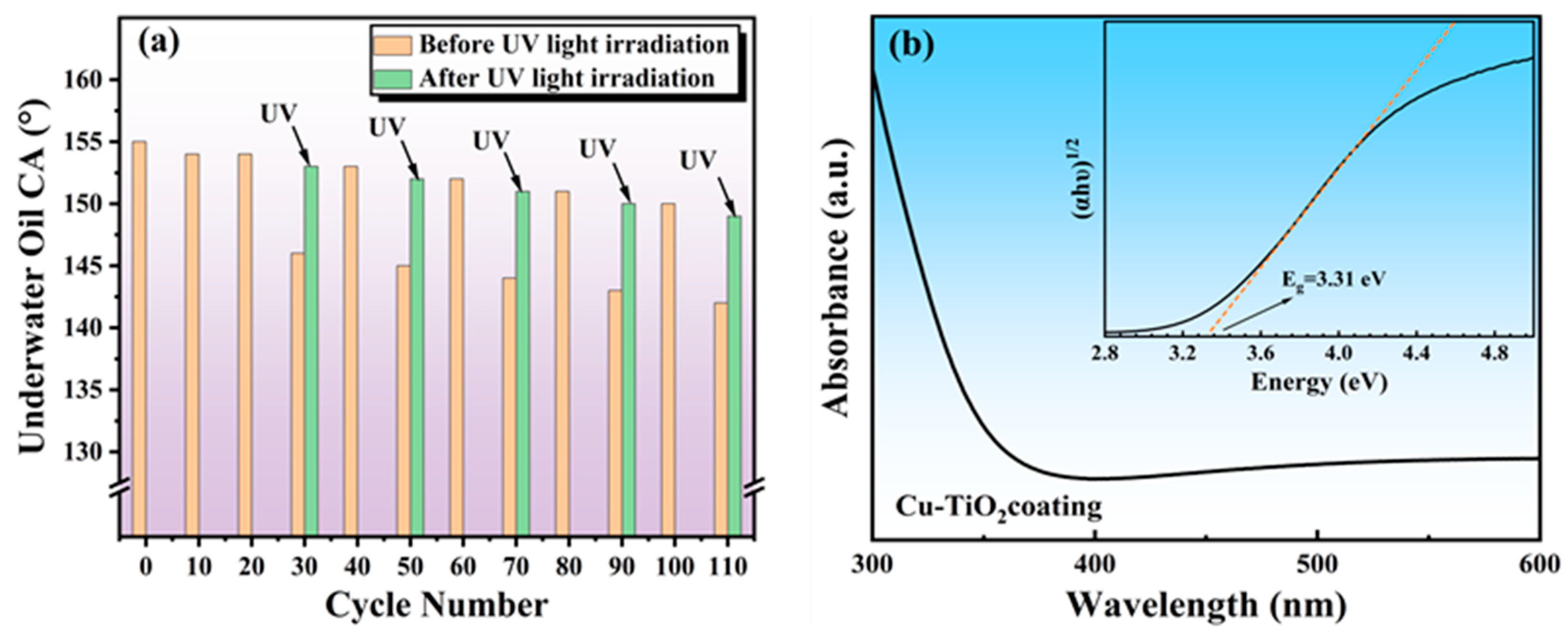

3.8. Regeneration Performance

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Sanghamitra, P.; Mazumder, D.; Mukherjee, S. Treatment of wastewater containing oil and grease by biological method—A review. J. Environ. Sci. Health. Part A 2021, 56, 394–412. [Google Scholar]

- Pekol, S. X-ray fluorescence spectrometry characteristics of oily waste water from steel processing and an evaluation of its impact on the environment. Environ. Sci. Pollut. Res. 2018, 25, 17100–17108. [Google Scholar] [CrossRef]

- Putatunda, S.; Bhattacharya, S.; Sen, D.; Bhattacharjee, C. A review on the application of different treatment processes for emulsified oily wastewater. Int. J. Environ. Sci. Technol. 2019, 16, 2525–2536. [Google Scholar] [CrossRef]

- Xu, J.L.; Peng, Z.Y.; Rong, S.Q.; Jin, H.; Guo, L.J.; Zhang, X.; Zhou, T. Model-based thermodynamic analysis of supercritical water gasification of oil-containing wastewater. Fuel 2021, 306, 121767. [Google Scholar] [CrossRef]

- Sun, H.Y.; Zhong, L.G.; Zhu, Y.; Zhu, J.J.; Li, Z.; Zhang, Z.L.; Zhou, Y.Y. Assessing sulfate-reducing bacteria influence on oilfield safety: Hydrogen sulfide emission and pipeline corrosion failure. Eng. Fail. Anal. 2024, 164, 108646. [Google Scholar] [CrossRef]

- Wang, Z.B.; Guo, P.; Heng, L.P.; Lei, J. Nano/submicrometer-emulsion oily wastewater treatment inspired by plant transpiration. Matter 2021, 4, 1274–1286. [Google Scholar]

- Madhura, L.; Kanchi, S.; Sabela, M.I.; Singh, S.; Bisetty, K.; Inamuddin. Membrane technology for water purification. Environ. Chem. Lett. 2018, 16, 343–365. [Google Scholar] [CrossRef]

- Aljuboury, D.A.D.A.; Palaniandy, P.; Abdul Aziz, H.B.; Feroz, S. Treatment of petroleum wastewater by conventional and new technologies-A review. Glob. Nest J. 2017, 19, 439–452. [Google Scholar]

- Li, B.F.; Qi, B.; Guo, Z.Y.; Wang, D.X.; Jiao, T.F. Recent developments in the application of membrane separation technology and its challenges in oil-water separation: A review. Chemosphere 2023, 327, 138528. [Google Scholar] [CrossRef]

- Yu, L.; Han, M.; He, F. A review of treating oily wastewater. Arab. J. Chem. 2017, 10, S1913–S1922. [Google Scholar] [CrossRef]

- Demirbas, A.; Bamufleh, H.S.; Edris, G.; Alalayah, W. Treatment of contaminated wastewater. Petrol. Sci. Technol. 2017, 35, 883–889. [Google Scholar]

- Adeyanju, O.A.; Ogundare, G. Experimental investigation of the centrifugal effect on demulsification of water in crude oil emulsion. J. Nat. Sci. Sustain. Technol. 2019, 13, 257–266. [Google Scholar]

- Wu, J.L.; Ma, X.Z.; Gnanasekar, P.; Wang, F.; Zhu, J.; Yan, N.; Chen, J. Superhydrophobic lignin-based multifunctional polyurethane foam with SiO2 nanoparticles for efficient oil adsorption and separation. Sci. Total Environ. 2023, 860, 160276. [Google Scholar] [CrossRef]

- Ma, F.X.; Hao, B.; Xi, X.Y.; Wang, R.; Ma, P.C. Aggregation-induced demulsification technology for the separation of highly emulsified oily wastewater produced in the petrochemical industry. J. Clean. Prod. 2022, 374, 134017. [Google Scholar] [CrossRef]

- Lee, S.Y.; Stuckey, D.C. Separation and biosynthesis of value-added compounds from food-processing wastewater: Towards sustainable wastewater resource recovery. J. Clean. Prod. 2022, 357, 131975. [Google Scholar] [CrossRef]

- Padaki, M.; Surya Murali, R.; Abdullah, M.S.; Misdan, N.; Moslehyani, A.; Kassim, M.A.; Hilal, N.; Ismail, A.F. Membrane technology enhancement in oil-water separation: A review. Desalination 2015, 357, 197–207. [Google Scholar]

- Ye, Q.; Xu, J.M.; Zhang, Y.J.; Chen, S.H.; Zhan, X.Q.; Ni, W.; Tsai, L.C.; Jiang, T.; Ma, N.; Tsai, F.C. Metal-organic framework modified hydrophilic polyvinylidene fluoride porous membrane for efficient degerming selective oil/water emulsion separation. Npj Clean Water 2022, 23, 1–9. [Google Scholar]

- Xin, Y.P.; Qi, B.; Wu, X.; Yang, C.; Li, B.F. Different types of membrane materials for oil-water separation: Status and challenges. Colloid Interface Sci. Commun. 2024, 59, 100772. [Google Scholar] [CrossRef]

- Yang, C.; Long, M.Y.; Ding, C.T.; Zhang, R.N.; Zhang, S.Y.; Yuan, J.Q.; Zhi, K.D.; Yin, Z.Y.; Zheng, Y.; Liu, Y.W.; et al. Antifouling graphene oxide membranes for oil-water separation via hydrophobic chain engineering. Nat. Commun. 2022, 13, 7334. [Google Scholar] [CrossRef]

- Nau, M.; Herzog, N.; Schmidt, J.; Meckel, T.; Brunsen, A.A.; Biesalski, M. Janus-type hybrid paper membranes. Adv. Mater. Interfaces 2019, 6, 1900892. [Google Scholar]

- Zuo, J.H.; Gu, Y.H.; Wei, C.; Yan, X.; Chen, Y.; Lang, W.Z. Janus polyvinylidene fluoride membranes fabricated with thermally induced phase separation and spray-coating technique for the separations of both W/O and O/W emulsions. J. Membr. Sci. 2020, 595, 117475. [Google Scholar] [CrossRef]

- Wei, Y.B.; Qi, H.; Gong, X.; Zhao, S.F. Specially wettable membranes for oil–water separation. Adv. Mater. Interfaces 2018, 5, 1800576. [Google Scholar] [CrossRef]

- Zhang, Y.Z.; Jia, B.B.; Li, B.; Shi, K.; Liu, B.S.; Zhang, S.H. Dual-functional superwetting CuCo2O4 coated stainless steel mesh for wastewater treatment: Highly efficient oil/water emulsion separation and photocatalytic degradation. Colloids Surf. A Physicochem. Eng. Asp. 2023, 659, 130730. [Google Scholar]

- Dong, K.S.; Bian, L.S.; Liu, Y.C.; Guan, Z.S. Superhydrophobic coating based on organic/inorganic double component adhesive and functionalized nanoparticles with good durability and anti-corrosion for protection of galvanized steel. Colloids Surf. A Physicochem. Eng. Asp. 2022, 640, 128360. [Google Scholar]

- Kang, Y.T.; Jiao, S.H.; Wang, B.R.; Lv, X.Y.; Wang, W.W.; Yin, W.; Zhang, Z.W.; Zhang, Q.; Tan, Y.M.; Pang, G.S. PVDF-modified TiO2 nanowires membrane with underliquid dual superlyophobic property for switchable separation of oil–water emulsions. ACS Appl. Mater. Interfaces 2020, 12, 40925–40936. [Google Scholar]

- He, S.; Li, K.W.; Du, C.H.; Li, Z.Q.; Huang, Y.J.; Cao, C.Y. Temperature and pH dual response flexible silica aerogel with switchable wettability for selective oil/water separation. Mar. Pollut. Bull. 2024, 199, 116011. [Google Scholar] [CrossRef]

- Cai, Y.H.; Shi, S.Q.; Fang, Z.; Li, J.Z. Design, development, and outlook of superwettability membranes in oil/water emulsions separation. Adv. Mater. Interfaces 2021, 8, 2170102. [Google Scholar]

- Liao, X.L.; Sun, D.X.; Cao, S.; Zhang, N.; Huang, T.; Lei, Y.Z.; Wang, Y. Freely switchable super-hydrophobicity and super-hydrophilicity of sponge-like poly(vinylidene fluoride) porous fibers for highly efficient oil/water separation. J. Hazard Mater. 2021, 416, 125926. [Google Scholar] [CrossRef]

- Yan, J.J.; Xiao, C.F.; Wang, C. Robust preparation of braid-reinforced hollow fiber membrane covered by PVDF nanofibers and PVDF/SiO2 micro/nanospheres for highly efficient emulsion separation. Sep. Purif. Technol. 2022, 298, 121593. [Google Scholar]

- Liu, Y.; Guo, Y.F.; Wang, L.L.; He, J.S.; Luo, L.; Tang, W.X.; Huang, C.Y.; Chen, C.; Shen, F.; Zhang, Y.Z. Rational designed of PVDF membrane based on surface modification of εPL anchored by PC for crude oil emulsion separation. J. Environ. Chem. Eng. 2024, 12, 111779. [Google Scholar] [CrossRef]

- Peng, Y.B.; Guo, F.; Wen, Q.Y.; Yang, F.C.; Guo, Z.G. A novel polyacrylonitrile membrane with a high flux for emulsified oil/water separation. Sep. Purif. Technol. 2017, 184, 72–78. [Google Scholar] [CrossRef]

- Zhang, Y.; Sun, T.Y.; Zhang, D.S.; Sun, S.S.; Liu, J.R.; Li, B.S.; Shi, Z.F. The preparation of superhydrophobic polylactic acid membrane with adjustable pore size by freeze solidification phase separation method for oil-water separation. Molecules 2023, 28, 5590. [Google Scholar] [CrossRef]

- Sosa, M.D.; Canneva, A.; Kaplan, A.; Accorso, N.B.; Negri, R.M. From superhydrophilic to superhydrophobic polymer-nanoparticles coated meshes for water-oil separation systems with resistance to hard water. J. Petrol. Sci. Eng. 2020, 194, 107513. [Google Scholar] [CrossRef]

- Li, J.; Gao, R.X.; Wang, Y.; Zhang, T.C.; Yuan, S.J. Superhydrophobic palmitic acid modified Cu(OH)2/CuS nanocomposite-coated copper foam for efficient separation of oily wastewater. Colloids Surf. A Physicochem. Eng. Asp. 2022, 637, 128249. [Google Scholar] [CrossRef]

- He, H.Q.; Zhang, T.C.; Li, Z.K.; Liang, Y.; Yuan, S.J. Superhydrophilic fish-scale-like CuC2O4 nanosheets wrapped copper mesh with underwater super oil-repellent properties for effective separation of oil-in-water emulsions. Colloids Surf. A Physicochem. Eng. Asp. 2021, 627, 127133. [Google Scholar] [CrossRef]

- Song, Y.J.; Yu, S.R.; Wang, K.; Li, W.; Gong, P.; Li, H.S.; Zhang, M.S.; Sun, D.J.; Yang, X.Z. Simple anodic oxidation method for the preparation of superhydrophobic stainless-steel mesh for oil-water separation. Colloids Surf. A Physicochem. Eng. Asp. 2023, 660, 130855. [Google Scholar] [CrossRef]

- Tian, G.Y.; Zhang, M.; Yan, H.; Zhang, J.; Sun, Q.; Guo, R.J. Nonfluorinated, mechanically stable, and durable superhydrophobic 3d foam iron for high efficient oil/water continuous separation. Appl. Surf. Sci. 2020, 527, 146861. [Google Scholar] [CrossRef]

- Qi, Y.F.; Jin, G.Q.; Gao, Y.; Zhou, X.H.; Li, Z.H.; Lyu, L.H.; Wei, C.Y. Superhydrophobicity PPS@MGFC composite membrane with nanofiber-like structure formed via TIPS and its oil-water separation performance. Colloids Surf. A Physicochem. Eng. Asp. 2024, 680, 132692. [Google Scholar] [CrossRef]

- Wang, J.Y.; Xiong, Z.M.; Guo, L.; Zhang, Y.F.; Zhang, F.; Du, F.P. Enhanced superhydrophobicity and durability of modified cotton cloth for efficient oil-water separation. Sep. Purif. Technol. 2025, 354, 128716. [Google Scholar] [CrossRef]

- Salhi, B.; Baig, N.; Abdulazeez, I.; Al-Ahmed, A.; Aljundi, I.H. High flux polyaniline-coated ceramic membrane for effective separation of emulsified oil-in-water. Ceram. Int. 2022, 48, 25246–25253. [Google Scholar] [CrossRef]

- Xu, B.Q.; Long, J.; Xu, G.L.; Yang, J.; Liang, Y.; Jiang, H.G. Facile fabrication of superhydrophobic and superoleophilic glass-fiber fabric for water-in-oil emulsion separation. Text. Res. J. 2018, 89, 2674–2681. [Google Scholar] [CrossRef]

- Al-Anzi, B.S.; Siang, O.C. Recent developments of carbon based nanomaterials and membranes for oily wastewater treatment. RSC Adv. 2017, 7, 20981–20994. [Google Scholar] [CrossRef]

- Aldosari, S.; Khan, M.; Rahatekar, S. Manufacturing carbon fibres from pitch and polyethylene blend precursors: A review. J. Mater. Res. Technol. 2020, 9, 7786–7806. [Google Scholar] [CrossRef]

- Sun, X.C.; Bai, L.Z.; Li, J.; Huang, L.L.; Sun, H.B.; Gao, X.L. Robust preparation of flexibly superhydrophobic carbon fiber membrane by electrospinning for efficient oil-water separation in harsh environments. Carbon 2021, 182, 11–22. [Google Scholar] [CrossRef]

- Sun, X.C.; Wang, X.Y.; Li, J.; Huang, L.L.; Sun, H.B.; Hao, Y.J.; Bai, L.Z.; Pan, J.; Gao, X.L. Enhanced oil–water separation via superhydrophobic electrospun carbon fiber membrane decorated with Ni nanoclusters. Sep. Purif. Technol. 2022, 287, 120617. [Google Scholar] [CrossRef]

- Yang, M.P.; Liu, W.Q.; Jiang, C.; Xie, Y.K.; Shi, H.Y.; Zhang, F.Y.; Wang, Z.F. Facile construction of robust superhydrophobic cotton textiles for effective UV protection, self-cleaning and oil-water separation. Colloids Surf. A Physicochem. Eng. Asp. 2019, 570, 172–181. [Google Scholar] [CrossRef]

- Chen, Y.Q.; Bian, W.B.; Huang, W.H.; Tang, X.N.; Zhao, G.Y.; Li, L.W.; Li, N.; Huo, W.; Jia, J.Q.; You, C.Y. High Critical Current Density of YBa2Cu3O7−x Superconducting Films Prepared through a DUV-assisted Solution Deposition Process. Sci. Rep. 2016, 6, 38257. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.Q.; Li, L.W.; Yin, X.R.; Yerramilli, A.; Shen, Y.X.; Song, Y.; Bian, W.B.; Li, N.; Zhao, Z.; Qu, W.W.; et al. Resistive Switching Characteristics of Flexible TiO2 Thin Film Fabricated by Deep Ultraviolet Photochemical Solution Method. IEEE Electron. Device Lett. 2017, 38, 1528–1531. [Google Scholar] [CrossRef]

- Li, F.; Gao, R.T.; Wu, T.; Li, Y.J. Role of layered materials in emulsified oil/water separation and anti-fouling performance of modified cellulose acetate membranes with hierarchical structure. J. Membr. Sci. 2017, 543, 163–171. [Google Scholar] [CrossRef]

- Fernandes, A.; Makoś, P.; Wang, Z.H.; Boczkaj, G. Synergistic effect of TiO2 photocatalytic advanced oxidation processes in the treatment of refinery effluents. Chem. Eng. J. 2020, 391, 123488. [Google Scholar] [CrossRef]

- Grao, M.; Ratova, M.; Amorim, C.C.; Marcelino, R.B.P.; Kelly, P. Crystalline TiO2 supported on stainless steel mesh deposited in a one step process via pulsed DC magnetron sputtering for wastewater treatment applications. J. Mater. Res. Technol. 2020, 9, 5761–5773. [Google Scholar] [CrossRef]

- Wongaree, M.; Bootwong, A.; ChooIn, S.; Sato, S. Photocatalytic reactor design and its application in real wastewater treatment using TiO2 coated on the stainless-steel mesh. Environ. Sci. Pollut. Res. 2022, 29, 46293–46305. [Google Scholar] [CrossRef]

- Hu, C.C.; Wang, C.Y.; Tsai, M.C.; Lecaros, R.L.G.; Hung, W.S.; Tsai, H.A.; Lee, K.R.; Lai, J.Y. Polyimide/Cu-doped TiO2 Janus membranes for direct capture and photocatalytic reduction of carbon dioxide from air. Chem. Eng. J. 2022, 450, 138008. [Google Scholar] [CrossRef]

- Jiang, Y.H.; Zhang, Y.Q.; Wang, Z.H.; An, Q.D.; Xiao, Z.Y.; Xiao, L.P.; Zhai, S.R. Cotton-derived green sustainable membrane with tailored wettability interface: Synergy of lignin and ethyl cellulose. Ind. Crops Prod. 2022, 183, 114993. [Google Scholar] [CrossRef]

- Yang, J.; Cui, J.Y.; Xie, A.T.; Dai, J.D.; Li, C.X.; Yan, Y.S. Facile preparation of superhydrophilic/underwater superoleophobic cellulose membrane with CaCO3 particles for oil/water separation. Colloids Surf. A. Physicochem. Eng. Asp. 2021, 608, 125583. [Google Scholar] [CrossRef]

- Zhang, X.X.; Wang, J.T.; Wang, X.H.; Cai, Z.Q. Facile preparation of hybrid coating-decorated cotton cloth with superoleophobicity in air for efficient light oil/water separation. Surf. Interfaces 2022, 31, 102033. [Google Scholar] [CrossRef]

- Perarasan, T.; John Peter, I.; Muthu Kumar, A.; Rajamanickam, N.; Ramachandran, K.; Raja Mohan, C. Copper doped titanium dioxide for enhancing the photovoltaic behavior in solar cell. Mater. Today Proc. 2021, 35, 66–68. [Google Scholar] [CrossRef]

- Lee, W.H.; Lee, J.G.; Reucroft, P.J. XPS study of carbon fiber surfaces treated by thermal oxidation in a gas mixture of O2/(O2 + N2). Appl. Surf. Sci. 2001, 171, 136–142. [Google Scholar] [CrossRef]

- Bharti, B.; Kumar, S.; Lee, H.N.; Kumar, R. Formation of oxygen vacancies and Ti3+ state in TiO2 thin film and enhanced optical properties by air plasma treatment. Sci. Rep. 2016, 6, 32355. [Google Scholar]

- Sanjines, R.; Berger, H.; Gozzo, F.; Margaritondo, G. Electronic structure of anatase TiO2 oxide. J. Appl. Phys. 1994, 75, 2945–2951. [Google Scholar] [CrossRef]

- Bhattacharyya, K.; Mane, G.P.; Rane, V.; Tripathi, A.K.; Tyagi, A.K. Selective CO2 Photoreduction with Cu-doped TiO2 photocatalyst: Delineating the crucial role of Cu-oxidation state and oxygen vacancies. J. Phys. Chem. C 2021, 125, 1793–1810. [Google Scholar] [CrossRef]

- Li, Y.F. Theoretical analysis of contact angle hysteresis of suspended drops on micropillared superhydrophobic surfaces. Colloids Surf. A Physicochem. Eng. Asp. 2023, 666, 131244. [Google Scholar] [CrossRef]

- Wang, Z.; Elimelech, M.; Lin, S. Environmental applications of interfacial materials with special wettability. Environ. Sci. Technol. 2016, 50, 2132–2150. [Google Scholar] [CrossRef]

- Wenzel, R.N. Resistance of solid surfaces to wetting by water. Ind. Eng. Chem. 1936, 28, 988–994. [Google Scholar] [CrossRef]

- Otitoju, T.A.; Ahmad, A.L.; Ooi, B.S. Superhydrophilic (superwetting) surfaces: A review on fabrication and application. J. Ind. Eng. Chem. 2017, 47, 19–40. [Google Scholar] [CrossRef]

- Cassie, A.B.D.; Baxter, S. Wettability of porous surfaces. Trans. Faraday Soc. 1944, 40, 546–551. [Google Scholar] [CrossRef]

- Liu, P.F.; Zhang, Y.P.; Liu, S.Q.; Zhang, Y.J.; Du, Z.L.; Qu, L.B. Bio-inspired fabrication of fire-retarding, magnetic-responsive, superhydrophobic sponges for oil and organics collection. Appl. Clay Sci. 2019, 172, 19–27. [Google Scholar] [CrossRef]

- Yan, Y.Y.; Gao, N.; Barthlott, W. Mimicking natural superhydrophobic surfaces and grasping the wetting process: A review on recent progress in preparing super hydrophobic surfaces. Adv. Colloid Interface Sci. 2011, 169, 80–105. [Google Scholar]

- Hooda, A.; Goyat, M.S.; Pandey, J.K.; Kumar, A.; Gupta, R. A review on fundamentals, constraints and fabrication techniques of superhydrophobic coatings. Prog. Org. Coat. 2020, 142, 105557. [Google Scholar]

- Zhang, H.M.; Guo, Z.G. Biomimetic materials in oil/water separation: Focusing on switchable wettabilities and applications. Adv. Colloid Interface 2023, 320, 103220. [Google Scholar]

- Naseem, M.; Sultan, M.; Islam, M.; Kareem, A.; Ali, N.; Khan, I.; Ahmad, S.; Nawaz, F.; Khan, A.; Ali, F.; et al. Superhydrophilic wettability porous materials from construction to oil/water separation applications. Fuel 2025, 386, 134195. [Google Scholar] [CrossRef]

- Holmberg, J.P.; Ahlberg, E.; Bergenholtz, J.; Hassellöv, M.; Abbas, Z. Surface charge and interfacial potential of titanium dioxide nanoparticles: Experimental and theoretical investigations. J. Colloid Interface Sci. 2013, 407, 168–176. [Google Scholar] [CrossRef]

- Rasouli, S.; Rezaei, N.; Hamedi, H.; Zendehboudi, S.; Duan, X.L. Superhydrophobic and superoleophilic membranes for oil-water separation application: A comprehensive review. Mater. Design. 2021, 204, 109599. [Google Scholar] [CrossRef]

- Chen, N.; Chen, S.; Yin, H.; Zhu, B.F.; Liu, M.Y.; Yang, Y.M.; Zhang, Z.; Wei, G.Y. Durable underwater super-oleophobic/super-hydrophilic conductive polymer membrane for oil-water separation. Water Res. 2023, 243, 120333. [Google Scholar] [CrossRef] [PubMed]

- Solomon, M.F.J.; Bhole, Y.; Livingston, A.G. High flux hydrophobic membranes for organic solvent nanofiltration (OSN)—Interfacial polymerization, surface modification and solvent activation. J. Membr. Sci. 2013, 434, 193–203. [Google Scholar] [CrossRef]

- Irfan, M.; Haidry, A.A. Multifunctional Cu-TiO2 porous nano-structures via post-synthesis LASER treatment for boosting energy storage and photocatalytic applications. J. Indian Chem. Soc. 2025, 102, 101683. [Google Scholar] [CrossRef]

- Russo, F.; Santoro, S.; Galiano, F.; Ursino, C.; Avruscio, E.; Di Nicolo, E.; Desiderio, G.; Lombardo, G.; Criscuoli, A.; Figoli, A. A luminescent thermosensitive coating for a non-invasive and in-situ study of thermal polarization in hollow fiber membranes. J. Membr. Sci. 2023, 685, 121928. [Google Scholar] [CrossRef]

- Heidari, M.K.; Fouladi, M.; Sooreh, H.A.; Tavakoli, O. Superhydrophobic and super-oleophilic natural sponge sorbent for crude oil/water separation. J. Water Process Eng. 2022, 48, 102783. [Google Scholar] [CrossRef]

- Li, N.B.; Chen, J.Y.; Li, J.L.; Wu, H.L.; Li, Z.Y.; He, X.M.; Cai, L. Facile construction of versatile cotton fabrics with robust hydrophobicity, self-cleaning and oil–water separation. Fibers Polym. 2024, 25, 565–575. [Google Scholar] [CrossRef]

| Membrane | Oil/Water | Water Flux (L·m−2·h−1) | Separation Efficiencies (%) | Ref. |

|---|---|---|---|---|

| CuCo2O4-SSM | Hexane/water | 172.3 | 99.5 | [23] |

| PVDF-PC-εPL | Crude oil/water | 487.26 | 99.4 | [30] |

| Polyaniline-modified ceramic | Diesel oil/water | 3451 | 97 | [40] |

| CuC2O4-nanosheet-wrapped copper mesh | Kerosene/water | 75,000 | - | [35] |

| Cu-TiO2@CF | 42,088.7–79,839.6 | >97.3 | This work |

| Membrane | Oil/Water | Oil Flux (L·m−2·h−1) | Separation Efficiencies (%) | Ref. |

|---|---|---|---|---|

| Polylactic acid | Hexane/water | 16,084 | 99.7 | [32] |

| CF/Ni/F | Dichloromethane/water | 3669 | 99.6 | [45] |

| PPS@MGFC | Kerosene/water | 6429 | 99.97 | [38] |

| SMS-O-CF | Chloroform/water | 11,557 | >96 | [39] |

| CFMHF | Petroleum ether/water | 3590 | >98 | [44] |

| OTMS/Cu-TiO2@CF | 47,375.9–86,593.4 | >98.1 | This work |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, Y.; Chen, Y.; Li, X.; Li, R.; Lei, G.; Jia, Z.; Liu, D.; Duan, Z. Superwettable Carbon Fiber Membranes Functionalized with Cu-TiO2: High-Performance Oil–Water Separation and Sustainable Reusability. Coatings 2025, 15, 1273. https://doi.org/10.3390/coatings15111273

Chen Y, Chen Y, Li X, Li R, Lei G, Jia Z, Liu D, Duan Z. Superwettable Carbon Fiber Membranes Functionalized with Cu-TiO2: High-Performance Oil–Water Separation and Sustainable Reusability. Coatings. 2025; 15(11):1273. https://doi.org/10.3390/coatings15111273

Chicago/Turabian StyleChen, Yuqiang, Yang Chen, Xiaojun Li, Renzhong Li, Gege Lei, Ziyang Jia, Dongjie Liu, and Zongfan Duan. 2025. "Superwettable Carbon Fiber Membranes Functionalized with Cu-TiO2: High-Performance Oil–Water Separation and Sustainable Reusability" Coatings 15, no. 11: 1273. https://doi.org/10.3390/coatings15111273

APA StyleChen, Y., Chen, Y., Li, X., Li, R., Lei, G., Jia, Z., Liu, D., & Duan, Z. (2025). Superwettable Carbon Fiber Membranes Functionalized with Cu-TiO2: High-Performance Oil–Water Separation and Sustainable Reusability. Coatings, 15(11), 1273. https://doi.org/10.3390/coatings15111273