Studies on the Tribocorrosion Properties of an Iron Alloy Produced by Wire Arc Additive Manufacturing Subjected to Multi-Stage Heat Treatment

Abstract

1. Introduction

- −

- Variable grain size within the material;

- −

- Directional grain orientation—usually vertical, and parallel to the material deposition direction.

2. Materials and Methods

2.1. Material

- −

- Austenitising, during which the material was heated to 950 °C and held at this temperature for 25 min;

- −

- Martensitic quenching in polymer coolant, directly following austenitisation;

- −

- Annealing, conducted at 760 °C for 60 min;

- −

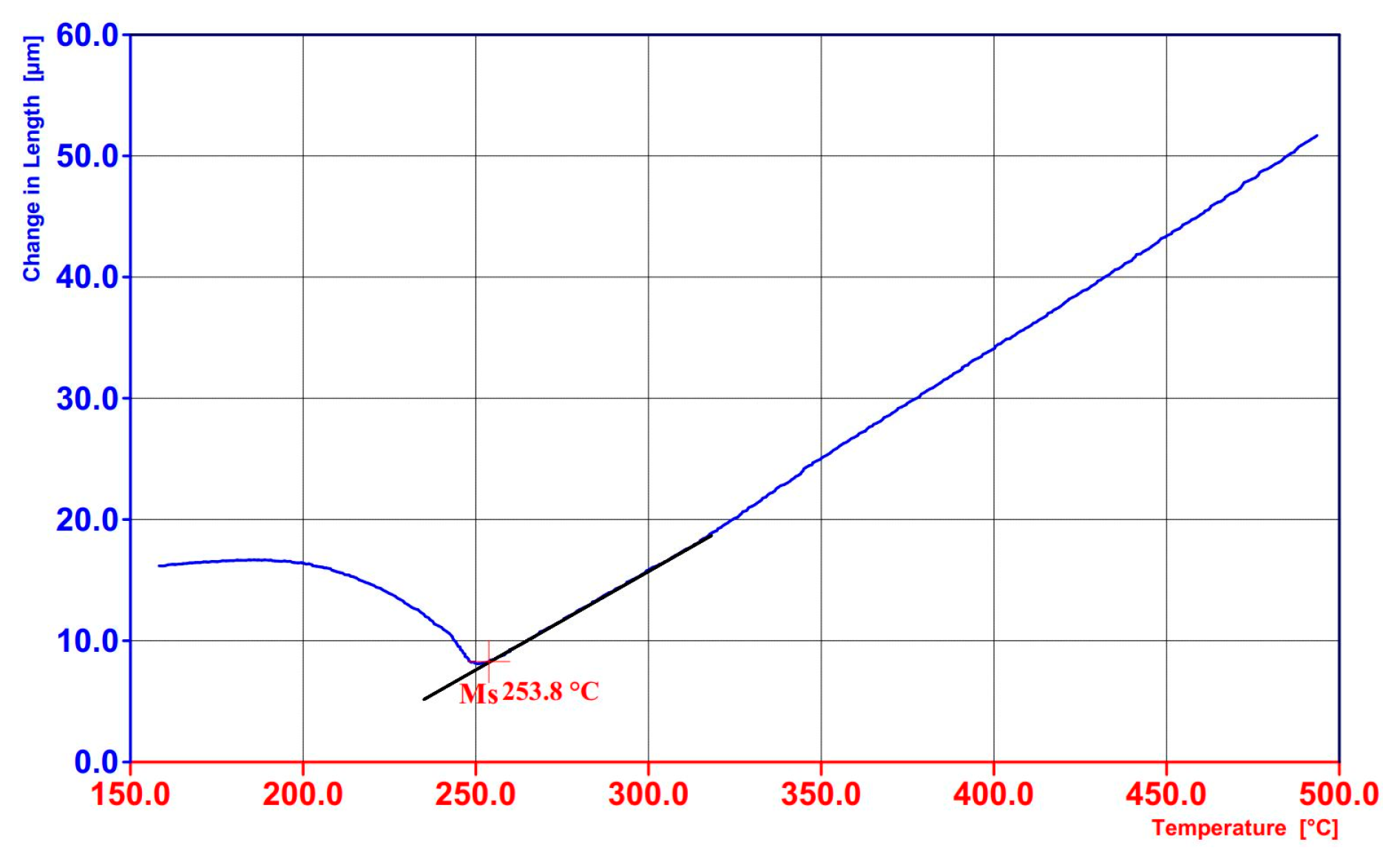

- Isothermal transformation hardening was carried out at 260 °C for 180 min in the high-temperature quenching oil Marquench 3500 from Petrofer, Hildesheim, Germany. The average cooling rate of this bath, measured using a thermocouple embedded in a 10 × 10 mm steel specimen, was approximately 25 °C/s in the temperature range from 800 °C to 500 °C.

2.2. Mechanical Tests

- Static tensile testing—the static tensile tests were performed on a Zwick/Roell Z250 universal testing machine (ZwickRoell GmbH & Co. KG, Ulm, Germany). The tests were conducted in accordance with PN-EN ISO 6892-1:2010 [38] at room temperature. Five time samples with a measuring diameter of 6 mm were used, applying a constant strain rate of 0.001 s−1.

- Impact testing—the impact test was performed on standardised samples of 55 × 10 × 10 mm in dimensions with a V notch in accordance with PN-EN ISO 148-1:2010 [39]. A Zwick/Roell RKP450 Charpy impact hammer with a nominal energy of 300 J was used for the measurements.

- Hardness testing—the hardness measurements were performed on the flat surfaces of samples cut out in a manner analogous to the samples used for strength and impact testing. A stationary HR-150 Rockwell Hardness Tester (Shandong Shancai Testing Instrument Co., Ltd., Jinan, China) was used to determine this parameter.

2.3. Microstructural and Phase Characteristics

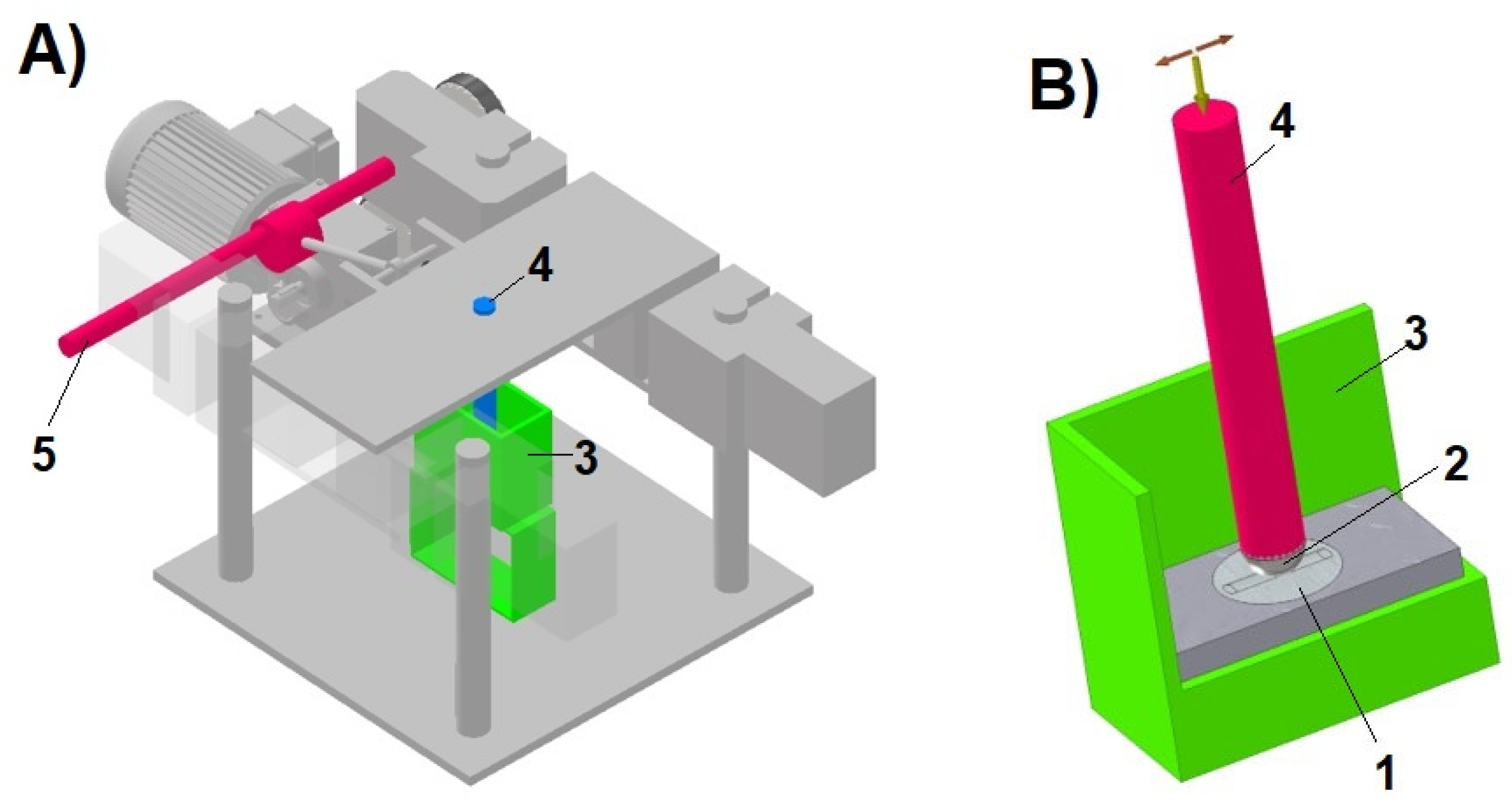

2.4. Tribological Tests

- −

- Cube-shaped samples with 10 mm edges;

- −

- Counter-samples (balls) made of Al2O3 with a diameter of 7.0 mm.

3. Results

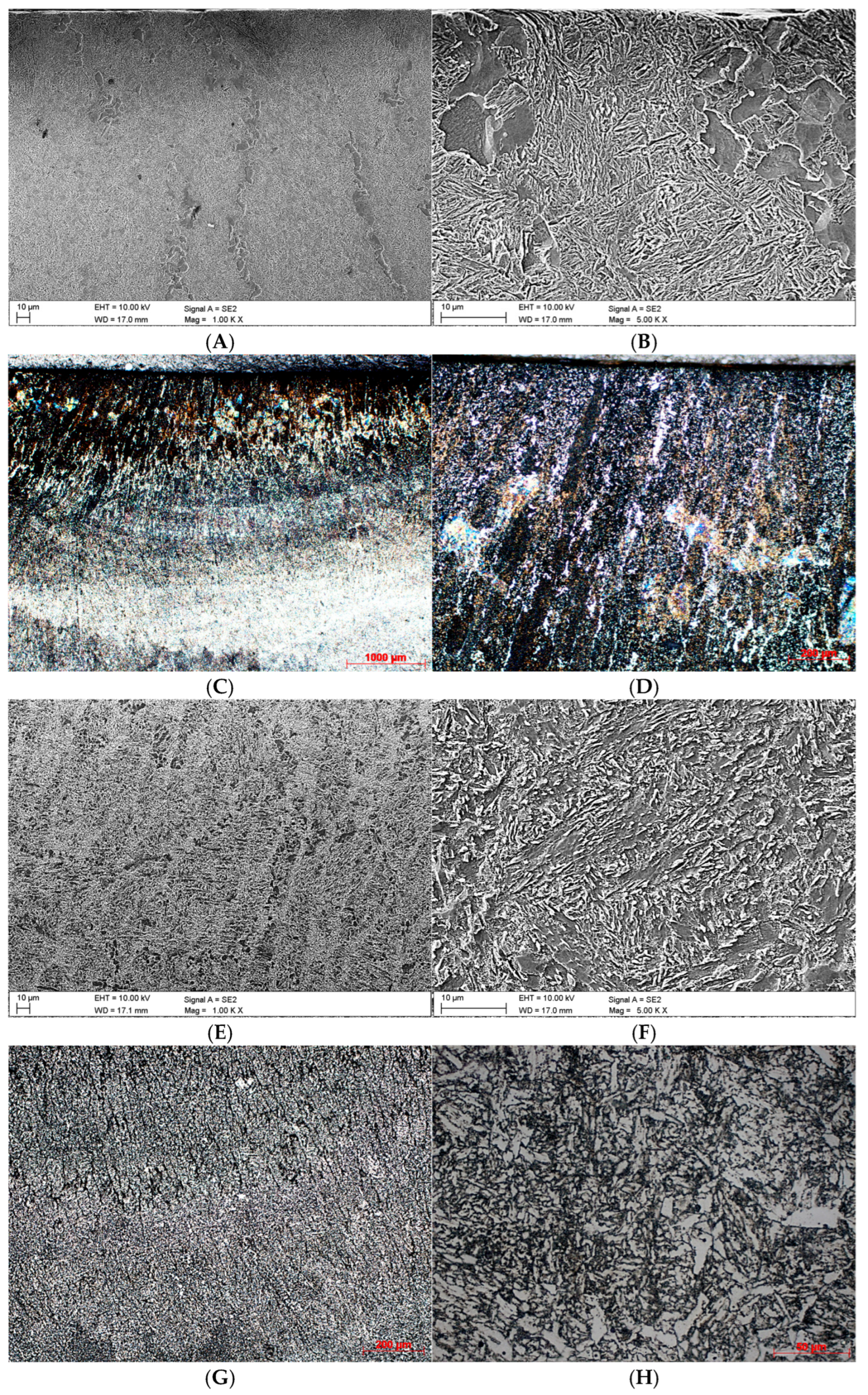

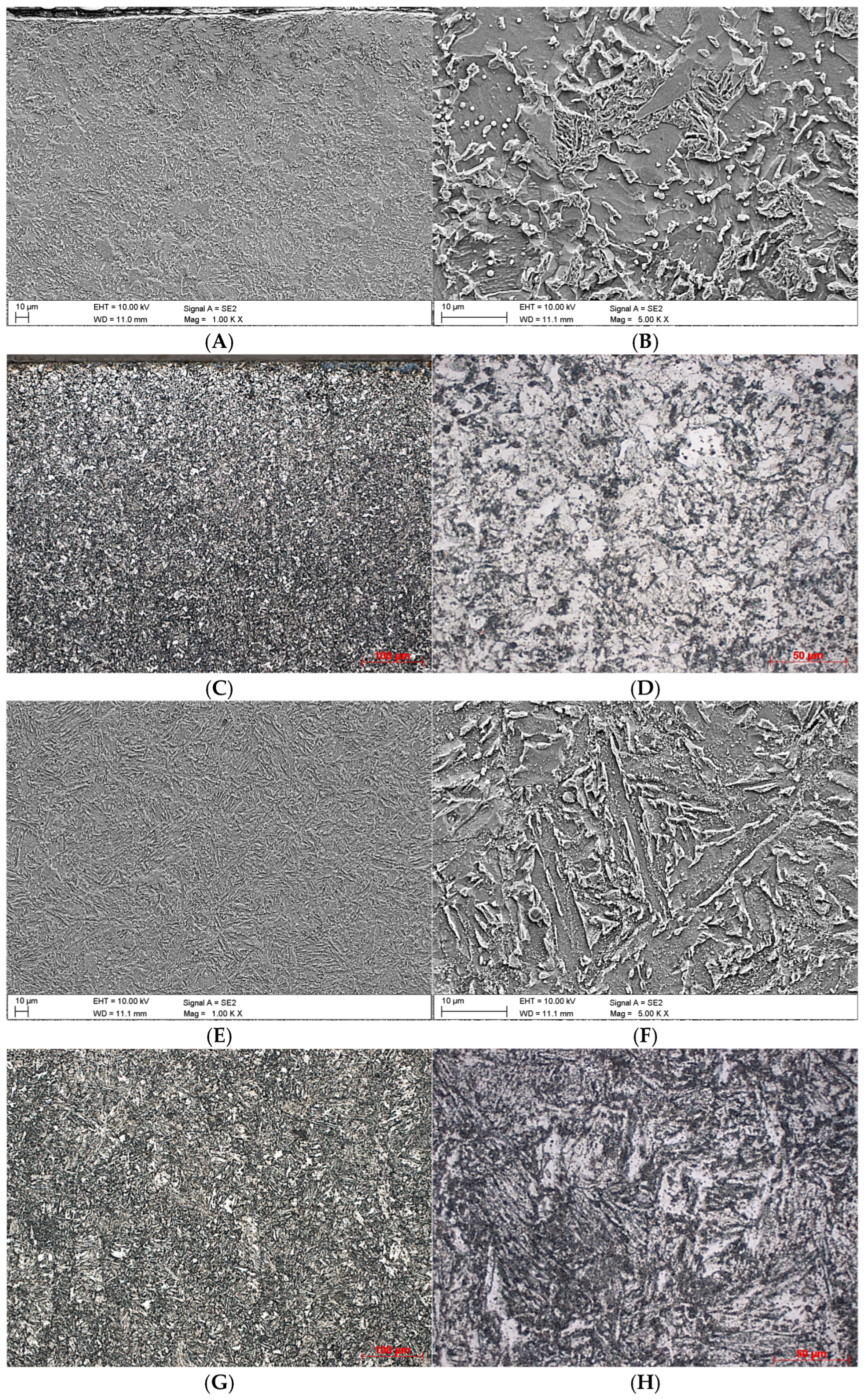

3.1. Microstructure and Mechanical Properties

3.2. Tests of Mechanical Properties

- −

- Hardness reduced by approx. 7 HRC, which could be interpreted as a direct result of the increased ferrite share in the near-surface layer following the heat treatment,

- −

- Yield strength decreased by approx. 25%,

- −

- Maximum strength decreased by approx. 15%,

- −

- Impact strength increased by 43 J/cm2, which represents an impressive increase of 238% compared to the reference material (Variant A).

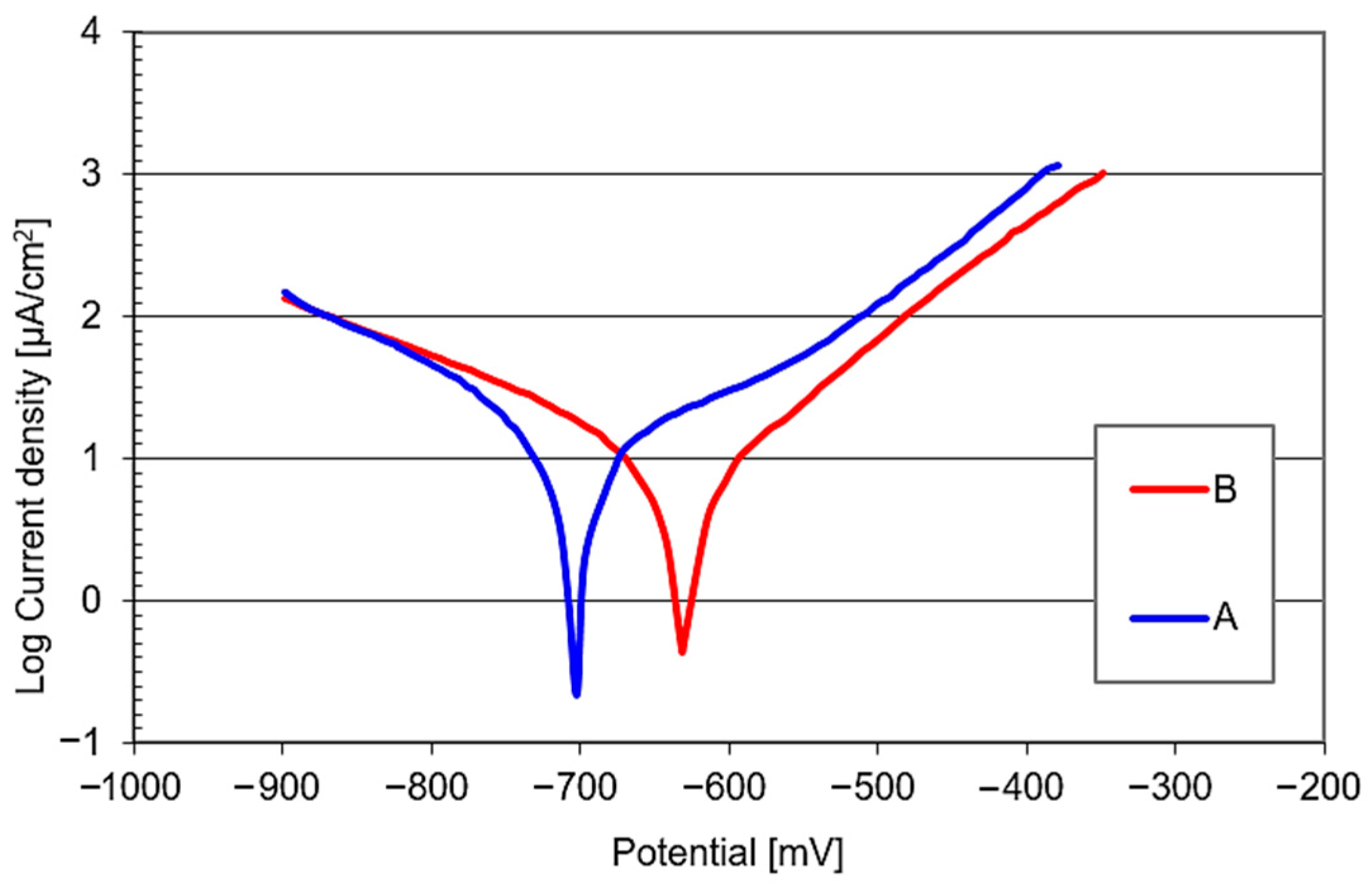

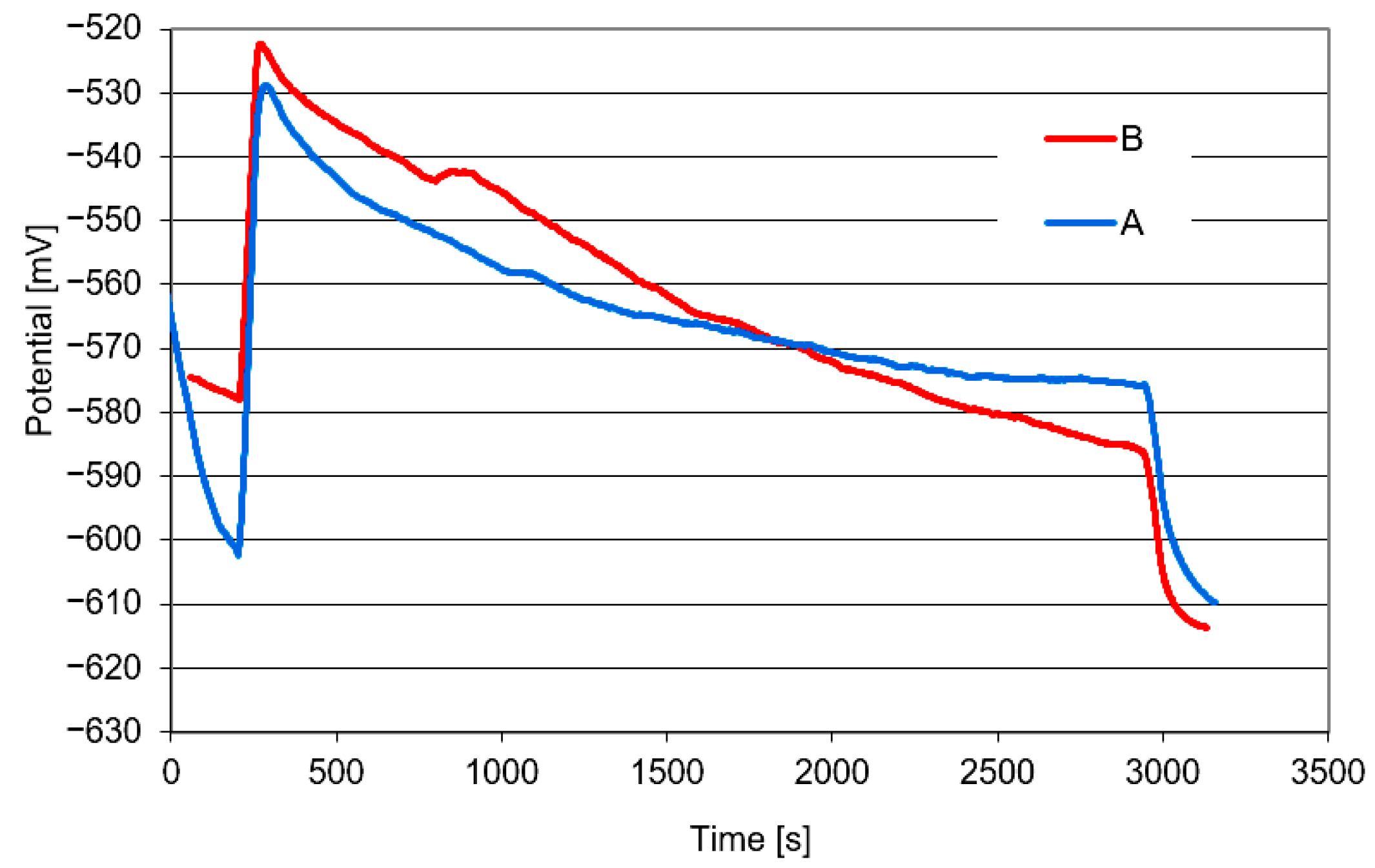

3.3. Corrosion Resistance

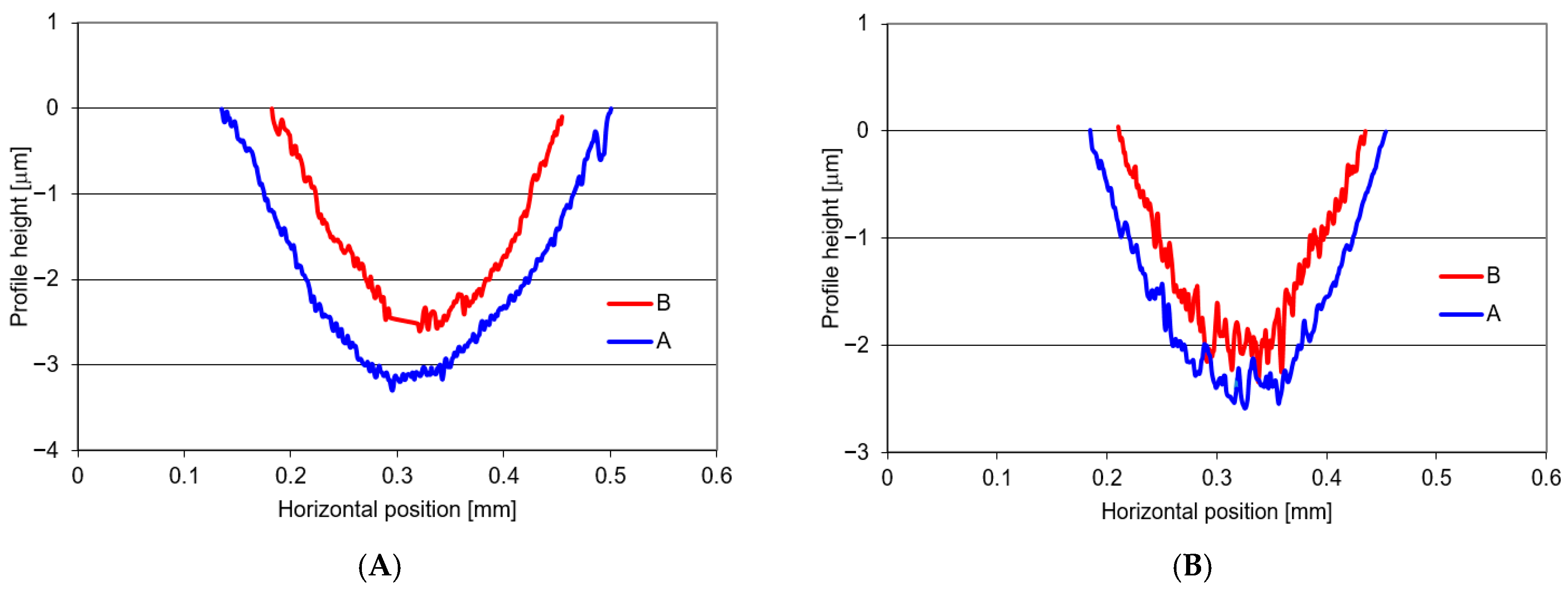

3.4. Tribocorrosion Results

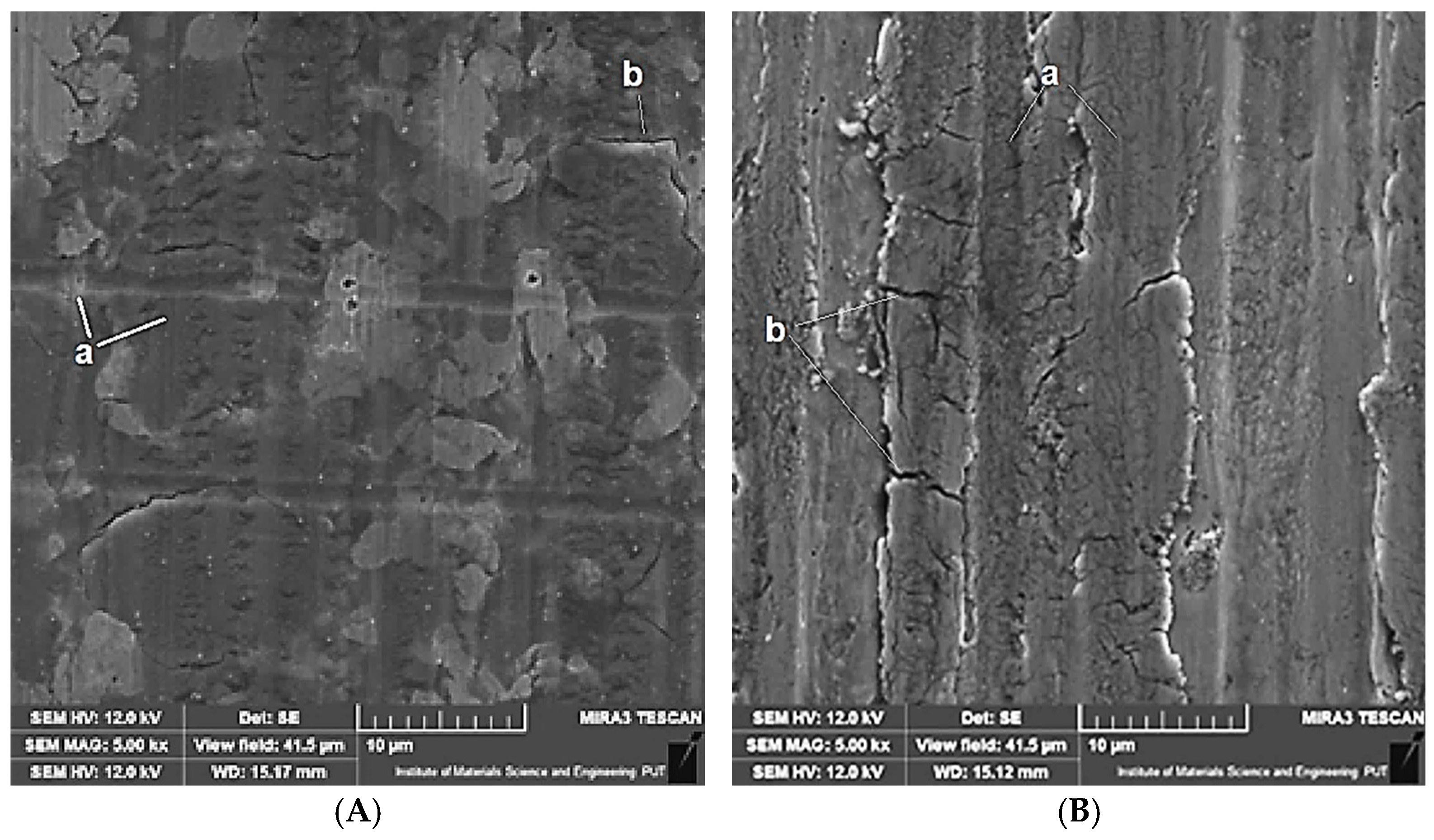

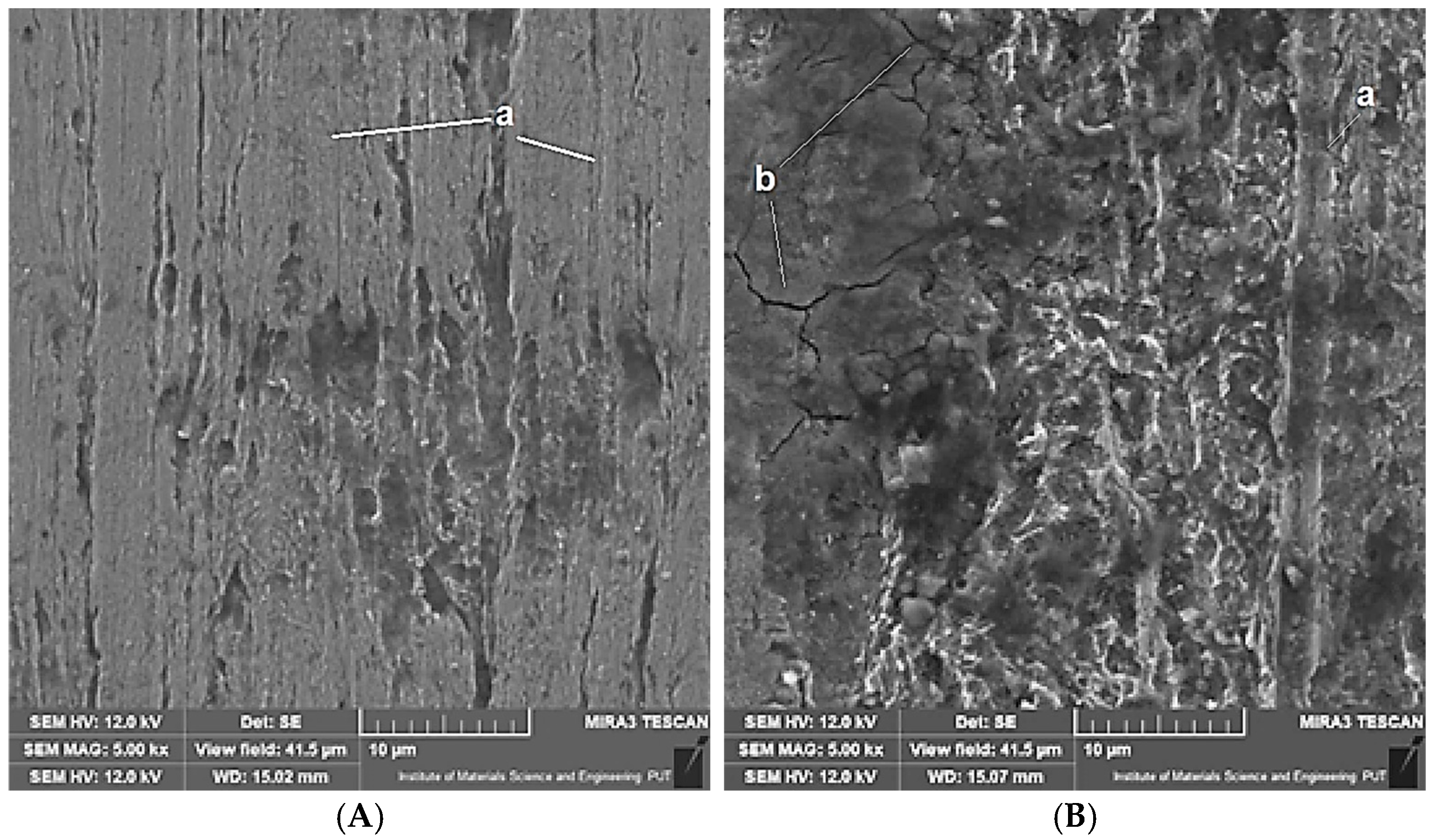

3.5. Worn Surface Damage

4. Discussion

5. Conclusions

- It has been confirmed that it is possible to produce workpieces of high plastic properties from Fe (0.21% C, 0.8% Si, 1.29% Mn, 1.34% Cr) alloys by way of additive welding methods and advanced heat treatment. Microscopic observations and phase tests have shown that the heat treatment proposed by the authors, being a combination of austenitising, martensitic quenching, annealing, and austempering, enables comminution of the columnar grain in the ferrous alloy produced by WAAM.

- The heat-treated material (Variant B) shows significantly lower tribocorrosion and mechanical wear. It is also characterised by higher wear resistance, even though the dedicated heat treatment has caused its hardness to drop (by approx. 30%).

- In line with the description of the interactions in the friction node examined, as proposed by the authors of the article, the wear resistance of the analysed ferrous alloy improves as a consequence of increased impact strength. The heat-treated material (Variant B), offering lower hardness, is more susceptible to plastic strain during frictional interactions. However, the detachment of deformed micro-areas of the near-surface layer occurs after a longer time than in the base material (Variant A). The main reason for this phenomenon may be the higher critical energy required for the wear particles to break off. The value of the said critical energy is determined by the increase in the impact strength of the heat-treated material (Variant B), being more than threefold.

- The heat treatment proposed in the article improves the corrosion resistance of the material subject of the studies in 3.5% NaCl. In the heat-treated samples (Variant B), the corrosion current density was found to be approximately 40% lower. Consequently, this also causes less material loss due to corrosion processes occurring on the sample surface, in the areas exposed to friction under tribocorrosion conditions (these processes being the main cause of the friction-corrosion synergy effect).

- The advanced heat treatment proposed in the article is an example of a technological procedure that makes it possible to achieve a specific combination of material properties (increased resistance to abrasion and the corrosive effects of 3.5% NaCl) that is particularly favourable in terms of tribocorrosion resistance.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Blakey-Milner, B.; Gradl, P.; Snedden, G. Metal Additive Manufacturing in Aerospace: A Review. Mater. Des. 2021, 209, 110008. [Google Scholar] [CrossRef]

- Bandyopadhyay, A.; Heer, B. Additive Manufacturing of Multi-Material Structures. Mater. Sci. Eng. R Rep. 2018, 129, 1–16. [Google Scholar]

- Sommer, D.; Götzendorfer, B.; Esen, C.; Hellmann, R. Design Rules for Hybrid Additive Manufacturing Combining Selective Laser Melting and Micromilling. Materials 2021, 14, 5753. [Google Scholar] [CrossRef]

- Thompson, M.K.; Moroni, G.; Vaneker, T.; Fadel, G.; Campbell, I.; Gibson, I.; Bernard, A.; Schulz, J.; Graf, P.; Ahuja, B. Design for Additive Manufacturing: Trends, Opportunities, Considerations, and Constraints. CIRP Ann. 2016, 65, 737–760. [Google Scholar] [CrossRef]

- Derekar, K.S. A Review of Wire Arc Additive Manufacturing and Advances in Wire Arc Additive Manufacturing of Aluminium. Mater. Sci. Technol. 2018, 34, 895–916. [Google Scholar] [CrossRef]

- Li, J.L.Z.; Alkahari, M.R.; Rosli, N.A.B.; Hasan, R.; Sudin, M.N.; Ramli, F.R. Review of Wire Arc Additive Manufacturing for 3D Metal Printing. Int. J. Autom. Technol. 2019, 13, 346–353. [Google Scholar] [CrossRef]

- Rodríguez-González, P.; Ruiz-Navas, E.M.; Gordo, E. Wire Arc Additive Manufacturing (WAAM) for Aluminum-Lithium Alloys: A Review. Materials 2023, 16, 1375. [Google Scholar] [CrossRef]

- Harshita, P.; Anisha, A.; Sutha, G.G. Applications of Wire Arc Additive Manufacturing (WAAM) for Aerospace Component Manufacturing. Int. J. Adv. Manuf. Technol. 2023, 127, 4995–5011. [Google Scholar] [CrossRef]

- Iván-Tabernero, P.; Pascual, A.; Álvarez, P. Study on Arc Welding Processes for High Deposition Rate Additive Manufacturing. Procedia CIRP 2018, 68, 358–362. [Google Scholar] [CrossRef]

- Rodrigues, T.A.; Duarte, V.; Miranda, R.M.; Santos, T.G.; Oliveira, J.P. Current Status and Perspectives on Wire and Arc Additive Manufacturing (WAAM). Materials 2019, 12, 1121. [Google Scholar] [CrossRef]

- Yan, L. Wire and Arc Additive Manufacture (WAAM) Reusable Tooling Investigation. Ph.D. Thesis, Cranfield University, Bedford, UK, 2012. [Google Scholar]

- Martina, F.; Williams, S.W. Wire+Arc Additive Manufacturing vs. Traditional Machining from Solid: A Cost Comparison. Mater. Sci. Technol. 2015, 32, 27. [Google Scholar]

- Allen, J. An Investigation into the Comparative Costs of Additive Manufacturing vs. Machine from Solid for Aero Engine Parts. In Cost Effective Manufacturing via Net-Shape Processing; Meeting Proceedings RTO-MP-AVT-139; NATO Research and Technology Organisation: Neuilly-sur-Seine, France, 2006; pp. 17-1–17-10. [Google Scholar]

- Buchanan, C.; Wan, W.; Gardner, L. Testing of Wire and Arc Additively Manufactured Stainless Steel Material and Cross-Sections. In Proceedings of the Ninth International Conference on Advances in Steel Structures, Hong Kong, China, 5–7 December 2018. [Google Scholar]

- Busachi, A.; Erkoyuncu, J.; Colegrove, P.; Martina, F.; Ding, J. Designing a WAAM-Based Manufacturing System for Defence Applications. Procedia CIRP 2015, 37, 48–53. [Google Scholar] [CrossRef]

- Evans, S.I.; Wang, J.; Qin, J.; He, Y.; Shepherd, P.; Ding, J. A Review of WAAM for Steel Construction—Manufacturing, Material and Geometric Properties, Design, and Future Directions. Structures 2022, 44, 1506–1522. [Google Scholar] [CrossRef]

- Jin, W.; Zhang, C.; Jin, S.; Tian, Y.; Wellmann, D.; Liu, W. Wire Arc Additive Manufacturing of Stainless Steels: A Review. Appl. Sci. 2020, 10, 1563. [Google Scholar] [CrossRef]

- Zhang, S.; Zhang, Y.; Gao, M.; Wang, F.; Li, Q.; Zeng, X. Effects of Milling Thickness on Wire Deposition Accuracy of Hybrid Additive/Subtractive Manufacturing. Sci. Technol. Weld. Join. 2019, 24, 375–381. [Google Scholar] [CrossRef]

- Nagamatsu, H.; Sasahara, H.; Mitsutake, Y.; Hamamoto, T. Development of a Cooperative System for Wire and Arc Additive Manufacturing and Machining. Addit. Manuf. 2020, 31, 100896. [Google Scholar] [CrossRef]

- Gordon, J.V.; Haden, C.V.; Nied, H.F.; Vinci, R.P.; Harlow, D.G. Fatigue Crack Growth Anisotropy, Texture and Residual Stress in Austenitic Steel Made by Wire and Arc Additive Manufacturing. Mater. Sci. Eng. A 2018, 724, 431–438. [Google Scholar] [CrossRef]

- Wu, Q.; Ma, Z.; Chen, G.; Liu, C.; Ma, D.; Ma, S. Obtaining Fine Microstructure and Unsupported Overhangs by Low Heat Input Pulse Arc Additive Manufacturing. J. Manuf. Process. 2017, 27, 198–206. [Google Scholar] [CrossRef]

- Bermingham, M.J.; StJohn, D.H.; Krynen, J.; Tedman-Jones, S.; Dargusch, M.S. Promoting the Columnar to Equiaxed Transition and Grain Refinement of Titanium Alloys during Additive Manufacturing. Acta Mater. 2019, 168, 261–274. [Google Scholar] [CrossRef]

- DebRoy, T.; Wei, H.L.; Zuback, J.S.; Mukherjee, T.; Elmer, J.W.; Milewski, J.O.; Beese, A.M.; Wilson-Heid, A.; De, A.; Zhang, W. Additive Manufacturing of Metallic Components—Process, Structure and Properties. Prog. Mater. Sci. 2018, 92, 112–224. [Google Scholar] [CrossRef]

- Wang, K.; Wang, D.; Han, F. Effect of Crystalline Grain Structure on the Mechanical Properties of Twinning-Induced Plasticity Steel. Theor. Appl. Mech. Lett. 2016, 32, 181–187. [Google Scholar] [CrossRef]

- Liu, P.; Wang, Z.; Xiao, Y.; Horstemeyer, M.; Cui, X.; Chen, L. Insight into the Mechanisms of Columnar to Equiaxed Grain Transition during Metallic Additive Manufacturing. Addit. Manuf. 2019, 26, 22–29. [Google Scholar] [CrossRef]

- Buchanan, C.; Gardner, L. Metal 3D Printing in Construction: A Review of Methods, Research, Applications, Opportunities and Challenges. Eng. Struct. 2019, 180, 332–348. [Google Scholar] [CrossRef]

- Brandl, E.; Baufeld, B.; Leyens, C.; Grault, R. Additive Manufactured Ti-6Al-4V Using Welding Wire: Comparison of Laser and Arc Beam Deposition and Evaluation with Respect to Aerospace Material Specifications. Phys. Procedia 2010, 5, 595–606. [Google Scholar] [CrossRef]

- Bermingham, M.J.; Kent, D.; Zhang, H.; StJohn, D.H.; Dargusch, M.S. Controlling the Microstructure and Properties of Wire Arc Additive Manufactured Ti-6Al-4V with Trace Boron Additions. Acta Mater. 2015, 91, 289–303. [Google Scholar] [CrossRef]

- Günen, A.; Gürol, U.; Koçak, M.; Çam, G. A New Approach to Improve Some Properties of Wire Arc Additively Manufactured Stainless Steel Components: Simultaneous Homogenization and Boriding. Surf. Coat. Technol. 2023, 460, 129395. [Google Scholar] [CrossRef]

- Wieczorek, A.N.; Stachowiak, A.; Marciniak, S.; Gołaszewski, A.; Staszuk, M.; Węglowski, M.S.; Rykała, J.; Kowalski, M. Improving the Tribocorrosion Resistance by Increasing the Impact Strength of an Iron Alloy Manufactured by the Wire Arc Additive Manufacturing Method. Wear 2025, 572–573, 206003. [Google Scholar] [CrossRef]

- Tuszyński, W.; Michalczewski, R.; Osuch-Słomka, E.; Snarski-Adamski, A.; Kalbarczyk, M.; Wieczorek, A.N.; Nędza, J. Abrasive Wear, Scuffing and Rolling Contact Fatigue of DLC-Coated 18CrNiMo7-6 Steel Lubricated by a Pure and Contaminated Gear Oil. Materials 2021, 14, 7086. [Google Scholar] [CrossRef] [PubMed]

- Hawk, J.A.; Wilson, R.D.; Tylczak, J.H.; Doğan, Ö.N. Laboratory Abrasive Wear Tests: Investigation of Test Methods and Alloy Correlation. Wear 1999, 225–229, 1031–1042. [Google Scholar] [CrossRef]

- Igual Munoz, A.; Espallargas, N.; Mischler, S. Tribocorrosion: Definitions and Relevance. In Tribocorrosion; Igual Munoz, A., Espallargas, N., Mischler, S., Eds.; Springer International Publishing: Cham, Switzerland, 2020; pp. 1–6. [Google Scholar]

- Stachowiak, A.; Wieczorek, A.N. Comparative Tribocorrosion Tests of 30CrMo12 Cast Steel and ADI Spheroidal Cast Iron. Tribol. Int. 2021, 155, 106763. [Google Scholar] [CrossRef]

- Wieczorek, D.; Ulbrich, D.; Stachowiak, A.; Bartkowski, D.; Bartkowska, A.; Petru, J.; Popielarski, P. Mechanical, Corrosion and Tribocorrosion Resistance of Additively Manufactured Maraging C300 Steel. Tribol. Int. 2024, 195, 109604. [Google Scholar] [CrossRef]

- Dong, Z.; Torbati-Sarraf, H.; Huang, C.; Xu, K.; Gu, X.-L.; Fu, C.; Liu, X.; Meng, Z. Microstructure and Corrosion Behaviour of Structural Steel Fabricated by Wire Arc Additive Manufacturing (WAAM). Mater. Des. 2024, 244, 113158. [Google Scholar] [CrossRef]

- Marques, D.A.; Oliveira, J.P.; Baptista, A.C. A Short Review on the Corrosion Behaviour of Wire and Arc Additive Manufactured Materials. Metals 2023, 13, 641. [Google Scholar] [CrossRef]

- ISO 6892-1:2010; Metallic Materials—Tensile Testing—Part 1: Method of Test at Room Temperature. ISO: Geneva, Switzerland, 2010.

- ISO 148-1:2010; Metallic Materials—Charpy Pendulum Impact Test—Part 1: Test Method. ISO: Geneva, Switzerland, 2010.

- Sugimoto, K.I.; Fiji, D.; Yoshikawa, N. Fatigue Strength of Newly Developed High-Strength Low Alloy TRIP-Aided Steels with Good Hardenability. Procedia Eng. 2010, 2, 359–362. [Google Scholar] [CrossRef]

- Song, S.M.; Sugimoto, K.I.; Kandaka, S.; Futamura, A.; Kobayashi, M.; Masuda, S. Effects of Prestraining on High-Cycle Fatigue Strength of High-Strength Low Alloy TRIP-Aided Steels. Mater. Sci. Res. Int. 2003, 9, 223–229. [Google Scholar] [CrossRef]

- Gołaszewski, A.; Szawłowski, J.; Świątnicki, W.A. Multiphase Steel Microstructure and Properties Optimisation through a New Heat Treatment Process. Mater. Sci. Technol. 2021, 37, 1083–1089. [Google Scholar] [CrossRef]

- Guerra-Linares, C.; Soria-Aguilar, M.J.; García-Guerra, J.; Martínez-Luevanos, A.; Carrillo-Pedroza, F.R.; Gutíerrez-Castañeda, E.; Díaz-Guillén, J.C.; Acevedo Dávila, J.L.; González de la Cruz, J.M. Electrochemical and Tribological Behavior of Dual-Phase Steels Obtained from a Commercial-Grade API 5CT Steel. Metals 2025, 15, 319. [Google Scholar] [CrossRef]

- Ku, M.-H.; Tsao, L.-C.; Tsai, Y.-J.; Lin, Z.-J.; Wu, M.-W. Improved Mechanical and Corrosion Properties of Powder Metallurgy Austenitic, Ferritic, and Martensitic Stainless Steels by Liquid Phase Sintering. Materials 2022, 15, 5483. [Google Scholar] [CrossRef] [PubMed]

- Fleischer, G. Energetische Methode der Bestimmung des Verschleisses. Schmierungstechnik 1973, 4, 269–274. [Google Scholar]

- Fleischer, G.; Gröger, H.; Thum, H. Verschleiß und Zuverlässigkeit; VEB Verlag Technik: Berlin, Germany, 1980. [Google Scholar]

- Zambrano, O.A. A Review on the Effect of Impact Toughness and Fracture Toughness on Impact-Abrasion Wear. J. Mater. Eng. Perform. 2021, 30, 7101–7116. [Google Scholar] [CrossRef]

- Salesky, W.J.; Thomas, G. Medium Carbon Steel Alloy Design for Wear Applications. Wear 1982, 75, 21–40. [Google Scholar] [CrossRef]

| C, % | Si, % | Mn, % | Cr, % | Mo, % | Ni, % |

|---|---|---|---|---|---|

| 0.201 ± 0.013 | 0.995 ± 0.14 | 1.444 ± 0.174 | 1.214 ± 0.171 | 0.036 ± 0.005 | 0.033 ± 0.005 |

| Current I, A | Wire Feed Speed Vd, m/min | Arc Voltage U, V | Travel Speed Vp, cm/min | Shielding Gas |

|---|---|---|---|---|

| 235–240 | 4.8 ± 0.1 | 23.3 ± 0.1 | 25 ± 0.1 | M21 |

| Position, °2θ | hkl | Intensity, Counts | FWHM, ° | |

|---|---|---|---|---|

| Variant A | 52.33 | 011 | 7246 | 0.402 |

| 77.11 | 002 | 378 | 0.813 | |

| 99.61 | 112 | 864 | 0.887 | |

| Variant B | 52.35 | 011 | 10,606 | 0.225 |

| 77.19 | 002 | 2112 | 0.378 | |

| 99.66 | 112 | 1777 | 0.496 |

| Variant No. | A | B |

|---|---|---|

| Material condition | Without heat treatment | Heat-treated |

| Hardness, HRC | 27 ± 1 | 20 ± 1 |

| Impact strength KCV, J/cm2 | 18 ± 1 | 61 ± 2 |

| Yield point Re, MPa | 656 ± 7 | 494 ± 5 |

| Maximum strength Rm, MPa | 920 ± 9 | 777 ± 8 |

| Material | Ecorr, mV (SCE) | icorr, µA/cm2 |

|---|---|---|

| Variant A | −699 ± 32 | 17.3 ± 1.5 |

| Variant B | −633 ± 27 | 9.2 ± 1.0 |

| Material | Material Loss in the Tribocorrosion (ZT) | Mechanical Component (ZM) | Corrosion Component (ZK) | Synergistic Effect (ΔZ) | ΔZ/ZT |

|---|---|---|---|---|---|

| mm3·10−3 | mm3·10−3 | mm3·10−3 | mm3·10−3 | % | |

| Variant A | 3.59 ± 0.16 | 2.49 ± 0.12 | 0.027 | 1.10 | 31 |

| Variant B | 2.59 ± 0.14 | 1.75 ± 0.09 | 0.013 | 0.83 | 32 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wieczorek, A.N.; Stachowiak, A.; Nuckowski, P.; Staszuk, M.; Węglowski, M.S.; Gołaszewski, A.; Marciniak, S. Studies on the Tribocorrosion Properties of an Iron Alloy Produced by Wire Arc Additive Manufacturing Subjected to Multi-Stage Heat Treatment. Coatings 2025, 15, 1265. https://doi.org/10.3390/coatings15111265

Wieczorek AN, Stachowiak A, Nuckowski P, Staszuk M, Węglowski MS, Gołaszewski A, Marciniak S. Studies on the Tribocorrosion Properties of an Iron Alloy Produced by Wire Arc Additive Manufacturing Subjected to Multi-Stage Heat Treatment. Coatings. 2025; 15(11):1265. https://doi.org/10.3390/coatings15111265

Chicago/Turabian StyleWieczorek, Andrzej N., Arkadiusz Stachowiak, Paweł Nuckowski, Marcin Staszuk, Marek S. Węglowski, Adam Gołaszewski, and Szymon Marciniak. 2025. "Studies on the Tribocorrosion Properties of an Iron Alloy Produced by Wire Arc Additive Manufacturing Subjected to Multi-Stage Heat Treatment" Coatings 15, no. 11: 1265. https://doi.org/10.3390/coatings15111265

APA StyleWieczorek, A. N., Stachowiak, A., Nuckowski, P., Staszuk, M., Węglowski, M. S., Gołaszewski, A., & Marciniak, S. (2025). Studies on the Tribocorrosion Properties of an Iron Alloy Produced by Wire Arc Additive Manufacturing Subjected to Multi-Stage Heat Treatment. Coatings, 15(11), 1265. https://doi.org/10.3390/coatings15111265