Research on Fireproof and Anti-Corrosion Integrated Coatings for Modular Integrated Buildings

Abstract

1. Introduction

2. Materials and Methods

2.1. Main Raw Materials

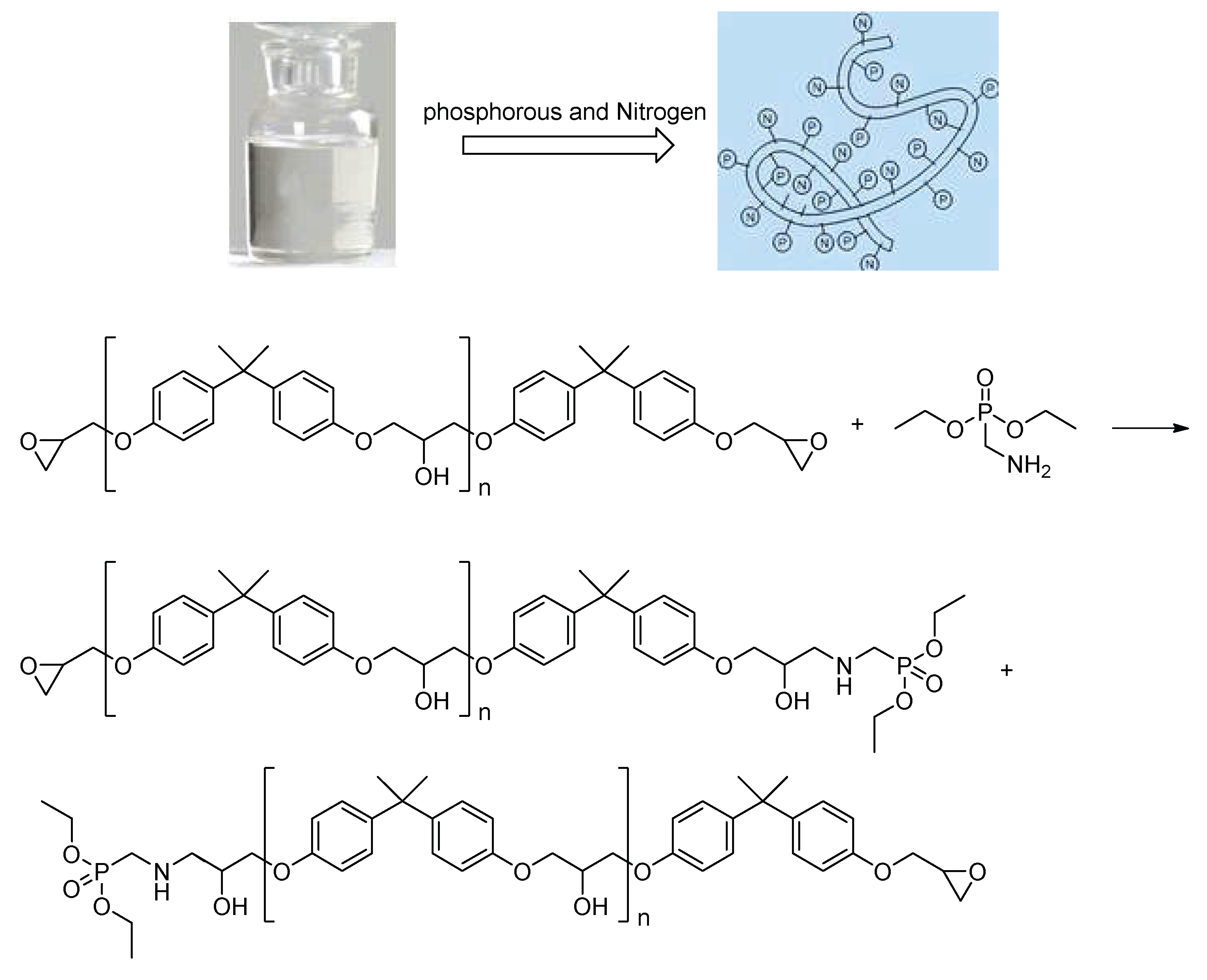

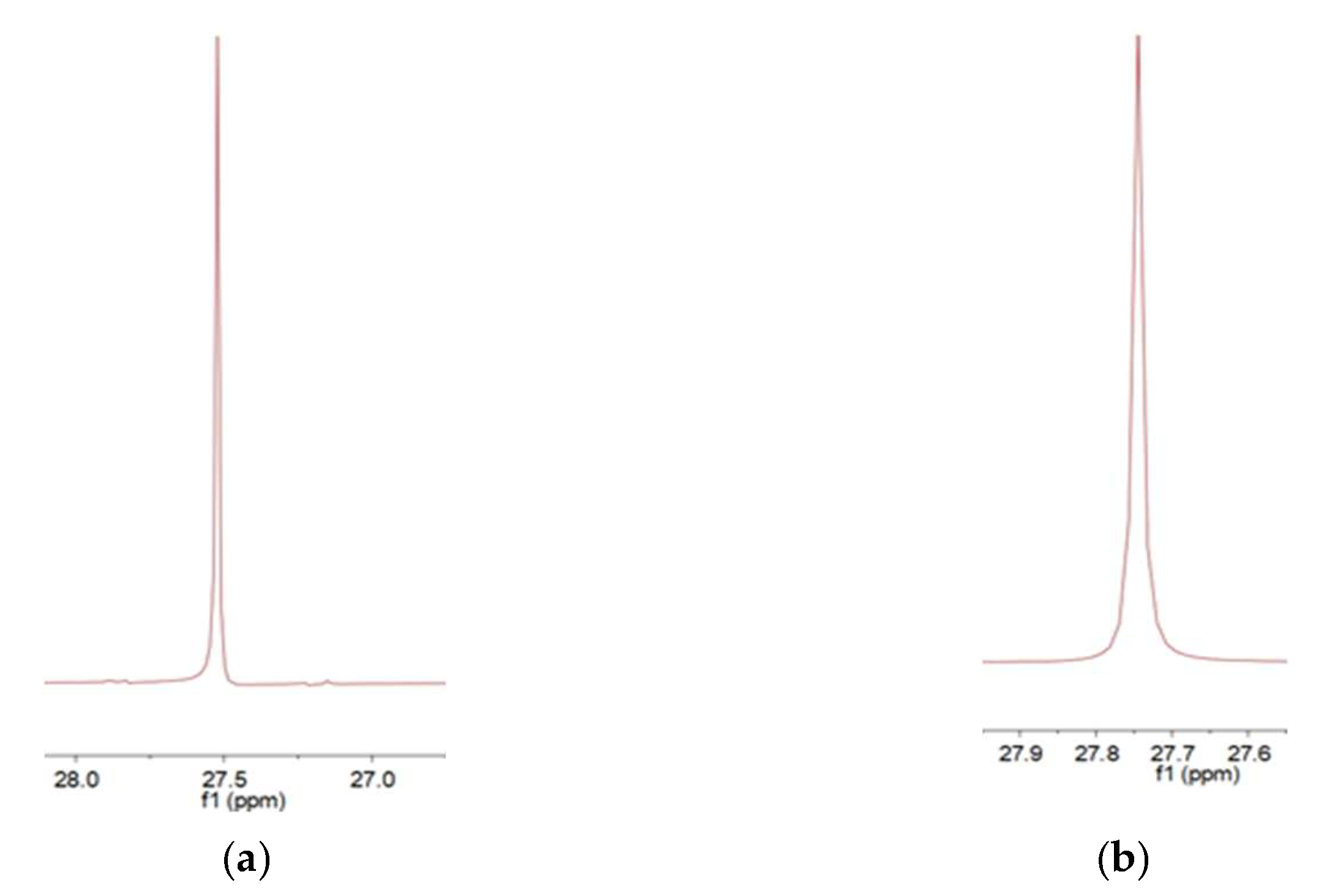

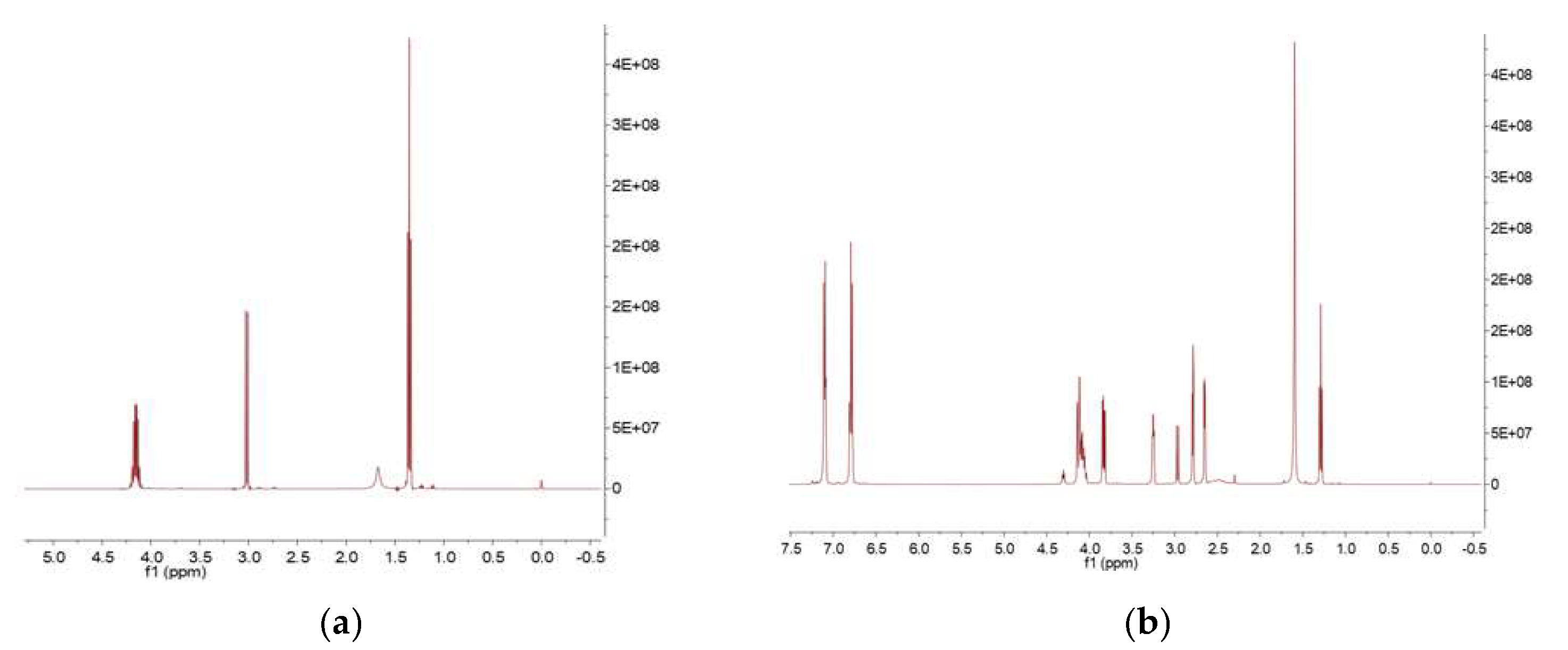

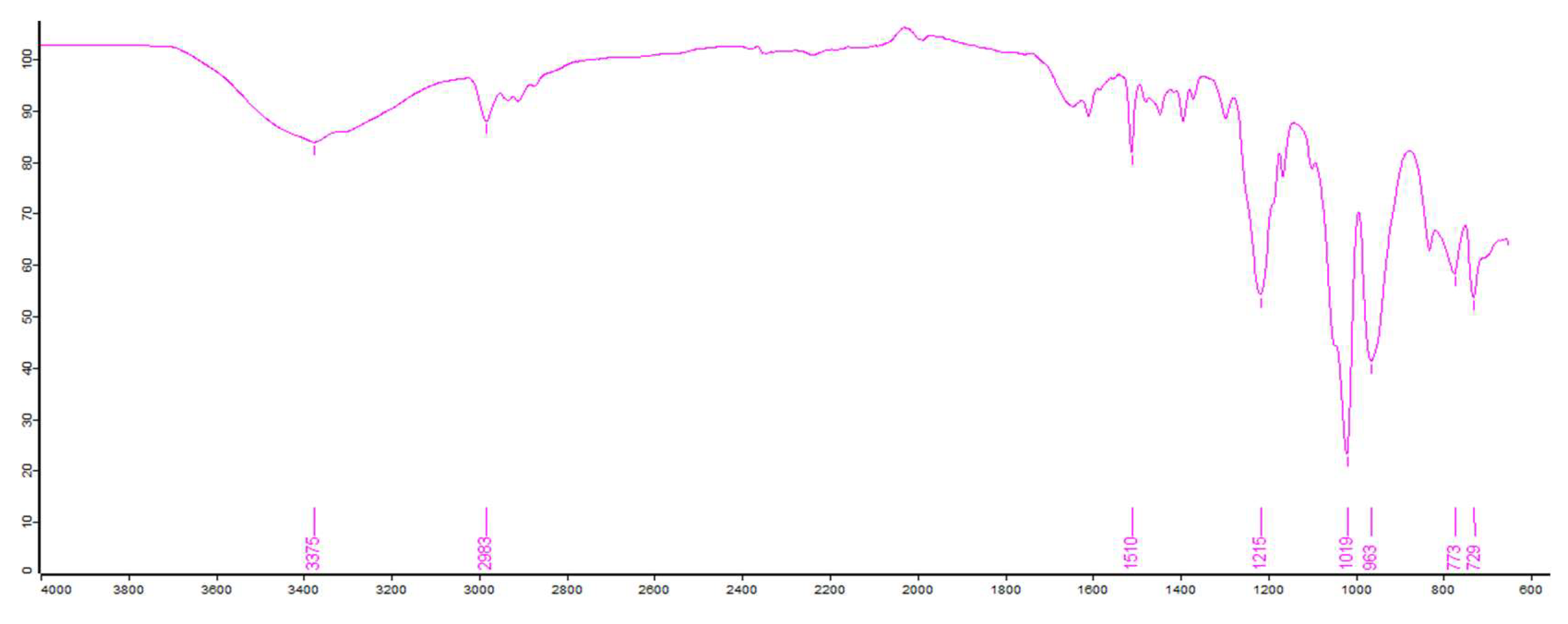

2.2. Preparation of Modified Resin

2.3. Experimental Procedure

2.4. Paint Preparation

- (1)

- At room temperature, we added self-made resin and the corresponding solvent to the paint mixing tank. We started stirring at a speed of 800 rpm until a vortex appeared at the center of the liquid surface;

- (2)

- Dispersants, defoamers, wetting agents, and anti-settling agents were slowly added to a flask, while leveling agents and other additives were added into the preparation tank from step (1). Then, the modified phosphorus nitrogen flame retardant, carbonization agent, and foaming agent were added into the preparation tank. After the addition of these reagents, the reaction mixture was dispersed at a stirring speed of 1800 rpm for 35 min to ensure thorough mixing. Afterwards, the pigment filler was added to the mixing tank and dispersed at a stirring speed of 2200 rpm for 45 min. Finally, the mixture was further stirred and dispersed at a speed of 1800 rpm for 65 min.

- (3)

- The curing agent was added according to the actual required ratio, followed by thorough stirring and curing. Then, this mixture was filtered with a fine mesh strainer. The shelling-out can be carried out with a brush coating or an airless spray coating on the surface of the substrate. Before coating, the surface needed to be thoroughly polished to remove dust and rust. The treated surface should be kept clean and coated within 2 h.

| Material | Mass Fraction (Phr) | Material | Mass Fraction (Phr) |

|---|---|---|---|

| Self-made resin | 100 | Flame retardant | 40–65 |

| Dispersant | 0.5–1.5 | Charring agent | 22–35 |

| Defoamer | 0.5–1.5 | Blowing agent | 38–58 |

| Wetting agent | 0.5–1.5 | Color fillers | 22–40 |

| Anti-settling agent | 0.5–2.5 | Solvent | 50–100 |

| Leveling agent | 0.5–2.5 | Curing agent | 10–40 |

3. Results and Discussion

- Excellent solubility and dispersibility: The resin kept stable in various polar solvents, such as xylene and alcohols. Moreover, the resin can be cured into a film with high integrity through simple processing.

- Controllable crosslinking: Retained epoxy groups in the resin enable the controlled crosslinking reactions with diverse curing agents, affording larger and more complex polymer networks that enhance water and salt spray resistance.

- Superior interfacial adhesion: The film demonstrated Grade 1 adhesion with cross-cut tests. The salt spray tests indicated that corrosion resistance can exceed that of traditional epoxy zinc-rich anti-corrosion coatings.

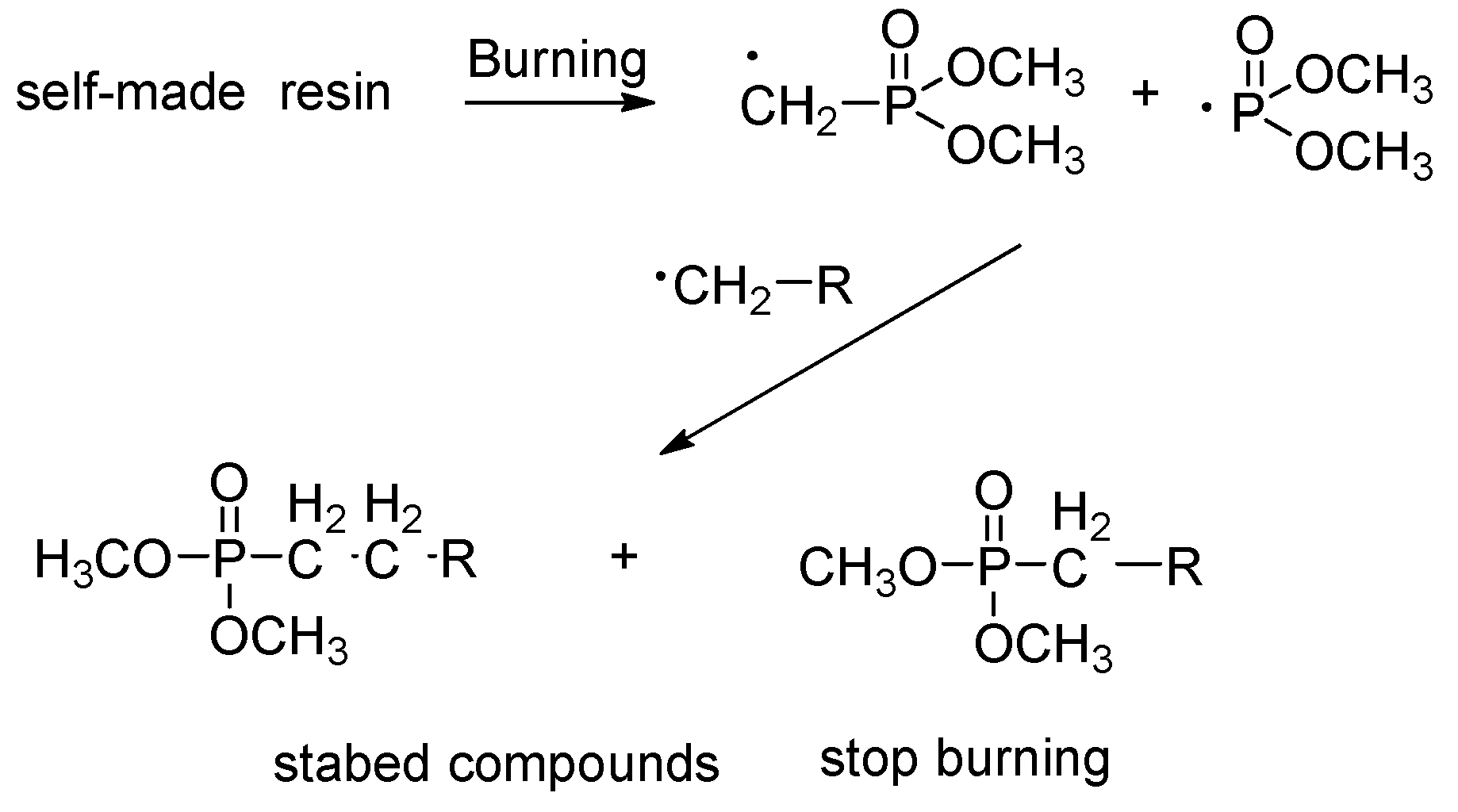

- Synergistic flame-retardant effects: Phosphorus–nitrogen structures in the resin backbone, combined with various flame retardants, produce significant synergy, meeting the requirements of the GB14907-2018 national standard.

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Shi, C.Q.; Su, J.H. Application of Functional Architectural Coatings in Assembled Steel Structures. China Coat. 2020, 35, 25–28+37. [Google Scholar]

- Xie, L.Y. Experimental Analysis of Synergistic Flame Retardant Modification of Acrylic Resin Fire Retardant Coating for Prefabricated Building. Adhesion 2020, 43, 27–31. [Google Scholar]

- Cheng, X.D.; Liu, W.; Wang, J.C.; Xu, K.; Yu, F. Research of Waterborne Heavy-Duty Anti-Corrosion Coatings for Fabricated Steel Structures. Paint Coat. Ind. 2021, 51, 68–74. [Google Scholar]

- Li, X.M. The Application and Improvement of Anti-corrosion and Fireproof Technologies in Prefabricated Steel Structure Buildings. Foshan Ceram. 2024, 34, 50–52. [Google Scholar]

- Guo, J.; Fan, G.D.; Li, D.B.; Chen, X.Y.; He, Y.P. Development of High Solid Organic Siloxane Hybrid Anticorrosive and Fireproof Coating. Guangzhou Chem. Ind. 2022, 50, 89–93. [Google Scholar]

- Xu, H.Z. A Kind of Anti-Corrosion and Fireproof Coating and Its Preparation Method. China Patent 113354988A, 7 September 2021. [Google Scholar]

- Deng, J.Y.; Yang, H.Q.; Yuan, Y. Development of N-P-C water and flame retarding coating. Electroplat. Finish. 2001, 20, 51–53+68. [Google Scholar]

- Yang, S.S. Application of Star -Shaped Unimolecular Intumescent Flame Retardant in Fireproof Coatings. Paint Coat. Ind. 2014, 44, 46–51. [Google Scholar]

- Weil, E. Weil Fire-Protective and Flame-Retardant Coatings—A state-of-the-Art Review. J. Fire Sci. 2011, 29, 59–296. [Google Scholar] [CrossRef]

- Huang, Y.G.; Sun, Y.M.; Wang, X.T.; Xu, J. Effect of Matrix Resin on Performance of Waterborne Ultra-Thin Intumescent Fireproof Coatings. Coat. Prot. 2024, 45, 55–60. [Google Scholar]

- Wu, P.P.; Zhang, Y.Q.; Tian, A.Q.; Cao, X.; Zhang, L.; Wang, J.; Zhang, D.H. Research Progress on the Intumescent Fire Retardant Coatings for Steel Structure. Paint Coat. Ind. 2024, 54, 59–65. [Google Scholar]

- Xuan, P.F.; Jiang, J.C. Study on Performance of Waterborne Fire Retardant Coatings Modified with Inorganic Clays. Paint Coat. Ind. 2014, 44, 48–52. [Google Scholar]

- Sun, W. The influence of different factors on the adhesion and fire resistance performance of fireproof coatings. Fire Sci. Technol. 2019, 38, 850–853. [Google Scholar]

- Dai, D.; Guo, J.; Fan, G.D.; Li, D.B.; Chen, X.Y.; He, Y.P. Development and Application of Quick-drying Waterborne and Environmental Friendly Lightweight Fire-retardant Damping Coatings. Paint Coat. Ind. 2022, 52, 40–45. [Google Scholar]

- Lin, Y.M.; Li, X.; Xiong, X.L.; Zhang, Y.; Yang, Z.X. Mechanical properties and fire resistance of non-intumescent fireproof paint: A case study. Electroplat. Finish. 2023, 42, 70–76. [Google Scholar]

- Guo, Q.-Q.; Chen, H.-Q. Prospects for the Development of Pigment and Fillers in Anti-corrosion Coatings. Paint Coat. Ind. 2003, 33, 35–38. [Google Scholar]

- Liu, M.H.; Zhang, B.X.; Pei, Y.; Zhang, P. Preparation of Waterborne Acrylic Primer for Light Anticorrosion of Steel Structures. Guangzhou Chem. Ind. 2022, 50, 96–98. [Google Scholar]

- Ou, M.; Cui, J.; Zhao, Z.; Li, R.; Guan, H.; Liu, L.; Jiao, C.; Chen, X. Solvent-free intumescent fire protection epoxy coatings with excellent smoke suppression, toxicity reduction, and durability enabled by a micro/nano-structured P/N/Si-containing flame retardant. Prog. Org. Coat. 2023, 183, 107762–107777. [Google Scholar] [CrossRef]

- Sun, S.; Yu, Q.; Yu, B.; Zhou, F. New Progress in the Application of Flame-Retardant Modified Epoxy Resins and Fire-Retardant Coatings. Coatings 2023, 13, 1663–1686. [Google Scholar] [CrossRef]

- Wang, H.; Wang, F.; Sun, R.-Y.; Song, F.; Wang, Y.-Z. Solvent-free epoxy coatings with enhanced cross-linking networks towards highly-efficient flame retardancy, water resistance and anticorrosion. Prog. Org. Coat. 2024, 197, 108835–108844. [Google Scholar] [CrossRef]

- Zhi, M.; Zhao, H.; Zhou, Z.; Zhang, M.; Liu, Q. Recent progress on flame-retardant bio-based epoxy resins: Preparation methods and performance evaluation. Int. J. Biol. Macromol. 2025, 327, 147069–147109. [Google Scholar] [CrossRef]

- Nasirzadeh, M.; Ebrahimi, M.; Zahedi, S. Enhancing the durability of fire-retardant epoxy coatings through an eco-friendly self-stratification approach. J. Coat. Technol. Res. 2025, 22, 1699–1712. [Google Scholar] [CrossRef]

- Rybyan, A.; Bilichenko, J.V.; Kireev, V.V.; Kolenchenko, A.A.; Chistyakov, E.M. Curing of DER-331 Epoxy Resin with Arylaminocyclo- triphosphazenes Based on o-, m-, and p-methylanilines. Polymers 2022, 14, 5334–5344. [Google Scholar] [CrossRef]

- Wang, S.; Huo, C.; Wang, G.; Ye, Q.; Zhang, P.; Song, H.; Wang, Z.; Liu, A. P/N/Si-containing hyperbranched flame retardant for improving mechanical performances, fire safety, and UV resistance of epoxy resins. Prog. Org. Coat. 2024, 193, 108562–108571. [Google Scholar] [CrossRef]

| Project | PT1 | PT2 | PT3 | PT4 | PT5 |

|---|---|---|---|---|---|

| Self-made resin | 100 | 100 | 100 | 100 | 100 |

| Flame retardant | 55 (P-N Flame retardant) | 55 ((NH4)3PO4) | 55 (APP) | 55 (C2H10N6·H3PO4:NH4)3PO4:APP = 1:2:3 | 55 (C2H10N6·H3PO4) |

| Charring agent | 26 (Dipentaerythritol) | 26 (Starch) | 26 (Cyclodextrin/Pentaerythritol = 1:2) | 26 (Starch) | Cyclodextrin/Glucose/Pentaerythritol = 1:3:4 |

| Blowing agent | 38 (Melamine) | 38 (Dicyandiamide) | 38 (Melamine cyanurate) | 38 (Dicyandiamide) | 38 (Dicyandiamide) |

| Dispersant | 1.2 | 1.2 | 1.2 | 1.2 | 1.2 |

| Defoamer | 1.2 | 1.2 | 1.2 | 1.2 | 1.2 |

| Wetting agent | 1.2 | 1.2 | 1.2 | 1.2 | 1.2 |

| Anti-settling agent | 2.3 (Hydrogenated Castor Oil) | 2 (polyamide wax) | 2 (Bentonite) | 2.2 (Hydrogenated Castor Oil) | 2.2 (Hydrogenated Castor Oil) |

| Color fillers | 30 (Titanium dioxide + zinc phosphate) | 30 (Titanium dioxide + zinc phosphate) | 30 (Titanium dioxide + zinc phosphate) | 30 (Titanium dioxide + zinc phosphate) | 30 (Titanium dioxide + zinc phosphate) |

| Leveling agent | 2 | 2 | 2 | 2 | 2 |

| Solvent | 65 (Xylene) | 70 (Xylene: n-butanol = 3:1) | 65 (Xylene/n-butanol = 3:2) | 70 (Xylene) | 70 (Xylene) |

| Curing agent | 25 (Amine-curing agent) | 25 (Polyamide-curing agent) | 25 (Polyether amine-curing agent) | 25 (Amine-curing agent) | 25 (Amine-curing agent) |

| Test Project | Chinese Standard | Corresponding ISO Standard | Test Indicator |

|---|---|---|---|

| Drying time (25 °C) | GB/T 1728-2020 | ISO 9117-1:2013 | Surface drying time, actual drying time |

| Fineness | GB 12441-2018 | ISO 1524:2020 | ≤50 μm |

| Adhesion | GB 12441-2018 | ISO 2409:2020 | Grade 1 (cross-cut method) |

| Limiting oxygen Index (LOI) | GB/T 2406.2-2009 | ISO 4589-2:2017 | ≥32% (V0 class) |

| Flame endurance time | GB 14907-2018 | ISO 834-2:2019 | Time to reach critical steel temperature (550 °C) |

| Neutral salt spray resistance | GB 10125-2012 | ISO 9227:2021 | No corrosion after 2000 h |

| Impact resistance | GB/T 1732-2020 | ISO 6272-1:2018 | 50 cm·kg no damage |

| Flexibility | GB/T 1731-2020 | ISO 1519:2002 | 1 mm bending no crack |

| Test Project | T1 | T2 | T3 | T4 | T5 | DT1 (Commercial Fireproof) | DT2 (Commercial Anti-Corrosion) | DT3 (Pure Resin) |

|---|---|---|---|---|---|---|---|---|

| Surface drying time (h) | 2.8 | 3.4 | 3.2 | 4.0 | 4.0 | 5.0 | 5.2 | 2.0 |

| Actual drying time (h) | 12 | 14 | 13 | 18 | 17 | 22 | 24 | 12 |

| Fineness (μm) | ≤50 | ≤50 | ≤50 | ≤50 | ≤50 | ≤50 | ≤50 | ≤50 |

| Adhesion (Grade) | 1 | 1 | 1 | 1 | 1 | 2 | 1 | 1 |

| LOI (%) | 45 | 39 | 41 | 40 | 42 | 20 | 17 | 28 |

| Flame endurance time (min) | 124 | 112 | 109 | 101 | 114 | 100 | 14 | 45 |

| Salt spray resistance (h) | 2540 | 2170 | 2200 | 2080 | 2370 | 168 | 1060 | 1690 |

| Impact resistance (cm·kg) | 50 | 50 | 45 | 45 | 48 | 30 | 50 | 50 |

| Flexibility (mm) | 1 | 1 | 1 | 1 | 1 | 2 | 1 | 1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, S.; Guan, J.; Ma, Z.; Sun, Q.; Li, K.; Wang, Z. Research on Fireproof and Anti-Corrosion Integrated Coatings for Modular Integrated Buildings. Coatings 2025, 15, 1253. https://doi.org/10.3390/coatings15111253

Liu S, Guan J, Ma Z, Sun Q, Li K, Wang Z. Research on Fireproof and Anti-Corrosion Integrated Coatings for Modular Integrated Buildings. Coatings. 2025; 15(11):1253. https://doi.org/10.3390/coatings15111253

Chicago/Turabian StyleLiu, Song, Jun Guan, Zhiheng Ma, Qi Sun, Kai Li, and Zhiyong Wang. 2025. "Research on Fireproof and Anti-Corrosion Integrated Coatings for Modular Integrated Buildings" Coatings 15, no. 11: 1253. https://doi.org/10.3390/coatings15111253

APA StyleLiu, S., Guan, J., Ma, Z., Sun, Q., Li, K., & Wang, Z. (2025). Research on Fireproof and Anti-Corrosion Integrated Coatings for Modular Integrated Buildings. Coatings, 15(11), 1253. https://doi.org/10.3390/coatings15111253