Influence of Laser Power on Crack Evolution During Selective Laser Melting Manufacturing Process of Aluminum–Lithium Alloys

Abstract

1. Introduction

2. Materials and Methods

2.1. Experimental Powders

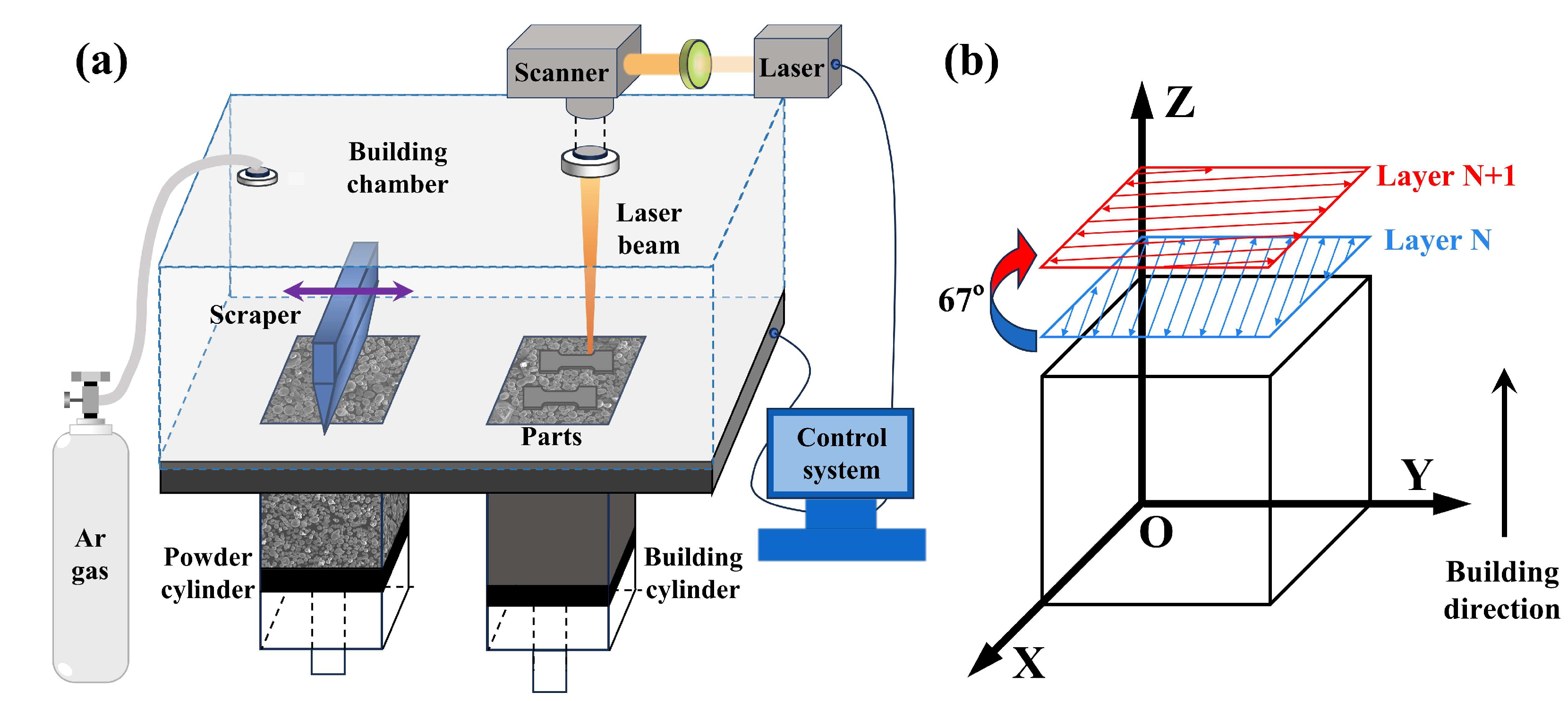

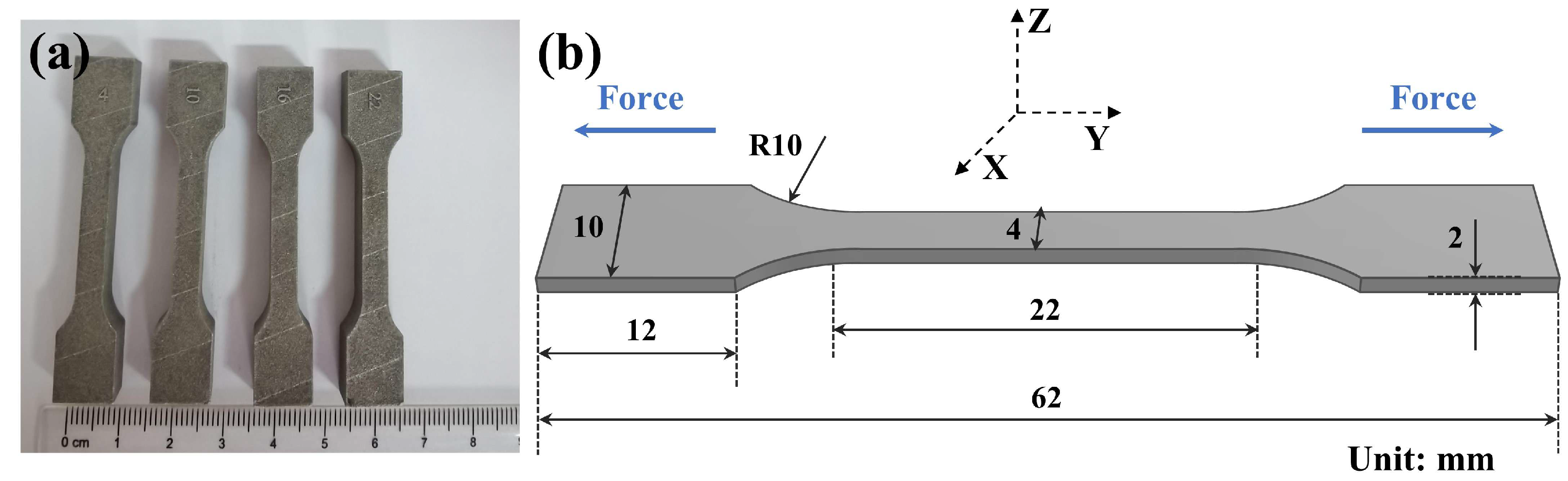

2.2. SLM Manufacturing Process

2.3. Material Characterization

3. Results and Discussion

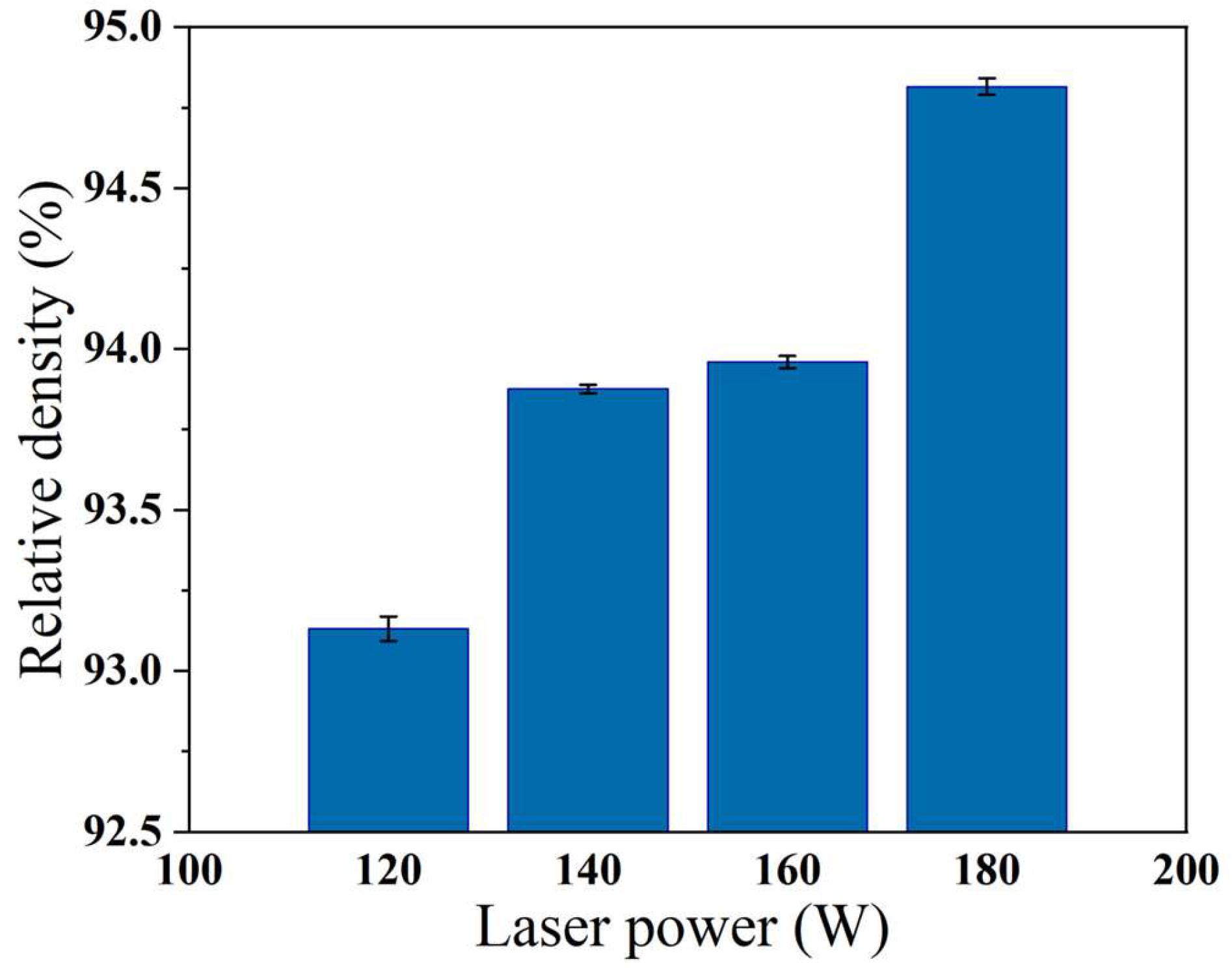

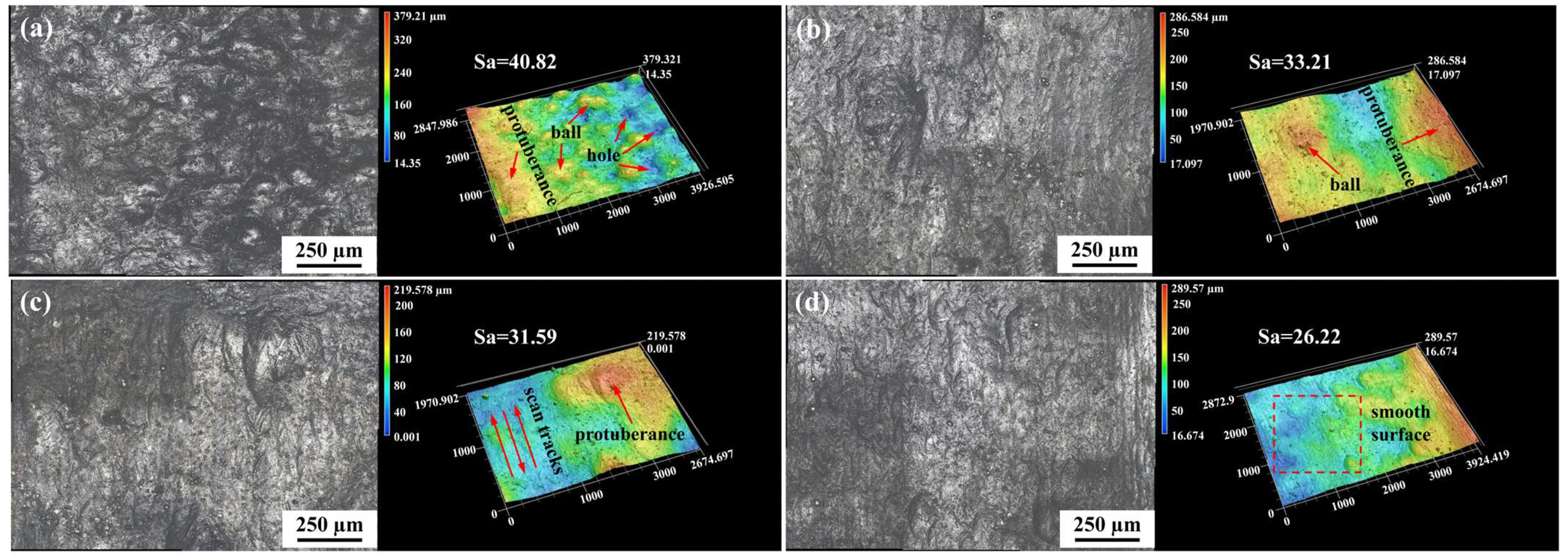

3.1. Densification and Surface Morphology

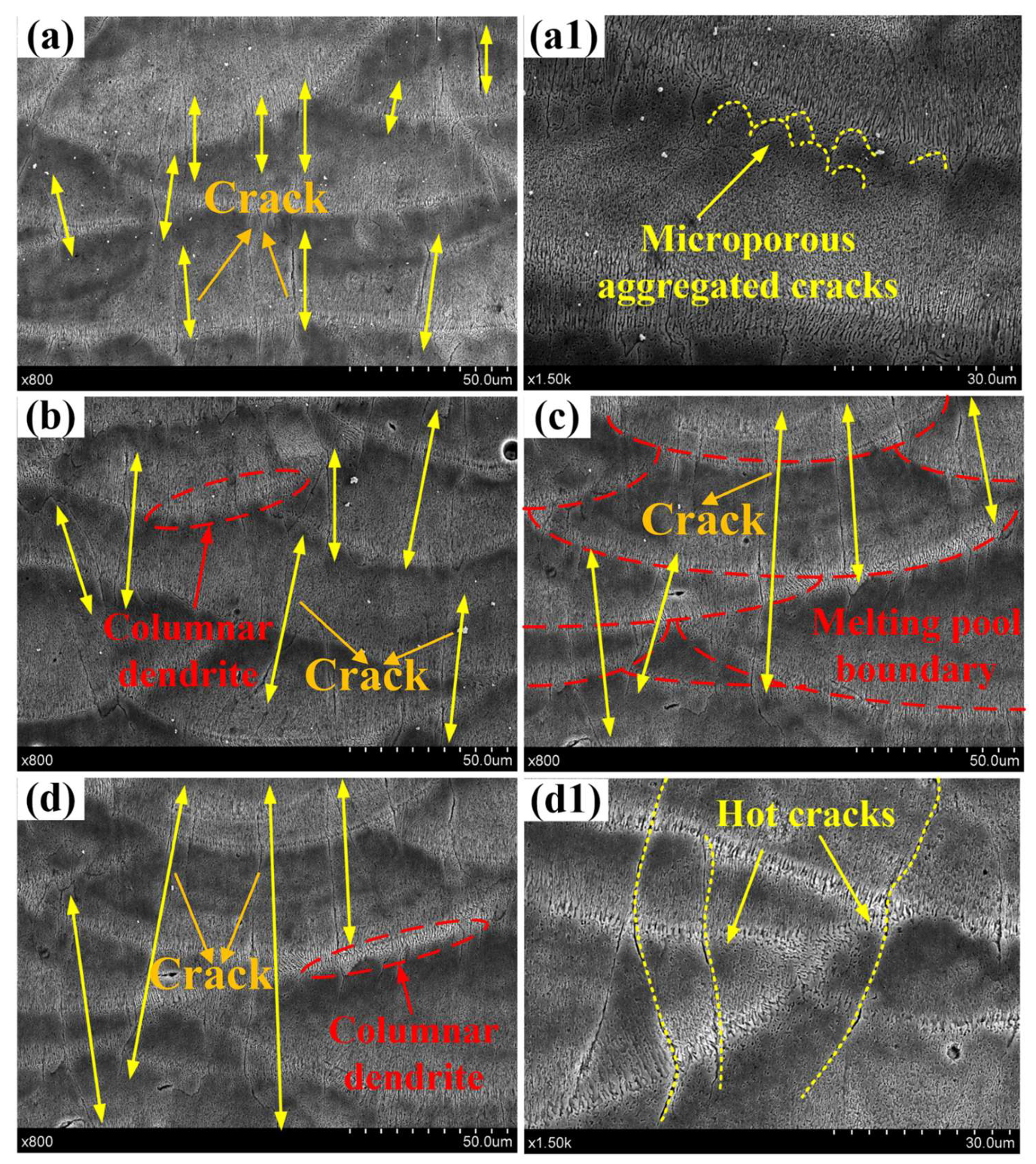

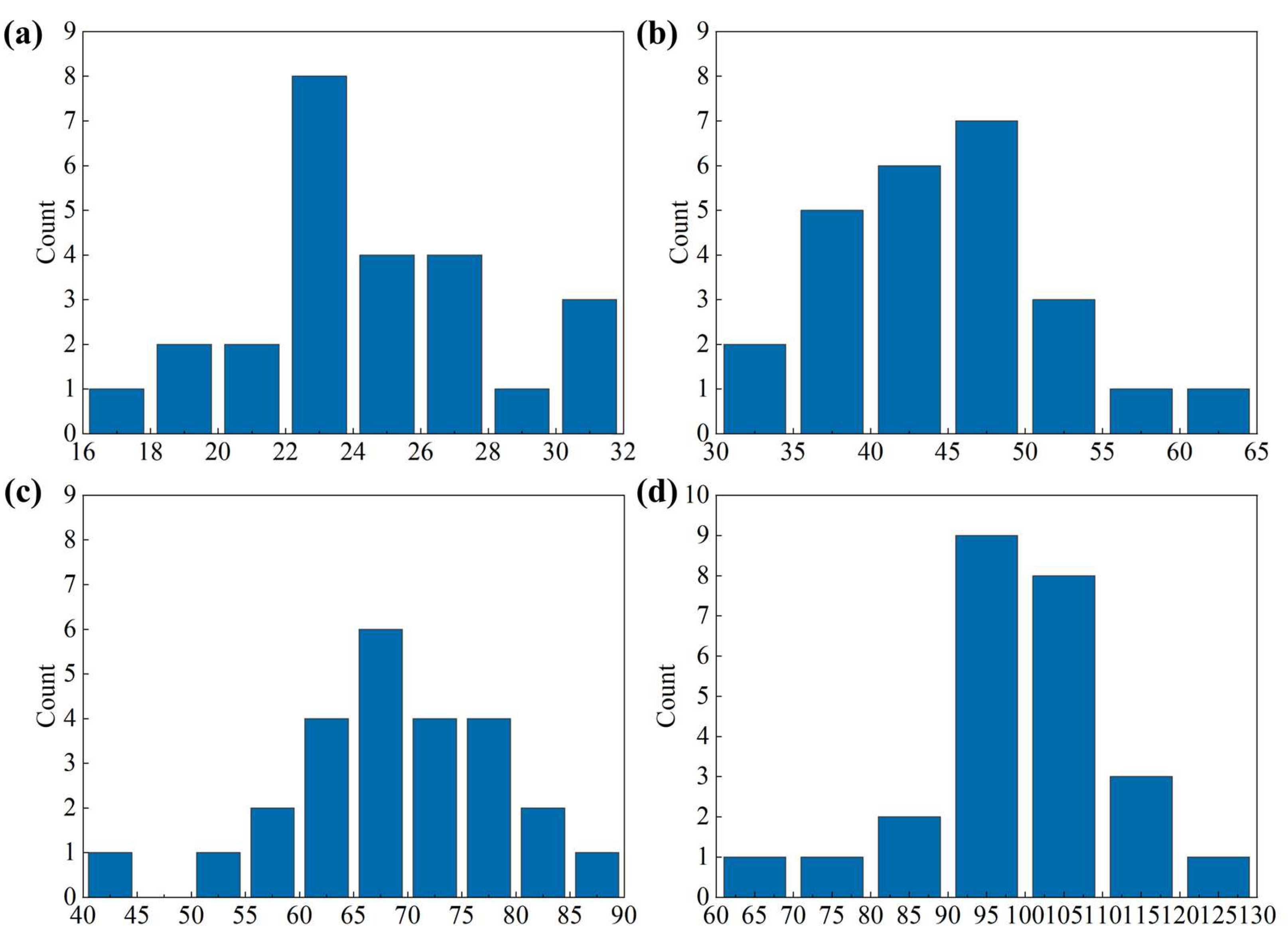

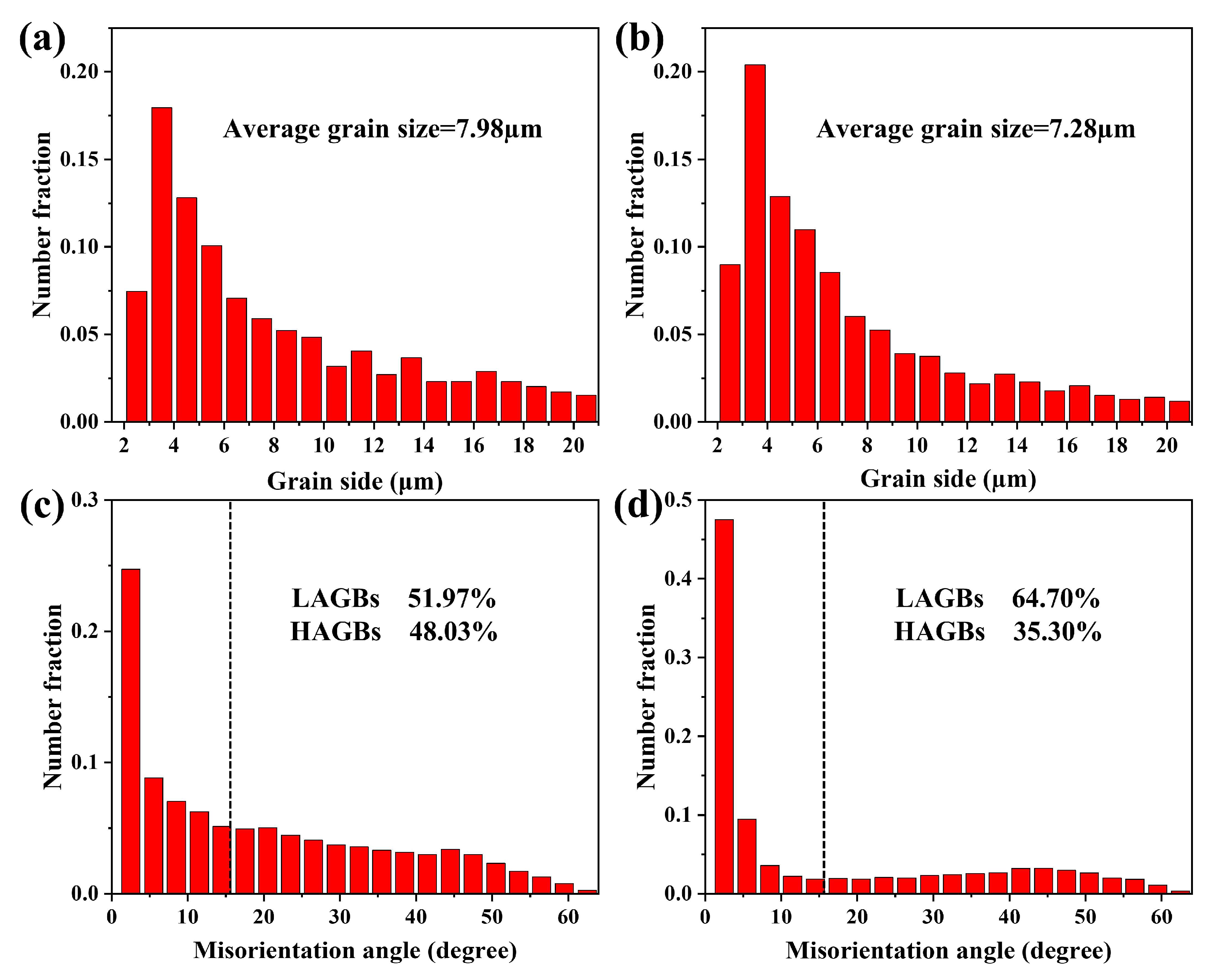

3.2. Defects and Microstructure

3.3. Phase Analysis

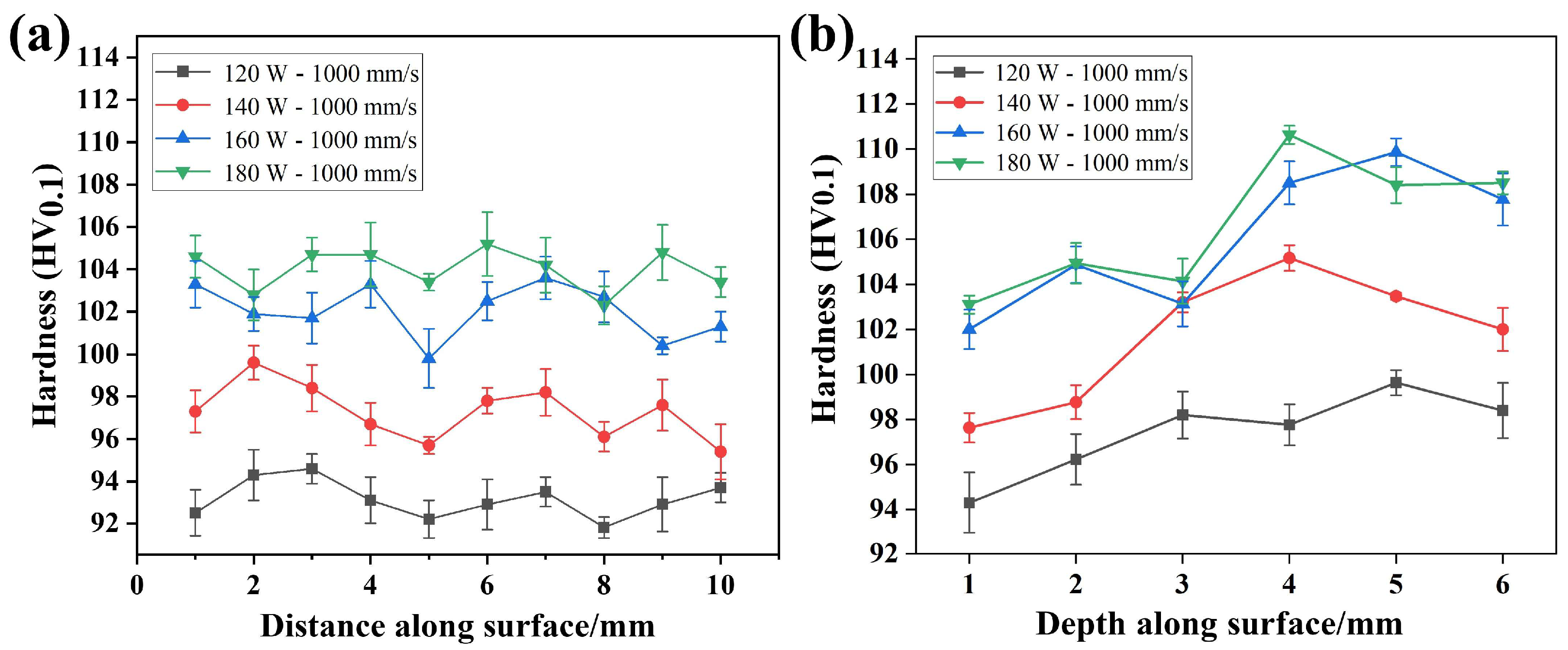

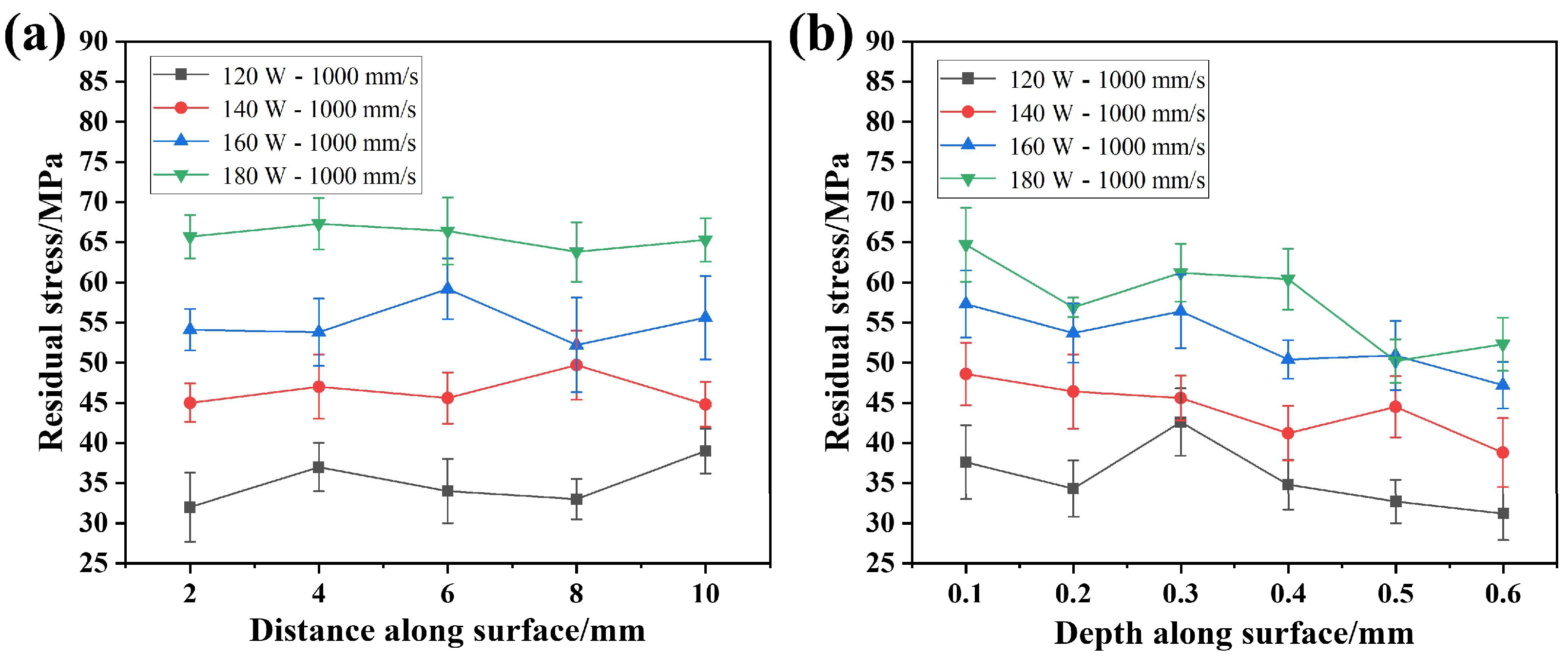

3.4. Microhardness and Residual Stress Analysis

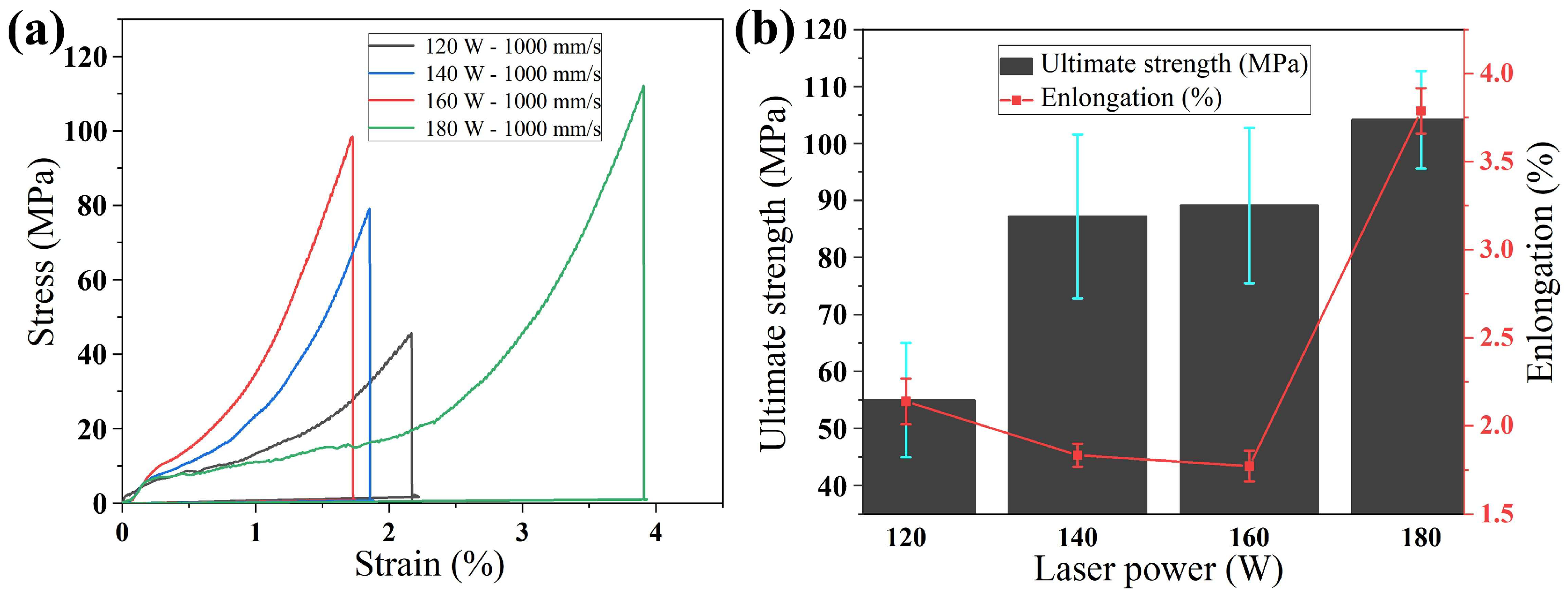

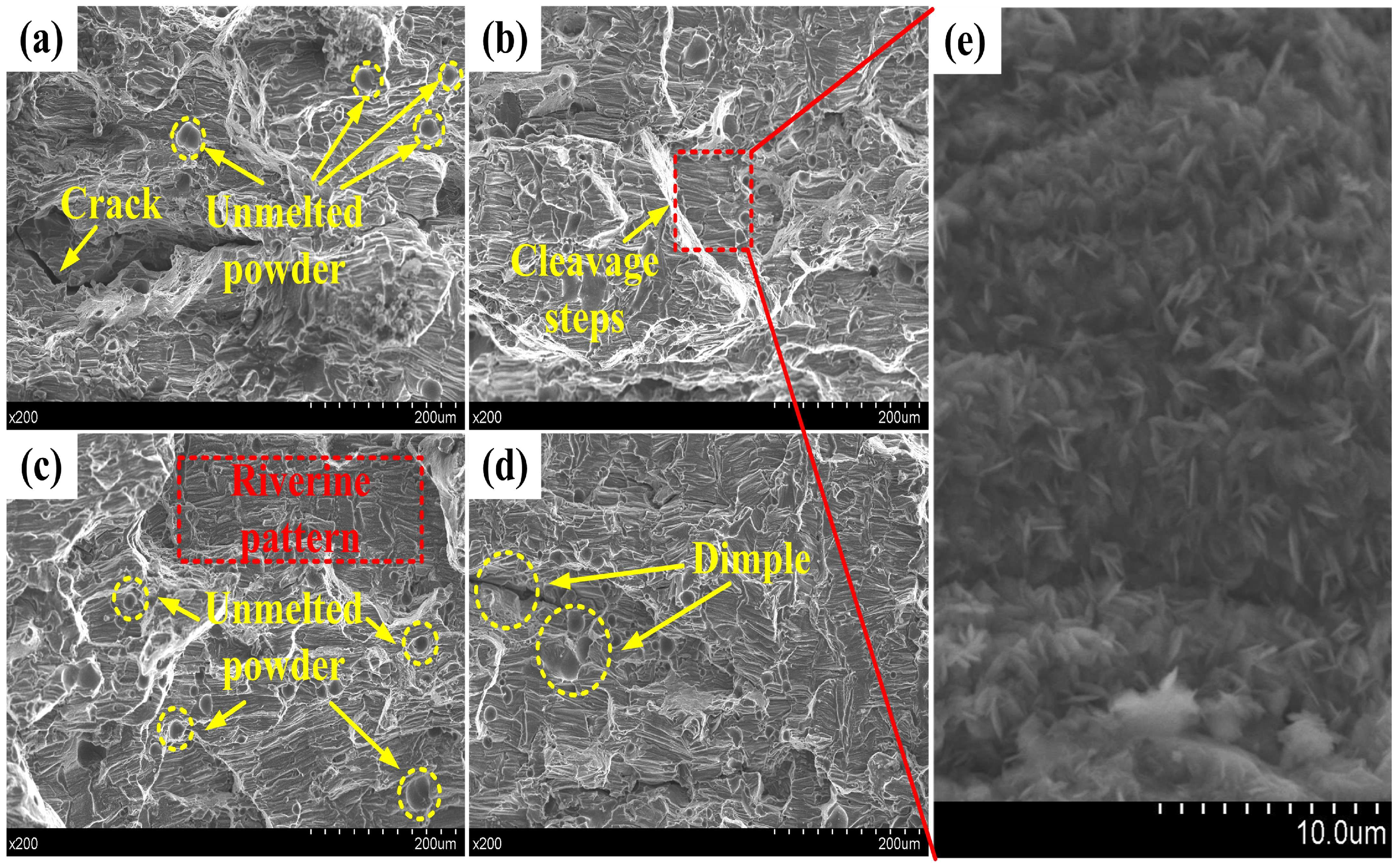

3.5. Tensile Behavior and Fracture Morphology

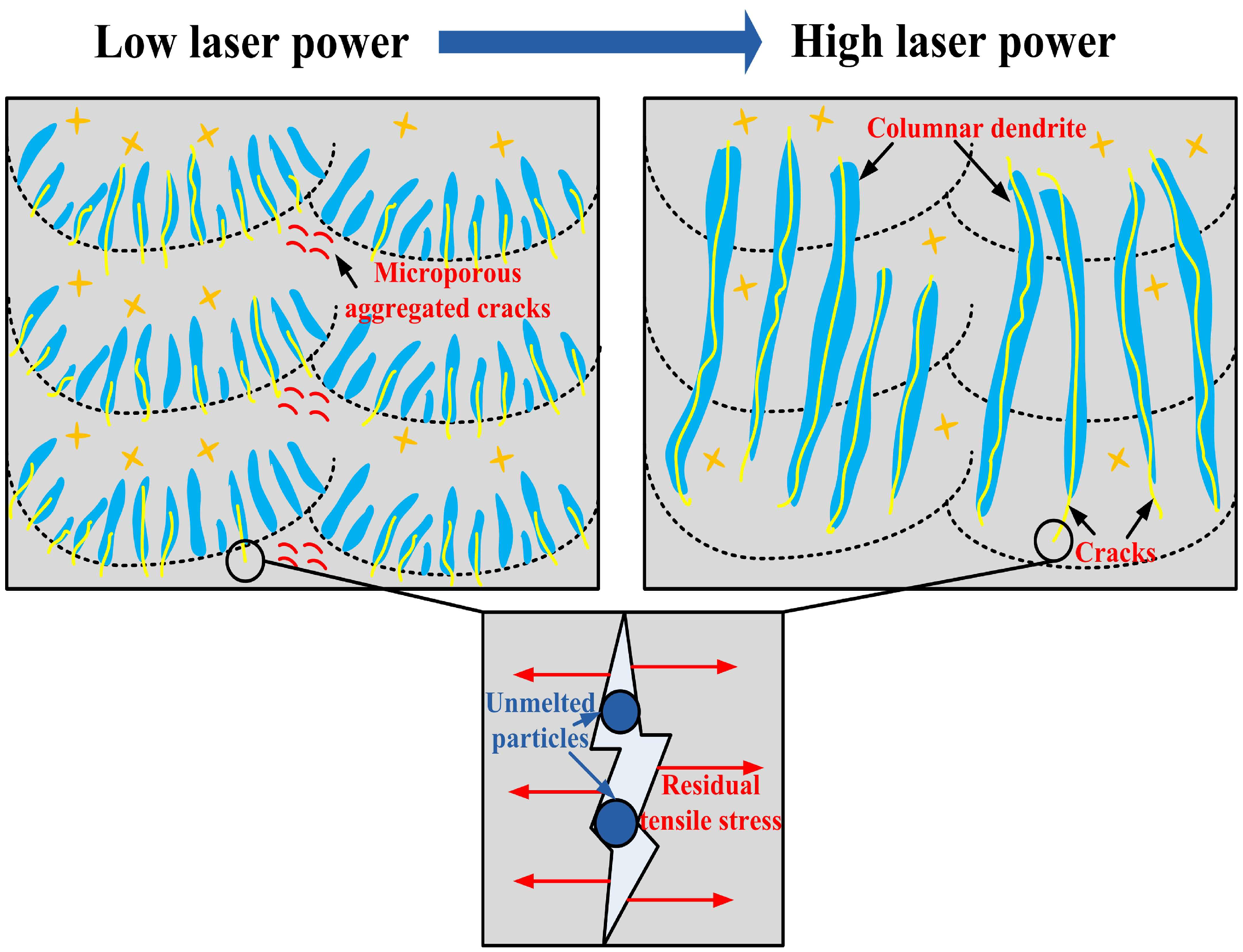

3.6. Mechanism of Cracking Manufacturation

4. Conclusions

- (1)

- The augmentation of laser power engenders a transmanufacturative impact on the alloy’s physical attributes. Enhanced energy absorption by the powder particles at higher power levels facilitates complete melting within the melt pool. Consequently, the metal melt exhibits accelerated flow dynamics, promoting unimanufactur metallurgical bonding and yielding a pronounced increase in density alongside a notable reduction in surface roughness. These findings are drawn under fixed process parameters, and future work will extend to multi-parameter studies to provide a more comprehensive understanding.

- (2)

- The SLM process exerts a profound influence on the material’s microstructural features. Increasing laser power prompts the progressive growth of columnar crystals within the melt pool. This growth trajectory correlates directly with the expansion of cracks, transitioning from micro-pore aggregate cracks at lower power settings to thermally induced cracks aligned with the elongation of the columnar crystals at higher power levels. Notably, augmented laser power corresponds to diminished grain size and a heightened prevalence of low-angle grain boundaries.

- (3)

- X-ray diffraction (XRD) analyses reveal a compelling correlation between laser power and solid solution content, underpinning subsequent microhardness variations. Higher laser power precipitates an elevated solid solution fraction within the fabricated component, in turn translating to enhanced microhardness values. Remarkably, the surface of the manufactured specimen adopts a state of residual tensile stress, which escalates progressively with increasing laser power.

- (4)

- The tensile testing of SLM-fabricated aluminum–lithium alloy unravels a fracture behavior predominantly characterized by brittleness. The highest laser power level yields maximal tensile strength and elongation, marked by distinct step-like cleavage facets adorned with river-like patterns. In addition, a limited presence of circular dimples on the fracture surface at elevated laser powers signifies an augmentation in ductility, indicative of a measured improvement in plasticity.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Santos, M.C.; Machado, A.R.; Sales, W.F.; Barrozo, M.A.S.; Ezugwu, E.O. Machining of aluminum alloys: A review. Int. J. Adv. Manuf. Technol. 2016, 86, 3067–3080. [Google Scholar] [CrossRef]

- Williams, J.C.; Starke, E.A. Progress in structural materials for aerospace systems. Acta Mater. 2003, 51, 5775–5799. [Google Scholar] [CrossRef]

- Zhang, X.S.; Chen, Y.J.; Hu, J.L. Recent advances in the development of aerospace materials. Prog. Aerosp. Sci. 2018, 97, 22–34. [Google Scholar] [CrossRef]

- Zhu, L.J.; Li, N.; Childs, P.R.N. Light-weighting in aerospace component and system design. Propuls. Power Res. 2018, 7, 103–119. [Google Scholar] [CrossRef]

- Abd El-Aty, A.; Xu, Y.; Guo, X.Z.; Zhang, S.H.; Ma, Y.; Chen, D.Y. Strengthening mechanisms, demanufacturation behavior, and anisotropic mechanical properties of Al-Li alloys: A review. J. Adv. Res. 2018, 10, 49–67. [Google Scholar] [CrossRef] [PubMed]

- Dursun, T.; Soutis, C. Recent developments in advanced aircraft aluminium alloys. Mater. Des. 2014, 56, 862–871. [Google Scholar] [CrossRef]

- Rioja, R.J.; Liu, J. The Evolution of Al-Li Base Products for Aerospace and Space Applications. Metall. Mater. Trans. A 2012, 43, 3325–3337. [Google Scholar] [CrossRef]

- Wu, L.; Li, X.F.; Wang, H.W. Significant roles of minor Mg addition in microstructural evolution and mechanical properties of cast Al–3Li–2Cu-0.15Zr alloy. J. Alloys Compd. 2021, 857, 157600. [Google Scholar] [CrossRef]

- El-Aty, A.A.; Xu, Y.; Zhang, S.H.; Ma, Y.; Chen, D.Y. Experimental investigation of tensile properties and anisotropy of 1420, 8090 and 2060 Al-Li alloys sheet undergoing different strain rates and fibre orientation: A comparative study. Procedia Eng. 2017, 207, 13–18. [Google Scholar] [CrossRef]

- Han, B.; Tao, W.; Chen, Y.B.; Li, H. Double-sided laser beam welded T-joints for aluminum-lithium alloy aircraft fuselage panels: Effects of filler elements on microstructure and mechanical properties. Opt. Laser Technol. 2017, 93, 99–108. [Google Scholar] [CrossRef]

- Gupta, R.K.; Nayan, N.; Nagasireesha, G.; Sharma, S.C. Development and characterization of Al–Li alloys. Mat. Sci. Eng. A 2006, 420, 228–234. [Google Scholar] [CrossRef]

- Han, B.; Chen, Y.B.; Tao, W.; Li, H.; Li, L.Q. Microstructural evolution and interfacial crack corrosion behavior of double-sided laser beam welded 2060/2099 Al-Li alloys T-joints. Mater. Des. 2017, 135, 353–365. [Google Scholar] [CrossRef]

- Akhtar, N.; Akhtar, W.; Wu, S.J. Melting and casting of lithium containing aluminium alloys. Int. J. Cast Met. Res. 2015, 28, 1–8. [Google Scholar] [CrossRef]

- Wang, C.C.; Min, G.H.; Lu, Q.L.; Lu, Z. Solidification structure and mechanical properties of Al–Li–Cu–Zr cast alloys. Int. J. Cast Met. Res. 2004, 17, 264–266. [Google Scholar] [CrossRef]

- Zhang, X.J.; Wang, H.W.; Yan, B.; Zou, C.M.; Wei, Z.J. The effect of grain refinement and precipitation strengthening induced by Sc or Er alloying on the mechanical properties of cast Al-Li-Cu-Mg alloys at elevated temperatures. Mat. Sci. Eng. A 2021, 822, 141641. [Google Scholar] [CrossRef]

- Kapil, R.; Joshi, A.; Jayaganthan, R.; Gairola, S.; Verma, R. Improvement of fracture toughness of ultra fine grained Al–Li 8090 alloy processed through multi axial forging. Mater. Res. Express 2019, 6, 085064. [Google Scholar] [CrossRef]

- Borkowski, L.B.; Staroselsky, A. Multiscale Model for Al–Li Material Processing Simulation Under Forging Conditions. In Light Metals 2018; Springer: Cham, Switzerland, 2018; pp. 355–364. [Google Scholar]

- Zhao, D.; Chen, X.H.; Li, J.B.; Tan, J.; Pan, F.S. Microstructure, texture and mechanical properties of the rolled high modulus Mg-Y-Zn-Al-Li alloy. Mat. Sci. Eng. A 2022, 831, 142242. [Google Scholar] [CrossRef]

- Qin, S.S.; Lee, S.; Tsuchiya, T.; Matsuda, K.; Horita, Z.; Kocisko, R.; Kvackaj, T. Aging behavior of Al-Li-(Cu, Mg) alloys processed by different demanufacturation methods. Mater. Des. 2020, 196, 109139. [Google Scholar] [CrossRef]

- Chen, X.X.; Zhao, G.Q.; Liu, G.L.; Sun, L.; Chen, L.; Zhang, C.S. Microstructure evolution and mechanical properties of 2196 Al-Li alloy in hot extrusion process. J. Mater. Process. Technol. 2020, 275, 116348. [Google Scholar] [CrossRef]

- Wang, Y.X.; Zhao, G.Q. Hot Extrusion Processing of Al–Li Alloy Profiles and Related Issues: A Review. Chin. J. Mech. Eng. 2020, 33, 64. [Google Scholar] [CrossRef]

- Uz, M.V.; Koçak, M.; Lemaitre, F.; Ehrström, J.C.; Kempa, S.; Bron, F. Improvement of damage tolerance of laser beam welded stiffened panels for airframes via local engineering. Int. J. Fatigue 2009, 31, 916–926. [Google Scholar] [CrossRef]

- Xiao, R.S.; Zhang, X.Y. Problems and issues in laser beam welding of aluminum–lithium alloys. J. Manuf. Process. 2014, 16, 166–175. [Google Scholar] [CrossRef]

- Yue, P.P.; Zhang, M.; Zhao, T.; Liu, P.; Peng, F.; Yang, L.Q. Eco-friendly epoxidized Eucommia ulmoides gum based composite coating with enhanced super-hydrophobicity and corrosion resistance properties. Ind. Crops Prod. 2024, 214, 118523. [Google Scholar] [CrossRef]

- Romanova, V.; Balokhonov, R.; Zinovieva, O.; Emelianova, E.; Dymnich, E.; Pisarev, M.; Zinoviev, A. Micromechanical simulations of additively manufactured aluminum alloys. Comput. Struct. 2021, 244, 106412. [Google Scholar] [CrossRef]

- Zhang, J.L.; Song, B.; Wei, Q.S.; Bourell, D.; Shi, Y.S. A review of selective laser melting of aluminum alloys: Processing, microstructure, property and developing trends. J. Mater. Sci. Technol. 2019, 35, 270–284. [Google Scholar] [CrossRef]

- Olakanmi, E.O.; Cochrane, R.F.; Dalgarno, K.W. A review on selective laser sintering/melting (SLS/SLM) of aluminium alloy powders: Processing, microstructure, and properties. Prog. Mater. Sci. 2015, 74, 401–477. [Google Scholar] [CrossRef]

- Guan, C.S.; Fu, J.J.; Cui, Z.C.; Wang, S.L.; Gao, Q.S.; Yang, Y.T. Evaluation of the tribological and anti-adhesive properties of different materials coated rotary tillage blades. Soil Till. Res. 2021, 209, 104933. [Google Scholar] [CrossRef]

- Chen, S.R.; Ding, H.T.; Tang, Z.; Hao, S.H.; Zhao, Y.F. Influence of rice straw manufacturing factors on ring die wear and improved wear prediction model during briquetting. Biosyst. Eng. 2022, 214, 122–137. [Google Scholar] [CrossRef]

- Tang, Z.; Liang, Y.Q.; Wang, M.L.; Zhang, H.; Wang, X.Z. Effect of mechanical properties of rice stem and its fiber on the strength of straw rope. Ind. Crops Prod. 2022, 180, 114729. [Google Scholar] [CrossRef]

- Sing, S.L.; An, J.; Yeong, W.Y.; Wiria, F.E. Laser and electron-beam powder-bed additive manufacturing of metallic implants: A review on processes, materials and designs. J. Orthop. Res. 2016, 34, 369–385. [Google Scholar] [CrossRef]

- Zhang, L.C.; Attar, H. Selective Laser Melting of Titanium Alloys and Titanium Matrix Composites for Biomedical Applications: A Review. Adv. Eng. Mater. 2016, 18, 463–475. [Google Scholar] [CrossRef]

- Yap, C.Y.; Chua, C.K.; Dong, Z.L.; Liu, Z.H.; Zhang, D.Q.; Loh, L.E.; Sing, S.L. Review of selective laser melting: Materials and applications. Appl. Phys. Rev. 2015, 2, 041101. [Google Scholar] [CrossRef]

- Aboulkhair, N.T.; Simonelli, M.; Parry, L.; Ashcroft, I.; Tuck, C.; Hague, R. 3D printing of Aluminium alloys: Additive Manufacturing of Aluminium alloys using selective laser melting. Prog. Mater. Sci. 2019, 106, 100578. [Google Scholar] [CrossRef]

- Schneller, W.; Leitner, M.; Pomberger, S.; Springer, S.; Beter, F.; Grün, F. Effect of Post Treatment on the Microstructure, Surface Roughness and Residual Stress Regarding the Fatigue Strength of Selectively Laser Melted AlSi10Mg Structures. J. Manuf. Mater. Process. 2019, 3, 89. [Google Scholar] [CrossRef]

- Bian, P.; Jammal, A.; Xu, K.; Ye, F.; Zhao, N.; Song, Y. A Review of the Evolution of Residual Stresses in Additive Manufacturing During Selective Laser Melting Technology. Materials 2025, 18, 1707. [Google Scholar] [CrossRef] [PubMed]

- Nie, X.J.; Zhang, H.; Zhu, H.H.; Hu, Z.H.; Ke, L.D.; Zeng, X.Y. Analysis of processing parameters and characteristics of selective laser melted high strength Al-Cu-Mg alloys: From single tracks to cubic samples. J. Mater. Process. Technol. 2018, 256, 69–77. [Google Scholar] [CrossRef]

- Wang, P.; Gammer, C.; Brenne, F.; Prashanth, K.G.; Mendes, R.G.; Rümmeli, M.H.; Gemming, T.; Eckert, J.; Scudino, S. Microstructure and mechanical properties of a heat-treatable Al-3.5Cu-1.5Mg-1Si alloy produced by selective laser melting. Mat. Sci. Eng. A 2018, 711, 562–570. [Google Scholar] [CrossRef]

- Zhang, H.; Zhu, H.H.; Qi, T.; Hu, Z.H.; Zeng, X.Y. Selective laser melting of high strength Al–Cu–Mg alloys: Processing, microstructure and mechanical properties. Mat. Sci. Eng. A 2016, 656, 47–54. [Google Scholar] [CrossRef]

- Qi, T.; Zhu, H.H.; Zhang, H.; Yin, J.; Ke, L.D.; Zeng, X.Y. Selective laser melting of Al7050 powder: Melting mode transition and comparison of the characteristics between the keyhole and conduction mode. Mater. Des. 2017, 135, 257–266. [Google Scholar] [CrossRef]

- Li, L.; Meng, X.K.; Huang, S.; Wang, H.; Li, P.F.; Zhou, J.Z. Investigating the effect of the scanning speed on the characteristics of Al-Li alloy fabricated by selective laser melting. J. Manuf. Process. 2022, 75, 719–728. [Google Scholar] [CrossRef]

- Niu, P.D.; Li, R.D.; Yuan, T.C.; Zhu, S.Y.; Chen, C.; Wang, M.B.; Huang, L. Microstructures andproperties of an equimolar AlCoCrFeNi high entropy alloy printed by selective lasermelting. Intermetallics 2019, 104, 24–32. [Google Scholar] [CrossRef]

- Gu, D.D.; Hagedorn, Y.C.; Meiners, W.; Meng, G.B.; Batista, R.J.; Wissenbach, K.; Poprawe, R. Densification behavior, microstructure evolution, and wear permanufacturance of selective laser melting processed commercially pure titanium. Acta Mater. 2012, 60, 3849–3860. [Google Scholar] [CrossRef]

- Khairallah, S.A.; Anderson, A.T.; Rubenchik, A.; King, W.E. Laser powder-bed fusion additive manufacturing: Physics of complex melt flow and manufacturation mechanisms of pores, spatter, and denudation zones. Acta Mater. 2016, 108, 36–45. [Google Scholar] [CrossRef]

- King, W.E.; Barth, H.D.; Castillo, V.M.; Gallegos, G.F.; Gibbs, J.W.; Hahn, D.E.; Kamath, C.; Rubenchik, A.M. Observation of keyhole-mode laser melting in laser powder-bed fusion additive manufacturing. J. Mater. Process. Technol. 2014, 214, 2915–2925. [Google Scholar] [CrossRef]

- Liang, J.W.; Lei, Z.L.; Chen, Y.B.; Wu, S.B.; Chen, X.; Jiang, M.; Cao, S.Y. Manufacturability, microstructure, and thermal crack characteristics of selective laser melting of ZK60 magnesium alloy. Mat. Sci. Eng. A 2022, 839, 142858. [Google Scholar] [CrossRef]

- Ardi, D.T.; Guowei, L.; Maharjan, N. Effects of post-processing route on fatigue permanufacturance of laser powder bed fusion Inconel 718. Addit. Manuf. 2020, 36, 101442. [Google Scholar]

- Sanjari, M.; Hadadzadeh, A.; Pirgazi, H. Selective laser melted stainless steel CX: Role of built orientation on microstructure and micro-mechanical properties. Mater. Sci. Eng. A 2020, 786, 139365. [Google Scholar] [CrossRef]

- Kamaya, M. A Smoothing Filter for Misorientation Mapping Obtained by EBSD. Mater. Trans. 2010, 51, 1516–1520. [Google Scholar] [CrossRef]

- Qi, Y.; Zhang, H.; Nie, X. A high strength Al–Li alloy produced by laser powder bed fusion: Densification, microstructure, and mechanical properties. Addit. Manuf. 2020, 35, 101346. [Google Scholar] [CrossRef]

- Li, R.; Wang, M.; Yuan, T. Selective laser melting of a novel Sc and Zr modified Al-6.2Mg alloy: Processing, microstructure, and properties. Powder. Technol. 2017, 319, 117–128. [Google Scholar] [CrossRef]

- Spierings, B.A.; Dawson, K.; Voegtlin, M. Microstructure and mechanical properties of as-processed scandium-modified aluminium using selective laser melting. CIRP Ann. 2016, 65, 213–216. [Google Scholar] [CrossRef]

- Liu, Y.; Liu, Z.; Jiang, Y. Gradient in microstructure and mechanical property of selective laser melted AlSi10Mg. J. Alloys Compd. 2018, 735, 1414–1421. [Google Scholar] [CrossRef]

- Xiao, Z.X.; Chen, C.P.; Zhu, H.L. Study of residual stress in selective laser melting of Ti6Al4V. Mater. Des. 2020, 193, 108846. [Google Scholar] [CrossRef]

- Fang, Z.C.; Wu, Z.L.; Huang, C.G. Review on residual stress in selective laser melting additive manufacturing of alloy parts. Opt. Laser Technol. 2020, 129, 106283. [Google Scholar] [CrossRef]

- Yakout, M.; Elbestawi, M.; Veldhuis, C.S. A study of the relationship between thermal expansion and residual stresses in selective laser melting of Ti-6Al-4V. J. Manuf. Process. 2020, 52, 181–192. [Google Scholar] [CrossRef]

- Sun, Y.M. A Study on High Permanufacturance Aluminum-Lithium Casting Alloy; Shenyang Aerospace University: Shenyang, China, 2018. [Google Scholar]

| Li | Fe | Si | Al |

|---|---|---|---|

| 3.20 | 0.08 | 0.02 | Bal. |

| Process Parameter | Value |

|---|---|

| Laser power | 120, 140, 160, 180 W |

| Scanning speed | 1000 mm/s |

| Layer thickness | 30 μm |

| Hatching space (block specimen) | 80 μm |

| Laser Power (W) | 120 | 140 | 160 | 180 |

|---|---|---|---|---|

| Volumetric energy density (J/mm3) | 50.00 | 58.33 | 66.67 | 75.00 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ji, H.; Lin, K.; Gao, Y.; Wei, S.; Shi, C. Influence of Laser Power on Crack Evolution During Selective Laser Melting Manufacturing Process of Aluminum–Lithium Alloys. Coatings 2025, 15, 1212. https://doi.org/10.3390/coatings15101212

Ji H, Lin K, Gao Y, Wei S, Shi C. Influence of Laser Power on Crack Evolution During Selective Laser Melting Manufacturing Process of Aluminum–Lithium Alloys. Coatings. 2025; 15(10):1212. https://doi.org/10.3390/coatings15101212

Chicago/Turabian StyleJi, Haibin, Ke Lin, Yingjie Gao, Shuai Wei, and Caiyun Shi. 2025. "Influence of Laser Power on Crack Evolution During Selective Laser Melting Manufacturing Process of Aluminum–Lithium Alloys" Coatings 15, no. 10: 1212. https://doi.org/10.3390/coatings15101212

APA StyleJi, H., Lin, K., Gao, Y., Wei, S., & Shi, C. (2025). Influence of Laser Power on Crack Evolution During Selective Laser Melting Manufacturing Process of Aluminum–Lithium Alloys. Coatings, 15(10), 1212. https://doi.org/10.3390/coatings15101212