A Review of the Developments in Capacity-Uprating Conductors for Overhead Transmission Lines

Abstract

1. Introduction

2. Calculation of Ampacity for Transmission Lines

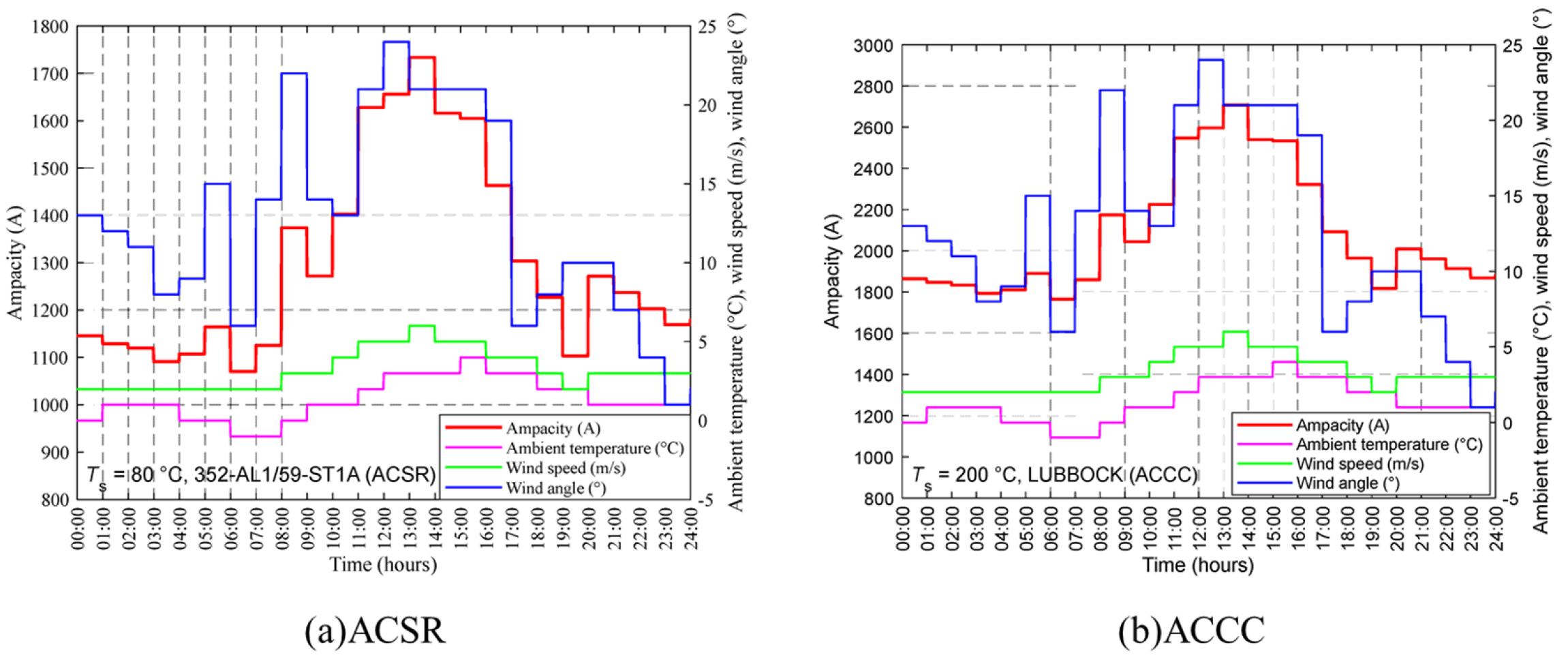

2.1. Dynamic Thermal Ratings for Transmission Lines

- (1)

- Sensor accuracy and computational model reliability, monitoring errors in environmental parameters (e.g., temperature, wind speed) may lead to ampacity calculation deviations. Meanwhile, the accuracy of computational models fundamentally determines the technology’s effectiveness and operational safety [24,25,26].

- (2)

- (3)

- (4)

- Variations in cooling conditions along the line result in the maximum current-carrying capacity being limited by the segment with the most unfavorable cooling performance. The inability to achieve full-segment monitoring poses a significant constraint for long-distance transmission lines [22,30,31].

2.2. Calculation of Steady-State Ampacity for Transmission Lines

3. Development Status of Capacity-Uprating Conductor

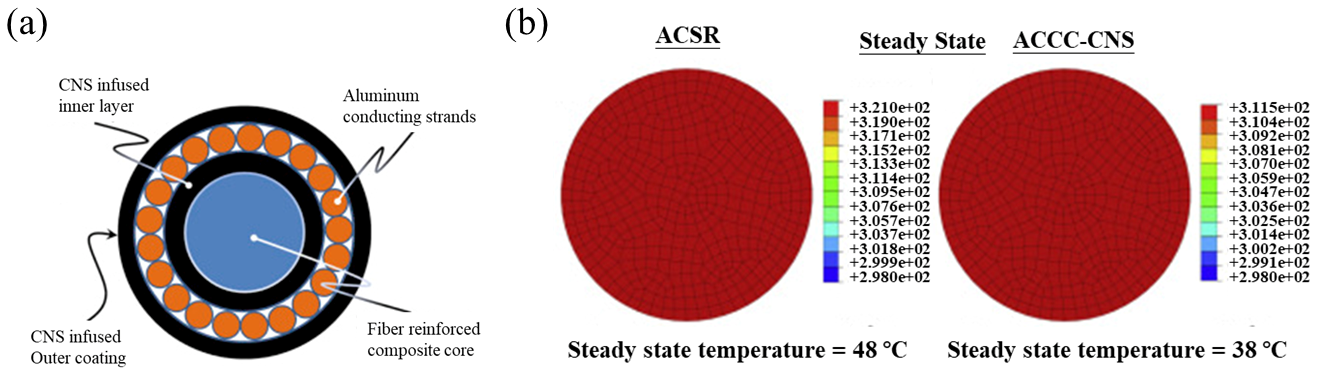

3.1. Rational Material Selection for Conductors

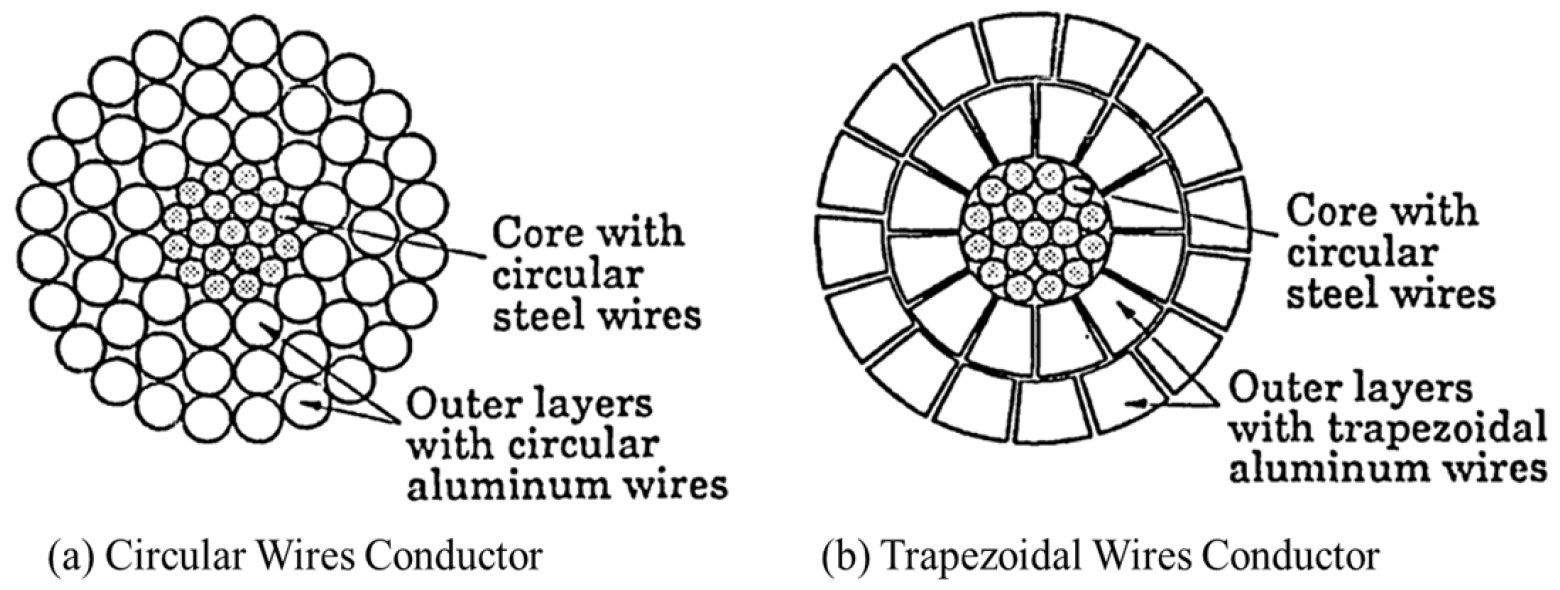

3.2. Conductor Structural Optimization

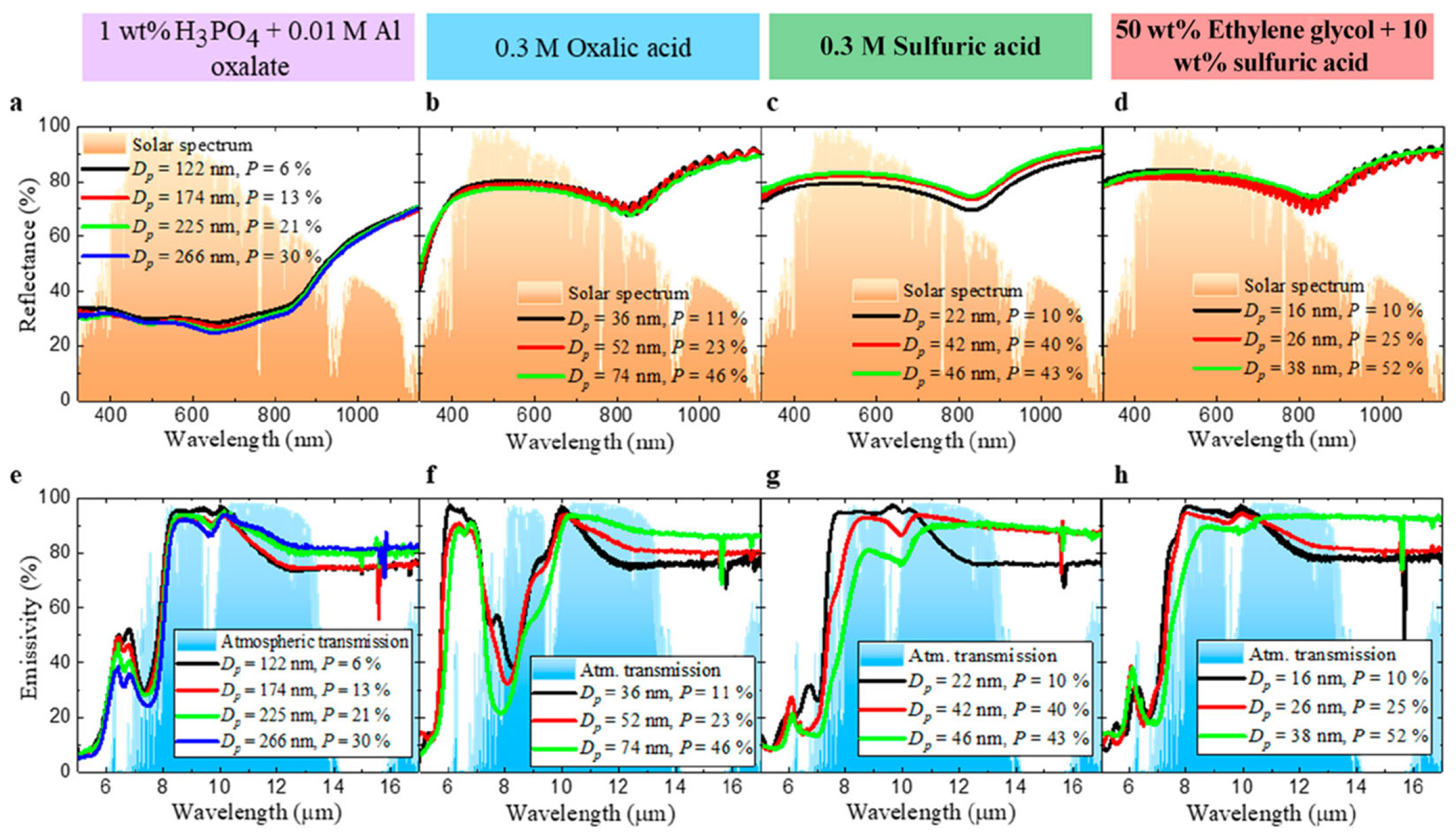

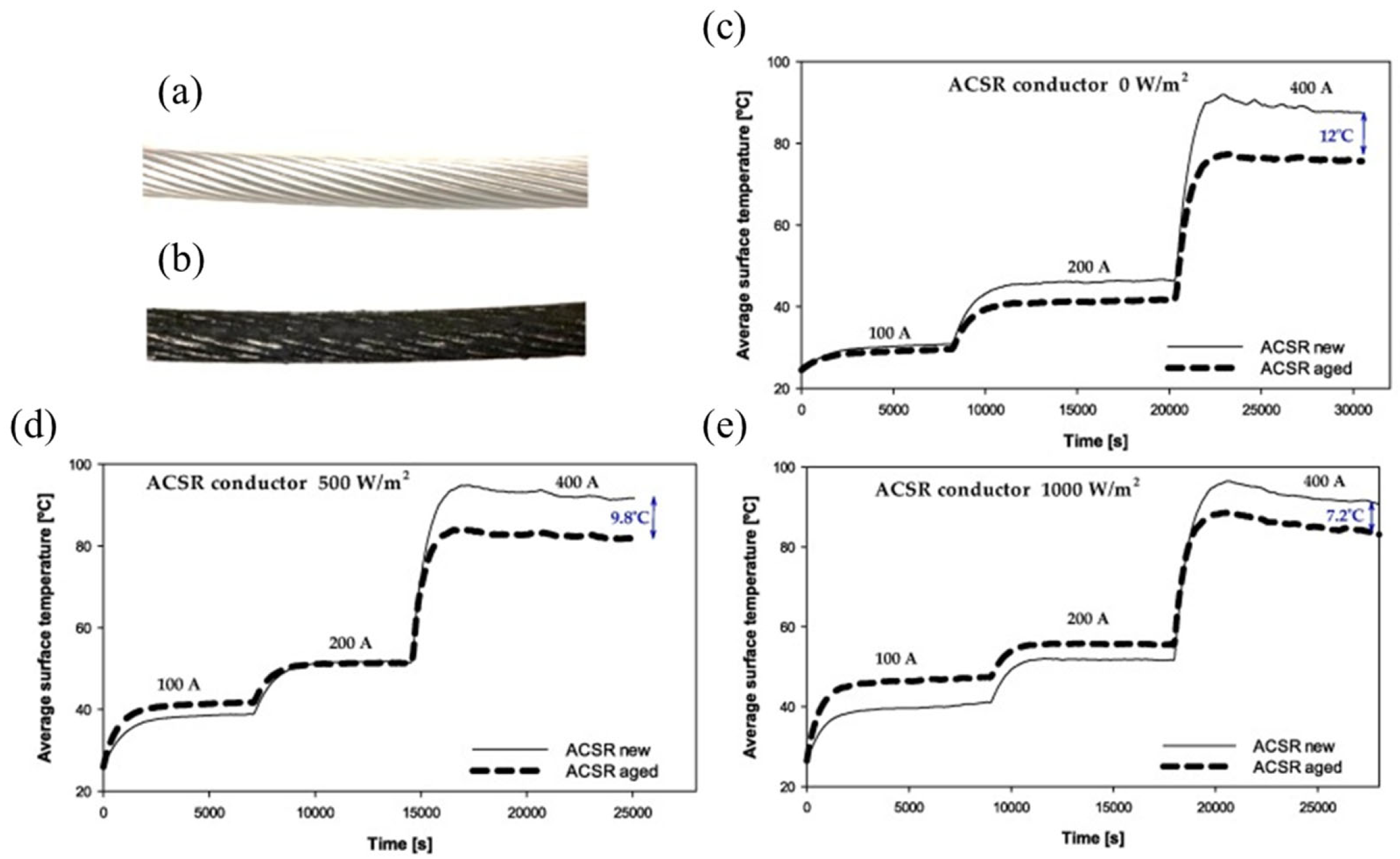

3.3. Radiative Cooling Coatings

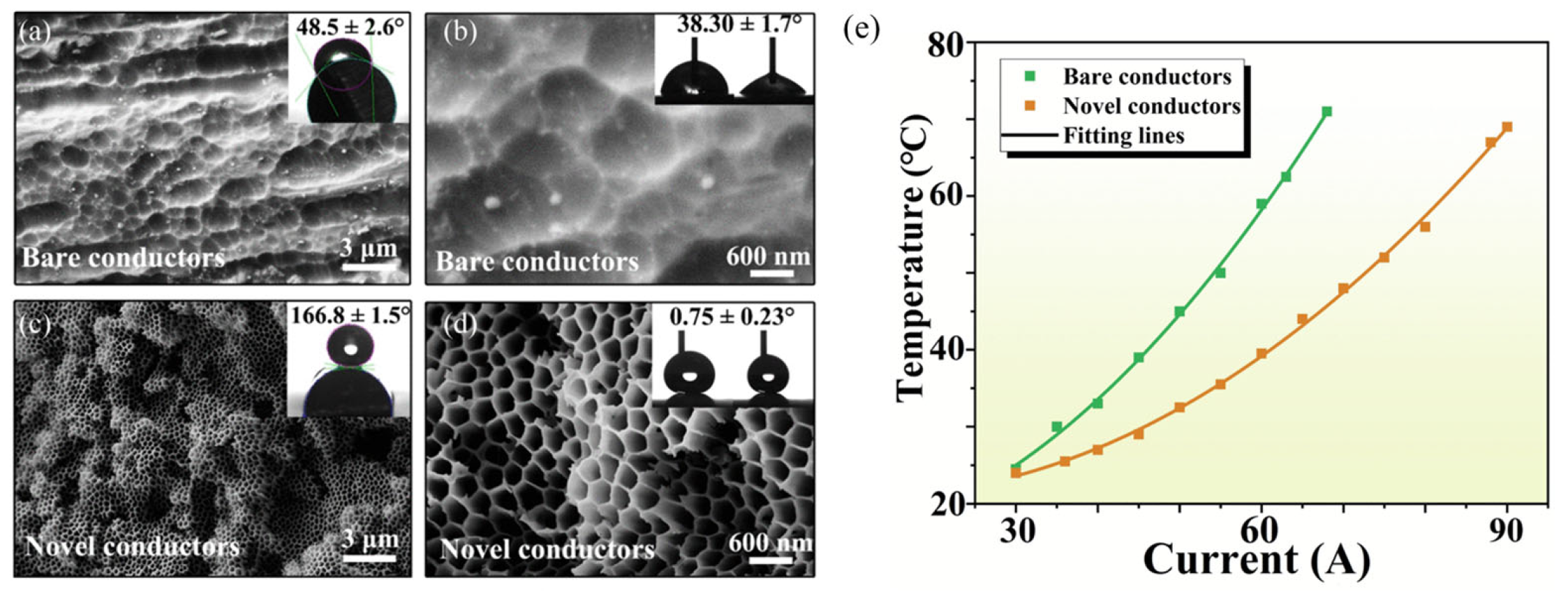

3.4. Surface Modification Technology

4. Evaluation of Application Potential for Capacity-Uprating Conductors

4.1. Potential Application Scenarios of Different Technologies

4.2. Application Potential for HTLS Conductors

5. Future Work of Capacity-Uprating Conductor

5.1. HTLS Conductor

5.2. Radiative Cooling Technology

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Parvizi, P.; Jalilian, M.; Dearn, K.D. Beyond traditional conductors: Aluminium conductor composite core’s role in next-generation high temperature-low sag technologies–A review. Electr. Power Syst. Res. 2025, 239, 111251. [Google Scholar] [CrossRef]

- Ujah, C.O.; Kallon, D.V.V.; Aikhuele, D.O.; Aigbodion, V.S. Advanced composite materials: A panacea for improved electricity transmission. Appl. Sci. 2022, 12, 8291. [Google Scholar] [CrossRef]

- Karimi, S.; Musilek, P.; Knight, A.M. Dynamic thermal rating of transmission lines: A review. Renew. Sustain. Energy Rev. 2018, 91, 600–612. [Google Scholar] [CrossRef]

- Sergio, M.-S.; Andrea, M. Assessment of the influence of climate change on power grid transmission capacity. Sustain. Energy Grids Netw. 2025, 42, 101695. [Google Scholar] [CrossRef]

- Shu, Y.; Chen, W. Research and application of UHV power transmission in China. High Volt. 2018, 3, 1–13. [Google Scholar] [CrossRef]

- Sun, Y.; Wang, X.L. Extreme weather loading risk model of overhead transmission line. Adv. Mater. Res. 2012, 383, 2005–2011. [Google Scholar] [CrossRef]

- Sahin, B.; Hasenbein, J.; Kutanoglu, E. Value of considering extreme weather resilience in grid capacity expansion planning. Reliab. Eng. Syst. Saf. 2025, 259, 110892. [Google Scholar] [CrossRef]

- Kgoete, F.M.; Uyor, U.O.; Popoola, A.P.; Popoola, O. Insight on the recent materials advances for manufacturing of high-voltage transmission conductors. Int. J. Adv. Manuf. Technol. 2024, 130, 4123–4136. [Google Scholar] [CrossRef]

- Reddy, B.S.; Mitra, G. Investigations on High Temperature Low Sag (HTLS) Conductors. IEEE Trans. Power Deliv. 2020, 35, 1716–1724. [Google Scholar] [CrossRef]

- Shokri, M.S.M.; Kasran, F.A.M.; Aziz, M.H.A.; Miswan, N.S.; Noran, M.N.; Rahim, A.A. Dynamic line rating (DLR) by weather-based calculation for power grid optimization in Tenaga Nasional Berhad (TNB). In Proceedings of the 2020 IEEE 17th International Conference on Smart Communities: Improving Quality of Life Using ICT, IoT and AI (HONET), Charlotte, NC, USA, 14–16 December 2020; IEEE: New York, NY, USA. [Google Scholar]

- Xia, Z.; Xia, Y.; Xu, Z.; Wu, J. Study on the calculation model of maximum allowable time and ampacity for overload operation of overhead transmission line in a short time. In Proceedings of the 2015 5th International Conference on Electric Utility Deregulation and Restructuring and Power Technologies (DRPT), Changsha, China, 26–29 November 2015; IEEE: New York, NY, USA. [Google Scholar]

- Xing, L.; Weidong, L.; Yuan, X.; Weijiang, C.; Jiangang, B. Surface charge accumulation and pre-flashover characteristics induced by metal particles on the insulator surfaces of 1100 kV GILs under AC voltage. High Volt. 2020, 5, 134–142. [Google Scholar] [CrossRef]

- Ou, Y.; Singh, C. Improvement of total transfer capability using TCSC and SVC. In Proceedings of the 2001 Power Engineering Society Summer Meeting. Conference Proceedings (Cat. No. 01CH37262), Vancouver, BC, Canada, 15–19 July 2001; IEEE: New York, NY, USA. [Google Scholar]

- Taha, R.; Saoudi, Y.; Chrifi-Alaoui, L.; Errachdi, A. Performance enhancement of smart grid using an optimal placement of facts: Case of TCSC. Przegląd Elektrotechniczny 2024, 1, 281–287. [Google Scholar]

- Li, Q.; Li, Y.; Rowland, S.; Hu, J.; Cotton, I.; Jiang, X. Audible noise evaluation for six-phase overhead lines transformed from existing three-phase double circuit infrastructures with uprated voltages. High Volt. 2022, 7, 866–876. [Google Scholar] [CrossRef]

- Zhang, D.G.; Wang, L.H.; Liu, J.; Ren, Y.N.; Gao, F.; Shen, X.L. Research on general design and application of double-circuit t-connection tower in 110kv. J. Phys. Conf. Ser. 2020, 1634, 012169. [Google Scholar] [CrossRef]

- Riba, J.-R.; Bogarra, S.; Gómez-Pau, Á.; Moreno-Eguilaz, M. Uprating of transmission lines by means of HTLS conductors for a sustainable growth: Challenges, opportunities, and research needs. Renew. Sustain. Energy Rev. 2020, 134, 110334. [Google Scholar] [CrossRef]

- Chen, S.L.; Black, W.Z.; Loard, H.W. High-temperature ampacity model for overhead conductors. IEEE Trans. Power Deliv. 2002, 17, 1136–1141. [Google Scholar] [CrossRef]

- Davis, M.W. A new thermal rating approach: The real time thermal rating system for strategic overhead conductor transmission lines—Part I: General description and justification of the real time thermal rating system. IEEE Trans. Power Appar. Syst. 1977, 96, 803–809. [Google Scholar] [CrossRef]

- Steeley, W.; Norris, B.; Deb, A. Ambient temperature corrected dynamic transmission line ratings at two PG&E locations. IEEE Trans. Power Deliv. 2002, 6, 1234–1242. [Google Scholar]

- Swain, A.; Abdellatif, E.; Mousa, A.; Pong, P.W. Sensor technologies for transmission and distribution systems: A review of the latest developments. Energies 2022, 15, 7339. [Google Scholar] [CrossRef]

- Li, J.; Lin, J.; Han, Y.; Zhu, L.; Chang, D.; Shao, C. Overload Risk Assessment of Transmission Lines Considering Dynamic Line Rating. Energies 2025, 18, 1822. [Google Scholar] [CrossRef]

- Adapa, R.; Douglass, D.A. Dynamic thermal ratings: Monitors and calculation methods. In Proceedings of the 2005 IEEE Power Engineering Society Inaugural Conference and Exposition in Africa, Durban, South Africa, 11–15 July 2005; IEEE: New York, NY, USA. [Google Scholar]

- Wang, S.; Hu, H.; Li, L.; Wang, Y.; Ning, N. Dynamic Capacity Increasing Method For Transmission Lines. In Proceedings of the 2023 IEEE World Conference on Applied Intelligence and Computing (AIC), Sonbhadra, India, 29–30 July 2023; IEEE: New York, NY, USA. [Google Scholar]

- Dabbaghjamanesh, M.; Kavousi-Fard, A.; Mehraeen, S. Effective Scheduling of Reconfigurable Microgrids With Dynamic Thermal Line Rating. IEEE Trans. Ind. Electron. 2019, 66, 1552–1564. [Google Scholar] [CrossRef]

- Rácz, L.; Németh, B. A Novel Concept of Dynamic Line Rating Systems Based on Soft Computing Models. In Proceedings of the 2022 10th International Conference on Smart Grid (icSmartGrid), Istanbul, Turkey, 27–29 June 2022; IEEE: New York, NY, USA. [Google Scholar]

- Dupin, R.; Kariniotakis, G.; Michiorri, A. Overhead lines Dynamic Line rating based on probabilistic day-ahead forecasting and risk assessment. Int. J. Electr. Power Energy Syst. 2019, 110, 565–578. [Google Scholar] [CrossRef]

- Albizu, I.; Fernández, E.; Mazón, A.J.; Bengoechea, J. Influence of the conductor temperature error on the overhead line ampacity monitoring systems. IET Gener. Transm. Distrib. 2011, 5, 440–447. [Google Scholar] [CrossRef]

- Michiorri, A.; Nguyen, H.-M.; Alessandrini, S.; Bremnes, J.B.; Dierer, S.; Ferrero, E.; Nygaard, B.-E.; Pinson, P.; Thomaidis, N.; Uski, S. Forecasting for dynamic line rating. Renew. Sustain. Energy Rev. 2015, 52, 1713–1730. [Google Scholar] [CrossRef]

- Hou, Y.; Wang, W.; Wei, Z.; Deng, X.; Ji, Q.; Wang, T.; Ru, X. Research and application of dynamic line rating technology. Energy Rep. 2020, 6, 716–730. [Google Scholar] [CrossRef]

- Zainuddin, N.M.; Rahman, M.S.A.; Kadir, M.Z.A.A.; Ali, N.H.N.; Ali, Z.; Osman, M.; Mansor, M.; Ariffin, A.M.; Rahman, M.S.A.; Nor, S.F.M.; et al. Review of Thermal Stress and Condition Monitoring Technologies for Overhead Transmission Lines: Issues and Challenges. IEEE Access 2020, 8, 120053–120081. [Google Scholar] [CrossRef]

- Nuchprayoon, S.; Chaichana, A. Performance Comparison of Using ACSR and HTLS Conductors for Current Uprating of 230-kV Overhead Transmission Lines. In Proceedings of the 2018 IEEE International Conference on Environment and Electrical Engineering and 2018 IEEE Industrial and Commercial Power Systems Europe (EEEIC/I&CPS Europe), Palermo, Italy, 12–15 June 2018; IEEE: New York, NY, USA. [Google Scholar]

- Kumar, P.; Singh, A.K. Optimal mechanical sag estimator for leveled span overhead transmission line conductor. Measurement 2019, 137, 691–699. [Google Scholar] [CrossRef]

- Qiao, X.; Zhu, Z.; Zhang, D.; Zhang, J.; Cheng, Y.; Wang, Y.; Zeng, W. Research on Dynamic Current Carrying Capacity Calculation Model Based on Conductor Sag Correction. IEEE Trans. Power Deliv. 2025, 40, 1656–1666. [Google Scholar] [CrossRef]

- Abboud, A.W.; Gentle, J.P.; McJunkin, T.R.; Lehmer, J.P. Using Computational Fluid Dynamics of Wind Simulations Coupled With Weather Data to Calculate Dynamic Line Ratings. IEEE Trans. Power Deliv. 2020, 35, 745–753. [Google Scholar] [CrossRef]

- Castro, P.; Lecuna, R.; Manana, M.; Martin, M.J.; del Campo, D. Infrared temperature measurement sensors of overhead power conductors. Sensors 2020, 20, 7126. [Google Scholar] [CrossRef]

- Kampik, M.; Kubek, P.; Krupanek, B.; Bogacz, R. Sag and Tension Calculations for High-Voltage Overhead Line Conductors. Energies 2024, 17, 2967. [Google Scholar] [CrossRef]

- Rashmi; Shivashankar, G.S.; Poornima. Overview of different overhead transmission line conductors. Mater. Today Proc. 2017, 4, 11318–11324. [Google Scholar] [CrossRef]

- Abas, N.H.; Kadir, M.Z.A.A.; Azis, N.; Jasnil, J.; Aziz, N.F.A.; Khurshid, Z.M. Optimizing Grid With Dynamic Line Rating of Conductors: A Comprehensive Review. IEEE Access 2024, 12, 9738–9756. [Google Scholar] [CrossRef]

- Maksić, M.; Djurica, V.; Souvent, A.; Slak, J.; Depolli, M.; Kosec, G. Cooling of overhead power lines due to the natural convection. Int. J. Electr. Power Energy Syst. 2019, 113, 333–343. [Google Scholar] [CrossRef]

- Dzobo, O.; Tazvinga, H. Impact of Weather Conditions on Line Ampacity of Overhead Transmission Lines. In Proceedings of the 2019 9th International Conference on Power and Energy Systems (ICPES), Perth, WA, Australia, 10–12 December 2019; IEEE: New York, NY, USA. [Google Scholar]

- Vejo Fernández, L.; Castro, P.B.A.; Canteli, M.M.; Pérez, A.L.; Tolosa, R.L.; Sánchez, S.B.; Ortiz, E.S. Experimental study of dynamic line rating applied to high-temperature low-sag conductors. Energies 2025, 18, 929. [Google Scholar] [CrossRef]

- Jalilian, M.; Riba, J.-R.; Parvizi, P. Aluminum conductor steel-supported conductors for the sustainable growth of power line capacity: A review and discussion. Materials 2024, 17, 4536. [Google Scholar] [CrossRef] [PubMed]

- Ujah, C.O.; Popoola, A.P.I.; Popoola, O.M. Review on materials applied in electric transmission conductors. J. Mater. Sci. 2022, 57, 1581–1598. [Google Scholar] [CrossRef]

- Hu, X.; Wang, C.; Ma, G.; He, K. Effect of Er on Microstructure, Electrical Conductivity, Mechanical Properties, and Corrosion Resistance of an Al-Zr Alloy. J. Mater. Eng. Perform. 2025, 34, 6026–6034. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, H.; Yi, D.; Wang, B.; Wang, H. Comparative study of Sc and Er addition on microstructure, mechanical properties, and electrical conductivity of Al-0.2Zr-based alloy cables. Mater. Charact. 2018, 145, 126–134. [Google Scholar] [CrossRef]

- Zhang, Y.-Z.; Jun, W. Effects of Y addition on microstructure and properties of Al-Zr alloys. Trans. Nonferrous Met. Soc. China 2014, 24, 2239–2243. [Google Scholar] [CrossRef]

- Kong, Y.; Jia, Z.; Liu, Z.; Liu, M.; Roven, H.J.; Liu, Q. Effect of Zr and Er on the microstructure, mechanical and electrical properties of Al-0.4Fe alloy. J. Alloy. Compd. 2021, 857, 157611. [Google Scholar] [CrossRef]

- Choi, Y.; Hong, S.I. Mechanical and Electrical Properties of Al–Fe–Cr and Al–Fe–Zr Alloys. Sci. Adv. Mater. 2018, 10, 480–483. [Google Scholar] [CrossRef]

- Li, S.; Jiang, H.; Li, Y.; Zhang, L.; Sun, H.; He, J.; Jiang, H.; Zhao, J. Influence of rare earth cerium on the microstructures and performances of Al-Fe alloy. Sci. China Technol. Sci. 2023, 66, 3317–3327. [Google Scholar] [CrossRef]

- Xu, H.-Y.; Jia, H.-F.; Ji, Z.-S.; Li, M.-L.; Yu, H.; Jiang, B.; Wang, Y.; Hu, M.-L. Effect of La content on microstructure, tensile properties, and electrical conductivity of cast Al-Mg-Si-xLa alloys. China Foundry 2025, 22, 385–394. [Google Scholar] [CrossRef]

- Yuan, W.; Liang, Z. Effect of Zr addition on properties of Al–Mg–Si aluminum alloy used for all aluminum alloy conductor. Mater. Des. 2011, 32, 4195–4200. [Google Scholar] [CrossRef]

- Shao, Q.; Elgallad, E.; Maltais, A.; Chen, X.G. Developing Al-Zr-Sc Alloys as High-Temperature-Resistant Conductors for Electric Overhead Line Applications. In Light Metals 2023; Springer Nature: Cham, Switzerland, 2023. [Google Scholar]

- Alvarez-Antolin, F.; Amghouz, Z.; Cofiño-Villar, A.; Gonzalez-Pociño, A.; Melero, M.G. Decrease in Electrical Resistivity below 28 nΩm by Aging in Hyperperitectic Al-Zr Alloys Treated at High Temperatures. Metals 2021, 11, 1171. [Google Scholar] [CrossRef]

- Zhang, J.; Peng, J. A review on aluminum alloy conductors influenced by alloying elements and thermomechanical treatments: Microstructure and properties. J. Mater. Res. 2023, 38, 1488–1509. [Google Scholar] [CrossRef]

- Mohtar, S.N.; Jamal, N.; Sulaiman, M. Analysis of all aluminum conductor (AAC) and all aluminum alloy conductor (AAAC). In Proceedings of the 2004 IEEE Region 10 Conference TENCON 2004, Chiang Mai, Thailand, 24 November 2004; IEEE: New York, NY, USA. [Google Scholar]

- Ujah, C.O.; Popoola, A.P.I.; Popoola, O.M.; Aigbodion, V.S. Electrical conductivity, mechanical strength and corrosion characteristics of spark plasma sintered Al-Nb nanocomposite. Int. J. Adv. Manuf. Technol. 2019, 101, 2275–2282. [Google Scholar] [CrossRef]

- Berjozkina, S.; Sauhats, A.; Bargels, V.; Vanzovichs, E. The technical and economic efficiency of using conductors with composite core in the transmission grid. In Proceedings of the 2012 9th International Conference on the European Energy Market, Florence, Italy, NY, USA, 10–12 May 2012; IEEE: New York, NY, USA. [Google Scholar]

- Deve, H.; Anderson, T. 3M Aluminum Conductor Composite Reinforced Technical Notebook (795 kcmil Family): Conductor and Accessory Testing; 3M: Maplewood, MN, USA, 2003. [Google Scholar]

- Lucas, J.R.; Munasinghe, N. A Consequence of Failure of Mid Span Compression Joint on the Kelanitissa-Kolonnawa Line. Eng. J. Inst. Eng. Sri Lanka 2023, 56, 93–97. [Google Scholar] [CrossRef]

- Parvizi, P.; Jalilian, M.; Dearn, K.D. Evaluating the mechanical and thermal performance of high-temperature low sag (HTLS) conductors: A comparative study of ACCC, ACSS, and ACSR conductors. Results Eng. 2025, 26, 104735. [Google Scholar] [CrossRef]

- Beryozkina, S. Evaluation Study of Potential Use of Advanced Conductors in Transmission Line Projects. Energies 2019, 12, 822. [Google Scholar] [CrossRef]

- Parvizi, P.; Amidi, A.M.; Jalilian, M.; Zangeneh, M.R.; Parvizi, H. High Temperature Low Sag Conductors: A Brief Review on Strategies Used To Prevent Destruction, and Maintenance Considerations. Trans. Indian Natl. Acad. Eng. 2025, 10, 271–292. [Google Scholar] [CrossRef]

- Parvizi, P.; Jalilian, M.; Mirazizi, P.S.; Zangeneh, M.R.; Amidi, A.M. Mechanical and physical properties of aluminum and its alloys for electrical conductors: A review. Next Mater. 2025, 9, 101090. [Google Scholar] [CrossRef]

- Reddy, B.S.; Chatterjee, D. Performance evaluation of high temperature high current conductors. IEEE Trans. Dielectr. Electr. Insul. 2016, 23, 1570–1579. [Google Scholar] [CrossRef]

- Kwon, J.; Hedman, K.W. Transmission expansion planning model considering conductor thermal dynamics and high temperature low sag conductors. IET Gener. Transm. Distrib. 2015, 9, 2311–2318. [Google Scholar] [CrossRef]

- Reddy, B.S.; Chatterjee, D. Analysis of High Temperature Low Sag Conductors Used for High Voltage Transmission. Energy Procedia 2016, 90, 179–184. [Google Scholar] [CrossRef]

- Hill, T.; Bryant, D. Experience and benefits of using high temperature low sag (HTLS) overhead conductors. In Proceedings of the 24th AMEU Technical Convention, Buffalo City, NY, USA, 6–9 October 2013. [Google Scholar]

- Rahman, S.A.; Kopsidas, K. Modelling of convective cooling on conductor thermal rating methods. In Proceedings of the 2017 IEEE Manchester PowerTech, Manchester, UK, 18–22 June 2017; IEEE: New York, NY, USA. [Google Scholar]

- Thrash, F. ACSS/TW-An improved high temperature conductor for upgrading existing lines or new construction. In Proceedings of the 2001 Power Engineering Society Summer Meeting. Conference Proceedings (Cat. No. 01CH37262), Vancouver, BC, Canada, 15–19 July 2001; IEEE: New York, NY, USA. [Google Scholar]

- Sharma, A.; Gumaste, A.; Agrawal, P.; Thapliyal, S.; Gupta, S.; Haridas, R.S.; McWilliams, B.A.; Cho, K.C.; Mishra, R.S. Strength-conductivity synergy via lean alloy design: A study on novel solid stir extrusion of an Al-2Cu-0.1 Nb-0.15Zr (∼wt.%) alloy. J. Alloys Compd. 2024, 976, 173082. [Google Scholar] [CrossRef]

- Ujah, C.O.; Popoola, P.; Popoola, O.; Aigbodion, V. Modification of Al alloy nanopowder with Nb nanopowder on its thermal and tribological properties with SPS for power conductors. Mater. Res. Express 2019, 6, 116592. [Google Scholar] [CrossRef]

- Malobi, U.I.; Ezema, I.I.-E.C.; Ujah, C.O. Investigation of the microstructure, electrical and mechanical properties of Al-CNTs-B4C composite prepared by double-step stir casting for power transmission conductor. Mater. Res. Express 2024, 11, 115602. [Google Scholar] [CrossRef]

- Cai, S.L.; Wu, S.; Ding, G.; Liu, Y.; Gu, J.; Dai, L.H.; Jiang, M.Q. Improving Comprehensive Properties of Aluminum Conductor via Hierarchical Compositions and Microstructures. Acta Mech. Solida Sin. 2025, 38, 884–896. [Google Scholar] [CrossRef]

- Ujah, C.O.; Popoola, P.; Popoola, O.; Aigbodion, V.; Oladijo, P. Improving tribological and thermal properties of Al alloy using CNTs and Nb nanopowder via SPS for power transmission conductor. Trans. Nonferrous Met. Soc. China 2020, 30, 333–343. [Google Scholar] [CrossRef]

- Foss, S.D.; Lin, S.H.; Carberry, R. Significance of the Conductor Radial Temperature Gradient within a Dynamic Line Rating Methodology. IEEE Trans. Power Deliv. 1987, 2, 502–511. [Google Scholar] [CrossRef]

- Lin, S.H. Heat transfer in an overhead electrical conductor. Int. J. Heat Mass Transf. 1992, 35, 795–801. [Google Scholar] [CrossRef]

- Xiao, K.; Liu, Y.; Zhou, H.; Li, W.; Li, P. Accurate Simulations of Thermal Field of Operational Conductors. IOP Conf. Ser. Mater. Sci. Eng. 2017, 231, 012100. [Google Scholar] [CrossRef]

- Riba, J.-R. Radial thermoelectric model for stranded transmission line conductors. Sensors 2023, 23, 9205. [Google Scholar] [CrossRef]

- Alvarez, J.R.; Franck, C.M. Radial Thermal Conductivity of all-Aluminum Alloy Conductors. IEEE Trans. Power Deliv. 2015, 30, 1983–1990. [Google Scholar] [CrossRef]

- Abatabai, M.; Krishnasamy, S.; Meale, J.; Cooper, K. Response of smooth body, trapezoidal wire overhead (compact) conductors to wind loading. J. Wind. Eng. Ind. Aerodyn. 1992, 41, 825–834. [Google Scholar] [CrossRef]

- Ahsan, M.; Baharom, N.R.; Khalil, I.U.; Zainal, Z. Analysis of high-ampacity and low-sag conductors of 275 kV overhead transmission lines using reconductoring technique. Electr. Power Syst. Res. 2025, 246, 111719. [Google Scholar] [CrossRef]

- Alawar, A.; Bosze, E.; Nutt, S. A Composite Core Conductor for Low Sag at High Temperatures. IEEE Trans. Power Deliv. 2005, 20, 2193–2199. [Google Scholar] [CrossRef]

- Phillips, J.; Ryan, M.; Glass, D. Thinking outside the Box: Tennessee Valley Authority Uses the ACCR Conductor on a 500-kV Transmission Line. In Electrical Transmission and Substation Structures; ASCE: Reston, VA, USA, 2015; pp. 227–236. [Google Scholar]

- Du, Y.; Cao, W.; Zhang, X.H. Analysis of ACCC Applied in the Capacity Expansion Reformation of Electric Transmission Lines in East China Power Grid. Adv. Mater. Res. 2013, 614, 1866–1871. [Google Scholar] [CrossRef]

- Zhou, L.; Li, Z.; Ma, J.; Chen, R.; Wang, Q.; Pei, K.; Zhang, X.; Zhang, Y. Technical and Economic Analysis of ACCC Applied in UHV-DC Power Transmission Lines. In Proceedings of the 2019 4th International Conference on Intelligent Green Building and Smart Grid (IGBSG), Hubei, China, 6–9 September 2019; IEEE: New York, NY, USA. [Google Scholar]

- Asorza, J.E.G.; Colqui, J.S.L.; Filho, J.P. Comprehensive Electromechanical Analysis of High-Temperature Low-Sag (HTLS) Conductors. IEEE Access 2025, 13, 141536–141546. [Google Scholar] [CrossRef]

- Czerwinski, F. Aluminum alloys for electrical engineering: A review. J. Mater. Sci. 2024, 59, 14847–14892. [Google Scholar] [CrossRef]

- Riba, J.-R.; Liu, Y.; Moreno-Eguilaz, M. Analyzing the role of emissivity in stranded conductors for overhead power lines. Int. J. Electr. Power Energy Syst. 2024, 159, 110027. [Google Scholar] [CrossRef]

- Abboud, A.W.; Gentle, J.P.; Parikh, K.; Coffey, J. Sensitivity Effects of High Temperature Overhead Conductors to Line Rating Variables; Idaho National Lab(INL): Idaho Falls, ID, USA, 2020. [Google Scholar]

- Hsu, P.-C.; Song, A.Y.; Catrysse, P.B.; Liu, C.; Peng, Y.; Xie, J.; Fan, S.; Cui, Y. Radiative human body cooling by nanoporous polyethylene textile. Science 2016, 353, 1019–1023. [Google Scholar] [CrossRef]

- Li, T.; Zhai, Y.; He, S.; Gan, W.; Wei, Z.; Heidarinejad, M.; Dalgo, D.; Mi, R.; Zhao, X.; Song, J.; et al. A radiative cooling structural material. Science 2019, 364, 760–763. [Google Scholar] [CrossRef]

- Xue, X.; Qiu, M.; Li, Y.; Zhang, Q.M.; Li, S.; Yang, Z.; Feng, C.; Zhang, W.; Dai, J.; Lei, D.; et al. Creating an Eco-Friendly Building Coating with Smart Subambient Radiative Cooling. Adv. Mater. 2020, 32, e1906751. [Google Scholar] [CrossRef]

- Lin, K.; Chen, S.; Zeng, Y.; Ho, T.C.; Zhu, Y.; Wang, X.; Liu, F.; Huang, B.; Chao, C.Y.-H.; Wang, Z.; et al. Hierarchically structured passive radiative cooling ceramic with high solar reflectivity. Science 2023, 382, 691–697. [Google Scholar] [CrossRef]

- Song, J.; Zhang, W.; Sun, Z.; Pan, M.; Tian, F.; Li, X.; Ye, M.; Deng, X. Durable radiative cooling against environmental aging. Nat. Commun. 2022, 13, 4805. [Google Scholar] [CrossRef]

- Zhao, B.; Xu, C.; Jin, C.; Lu, K.; Chen, K.; Li, X.; Li, L.; Pei, G. Superhydrophobic bilayer coating for passive daytime radiative cooling. Nanophotonics 2023, 13, 583–591. [Google Scholar] [CrossRef]

- Khosla, R.; Miranda, N.D.; Trotter, P.A.; Mazzone, A.; Renaldi, R.; McElroy, C.; Cohen, F.; Jani, A.; Perera-Salazar, R.; McCulloch, M. Cooling for sustainable development. Nat. Sustain. 2021, 4, 201–208. [Google Scholar] [CrossRef]

- Tang, C.; He, H.; Wu, E.; Li, H.; Hu, Y.; Liu, C.; Wang, X.; Zhuang, X. Radiative cooling PVDF aerogels with hierarchical porous structure for building energy savings. Colloids Surf. A Physicochem. Eng. Asp. 2025, 723, 137402. [Google Scholar] [CrossRef]

- Yang, Z.; Yang, Z.; Zhang, Z.; Wang, X.; Chen, Z.; Li, Y.; Cai, Y.; Zhang, H.; Liu, L.; Zhang, W.; et al. Daytime radiative cooling coating for cooling energy efficiency of conventional air conditioners. Appl. Therm. Eng. 2024, 261, 125060. [Google Scholar] [CrossRef]

- Marchini, F.; Bondi, R.; Duri, A.; Fabiani, C.; Latterini, L.; Pisello, A.L. Coupling vanadium oxide and lead-free perovskite for sustainable passive daytime radiative cooling. Renew. Energy 2025, 256, 123755. [Google Scholar] [CrossRef]

- Xie, A.-Q.; Qiu, H.; Jiang, W.; Wang, Y.; Niu, S.; Zhang, K.-Q.; Ho, G.W.; Wang, X.-Q. Recent Advances in Spectrally Selective Daytime Radiative Cooling Materials. Nano-Micro Lett. 2025, 17, 264. [Google Scholar] [CrossRef] [PubMed]

- Jeon, S.K.; Kim, J.T.; Kim, M.S.; Kim, I.S.; Park, S.J.; Jeong, H.; Lee, G.J.; Kim, Y.J. Scalable, Patternable Glass-Infiltrated Ceramic Radiative Coolers for Energy-Saving Architectural Applications. Adv. Sci. 2023, 10, e2302701. [Google Scholar] [CrossRef] [PubMed]

- Kumar, S.; Pal, G.; Shah, T. High performance overhead power lines with carbon nanostructures for transmission and distribution of electricity from renewable sources. J. Clean. Prod. 2017, 145, 180–187. [Google Scholar] [CrossRef]

- Lee, H.; Kim, Y.S.; Cho, H.J.; Oh, S.; Shim, J.; Nam, Y.; Sohn, S.H.; Jung, Y.C.; Han, S.C.; Lee, S.Y. Evaluation of Icephobic and Dissipation Performance on Coating Materials for Preventing Overhead Transmission Line from Ice/Snow Damages. Polymer 2020, 44, 342–348. [Google Scholar]

- Lee, J.; Kim, D.; Choi, C.-H.; Chung, W. Nanoporous anodic alumina oxide layer and its sealing for the enhancement of radiative heat dissipation of aluminum alloy. Nano Energy 2017, 31, 504–513. [Google Scholar] [CrossRef]

- Fu, Y.; Yang, J.; Su, Y.; Du, W.; Ma, Y. Daytime passive radiative cooler using porous alumina. Sol. Energy Mater. Sol. Cells 2019, 191, 50–54. [Google Scholar] [CrossRef]

- Díaz-Lobo, A.; Martin-Gonzalez, M.; Morales-Sabio, Á.; Manzano, C.V. Suitability of Anodic Porous Alumina as a Passive Radiative Cooler: An In-Depth Study. ACS Appl. Opt. Mater. 2023, 2, 980–990. [Google Scholar] [CrossRef] [PubMed]

- Dai, X.; Yuan, Y.; Liao, R.; Liu, G.; Zhang, C.; Huang, H. Experimental Studies of a Novel Anti-Icing Aluminum Conductor With Excellent Durability and Improved Electrical Performance. IEEE Trans. Power Deliv. 2023, 38, 4489–4500. [Google Scholar] [CrossRef]

- Tang, H.; Zhou, Z.; Jiao, S.; Zhang, Y.; Li, S.; Zhang, D.; Zhang, J.; Liu, J.; Zhao, D. Radiative cooling of solar cells with scalable and high-performance nanoporous anodic aluminum oxide. Sol. Energy Mater. Sol. Cells 2022, 235, 111498. [Google Scholar] [CrossRef]

- Lee, D.; Go, M.; Son, S.; Kim, M.; Badloe, T.; Lee, H.; Kim, J.K.; Rho, J. Sub-ambient daytime radiative cooling by silica-coated porous anodic aluminum oxide. Nano Energy 2021, 79, 105426. [Google Scholar] [CrossRef]

- Margita, F.; Beňa, Ľ.; Malska, W.; Pijarski, P. Possibilities of Increasing the Ampacity of Overhead Lines Using High-Temperature Low-Sag Conductors in the Electric Power System of the Slovak Republic. Appl. Sci. 2024, 14, 7846. [Google Scholar] [CrossRef]

- Kavanagh, T.; Armstrong, O. An evaluation of High Temperature Low Sag conductors for uprating the 220kV transmission network in Ireland. In Proceedings of the 45th International Universities Power Engineering Conference UPEC2010, Cardiff, UK, 31 August–3 September 2010; IEEE: New York, NY, USA. [Google Scholar]

- Zhang, Y.; Sun, H.; Zhang, X.; Chen, Z.; Zhou, L.; Huang, X. Economic analysis of aluminium conductor composite core and conventional aluminium conductor steel reinforced conductors in overhead ultra-high voltage transmission lines. IET Gener. Transm. Distrib. 2022, 17, 1098–1110. [Google Scholar] [CrossRef]

- Filippone, G.; Ippolito, M.; Massaro, F.; Puccio, A. On the roadmap to Supergrid in Sicily: LIDAR technology and HTLS conductors for uprating the 150 kV lines. In Proceedings of the IEEE PES Innovative Smart Grid Technologies, Europe, Istanbul, Turkey, 12–15 October 2014; IEEE: New York, NY, USA. [Google Scholar]

- Xu, X.; Feng, Y.; Yang, P.; Zhang, B.; Wang, Y.; Wang, Q.; Fan, X.; Ding, H. The influence of trace elements on the microstructures and properties of the aluminum conductors. Results Phys. 2018, 11, 1058–1063. [Google Scholar] [CrossRef]

- Dissado, L. Understanding electrical trees in solids: From experiment to theory. IEEE Trans. Dielectr. Electr. Insul. 2002, 9, 483–497. [Google Scholar] [CrossRef]

- Kopsidas, K.; Al Aqil, M.A.; Haldar, A.; Kavanagh, T. Evaluating Aeolian Vibration Performance of High-Temperature Low-Sag OHL Conductors. IEEE Trans. Power Deliv. 2022, 37, 1775–1784. [Google Scholar] [CrossRef]

- Nuchprayoon, S.; Chaichana, A. Cost evaluation of current uprating of overhead transmission lines using ACSR and HTLS conductors. In Proceedings of the 2017 IEEE International Conference on Environment and Electrical Engineering and 2017 IEEE Industrial and Commercial Power Systems Europe (EEEIC/I&CPS Europe), Milan, Italy, 6–9 June 2017; IEEE: New York, NY, USA, 2017. [Google Scholar]

- Dong, S.; Wu, Q.; Zhang, W.; Xia, G.; Yang, L.; Cui, J. Slippery Passive Radiative Cooling Supramolecular Siloxane Coatings. ACS Appl. Mater. Interfaces 2022, 14, 4571–4578. [Google Scholar] [CrossRef] [PubMed]

- Wang, T.; Wu, Y.; Shi, L.; Hu, X.; Chen, M.; Wu, L. A structural polymer for highly efficient all-day passive radiative cooling. Nat. Commun. 2021, 12, 365. [Google Scholar] [CrossRef] [PubMed]

| Alloys Series | Alloys | Tensile Strength (MPa) | Electrical Conductivity (%) | Reference |

|---|---|---|---|---|

| Al-Zr | Al-0.08Zr-0.16Er | 78.09 | 63.01% IACS | [45] |

| Al-0.2Zr-0.1Sc | - | 59.48% IACS | [46] | |

| Al−0.30Zr−0.08Y | - | 58.91% IACS | [47] | |

| Al-Fe | Al-0.4Fe-0.2Er | - | 61.2% IACS | [48] |

| Al–Fe–Cr | 158 | 51.0% IACS | [49] | |

| Al-0.5%Fe-0.8%Ce | 90 | 61.5%IACS | [50] | |

| Al–Mg–Si | Al-Mg-Si | 156 | 37.5% IACS | [51] |

| Al-Mg-Si-0.2La | 170 | 44.0% IACS | [51] | |

| Al-Mg-Si-0.145% Zr | 265 | 54.0% IACS | [52] |

| Conductor | Aluminum Wire Material | Core Material | Max. Operating Temperature (°C) | Electrical Conductivity | Reference |

|---|---|---|---|---|---|

| ACSR | Hard drawn Al | Steel | 100 | 61.2% IACS | [61,67] |

| ACCR | Annealed Al | Zn–Al | 210 | 63% IACS | [67,68] |

| ACCC | Annealed Al | Carbon-E glass | 180 | 63% IACS | [61,67,69] |

| ACSS | Annealed Al | Galvanized Steel | 250 | 63% IACS | [61,67,70] |

| ZTACIR | resistant (Z)TAL | Fe/Ni36 | 200 | 60% IACS | [32,44,67] |

| Conductor | Core Advantages | Applicable Voltage Levels | Typical Operational Environments | Reference |

|---|---|---|---|---|

| ACSR | Mature fabrication processes, wide applicability, and low cost | 10 kV–1100 kV | A universal type, applicable in diverse environments without specific requirements | [32,44,83] |

| ACCR | Excellent tensile strength, high-temperature resistance, high-conductivity, and minimal sag | 110 kV–1100 kV or higher | 1. Areas with severe ice accumulation 2. Regions with extremely high mechanical strength requirements 3. ultra-high voltage (UHV) transmission lines | [8,44,84] |

| ACCC | High electrical conductivity, light weight, excellent corrosion resistance and low sag | 110 kV–500 kV | 1. Constrained urban/corridor areas 2. Segments with significant elevation differences between transmission towers 3. Areas with severe corrosion 4. Not applicable in areas with severe ice accumulation | [44,85,86,87] |

| ACSS | High-conductivity, high-temperature resistance | 110 kV–500 kV | 1. Suitable for capacity-uprating retrofits of existing transmission lines where the original towers possess sufficient design margin 2. Not applicable in areas with severe ice accumulation | [44,61,70] |

| ZTACIR | Low thermal expansion, high-temperature resistance | 110 kV–500 kV | Suitable for newly constructed transmission lines with stringent sag limitations during high-temperature operation | [44,70] |

| GZTACSR | high-temperature resistance, relatively low cost | 110 kV–500 kV | Suitable for newly constructed transmission lines with cost-sensitivity | [44,58,88] |

| Primary Application Scenario | Dominant Challenges | Key Technology | Feasible Solution | Technical Rationale & Key Advantage |

|---|---|---|---|---|

| Urban grid upgrade or congestion relief | Limited right-of-way, need for maximum ampacity in confined space |

| ACCC conductor with high emissivity coating | Highest ampacity uprating. Radiative cooling further mitigates the current-induced temperature rise of the conductor. |

| Long-span & Mountainous terrain | High mechanical load (tension), ice/snow loading, large sag |

| ACSS, ZTACIR conductor | Superior strength-to-weight ratio, reduced sag, enhanced self-damping properties |

| Coastal or highly corrosive environments | Corrosion from salt spray, reducing conductor lifespan |

| Corrosion-resistant alloys | Dramatically improved corrosion resistance, ensuring long-term reliability and minimal maintenance |

| Arid or hot climate regions | High ambient temperature, intense solar radiation, limiting heat dissipation |

| HTLS conductor with High reflectance coating | Directly rejects heat to cold universe, effective even under full sun. Higher maximum operating temperature |

| Integration of variable renewables | Dynamic and cyclic loading, requiring robust sag performance |

| HTLS conductor with high fatigue resistance | Maintains safe ground clearance under frequent load cycles, compatible with Dynamic Thermal Rating systems |

| Uprating existing lines | Must fit existing towers and hardware, minimizing structural modification |

| ACCC, ACSS conductors with radiative cooling coating | Enables significant capacity increase and delay of building new towers and right-of-way |

| Conductor Type | Country | Voltage Levels | Circuit Length | Reference |

|---|---|---|---|---|

| ACCR | Ireland | 220 kV | 800 km | [112] |

| - | 230 kV | 11 km | [32] | |

| Latvia | 110 kV | - | [62] | |

| ACCC | Latvia | 110 kV | - | [62] |

| Slovakia | - | - | [44] | |

| - | 230 kV | 11 km | [32] | |

| China | 1000 kV | - | [113] | |

| ACSS | - | 230 kV | 11 km | [32] |

| Italy | 150 kV | - | [114] | |

| ZTACIR | Ireland | 220 kV | 800 km | [112] |

| - | 230 kV | 11 km | [32] | |

| Italy | 150 kV | - | [114] | |

| GZTACSR | Ireland | 220 kV | 800 km | [112] |

| - | 230 kV | 11 km | [32] | |

| Italy | 150 kV | - | [114] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, B.; Hu, Q.; Guo, R.; Hu, J.; Fen, Z.; Hua, X.; Zhu, T.; Yuan, Y. A Review of the Developments in Capacity-Uprating Conductors for Overhead Transmission Lines. Coatings 2025, 15, 1203. https://doi.org/10.3390/coatings15101203

Li B, Hu Q, Guo R, Hu J, Fen Z, Hua X, Zhu T, Yuan Y. A Review of the Developments in Capacity-Uprating Conductors for Overhead Transmission Lines. Coatings. 2025; 15(10):1203. https://doi.org/10.3390/coatings15101203

Chicago/Turabian StyleLi, Bo, Quan Hu, Ruyue Guo, Jin Hu, Zhouzhuang Fen, Xujiang Hua, Tao Zhu, and Yuan Yuan. 2025. "A Review of the Developments in Capacity-Uprating Conductors for Overhead Transmission Lines" Coatings 15, no. 10: 1203. https://doi.org/10.3390/coatings15101203

APA StyleLi, B., Hu, Q., Guo, R., Hu, J., Fen, Z., Hua, X., Zhu, T., & Yuan, Y. (2025). A Review of the Developments in Capacity-Uprating Conductors for Overhead Transmission Lines. Coatings, 15(10), 1203. https://doi.org/10.3390/coatings15101203