Substrate Temperature-Induced Crystalline Phase Evolution and Surface Morphology in Zirconium Thin Films Deposited by Pulsed Laser Ablation

Abstract

1. Introduction

2. Experimental Setup

3. Results and Discussions

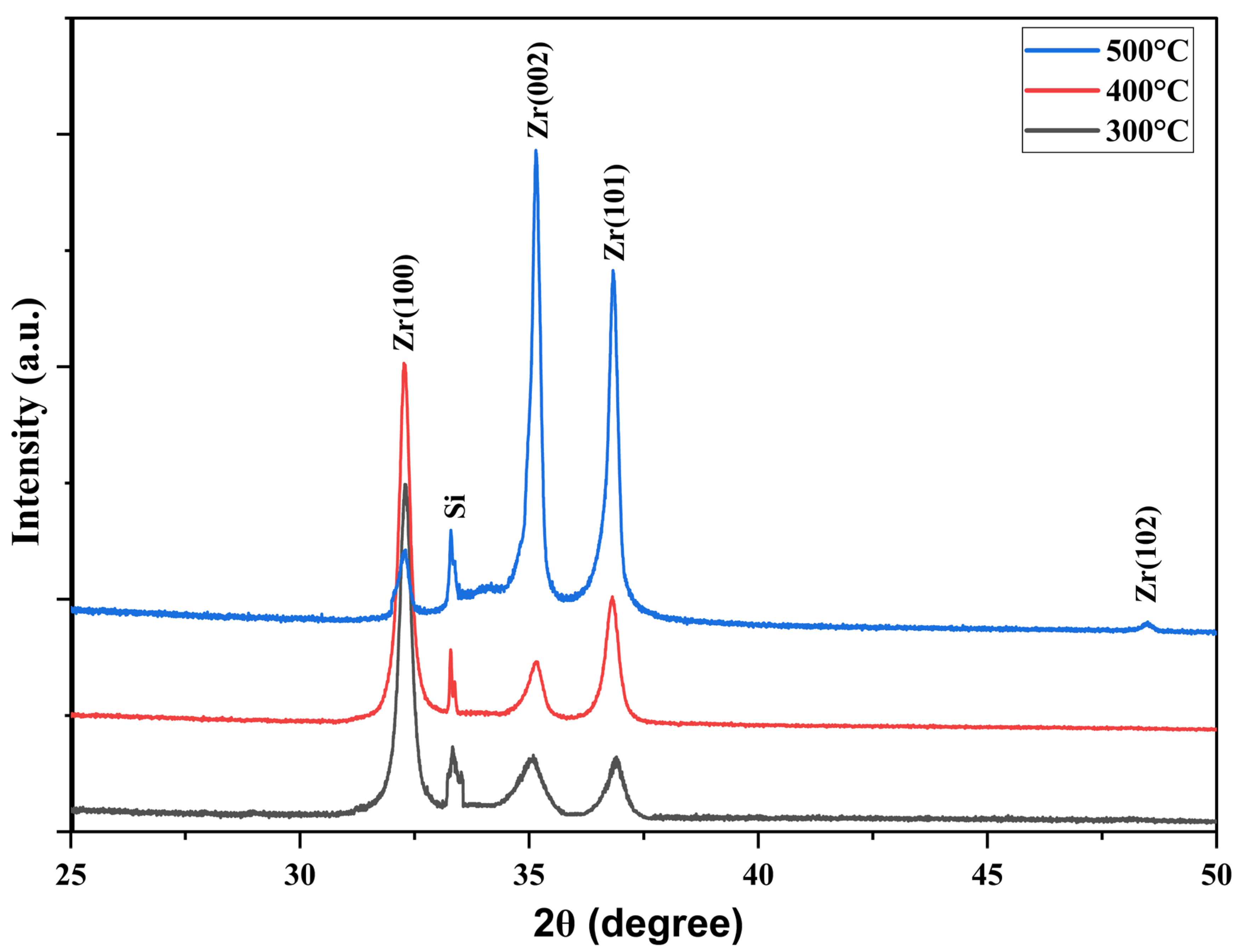

3.1. Effect of Substrate Temperature on Crystallinity (XRD)

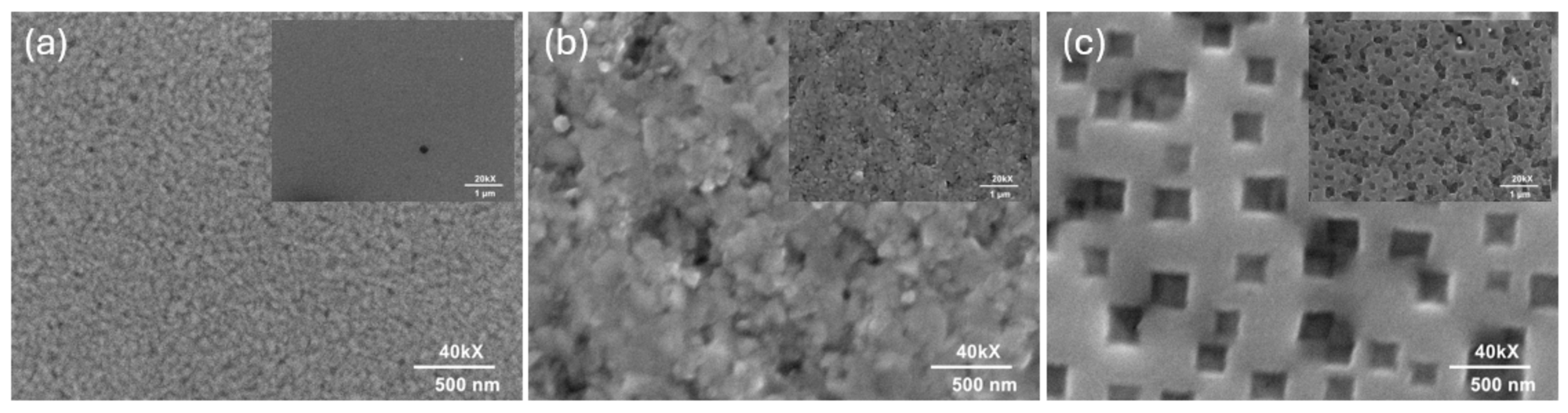

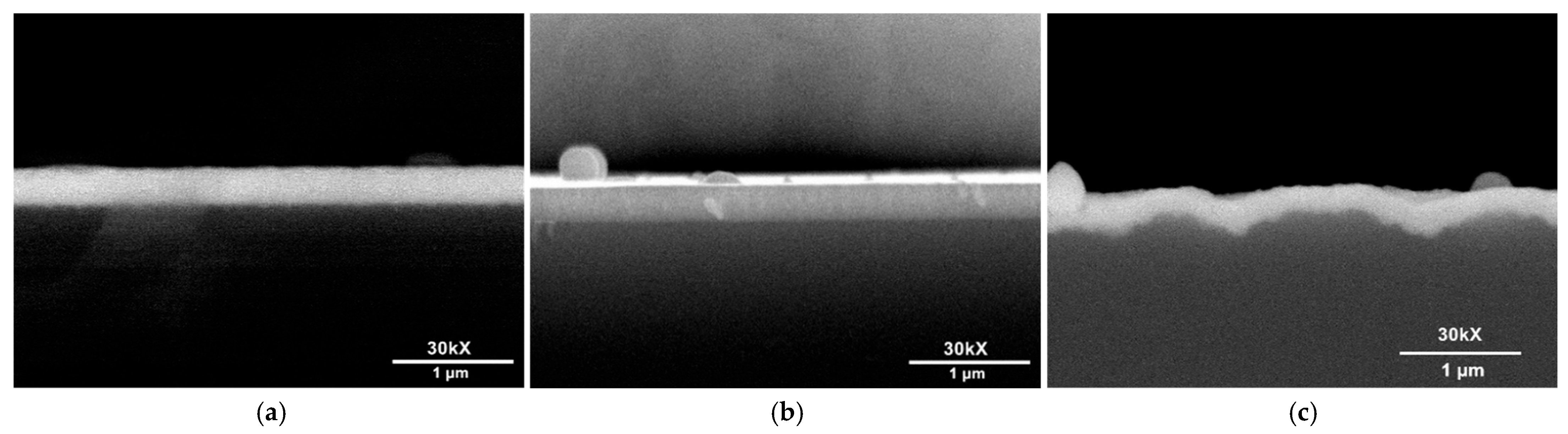

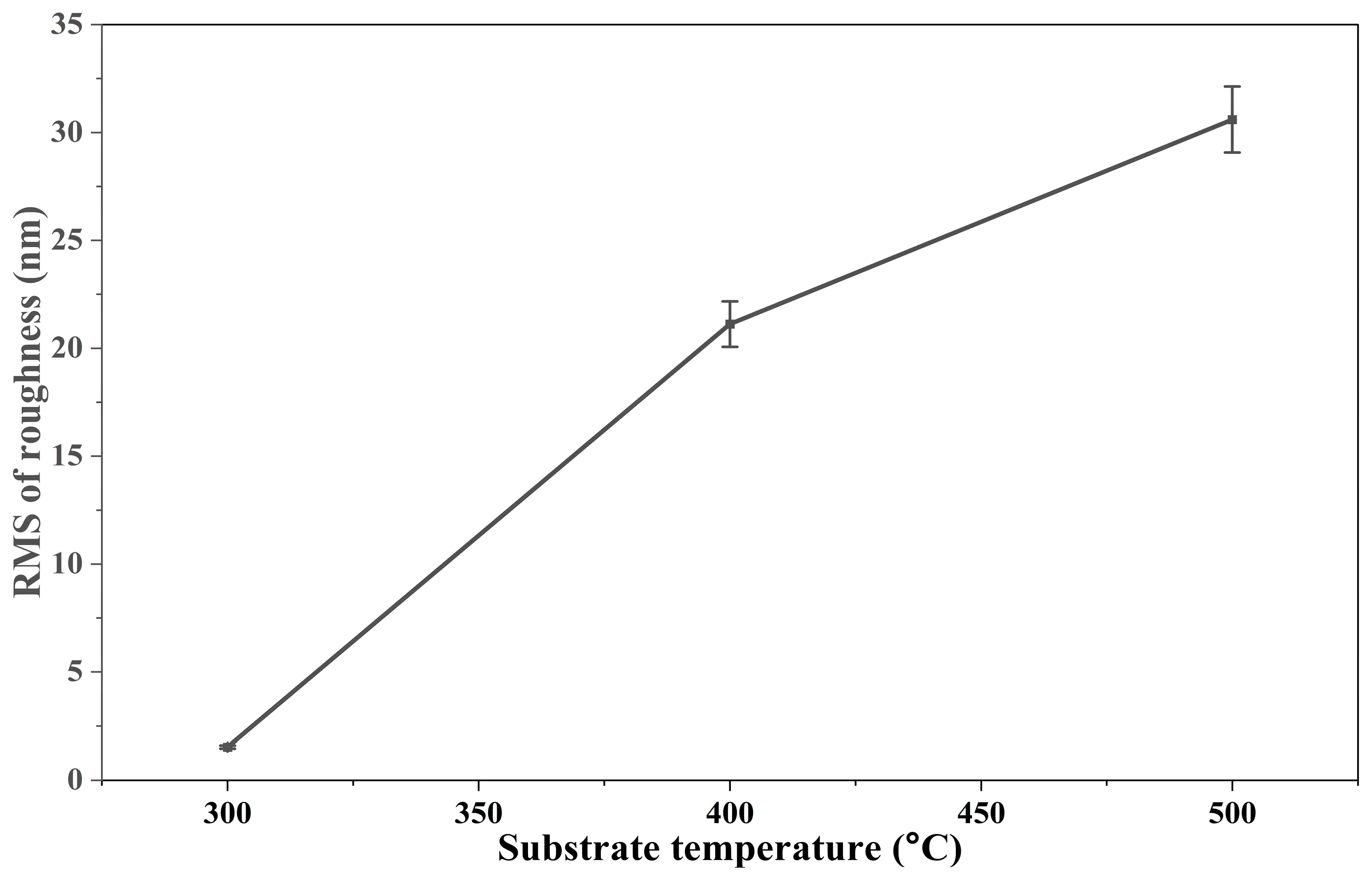

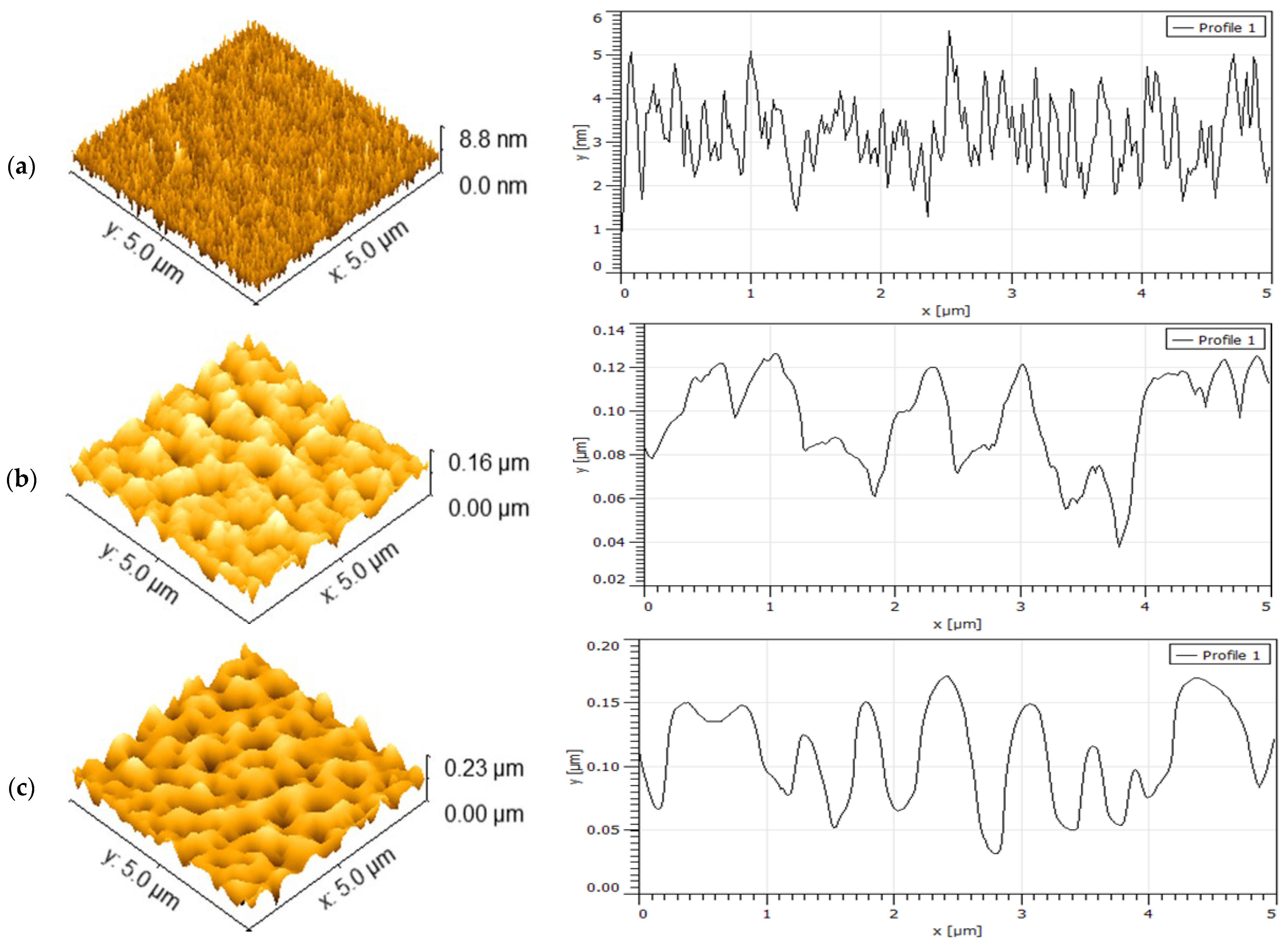

3.2. Effect of Substrate Temperature on Morphology

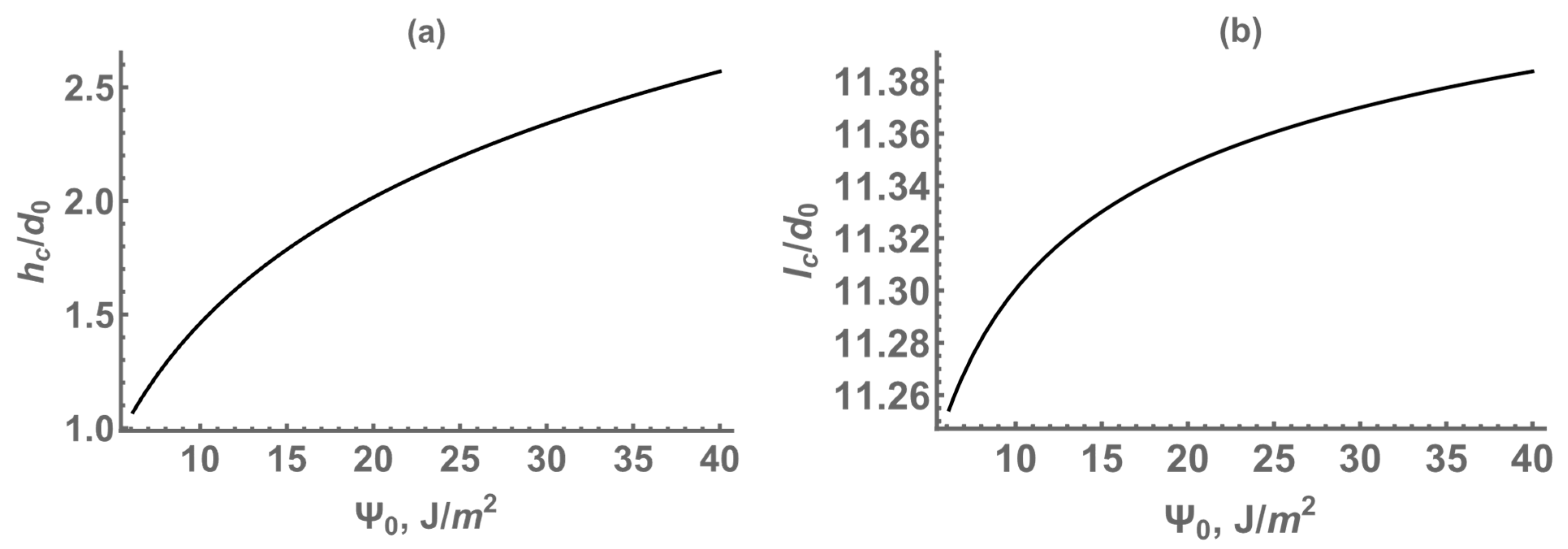

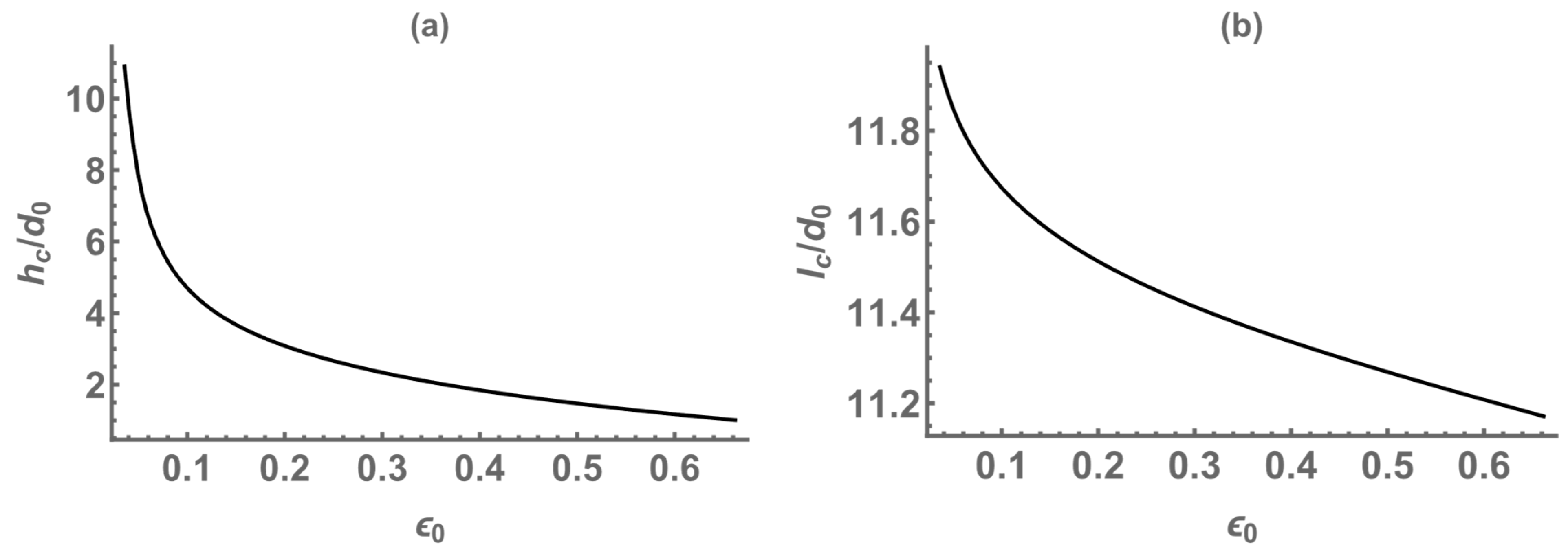

3.3. Computation of a Critical Film Thickness and the Island Size

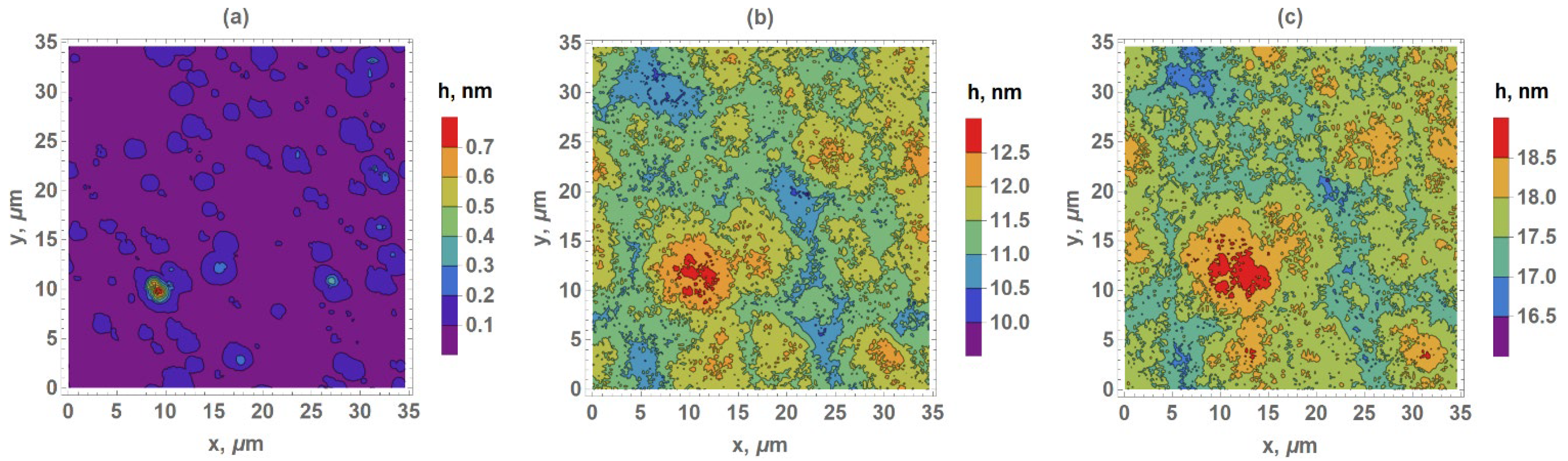

3.4. Computation of Kinetics of Island Nucleation and Growth

4. Summary

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ul-Hamid, A. The Effect of Deposition Conditions on the Properties of Zr-Carbide, Zr-Nitride and Zr-Carbonitride Coatings—A Review. Mater. Adv. 2020, 1, 988–1011. [Google Scholar] [CrossRef]

- Singh, D.P.; Gupta, S.K.; Manohar, R.; Varia, M.C.; Kumar, S.; Kumar, A. Effect of Cadmium Selenide Quantum Dots on the Dielectric and Physical Parameters of Ferroelectric Liquid Crystal. J. Appl. Phys. 2014, 116, 034106. [Google Scholar] [CrossRef]

- Almyras, G.A.; Matenoglou, G.M.; Komninou, P.; Kosmidis, C.; Patsalas, P.; Evangelakis, G.A. On the Deposition Mechanisms and the Formation of Glassy Cu–Zr Thin Films. J. Appl. Phys. 2010, 107, 084313. [Google Scholar] [CrossRef]

- Zhu, S.; Song, Y.; Zhao, X.; Shao, J.; Zhang, J.; Yang, B. The Photoluminescence Mechanism in Carbon Dots (Graphene Quantum Dots, Carbon Nanodots, and Polymer Dots): Current State and Future Perspective. Nano Res. 2015, 8, 355–381. [Google Scholar] [CrossRef]

- Balakrishnan, G.; Kuppusami, P.; Sastikumar, D.; Song, J.I. Growth of Nanolaminate Structure of Tetragonal Zirconia by Pulsed Laser Deposition. Nanoscale Res. Lett. 2013, 8, 82. [Google Scholar] [CrossRef] [PubMed]

- Dubbink, D.; Koster, G.; Rijnders, G. Growth Mechanism of Epitaxial YSZ on Si by Pulsed Laser Deposition. Sci. Rep. 2018, 8, 5774. [Google Scholar] [CrossRef]

- Zhang, B.; Yang, X.; Cao, G.; Liu, G.; Wei, Z.; Zong, H.; Yin, Y.; Bala, H. Characteristic Studies on the ZrCuAlSi Multi-Component Thin-Film Metallic Glasses Fabricated by Pulsed Laser Deposition. Appl. Phys. A 2020, 126, 453. [Google Scholar] [CrossRef]

- Wan, X.; Fang, S.; Xu, S.; Yu, L.; Zhou, J.; Qian, S.; Huang, F.; Ma, C. Enhanced Anti-Corrosion and Biological Performance of Plasma-Sprayed Nb/ZrO2/HA Coatings on ZK60 Mg Alloy. Coatings 2024, 14, 1282. [Google Scholar] [CrossRef]

- Zhong, Q.; Zhang, Z.; Qi, R.; Li, J.; Wang, Z.; Le Guen, K.; André, J.-M.; Jonnard, P. Enhancement of the Reflectivity of Al/Zr Multilayers by a Novel Structure. Opt. Express 2013, 21, 14399–14408. [Google Scholar] [CrossRef]

- Hettiarachchi, B.S.; Takaoka, Y.; Uetake, Y.; Yakiyama, Y.; Yoshikawa, H.Y.; Maruyama, M.; Sakurai, H. Mechanistic Study in Gold Nanoparticle Synthesis through Microchip Laser Ablation in Organic Solvents. Metals 2024, 14, 155. [Google Scholar] [CrossRef]

- Axente, E.; Socol, G. Special Issue “Pulsed Laser Deposition of Thin Films: Recent Advances and Challenge”. Coatings 2022, 12, 368. [Google Scholar] [CrossRef]

- Singh, A.; Kuppusami, P.; Thirumurugesan, R.; Ramaseshan, R.; Kamruddin, M.; Dash, S.; Ganesan, V.; Mohandas, E. Study of Microstructure and Nanomechanical Properties of Zr Films Prepared by Pulsed Magnetron Sputtering. Appl. Surf. Sci. 2011, 257, 9909–9914. [Google Scholar] [CrossRef]

- Bastianini, A.; Battiston, G.A.; Gerbasi, R.; Porchia, M.; Daolio, S. Chemical Vapor Deposition of ZrO2 Thin Films Using Zr(NEt2)4 as Precursor. J. Phys. IV Fr. 1995, 5, C5–C525. [Google Scholar] [CrossRef]

- Sirjita, E.N.; Rusen, L.; Brajnicov, S.; Craciun, C.; Ion, V.; Filipescu, M.; Dinescu, M. Properties of Hafnium and Aluminium Silicates Coatings Obtained by PLD. Coatings 2021, 11, 753. [Google Scholar] [CrossRef]

- Allamyradov, Y.; Yosef, J.B.; Kylychbekov, S.; Majidov, I.; Khuzhakulov, Z.; Er, A.Y.; Kitchens, C.; Banga, S.; Er, A.O. The Role of Efflux Pump Inhibitor in Enhancing Antimicrobial Efficiency of Ag NPs and MB as an Effective Photodynamic Therapy Agent. Photodiagnosis Photodyn. Ther. 2024, 47, 104212. [Google Scholar] [CrossRef]

- Khuzhakulov, Z.; Kylychbekov, S.; Allamyradov, Y.; Majidov, I.; Ben Yosef, J.; Er, A.Y.; Kitchens, C.; Banga, S.; Badarudeen, S.; Er, A.O. Formation of Picosecond Laser-Induced Periodic Surface Structures on Steel for Knee Arthroplasty Prosthetics. Front. Met. Alloys 2023, 1, 1090104. [Google Scholar] [CrossRef]

- Kylychbekov, S.; Allamyradov, Y.; Khuzhakulov, Z.; Majidov, I.; Banga, S.; Ben Yosef, J.; Duta, L.; Er, A.O. Bioactivity and Mechanical Properties of Hydroxyapatite on Ti6Al4V and Si(100) Surfaces by Pulsed Laser Deposition. Coatings 2023, 13, 1681. [Google Scholar] [CrossRef]

- Majidov, I.; Allamyradov, Y.; Kylychbekov, S.; Khuzhakulov, Z.; Er, A.O. Phase Transition and Controlled Zirconia Implant Patterning Using Laser-Induced Shockwaves. Appl. Sci. 2025, 15, 362. [Google Scholar] [CrossRef]

- Hakimov, S.; Kylychbekov, S.; Harness, B.; Neupane, S.; Hurley, J.; Brooks, A.; Banga, S.; Er, A.O. Evaluation of Silver Nanoparticles Attached to Methylene Blue as an Antimicrobial Agent and Its Cytotoxicity. Photodiagnosis Photodyn. Ther. 2022, 39, 102904. [Google Scholar] [CrossRef]

- Belekov, E. Improved Antimicrobial Properties of Methylene Blue Attached to Silver Nanoparticles. Photodiagn. Photodyn. Ther. 2020, 32, 102012. [Google Scholar] [CrossRef]

- Ohring, M. Materials Science of Thin Films; Academic Press: Cambridge, MA, USA, 2002. [Google Scholar]

- Iljinas, A.; Stankus, V.; Virbukas, D.; Kaliasas, R. Synthesis of (Bi2O3)1-x(PbO)x Thin Films by Plasma-Assisted Reactive Evaporation. Coatings 2025, 15, 748. [Google Scholar] [CrossRef]

- Wang, Y.; He, T.; Du, X.; Vereschaka, A.; Sotova, C.; Ding, Y.; Chen, K.; Li, J.; He, P. Influence of Aluminum Alloy Substrate Temperature on Microstructure and Corrosion Resistance of Cr/Ti Bilayer Coatings. Coatings 2025, 15, 891. [Google Scholar] [CrossRef]

- Zou, H.; Zhao, X.; Fu, B.; Yang, H.; Sun, C. Numerical and Experimental Study on Deposition Mechanism of Laser-Assisted Plasma-Sprayed Y2O3 Coating. Coatings 2025, 15, 904. [Google Scholar] [CrossRef]

- Eason, R. Pulsed Laser Deposition of Thin Films: Applications; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2007. [Google Scholar]

- Chrisey, D.B.; Hubler, G.K. Pulsed Laser Deposition of Thin Films; Wiley Inc.: New York, NY, USA, 1994. [Google Scholar]

- Miao, J.; Yang, H.; Hao, W.; Yuan, J.; Xu, B.; Qiu, X.Q.; Cao, L.X.; Zhao, B.R. Temperature Dependence of the Ferroelectric and Dielectric Properties of the Ba0.5Sr0.5TiO3/La0.67Sr0.33MnO3 Heterostructure. J. Phys. D Appl. Phys. 2004, 38, 5. [Google Scholar] [CrossRef]

- Mazurek, P.; Daniluk, A.; Paprocki, K. Substrate Temperature Control from RHEED Intensity Measurements. Vacuum 2004, 72, 363–367. [Google Scholar] [CrossRef]

- Farha, A.H.; Er, A.O.; Ufuktepe, Y.; Myneni, G.; Elsayed-Ali, H.E. Effects of Substrate Temperature on Properties of NbNx Films Grown on Nb by Pulsed Laser Deposition. Appl. Surf. Sci. 2011, 258, 1613–1618. [Google Scholar] [CrossRef]

- Khuzhakulov, Z.; Annamuradov, B.; Kylychbekov, S.; Allamyradov, Y.; Majidov, I.; Khenner, M.; Terzic, J.; Gurgew, D.; Er, A.O. Fabrication and Analysis of Zirconium Thin Films on Silicon (Si) by Pulsed Laser Deposition. In Proceedings of the Nanoscale and Quantum Materials: From Synthesis and Laser Processing to Applications, San Francisco, CA, USA, 12 March 2024; Volume 12874, p. 128740C. [Google Scholar]

- Liu, W.; Wen, C.; Zhang, X.; Liu, J.; Liang, J.; Long, X. Investigation of Deposition Rate, Liquid Droplets and Surface Morphology of Zirconium Films Deposited by Pulsed Laser Ablation. Phys. Scr. 2015, 90, 035402. [Google Scholar] [CrossRef]

- Chen, H.-L.; Ju, S.-P.; Wu, T.-Y.; Hsieh, J.-Y.; Liu, S.-H. Investigation of Zr and Si Diffusion Behaviors during Reactive Diffusion—A Molecular Dynamics Study. RSC Adv. 2015, 5, 26316–26320. [Google Scholar] [CrossRef]

- Khuzhakulov, Z.; Kylychbekov, S.; Allamyradov, Y.; Majidov, I.; Khenner, M.; Terzic, J.; Gurgew, D.; Er, A.O. Synthesis and Characterization of a Zirconium (Zr) Thin Film on Si(100) via Pulsed Laser Deposition. Coatings 2023, 13, 1748. [Google Scholar] [CrossRef]

- Annamuradov, B.; Khuzhakulov, Z.; Terzic, J.; Khenner, M.; Er, A.O. Surface Morphologies and Crystallinities of a Zirconium (Zr) Thin Film on Si(100) by Pulsed Laser Deposition. In Proceedings of the Nanoscale and Quantum Materials: From Synthesis and Laser Processing to Applications 2025, San Francisco, CA, USA, 19 March 2025; Volume 13352, p. 133520A. [Google Scholar]

- Liu, W.; Liang, J.; Zhou, X.; Long, X. Formation of Zirconium Silicide between Silicon Substrate and Zirconium Films. Mater. Lett. 2014, 122, 220–222. [Google Scholar] [CrossRef]

- Troglia, A.; van Vliet, S.; Yetik, G.; El Wakil, I.; Momand, J.; Kooi, B.J.; Bliem, R. Free-Standing Nanolayers Based on Ru Silicide Formation on Si(100). Phys. Rev. Mater. 2022, 6, 043402. [Google Scholar] [CrossRef]

- Vasco, E.; Sacedón, J.L. Role of Cluster Transient Mobility in Pulsed Laser Deposition-Type Growth Kinetics. Phys. Rev. Lett. 2007, 98, 036104. [Google Scholar] [CrossRef]

- Shepelin, N.A.; Tehrani, Z.P.; Ohannessian, N.; Schneider, C.W.; Pergolesi, D.; Lippert, T. A Practical Guide to Pulsed Laser Deposition. Chem. Soc. Rev. 2023, 52, 2294–2321. [Google Scholar] [CrossRef]

- Tarasenka, N.; Butsen, A.; Pankov, V.; Tarasenko, N. Structural Defects and Magnetic Properties of Gadolinium Silicide Nanoparticles Synthesized by Laser Ablation Technique in Liquid. Phys. Status Solidi (b) 2013, 250, 809–814. [Google Scholar] [CrossRef]

- Goldak, J.; Lloyd, L.T.; Barrett, C.S. Lattice Parameters, Thermal Expansions, and Grüneisen Coefficients of Zirconium, 4.2 to 1130°K. Phys. Rev. 1966, 144, 478–484. [Google Scholar] [CrossRef]

- Cho, H.W.; Pujar, P.; Choi, M.; Kang, S.; Hong, S.; Park, J.; Baek, S.; Kim, Y.; Lee, J.; Kim, S. Direct Growth of Orthorhombic Hf0.5Zr0.5O2 Thin Films for Hysteresis-Free MoS2 Negative Capacitance Field-Effect Transistors. npj 2D Mater. Appl. 2021, 5, 46. [Google Scholar] [CrossRef]

- Kang, S.J.; Joung, Y.H.; Shin, H.H.; Yoon, Y.S. Effect of Substrate Temperature on Structural, Optical and Electrical Properties of ZnO Thin Films Deposited by Pulsed Laser Deposition. J. Mater. Sci. Mater. Electron. 2008, 19, 1073–1078. [Google Scholar] [CrossRef]

- Rabo, J.R.; Takayanagi, M.; Tsuchiya, T.; Nakajima, H.; Terabe, K.; Cervera, R.B.M. Effects of Oxygen Partial Pressure and Substrate Temperature on the Structure and Morphology of Sc and Y Co-Doped ZrO2 Solid Electrolyte Thin Films Prepared via Pulsed Laser Deposition. Materials 2022, 15, 410. [Google Scholar] [CrossRef]

- Vogt, S.; Petersen, C.; von Wenckstern, H.; Grundmann, M.; Schultz, T.; Koch, N. Zr doping in pulsed-laser-deposited α-Ga2O3 for device applications. Phys. Rev. Appl. 2024, 21, 064016. [Google Scholar] [CrossRef]

- Sisodia, V.; Bolse, W.; Avasthi, D.K.; Kabiraj, D.; Jain, I.P. Silicide Formation Study at the Interface of Zr/Si System Using High-Energy Swift Heavy Ion. Radiat. Meas. 2005, 40, 762–764. [Google Scholar] [CrossRef]

- Wong, Y.H.; Cheong, K.Y. ZrO2 Thin Films on Si Substrate. J. Mater. Sci. Mater. Electron. 2010, 21, 980–993. [Google Scholar] [CrossRef]

- Edwards, A.M.; Dao, Y.; Nemanich, R.J.; Sayers, D.E.; Kemner, K.M. Structural Investigation of the Initial Interface Region Formed by Thin Zirconium Films on Silicon (111). J. Appl. Phys. 1994, 76, 4630–4635. [Google Scholar] [CrossRef]

- Cheng, J.Y.; Chen, L.J. Formation of Amorphous Interlayers by a Solid-state Diffusion in Zr and Hf Thin Films on Silicon. Appl. Phys. Lett. 1990, 56, 457–459. [Google Scholar] [CrossRef]

- Abed, N.Z.; Ismail, R.A.; Shaker, S.S. Role of Substrate Temperature on the Performance of BaTiO3/Si Photodetector Prepared by Pulsed Laser Deposition. Sci. Rep. 2024, 14, 4531. [Google Scholar] [CrossRef]

- Zhou, G.; Qu, P.; Huo, X.; Jin, P.; Wu, J.; Wang, Z. The Deposition of Ir/YSZ Double-Layer Thin Films on Silicon by PLD and Magnetron Sputtering: Growth Kinetics and the Effects of Oxygen. Results Phys. 2023, 47, 106357. [Google Scholar] [CrossRef]

- Elofsson, V.; Lü, B.; Magnfält, D.; Münger, E.P.; Sarakinos, K. Unravelling the Physical Mechanisms That Determine Microstructural Evolution of Ultrathin Volmer-Weber Films. J. Appl. Phys. 2014, 116, 044302. [Google Scholar] [CrossRef]

- Ichino, Y.; Yoshida, Y.; Yoshimura, T.; Ono, I.; Takai, Y.; Yoshizumi, M.; Izumi, T.; Shiohara, Y. Possibility of Nd:YAG-PLD Method for Fabricating REBCO Coated Conductors. IEEE Trans. Appl. Supercond. 2011, 21, 2949–2952. [Google Scholar] [CrossRef]

- Kao, Q.; Xiao, Y.; Jia, Y.; Wang, J.; Wang, C. Infrared Photoelectric Detection of Polycrystalline Bi2Te3 Thin Films Prepared by Pulsed Laser Deposition. J. Vac. Sci. Technol. A 2024, 42, 023421. [Google Scholar] [CrossRef]

- Chaluvadi, S.K.; Punathum Chalil, S.; Mazzola, F.; Dolabella, S.; Rajak, P.; Ferrara, M.; Ciancio, R.; Fujii, J.; Panaccione, G.; Rossi, G.; et al. Nd:YAG Infrared Laser as a Viable Alternative to Excimer Laser: YBCO Case Study. Sci. Rep. 2023, 13, 3882. [Google Scholar] [CrossRef]

- To, T.B.T.; Almeida, R.; Ferreira, S.O.; Aarão Reis, F.D.A. Roughness and Correlations in the Transition from Island to Film Growth: Simulations and Application to CdTe Deposition. Appl. Surf. Sci. 2021, 560, 149946. [Google Scholar] [CrossRef]

- Lozovoy, K.A.; Korotaev, A.G.; Kokhanenko, A.P.; Dirko, V.V.; Voitsekhovskii, A.V. Kinetics of Epitaxial Formation of Nanostructures by Frank–van Der Merwe, Volmer–Weber and Stranski–Krastanow Growth Modes. Surf. Coat. Technol. 2020, 384, 125289. [Google Scholar] [CrossRef]

- Lozovoy, K.A.; Kokhanenko, A.P.; Dirko, V.V.; Akimenko, N.Y.; Voitsekhovskii, A.V. Evolution of Epitaxial Quantum Dots Formed by Volmer–Weber Growth Mechanism. Cryst. Growth Des. 2019, 19, 7015–7021. [Google Scholar] [CrossRef]

- Ortiz, M.; Repetto, E.A.; Si, H. A Continuum Model of Kinetic Roughening and Coarsening in Thin Films. J. Mech. Phys. Solids 1999, 47, 697–730. [Google Scholar] [CrossRef]

- Modabberasl, A.; Sharifi, M.; Shahbazi, F.; Kameli, P. Multifractal Analysis of DLC Thin Films Deposited by Pulsed Laser Deposition. Appl. Surf. Sci. 2019, 479, 639–645. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Annamuradov, B.; Khuzhakulov, Z.; Khenner, M.; Terzic, J.; Gurgew, D.; Er, A.O. Substrate Temperature-Induced Crystalline Phase Evolution and Surface Morphology in Zirconium Thin Films Deposited by Pulsed Laser Ablation. Coatings 2025, 15, 1198. https://doi.org/10.3390/coatings15101198

Annamuradov B, Khuzhakulov Z, Khenner M, Terzic J, Gurgew D, Er AO. Substrate Temperature-Induced Crystalline Phase Evolution and Surface Morphology in Zirconium Thin Films Deposited by Pulsed Laser Ablation. Coatings. 2025; 15(10):1198. https://doi.org/10.3390/coatings15101198

Chicago/Turabian StyleAnnamuradov, Berdimyrat, Zikrulloh Khuzhakulov, Mikhail Khenner, Jasminka Terzic, Danielle Gurgew, and Ali Oguz Er. 2025. "Substrate Temperature-Induced Crystalline Phase Evolution and Surface Morphology in Zirconium Thin Films Deposited by Pulsed Laser Ablation" Coatings 15, no. 10: 1198. https://doi.org/10.3390/coatings15101198

APA StyleAnnamuradov, B., Khuzhakulov, Z., Khenner, M., Terzic, J., Gurgew, D., & Er, A. O. (2025). Substrate Temperature-Induced Crystalline Phase Evolution and Surface Morphology in Zirconium Thin Films Deposited by Pulsed Laser Ablation. Coatings, 15(10), 1198. https://doi.org/10.3390/coatings15101198