Effect of Solution and Aging Treatment on the Microstructural Evolution and Mechanical Properties of Cold-Rolled 2024 Aluminum Alloy Sheets

Abstract

1. Introduction

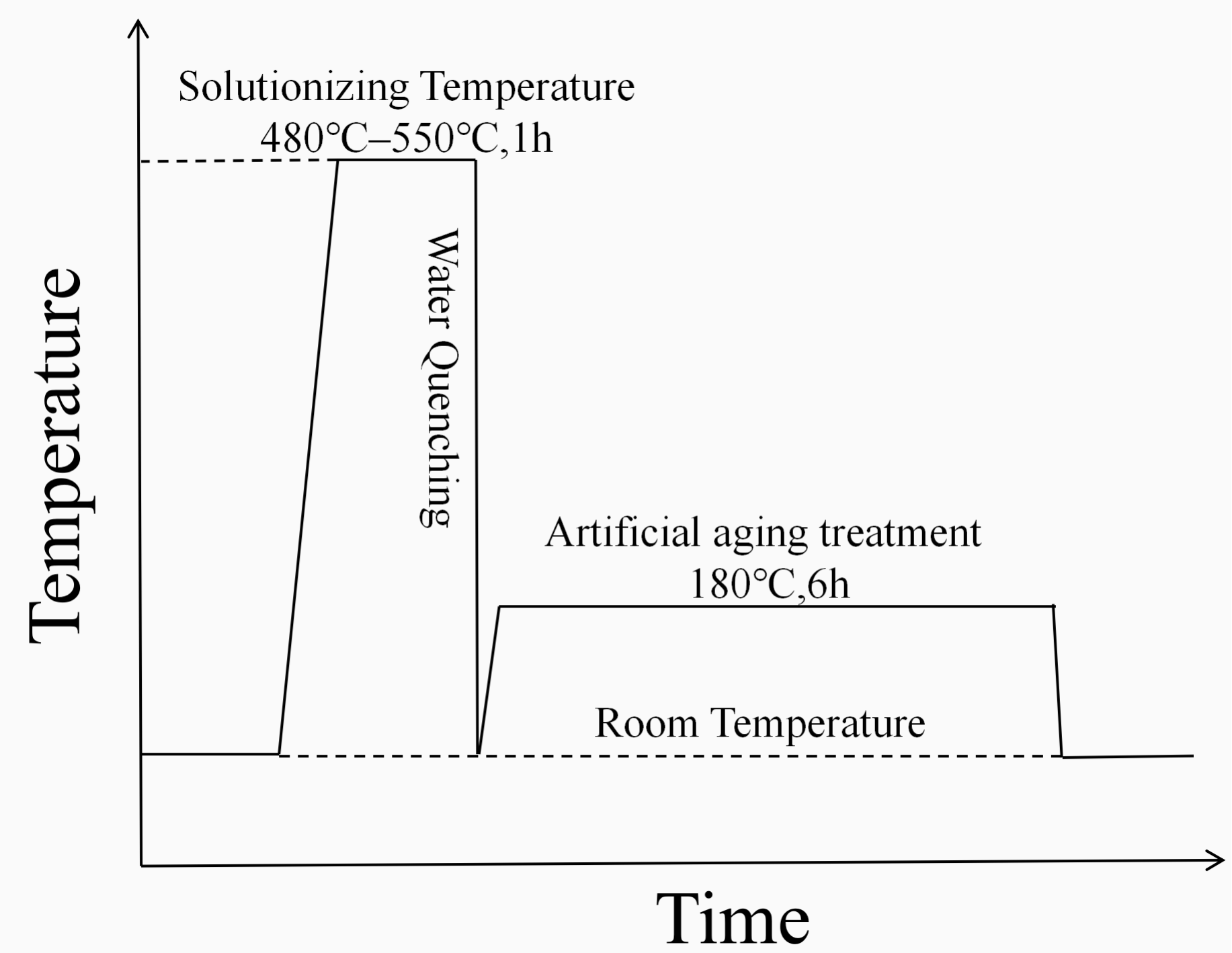

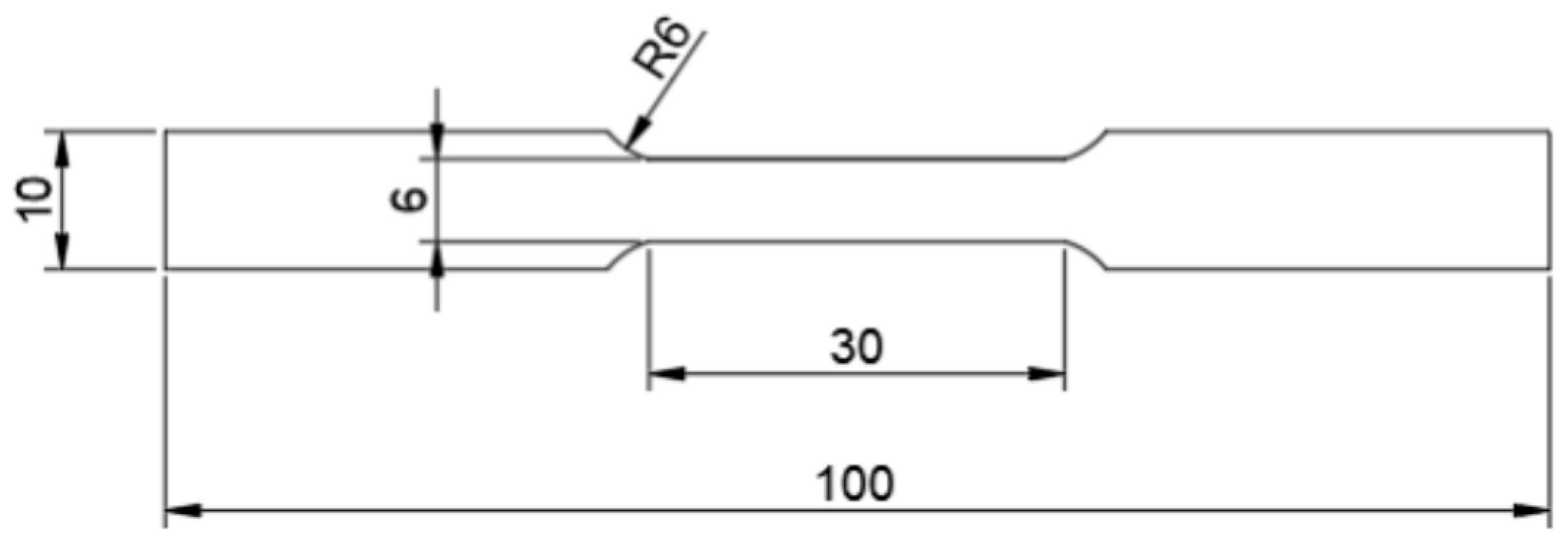

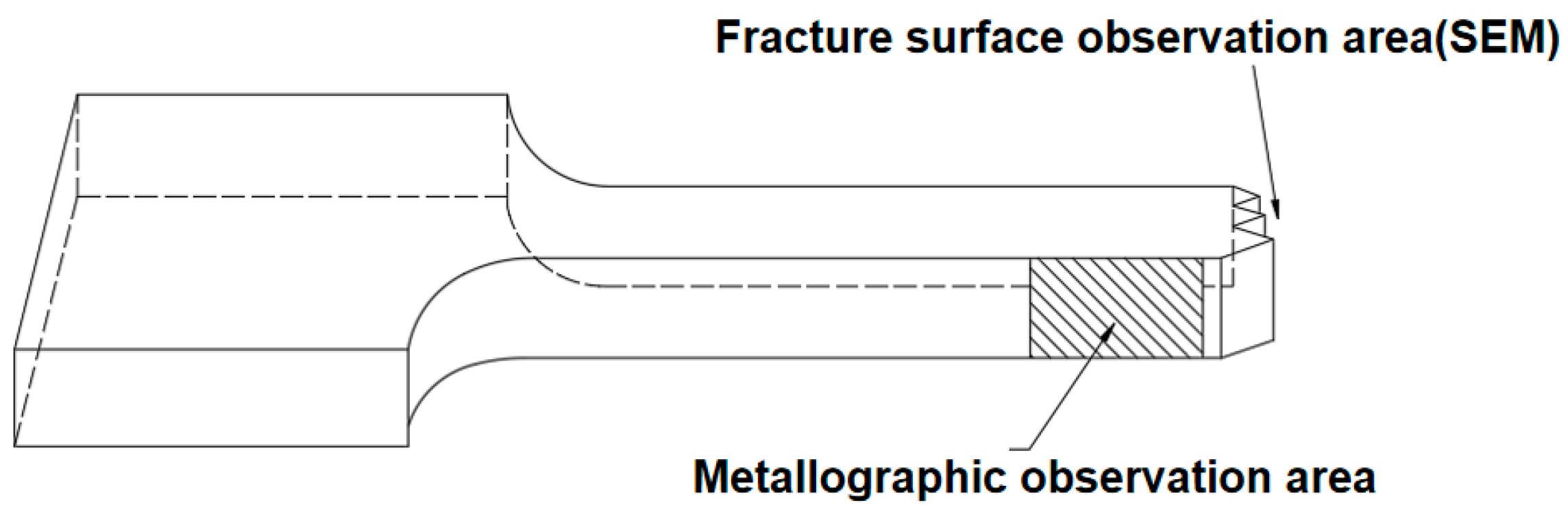

2. Materials and Methods

3. Experimental Results and Discussion

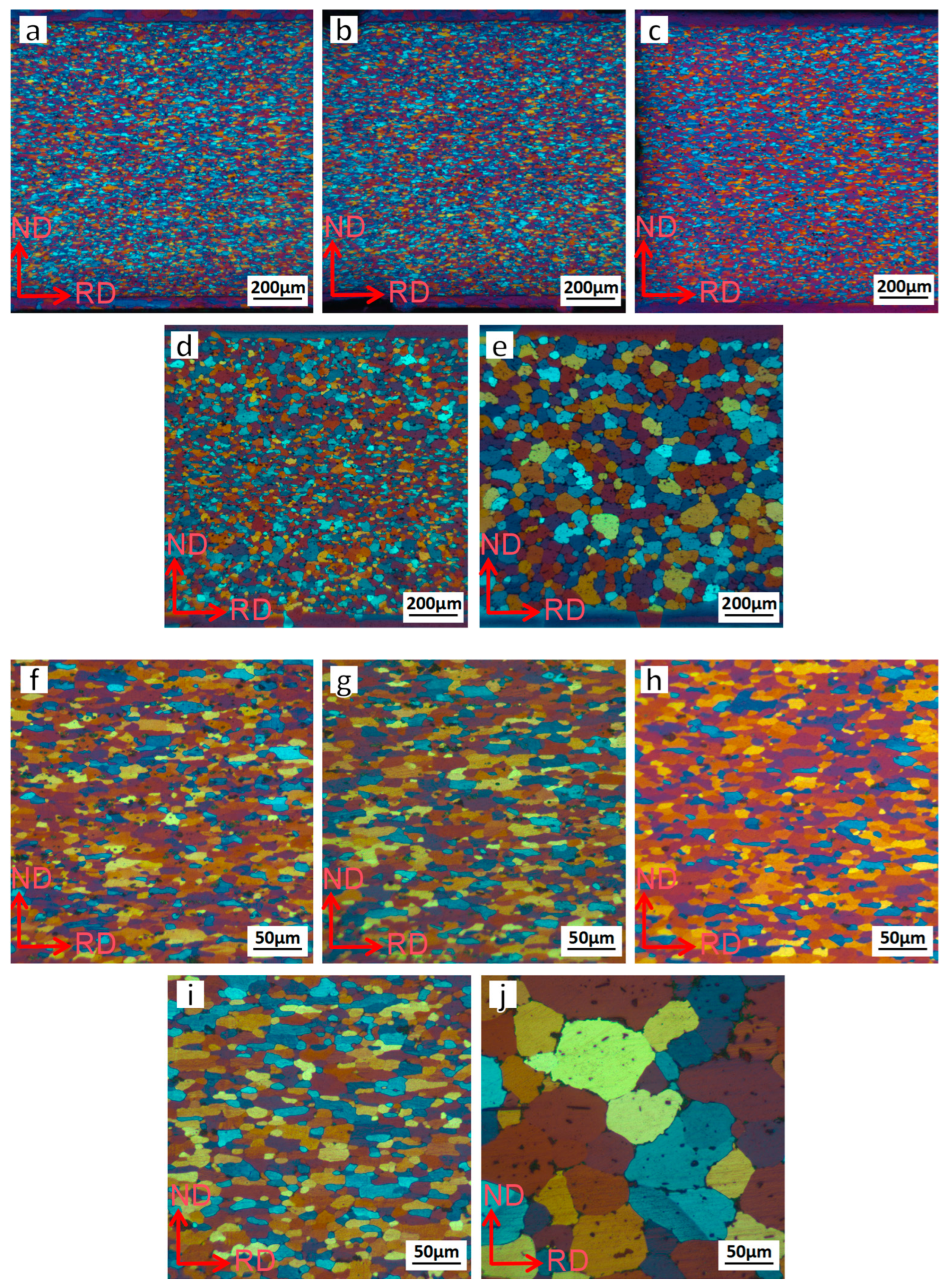

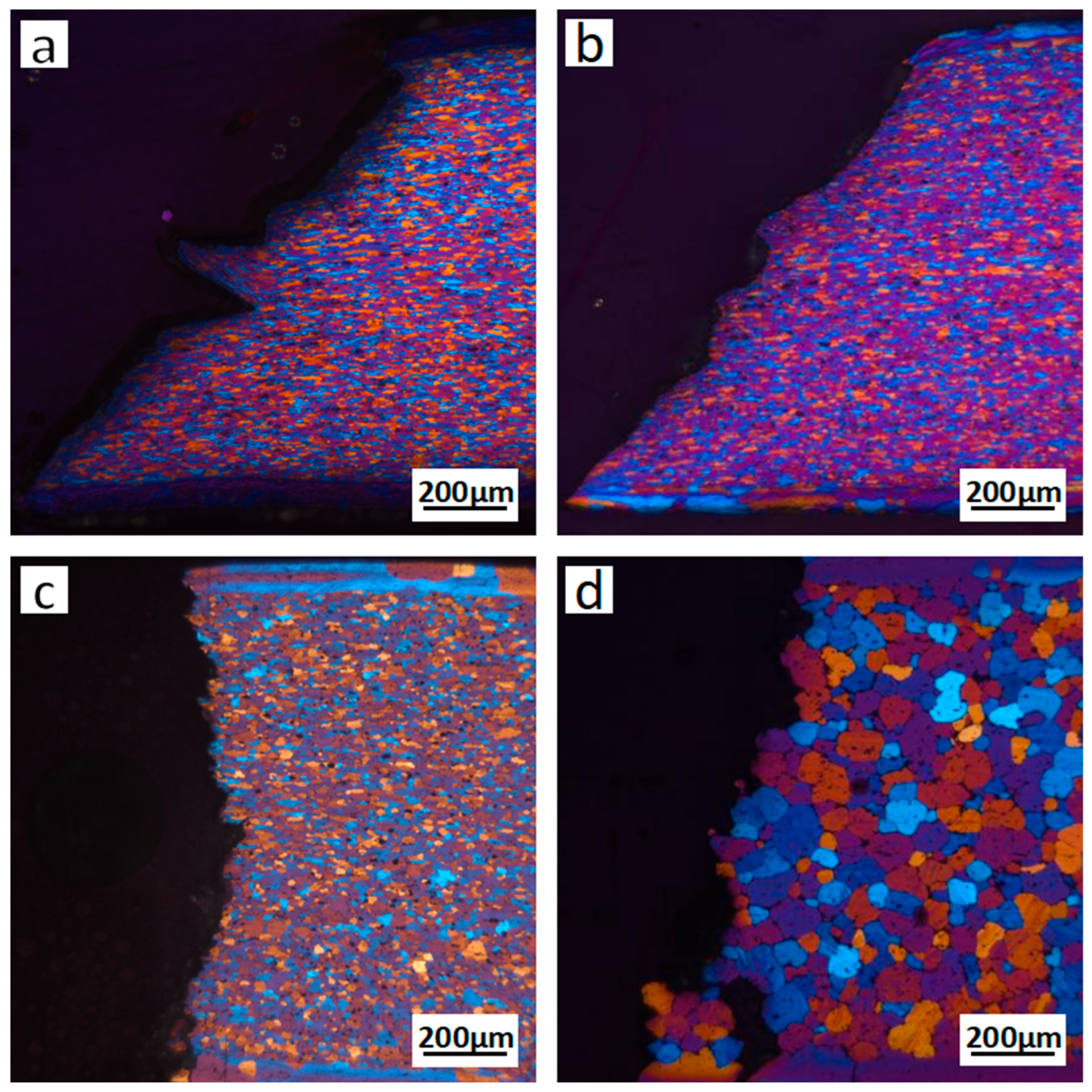

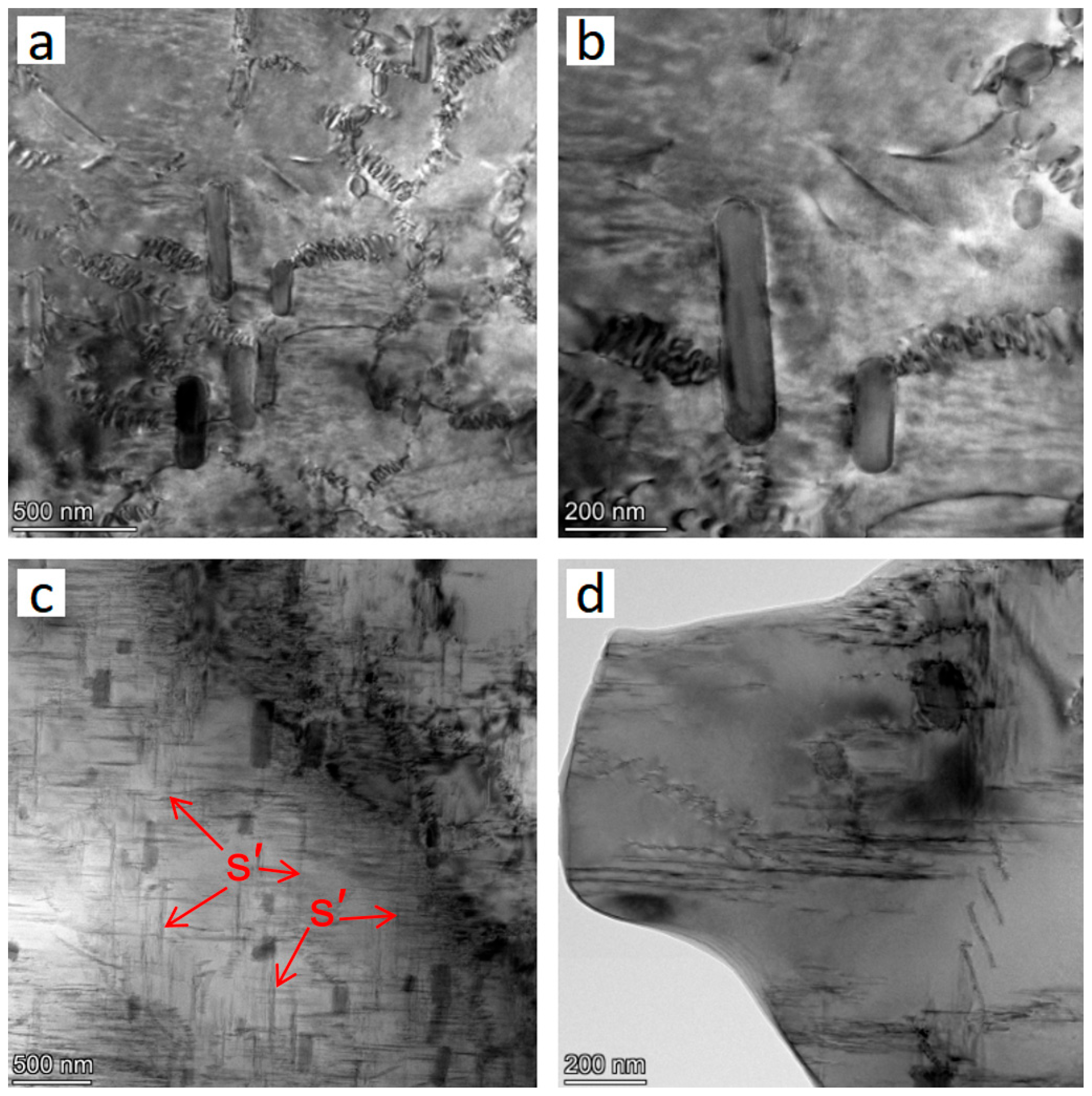

3.1. Microstructure

3.2. Vickers Microhardness

3.3. Stress–Strain Behavior

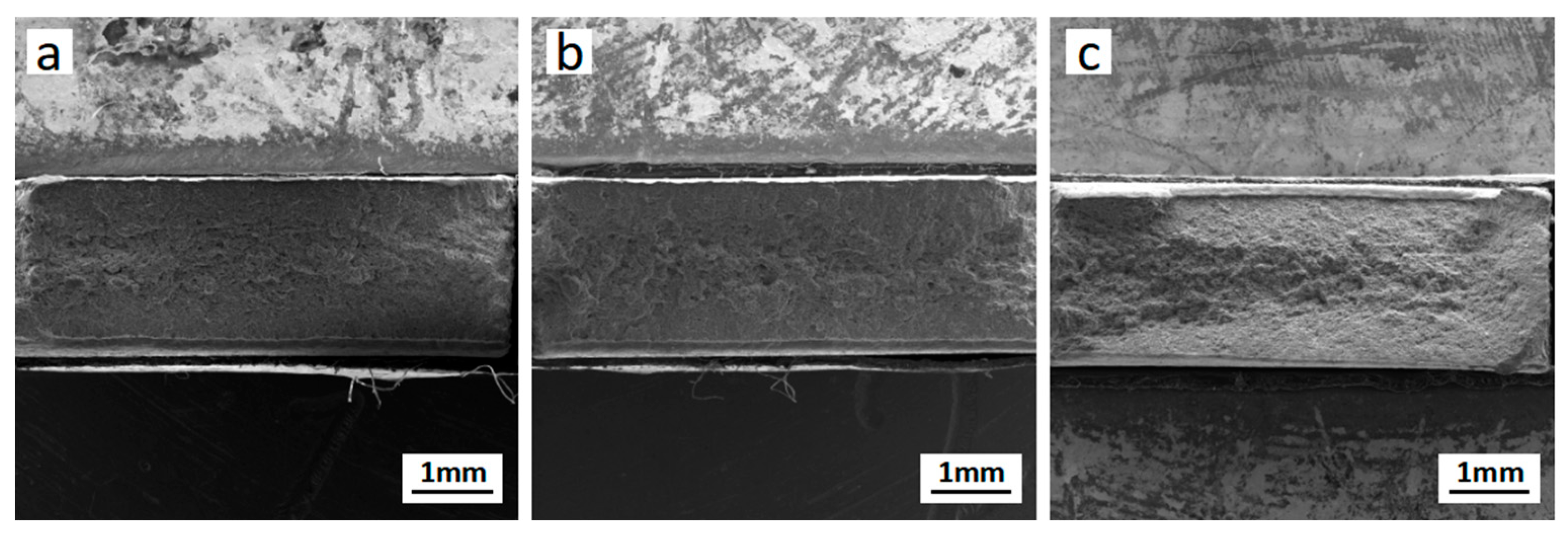

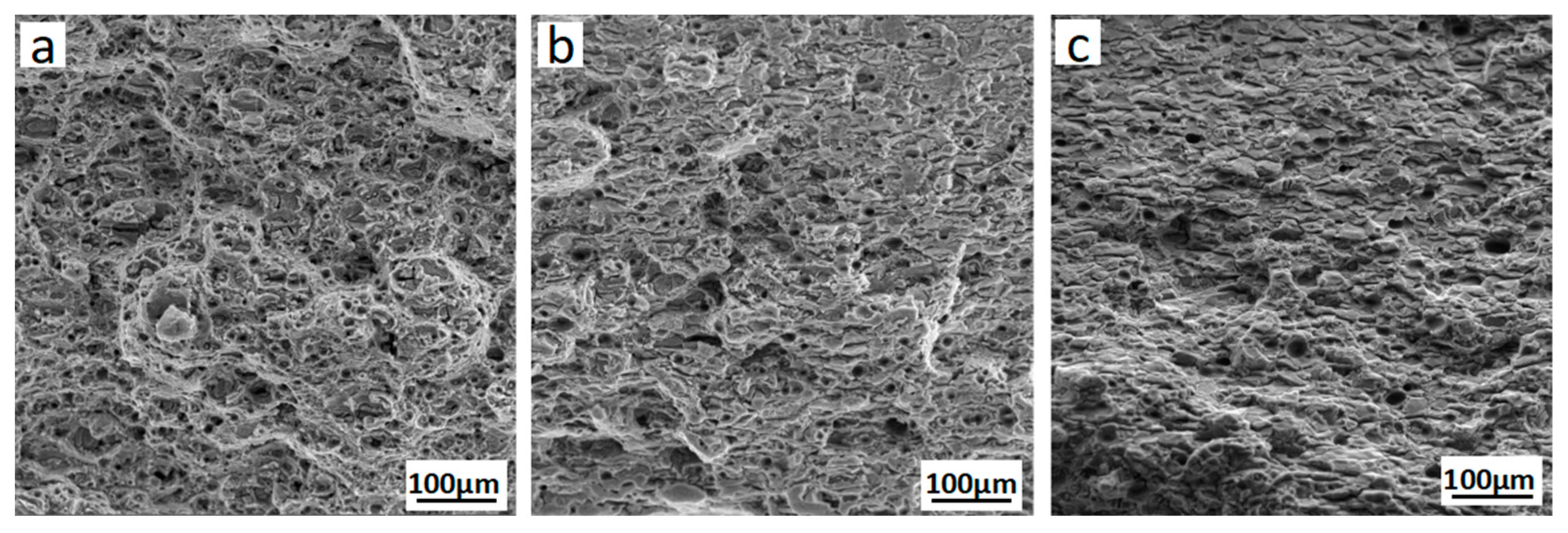

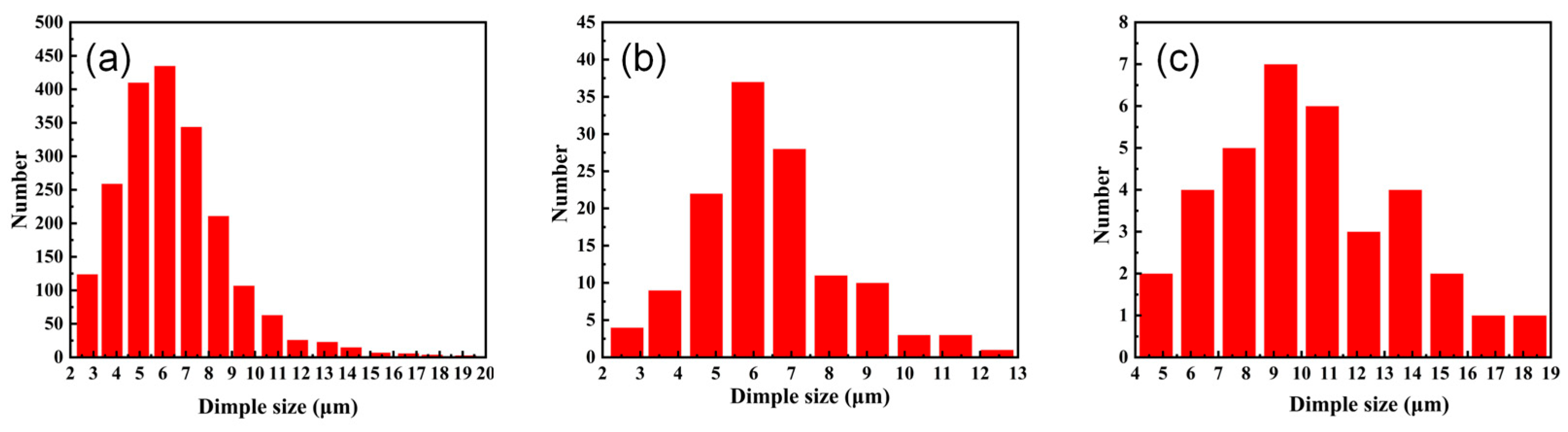

3.4. Room Temperature Tensile Fracture Behavior

4. Conclusions

- (1)

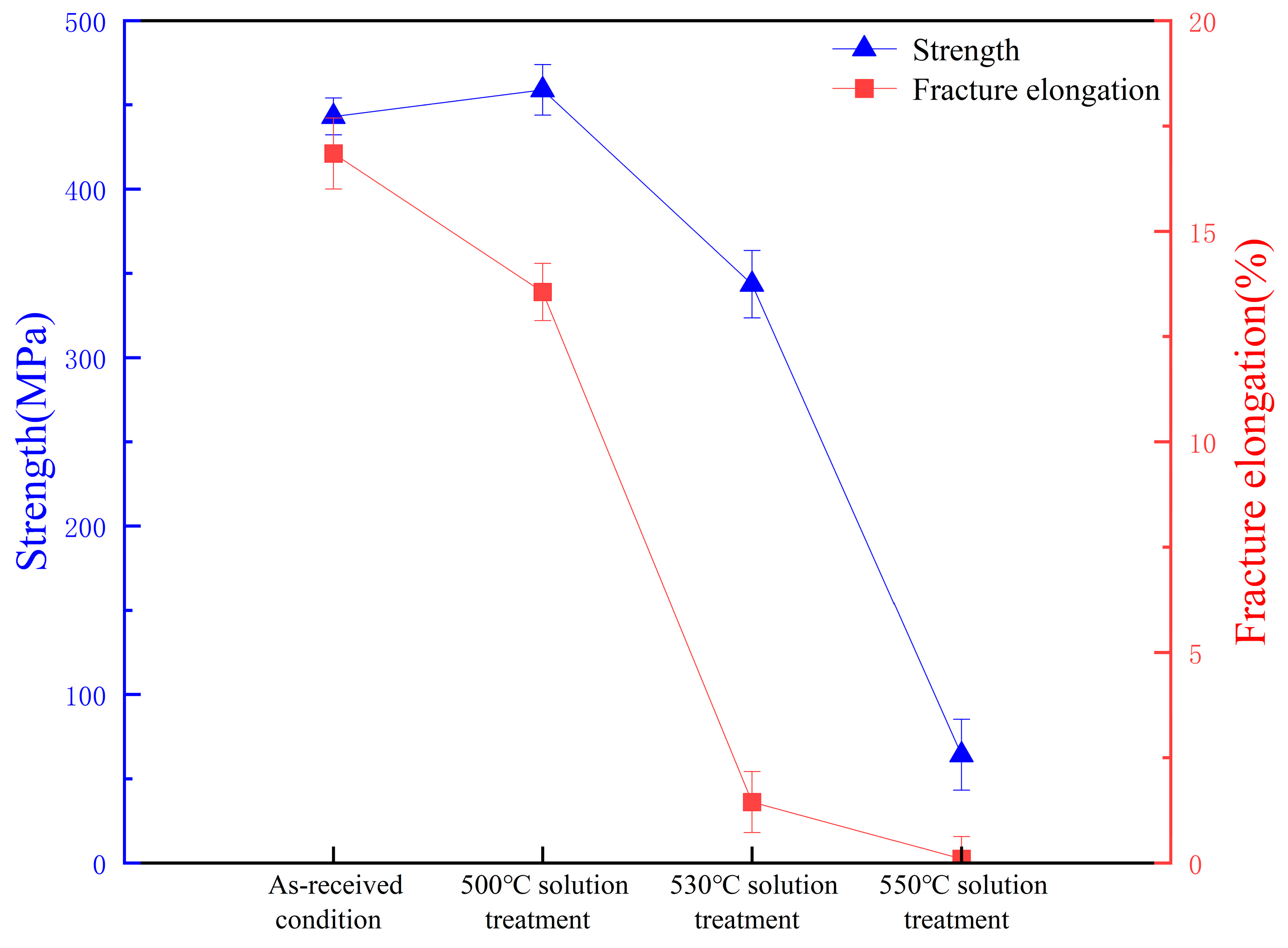

- The hardness and strength peak at a solution temperature of 500 °C and then decrease at 530 °C due to overburning, while elongation declines continuously. The optimal heat treatment condition is solution at 500 °C for 1 h followed by aging at 180 °C for 6 h, yielding a favorable balance of strength and ductility.

- (2)

- The cold-rolled 2024 aluminum alloy sheet exhibits ductile fracture at room temperature with numerous dimples, which become shallower and fewer as the solution temperature increases, indicating a ductile-to-brittle transition.

- (3)

- During solution treatment, coarse particles dissolve and grains grow, with higher temperatures leading to larger grain sizes and more complete dissolution. Subsequent aging at 500 °C/1 h + 180 °C/6 h produces fine rod- or plate-like precipitates, strengthening the alloy via the Orowan mechanism. This enhances strength but slightly reduces ductility, offering practical guidance for aerospace applications where both properties are critical.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhao, N.; Sun, Q.; Pang, Q.; Hu, Z. Comprehensive study of hot compression behaviors and microstructure evolution of solutionized 6082 aluminum alloy extruded bar. J. Alloys Compd. 2023, 931, 167541. [Google Scholar] [CrossRef]

- Li, Q.; Zhang, X.; Wang, L.; Qiao, J. The Effect of Extrusion and Heat Treatment on the Microstructure and Tensile Properties of 2024 Aluminum Alloy. Materials 2022, 15, 7566. [Google Scholar] [CrossRef]

- Vijay, R.; Aju Kumar, V.N.; Sadiq, A.; Thomas, L. Influence of cryogenic treatment on bulk and surface properties of aluminium alloys: A review. Adv. Mater. Process. Technol. 2022, 8, 4335–4346. [Google Scholar] [CrossRef]

- Chen, G.; Liu, J.; Shu, X.; Gu, H.; Zhang, B.; Feng, J. Beam scanning effect on properties optimization of thick-plate 2A12 aluminum alloy electron-beam welding joints. Mater. Sci. Eng. A 2019, 744, 583–592. [Google Scholar] [CrossRef]

- Haghdadi, F.; Jamaati, R.; Hosseinipour, S.J. Evading the strength-ductility trade-off dilemma in AA2024 alloy by short-term natural re-aging after T351 temper. Heliyon 2024, 10, e27257. [Google Scholar] [CrossRef]

- Wang, F.; Xiong, B.Q.; Zhang, Y.A.; Liu, H.W.; Li, Z.H.; Li, X.W.; Xia, F.B. Microstructure and Mechanical Properties of Laser Beam Welded AA7021 Aluminum Alloy. Appl. Mech. Mater. 2014, 488–489, 106–110. [Google Scholar] [CrossRef]

- Liang, M.; Chen, L.; Zhao, G.; Guo, Y. Effects of solution treatment on the microstructure and mechanical properties of naturally aged EN AW 2024 Al alloy sheet. J. Alloys Compd. 2020, 824, 153943. [Google Scholar] [CrossRef]

- Sun, L.; Guo, Y.; Chen, L.; Zhao, G. Effects of solution and aging treatments on the microstructure and mechanical properties of cold rolled 2024 Al alloy sheet. J. Mater. Res. Technol. 2021, 12, 1126–1142. [Google Scholar] [CrossRef]

- Mu, D.; Zhang, Z.; Liang, J.; Wang, J.; Zhang, D. Investigation of Microstructures and Mechanical Properties of SiC/AA2024 Nanocomposites Processed by Powder Metallurgy and T6 Heat Treatment. Materials 2022, 15, 3547. [Google Scholar] [CrossRef]

- Staszczyk, A.; Sawicki, J.; Adamczyk-Cieslak, B. A Study of Second-Phase Precipitates and Dispersoid Particles in 2024 Aluminum Alloy after Different Aging Treatments. Materials 2019, 12, 4168. [Google Scholar] [CrossRef]

- Radutoiu, N.; Alexis, J.; Lacroix, L.; Abrudeanu, M.; Petit, J.A. Study of the Influence of the Artificial Ageing Temperature on the AA2024 Alloy Microstructure. Key Eng. Mater. 2013, 550, 115–125. [Google Scholar] [CrossRef]

- Xie, Z.; Zhou, L.; Li, J.; Duan, Y.; Peng, M.; Xiao, H.; Du, X.; Zhao, Y.; Li, M. Mechanical and Corrosion Properties of AA2024 Aluminum Alloy with Multimodal Gradient Structures. Metals 2025, 15, 177. [Google Scholar] [CrossRef]

- Beroual, S.; Boumerzoug, Z.; Paillard, P.; Borjon-Piron, Y. Effects of heat treatment and addition of small amounts of Cu and Mg on the microstructure and mechanical properties of Al-Si-Cu and Al-Si-Mg cast alloys. J. Alloys Compd. 2019, 784, 1026–1035. [Google Scholar] [CrossRef]

- Zhu, H.; Ghosh, A.K.; Maruyama, K. Effect of cold rolling on microstructure and material properties of 5052 alloy sheet produced by continuous casting. Mater. Sci. Eng. A 2006, 419, 115–121. [Google Scholar] [CrossRef]

- Ruano Oscar, A.; Orozco-Caballero, A.; Álvarez-Leal, M.; Carreño, F. Influence of Solid Solutions on the Al2024 High-Temperature Deformation Behavior. Materials 2023, 16, 6251. [Google Scholar] [CrossRef] [PubMed]

- Liu, W.; Zhao, H.; Li, D.; Zhang, Z.; Huang, G.; Liu, Q. Hot deformation behavior of AA7085 aluminum alloy during isothermal compression at elevated temperature. Mater. Sci. Eng. A 2014, 596, 176–182. [Google Scholar] [CrossRef]

- ISO 6892-1:2019; Metallic materials—Tensile Testing—Part 1: Method of Test at Room Temperature. ISO: Geneva, Switzerland, 2019.

- Chiang, M.T.; Chiu, K.Y.; Wu, P.C.; Chang, S.Y.; Sun, Y.K.; Chuang, T.H. Improvement of the Mechanical Properties of the Diffusion-Bonded 2024 Aluminum Alloy through Post-Weld Heat Treatments. Metals 2022, 12, 1738. [Google Scholar] [CrossRef]

- Liu, H.; Gao, Y.; Qi, L.; Wang, Y.; Nie, J.F. Phase-Field Simulation of Orowan Strengthening by Coherent Precipitate Plates in an Aluminum Alloy. Metall. Mater. Trans. A-Phys. Metall. Mater. Sci. 2015, 46, 3287–3301. [Google Scholar] [CrossRef]

- Panda, R.; Gupta, R.K.; Mandal, A.; Chakravarthy, P. Processing, Microstructure Evolution, and Heat Treatment Response of AA2024 and Its Metal Matrix Composites of In Situ TiB2 Dispersoids. J. Mater. Eng. Perform. 2025, 34, 2972–2988. [Google Scholar] [CrossRef]

- Zhu, Z.; Qin, R.; Sun, Y.; Tang, J.; Jiang, F.; You, C. Improvement in Mechanical Properties of Al2024 Alloy Using Mechanical Working and Heat Treatment. Materials 2023, 16, 5568. [Google Scholar] [CrossRef]

- Styles, M.J.; Hutchinson, C.R.; Chen, Y.; Deschamps, A.; Bastow, T.J. The coexistence of two S (Al2CuMg) phases in Al–Cu–Mg alloys. Acta Mater. 2012, 60, 6940–6951. [Google Scholar] [CrossRef]

- Mao, X.; Yi, Y.; He, H.; Huang, S.; Guo, W. Second phase particles and mechanical properties of 2219 aluminum alloys processed by an improved ring manufacturing process. Mater. Sci. Eng. A 2020, 781, 139226. [Google Scholar] [CrossRef]

- Li, P.; Zhang, M.; Zhang, B.; Liu, K. Impact of Aging Treatment on Microstructure and Performance of Al-Zn-Mg-Cu Alloy Thin Sheets. Metals 2023, 13, 1638. [Google Scholar] [CrossRef]

- Li, Y.; Chen, C.; Sun, W.; Qi, M.; Yan, J.; Zhang, C.; Liu, H.; Ren, Y.; Liu, X. Synergistic enhancement of strength-ductility in ODS copper alloy by exploring heterogeneous structure. Mater. Sci. Eng. A 2025, 931, 148194. [Google Scholar] [CrossRef]

- Morozova, I.; Naumov, A.; Doynov, N.; Michailov, V. Influence of Plastic Deformation on the Precipitation Evolution in the Aluminum Alloys in Friction Stir Welding. Machines 2025, 13, 45. [Google Scholar] [CrossRef]

- Xu, D.; Chen, K.; Chen, Y.; Chen, S. Evolution of the second-phase particles and their effect on tensile fracture behavior of 2219 Al-xCu alloys. Metals 2020, 10, 197. [Google Scholar] [CrossRef]

- Chen, M.; Fan, G.; Tan, Z.; Yuan, C.; Guo, Q.; Xiong, D.; Chen, M.; Zheng, Q.; Li, Z.; Zhang, D. Heat treatment behavior and strengthening mechanisms of CNT/6061Al composites fabricated by flake powder metallurgy. Mater. Charact. 2019, 153, 261–270. [Google Scholar] [CrossRef]

- Zhang, J.; Yi, Y.; He, H.; Huang, S.; Mao, X.; Guo, W.; You, W.; Guo, Y.; Dong, F.; Tang, J. Kinetic model for describing continuous and discontinuous dynamic recrystallization behaviors of 2195 aluminum alloy during hot deformation. Mater. Charact. 2021, 181, 111492. [Google Scholar] [CrossRef]

- Anijdan, S.M.; Sadeghi-Nezhad, D.; Lee, H.; Shin, W.; Park, N.; Nayyeri, M.J.; Jafarian, H.R.; Eivani, A.R. TEM study of S’ hardening precipitates in the cold rolled and aged AA2024 aluminum alloy: Influence on the microstructural evolution, tensile properties & electrical conductivity. J. Mater. Res. Technol. 2021, 13, 798–807. [Google Scholar] [CrossRef]

- Irmer, D.; Sennour, M.; Sun, F.; Vermaut, P.; Moussa, C.; Esin, V.A. From heterogeneous nucleation to homogeneous spatial distribution of hardening precipitates: An in situ TEM study on cold-rolled AA2024-T3 (Al–Cu–Mg). MRS Commun. 2024, 14, 633–638. [Google Scholar] [CrossRef]

- Irmer, D.; Yildirim, C.; Sennour, M.; Esin, V.A.; Moussa, C. Effect of second-phase precipitates on deformation microstructure in AA2024 (Al–Cu–Mg): Dislocation substructures and stored energy. J. Mater. Sci. 2024, 59, 18978–19002. [Google Scholar] [CrossRef]

- Zhu, C.; Lv, K.; Chen, B. On the S-phase precipitates in 2024 aluminum alloy: An atomic-scale investigation using high-angle annular dark-field scanning transmission electron microscopy. J. Mater. Res. 2020, 35, 1582–1589. [Google Scholar] [CrossRef]

- Alexopoulos Nikolaos, D.; Velonaki, Z.; Stergiou Constantinos, I.; Kourkoulis Stavros, K. Effect of ageing on precipitation kinetics, tensile and work hardening behavior of Al–Cu–Mg (2024) alloy. Mater. Sci. Eng. A 2017, 700, 457–467. [Google Scholar] [CrossRef]

| Element | Cu | Mg | Mn | Fe | Si | Zn | Ti | Al |

|---|---|---|---|---|---|---|---|---|

| wt% | 3.95 | 1.33 | 0.61 | 0.19 | 0.091 | 0.032 | 0.035 | Bal. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, L.; Liu, W.; Xia, E.; Chen, W.; He, X.; Tang, D. Effect of Solution and Aging Treatment on the Microstructural Evolution and Mechanical Properties of Cold-Rolled 2024 Aluminum Alloy Sheets. Coatings 2025, 15, 1139. https://doi.org/10.3390/coatings15101139

Zhang L, Liu W, Xia E, Chen W, He X, Tang D. Effect of Solution and Aging Treatment on the Microstructural Evolution and Mechanical Properties of Cold-Rolled 2024 Aluminum Alloy Sheets. Coatings. 2025; 15(10):1139. https://doi.org/10.3390/coatings15101139

Chicago/Turabian StyleZhang, Luxiang, Wei Liu, Erli Xia, Wanting Chen, Xuanxuan He, and Dewen Tang. 2025. "Effect of Solution and Aging Treatment on the Microstructural Evolution and Mechanical Properties of Cold-Rolled 2024 Aluminum Alloy Sheets" Coatings 15, no. 10: 1139. https://doi.org/10.3390/coatings15101139

APA StyleZhang, L., Liu, W., Xia, E., Chen, W., He, X., & Tang, D. (2025). Effect of Solution and Aging Treatment on the Microstructural Evolution and Mechanical Properties of Cold-Rolled 2024 Aluminum Alloy Sheets. Coatings, 15(10), 1139. https://doi.org/10.3390/coatings15101139