Abstract

To investigate the effect of recovery treatment on the microstructure and tribological properties of ultrasonic impact-treated Al2FeCoNiCrW0.5 high-entropy alloy coatings, laser cladding technology was used to fabricate coatings on a G10450 steel substrate, followed by ultrasonic impact treatment (UIT) and recovery treatment (HR, 300 °C). The results showed that the Al2FeCoNiCrW0.5 high-entropy alloy coating consisted of BCC and FCC phases. Ultrasonic impact treatment slightly broadened the XRD diffraction peaks, while the recovery treatment had minimal effect on them. Ultrasonic impact also refined the coating grains. Ultrasonic impact treatment increased the coating hardness from 738 HV0.5 to 856 HV0.5. Although the subsequent post-annealing slightly reduced the hardness to 806 HV0.5, it significantly improved wear resistance, with wear loss decreasing from 3.273 mm3 to 2.881 mm3, representing a 15% reduction in wear rate. The improvement in wear resistance was attributed to a change in the wear mechanism of the high-entropy alloy coating. Before and after post-annealing, the mechanism transitioned from abrasive wear, adhesive wear, and oxidative wear to primarily abrasive wear and oxidative wear. Additionally, the recovery treatment transformed the surface from hard and brittle to ductile and resilient.

1. Introduction

High-entropy alloys (HEAs) are a novel class of materials that have rapidly developed in recent years. Since their introduction by Yeh et al. [1] in 2004, they have attracted significant attention due to their unique concept and outstanding properties. HEAs are composed of five or more metallic elements, with atomic ratios of each element ranging from 5% to 35%. This unconventional alloy exhibits unique characteristics in terms of structure, mechanisms, and properties. The key features include the thermodynamic high-entropy effect, structural lattice distortion effect, kinetic sluggish diffusion effect, and the performance “cocktail” effect [2]. Due to these unique effects, HEAs exhibit significant advantages over traditional alloys, such as high strength, high hardness, and excellent wear and corrosion resistance [3].

Common methods for fabricating HEA coatings include magnetron sputtering, electrochemical deposition, thermal spraying, laser surface alloying, and laser cladding. Among these, laser cladding is particularly favored for its high energy density, rapid heating, minimal thermal influence on the substrate, fast cooling rate, dense microstructure, low dilution rate, and strong bonding strength [4,5]. However, the complex thermal accumulation and cycling during the laser cladding process can result in high residual stresses and structural inhomogeneities in the substrate. These defects not only degrade the performance of the clad layer but also shorten the service life of HEAs. Consequently, ultrasonic impact (UI) technology has become a research hotspot for mitigating defects in laser-cladded HEA coatings.

Ultrasonic impact applies high energy input and strain rates to the surface of the sample through point contact, forming a deformation layer with a thickness of up to several hundred micrometers within a short time [6]. Compared to ultrasonic rolling and surface mechanical grinding treatments, ultrasonic impact technology features a simpler equipment structure, making it more flexible for processing complex workpieces. Ultrasonic impact-treated samples undergo significant plastic deformation at the surface, leading to dislocation tangling, dislocation wall formation, and the generation of subgrain structures. This typically results in increased hardness, primarily due to strain hardening and grain refinement effects [7,8]. During the deformation process, part of the kinetic energy is converted into thermal energy, promoting grain recovery and recrystallization. This eventually transforms subgrain boundaries into high-angle grain boundaries, achieving grain refinement [9]. Zhang et al. [10] observed that ultrasonic impact treatment increased the hardness of Al1.5CoCrFeMnNi high-entropy alloy coatings from 167.9 HV0.2 to 336.6 HV0.2, which was closely associated with grain refinement and work hardening induced by the treatment. Moreover, ultrasonic impact treatment fragmented the precipitate particles in the high-entropy alloy, further enhancing the hardness of the coatings. Li et al. [11] found that ultrasonic impact treatment on a laser-cladded Al0.5CoCrFeMnNi high-entropy alloy caused the original Fe-Si-rich and Al-rich precipitates to fragment into smaller precipitates. This effectively hindered dislocation motion and grain boundary sliding, enhanced dispersion strengthening, and increased surface microhardness from approximately 175 HV0.2 to 350 HV0.2.

Ultrasonic impact treatment can enhance the surface hardness of materials, thereby improving their wear resistance [12]. However, it also reduces the ductility and toughness of metallic materials, affecting their overall mechanical performance. Recovery treatment allows atoms to gain thermal energy, increasing thermal motion and restoring their normal arrangement. This eliminates lattice distortion and partially alleviates work hardening, effectively improving the ductility and toughness of alloys. Li et al. [13] conducted a 150 °C recovery treatment on an AZ31 magnesium alloy after surface hammering treatment. The results showed that post-annealing facilitated the transformation of dislocation cells at diffuse boundaries into nanoparticles, thereby improving the alloy’s ductility, toughness, and wear resistance. Zhao et al. [14] performed recovery treatments at various temperatures on an AZ91D magnesium alloy after ultrasonic rolling treatment. Their findings revealed that the wear resistance of the samples improved further after recovery treatment, which was attributed to enhanced toughness. The wear resistance of an AZ91D magnesium alloy depends not only on hardness but also on toughness. The above studies indicate that recovery treatment may improve the tribological performance of metallic samples subjected to ultrasonic impact treatment. The application of recovery treatment to other ultrasonic impact-treated metal samples has been widely studied, whereas research on its application to high-entropy alloy coating samples after ultrasonic impact treatment is scarce. The Al2FeCoNiCrW0.5 high-entropy alloy coating possesses good hardness and wear resistance. In this study, Al2FeCoNiCrW0.5 high-entropy alloy coatings were fabricated on the surface of a G10450 steel substrate using laser cladding technology. The coating surface was then subjected to ultrasonic impact treatment (UIT) and 300 °C recovery treatment (HR). The effects of recovery treatment on the microstructure and wear resistance of the ultrasonic impact-treated Al2FeCoNiCrW0.5 high-entropy alloy coatings were comparatively analyzed, and the friction and wear mechanisms were explored.

2. Materials and Methods

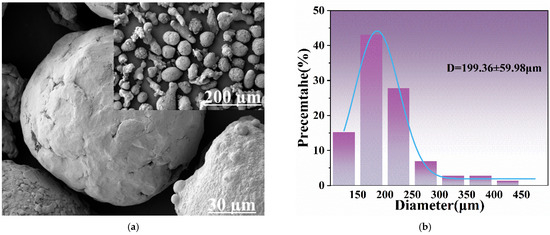

The experiment selected G10450 steel as the substrate material, with dimensions of 40 mm × 20 mm × 5 mm. The chemical composition of the substrate is shown in Table 1. The cladding powder consisted of elemental metal powders of Al, Fe, Co, Ni, Cr, and W with a purity of 99.99%, mixed in a molar ratio of 2:1:1:1:1:0.5. The particle size range of the powders was between 148 and 248 μm, as shown in Figure 1.

Table 1.

Chemical composition of G10450 steel substrate (wt%).

Figure 1.

(a) SEM image of Al₂FeCoNiCrW₀.₅ powder; (b) particle size distribution of the high-entropy alloy powder.

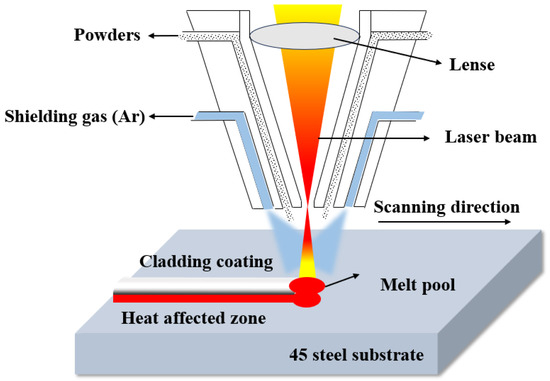

A planetary ball mill (QXQM-4L, Changsha, China) was used for powder preparation at a rotation speed of 180 r/min for 60 min. Si3N4 ceramic balls were used as grinding media, with a ball-to-powder mass ratio of 2:1. The mixed high-entropy alloy powder was air-dried for 24 h and then dried at 120 °C for 2 h before being stored in sealed bags for further use. The coating was processed using a laser cladding system (JSD-3000W, Shanghai, China) with a synchronous powder-feeding method. Argon gas was used as a protective atmosphere at a flow rate of 5 L/min. The laser cladding process parameters are listed in Table 2. A schematic diagram of the laser cladding process is shown in Figure 2.

Table 2.

Process parameters for laser cladding.

Figure 2.

Schematic diagram of laser cladding.

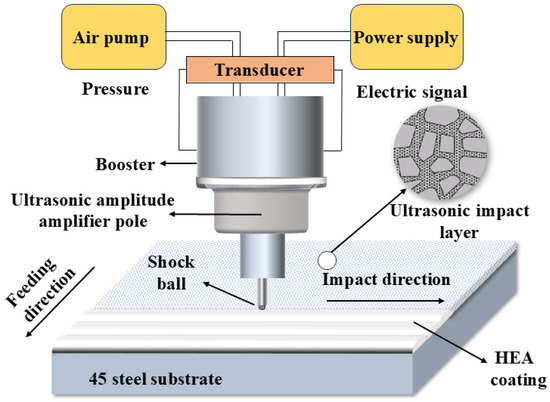

Ultrasonic impact treatment was performed on the Al2FeCoNiCrW0.5 high-entropy alloy samples using an ultrasonic impact device (HI-T002015A, Hightower, Handan, China). The specific parameters were as follows: input current of 0.2 A, impact head diameter of 8 mm, impact head stroke speed of 6 mm/s, impact amplitude of 30 μm, and impact frequency of 25 kHz. A schematic diagram of the ultrasonic impact process is shown in Figure 3.

Figure 3.

Schematic diagram of UIT.

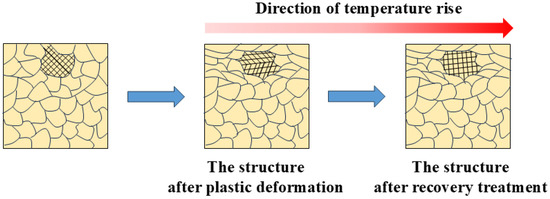

A box-type resistance furnace (JXR1750-30, Wuhan, China) was used for recovery treatment, with argon gas as the protective atmosphere. The ultrasonic impact-treated samples were placed in the furnace, heated at a rate of 7.5 °C/min for 40 min, held at the target temperature of 300 °C for 1 h, and then gradually cooled to room temperature with the furnace. A schematic diagram illustrating the plastic deformation and recovery of metals is shown in Figure 4. The process parameters in this study were selected based on preliminary experiments and the relevant research of Li et al [15].

Figure 4.

Schematic diagram of plastic deformation and recovery treatment of metal.

Samples with dimensions of 20 mm × 20 mm × 5 mm were cut and sequentially ground using sandpapers ranging from 180 to 2000 grit, followed by polishing. A Rigaku ULTIMA IV X-ray diffractometer (XRD, Tokyo, Japan) was used for phase analysis of the coating, with a Cu target radiation source (wavelength: 0.154 nm), tube voltage of 40 kV, current of 40 mA, scan speed of 10°/min, and a diffraction angle range of 20° to 90°. A Sigma 300 scanning electron microscope (SEM, St. Louis, MO, USA) was employed to observe the cross-sectional morphology of the cladding layer.

The cross-sectional hardness distribution of the coating was tested using an microhardness tester (TMVS-1, Shenzhen, China) with a load of 4.9 N and a dwell time of 10 s. Three test points were taken every 0.2 mm along the cross-section of the coating toward the center of the substrate, with a horizontal spacing of 0.4 mm between points. The average hardness value was calculated. The dry sliding wear performance of the coating at room temperature was tested using an pin-on-disk apparatus (SFT-2M, Lanzhou, China). A Si3N4 ceramic ball was used as the counterpart. The test parameters included a load of 100 N, a rotation speed of 200 r/min, and a duration of 120 min. The wear tests were repeated three times to ensure the reliability of the results.

3. Results and Discussion

3.1. Microstructural Analysis

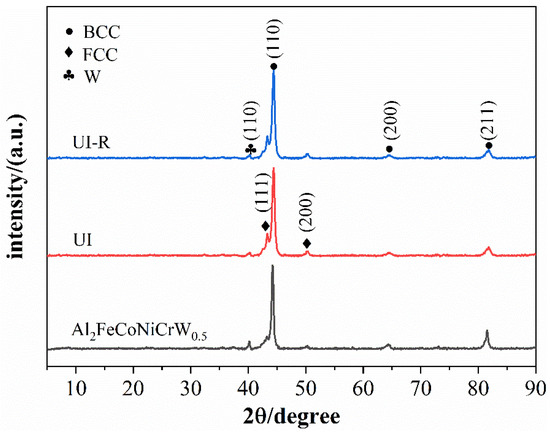

Figure 5 shows the XRD diffraction patterns of samples subjected to different treatments. As shown in Figure 5, the Al2FeCoNiCrW0.5 high-entropy alloy coating is primarily composed of FCC and BCC solid solution phases. After ultrasonic impact treatment, the surface microstructure of the Al2FeCoNiCrW0.5 high-entropy alloy shows significant differences compared to the substrate, leading to corresponding changes in the XRD diffraction peaks. The XRD peaks of the Al2FeCoNiCrW0.5 high-entropy alloy slightly broaden after ultrasonic impact treatment, while there are no significant differences in XRD peaks before and after recovery treatment. All samples exhibit an FCC + BCC dual-phase structure, indicating that neither ultrasonic impact nor recovery treatment induces the formation of new phases. The surface grain size of the nanocrystalline layer can be calculated using the Debye–Scherrer equation [16]:

where D is the grain size (nm), K is the Scherrer constant (0.89), λ is the X-ray wavelength (0.15406 nm), β is the full width at half maximum (FWHM) in radians, and θ is the Bragg diffraction angle (°). Using this method, the surface grain size of the UI sample was estimated to be approximately 80–100 nm, while the surface grain size of the UI-R sample was approximately 110–140 nm.

Figure 5.

X-ray diffraction patterns of Al2FeCoNiCrW0.5 high-entropy alloy coatings for UI and UI-R samples.

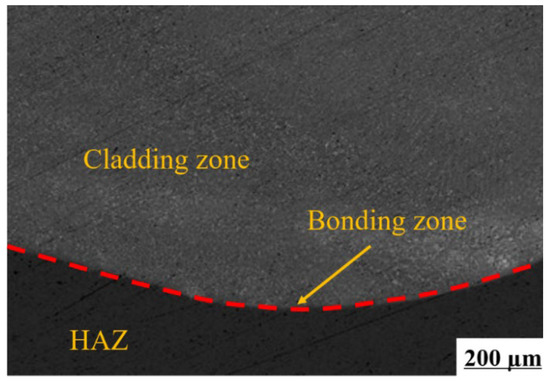

Figure 6 shows the SEM image of the cross-section of the laser-cladded Al₂FeCoNiCrW0.5 high-entropy alloy coating. As shown in Figure 6, the substrate is G10450 steel, and the fabricated high-entropy alloy coating exhibits a uniform microstructure without noticeable pores or cracks. The coating is metallurgically well bonded to the substrate. The thickness of the high-entropy alloy coating is 1.3 mm.

Figure 6.

SEM morphology of cross-section of Al2FeCoNiCrW0.5 high-entropy alloy coating.

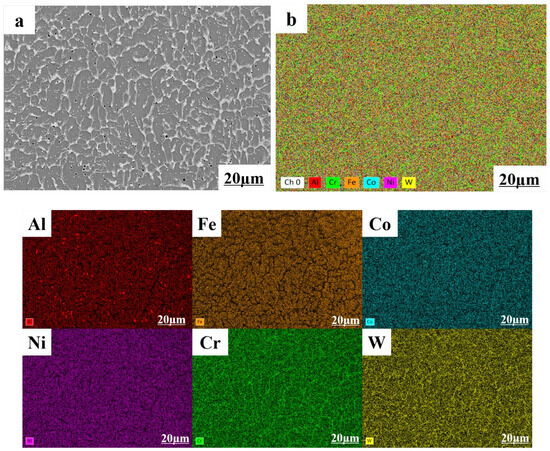

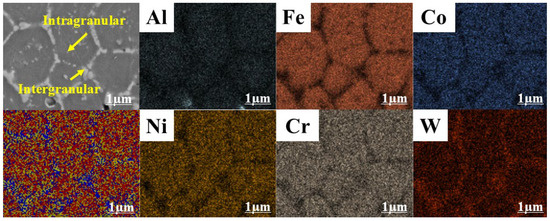

Figure 7 shows the microstructure and elemental energy dispersive spectroscopy (EDS) analysis of the top region of the Al2FeCoNiCrW0.5 high-entropy alloy coating. The analysis reveals that the top region of the coating primarily consists of Al, Fe, Co, Ni, Cr, and W elements. As shown in Figure 7b, Fe is concentrated at the grain boundaries, while no significant elemental segregation is observed within the grains, indicating a relatively uniform elemental distribution.

Figure 7.

(a) SEM morphology of Al2FeCoNiCrW0.5 high-entropy alloy coating, (b) Energy spectrum analysis of Al2FeCoNiCrW0.5 high-entropy alloy coating.

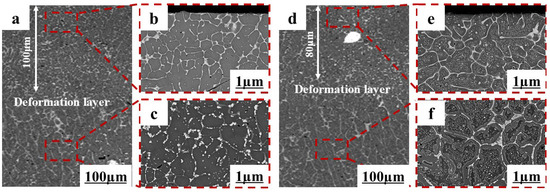

Figure 8 shows the cross-sectional microstructure of the UI and UI-R samples. As shown in Figure 8a,d, after ultrasonic impact treatment, a fine-grained layer with a significant gradient in size from the surface to the interior is formed, with a thickness of approximately 100 μm. The samples after recovery treatment exhibit a similar morphology, with the fine-grained layer thickness reduced to approximately 80 μm. Figure 8b shows the microstructure at the top of the UI sample coating. As indicated, after ultrasonic impact treatment, the grain size of the cladding layer gradually refines, forming a fine-grained layer. This is due to the strong plastic deformation induced by ultrasonic impact treatment at the surface, which promotes grain refinement [17,18,19]. As shown in Figure 8f, the particle size of the UI-R sample is slightly larger than that of the UI sample, which may be attributed to grain growth following recovery treatment. Figure 9 and Figure 10 show the energy dispersive spectroscopy (EDS) analysis of the middle layer of the UI and UI-R samples. As shown, the element distribution in the UI sample is uniform, with no obvious segregation or accumulation, which contributes to the stability of the coating’s performance. The distribution of major elements on the surface of the UI-R sample remains relatively uniform, with slight enrichment of tungsten (W) in some areas. This is attributed to the recovery treatment, which effectively reduces dislocation density, relieves residual stress, and allows W to diffuse slightly along the grain boundaries [20].

Figure 8.

Cross-sectional SEM morphologies of different sample coatings: (a) cross-section of the UI sample coating, (b) top of the UI sample coating, (c) bottom of the UI sample coating, (d) cross-section of the UI-R sample coating, (e) top of the UI-R sample coating, and (f) bottom of the UI-R sample coating.

Figure 9.

EDS analysis of the middle region of the UI sample.

Figure 10.

EDS analysis of the middle region of the UI-R sample.

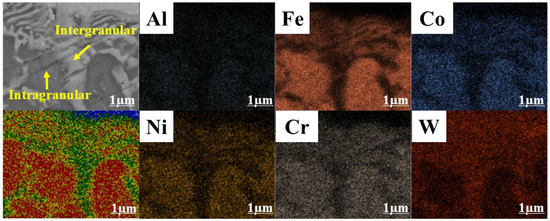

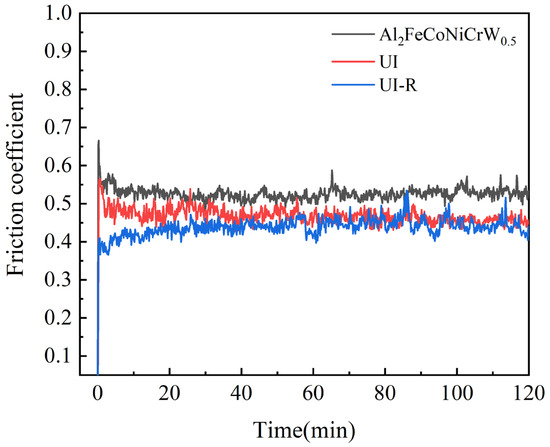

3.2. Microhardness Analysis

Figure 11 shows the microhardness profiles along the cross-section of the Al2FeCoNiCrW0.5 high-entropy alloy, UI sample, and UI-R sample. The results indicate that the hardness variation from the coating surface to the substrate can be divided into three stages: the coating, heat-affected zone (HAZ), and substrate, with the coating’s average hardness being 3–4 times that of the G10450 steel substrate. For the untreated coating, the maximum surface microhardness reached 738 HV0.5, showing a trend of increasing and then decreasing from the coating top to the substrate, stabilizing at the substrate. After ultrasonic impact treatment, the coating hardness increased significantly, with the maximum surface microhardness of the UI sample reaching 856 HV0.5. After recovery treatment at 300 °C, the surface microhardness of the UI-R sample decreased to 806 HV0.5.

Figure 11.

Microhardness of sample coatings after different treatments: (a) microhardness distribution; and (b) average microhardness.

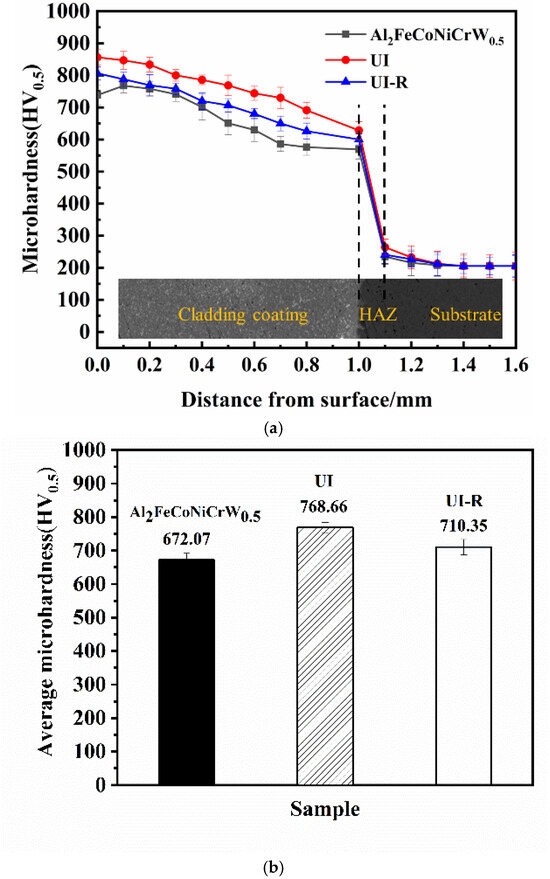

3.3. Friction and Wear Performance

The friction coefficient curves of different samples are shown in Figure 12. As shown in Figure 12, the friction coefficients of the UI and UI-R samples are lower than that of the Al2FeCoNiCrW0.5 high-entropy alloy. The reduction in the friction coefficient can be attributed to grain refinement. As shown in Figure 12, the UI and UI-R samples with nanostructured surfaces exhibit higher surface hardness, resulting in lower friction coefficients. This is because harder surfaces reduce the contact area under the same applied load [20,21,22].

Figure 12.

Friction coefficient curves of Al₂FeCoNiCrW₀.₅ high-entropy alloy, UI, and UI-R sample coatings.

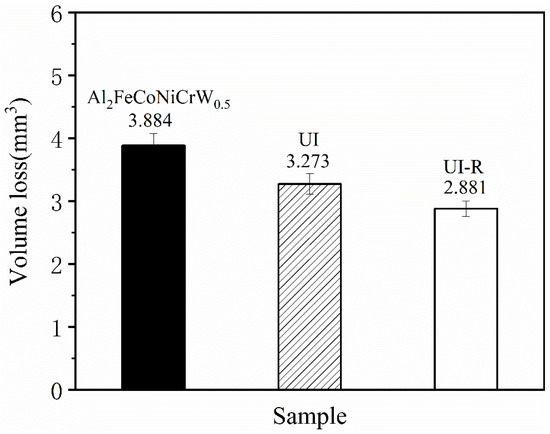

Volume loss caused by wear is a critical parameter for evaluating the wear resistance of metals. The wear volume loss of the Al2FeCoNiCrW0.5 high-entropy alloy, UI sample, and UI-R sample coatings is shown in Figure 13. As shown in the figure, the wear volume loss of the Al2FeCoNiCrW0.5 high-entropy alloy is greater than that of the UI and UI-R samples. According to the Hall–Petch relationship, the UI and UI-R samples exhibit higher wear resistance, which is attributed to grain refinement induced by ultrasonic impact. Additionally, the wear volume of the UI-R sample is lower than that of the UI sample. Although the hardness of the UI sample is slightly higher than that of the UI-R sample, the friction and wear performance of metallic materials depends not only on hardness but also on toughness. Appropriate recovery treatment can release the residual internal stress of the metal, resulting in improved toughness [23,24]. In this process, post-annealing transforms the dislocation cells in the impact layer into fine grains, leading to enhanced toughness and strength [25,26,27]. The results indicate that the Al2FeCoNiCrW0.5 high-entropy alloy coating, after ultrasonic impact treatment, exhibited improved wear resistance due to enhanced mechanical properties. Subsequent post-annealing further enhanced its wear resistance [28,29].

Figure 13.

Wear volume loss of Al₂FeCoNiCrW₀.₅ high-entropy alloy, UI sample, and UI-R sample coatings.

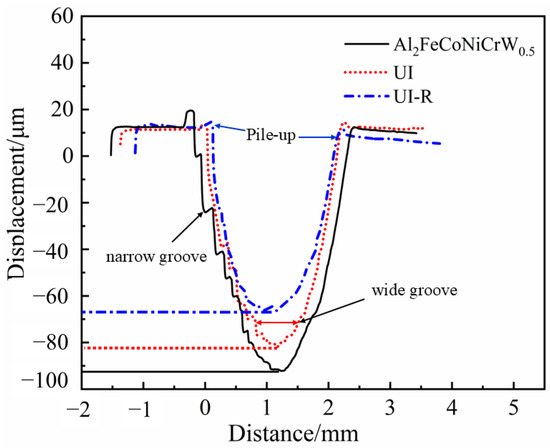

The cross-sectional profiles of wear scars for different samples are shown in Figure 14. The results indicate that the Al2FeCoNiCrW0.5 high-entropy alloy sample exhibits significant wrinkling, whereas the wear scar profiles of the UI and UI-R samples, after ultrasonic impact and recovery treatments, are smoother. For all samples, the maximum depth of the wear scar is located near the center of the scar, and the depth gradually decreases with increasing distance from the center. The maximum wear scar depths for the Al2FeCoNiCrW0.5 high-entropy alloy, UI, and UI-R samples are 92 μm, 82 μm, and 68 μm, respectively. Thus, the UI-R sample exhibits the smallest maximum wear scar depth, indicating superior wear resistance compared to the other samples.

Figure 14.

Cross-sectional profiles of wear scars for Al₂FeCoNiCrW₀.₅ high-entropy alloy, UI sample, and UI-R sample coatings.

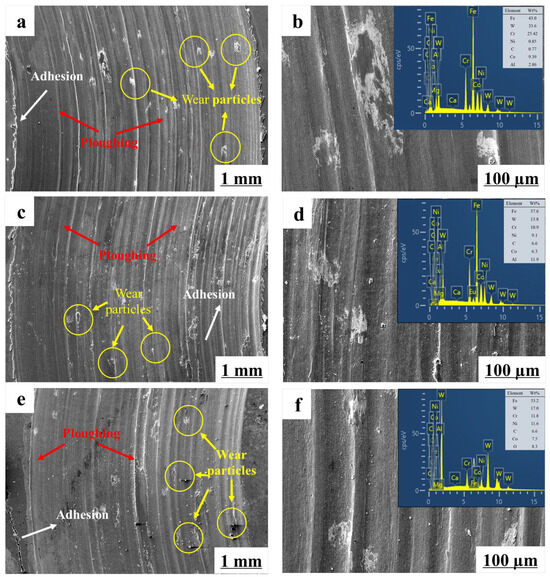

Figure 15 shows the wear surface morphology and EDS analysis of different coatings. As shown in Figure 15a,b, the wear surface of the Al2FeCoNiCrW0.5 high-entropy alloy sample exhibits a small number of abrasive particles, parallel grooves, and significant spalling, indicating severe adhesive wear under dry sliding conditions. Black oxide bands are observed on the wear surface [30]. Combined with EDS analysis, a small amount of oxygen was detected, indicating the occurrence of oxidative wear. This is mainly due to the high temperature generated at the contact points during dry sliding, which promotes oxidation. Therefore, the wear mechanisms of the Al2FeCoNiCrW0.5 high-entropy alloy sample are abrasive wear, oxidative wear, and adhesive wear. The wear surface of the UI sample shows shallow, parallel grooves along the sliding direction and minor spalling (Figure 15c,d). Adhesion and spalling on the wear surface indicate adhesive wear. The results indicate that the wear mechanisms of the UI sample are abrasive wear and adhesive wear. In contrast, the wear surface of the UI-R sample is relatively smooth, with only a small number of abrasive particles and narrow, shallow wear tracks (Figure 15e,f). This indicates that the wear resistance of the UI-R sample is significantly improved after post-annealing at 300 °C. Additionally, the heat generated during sliding forms an oxide film on the wear surface, leading to oxidative wear. Therefore, the wear mechanisms of the UI-R sample are abrasive wear and oxidative wear. Microstructural analysis shows that ultrasonic impact treatment refines the coating grains, increases hardness, and enhances the coating’s resistance to deformation, resulting in sustained improvement in wear resistance. Compared to the UI sample, the UI-R sample exhibits superior wear resistance. This is because post-annealing transforms the dislocation cells in the impact layer into fine grains and releases residual stress introduced by ultrasonic impact treatment, improving both the toughness and strength of the coating and further enhancing wear resistance [31,32].

Figure 15.

Wear morphology of coatings for different samples: (a) Al₂FeCoNiCrW₀.₅ sample, (b) Wear morphology of the Al₂FeCoNiCrW₀.₅ sample at higher magnification and EDS analysis of the wear surface, (c) UI sample, (d) Wear morphology of the UI sample at higher magnification and EDS analysis of the wear surface, (e) UI-R sample, (f) Wear morphology of the UI-R sample at higher magnification and EDS analysis of the wear surface.

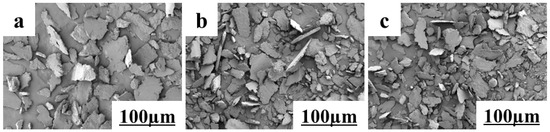

The wear debris morphology of different samples after wear testing is shown in Figure 16. The wear debris primarily consists of flaky spallation and granular particles. During the wear process, plastic deformation causes the coating to harden and lose ductility, making the material more prone to spalling. Large debris fragments are compressed and crushed under shear forces, forming smaller debris particles. As wear progresses, accumulated debris between contact surfaces creates grooves, resulting in abrasive wear [33]. As shown in Figure 16a, the wear debris of the Al2FeCoNiCrW0.5 sample is relatively large and flaky, indicating significant spalling on the wear surface. In the high-entropy alloy, the BCC phase, characterized by high hardness but lower toughness, bears most of the load and develops cracks and debris, while the FCC phase, with better toughness, deforms under wear, producing plowing wrinkles. The wear debris of the UI and UI-R samples is smaller than that of the untreated sample. However, the UI sample produces larger debris and experiences more severe wear compared to the UI-R sample. Due to work hardening induced by ultrasonic impact treatment, the UI sample exhibits lower toughness, making it more prone to crack propagation, which leads to flaky debris separating from the sample surface under plowing forces. In contrast, the UI-R sample, after ultrasonic impact and recovery treatment, maintains high hardness while also exhibiting improved toughness [34]. This results in smaller debris and better wear resistance, consistent with the wear mechanism and friction coefficient analyses.

Figure 16.

Wear debris morphology of different sample coatings: (a) Al2FeCoNiCrW0.5, (b) UI sample, and (c) UI-R sample.

4. Conclusions

In this study, Al2FeCoNiCrW0.5 high-entropy alloy coatings were fabricated on the surface of G10450 steel substrates using laser cladding technology, followed by ultrasonic impact treatment (UIT) and post-annealing at 300 °C (HR). The microstructure, microhardness, and tribological performance of the coatings were analyzed to investigate the effects of recovery treatment on the microstructure and wear properties of ultrasonic impact-treated Al2FeCoNiCrW0.5 high-entropy alloy coatings. The main conclusions are summarized as follows:

- (1)

- After ultrasonic impact treatment and recovery treatment, the fine-grained layer thicknesses were approximately 100 μm and 80 μm, respectively. Ultrasonic impact treatment induced severe plastic deformation on the coating surface, resulting in high-density dislocation tangling and dislocation walls, promoting grain refinement. Recovery treatment released residual stresses introduced during the ultrasonic impact process, facilitating the transformation of dislocation cells into fine grains, with minimal impact on the phase structure of the high-entropy alloy coating.

- (2)

- The maximum microhardness of the Al2FeCoNiCrW0.5 high-entropy alloy coating after ultrasonic impact treatment was 856 HV0.5, representing a 13.8% increase compared to the untreated coating (738 HV0.5). After recovery treatment, the surface microhardness of the UI-R sample decreased to 806 HV0.5. The UI-R sample exhibited the lowest average friction coefficient and wear volume loss, with its wear resistance improving by 15% compared to the untreated coating.

- (3)

- After recovery treatment, the wear surface of the sample became smoother, and the wear debris finer, indicating that recovery treatment effectively enhanced the toughness and wear resistance of the coating. The wear mechanisms of the high-entropy alloy coating transitioned from abrasive wear, oxidative wear, and adhesive wear to primarily abrasive wear and oxidative wear after recovery treatment combined with ultrasonic impact treatment. These treatments effectively improve the tribological performance of the high-entropy alloy coating.

Author Contributions

Conceptualization, Q.L. and C.Z.; methodology, C.Z.; validation, C.Z. and J.H.; formal analysis, C.Z.; investigation, Q.L.; resources, Q.L.; data curation, S.Z.; writing—original draft preparation, J.H.; writing—review and editing, X.Z.; visualization, H.L.; supervision, H.W.; project administration, Q.L.; funding acquisition, C.Z. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Heilongjiang Province’s Outstanding Young Teacher Basic Research Support Program (No. YQJH2023019) and Heilongjiang Provincial Natural Science Foundation of China (No. PL2024E024).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data are contained within the article.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Tsai, M.H.; Yeh, J.W. High-Entropy Alloys: A Critical Review. Mater. Res. Lett. 2014, 2, 107–123. [Google Scholar] [CrossRef]

- George, E.P.; Raabe, D.; Ritchie, R.O. High-entropy alloys. Nat. Rev. Mater. 2019, 4, 515–534. [Google Scholar] [CrossRef]

- Vaidya, M.; Muralikrishna, G.M.; Murt, B.S. High-entropy alloys by mechanical alloying: A review. J. Mater. Res. 2019, 34, 664–686. [Google Scholar] [CrossRef]

- Miracle, D.B.; Senkov, O.N. A critical review of high entropy alloys and related concepts. Acta Mater. 2017, 122, 448–511. [Google Scholar] [CrossRef]

- Liu, Y.; Ding, Y.; Ying, L.; Sun, R.; Zhang, T.; Yang, X. Research and progress of laser cladding on engineering alloys: A review. J. Manuf. Process. 2021, 66, 341–363. [Google Scholar] [CrossRef]

- Lu, J.Z.; Wu, L.J.; Sun, G.F.; Luo, K.Y.; Zhang, Y.K.; Cai, J.; Luo, X.M. Microstructural Response and Grain Refinement Mechanism of Commercially Pure Titanium Subjected to Multiple Laser Shock Peening Impacts. Acta Mater. 2017, 127, 252–266. [Google Scholar] [CrossRef]

- Zhang, S.; Han, B.; Li, M.; Hu, C.; Zhang, Q.; Liu, X.; Wang, Y. Investigation on microstructure and properties of laser cladded AlCoCrCuFeNi high entropy alloy coating by ultrasonic impact treatment. Intermetallics 2021, 128, 107017. [Google Scholar] [CrossRef]

- Zhang, Y.; Huang, C.; Liu, F.; Song, M.; Ke, L. Nanocrystallization of a Ti40 cladding layer by ultrasonic impact to improve burn resistance. J. Mater. Res. Technol. 2021, 11, 1331–1342. [Google Scholar] [CrossRef]

- Zhang, M.; Wang, W.Y.; Zhang, J.H.; Liu, C.Y.; Wang, Z.X.; Wan, J.; Zhao, H.W. The Recovery Behavior of AZ31B Magnesium Alloy Stimulated by Electropulsing Treatment and Heat Treatment. J. Mater. Eng. Perform. 2022, 31, 8346–8354. [Google Scholar] [CrossRef]

- Zhang, Q.; Li, M.; Han, B.; Zhang, S.; Li, Y.; Hu, C. Investigation on Microstructures and Properties of Al1.5CoCrFeMnNi High Entropy Alloy Coating Before and After Ultrasonic Impact Treatment. J. Alloys Compd. 2021, 884, 160989. [Google Scholar] [CrossRef]

- Li, M.; Zhang, Q.; Han, B.; Song, L.; Li, J.; Yang, J. Investigation on microstructure and properties of AlxCoCrFeMnNi high entropy alloys by ultrasonic impact treatment. J. Alloys Compd. 2020, 816, 152626. [Google Scholar] [CrossRef]

- Wang, C.; Li, R.; Bi, X.; Yuan, W.; Gu, J.; Chen, J.; Zhang, Z. Microstructure and Wear Resistance Property of Laser Cladded CrCoNi Coatings Assisted by Ultrasonic Impact Treatment. J. Mater. Res. Technol. 2023, 22, 853–864. [Google Scholar] [CrossRef]

- Li, Q.; Lu, H.; Li, D.Y. Effect of recovery treatment on the wear resistance of surface ham-mered AZ31 Mg alloy. Wear 2019, 426, 981–988. [Google Scholar] [CrossRef]

- Zhao, X.; Liu, K.; Xu, D.; Liu, Y.; Hu, C. Effects of ultrasonic surface rolling processing and subsequent recovery treatment on the wear resistance of AZ91D Mg alloy. Materials 2020, 13, 5705. [Google Scholar] [CrossRef] [PubMed]

- Li, Q.; Wang, H.; Che, C.; Wan, L.; Dong, X.; Wang, S.; Zhang, C. Effect of ultrasonic impact on the organization and friction wear performance of AZ31B magnesium alloy micro-arc oxidation composite coating. Coatings 2023, 13, 1161. [Google Scholar] [CrossRef]

- Li, M.; Zhang, Q.; Han, B.; Song, L.; Li, J.; Zhang, S. Effects of ultrasonic impact treatment on structures and properties of laser cladding Al0. 5CoCrFeMnNi high entropy alloy coatings. Mater. Chem. Phys. 2021, 258, 123850. [Google Scholar] [CrossRef]

- Li, M.; Guo, L.; Li, J.; Zhang, Q.; Han, B.; Song, L. Effect of Ultrasonic Impact Treatment on the Microstructure and Properties of Laser Cladded CoCrFeNiMoX High Entropy Alloy Coatings. Surf. Coat. Technol. 2024, 476, 130243. [Google Scholar] [CrossRef]

- Song, Z.; Liu, S.; Qiu, X.; Zhang, L.; Wu, C.; Ren, X.; Meng, C. Effect of Ultrasonic Impact Treatment on the Properties of CoCrFeNiCu High-Entropy Alloy Coatings on Steel by Induction Cladding. Surf. Coat. Technol. 2023, 459, 129390. [Google Scholar] [CrossRef]

- Edalati, K.; Bachmaier, A.; Beloshenko, V.A.; Beygelzimer, Y.; Blank, V.D.; Botta, W.J.; Zhu, X. Nanomaterials by Severe Plastic Deformation: Review of Historical Developments and Recent Advances. Mater. Res. Lett. 2022, 10, 163–256. [Google Scholar] [CrossRef]

- Qu, S.; Ren, Z.; Hu, X.; Lai, F.; Sun, F.; Li, X.; Yang, C. The effect of electric pulse aided ultrasonic rolling processing on the microstructure evolution, surface properties, and fatigue properties of a titanium alloy Ti5Al4Mo6V2Nb1Fe. Surf. Coat. Technol. 2021, 421, 127408. [Google Scholar] [CrossRef]

- Rui, H.; Wang, M.P.; Chen, C.; Jiang, D.; Gao, Y.; Ma, X.J. Microstructure Evolution, Mechanical Properties of FeCrNiMnAl High Entropy Alloy Coatings Fabricated by Laser Cladding. Surf. Coat. Technol. 2022, 447, 128851. [Google Scholar] [CrossRef]

- Lou, L.Y.; Liu, K.C.; Jia, Y.J.; Ji, G.; Wang, W.; Li, C.J.; Li, C.X. Microstructure and properties of lightweight Al0. 2CrNbTiV refractory high entropy alloy coating with different dilutions deposited by high speed laser cladding. Surf. Coat. Technol. 2022, 447, 128873. [Google Scholar] [CrossRef]

- Reddy, T.S.; Wani, I.S.; Bhattacharjee, T.; Reddy, S.R.; Saha, R.; Bhattacharjee, P.P. Severe plastic deformation driven nanostructure and phase evolution in a Al0. 5CoCrFeMnNi dual phase high entropy alloy. Intermetallics 2017, 91, 150–157. [Google Scholar] [CrossRef]

- Wang, L.; Wang, L.; Yingchun, T.; Lei, L.; Luo, L.S.; Su, Y.Q.; Guo, J.J.; Fu, H.Z. Microstructure and Mechanical Properties of CoCrFeNiW High Entropy Alloys Reinforced by μ Phase Particles. J. Alloys Compd. 2020, 843, 155997. [Google Scholar] [CrossRef]

- Cheng, Q.; Shi, H.; Jiang, Q.; Yu, Z.; Zhang, P.; Ye, X. Effect of phase composition on microstructure and wear resistance of (Al16. 80Co20. 74Cr20. 49Fe21. 28Ni20. 70) 99.5 Ti0.5 high-entropy alloy coatings. Mater. Today Commun. 2022, 31, 103765. [Google Scholar] [CrossRef]

- Han, B.; Zhang, S.; Zhang, T.; Chen, Y.; Qin, X.; Li, M.; Xue, X. Hardness enhancement mechanism of AlxCoCrFeNiSi high-entropy alloy coatings prepared by laser cladding. Intermetallics 2023, 158, 107909. [Google Scholar] [CrossRef]

- Wang, P.; Wang, Y.; Cui, F.; Yang, X.; Pan, A.; Wu, W. Microstructural Evolution, Mechanical Properties and Corrosion Resistance of CoCrFeNiW0.5 High Entropy Alloys with Various Annealing Heat Treatment. J. Alloys Compd. 2022, 918, 165602. [Google Scholar] [CrossRef]

- Meng, Y.; Xu, J.; Jin, Z.; Prakash, B.; Hu, Y. A Review of Recent Advances in Tribology. Friction 2020, 8, 221–300. [Google Scholar] [CrossRef]

- Joseph, J.; Haghdadi, N.; Shamlaye, K.; Hodgson, P.; Barnett, M.; Fabijanic, D. The Sliding Wear Behaviour of CoCrFeMnNi and AlxCoCrFeNi High Entropy Alloys at Elevated Temperatures. Wear 2019, 428, 32–44. [Google Scholar] [CrossRef]

- Patel, P.; Roy, A.; Sharifi, N.; Stoyanov, P.; Chromik, R.R.; Moreau, C. Tribological Performance of High-Entropy Coatings (HECs): A Review. Materials 2022, 15, 3699. [Google Scholar] [CrossRef]

- Xin, B.; Zhang, A.; Han, J.; Meng, J. The tribological properties of carbon doped Al0. 2Co1. 5CrFeNi1. 5Ti0. 5 high entropy alloys. Wear 2021, 484–485, 204045. [Google Scholar] [CrossRef]

- Jing, P.; Wang, H.; Chen, W.; Chen, L.; Yin, H.; Wu, H.; Li, D.Y. Effect of Ti Addition on Microstructure and Tribological Properties of Laser Cladding Ni35/WC Coating in an Oxygen-Free Environment. Surf. Coat. Technol. 2022, 440, 128480. [Google Scholar] [CrossRef]

- Guo, B.Q.; Ray, R.K.; Yoshida, S.; Bai, Y.; Tsuji, N. In-situ Observations of Static Recrystallization and Texture Formation in a Cold-Rolled CoCrFeMnNi High Entropy Alloy. Scr. Mater. 2022, 208, 114706. [Google Scholar] [CrossRef]

- Chen, L.; Wang, H.; An, X.G.; Huang, X.F. Recovery, Recrystallization and Precipitation Behavior in an ATF FeCrAl Alloy During Annealing Treatment. Mater. Charact. 2022, 190, 112026. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).