Mechanical Performance of Diamine Silane Modified Carbon Nanotubes Reinforced Epoxy Resin Composites

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

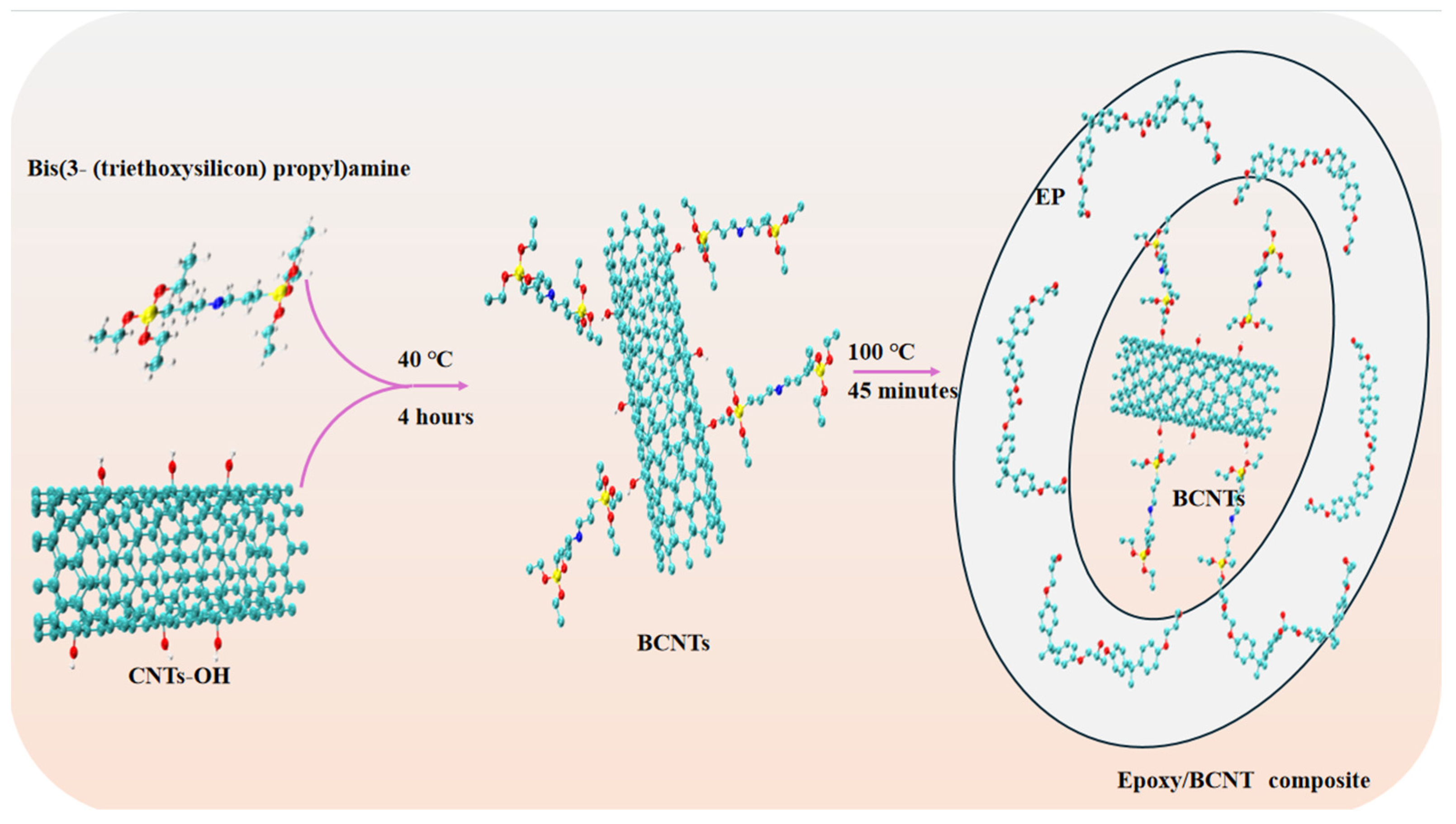

2.2. Silane Grafting Modification

2.3. Fabrication of CNT–Reinforced Epoxy Resin Composites

2.4. Characterization

3. Results and Discussion

3.1. Chemical Structural Analysis of CNT Modification

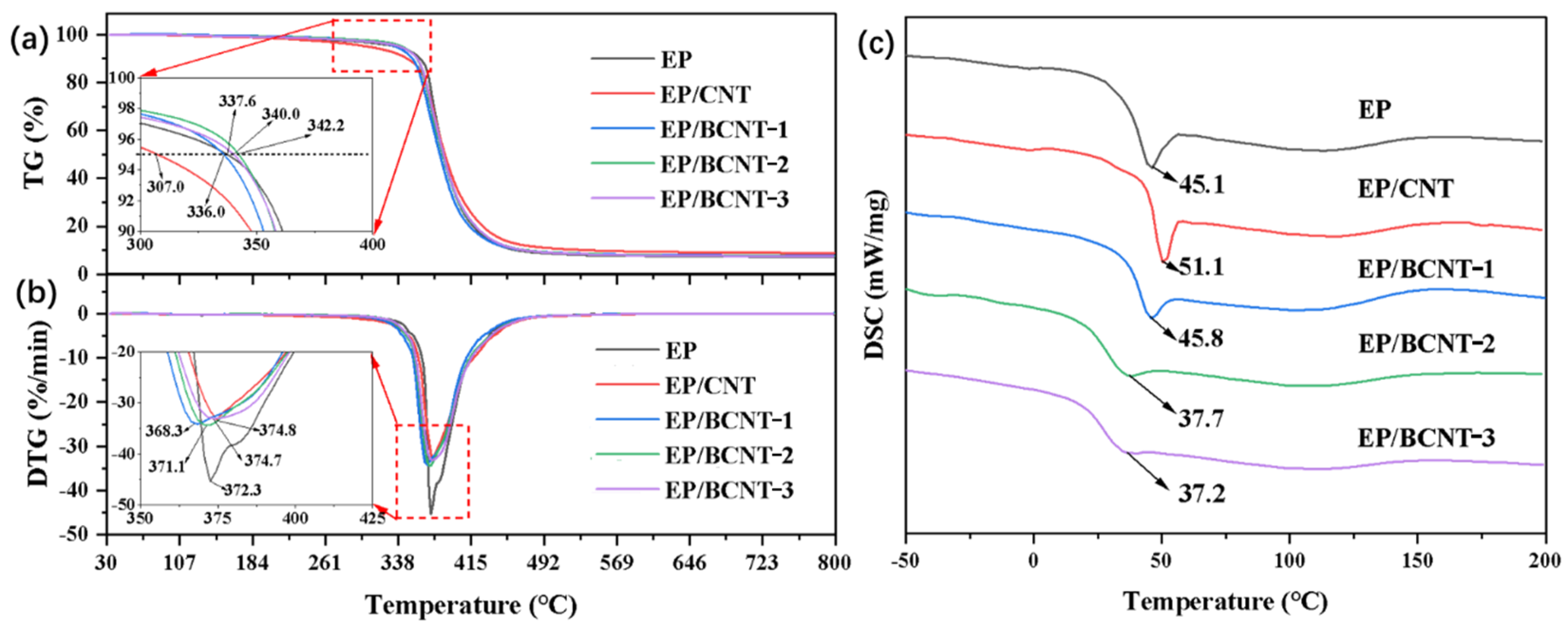

3.2. Thermal Analysis

3.3. Mechanical Properties of EP/CNT Composite Materials

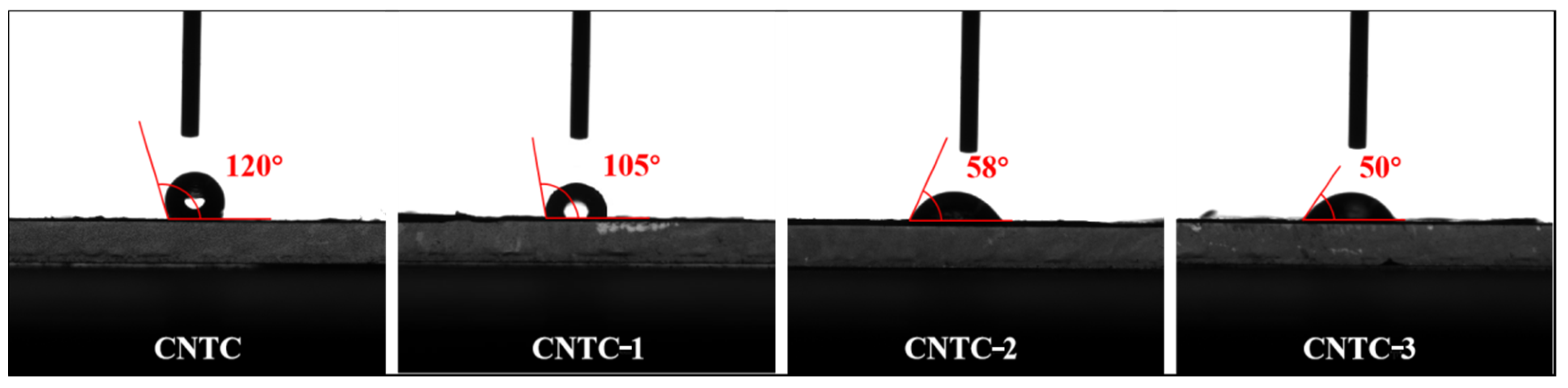

3.4. Surface Wettability Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Brennan, L.J.; Gun Ko, Y.K. Advances in the Organometallic Chemistry of Carbon Nanomaterials. Organometallics 2015, 34, 2086–2097. [Google Scholar] [CrossRef]

- Yi, S.; Sun, H.; Jin, Y.; Zou, K.; Li, J.; Jia, L.; Yan, D.; Li, Z. Cnt-Assisted Design of Stable Liquid Metal Droplets for Flexible Multifunctional Composites. Compos. Part B Eng. 2022, 239, 109961. [Google Scholar] [CrossRef]

- Fan, J.; Zhao, D.; Wu, M.; Xu, Z.; Song, J. Preparation and Microstructure of Multi-Wall Carbon Nanotubes-Toughened Al2O3 Composite. J. Am. Ceram. Soc. 2006, 89, 750–753. [Google Scholar] [CrossRef]

- Liu, W.; Zhu, C.; Meng, C.; Zeng, F. On the Uniformity of Field Emission in Screen Printed Cnt-Cathodes: The Effects of the Cathode Roughness. Microelectron. J. 2006, 37, 404–408. [Google Scholar] [CrossRef]

- Tam, D.T.; Long, T.T.; Quan, N.H. Application of Similarity Method and Dimensional Analysis in Determining the Performance Parameters of Agitator Paddles for Caltex Aquatex 3180 Cutting Oil. Int. J. Eng. Technol. Manag. Res. 2019, 6, 47–54. [Google Scholar] [CrossRef]

- Ghoreishi, S.M.; Behpour, M.; Hajisadeghian, E.; Golestaneh, M. Voltammetric Determination of Resorcinol On the Surface of a Glassy Carbon Electrode Modified with Multi-Walled Carbon Nanotube. Arab. J. Chem. 2016, 9, S1563–S1568. [Google Scholar] [CrossRef]

- Tang, L.; Zhang, H.; Han, J.; Wu, X.; Zhang, Z. Fracture Mechanisms of Epoxy Filled with Ozone Functionalized Multi-Wall Carbon Nanotubes. Compos. Sci. Technol. 2011, 72, 7–13. [Google Scholar] [CrossRef]

- Abdalla, M.; Dean, D.; Robinson, P.; Nyairo, E. Cure Behavior of Epoxy/Mwcnt Nanocomposites: The Effect of Nanotube Surface Modification. Polymer 2008, 49, 3310–3317. [Google Scholar] [CrossRef]

- He, J.; Shi, R.; Ji, R. Effect of Ultrasound Pre-Treatment On Extraction and Characterization of Collagen From Bactrian Camel Skin. Polymers 2023, 19, 1943. [Google Scholar] [CrossRef] [PubMed]

- Gao, B.; Zhang, R.; He, M.; Sun, L.; Wang, C.; Liu, L.; Zhao, L.; Cui, H.; Cao, A. Effect of a Multiscale Reinforcement by Carbon Fiber Surface Treatment with Graphene Oxide/Carbon Nanotubes On the Mechanical Properties of Reinforced Carbon/Carbon Composites. Compos. Part A Appl. Sci. Manuf. 2016, 90, 433–440. [Google Scholar] [CrossRef]

- Lotfi, M.; Yari, H.; Sari, M.G.; Azizi, A. Fabrication of a Highly Hard Yet Tough Epoxy Nanocomposite Coating by Incorporating Graphene Oxide Nanosheets Dually Modified with Amino Silane Coupling Agent and Hyperbranched Polyester-Amide. Prog. Org. Coat. 2022, 162, 106570. [Google Scholar] [CrossRef]

- Tanaka, K.; Kyoyama, S. The Effect of Pulse Current On Electrolytically Plating Nickel as a Catalyst for Grafting Carbon Nanotubes Onto Carbon Fibers Via the Chemical Vapor Deposition Method. J. Compos. Sci. 2023, 7, 88. [Google Scholar] [CrossRef]

- Song, B.; Liu, Z.; Wang, T.; Wang, L. Grafting of Cnts Onto the Surface of Pbo Fibers at High-Density for Enhancing Interfacial Adhesion, Mechanical Properties and Stability of Composites. J. Colloid Interface Sci. 2021, 598, 113–125. [Google Scholar] [CrossRef] [PubMed]

- Pourasghar, A.; Yas, M.H.; Kamarian, S. Local Aggregation Effect of Cnt On the Vibrational Behavior of Four-Parameter Continuous Grading Nanotube-Reinforced Cylindrical Panels. Polym. Compos. 2013, 34, 707–721. [Google Scholar] [CrossRef]

- Mostovoy, A.; Yakovlev, A.; Tseluikin, V.; Lopukhova, M. Epoxy Nanocomposites Reinforced with Functionalized Carbon Nanotubes. Polymers 2020, 12, 1816. [Google Scholar] [CrossRef] [PubMed]

- Yang, D.Q.; Hennequin, B.; Sacher, E. Xps Demonstration of Π–Π Interaction Between Benzyl Mercaptan and Multiwalled Carbon Nanotubes and their Use in the Adhesion of Pt Nanoparticles. Chem. Mater. 2006, 18, 5033–5038. [Google Scholar] [CrossRef]

- Yang, M.; Iizumi, Y.; Chen, L.; Okazaki, T.; Futaba, D.; Zhang, M. Rapid Room Temperature Degradation of Carbon Nanotubes by Sodium Hypochlorite and Uv-Light Irradiation. Carbon 2023, 208, 238–246. [Google Scholar] [CrossRef]

- Wulf, V.; Pui-yan Hung, A.; Hendler-Neumark, A.; Li, W.; Shamis, O.; Gozin, M.; Huang, X.; Kin Tak Lau, A.; Bisker, G. Acoustic Performance of Epoxy-Based Composites Incorporating Fluorescent Single-Walled Carbon Nanotubes. Compos. Part A Appl. Sci. Manuf. 2023, 173, 107667. [Google Scholar] [CrossRef]

- Pejcic, B.; Myers, M.; Ranwala, N.; Boyd, L.; Baker, M.; Ross, A. Modifying the Response of a Polymer-Based Quartz Crystal Microbalance Hydrocarbon Sensor with Functionalized Carbon Nanotubes. Talanta 2011, 85, 1648–1657. [Google Scholar] [CrossRef]

- Lyu, J.; Xu, K.; Zhang, N.; Lu, C.; Zhang, Q.; Yu, L.; Feng, F.; Li, X. In Situ Incorporation of Diamino Silane Group Into Waterborne Polyurethane for Enhancing Surface Hydrophobicity of Coating. Molecules 2019, 24, 1667. [Google Scholar] [CrossRef] [PubMed]

- Zhang, W.; Li, J.; Xu, F.; Tang, Y.; Cheng, S.; Cao, F. Isolation and Characterization of a Phenylalanine Ammonia-Lyase Gene (Pal) Promoter From Ginkgo Biloba and its Regulation of Gene Expression in Transgenic Tobacco Plants. Plant Omics 2014, 7, 353–360. [Google Scholar]

- Karger-Kocsis, J. Thermal Analysis of Polymers: Fundamentals and Applications. Macromol. Chem. Phys. 2009, 210, 1661. [Google Scholar] [CrossRef]

- García-Manrique, J.A.; Marí, B.; Ribes-Greus, A.; Monreal, L.; Teruel, R.; Gascón, L.; Sans, J.A.; Marí-Guaita, J. Study of the Degree of Cure through Thermal Analysis and Raman Spectroscopy in Composite-Forming Processes. Materials 2019, 12, 3991. [Google Scholar] [CrossRef] [PubMed]

- Datta Sarma, A.; Gowd, E.B.; Das, A.K.; Heinrich, G.D.I. The Effect of Crosslink Density On the Cold Crystallization Behavior of Polybutadiene Elastomers. Express Polym. Lett. 2023, 17, 690–698. [Google Scholar] [CrossRef]

- Nhu Trang, L.T.; Tung, H.V. Thermo-Torsional Postbuckling of Cnt-Reinforced Composite Toroidal Shell Segments with Surrounding Elastic Media and Tangentially Restrained Edges. J. Thermoplast. Compos. Mater. 2022, 36, 3137–3167. [Google Scholar] [CrossRef]

- Even, N.; Adler-Abramovich, L.; Buzhansky, L.; Dodiuk, H.; Gazit, E. Improvement of the Mechanical Properties of Epoxy by Peptide Nanotube Fillers. Small 2011, 7, 1007–1011. [Google Scholar] [CrossRef] [PubMed]

- Babaei, A.; Garrett, D.J.; Downard, A.J. Electrochemical Investigations On a Third Generation Biosensor for Determination of Hydrogen Peroxide Based On Immobilization of Myoglobin On a Novel Platinum Nanoparticle/Carbon Nanotube/Ionic Liquid/Nafion Composite. Int. J. Electrochem. Sci. 2012, 7, 3141–3154. [Google Scholar] [CrossRef]

- Bi, C.; Wang, Q.; Shao, Y.; Yuan, Y.; Xiao, Z.; Huang, J. Non-Wetting Surface-Driven High-Aspect-Ratio Crystalline Grain Growth for Efficient Hybrid Perovskite Solar Cells. Nat. Commun. 2015, 6, 7747. [Google Scholar] [CrossRef] [PubMed]

- Andriano, K.P.; Daniels, A.U.; Heller, J. Effectiveness of Silane Treatment on Absorbable Microfibers. J. Appl. Biomater. 1992, 3, 191–195. [Google Scholar] [CrossRef] [PubMed]

- Ouarhim, W.; Zari, N.; Bouhfid, R.; Qaiss, A.E.K. 3-Mechanical Performance of Natural Fibers–Based Thermosetting Composites. In Mechanical and Physical Testing of Biocomposites, Fibre-Reinforced Composites and Hybrid Composites; Jawaid, M., Thariq, M., Saba, N., Eds.; Woodhead Publishing: Sawston, UK, 2019; pp. 43–60. [Google Scholar] [CrossRef]

| Chemical Name | Specification | Manufacturer |

|---|---|---|

| Hydroxylated multi-walled carbon nanotubes (MWCNTs) | ≥98%, L ≈ 6 nm | Beijing Deke Island Gold Technology Co., Ltd., Beijing, China. |

| Epoxy resin | E51 | Huntsman New Materials (Guangdong) Co., Ltd., Guangzhou, China |

| Anhydrous ethanol | AR, 99% | Huzhou Shuanglin Chemical Technology Co., Ltd., Huzhou, China |

| Bis [3-(triethoxysilicon)propyl] amine | 97.04% | Bijiasuo Biochemical Technology Co., Ltd., Guangzhou, China |

| Curing Agent | Industrial Grade | Huntsman New Materials (Guangdong) Co., Ltd., Guangzhou, China |

| Sample | EP | EP/CNT | EP/BCNTs–1 | EP/BCNTs–2 | EP/BCNTs–3 |

|---|---|---|---|---|---|

| TGA @ T5% (°C) | 337.6 | 307.0 | 336.0 | 342.2 | 340.0 |

| DTG @ Tmax (°C) | 372.3 | 374.8 | 368.3 | 371.1 | 374.7 |

| DSC @ Tg (°C) | 45.1 | 51.1 | 45.8 | 37.7 | 37.22 |

| Sample | EP | EP/CNT | EP/BCNTs–1 | EP/BCNTs–2 | EP/BCNTs–3 |

|---|---|---|---|---|---|

| Stress @ peak(MPa) | 27.2 ± 1.41 | 53.4 ± 2.14 | 58.5 ± 1.87 | 62.0 ± 2.35 | 65.9 ± 2.56 |

| Strain @ peak (%) | 4.7 ± 0.24 | 5.0 ± 0.32 | 7.4 ± 0.42 | 6.6 ± 0.35 | 6.1 ± 0.29 |

| Stress @ rupture (MPa) | 8.0 ± 1.24 | 19.2 ± 1.96 | 30.0 ± 1.53 | 33.4 ± 1.69 | 24.7 ± 1.82 |

| Strain @ rupture (%) | 54.6 ± 0.37 | 6.7 ± 0.27 | 8.6 ± 0.33 | 8.4 ± 0.48 | 24.7 ± 0.45 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cao, S.; Yan, X.; Zhang, Y.; Wu, X.; Wang, L.; Shi, B.; Li, K.; Feng, C.; Wang, Q.; Wu, B. Mechanical Performance of Diamine Silane Modified Carbon Nanotubes Reinforced Epoxy Resin Composites. Coatings 2025, 15, 60. https://doi.org/10.3390/coatings15010060

Cao S, Yan X, Zhang Y, Wu X, Wang L, Shi B, Li K, Feng C, Wang Q, Wu B. Mechanical Performance of Diamine Silane Modified Carbon Nanotubes Reinforced Epoxy Resin Composites. Coatings. 2025; 15(1):60. https://doi.org/10.3390/coatings15010060

Chicago/Turabian StyleCao, Shengbin, Xiaofei Yan, Yaoyu Zhang, Xueyu Wu, Lisheng Wang, Binhua Shi, Kailang Li, Chunlan Feng, Qinling Wang, and Bei Wu. 2025. "Mechanical Performance of Diamine Silane Modified Carbon Nanotubes Reinforced Epoxy Resin Composites" Coatings 15, no. 1: 60. https://doi.org/10.3390/coatings15010060

APA StyleCao, S., Yan, X., Zhang, Y., Wu, X., Wang, L., Shi, B., Li, K., Feng, C., Wang, Q., & Wu, B. (2025). Mechanical Performance of Diamine Silane Modified Carbon Nanotubes Reinforced Epoxy Resin Composites. Coatings, 15(1), 60. https://doi.org/10.3390/coatings15010060